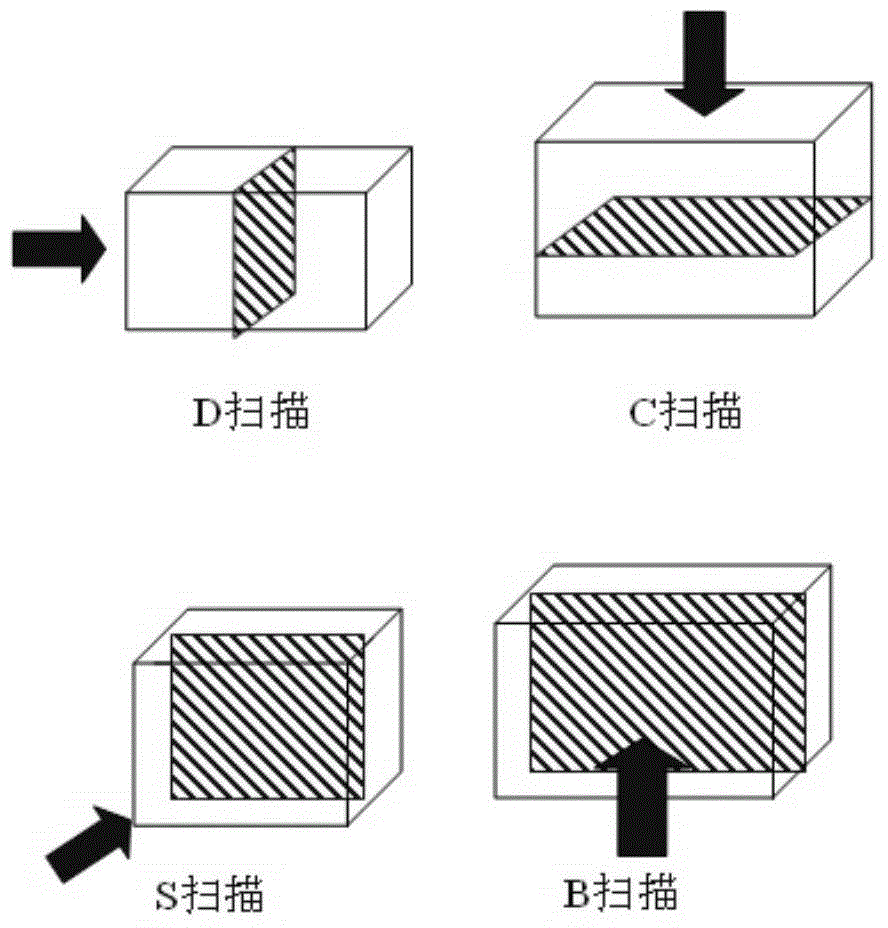

Ultrasonic B+C+D+S scanning identification method of internal defect of steel ingot

A scanning method and a technology for internal defects, which are applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, which can solve the problems of insufficient image and intuitive judgment, and achieve the effect of eliminating the universal forging process card, accurate description of map features, and comprehensive detection results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

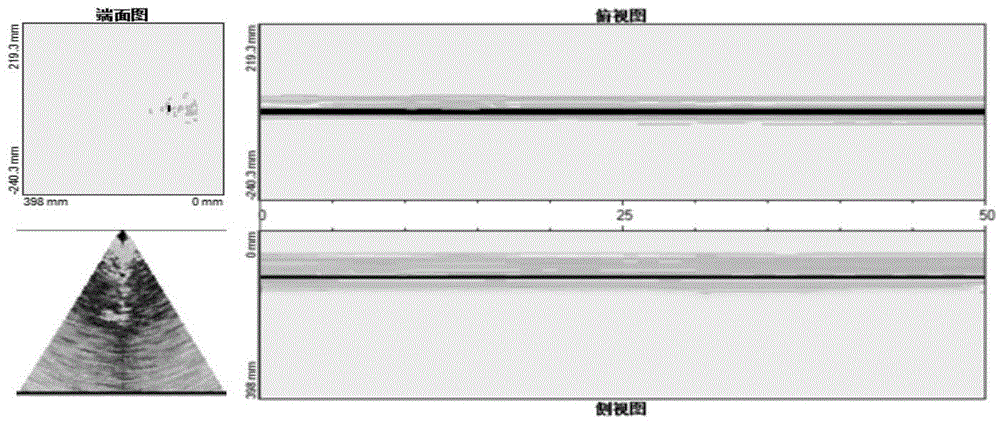

[0044] Example 1 The continuous casting ingot is detected. In the ultrasonic B+C+D+S scanning atlas, the B-scan image is a non-central intermittent strip, the C-scan image is a central intermittent strip, and the D-scan image is A spot in the center; the S-scan image shows a spot in the center. Defects are single point defects. see figure 2 shown.

Embodiment 2

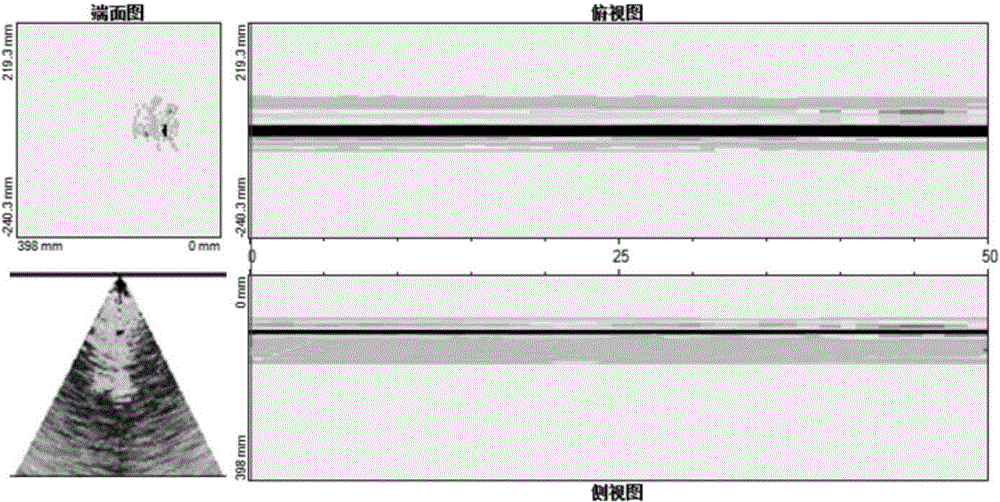

[0045] Example 2 The die-casting ingot is detected, in the ultrasonic B+C+D+S scanning atlas, the B-scan image is a non-central intermittent strip, the C-scan image is a central intermittent strip, and the D-scan image is A spot in the center; the S-scan image shows a spot in the center. Defects are single point defects. see image 3 shown.

Embodiment 3

[0046] Example 3 Electroslag remelting ingots are detected, in the ultrasonic B+C+D+S scanning atlas, the B-scan image is a non-central intermittent strip, the C-scan image is a central intermittent strip, and the D-scan The image is a non-central spot; the S-scan image is a non-central spot. Defects are single point defects. see Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com