Small-size meat grinder for kitchen

A grinding machine, a small technology, applied in the direction of kitchen utensils, applications, household utensils, etc., can solve the problems of insufficient grinding, low grinding efficiency, etc., to achieve the effect of improving efficiency and quality, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

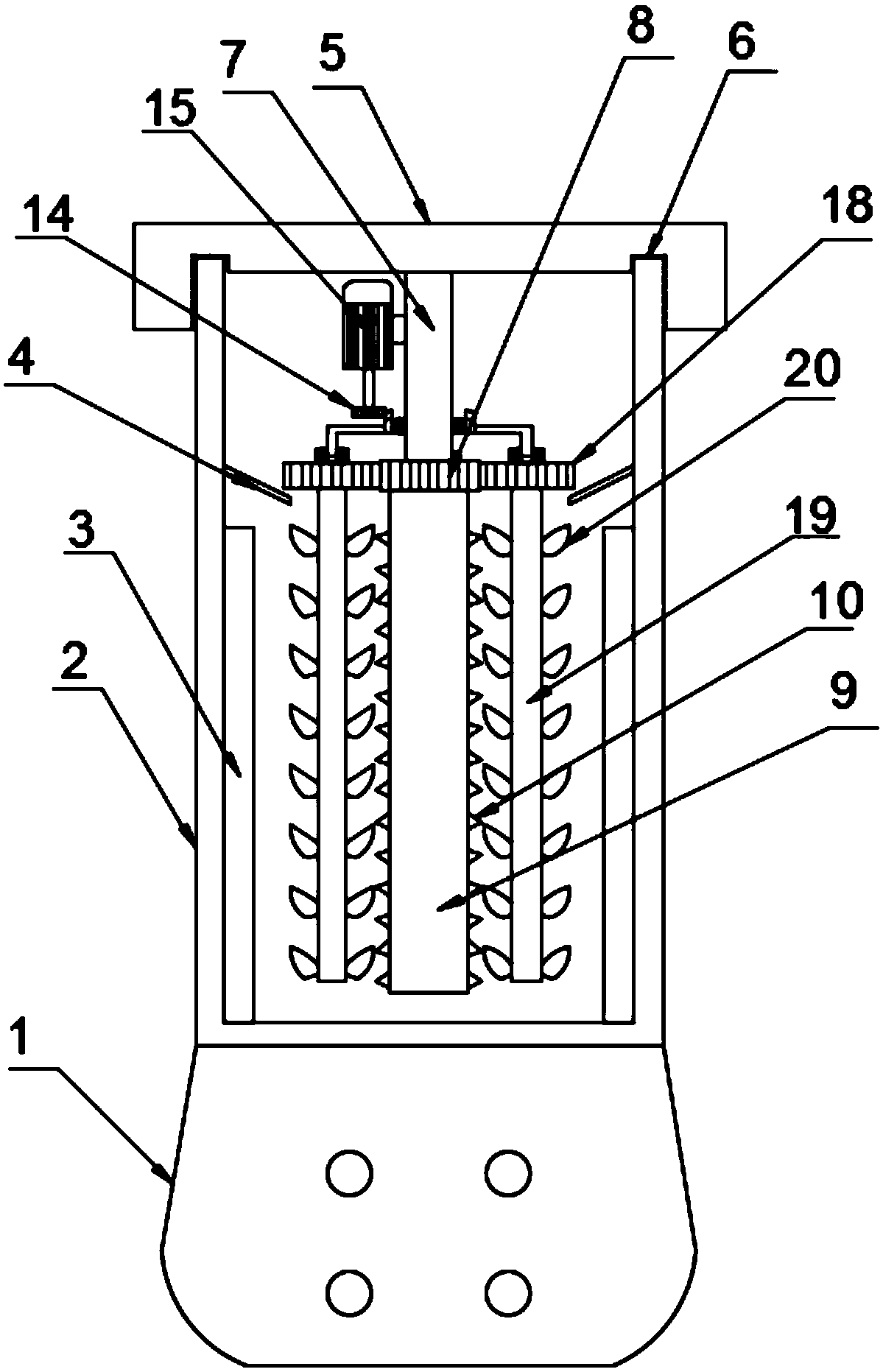

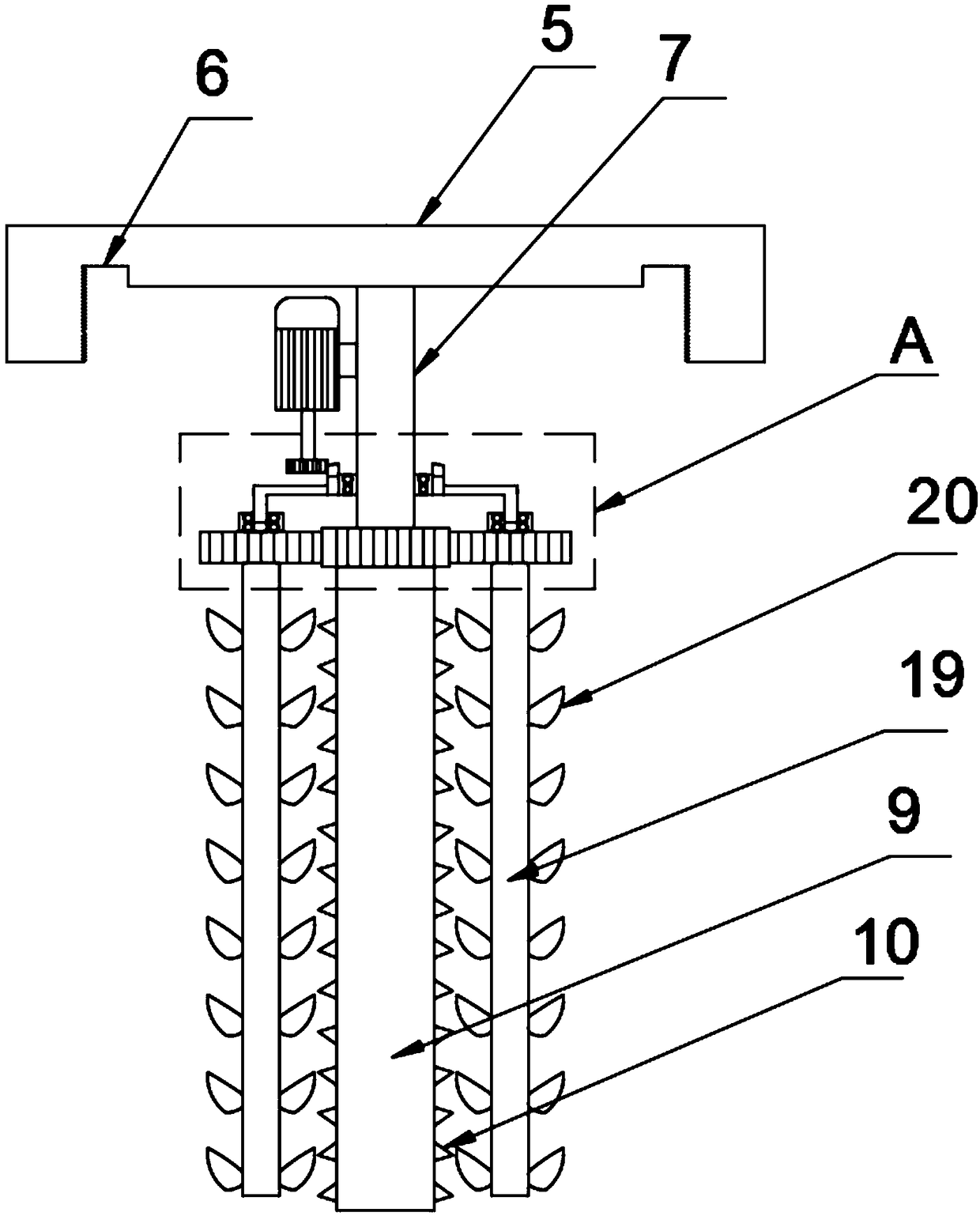

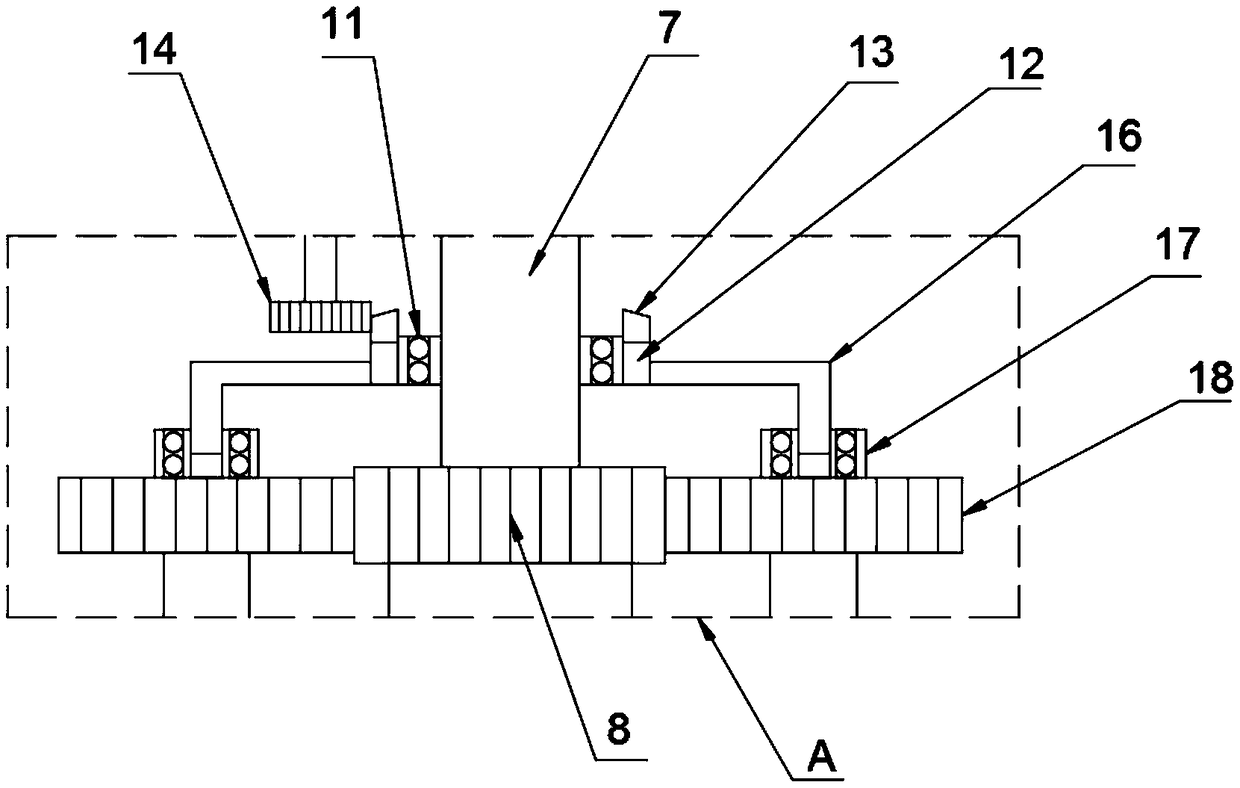

[0025] like Figure 1-5 A small meat grinder for kitchen is shown, which includes a machine base 1, a cylinder body 2 is arranged on the top of the machine base 1, a fixed baffle 3 is arranged on the inner wall of the cylinder body 2, and a fixed baffle 3 is provided on the top of the fixed baffle 3 An annular baffle 4 is provided, a cylinder cover 5 is provided on the top of the cylinder body 2, a slot 6 is provided on the bottom wall of the cylinder cover 5, a fixing rod 7 is provided at the bottom of the cylinder cover 5, and a fixing rod 7 is provided at the bottom of the fixing rod 7. The end is fixedly provided with a first gear 8, the bottom of the first gear 8 is fixedly provided with a first grinding rod 9, the outer wall of the first grinding rod 9 is provided with grinding teeth 10, and the outer wall of the fixed rod 7 is sleeved with The first bearing 11, the outer wall of the first bearing 11 is provided with a connecting ring 12, the top of the connecting ring 1...

Embodiment 2

[0028] like Figure 1-5 As shown in the small meat grinder for kitchen, the number of the fixed baffles 3 is set to be multiple, and the multiple fixed baffles 3 are arranged obliquely, and the multiple fixed baffles 3 are circular and uniform. It is arranged on the inner wall of the cylinder body 2, the annular baffle plate 4 is recessed, the section of the cylinder cover 5 is set in the shape of "冖", the card slot 6 is arranged at the bottom edge of the cylinder cover 5, and the cylinder body 2 The top end is embedded in the card groove 6, the cylinder cover 5 and the cylinder body 2 are detachably connected by threads, and a concave arc-shaped baffle 4 is provided on the top of the fixed baffle 3, so that the bottom of the cylinder 2 is grinding The raw material is not easy to be splashed to the top of the cylinder body 2 to cause damage to the mechanical structural parts, prolonging the service life.

[0029] The inner wall of the connecting ring 12 is attached to the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com