Wind power generation hydraulic system

A technology of hydraulic system and solenoid valve, applied in wind power generation, wind turbine, wind turbine control, etc., can solve the problems of loss of pipeline pressure, excessive braking force, failure of main shaft braking device and yaw braking device to work properly, etc. , to achieve the effect of balanced flow speed and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further described below in conjunction with specific embodiment:

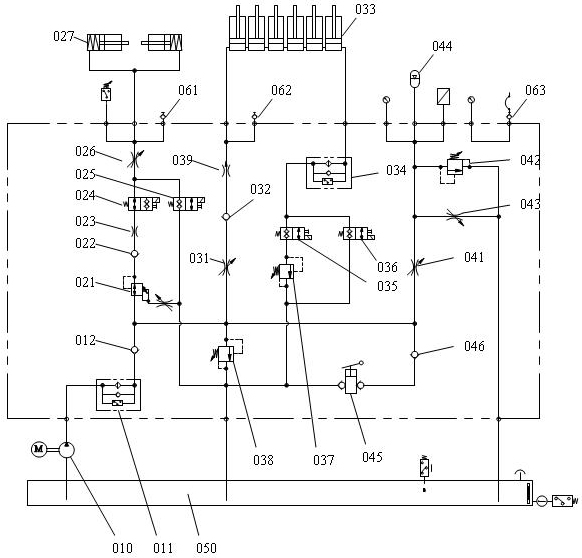

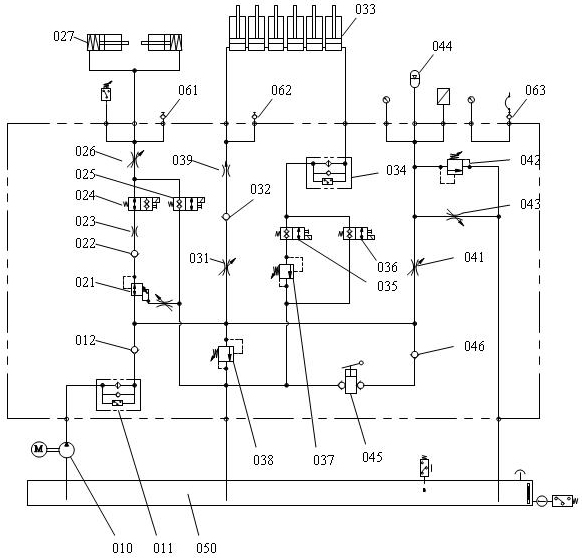

[0025] See figure 1 , which is a schematic diagram of the system of the present invention, including an oil pump 010 , a main shaft braking unit, a yaw braking unit, a safety pressure maintaining unit and an external fuel tank 050 .

[0026] The oil pump 010 is connected to the main shaft brake unit, the yaw brake unit and the safety pressure maintaining unit through the pipelines of the first filter 011 and the second one-way valve 012 through the same pipeline.

[0027] The spindle brake unit is composed of the oil pump 010 through the first filter 011, the second one-way valve 012, the pressure reducing valve 021, the third one-way valve 022, the throttle plug 023, the first electromagnetic valve 024, and the third adjustable flow valve. The valve 026 is connected with the pipeline of the spindle brake oil cylinder group 027.

[0028] Main shaft brake oil cylinder group 027 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com