Patents

Literature

74results about How to "Eliminate bad situations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

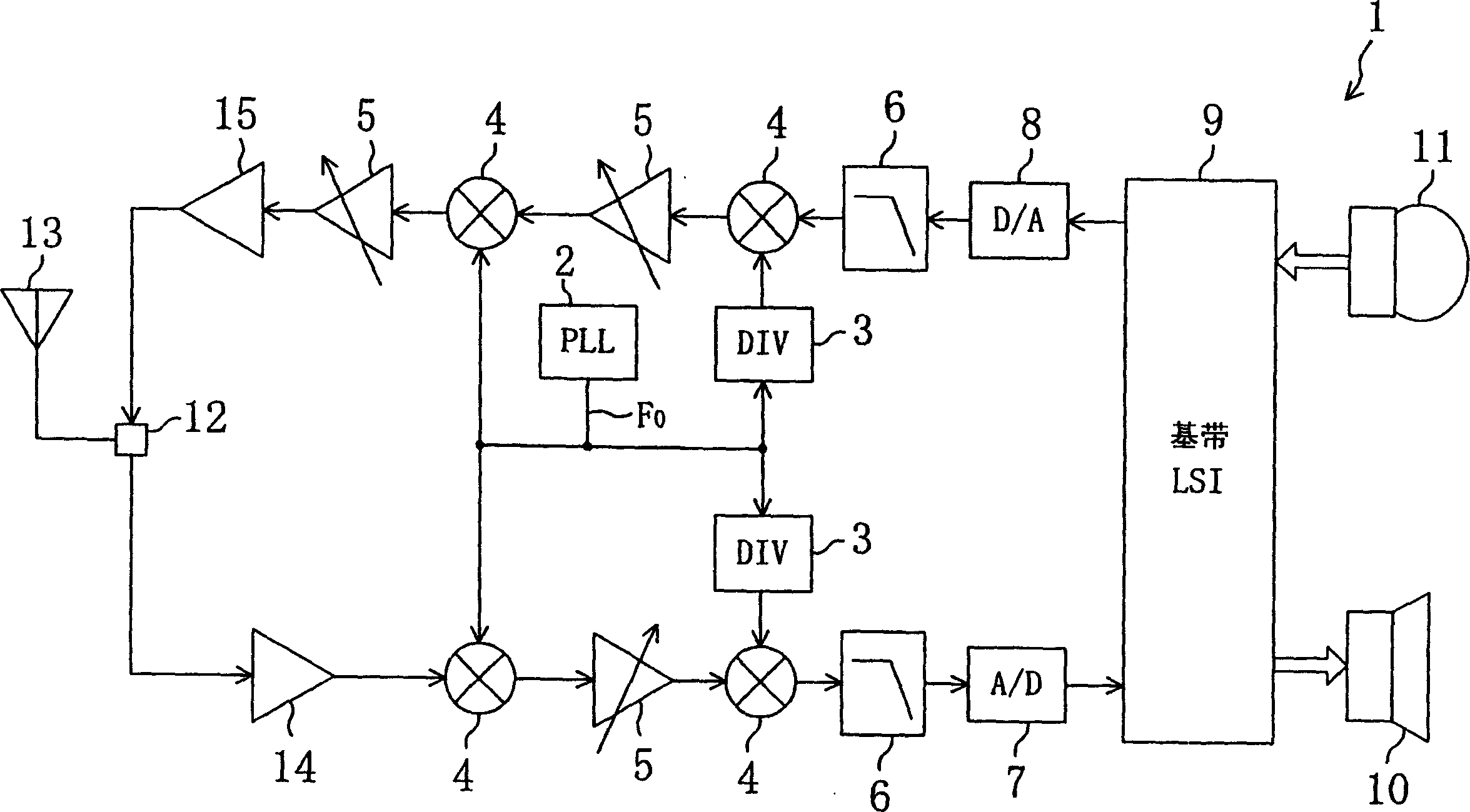

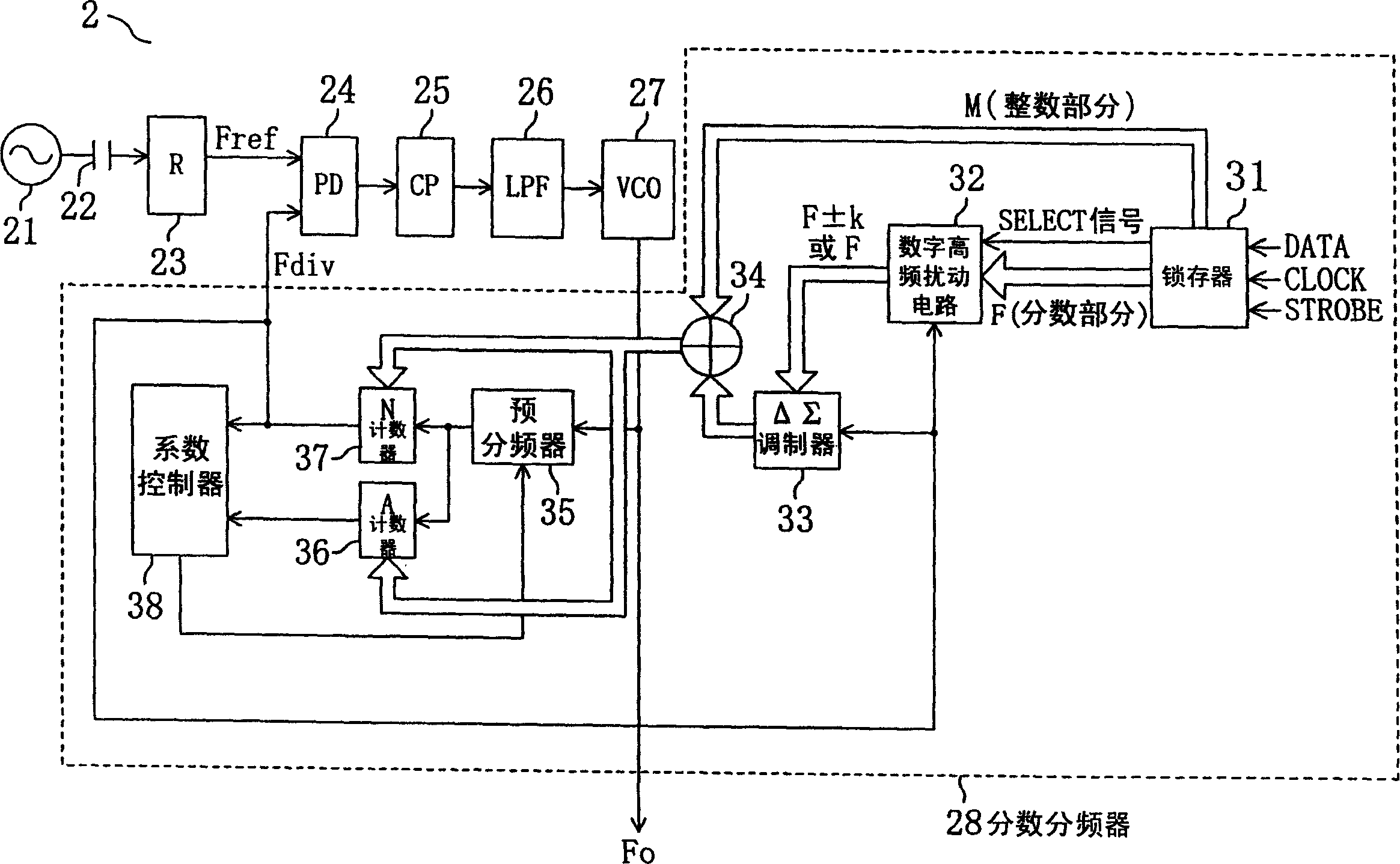

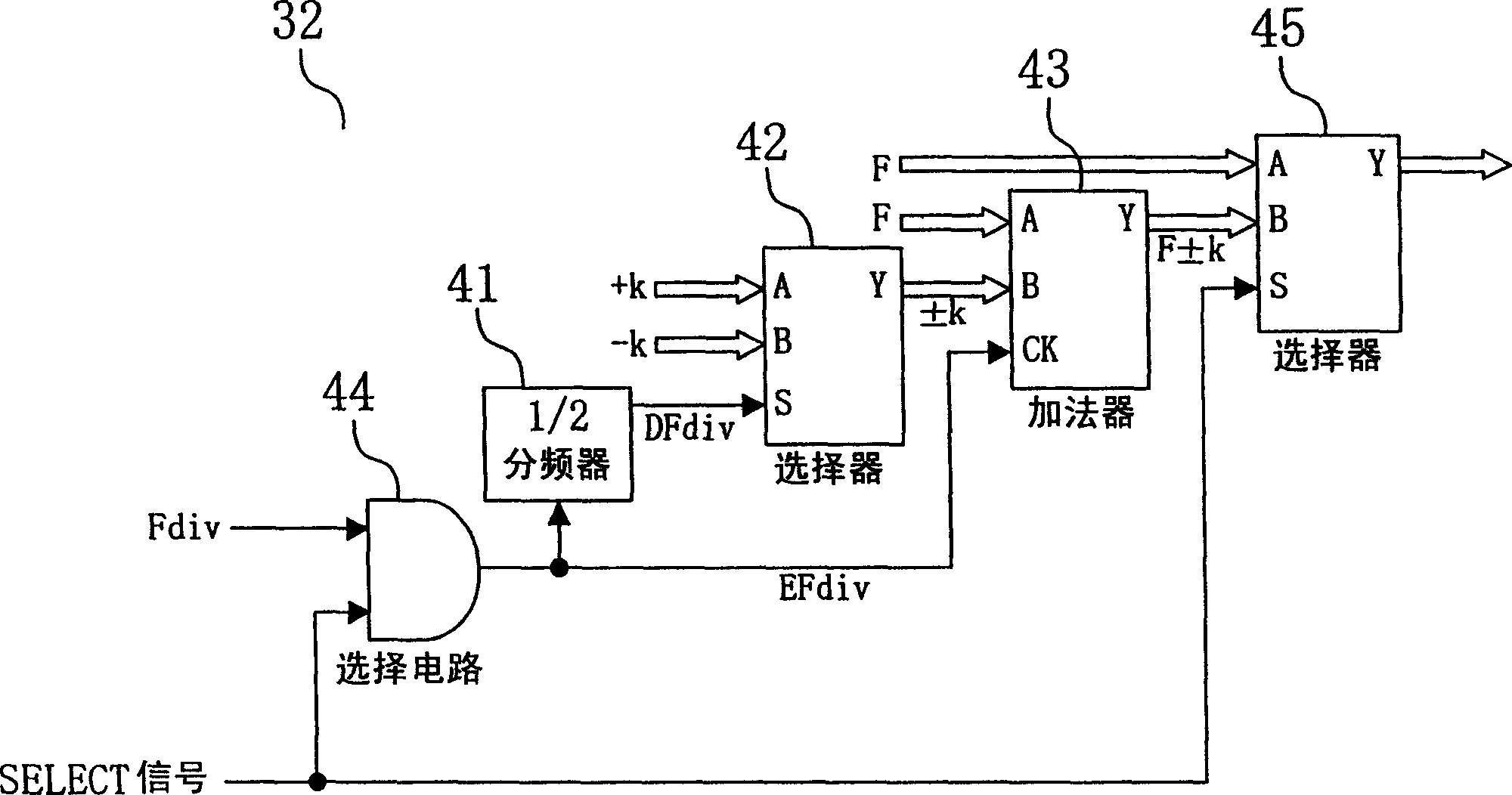

Signal processing device, signal processing method, delta-sigma modulation type fractional division PLL frequency synthesizer, radio communication device, delta-sigma modulation type D/A converter

InactiveCN1586041AReduce bit widthEliminate bad situationsPulse automatic controlDelta modulationFrequency synthesizerDelta-sigma modulation

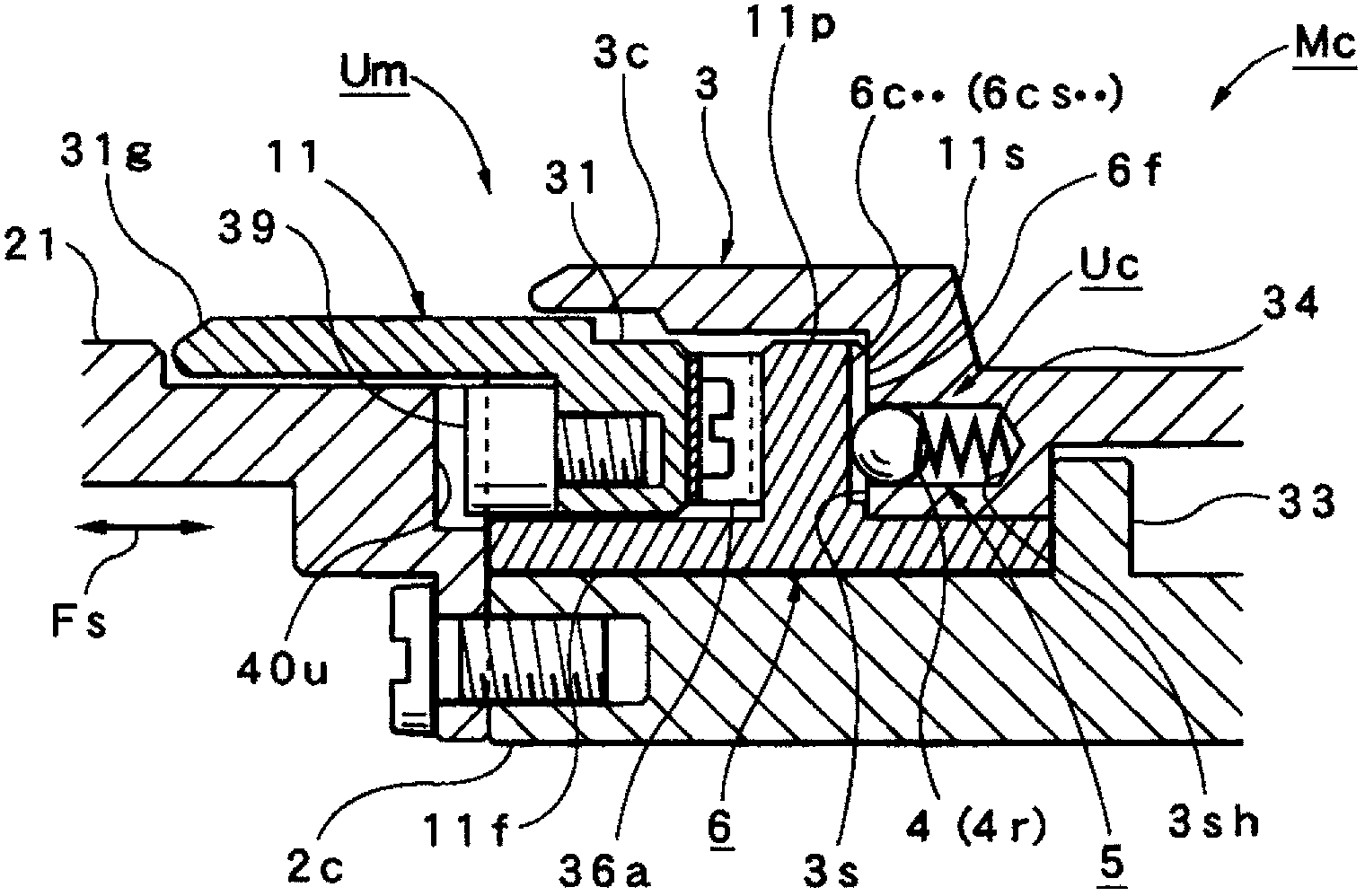

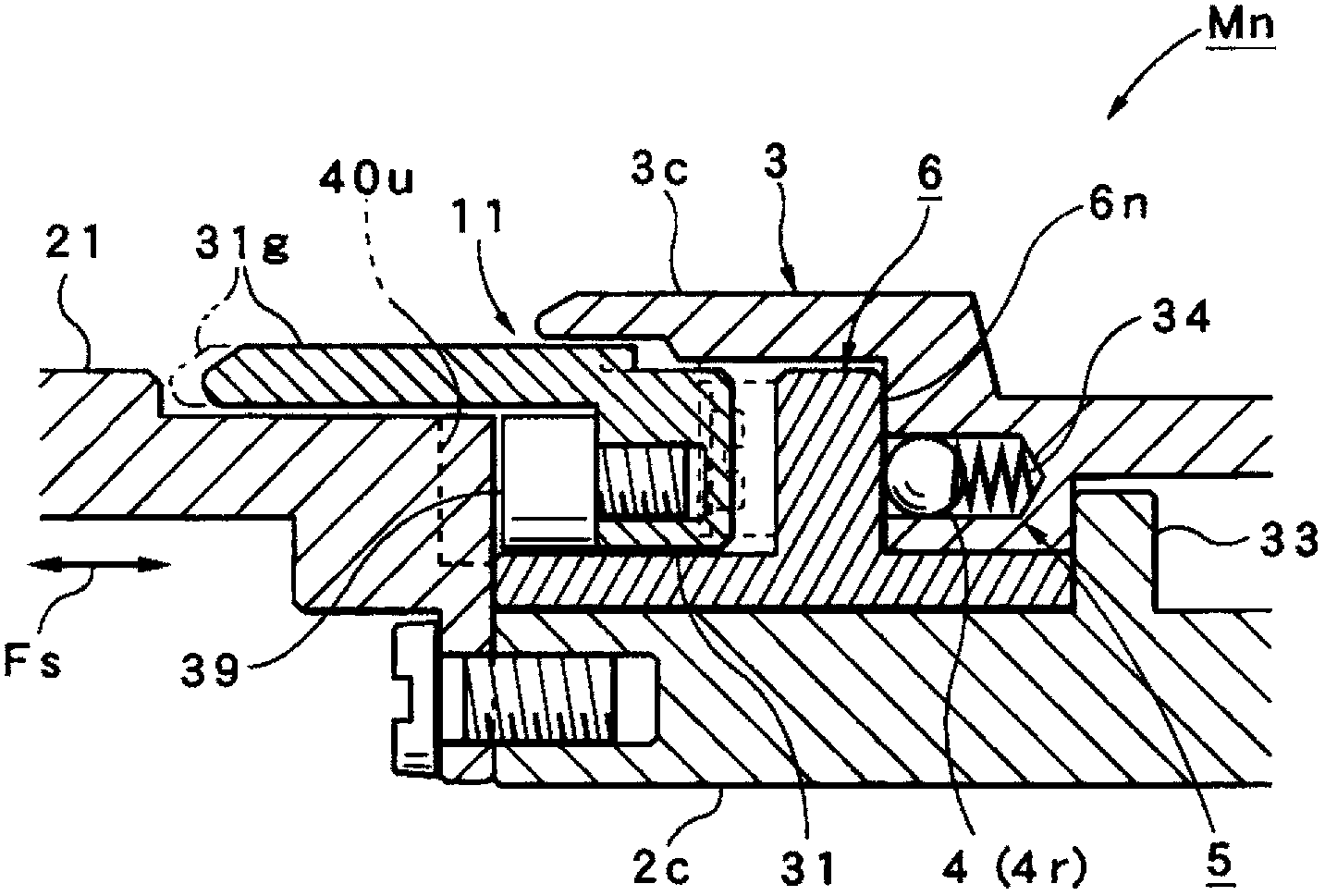

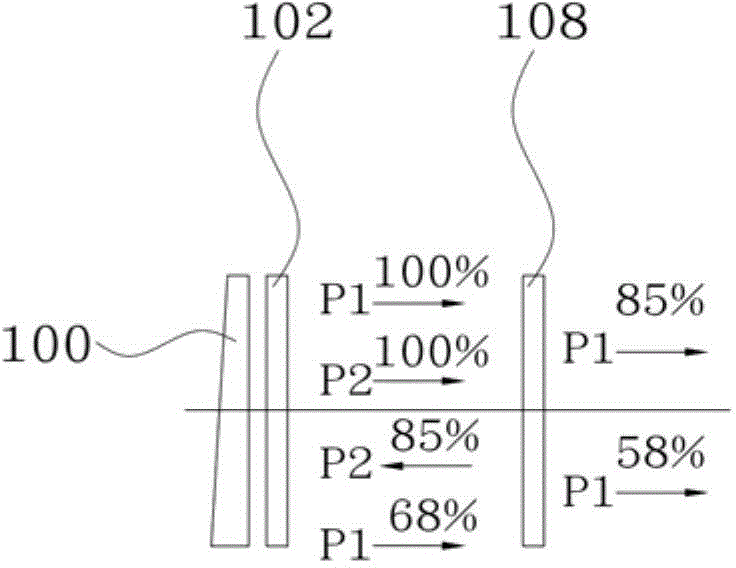

A fractional frequency divider (28) includes a latch (31) for holding frequency division data, a DeltaSigma modulator (33), a digital dither circuit (32) for receiving a digital input F representing fraction part of the frequency division data from the latch (31) and supplying a digital output alternately changing between F+k and F-k (where k is an integer) or a F value itself to the DeltaSigma modulator (33), and circuit means (34 through 38) for executing fractional frequency division based on integer part (M value) of the frequency division data and an output of the DeltaSigma modulator (33). The digital dither circuit (32) is useful for suppressing a spurious signal generated as a result of concentration of quantization noise at a particular frequency when the DeltaSigma modulator (33) receives a particular F value (e.g., F=2).

Owner:PANASONIC CORP

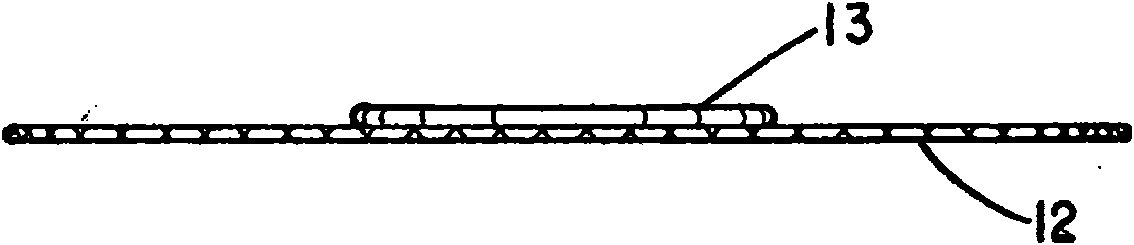

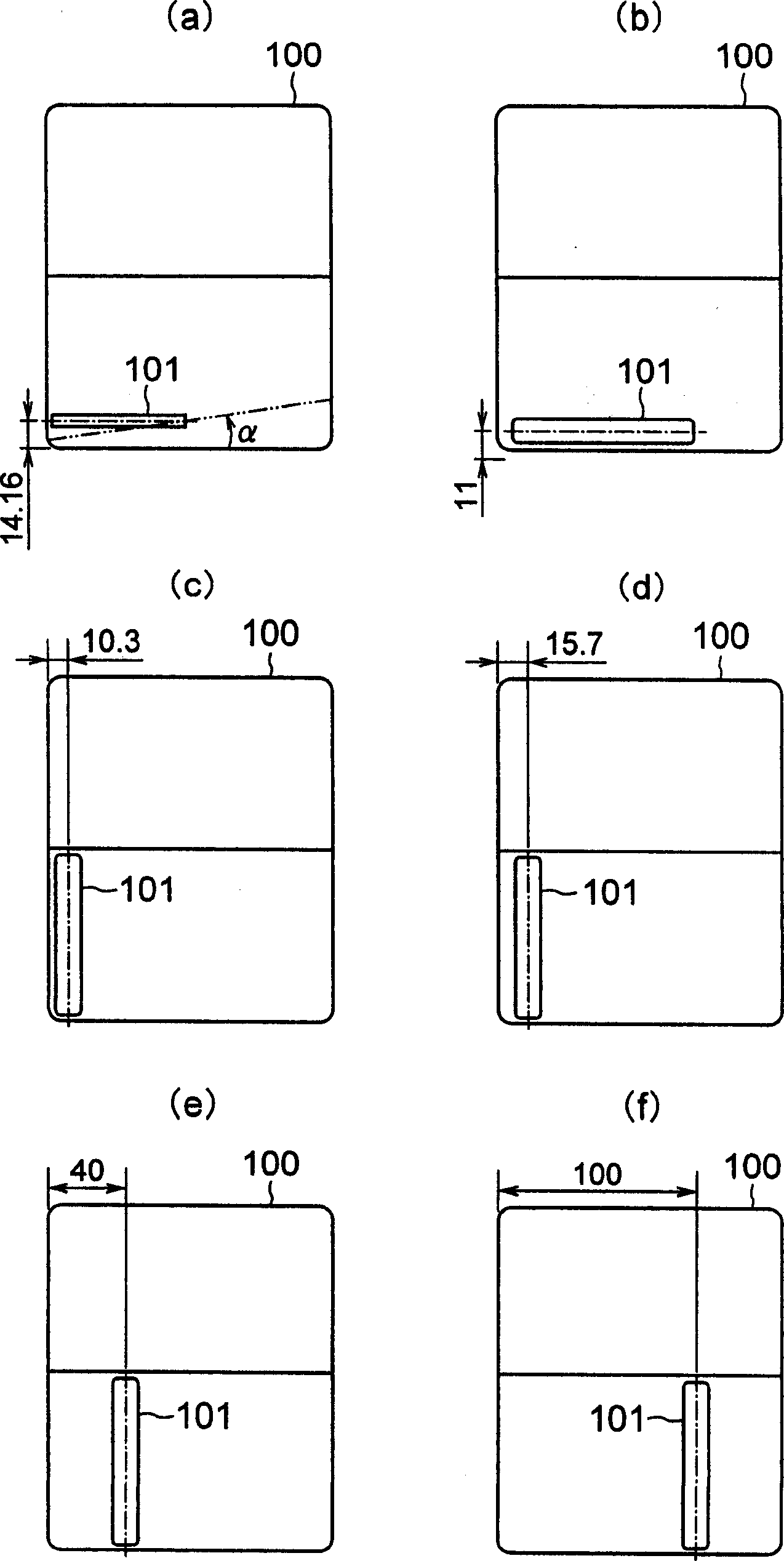

Sealing cushion

A gasket installed on the inner peripheral surface of an opening of a housing such as a cylinder head cover and sealing the gap between the housing and an insertion member such as a plug tube inserted in the opening. The gasket has good installability, so that, even if the inner diameter of the opening is not made to high precision, an outer periphery installation section of the gasket is prevented from being nipped in fitting of the gasket into the housing, or the gasket can be reliably fitted into the housing. To achieve the above, the outer diameter of the outer periphery installation section is set equal to or less than the inner diameter of the opening, and a tightening allowance setting means and a radial direction positioning means are provided on an outer peripheral section of the outer periphery installation section of the gasket. The tightening allowance setting means sets a tightening allowance of the gasket relative to the inner peripheral surface of the opening, and the radial direction positioning means performs radial positioning of the gasket relative to the inner peripheral surface of the opening. The tightening allowance setting means is inclined in the axially opposite direction to the direction of fitting of the gasket into the housing and has a lip shape whose outer diameter in a free state is set greater than the inner diameter of the opening.

Owner:NOK CORP

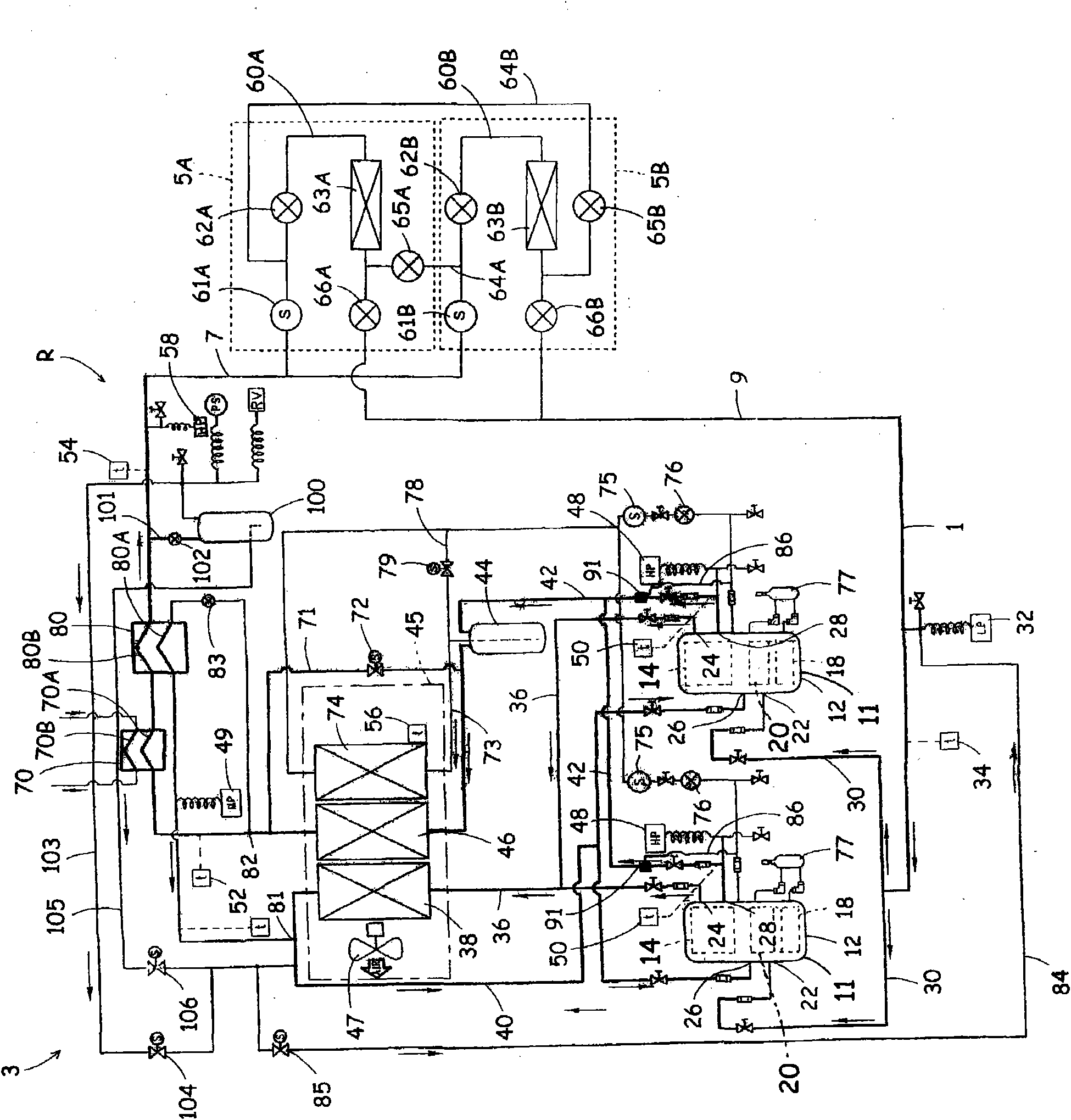

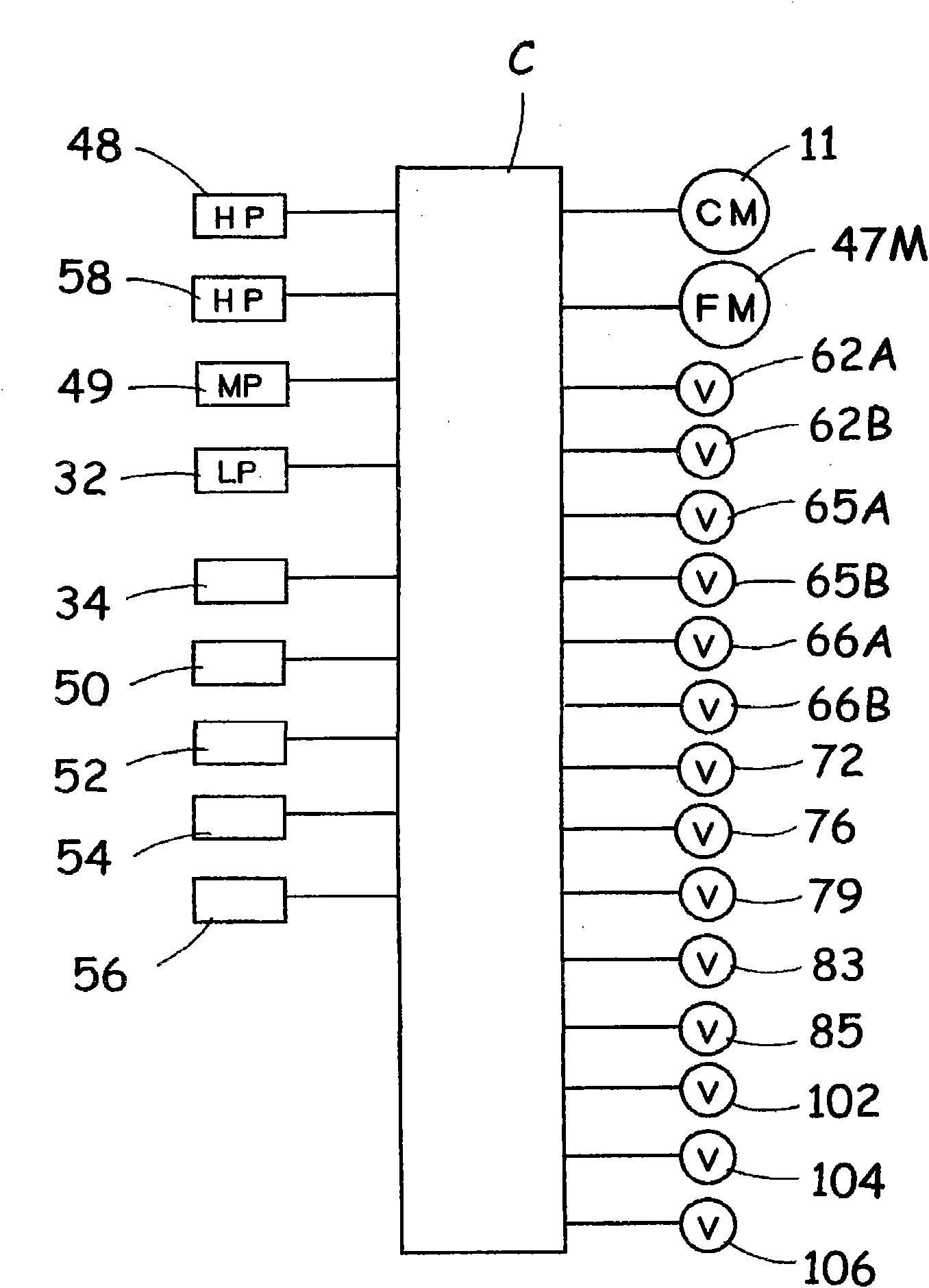

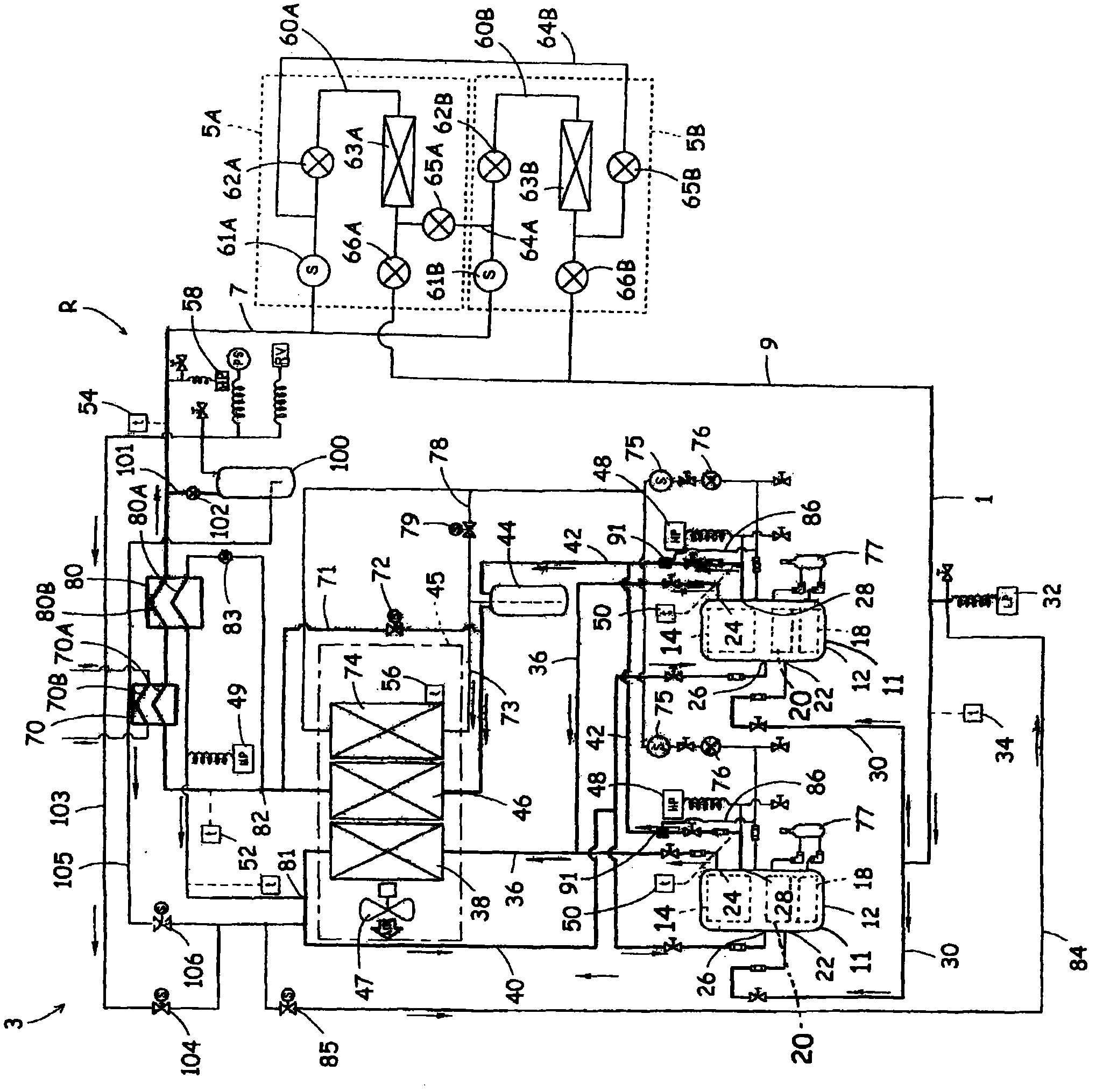

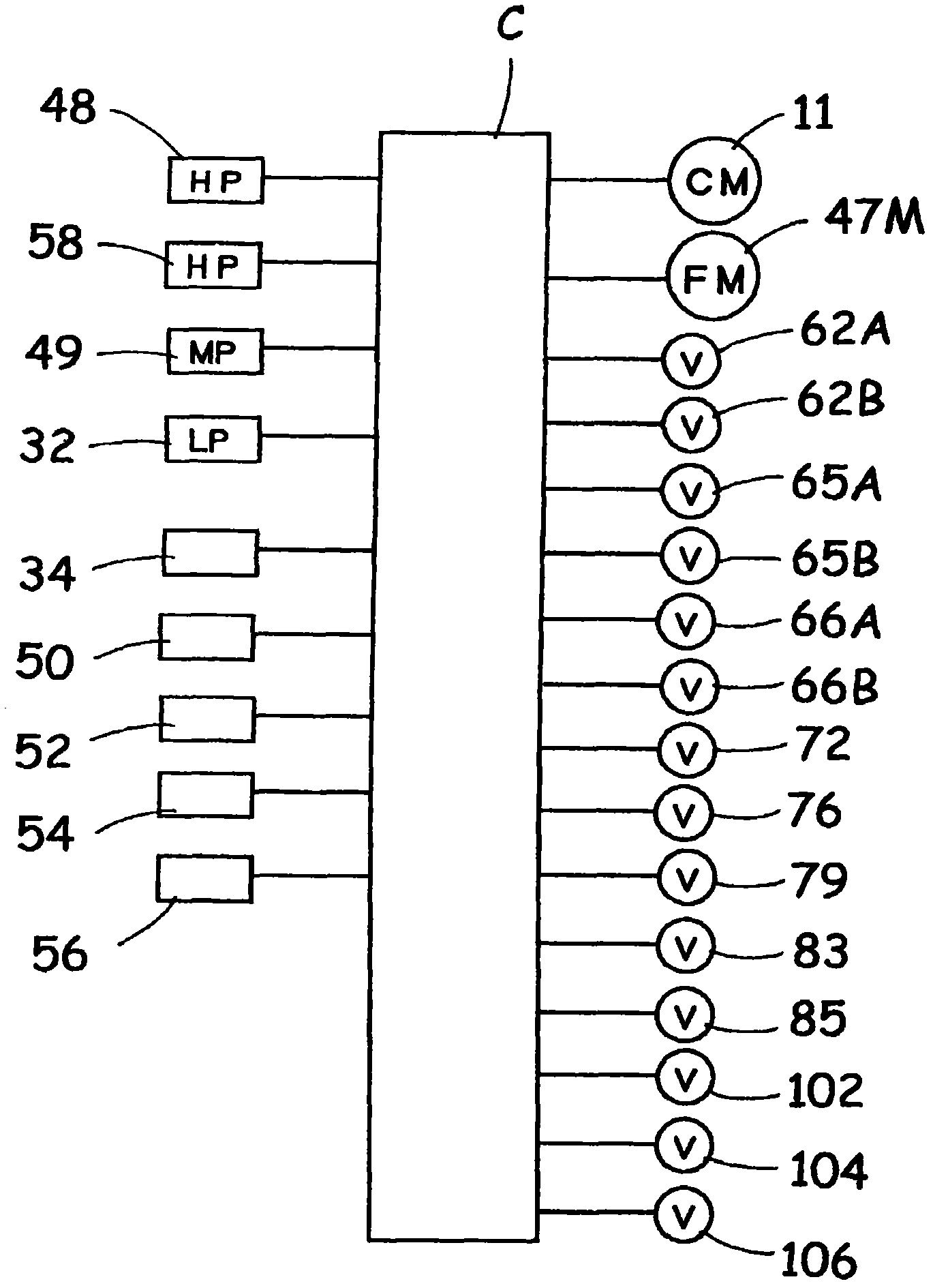

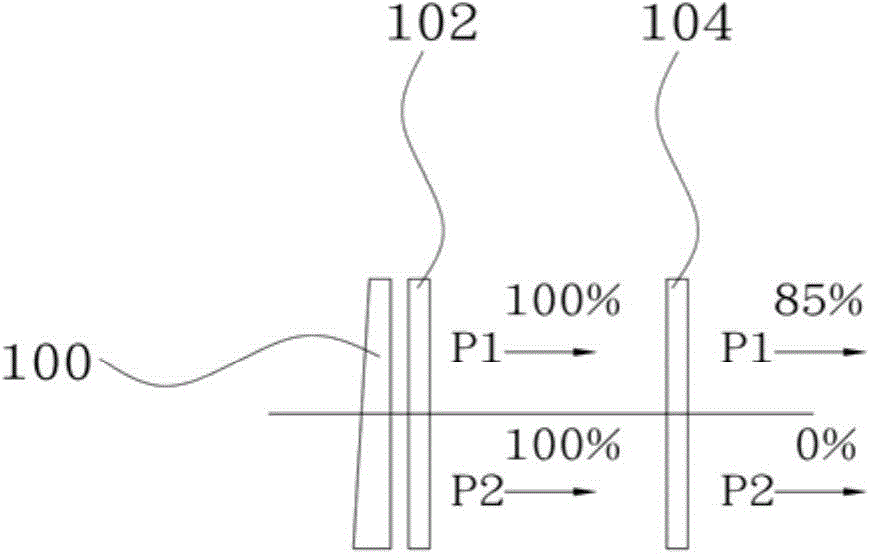

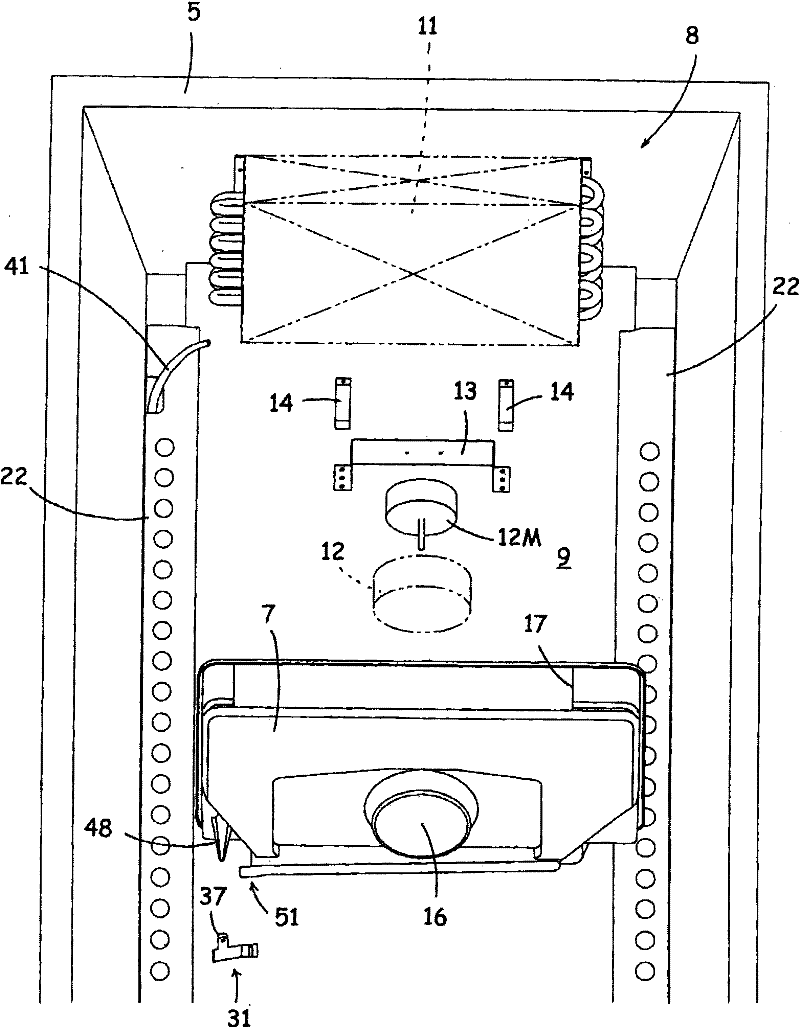

Cooling device

ActiveCN102109240AWith throttling functionMaintain cycle refrigerant quantityMechanical apparatusCompression machines with non-reversible cycleRefrigerantIntermediate pressure

The invention provides a cooling device, and thus in a cooling device with a critical pressure formed at a high-pressure side, the amount of a circulatory refrigerant in a refrigerant circuit can be properly maintained, and the overload operation of a compressing mechanism due to an abnormally high pressure can be prevented. The invention relates to a cooling device (R) with a supercritical pressure formed at the high-pressure side, and the device comprises: a refrigerant amount adjusting box (100) connected to the high-pressure side through a communicating circuit (101); a communicating circuit (103) communicating the upper part of the box and an intermediate-pressure region in the refrigerant circuit; a communicating circuit (105) communicating the lower part of the box and the intermediate-pressure region in the refrigerant circuit; an electric expansion valve (102) of the communicating circuit (101); a solenoid valve (104) of the communicating circuit (13); a solenoid valve (106) of the communicating circuit (105); and a control device (C) controlling the electric expansion valve (102) and various valve devices to recover the circulatory refrigerant in the refrigerant circuit into the box and to charge the refrigerant into the refrigerant circuit (1).

Owner:SANYO ELECTRIC CO LTD

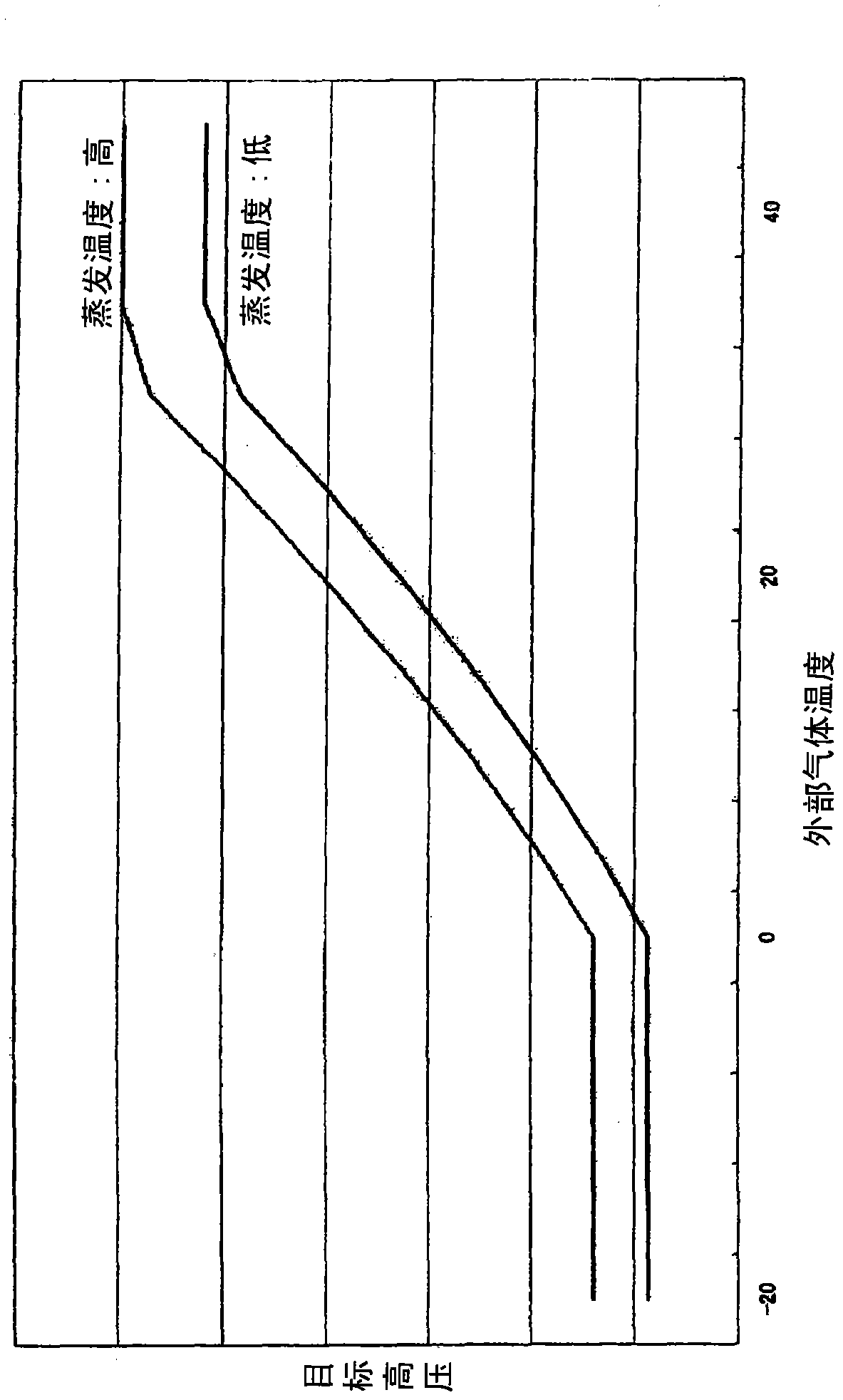

Refrigeration device

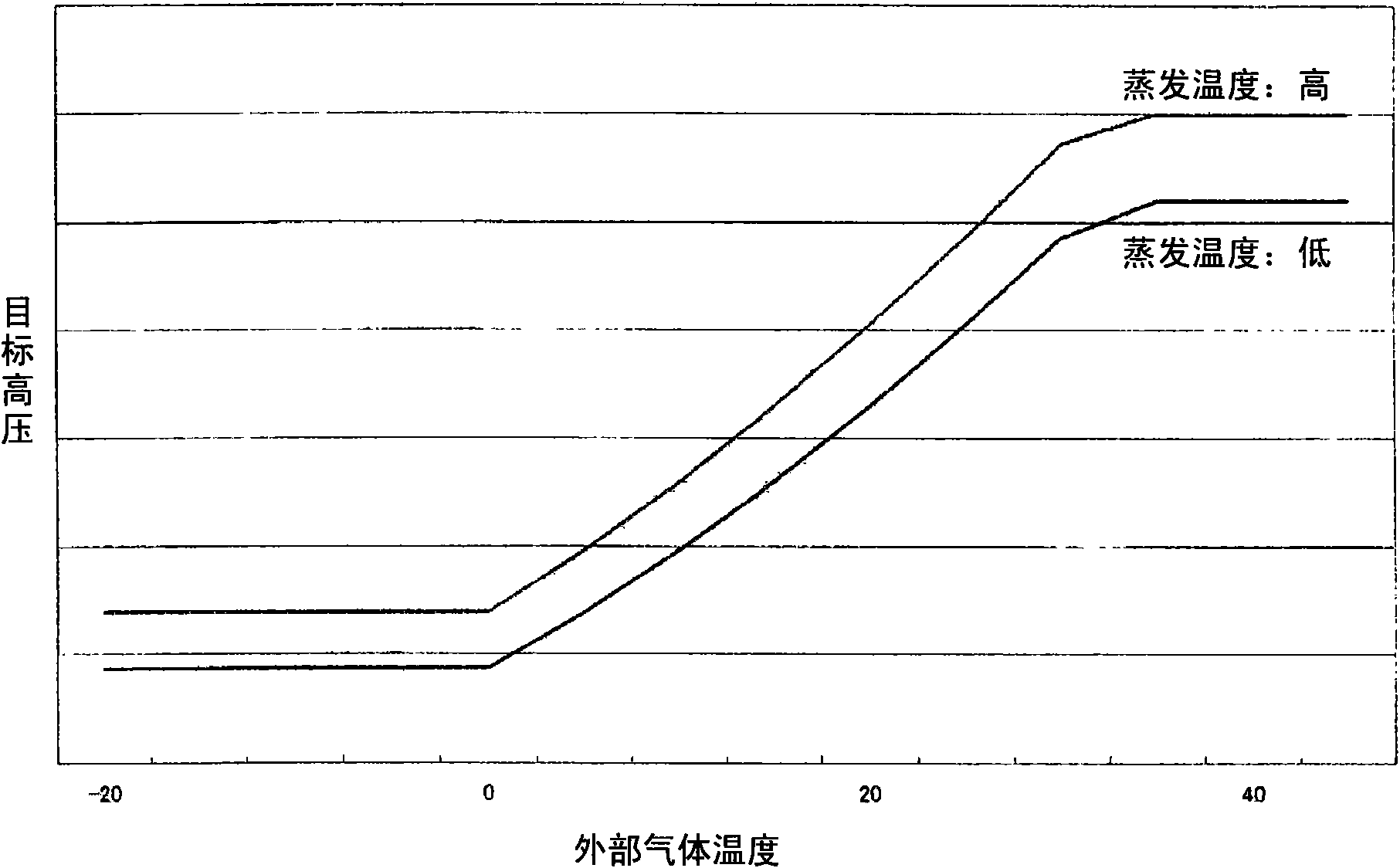

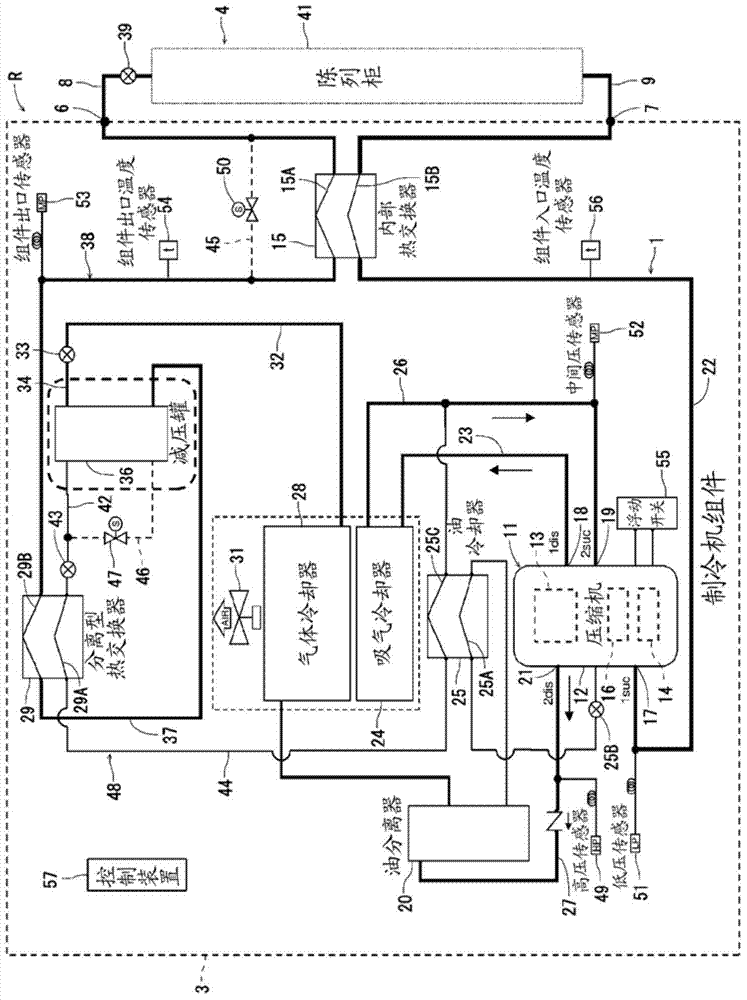

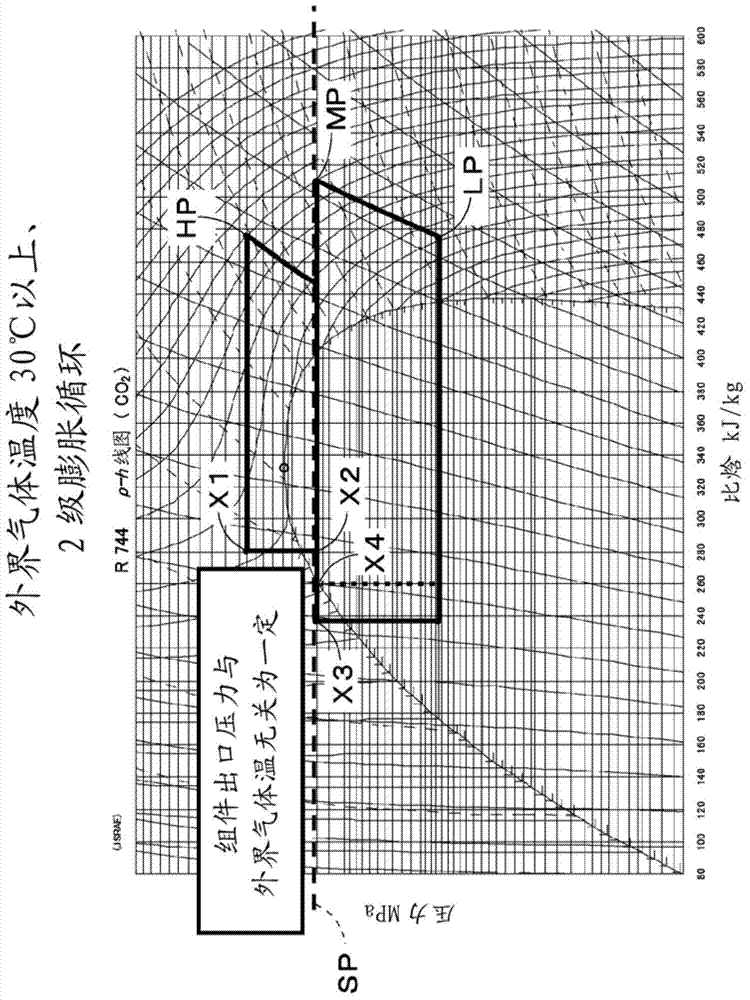

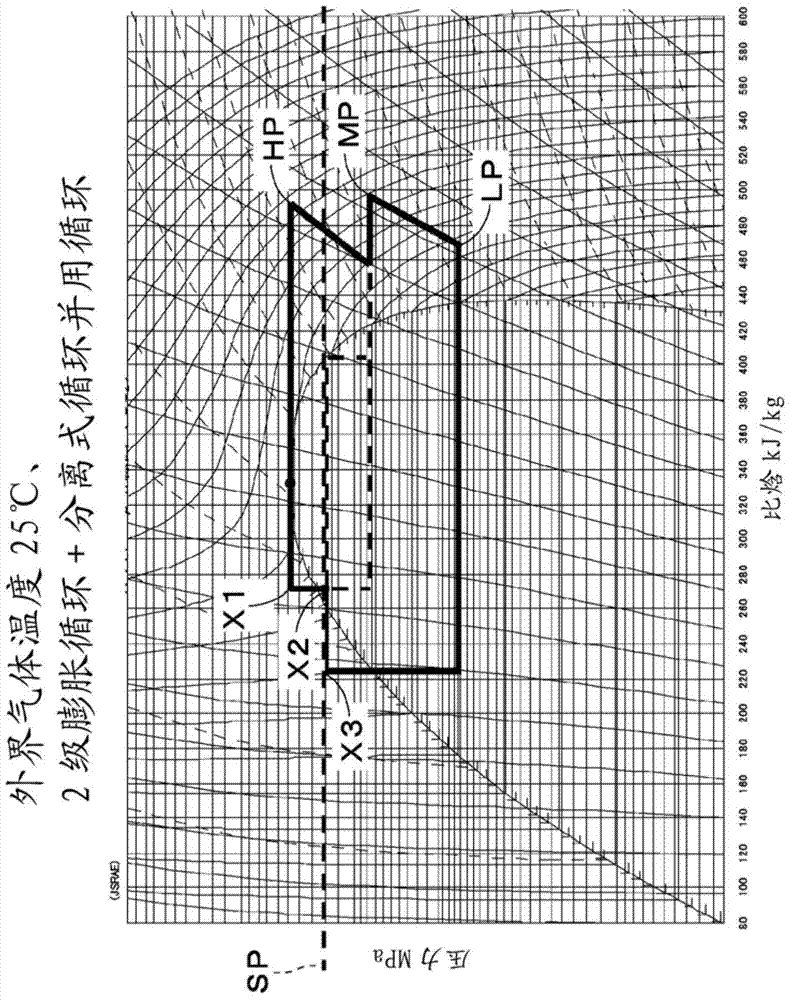

InactiveCN104755858AReduce specific enthalpyImprove cooling effectCompressorCompression machines with non-reversible cycleEngineeringGas cooler

Provided is a refrigeration device which can, independently of outside air temperature, ensure stable refrigeration performance when the high-pressure side has a supercritical pressure, and which can improve cost and the easiness of construction. A refrigeration device is provided with: a pressure regulating throttle means which is connected to a refrigerant circuit which is located downstream of a gas cooler and upstream of a main throttle means; a decompression tank which is connected to a refrigerant circuit which is located downstream of the pressure regulating throttle means and upstream of the main throttle means; a split heat exchanger which is provided in a refrigerant circuit which is located downstream of the decompression tank and upstream of the main throttle means; an auxiliary circuit which allows a refrigerant within the decompression tank to be sucked into the intermediate pressure section of a compressor after causing the refrigerant to flow to a first flow passage in the split heat exchanger through an auxiliary throttle means; and a main circuit which allows a refrigerant to flow out from the lower part of the decompression tank, causes the refrigerant to flow to a second flow passage in the split heat exchanger, subjects the refrigerant to heat exchange with a refrigerant flowing through the first flow passage, and then causes the refrigerant, having been subjected to heat exchange with the refrigerant flowing through the first flow passage, to flow into the main throttle means.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Liquid ejection apparatus and drive circuit thereof

Provided are a liquid ejection apparatus and a drive circuit thereof, which can drive an actuator quickly enough and can eliminate problems of producing foreign substances in the ink in the pressure chambers and of dissolving or corroding the electrodes and prevent the ink from changing in quality. A direct current voltage which has positive and negative potentials relative to a ground potential interposed therebetween is used as a drive voltage for electric charging / discharging to / from an actuator.

Owner:TOSHIBA TEC KK

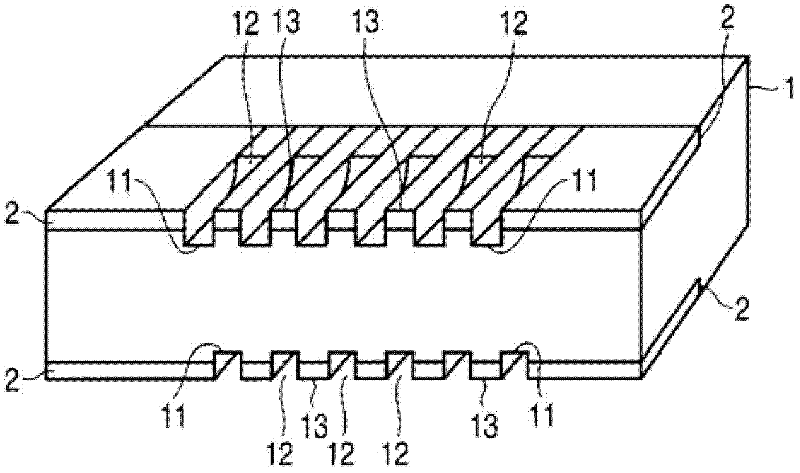

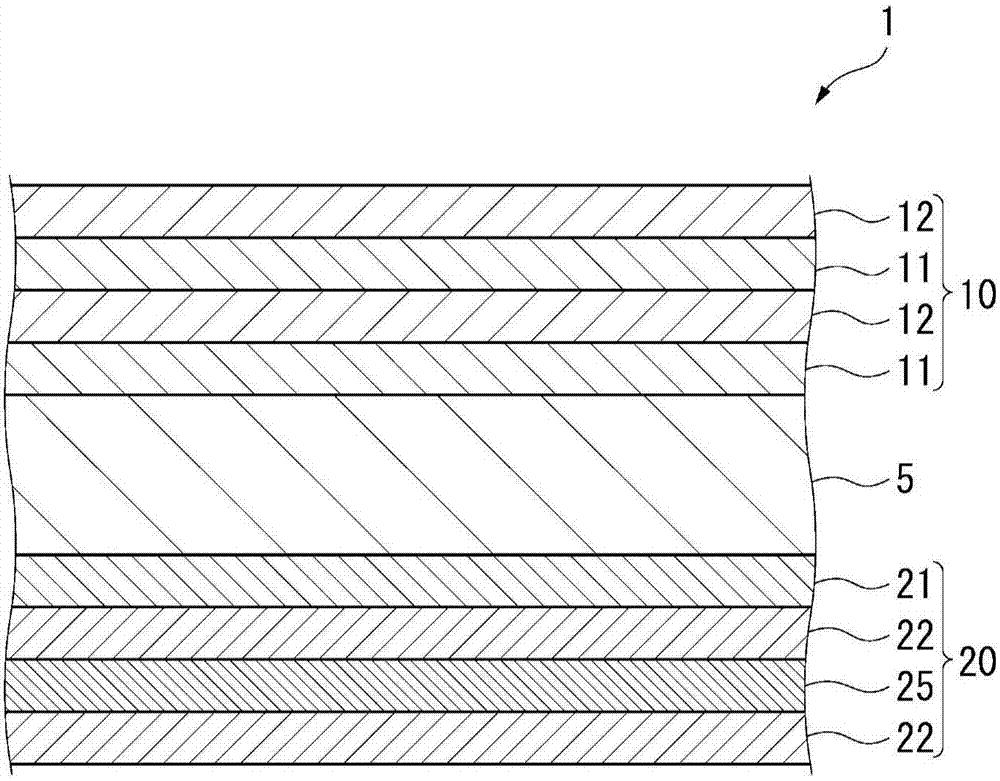

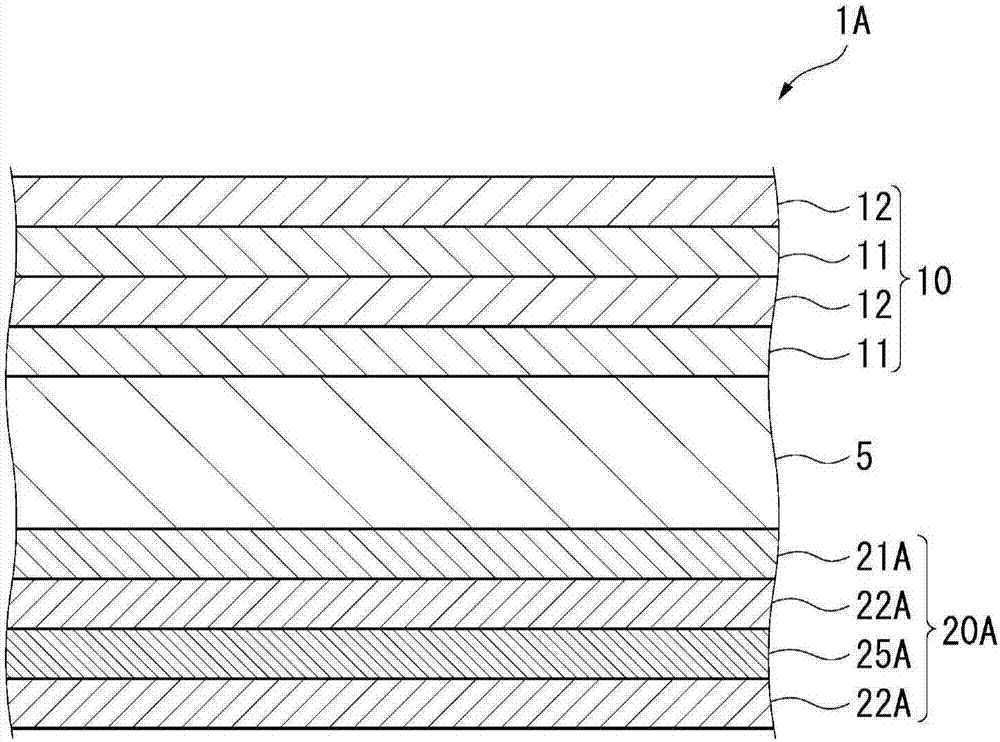

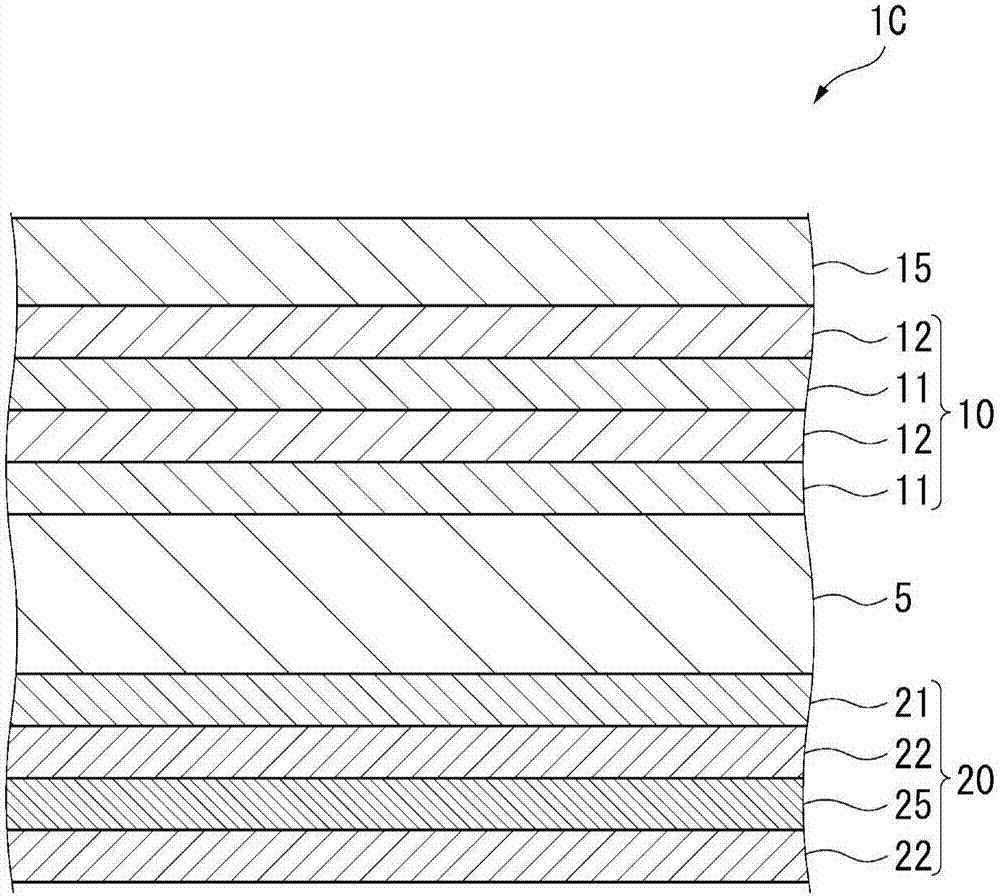

Light transmissive member, timepiece, and light transmissive member production method

InactiveCN106977113AExcellent optical propertiesEliminate bad situationsElectronic time-piece structural detailsVacuum evaporation coatingVisibilityRefractive index

The present invention relates to a light transmissive member which has enhanced visibility and also is hardly electrified, a timepiece using the light transmissive member as a cover glass, and a light transmissive member production method. The light transmissive member (1) includes a substrate (5) having a light transmission property, wherein on one surface of the substrate (5), an antireflection layer (10) in which a low-refractive index layer (12) composed mainly of silicon oxide (SiO2) and a high-refractive index layer (11) composed mainly of silicon nitride (SiN) are alternately stacked is formed, and on the other surface of the substrate (5), an antistatic layer (20) including at least a transparent electrically conductive film layer (25) is formed.

Owner:SEIKO EPSON CORP

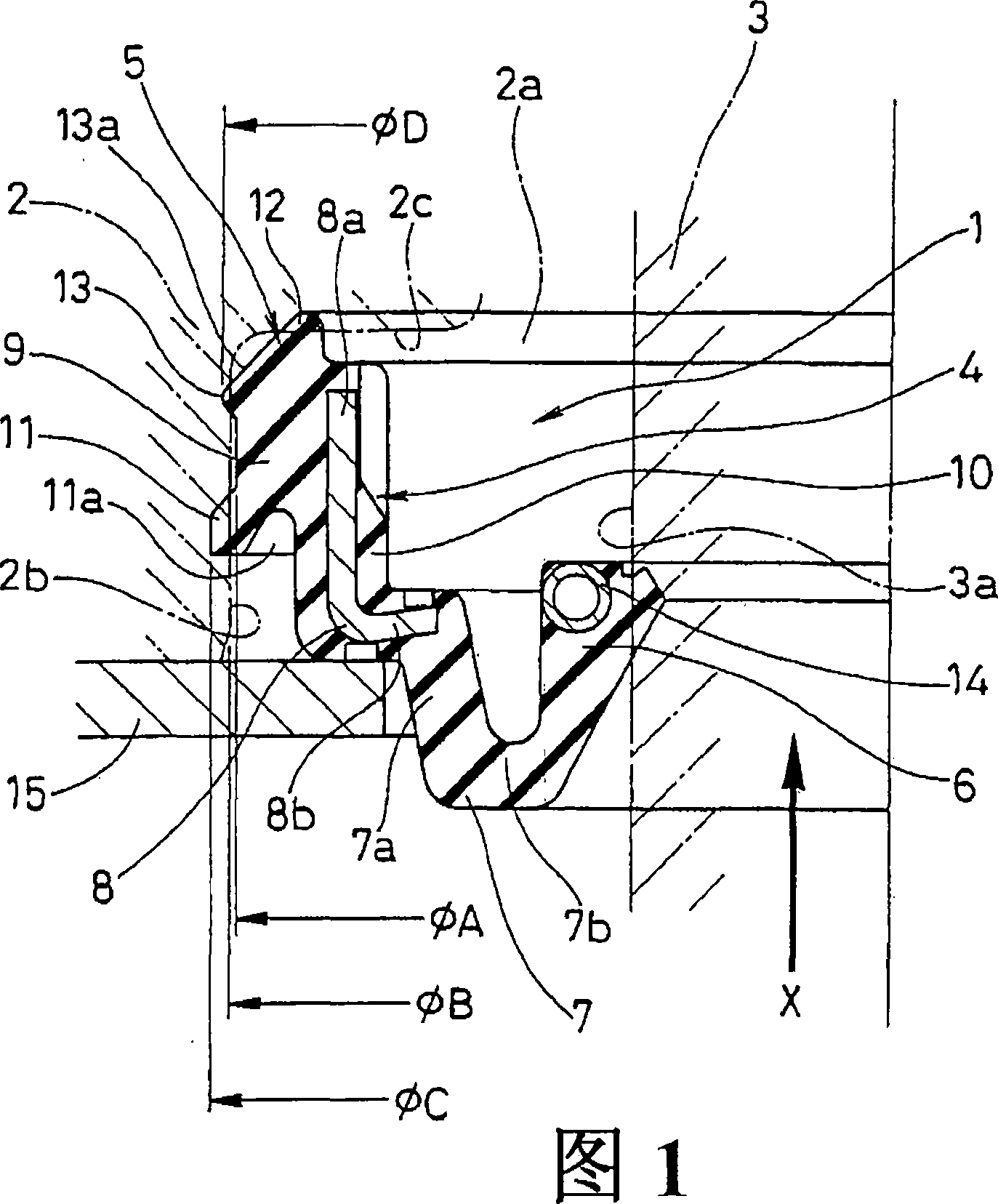

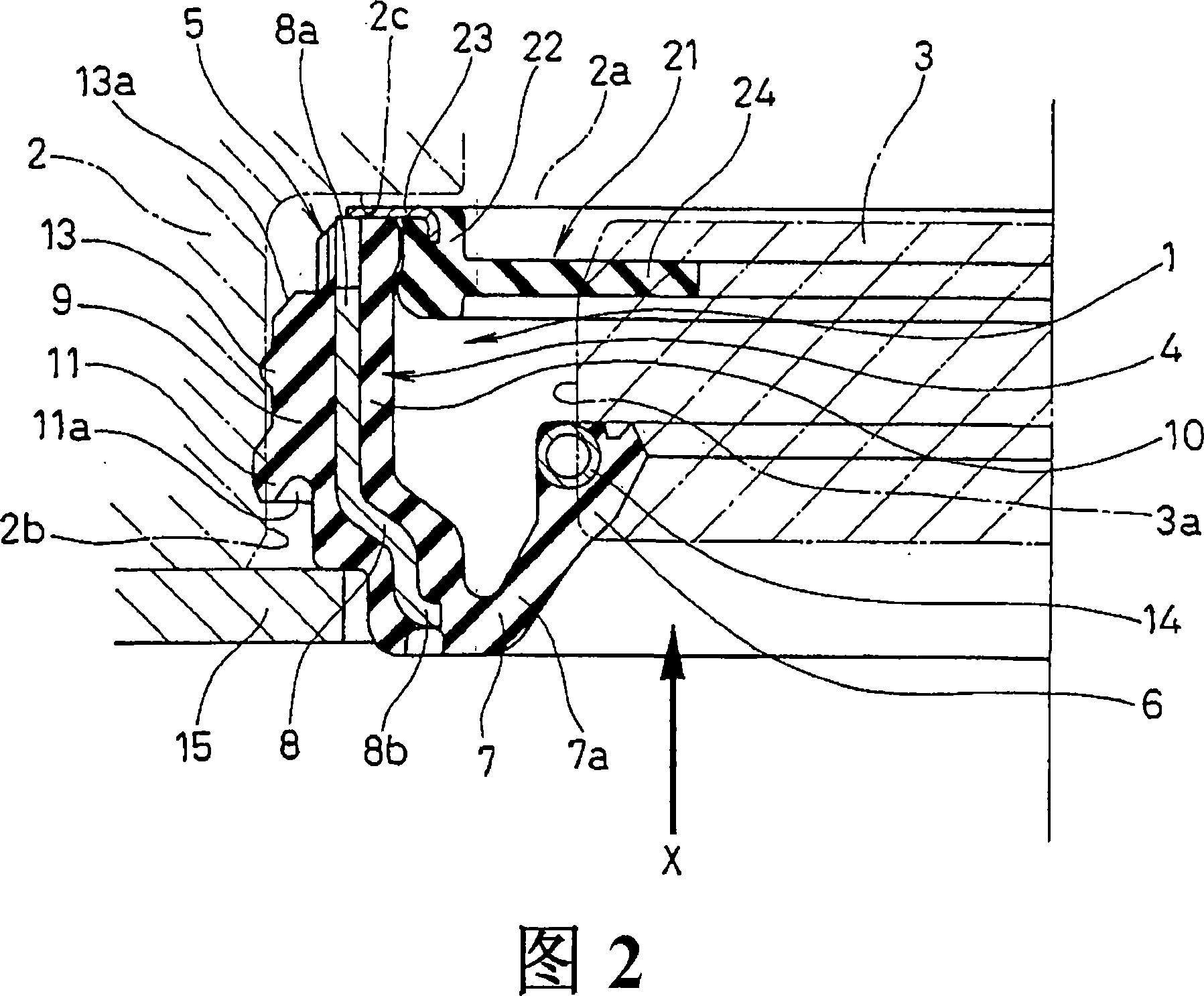

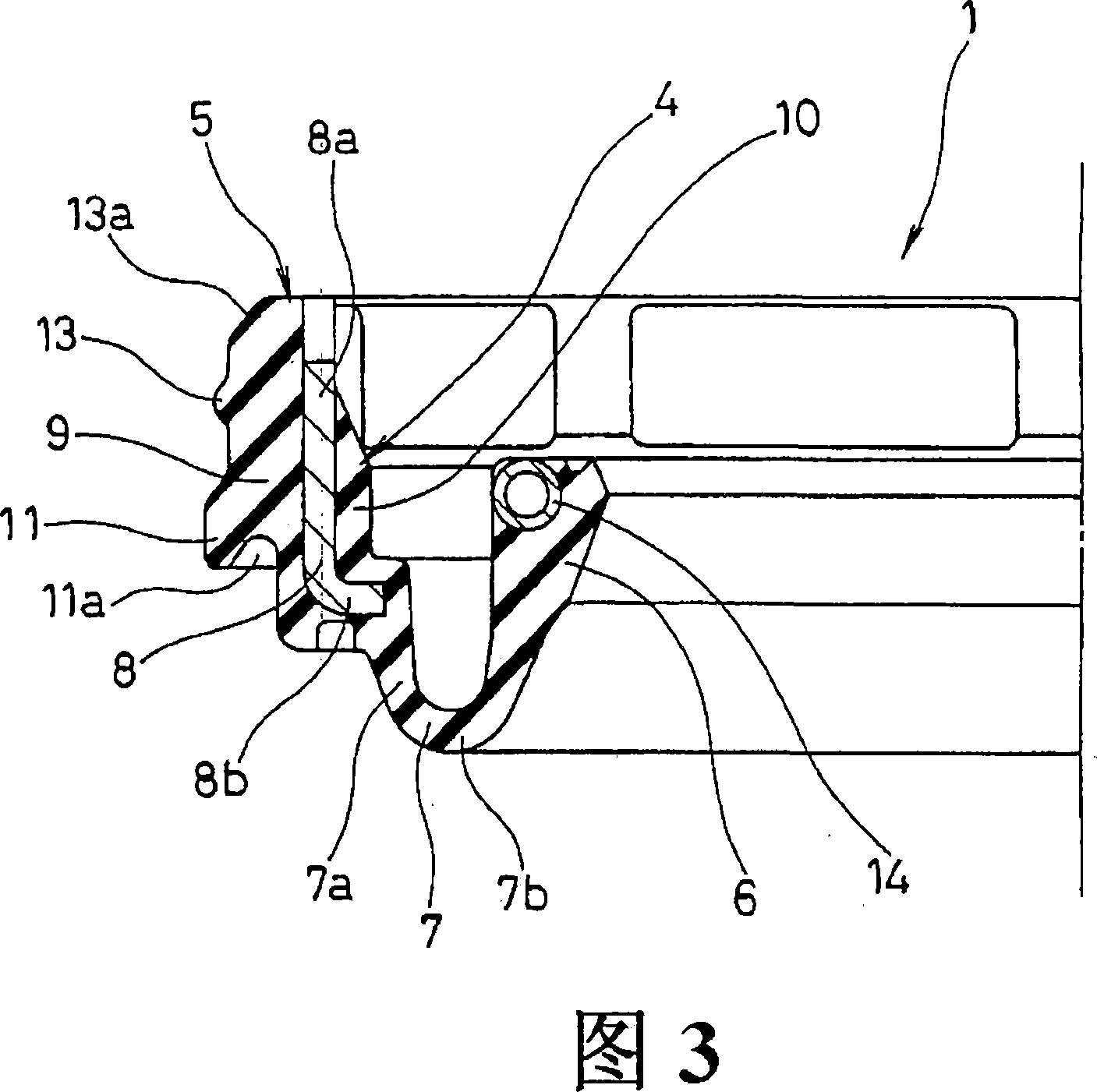

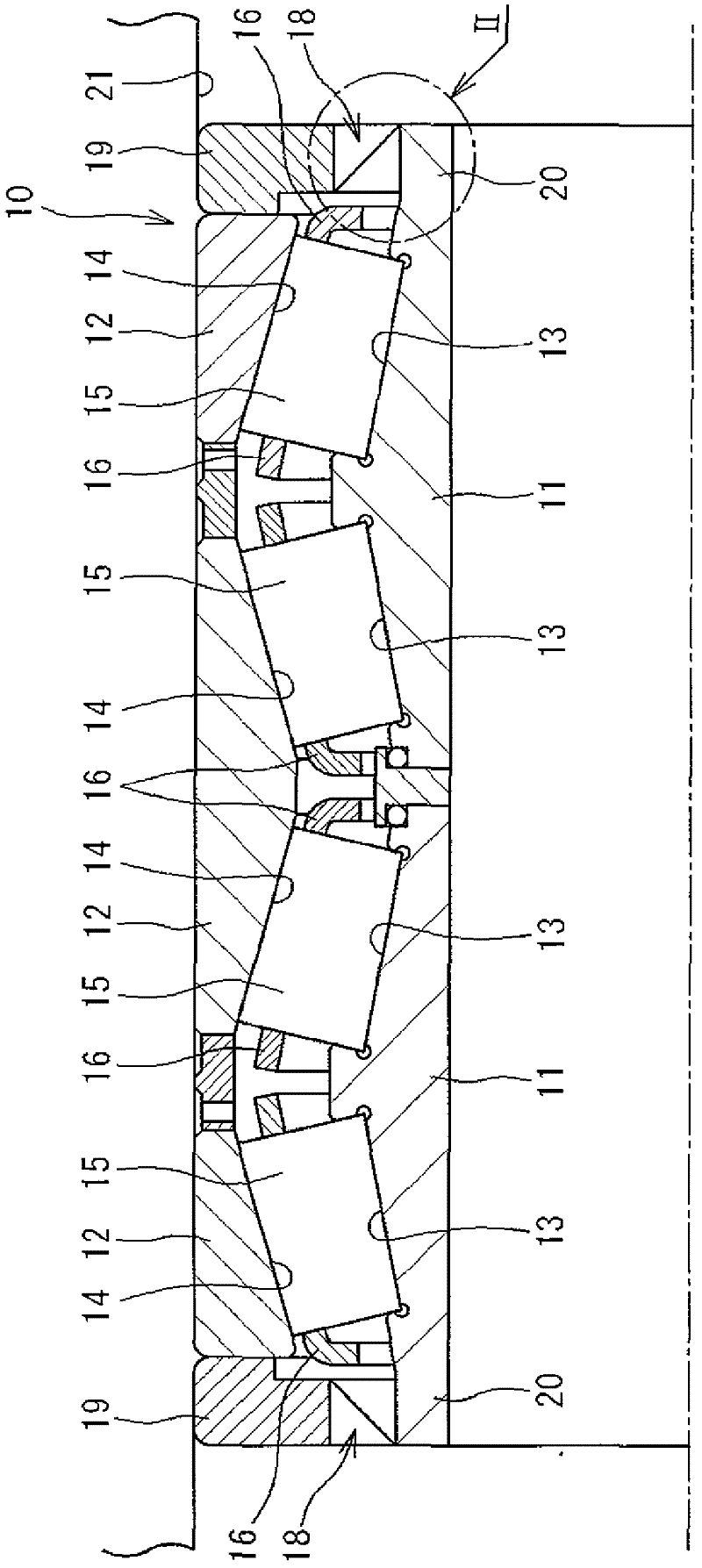

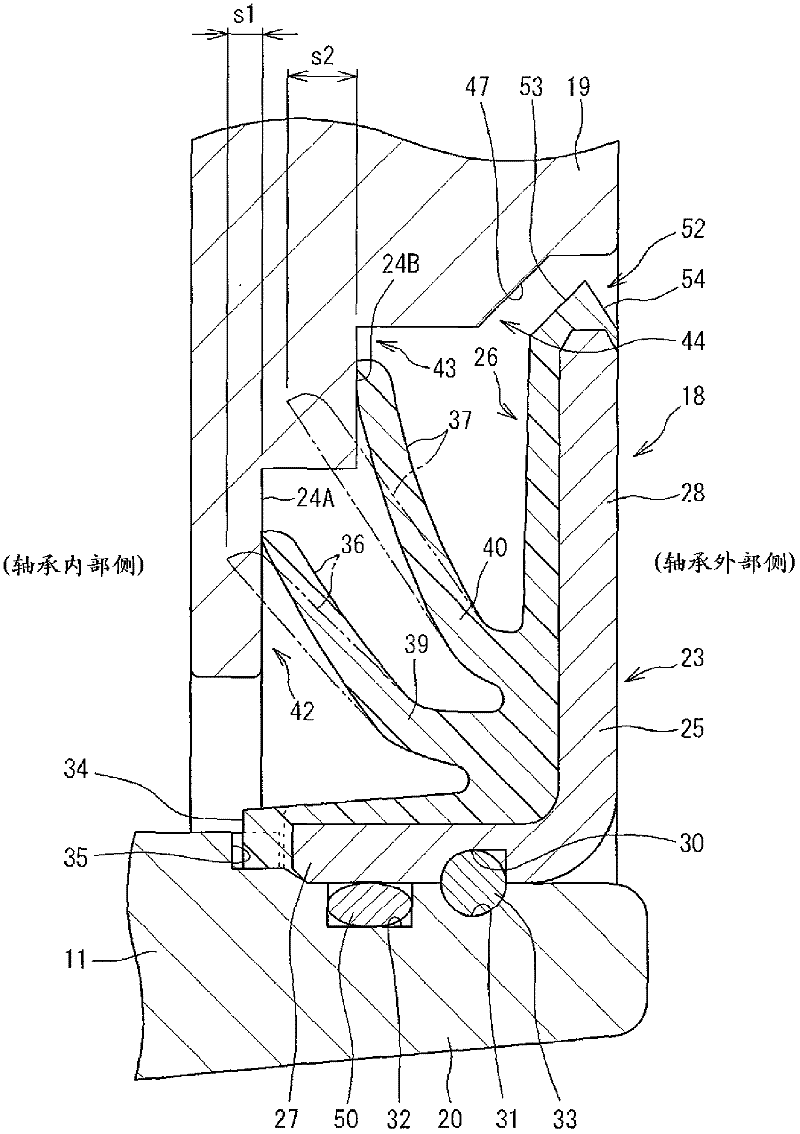

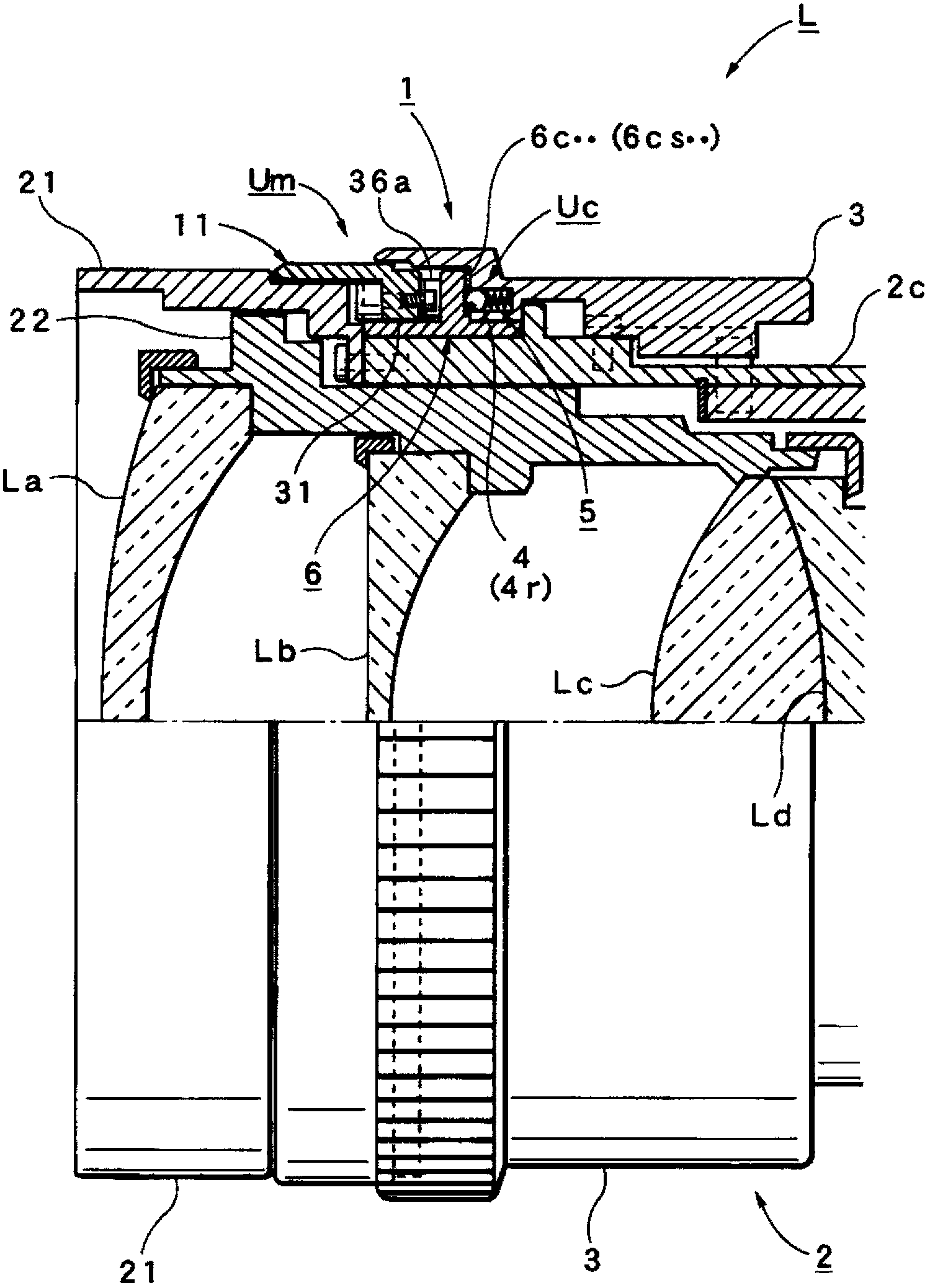

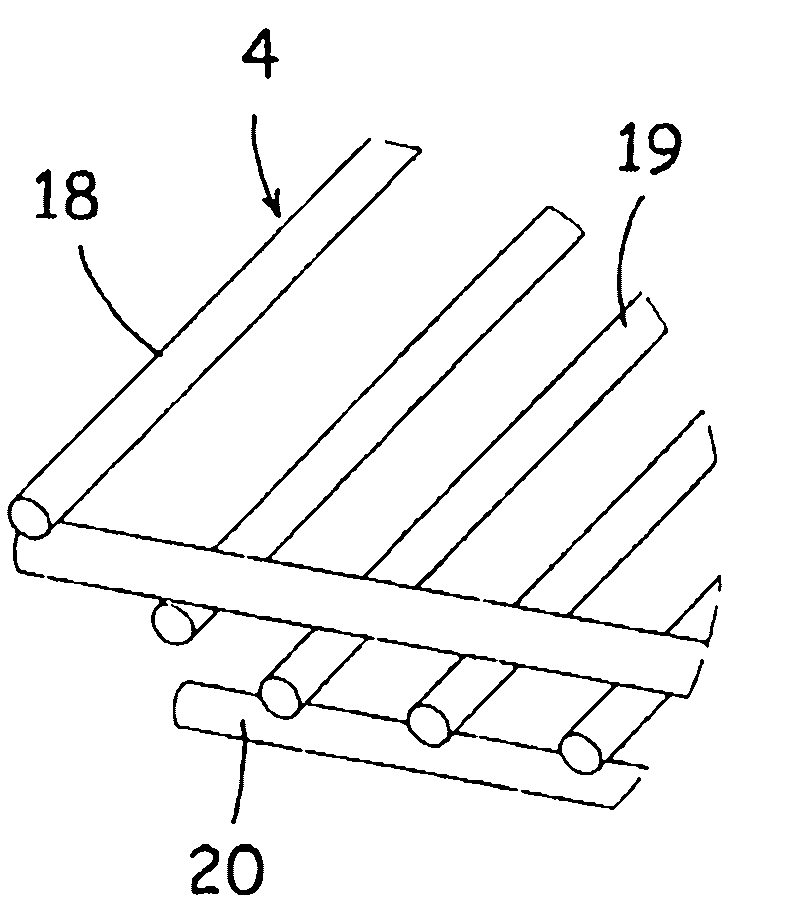

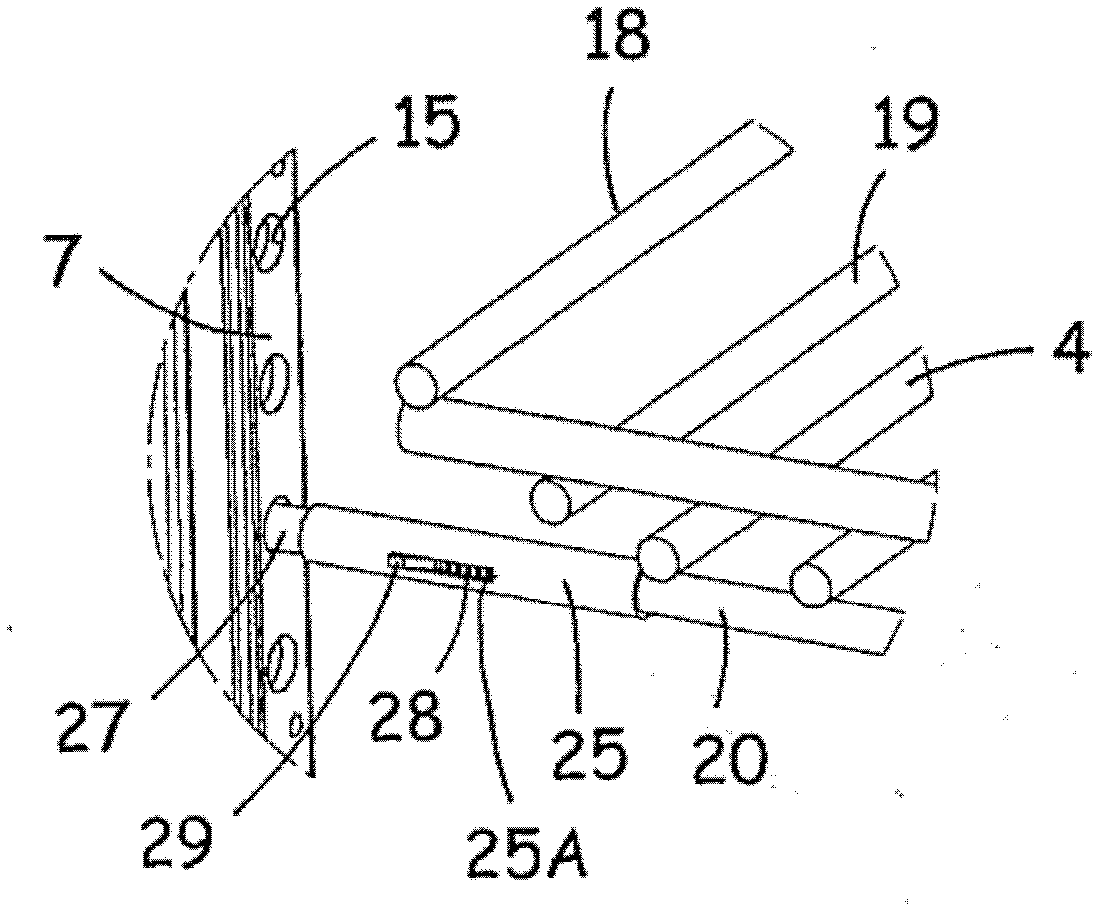

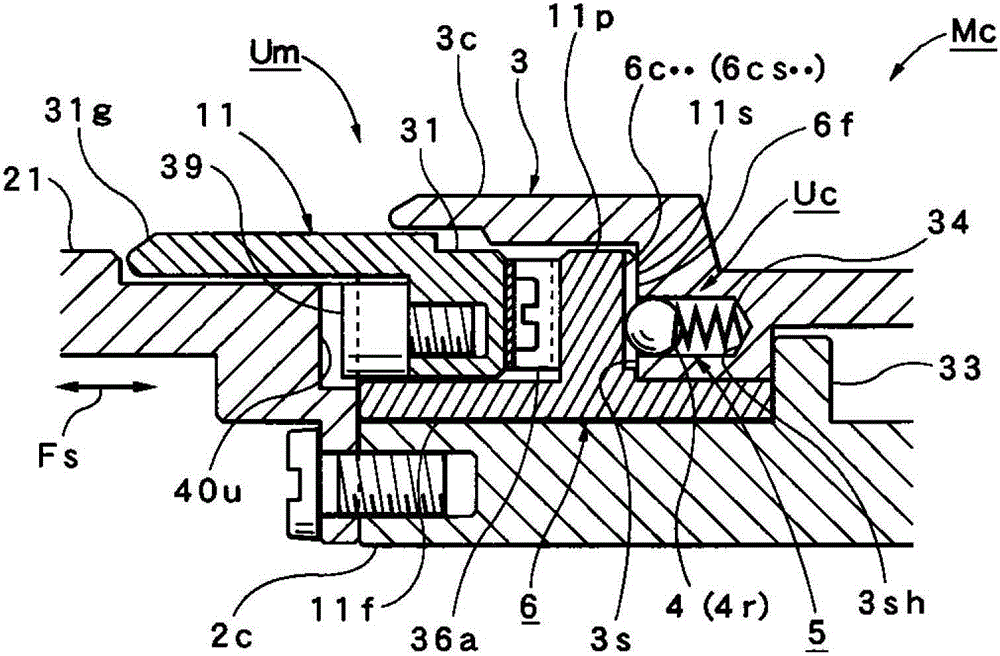

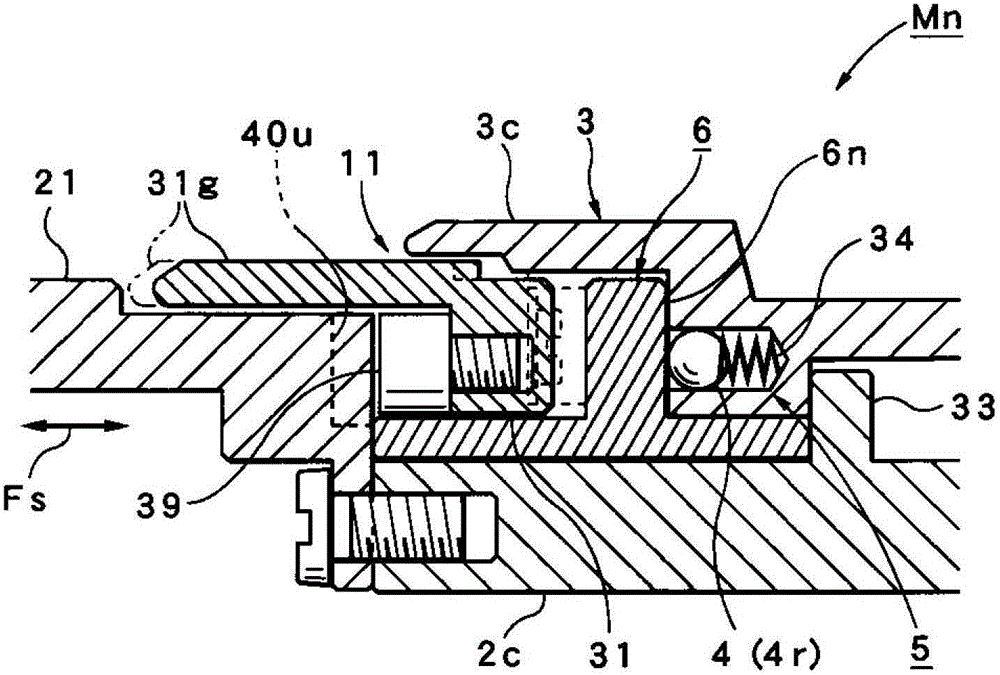

Sealing device and rolling bearing device provided with sealing device

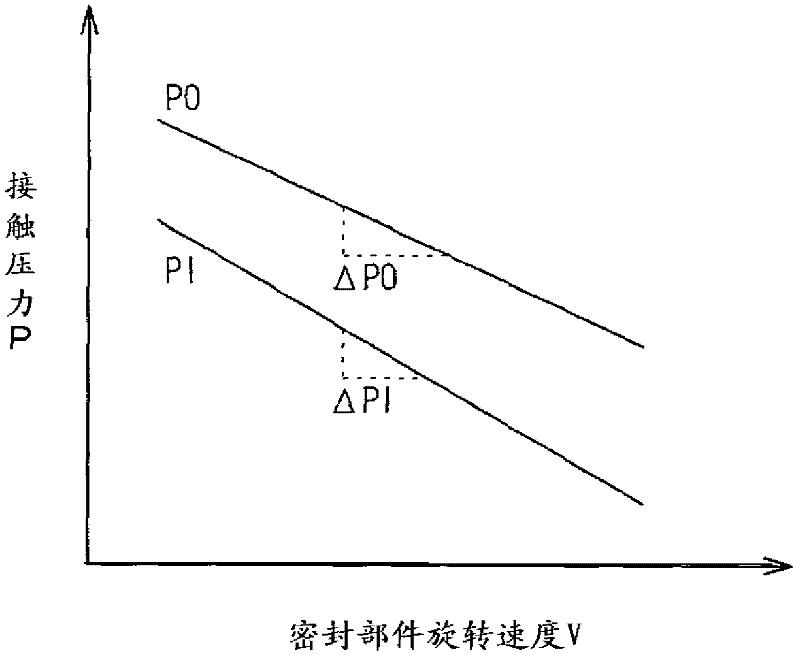

InactiveCN102562816AEliminate bad situationsGuaranteed tightnessEngine sealsRoller bearingsContact pressureEngineering

The invention provides a sealing device and a rolling bearing device provided with the sealing device. The sealing device (18) seals an annular space between a first member (19) and a second member (20) that relatively rotate with respect to each other at a boundary portion between an inside and outside of a rolling bearing (10). The sealing device (18) includes a seal member (23) that is connected to one of the first member (19) and the second member (20) and that has a first seal lip (36) and a second seal lip (37) and a first sliding surface (24A) and a second sliding surface (24B) that are provided for the other one of the first member (19) and the second member (20) and over which the seal lips (36, 37) slide. A second contact pressure (PO) of the second seal lip (37) against the second sliding surface (24B) is higher than a first contact pressure (PI) of the first seal lip (36) against the first sliding surface (24A).

Owner:JTEKT CORP +1

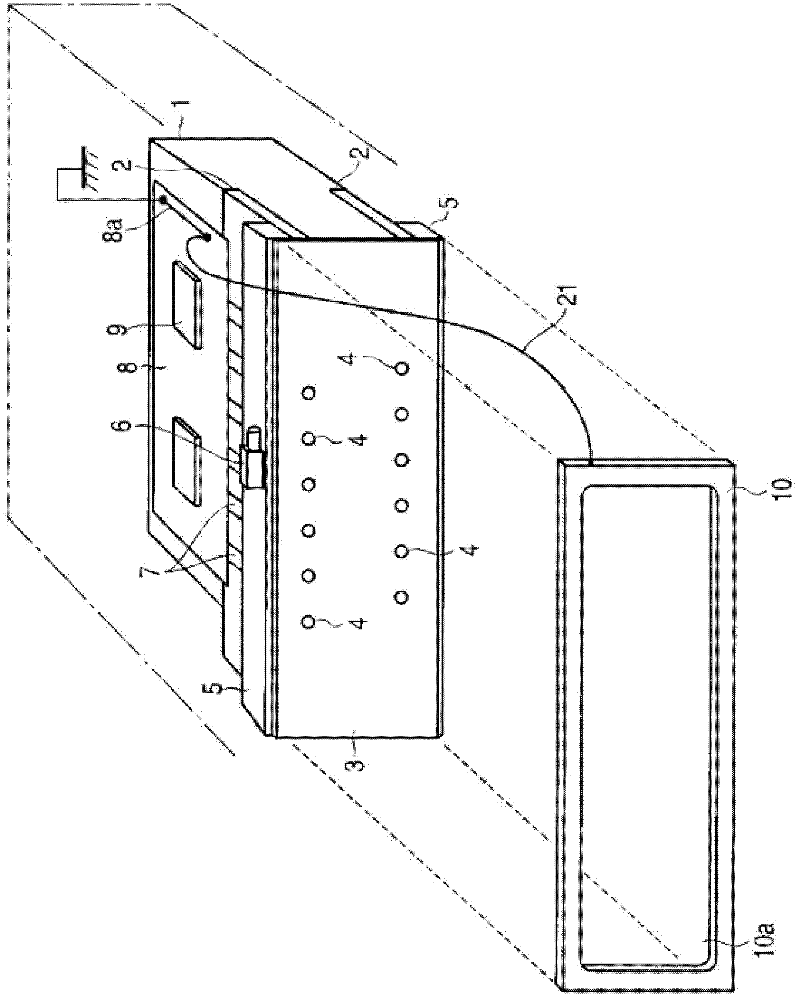

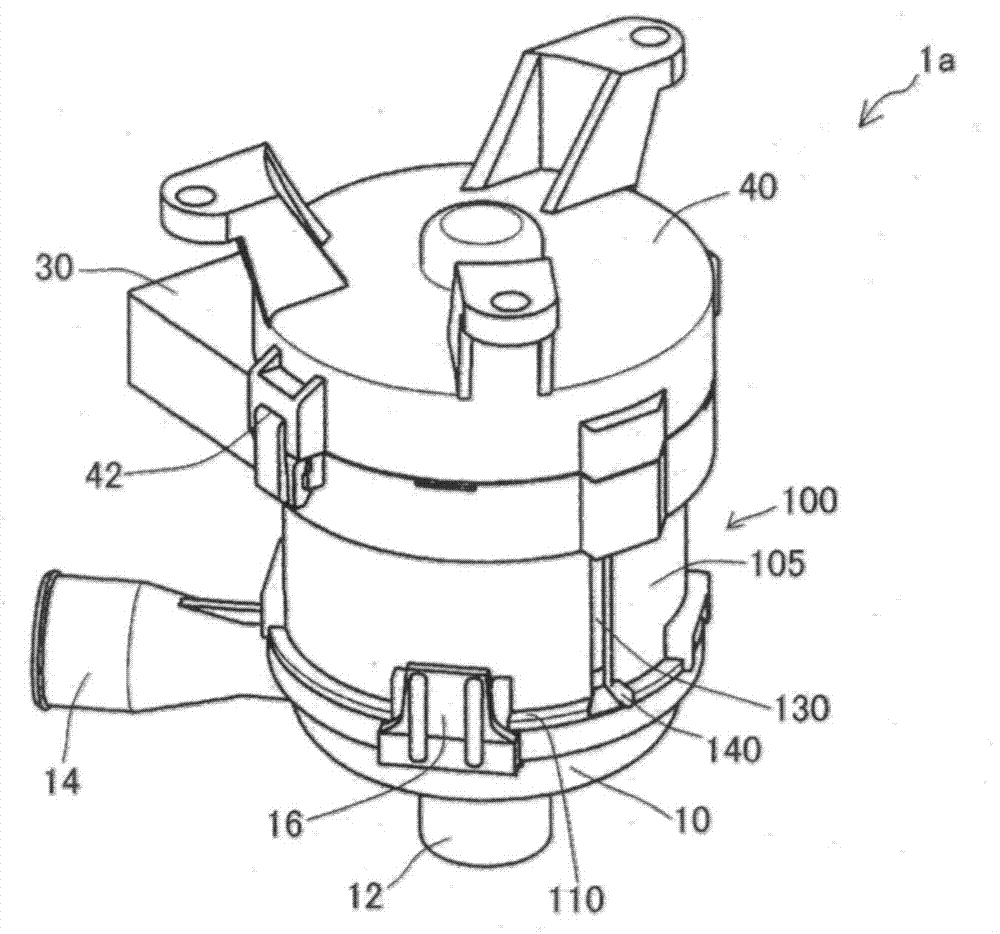

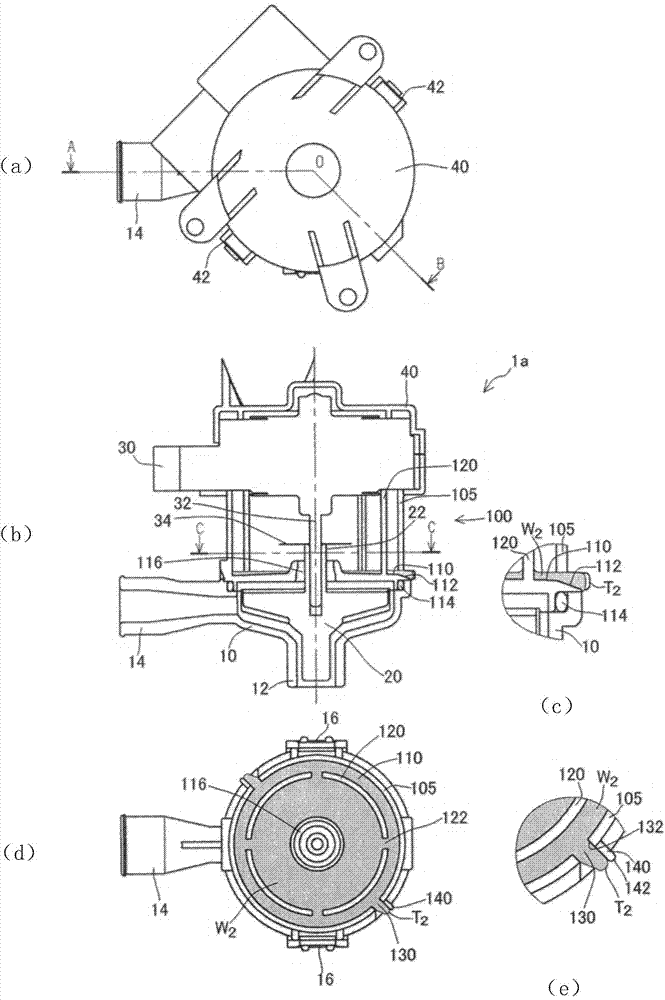

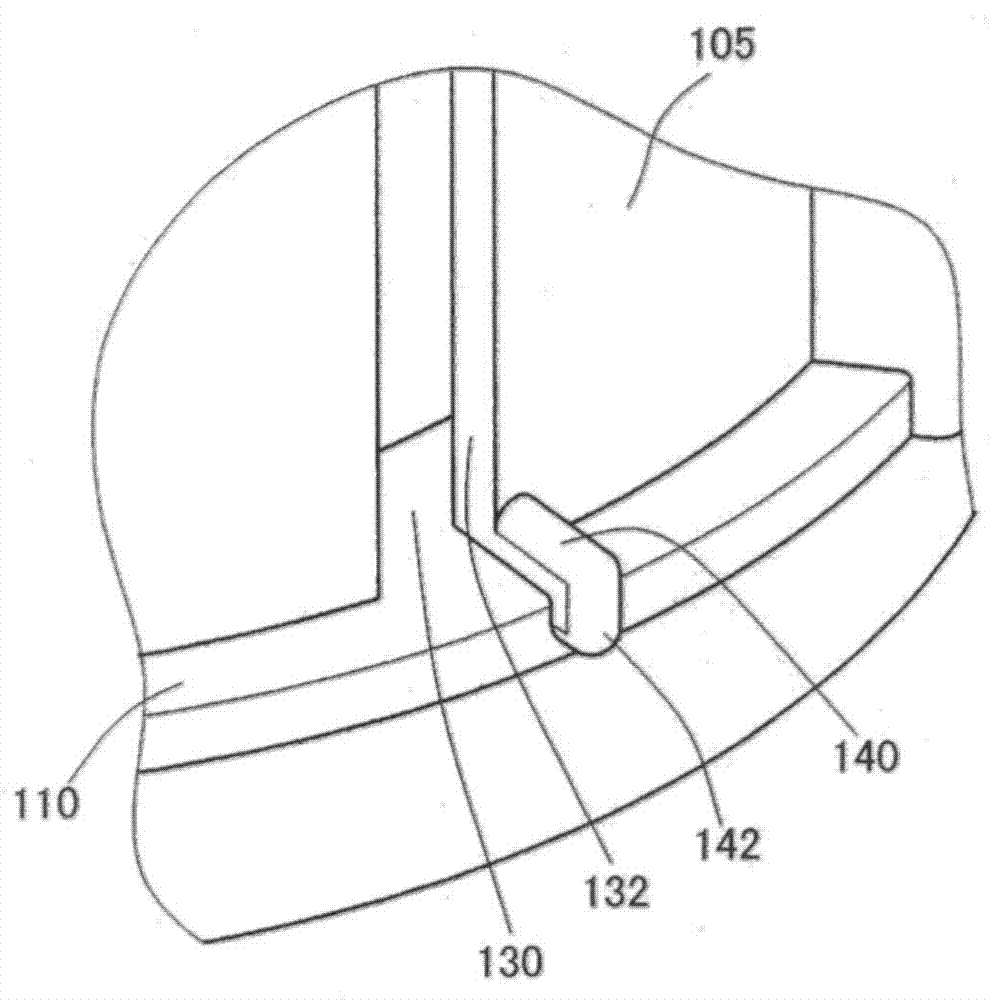

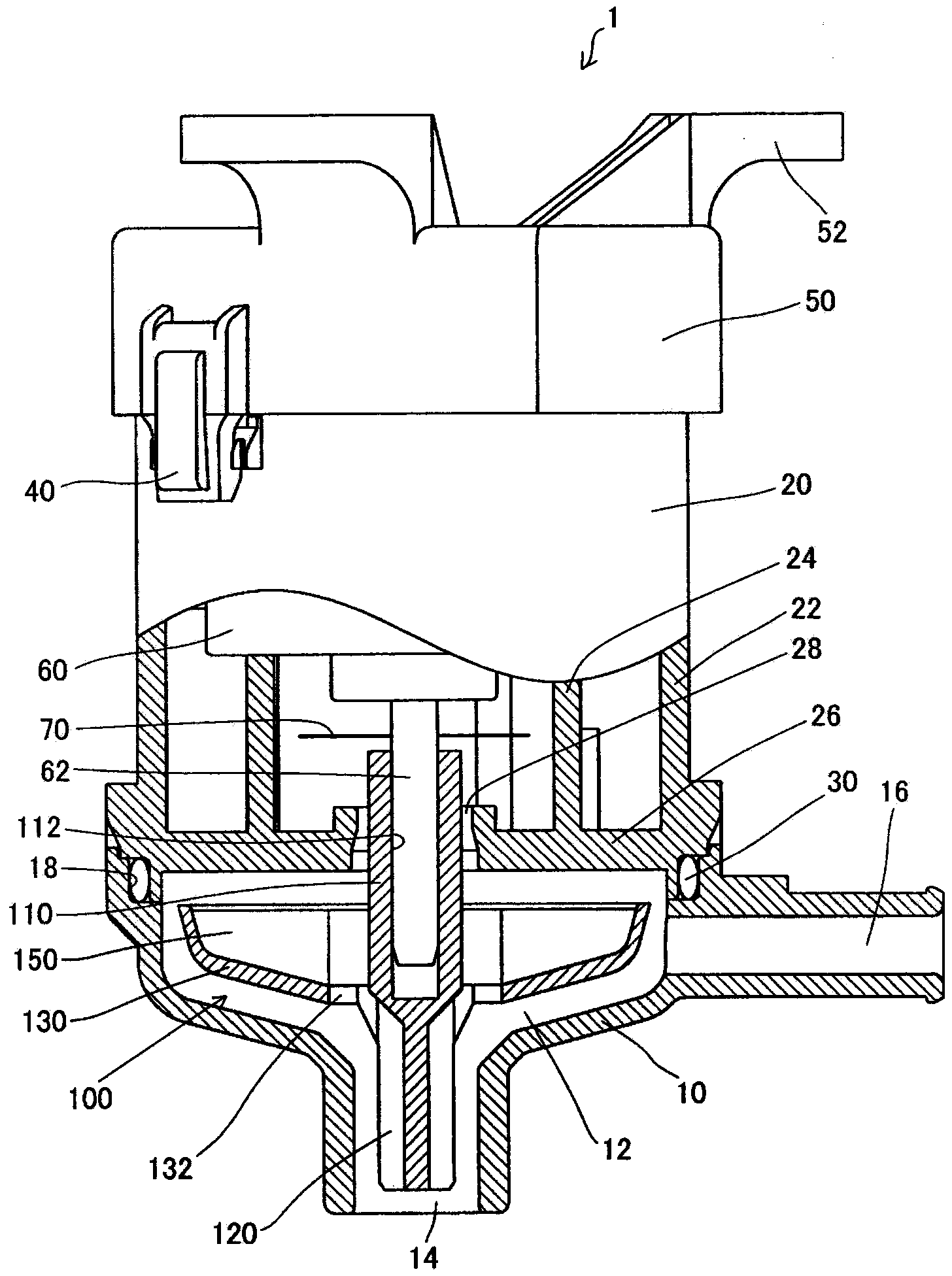

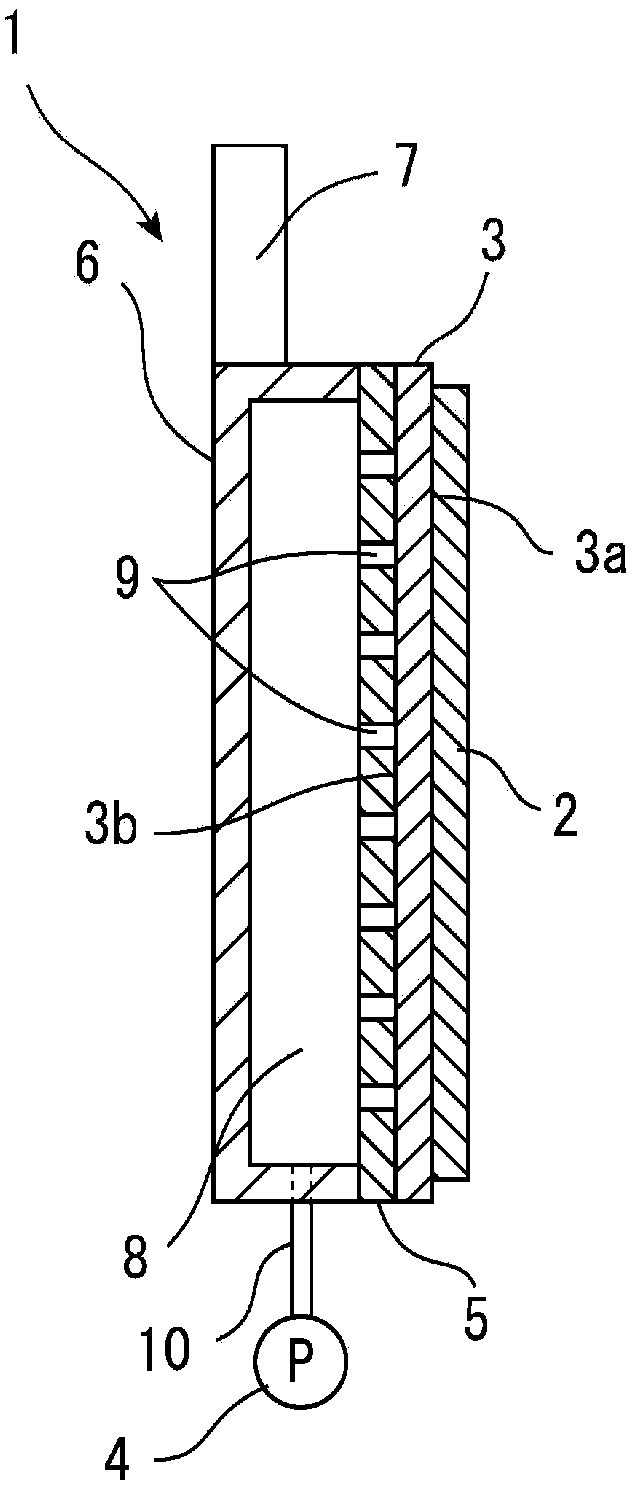

Drain pump

ActiveCN104514728AReduce backflowEliminate bad situationsPump componentsLighting and heating apparatusElectric motorWater pumping

A drain pump (1a) includes rotating blades (20) inside a pump case (10), and is driven by a motor (30). A motor lower case (100), which is mounted at the upper part of the pump case (10) and supports the motor (30), includes: an inner cylinder (120) and an outer cylinder (105). When the pump is stopped, return water from a water pumping pipe spouts out through an opening (116) of a lid (110). Residual water (W2) on the upper surface of the lid (110) is drained through inner cylinder slits (122) and drainage slits (130). At this time, the residual water (W2) is discharged to the external smoothly under the action of surface tension generated by guide parts (ribs) (140). By using the drain pump provided by the present invention, residual water of the drain pump mounted to an inner unit of an air conditioner can be effectively discharged.

Owner:FUJIKOKI MFG CO LTD

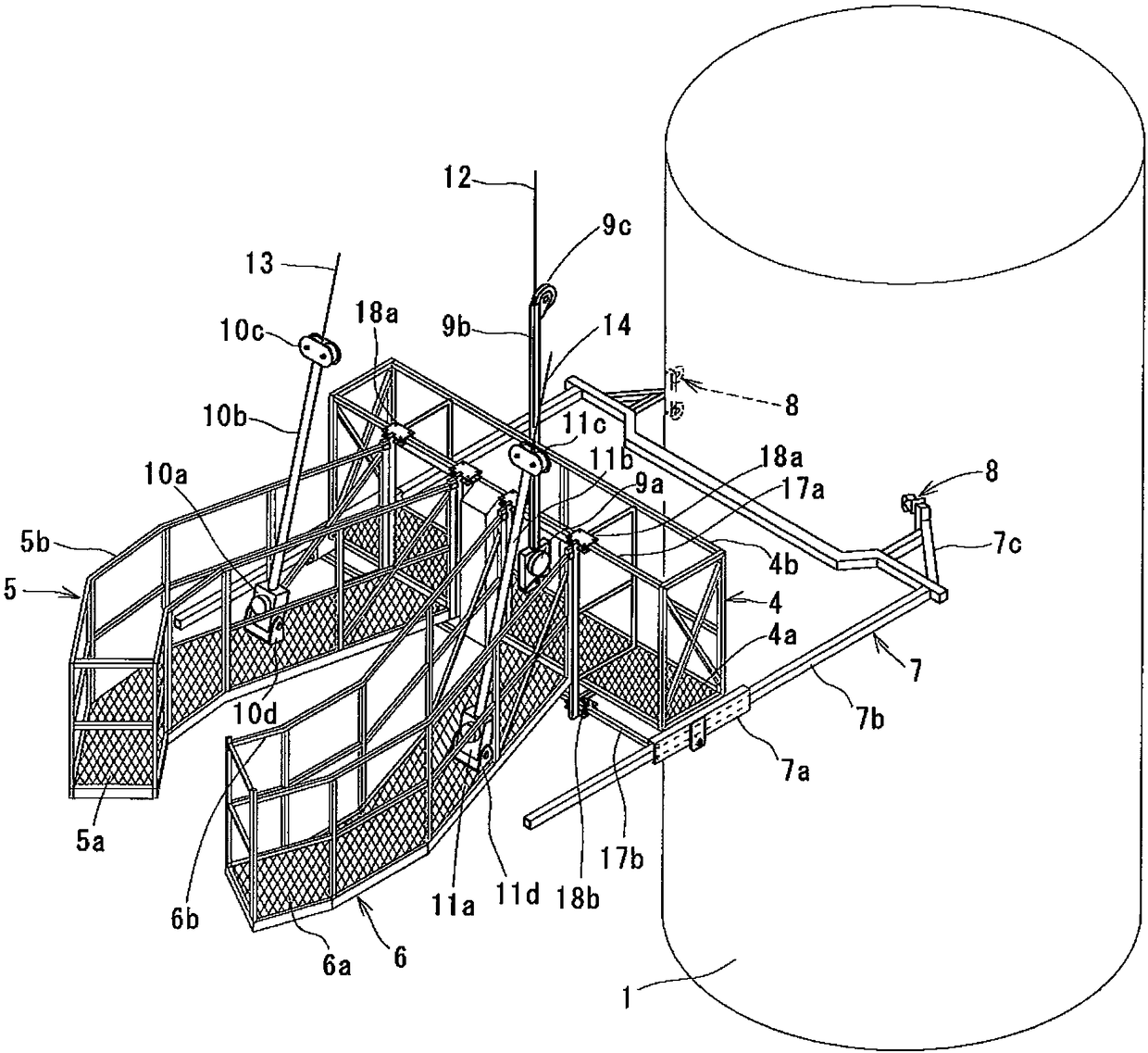

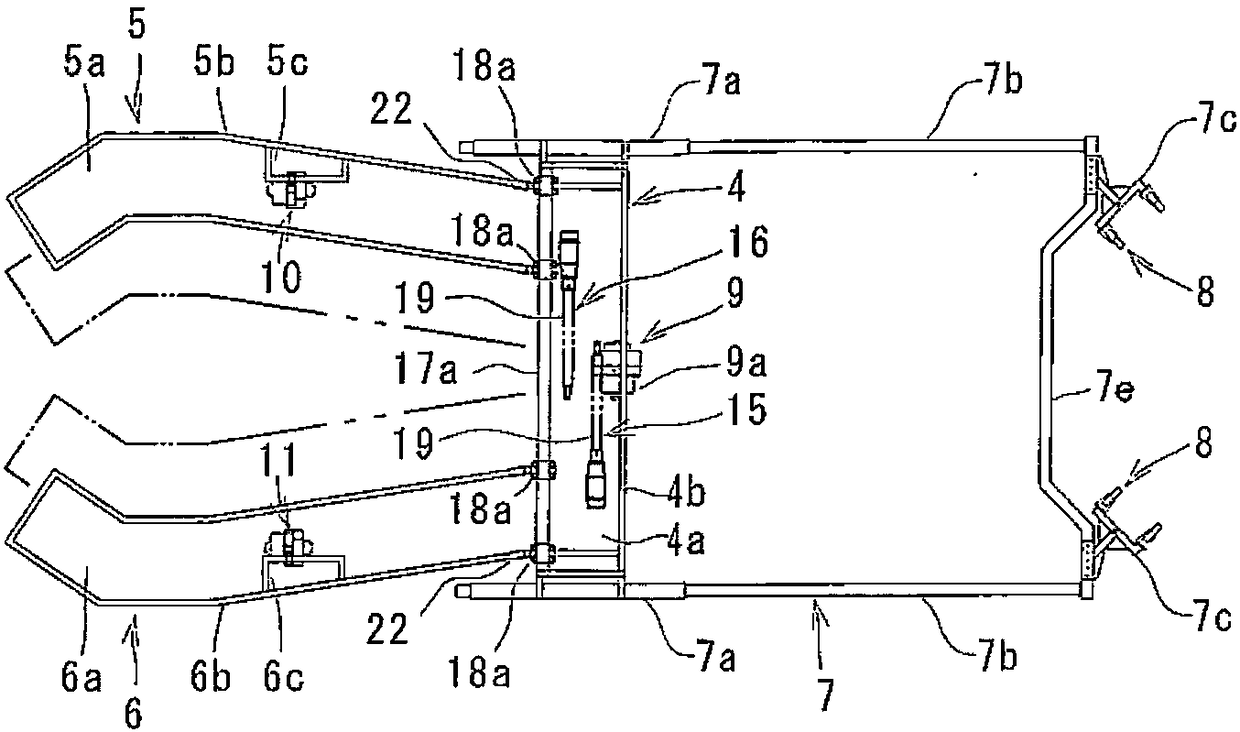

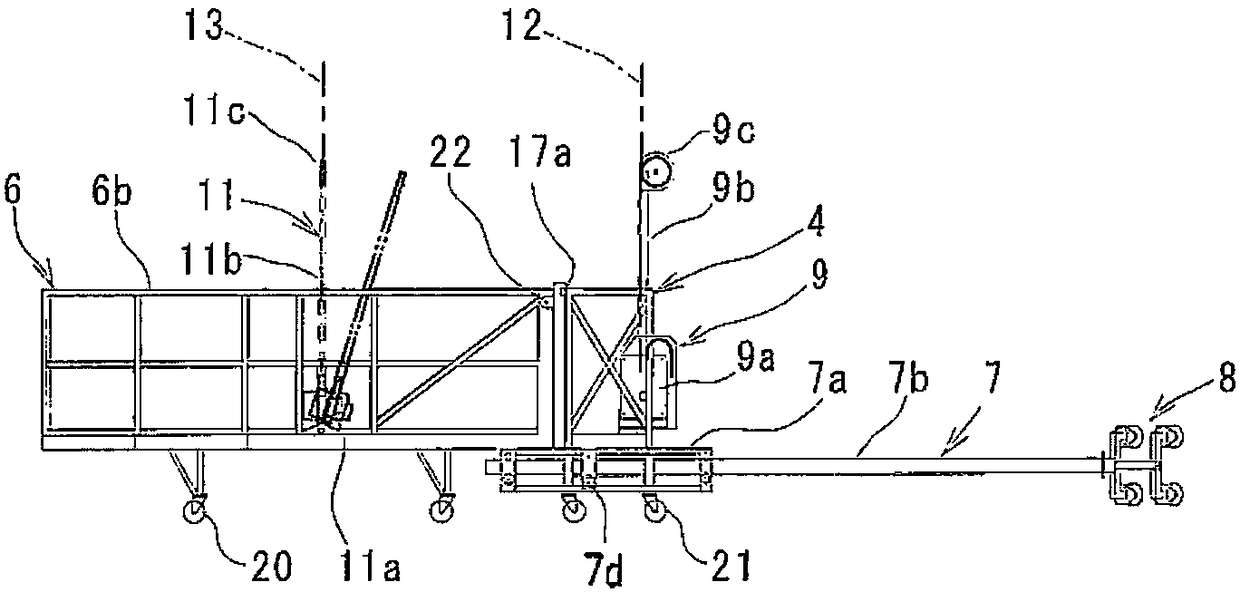

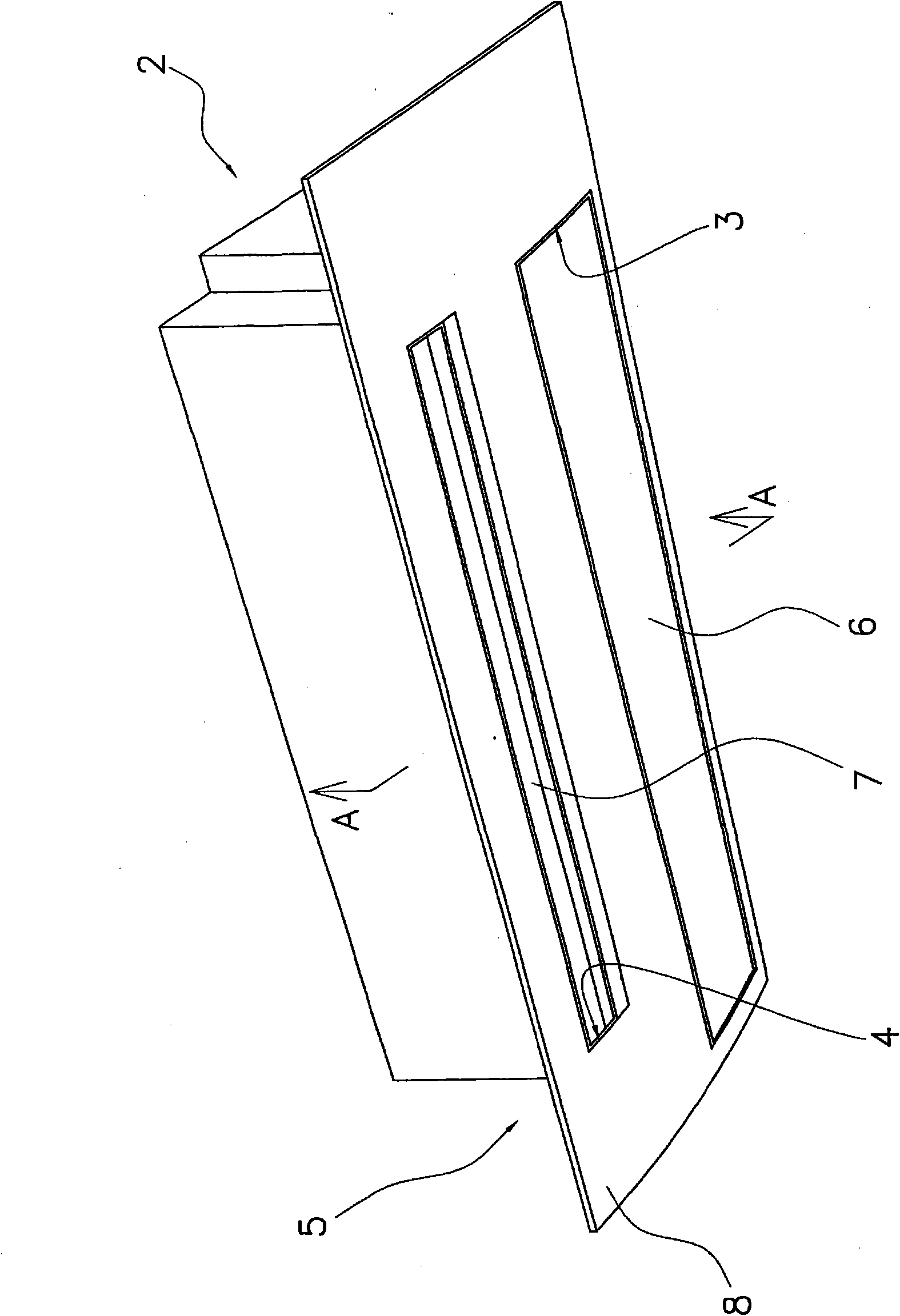

Gondola device

ActiveCN108431346AEliminate bad situationsMachines/enginesEngine componentsNacelleClassical mechanics

A gondola device comprises: a horizontal front scaffolding frame (4) that faces the back of a blade (3) as well as a first and a second side scaffolding frame (5, 6) that are mounted to the front scaffolding frame (4) so as to be able to move freely in the horizontal direction; a snubber member (7) that is telescopically mounted on both sides of the front scaffolding frame (4) and that abuts the outer face of a tower (1); a first lifting device (9) that is provided on the front scaffolding frame (4) as well as a second and a third lifting device (10, 11) that are mounted on the first and the second side scaffolding frames (5, 6), respectively, so as to be able to swing; a first and a second driving device (15, 16) that are provided on the front scaffolding frame 4 and that drive the firstand the second side scaffolding frames (5, 6), respectively, in the horizontal direction; and a first, a second, and a third pull rope (12, 13, 14) that are provided between a nacelle (2) and the first, the second, and the third lifting device (9, 10, 11).

Owner:NISSO IND CO LTD

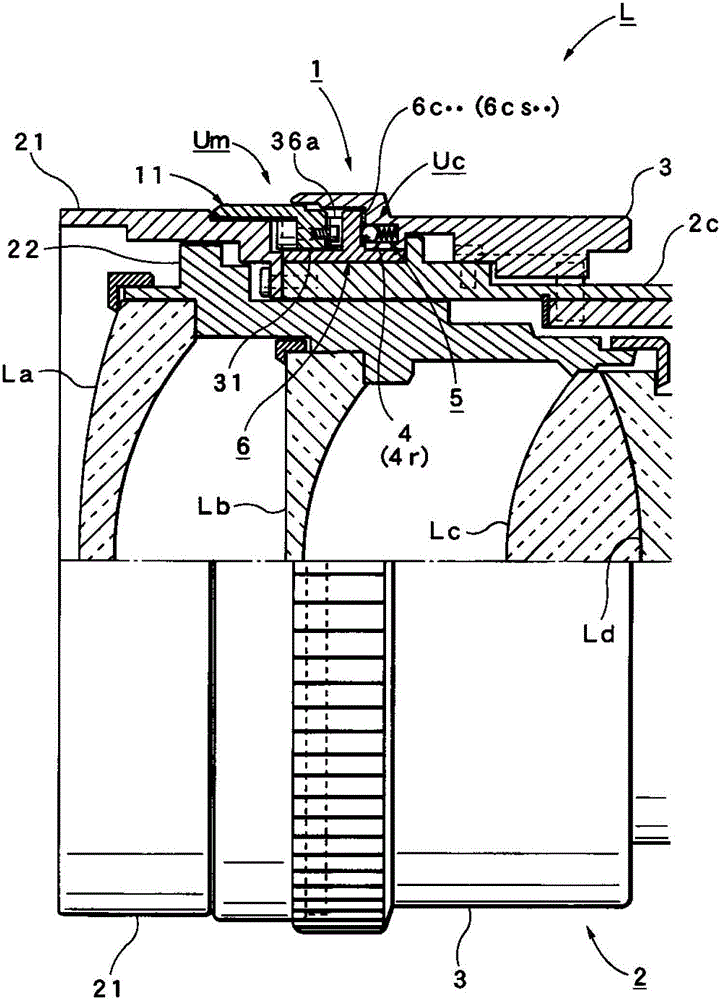

Diaphragm device of lens

ActiveCN103186012APlay a significant roleQuality improvementCamera diaphragmsOptical elementsCamera lensEngineering

Diaphragm device of a lens includes a click mechanism with a locking portion disposed in one of a stationary tube and a diaphragm setting ring, the locking portion having an elastically supported locking element, and an entrapment body disposed on the other of the stationary tube and the diaphragm setting ring. The entrapment body having an entrapment surface wherein a plurality of entrapment portions are formed for catching the locking element pressed against the entrapment surface at one of a plurality of aperture numbers when the diaphragm setting ring is turned. A mode select mechanism for switching between a click mode wherein the locking element is pressed against the entrapment surface and a non-click mode wherein a click function is deactivated with the locking element and the entrapment surface separated from each other by altering the position of at least one of the locking portion and the entrapment body.

Owner:COSINA CO LTD

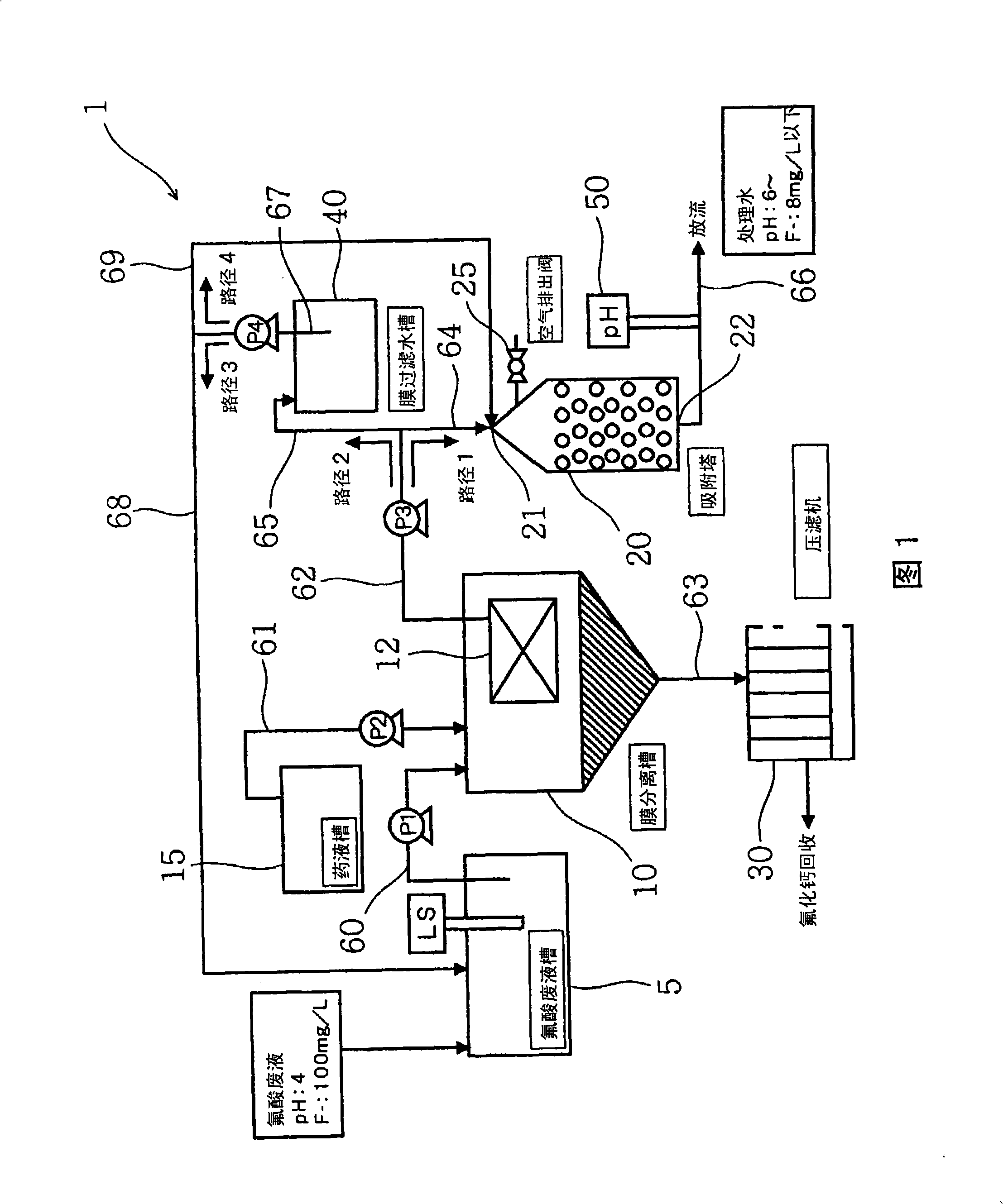

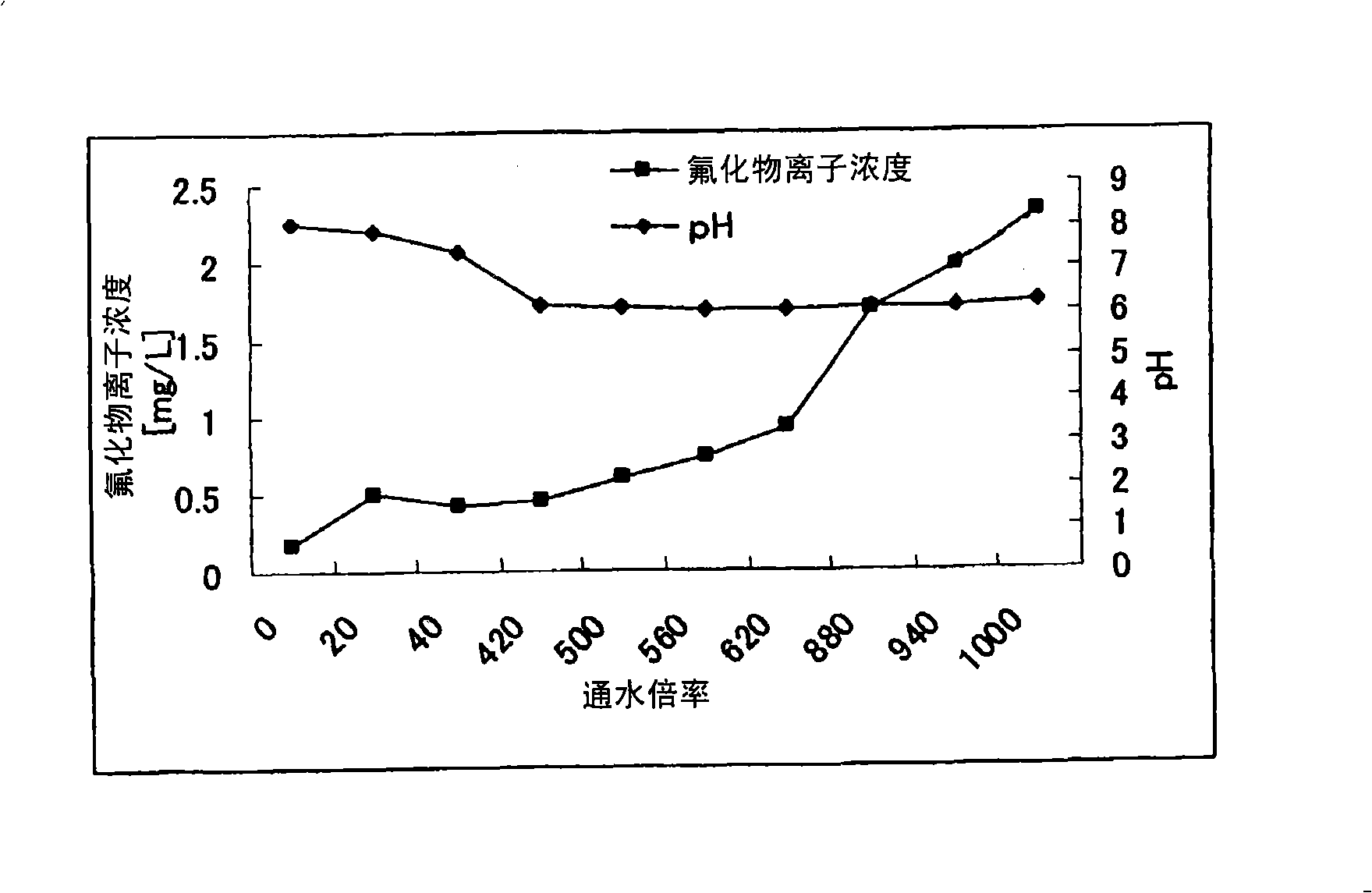

Method and device for treating fluorine-containing water

InactiveCN101259972ALow running costAchieve simplicityWater treatment parameter controlSludge treatmentTreatments waterFluoride

There is disclosed a device for treating fluorine-containing water in which for-treatment water can be treated so as to set a fluorine concentration to a drainage standard or less without adding a reagent such as a pH adjuster to change a pH of the for-treatment water if possible. A treatment device includes a first treatment means for adding, to fluorine-containing for-treatment water, a reactive compound which reacts with fluorine to form a fluoride and which does not apply an OH group, so that a suspension is formed; a second treatment means for separating the suspension obtained by the first treatment means into a solid and a liquid; and a third treatment means for bringing a permeation liquid separated by the second treatment means into contact with a fluoride ion adsorbent.

Owner:SANYO ELECTRIC CO LTD

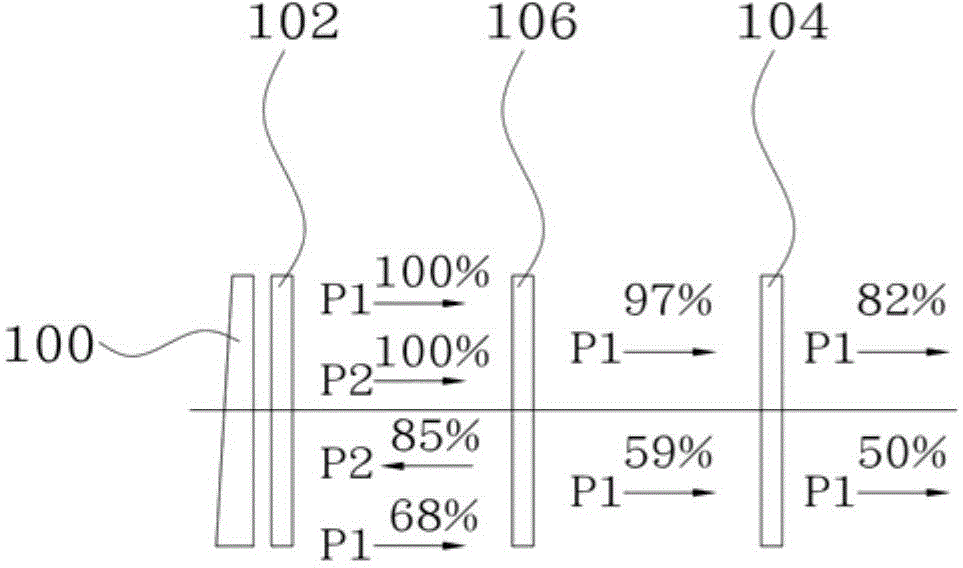

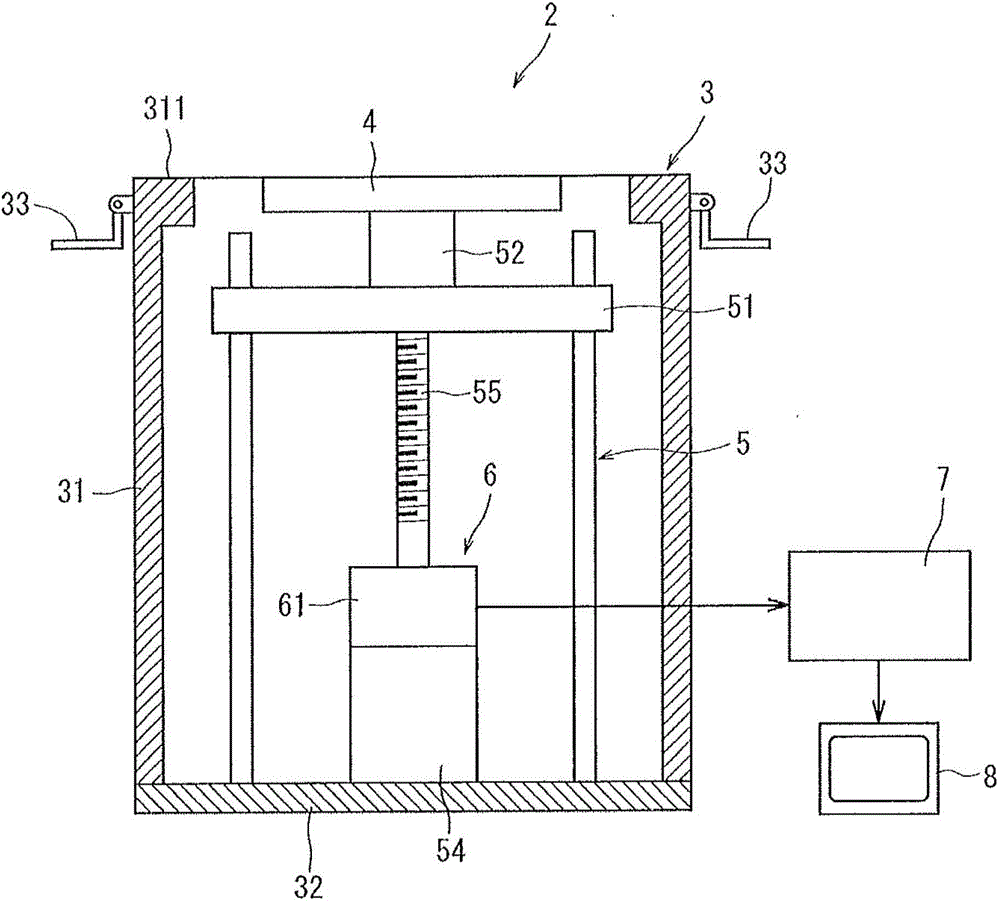

Cooling device

ActiveCN102109238AImprove cooling capacityAchieve performanceMechanical apparatusCompression machines with non-reversible cycleEvaporatorEngineering

The invention provides a cooling device (R) which can improve the starting problem of a compressing mechanism and realize a stable and high-efficient operation, wherein a refrigerant circuit (1) is composed of a compressor (11), a gas cooler (46), a main throttle mechanism (62A, 62B), and an evaporator (63A, 63B), and has a supercritical pressure at a high-pressure side. The cooling device (R) comprises a bypass circuit (84) which communicates an intermediate-pressure region and a low-pressure side region of the refrigerant circuit (1); a solenoid valve (85) which is disposed in the bypass circuit; a control mechanism (C) which controls the solenoid valve (85) and opens the flow path of the bypass circuit (84) using the solenoid valve (85) from the starting of the compressor (11) till the operation frequency is increased to a defined value.

Owner:SANYO ELECTRIC CO LTD

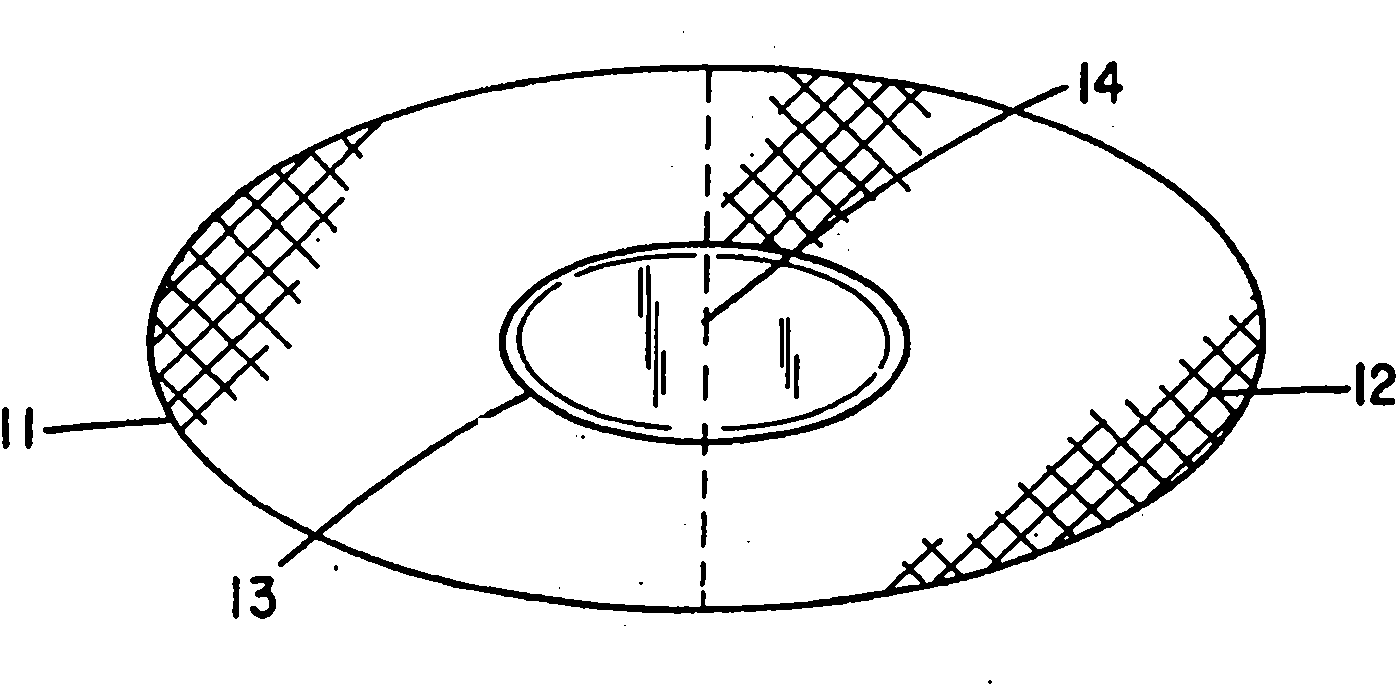

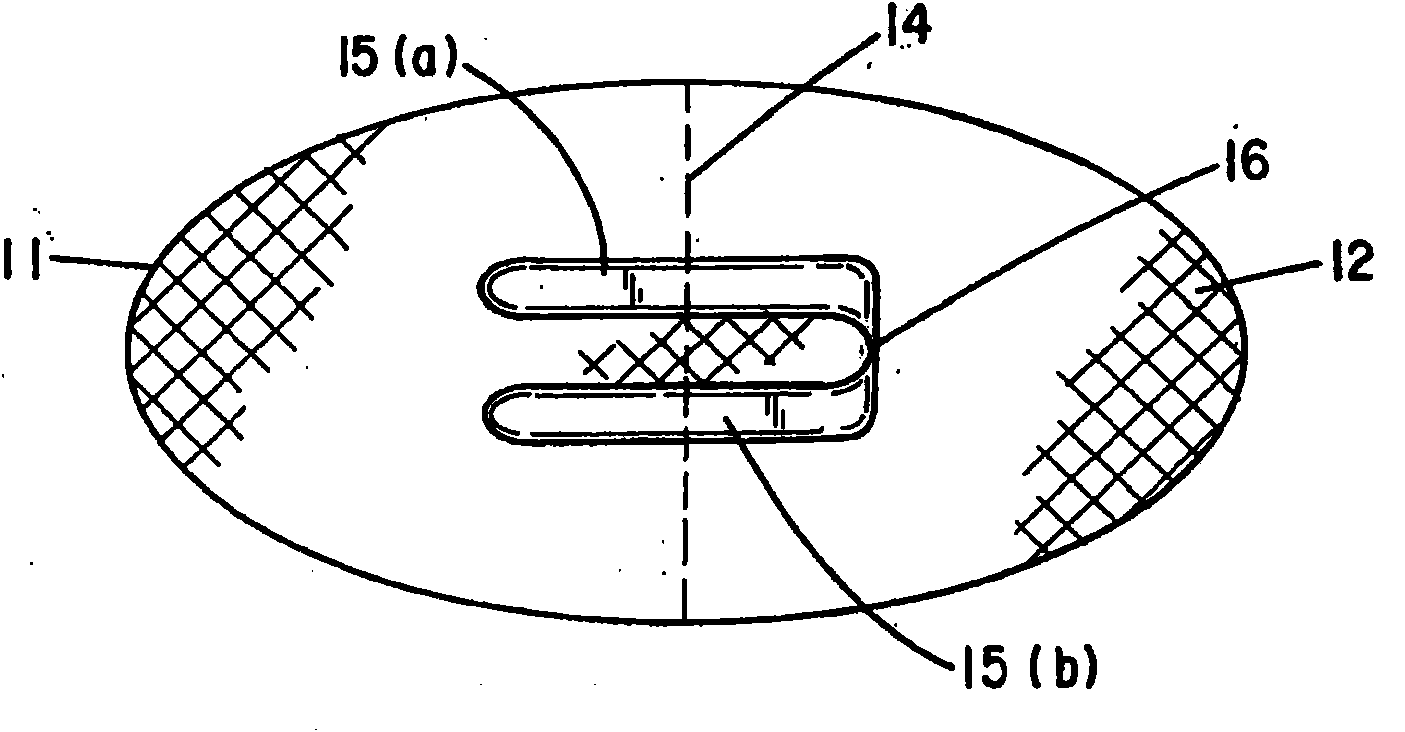

Partial cuff

ActiveCN101917928ANatural and normal urinationIncrease resistanceAnti-incontinence devicesUrethraNormal voiding

To increase the resistance to liquid and substance flow through a lumen of a tubular organ, a cuff comprising a flexible, mesh base member is appended to an exterior wall of the tubular organ such that it only partially surrounds the tubular organ. Ultimately, tissue ingrowth through the mesh base member integrates the cuff into the wall of the tubular organ. When the cuff is applied to the urethra of an incontinent patient, the increased resistance to flow renders the patient continent while still allowing normal voiding. The base member may also support an optional expandable component, e.g., a balloon-like element that can be selectively inflated and / or deflated to restrict the lumen of the tubular organ by a desired degree.

Owner:克劳德·吉洪

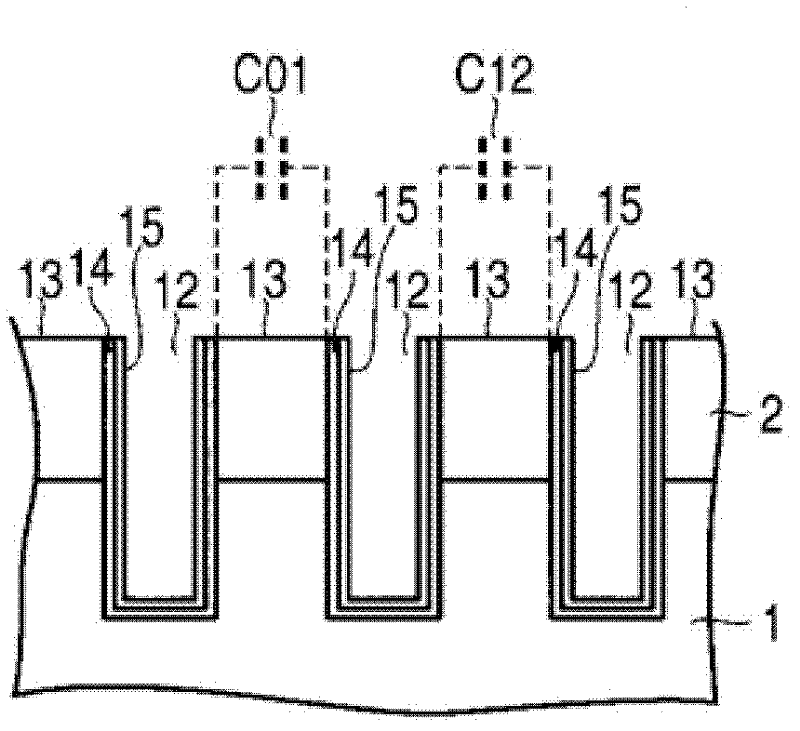

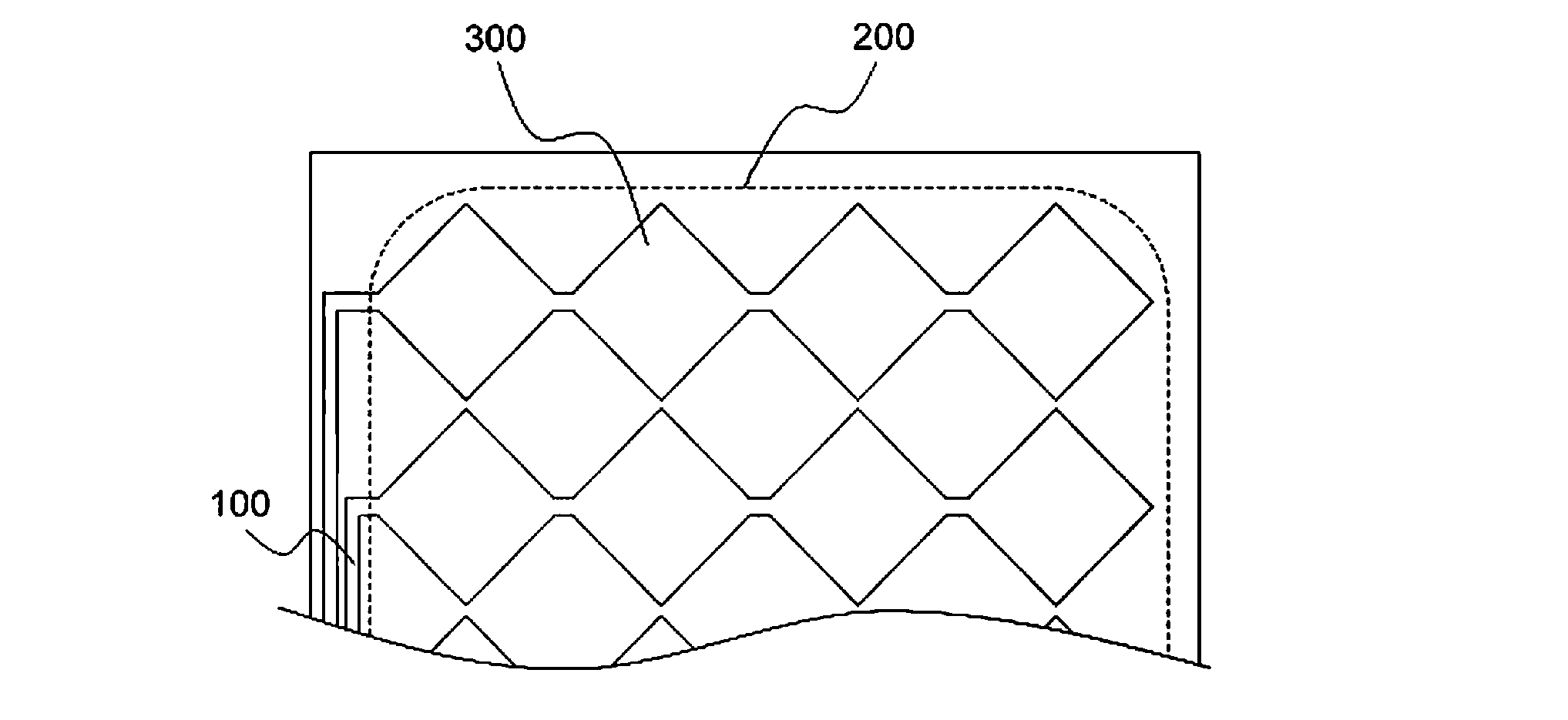

Wire grid polarizer and manufacturing method thereof

InactiveCN104865630AImprove viewing angle defectsEliminate bad situationsPolarising elementsWire gridGrating

The invention provides a wire grid polarizer and a manufacturing method thereof. The wire grid polarizer comprises an absorbing layer and a metal wire grid, wherein the absorbing layer comprises a base plate, multiple first bulge parts arranged on the upper surface of the base plates at intervals, aluminium wires arranged on the surfaces of the first bulge parts, and silicon dioxide layers; the metal wire grid comprises flat layers, aluminium layers arranged on the flat layers, and second bulge parts arranged on the upper surfaces of the aluminium layers at intervals; the surfaces of the silicon dioxide layers are coated with the flat layers; the second bulge parts are adopted to etch the aluminium layers so as to form a grating structure. Compared with the prior art, the overlapped double-grating structure can improve the visual angle defects of the existing wire grid polarizer and also can eliminate the bad situation of dark state light leakage.

Owner:AU OPTRONICS CORP

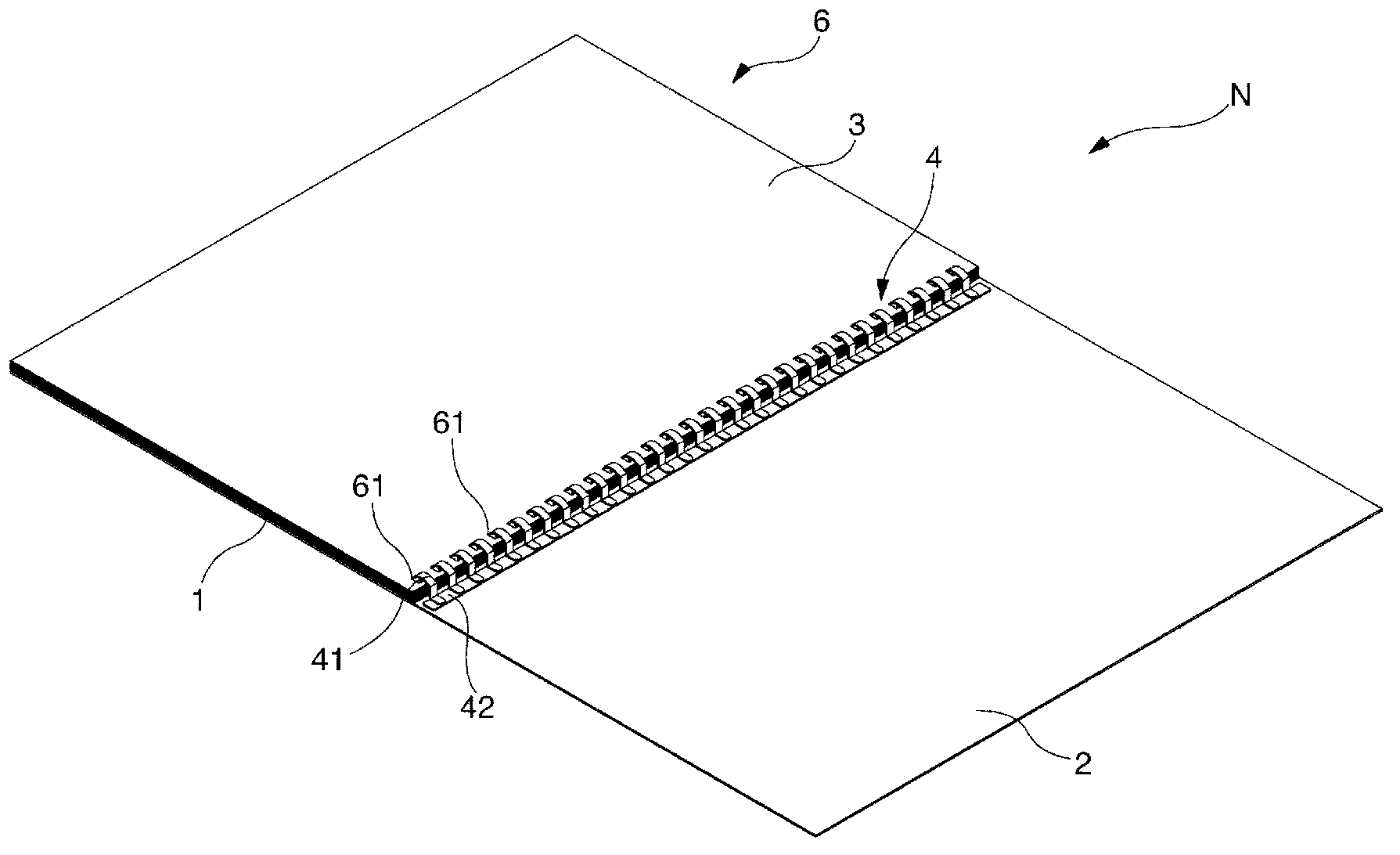

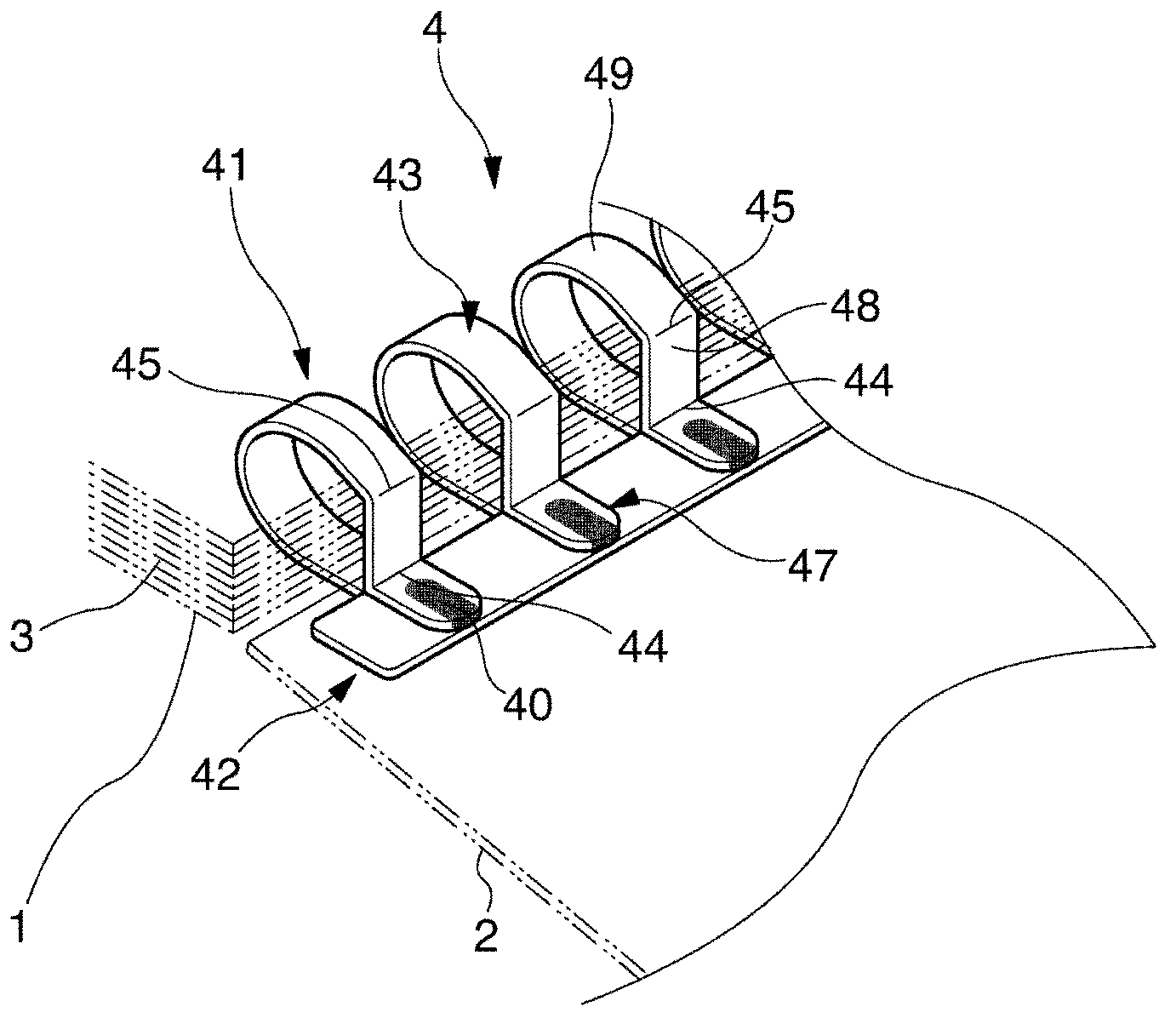

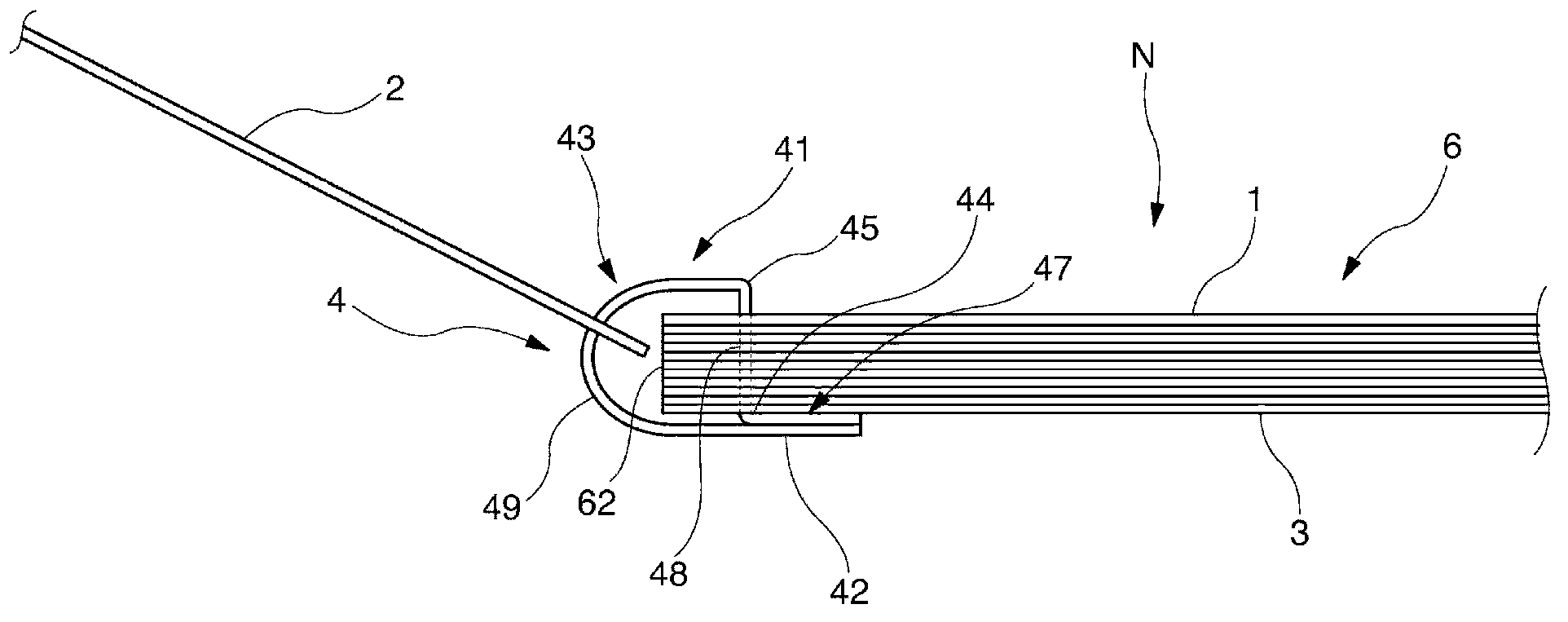

Notebook

ActiveCN102844197AEliminate bad situationsFeel goodOther printing matterFiling appliancesEngineeringMechanical engineering

Disclosed is a notebook (N) formed by binding a plurality of pieces of paper (6) having binding holes (61) by a ring (4), wherein the ring (4) is provided with a plurality of ring bodies (41) which are respectively inserted through the binding holes (61), and a connecting unit (42) which connects base ends of the mutual ring bodies (41) and holds tip end sides of the ring bodies (41) so as to maintain the respective ring bodies (41) in closed ring shapes, and wherein the tip end sides of the respective ring bodies (41) and the connecting unit (42) are connected by welding in connection areas (40).

Owner:KOKUYO CO LTD

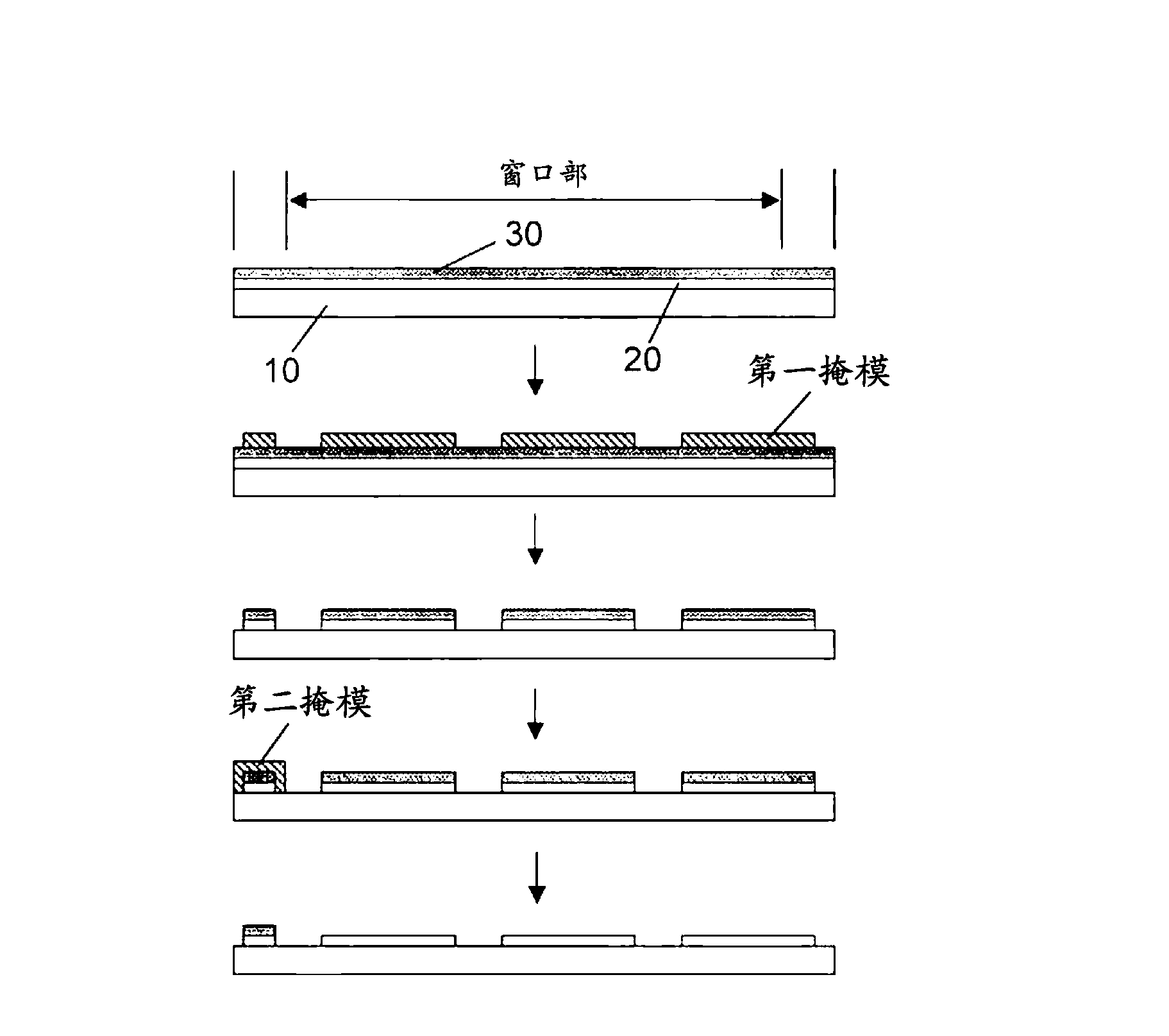

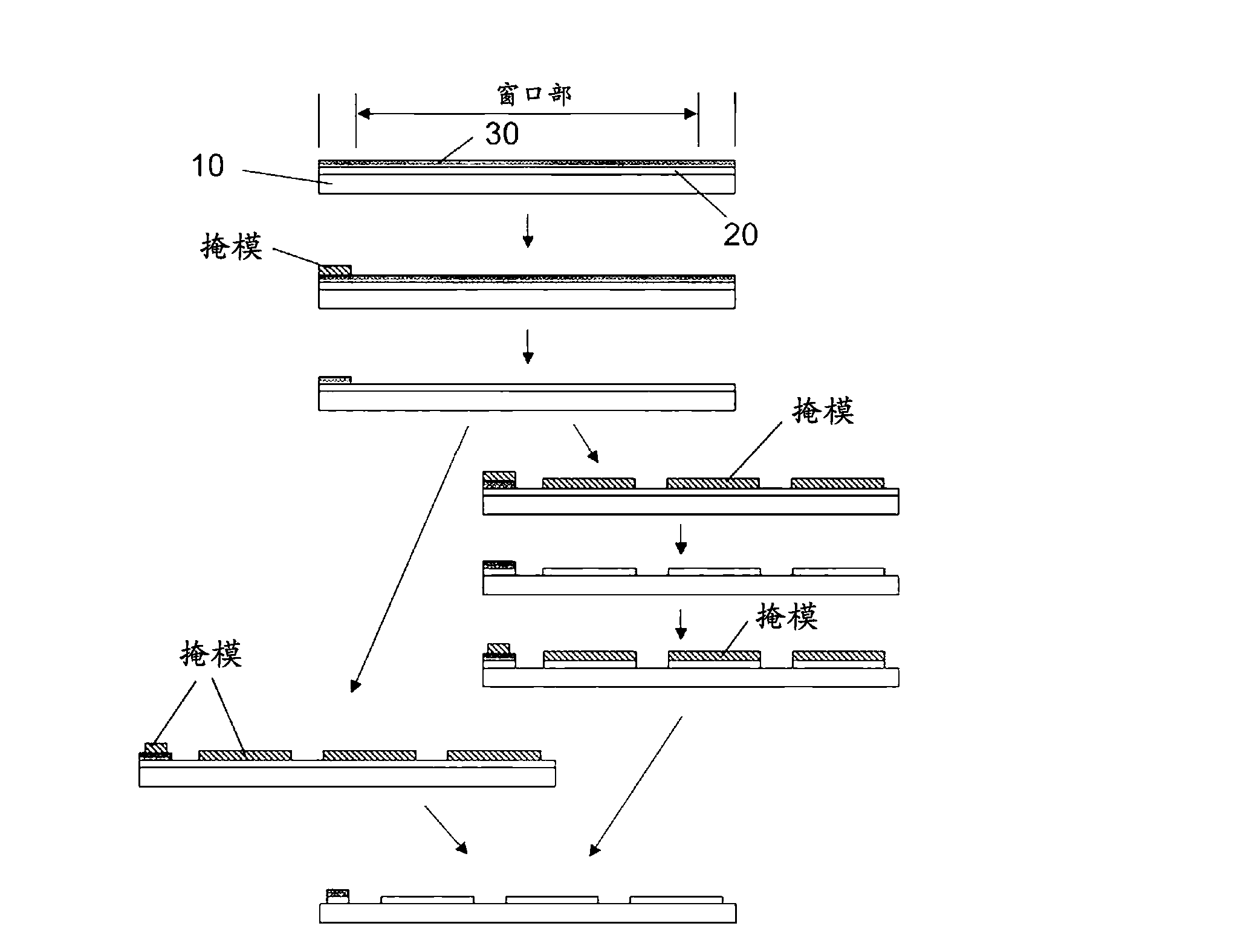

Method for manufacturing a pad for a touch panel, and pad for a touch panel manufactured by same

InactiveCN102870070AImprove productivityEliminate bad situationsInput/output processes for data processingMetal coatingProduction rate

The present invention relates to a method for manufacturing a pad for a touch panel and to a pad for a touch panel manufactured by same, wherein the method comprises the steps of: preparing a pad, which includes a light-transmitting insulator layer made of an organic insulator or an inorganic insulator, a light-transmitting conductor coating layer formed at a top of the light-transmitting insulator layer, and a metal coating layer formed at a top of the light-transmitting conductor coating layer, for manufacturing a touch panel; etching, from the metal coating layer of the pad for manufacturing the touch panel, at least a portion of the metal coating layer corresponding to a window, while leaving a portion of the metal coating layer corresponding to a lead line unetched; and etching the etched pad for manufacturing the touch panel to form the lead line and a touch pattern.; Through such operations, residual defects, consisting of metal dots left due to defective etching of the metal coating layer, are removed from a window portion, which is required to be transparent without blemishes when the pad is coupled to a display device such as an LCD, and thus the manufacturing yield of the pad for a touch panel can be improved.

Owner:TMAY +1

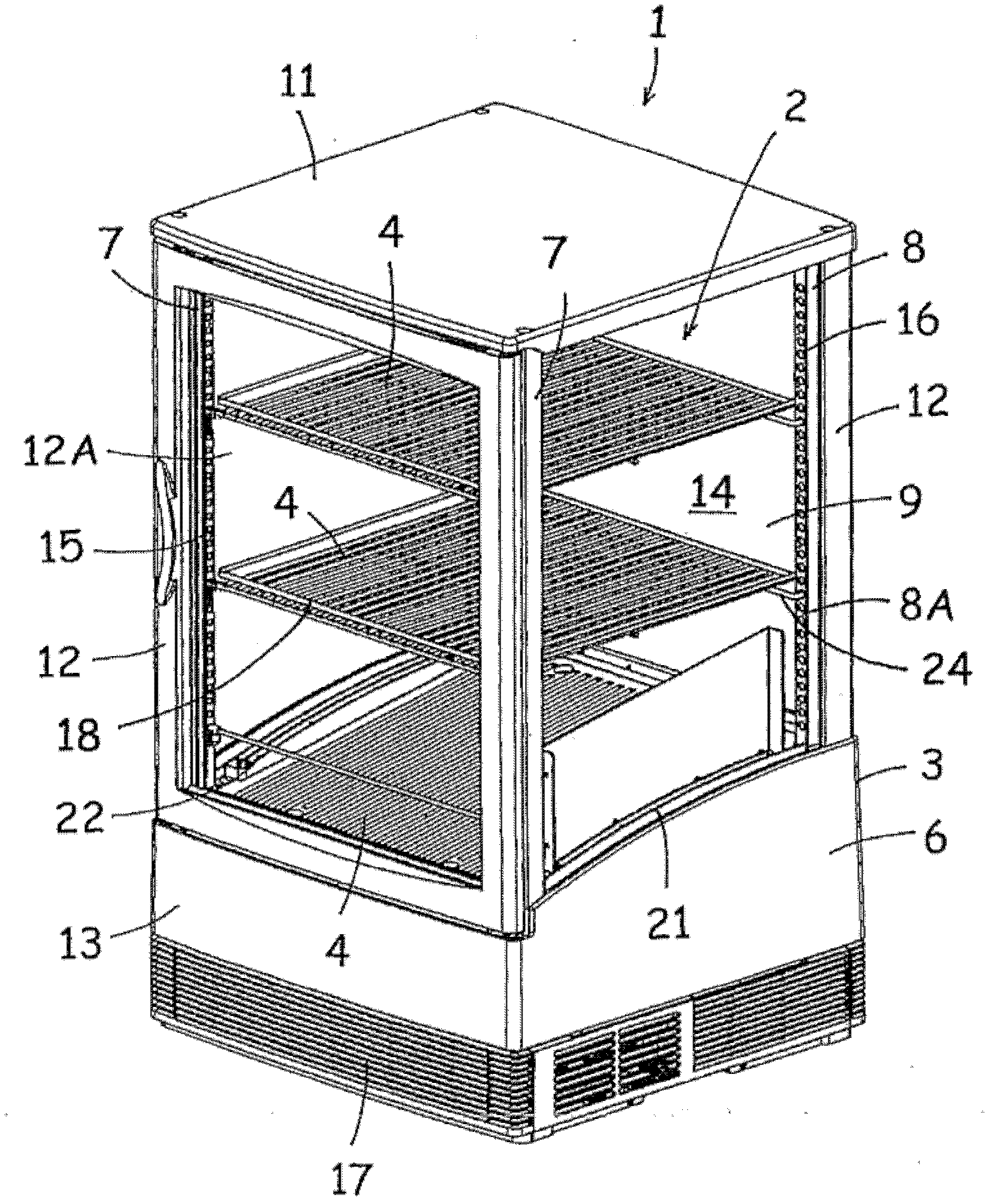

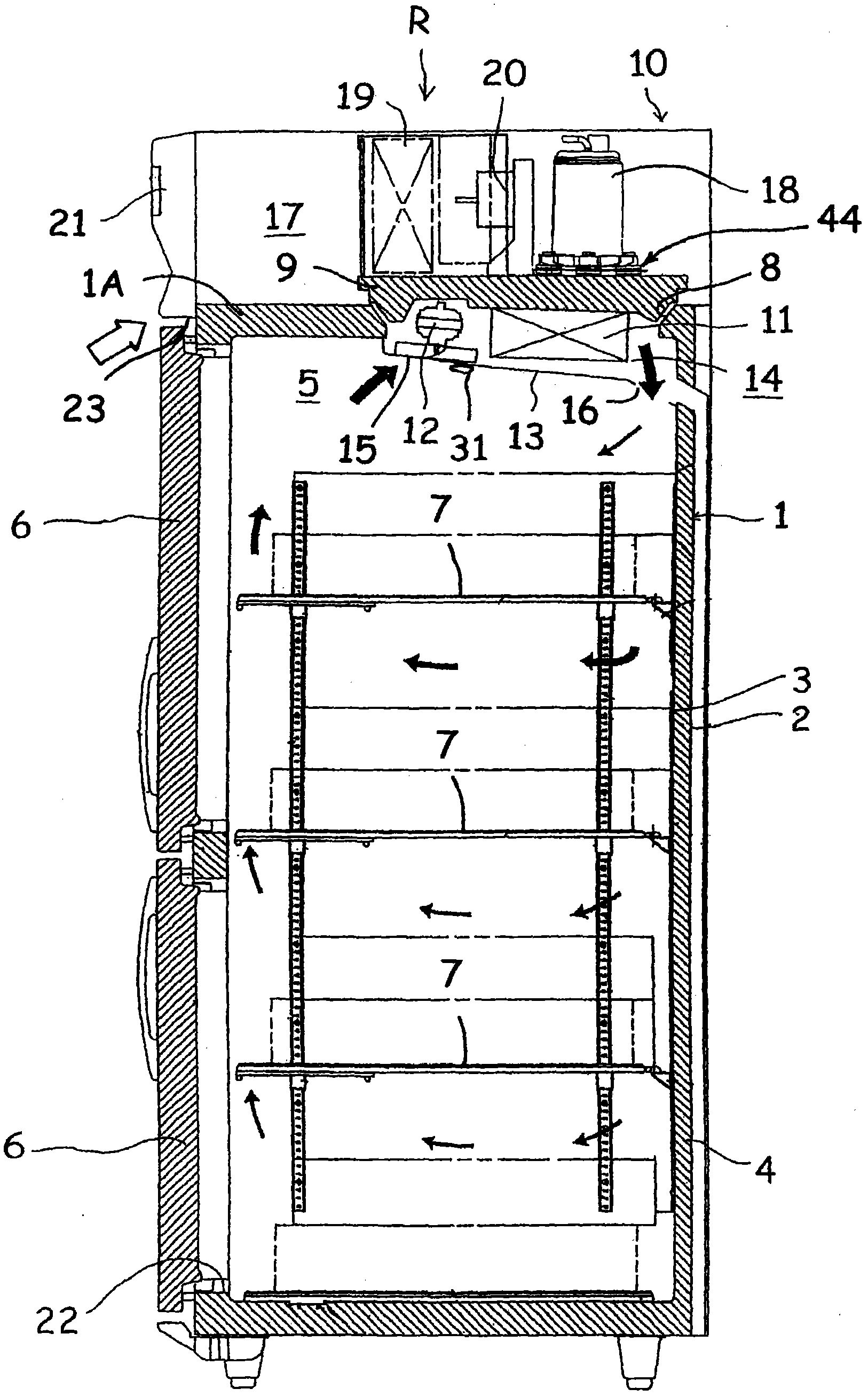

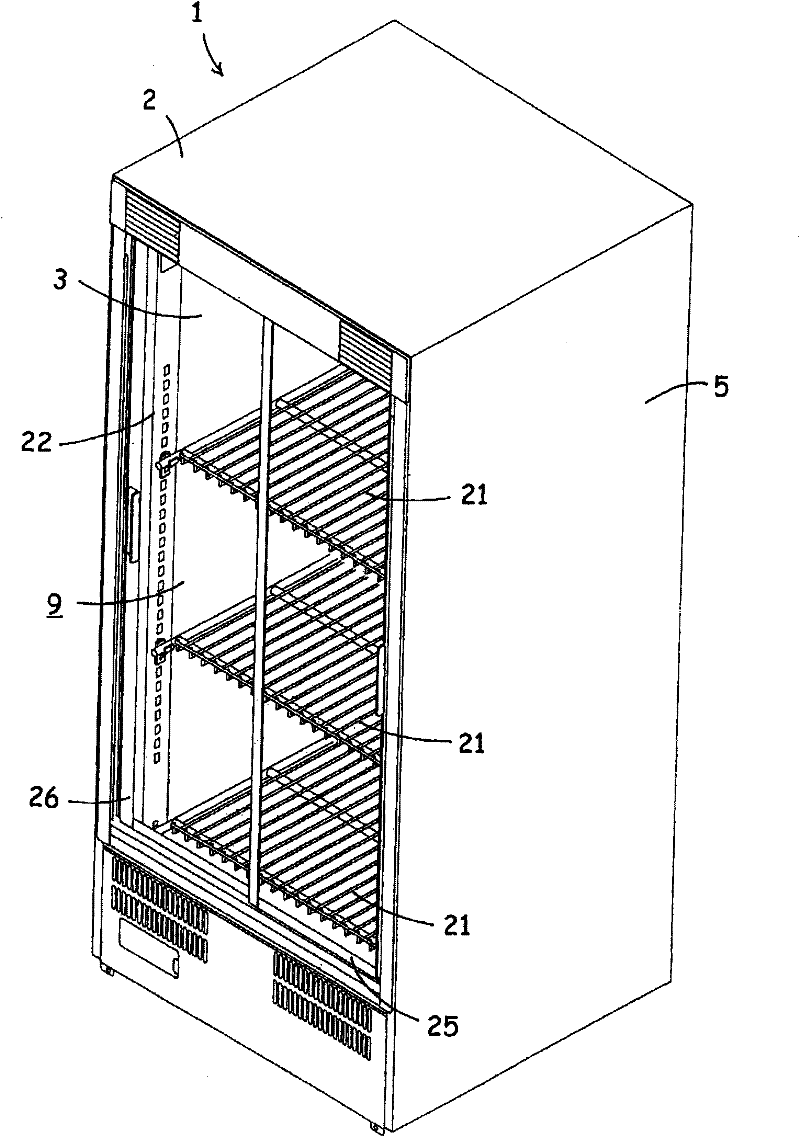

Shelf device

InactiveCN102415742APrevent bad situationsImprove convenienceShow cabinetsFurniture partsEngineeringMechanical engineering

Owner:SANYO ELECTRIC CO LTD

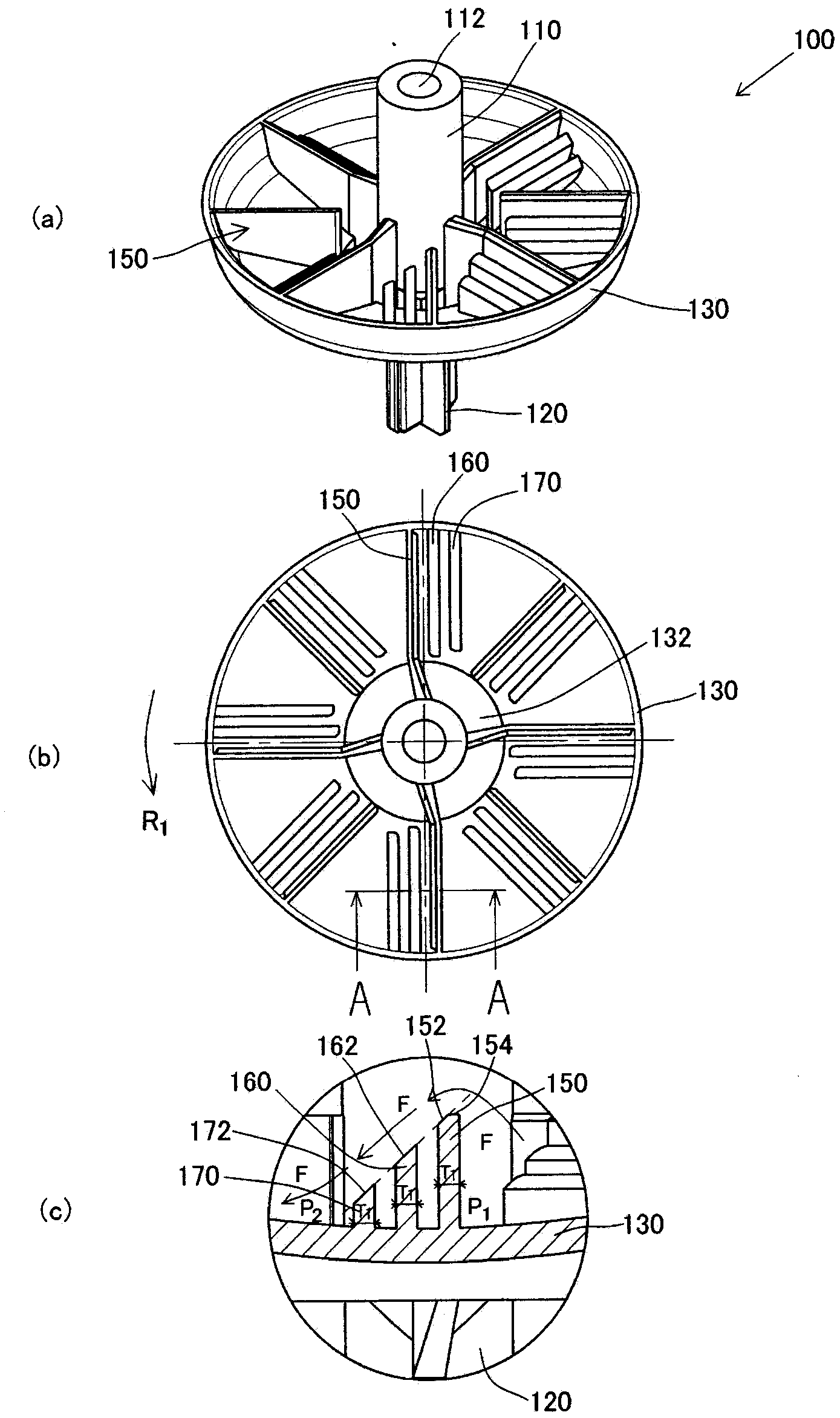

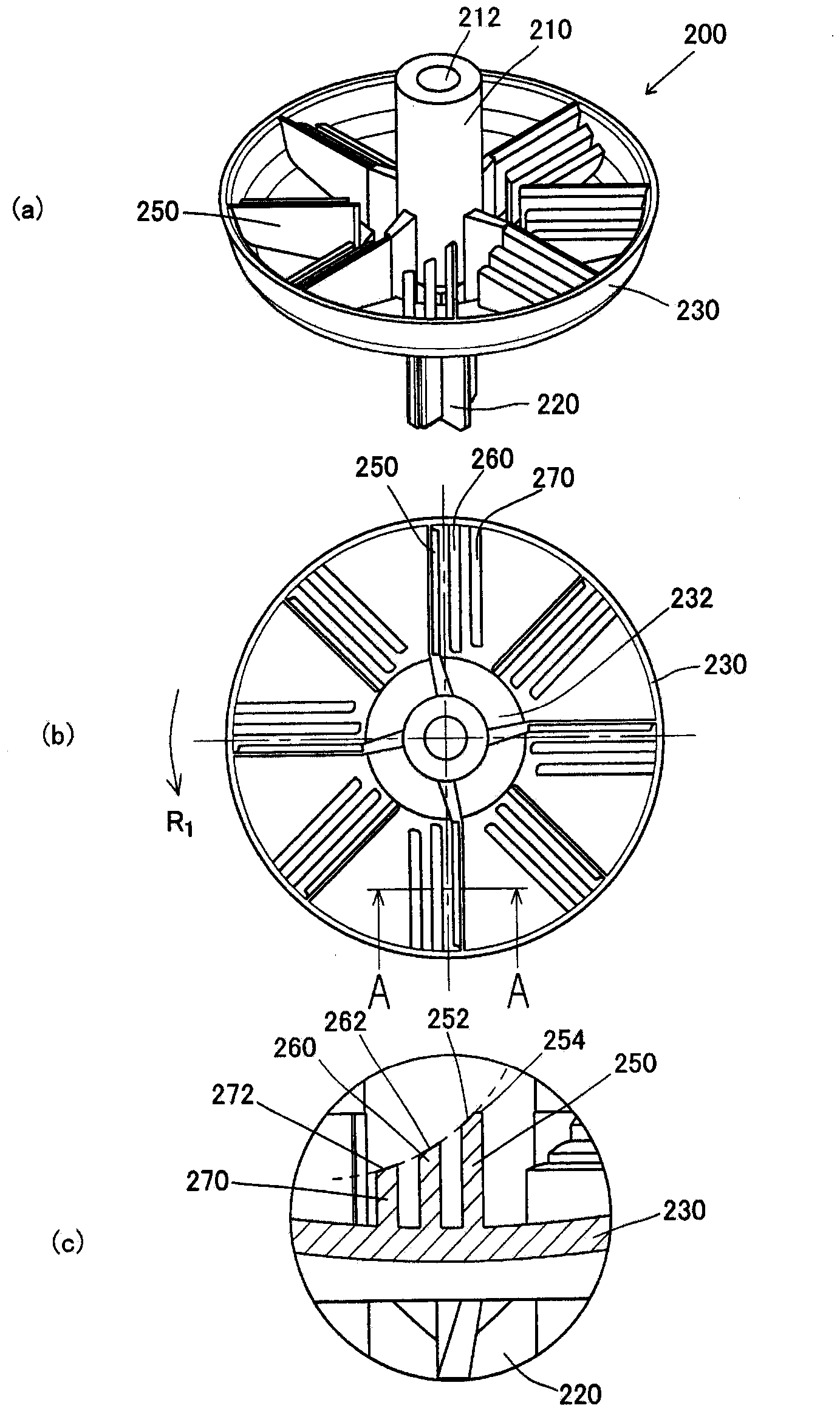

Drain pump

A rotating blade (100) comprises a large-diameter blade (150), a small-diameter blade (120) and an annular member (130) and rotates in the direction of an arrow (R1). The rear side of the large-diameter blade (150) is provided with a first large-diameter auxiliary blade (160) and a second large-diameter auxiliary blade (170). The upper surfaces (152, 162, 172) of the large-diameter blade (150), the first large-diameter auxiliary blade (160) and the second large-diameter auxiliary blade (170) are set to become lower and lower. Water (F) flows smoothly, so that the generation of vortex cavitation can be prevented. According to the invention, the vibration and the noise of the rotating blade of a drain pump mounted on an air conditioner can be reduced.

Owner:FUJIKOKI MFG CO LTD

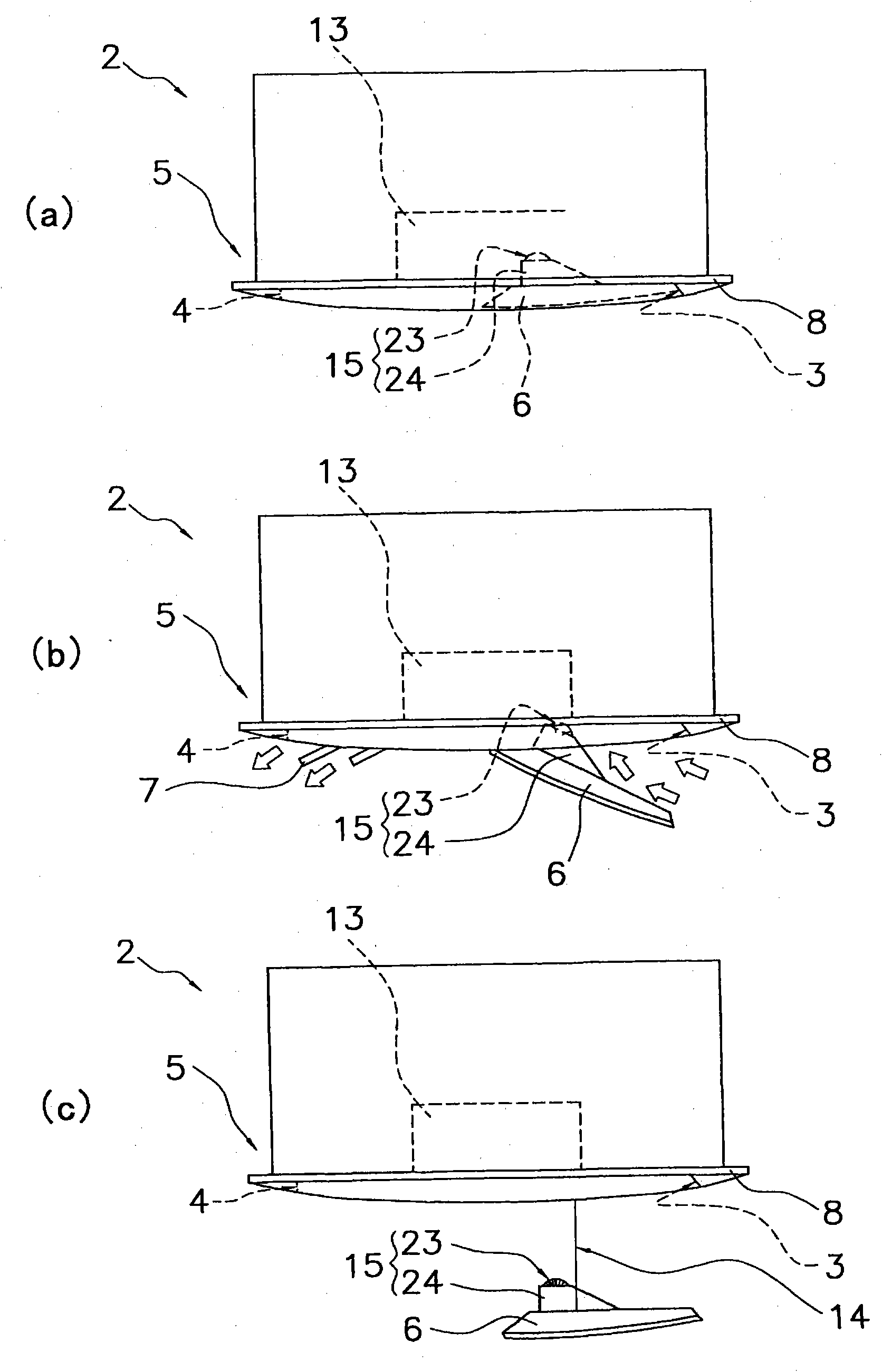

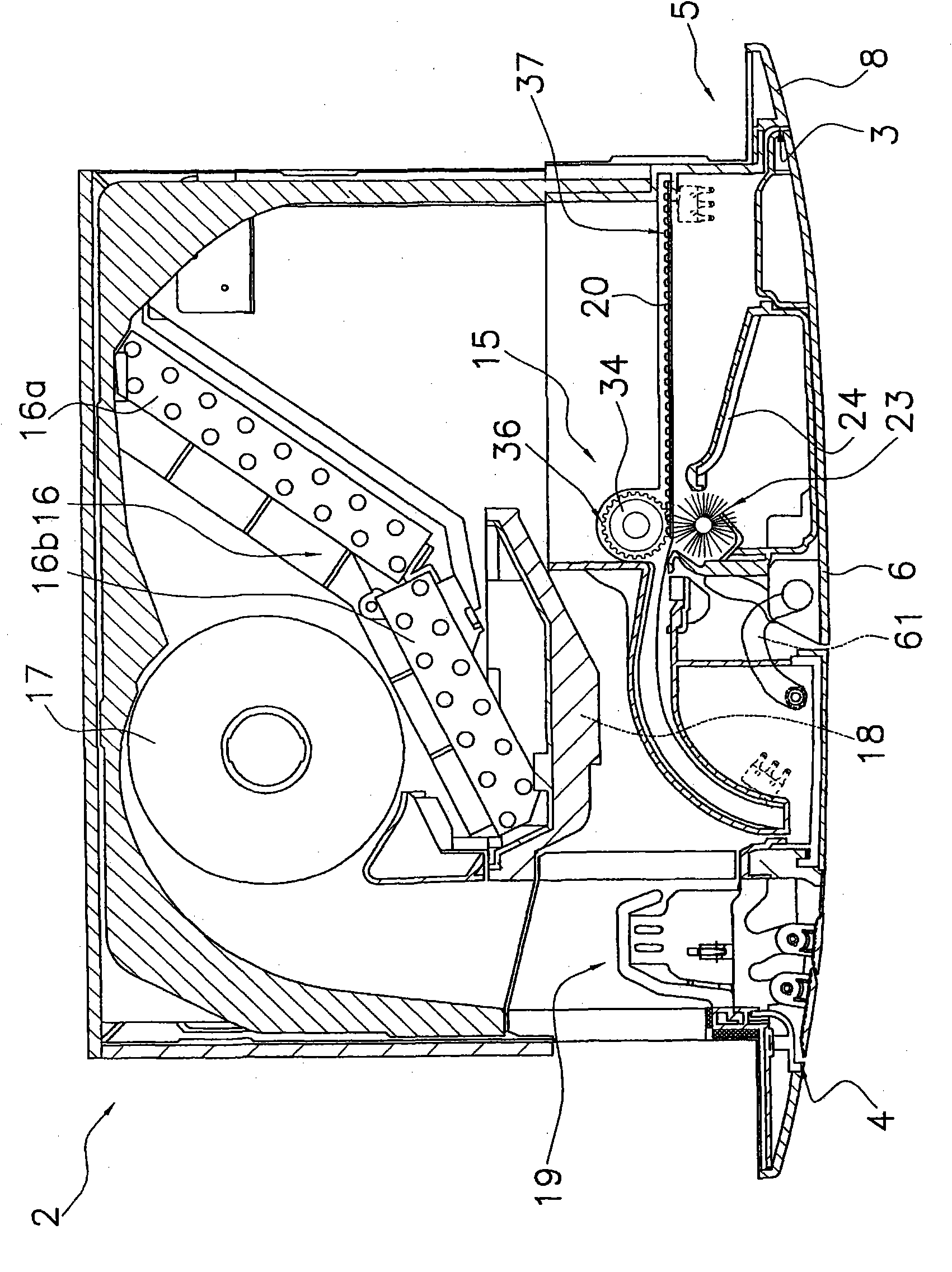

Indoor unit for air conditioner

InactiveCN101929710AEliminate undesirable situations of abnormal actionsPrevent bad situationsLighting and heating apparatusHeating and ventilation casings/coversElectric motorEngineering

The invention provides an indoor unit for an air conditioner, capable of preventing a movable panel from descending in the cleaning process of a filter to normally clean the filter. The indoor unit has a housing with a suction inlet, the movable panel for opening and closing the suction inlet, a panel moving mechanism, the filter, a brush and a brush driving device. The panel moving mechanism hasan elevating motor for generating a driving force to drive the movable panel to move and drive the movable panel to reciprocate between the preset opening position and the preset closing position. The filter is arranged in the housing to filter the air introduced from the suction inlet. The brush is mounted on the movable panel in a rotatable way to clean the filter. The brush driving device is disposed in the housing to drive the brush to rotate. The brush driving device acts to excite the elevating motor of the panel moving mechanism, so that the elevating motor can not run, thus the movable panel can not move, or the elevating motor generates the power for applying the force to close the movable panel.

Owner:DAIKIN IND LTD

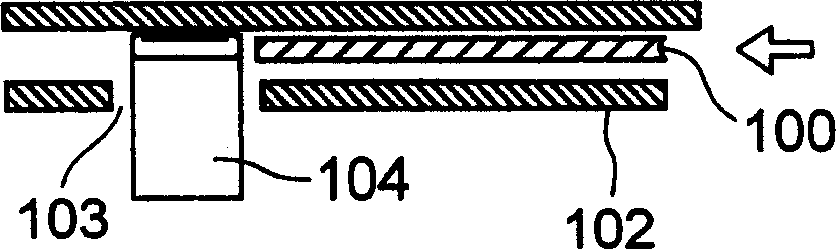

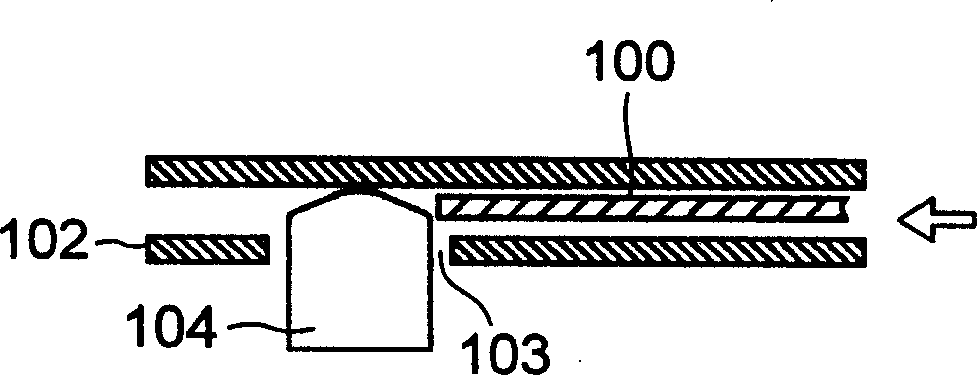

Magnetic recording reproducing device, chit printer attached the magnetic recording reproducing device and magnetic recording reproducing method

InactiveCN1912896AReduce failure factorsIncreased durabilityDriving/moving recording headsCo-operative working arrangementsPaper sheetEngineering

A magnetic recording and reproducing device is provided which prevents the tip of a magnetic head from being caught by a paper sheet and a magnetic recording medium carelessly, that can read and write magnetic information by coping with diversified paper sheets that have different bonding positions of the magnetic recording medium, and is less likely to be affected easily by position misalignment, when inserting the paper sheet. While the magnetic head (13) is retracted downward, as compared with a guide plate (5) for supporting a passbook (100) from the lower-surface side, the magnetic head (13) is moved in a direction of orthogonally crossing the insertion direction of the passbook (100) and positioning the magnetic head (13). After that, the magnetic head (13) is made to project from a slit (15) and made to come into contact with a magnetic stripe (101) of the passbook (100).

Owner:NEC CORP

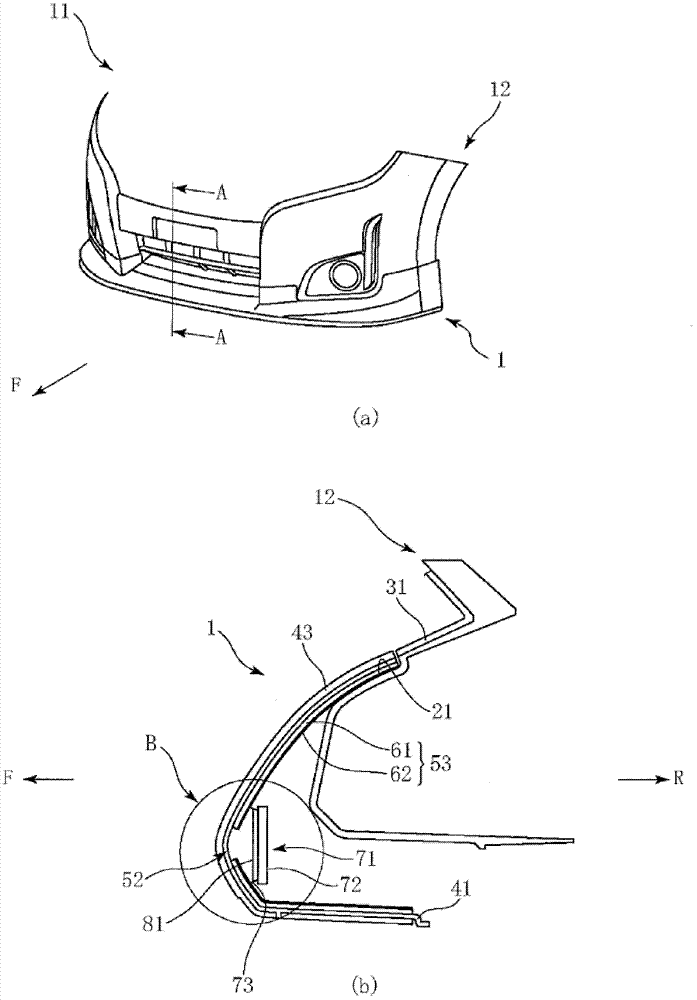

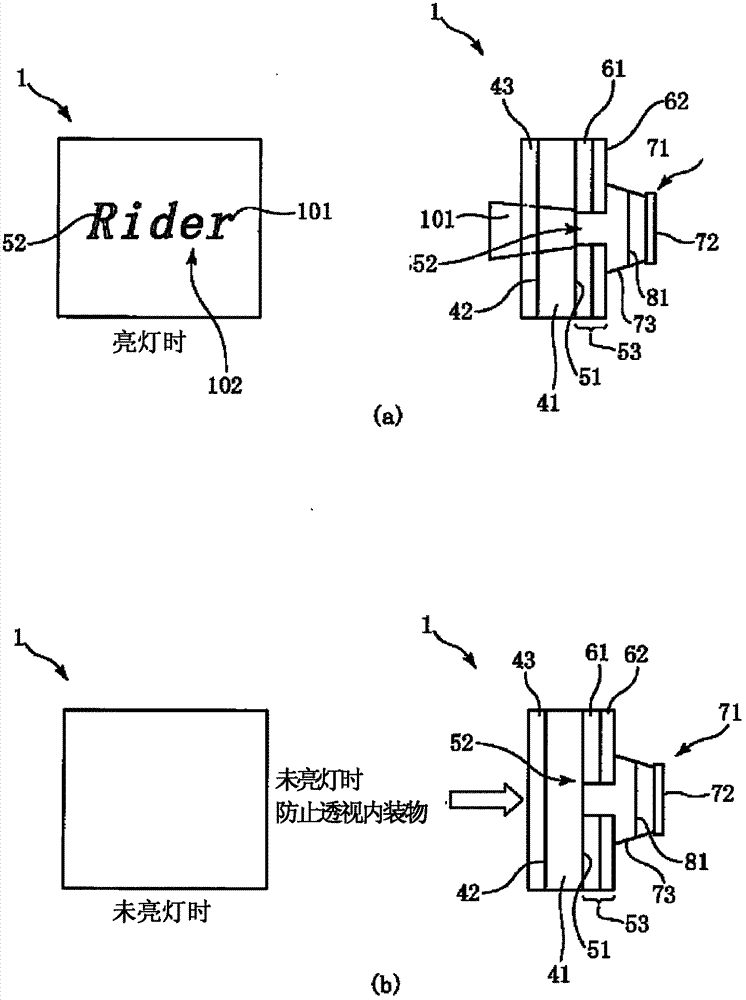

External part structure

InactiveCN102729915AEliminate undesirable cases of apparent chromatic aberration of colorsBeautify the appearanceVehicle componentsBiomedical engineeringLight source

The invention provides an external part structure which can eliminate the poor condition when the external part structure is used with other parts. A part main body (41) of a front protection device (1) is made of transparent resin, a surface (42) is provided with a surface side coating layer (43) which has the same color as a front bumper (12) and is nonopaque. The back (51) of the part main body (41) is provided with a mark forming part (52), and the part except the mark forming part is provided with a back layer (53). The back layer (53) includes a back side coating layer (61) which is laminated on the back (51) of the part main body (41) and a shading layer (62) which is laminated on the back side coating layer (61). The back side coating layer (61) has the same color or tone as the surface side coating layer (43). The back of the front protection device (1) is provided with a light source unit (71) which illuminates the mark forming part (52).

Owner:AUTECH JAPAN INC +1

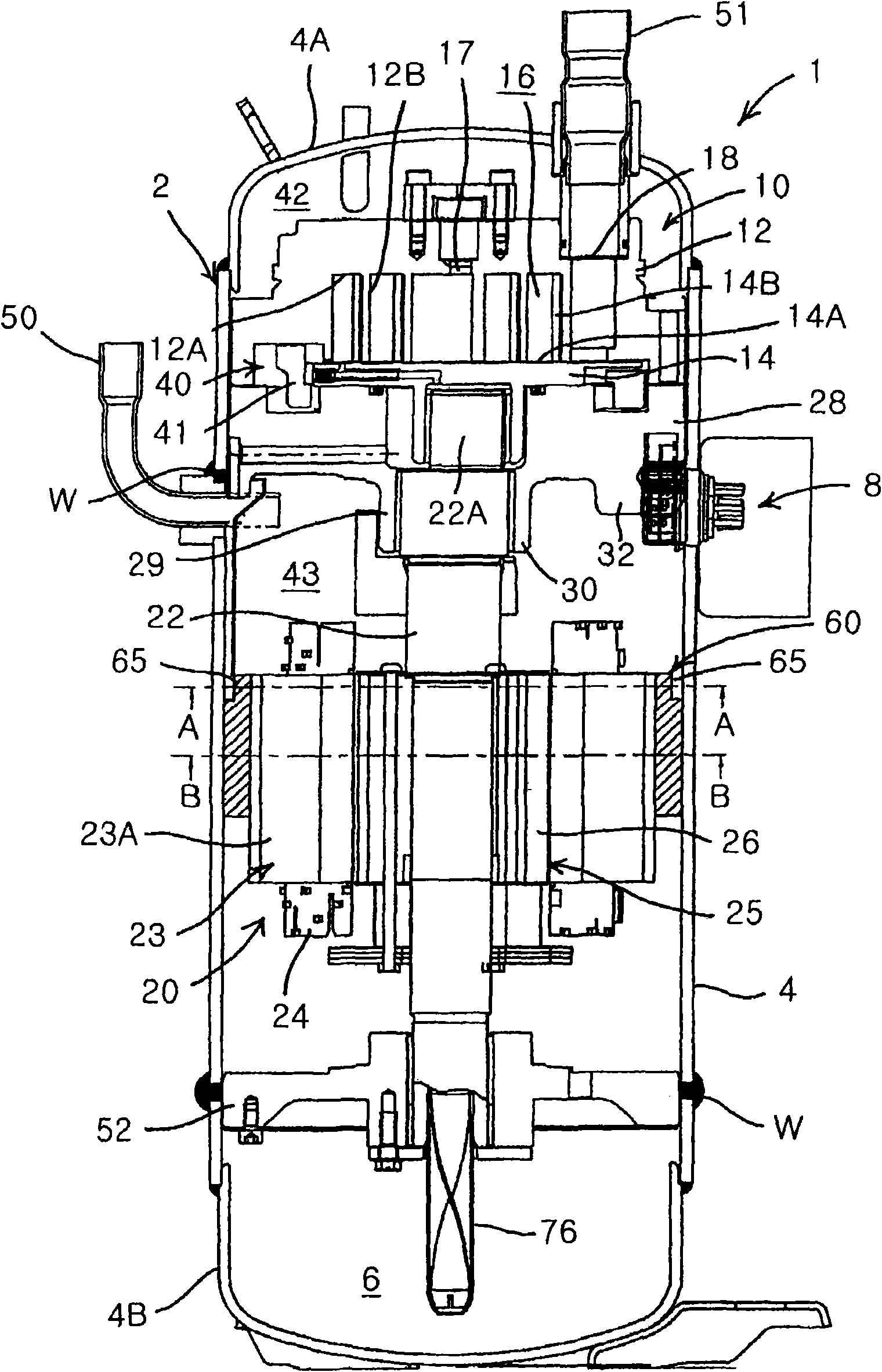

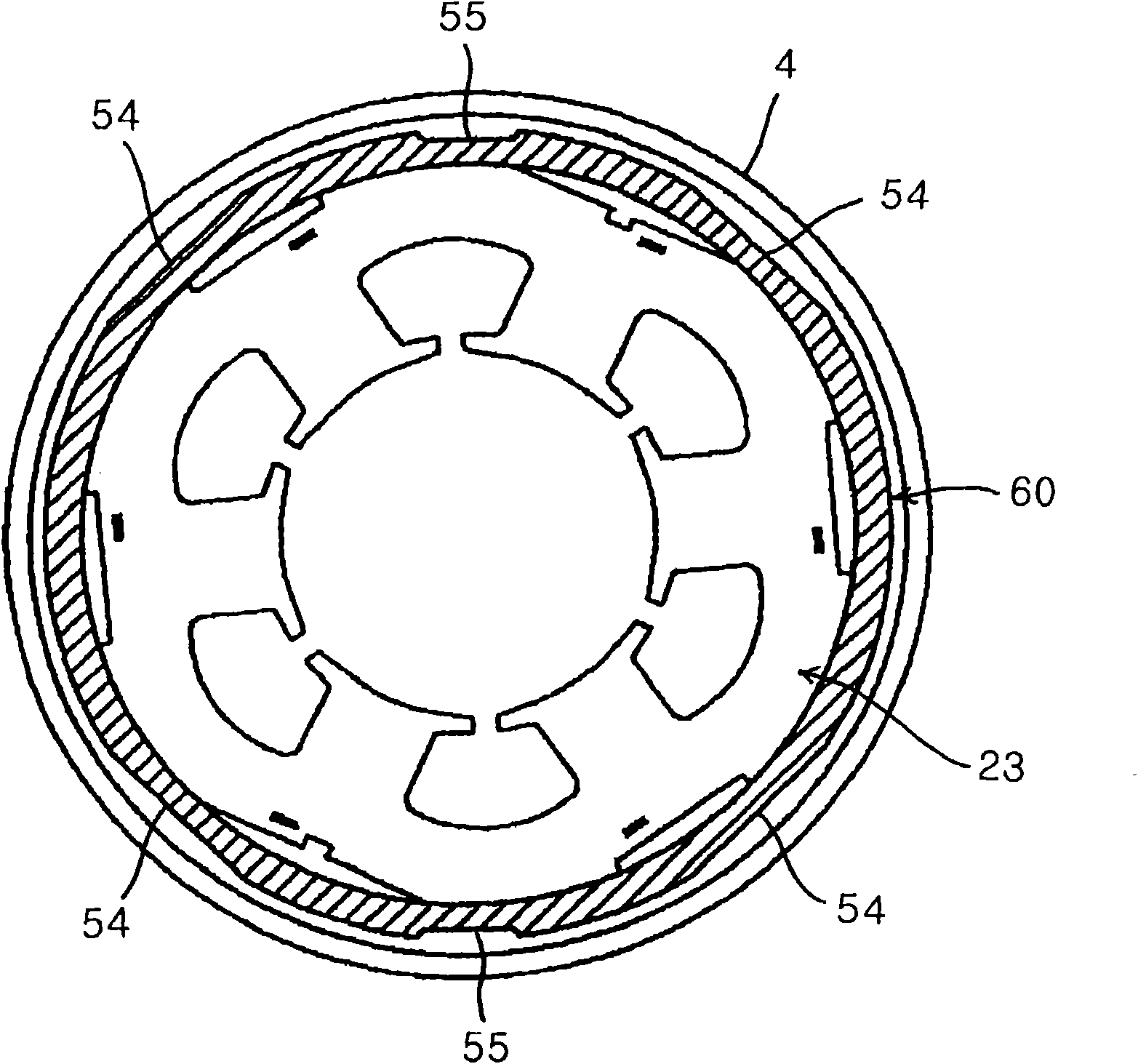

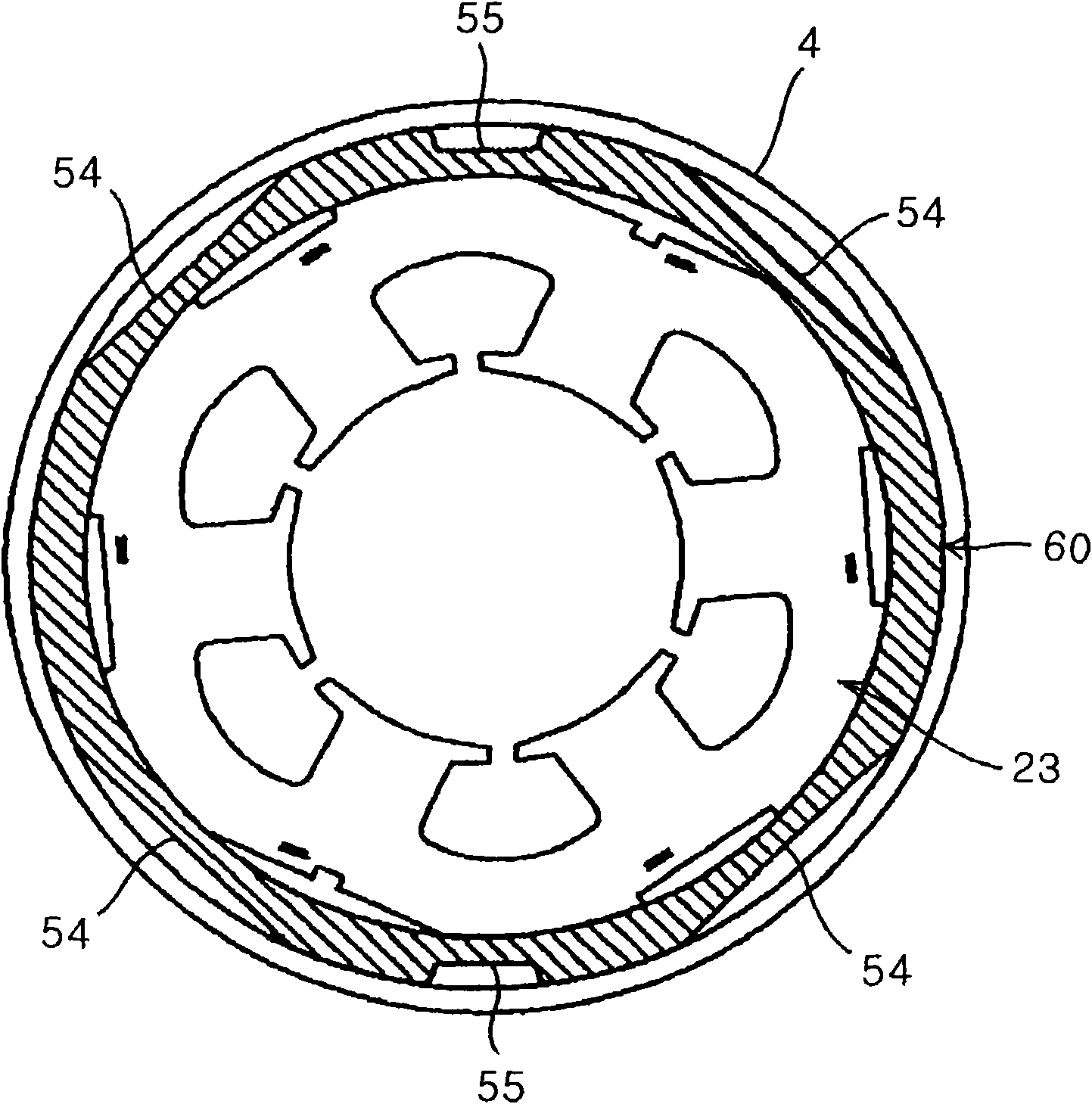

Compressor

InactiveCN101994700AAvoid deformationSuppresses transmitted vibrationRotary/oscillating piston pump componentsLiquid fuel engine componentsEngineeringContainer space

The present invention provides a compressor, capable of eliminating electromagnetic vibration of an electric component from transmitting to a closed container to the utmost so as to reduce vibration and noise of the compressor. The compressor (1) comprises an eddy compression component(compression component) (10) accepted in the closed container (2) and the electric component (20) for driving the compression component (10), the electric component (20) including a stator (23) formed by laminating multiple electromagnetic steel plates; a rotor (25) fixed on a rotating shaft (22) that drives the compression component (10) and rotating on an inner side of the stator (23), the stator (23) being fixed in the closed container spacing a distance piece (60), and an area of the distance piece (60) contacted with the closed container being less than that of the stator.

Owner:SANYO ELECTRIC CO LTD

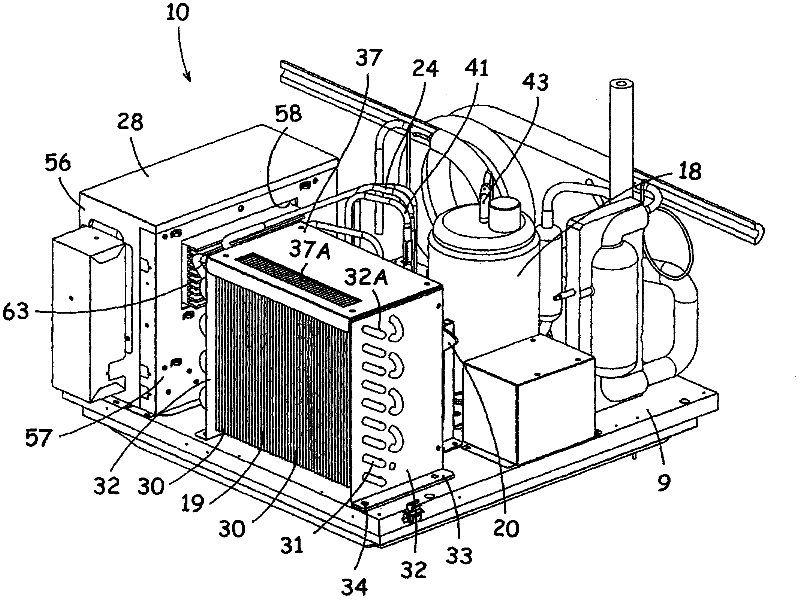

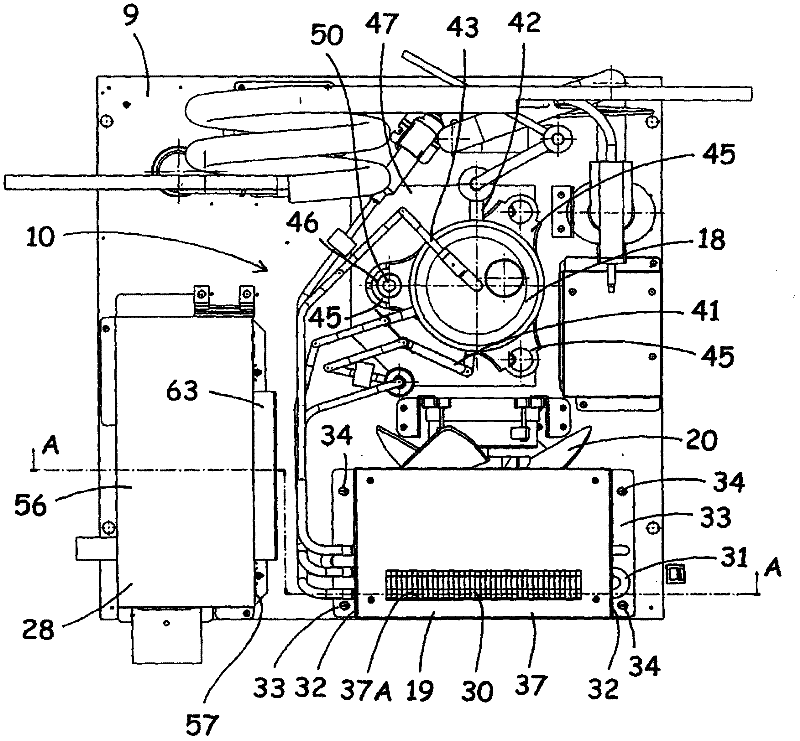

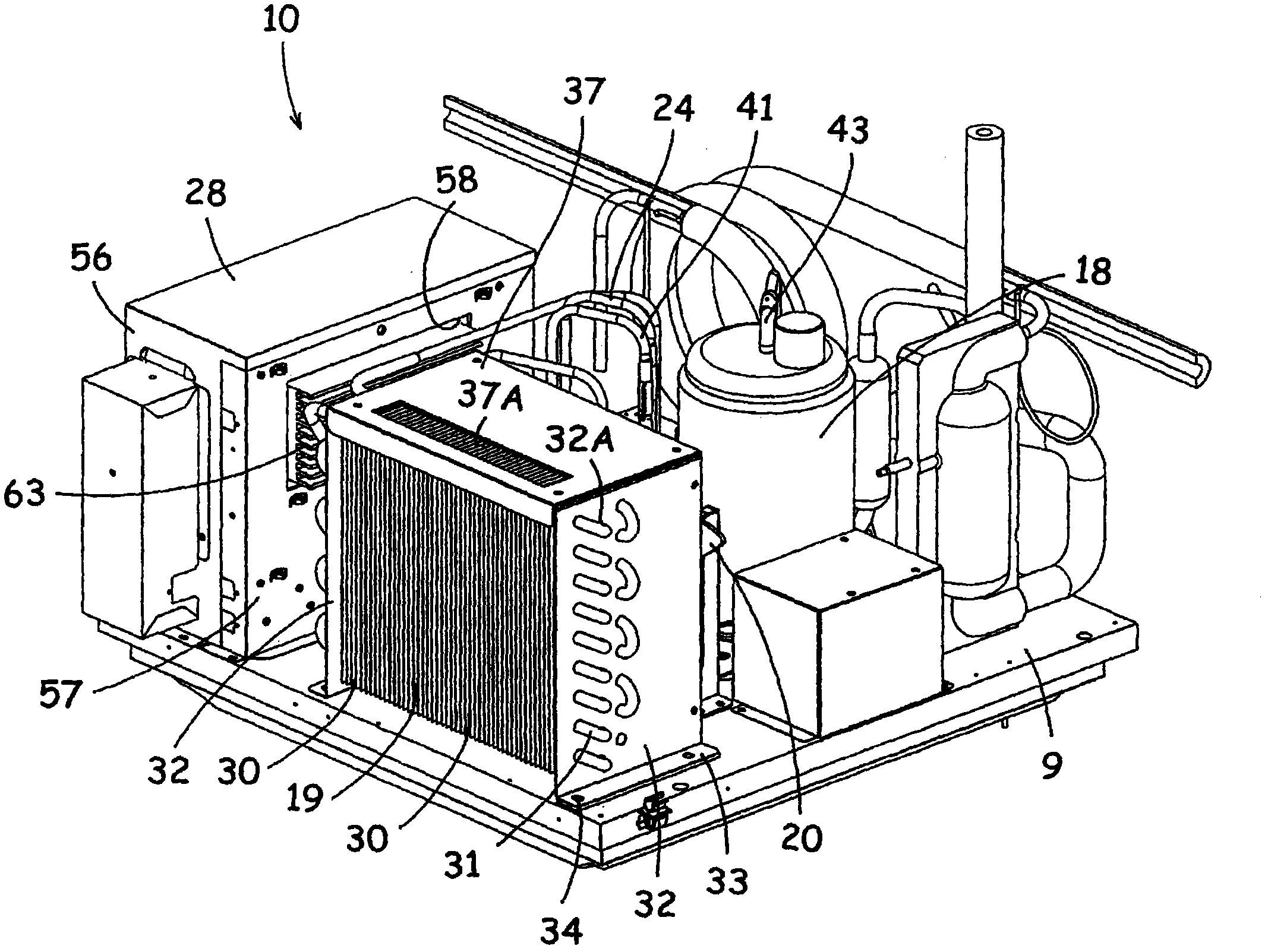

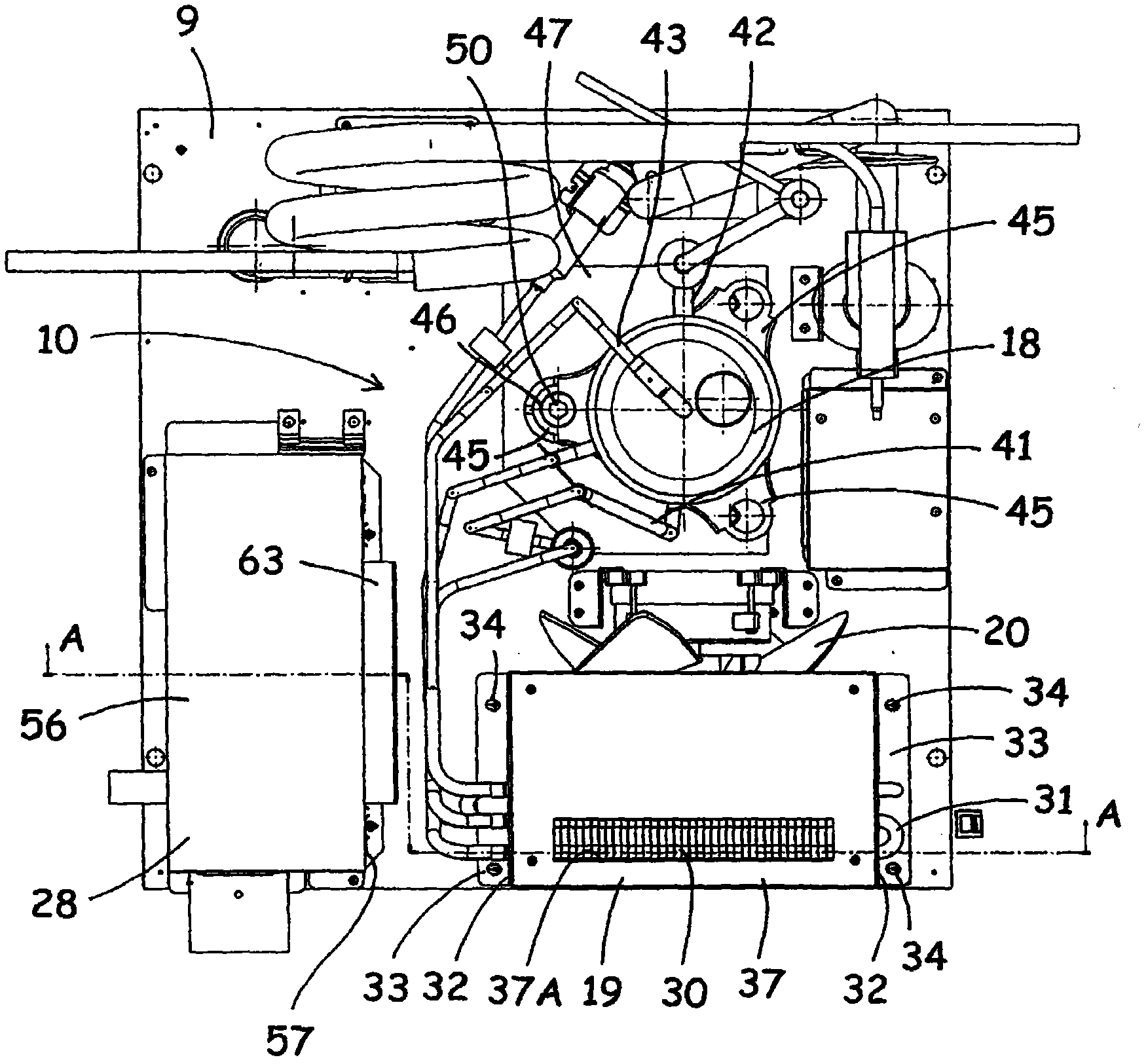

Refrigerator

ActiveCN102207349ASmooth outImprove cooling effectDomestic cooling apparatusLighting and heating apparatusEngineeringHeat sink

The invention provides a refrigerator which effectively discharges waste heat generated by heating elements on a circuit board arranged in a distribution box to achieve balance control. The refrigerator (R) is composed by a cooling device (10) comprising a compressor (18), a condenser (19), and a blower (20) for the condenser, the cooling device (10) being installed in a mechanical chamber (17). The refrigerator (R) comprises a distribution box (28) arranged in the mechanical chamber (17) and accommodating the circuit board (60) for controlling the cooling device (10), and radiating fins (63) facing outside the distribution box (28) and configured to be heat conductive with the heating elements on the circuit board (60).

Owner:SANYO ELECTRIC CO LTD

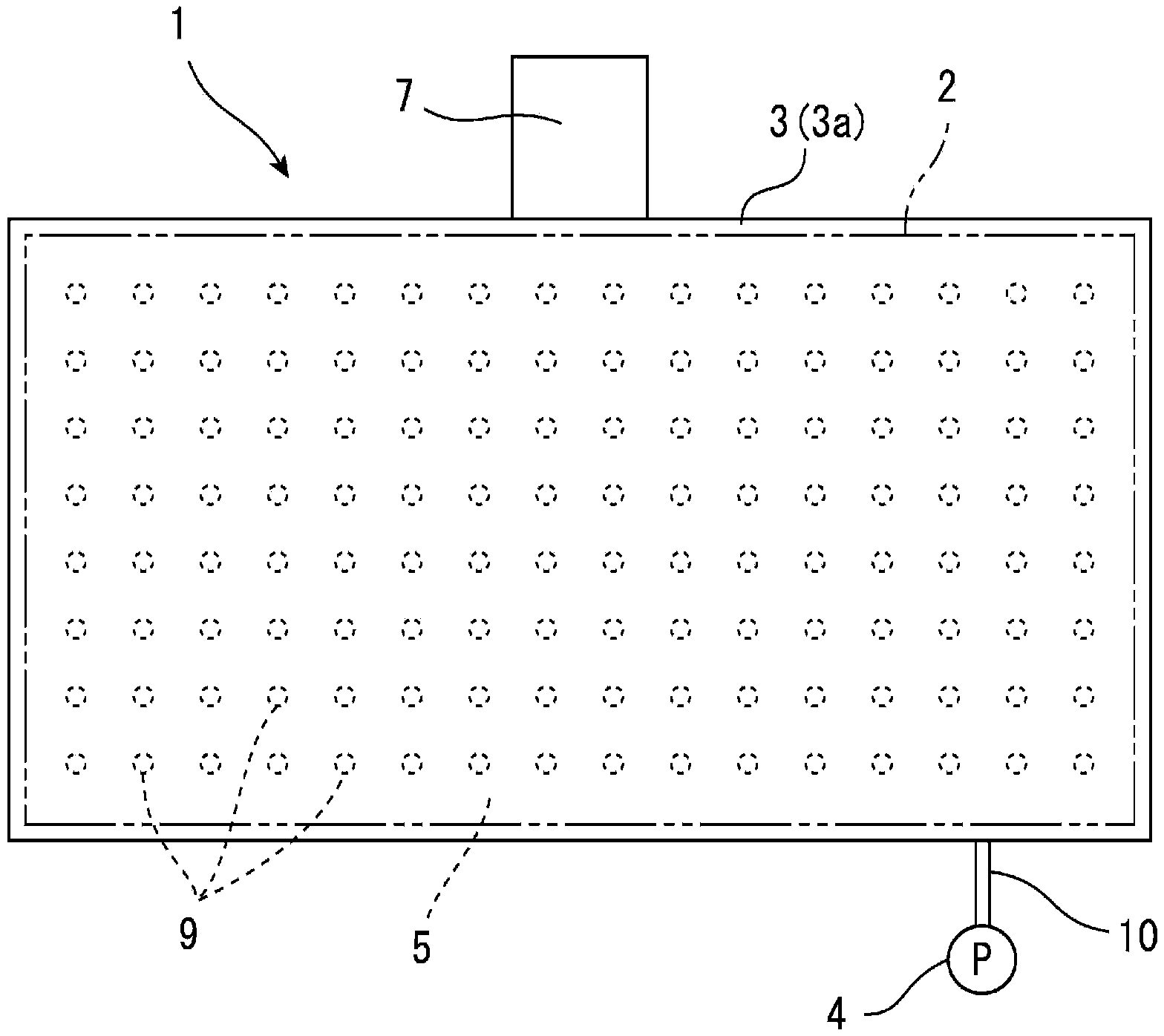

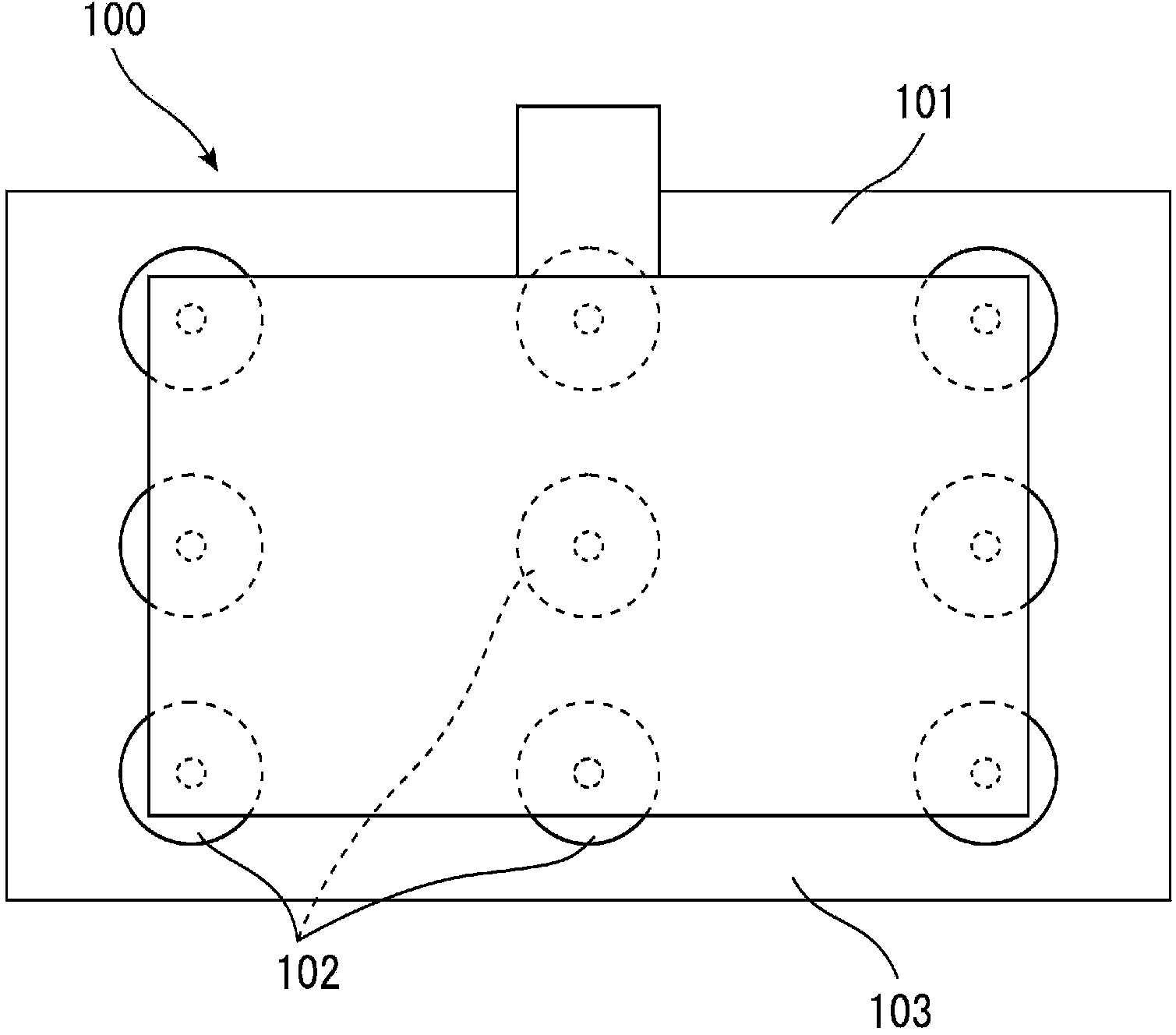

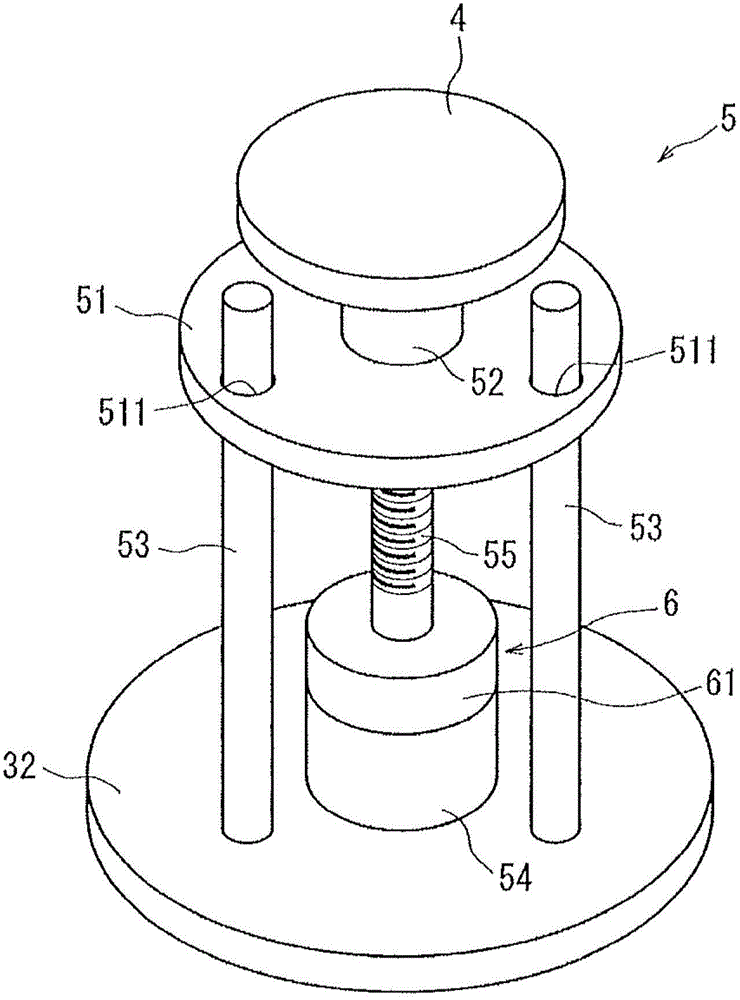

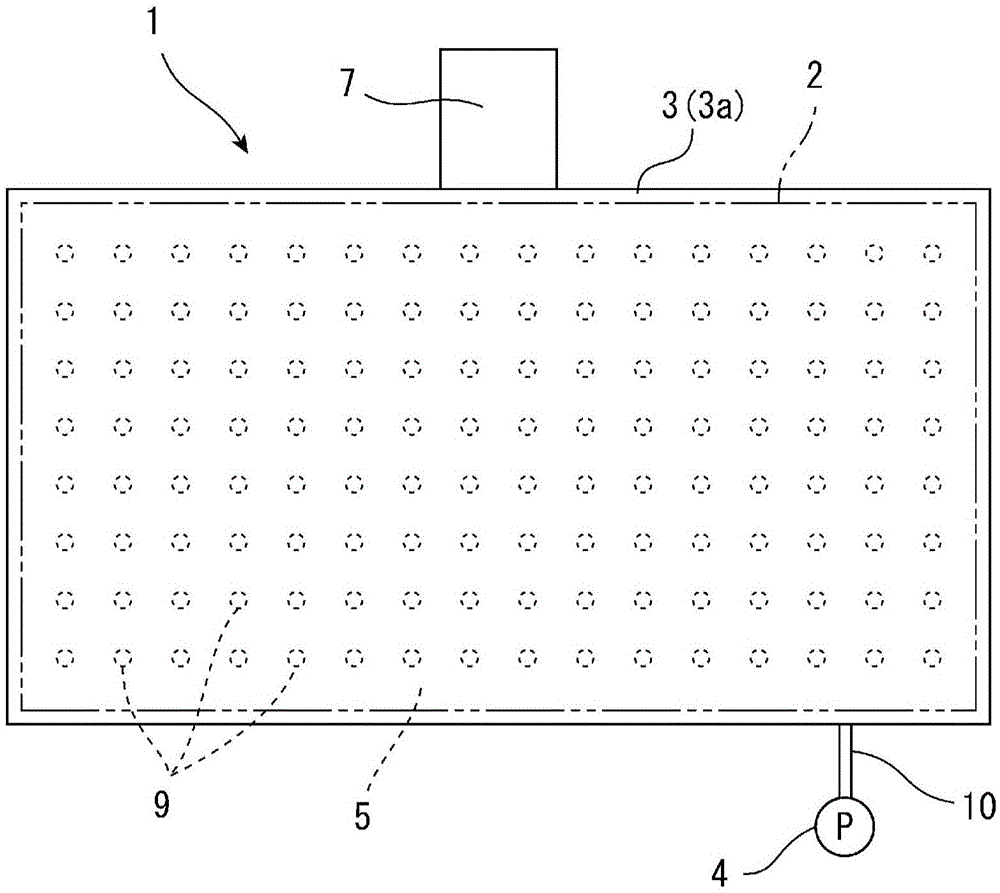

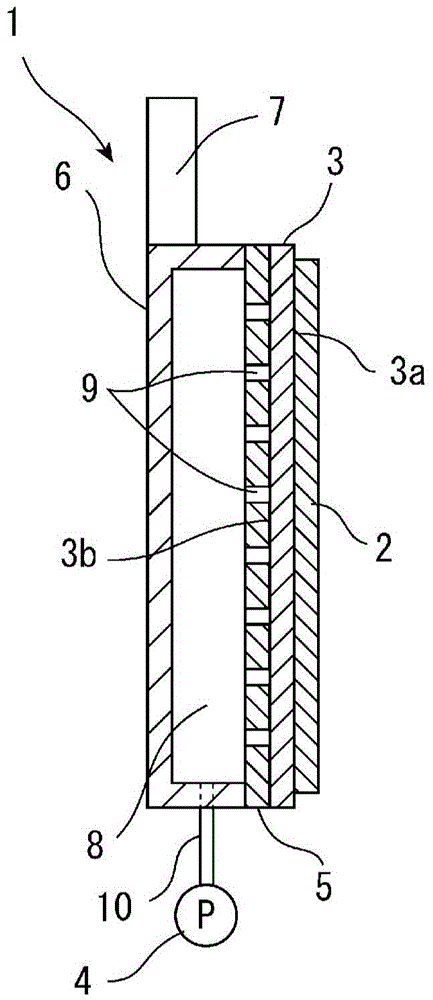

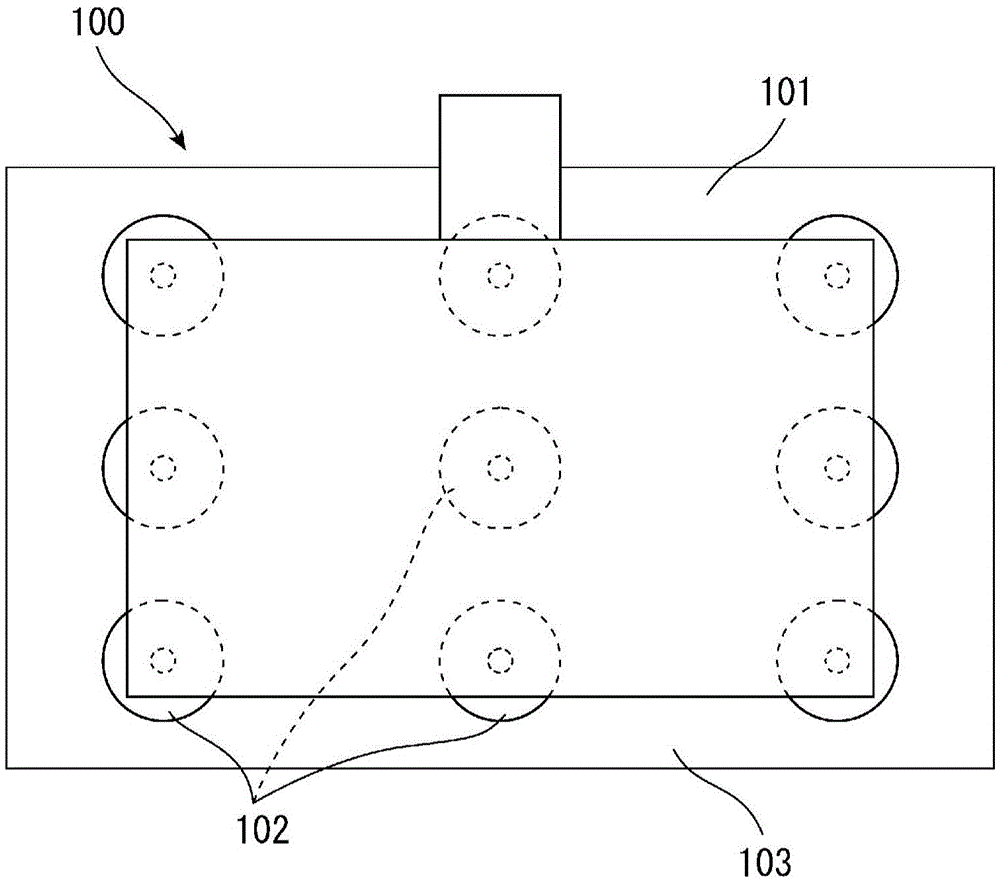

Extraction device and method for extracting resin molded article

Provided is an extraction device that can prevent a resin molded article such as a light guide plate from deforming when extracting the resin molded article by means of suctioning. In the extraction device (51), which suctions the light guide plate (52), which is the resin molded article molded in a die, by means of a suctioning body (53) to extract the light guide plate (52) from the die, the suctioning body (53) is provided with a high-density pore disposed region (H) at which a plurality of pores (59a) are disposed at a high density, and a low-density pore disposed region (L) at which a plurality of pores (59b) are disposed at a low density having a coarser density than the plurality of pores (59a) of the high-density pore disposed region (H).

Owner:TOYO MACH & METAL CO LTD

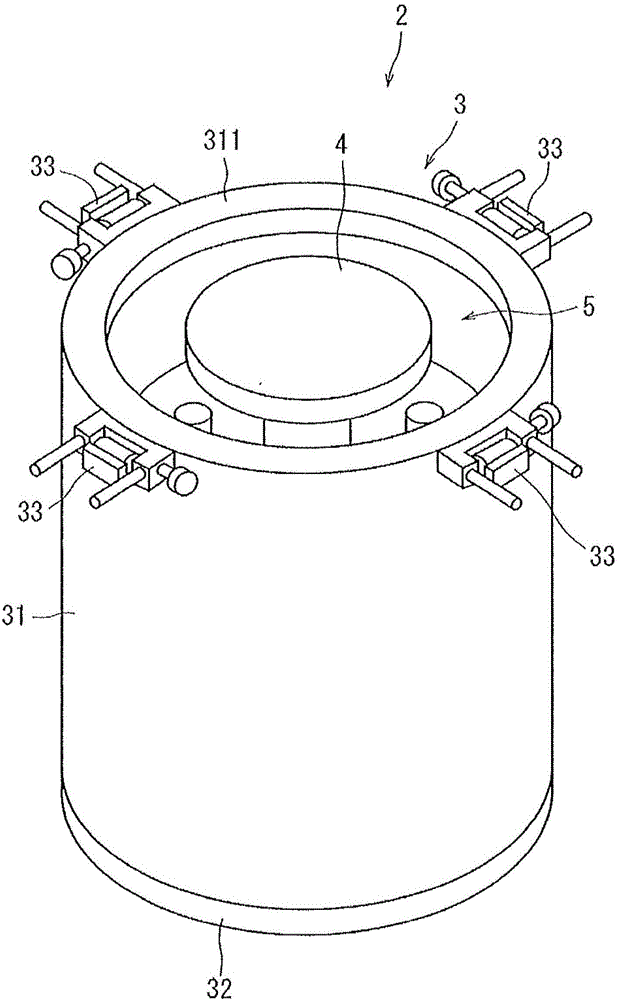

Tape expansion device

ActiveCN105321877AAvoid handlingEliminate bad situationsSemiconductor/solid-state device manufacturingWork unitEngineering

The invention provides a tape expansion device. The tape expansion device comprises a frame maintaining unit, an expansion part, an expansion part work unit, a drive lode detection unit, a control unit and a display unit. The frame maintaining unit is provided with an annular maintaining surface used for maintaining an annular frame. The expansion part has the diameter less than the inner diameter of the annular frame and larger than the diameter of a chip, and acts on a cutting tape mounted on the annular frame on the annular maintaining surface of the frame maintaining unit, and makes the cutting tape expand. The expansion part work unit enables the expansion part to work in the direction perpendicular to the annular maintaining surface of the frame maintaining unit. The drive load detection unit detects the drive load of the expansion part work unit. The control unit determines whether the cutting tape is broken according to a detection signal output by the drive load detection unit. The display unit displays determine results of the control unit. Under a condition that the control unit makes the expansion part work unit works and expands the cutting tape, the control unit determines that the cutting tape is broken according to the detection signal output by the drive lode detection unit when the drive load decreases under a condition that the drive load increases as the cutting tape is expanded.

Owner:DISCO CORP

Extraction device and extraction method of resin molded products

Owner:TOYO MACH & METAL CO LTD

Refrigerator

ActiveCN102207349BSmooth outReduce in quantityDomestic cooling apparatusLighting and heating apparatusEngineeringHeat sink

Owner:SANYO ELECTRIC CO LTD

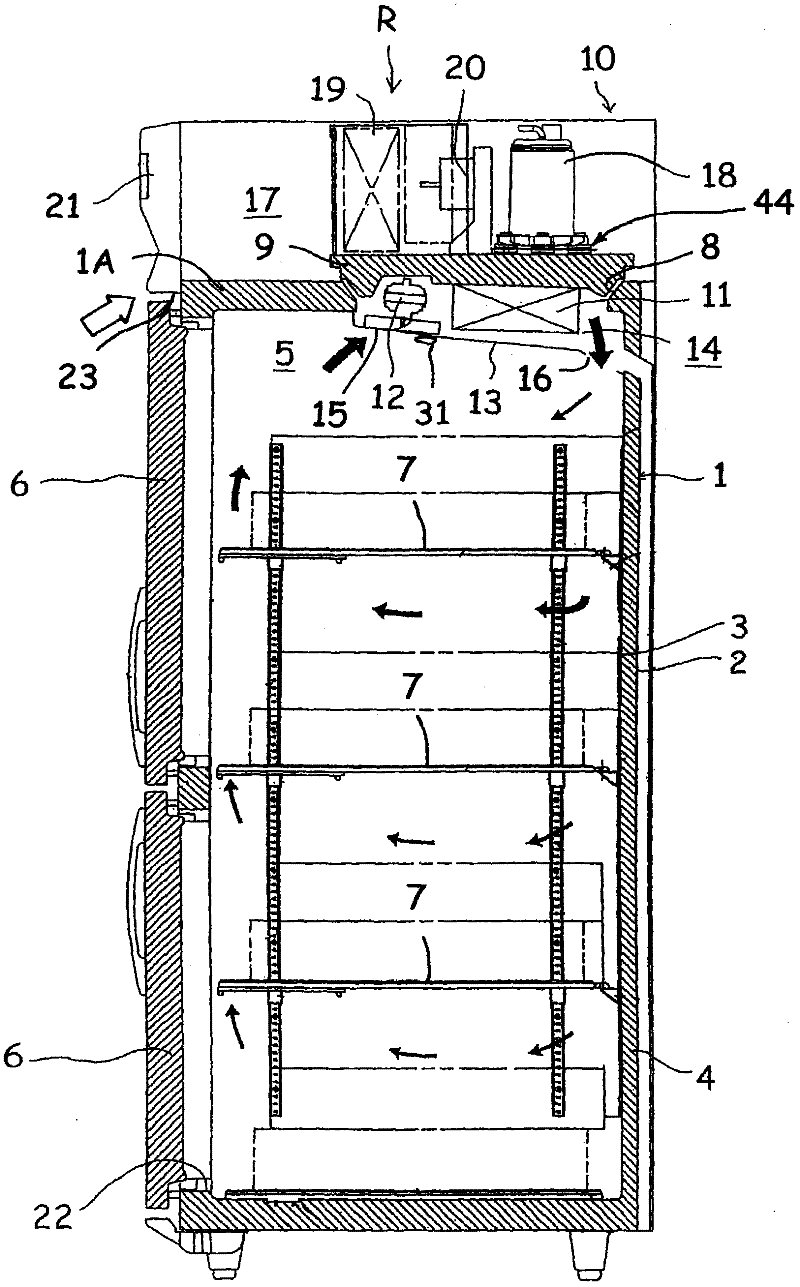

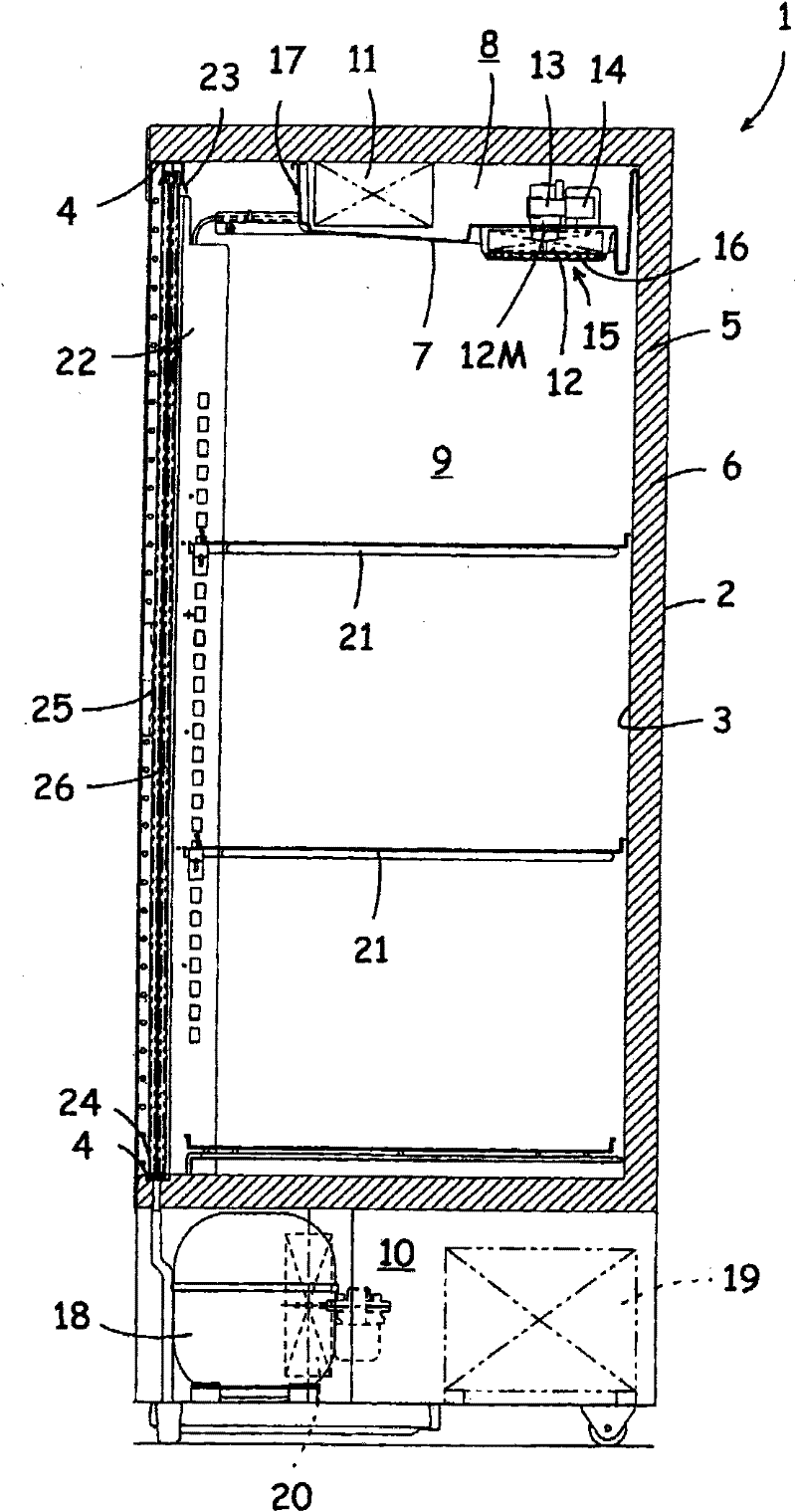

Cooling storage cabinet

ActiveCN101818982BEasy to installReduce tiltLighting and heating apparatusDefrostingCool storageChiller

The invention relates to a cooling storage cabinet, in which a draining flexible pipe is properly mounted on a draining socket arranged on a drip tray, and the draining is smoothly performed. In the cooling storage cabinet (1), the transversely-projecting draining socket (51) formed on the drip tray (7) receiving the water from a cooler (11) is connected with the draining flexible pipe (41), wherein, a draining flexible pipe fixed part (31) mounted on the drip tray (7), from a pipe expanding part (42) of the draining flexible pipe (41) to a predetermined range, supports the draining flexible pipe (41) from the lower side, and in this time, is fixed on the draining flexible pipe (41) by bands (45, 46), and lowers and inclines with the depart from the drain socket (51).

Owner:SANYO ELECTRIC CO LTD

lens aperture device

ActiveCN103186012BQuality improvementEliminate bad situationsCamera diaphragmsOptical elementsEngineeringMechanical engineering

The present invention provides an aperture device for a lens, which includes: a striker mechanism portion, which is configured such that an engaging portion having an elastically supported engaging body is provided on one of a fixed cylinder portion and an aperture adjusting ring, and an engaging portion is provided on the other. There is an engaged base part, the engaged base part has an engaged surface, the engaging body is in pressure contact with the engaged surface, and the engaged surface is formed with a plurality of engaged parts. When the aperture adjustment ring rotates, the engaging body can engage with a plurality of engaged parts at positions corresponding to the aperture value; and a mode switching mechanism part, which changes the position of at least one of the engaging part and the engaged base part It is possible to switch between the strike mode and the non-strike mode, the strike mode is a mode in which the engaging body is pressed against the engaged surface, and the non-strike mode is released when the engaging body is separated from the engaged surface mode with the touch function enabled.

Owner:COSINA CO LTD

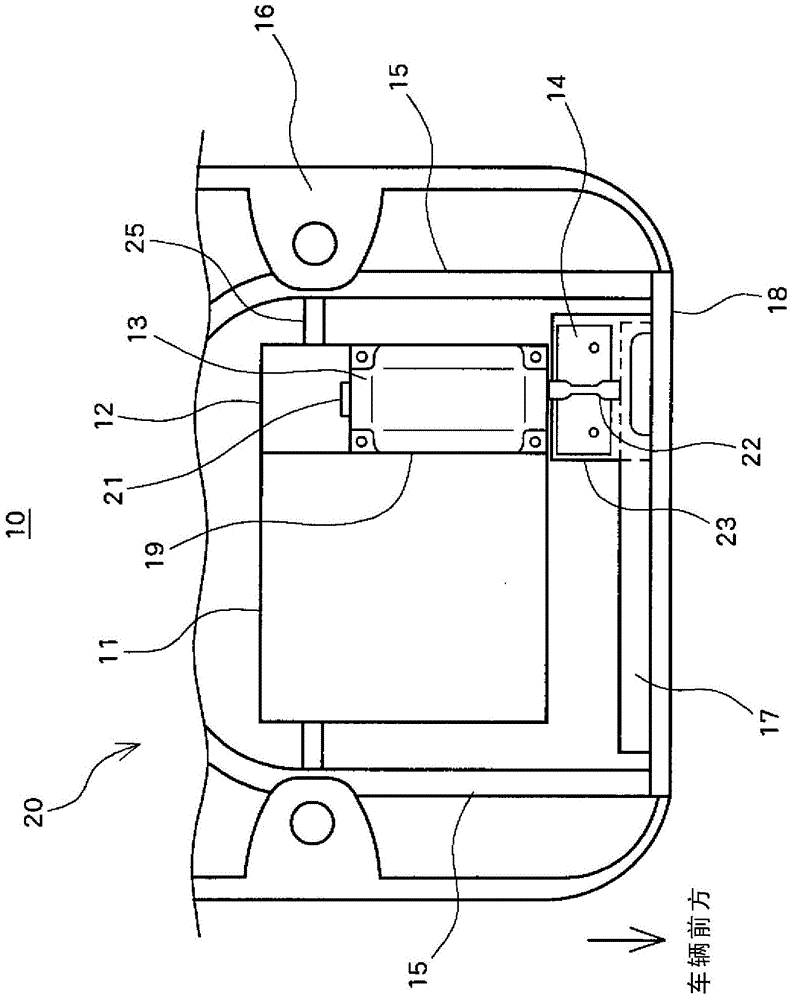

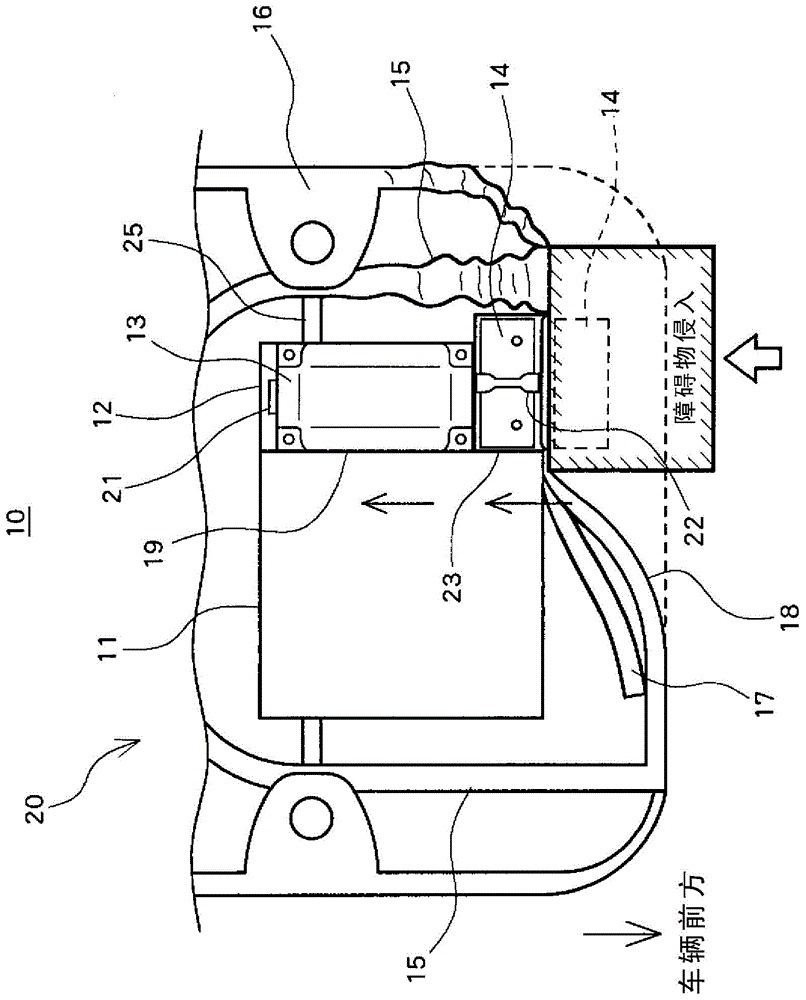

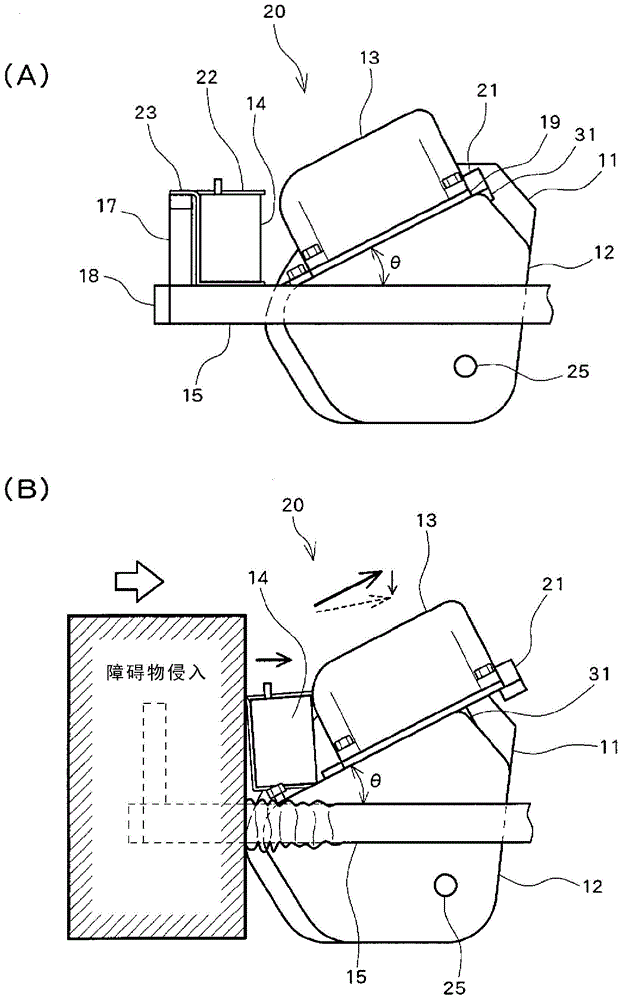

Vehicle Equipment Mounting Structure

ActiveCN103370230BIncrease freedomEasy dischargeElectric propulsion mountingVehicle sub-unit featuresEngine mountHybrid vehicle

The present invention comprises side members (15), which are vehicular skeleton members of a hybrid vehicle (10); a front cross member (18) for connecting the two side members (15); spring supports (16) connected to the side members (15); an auxiliary battery arranged further towards the vehicle front relative to a PCU (13) and attached to the front cross member (18) via a support platform (23) and a securing piece (22); a radiator (17) attached to the front cross member (18); a motor case (12) and an engine (11) connected to the vehicular skeleton member via an engine mount; an axle (25) extending from the motor case (12); and a PCU (13) connected to the motor case (12) via a guide plate (19) and a linkage bolt. Thus, there is provided a vehicular instrument-mounting structure capable of inhibiting collision of a power control device or other vehicle-mounted instrument with another member, and inhibiting damage caused to the power control device or other vehicle-mounted instrument during a vehicle collision.

Owner:TOYOTA JIDOSHA KK +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com