Sealing cushion

A sealing gasket and sealing lip technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of difficult elastic deformation, poor installation, difficult to press into the opening of the casing, etc., to eliminate the bad situation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

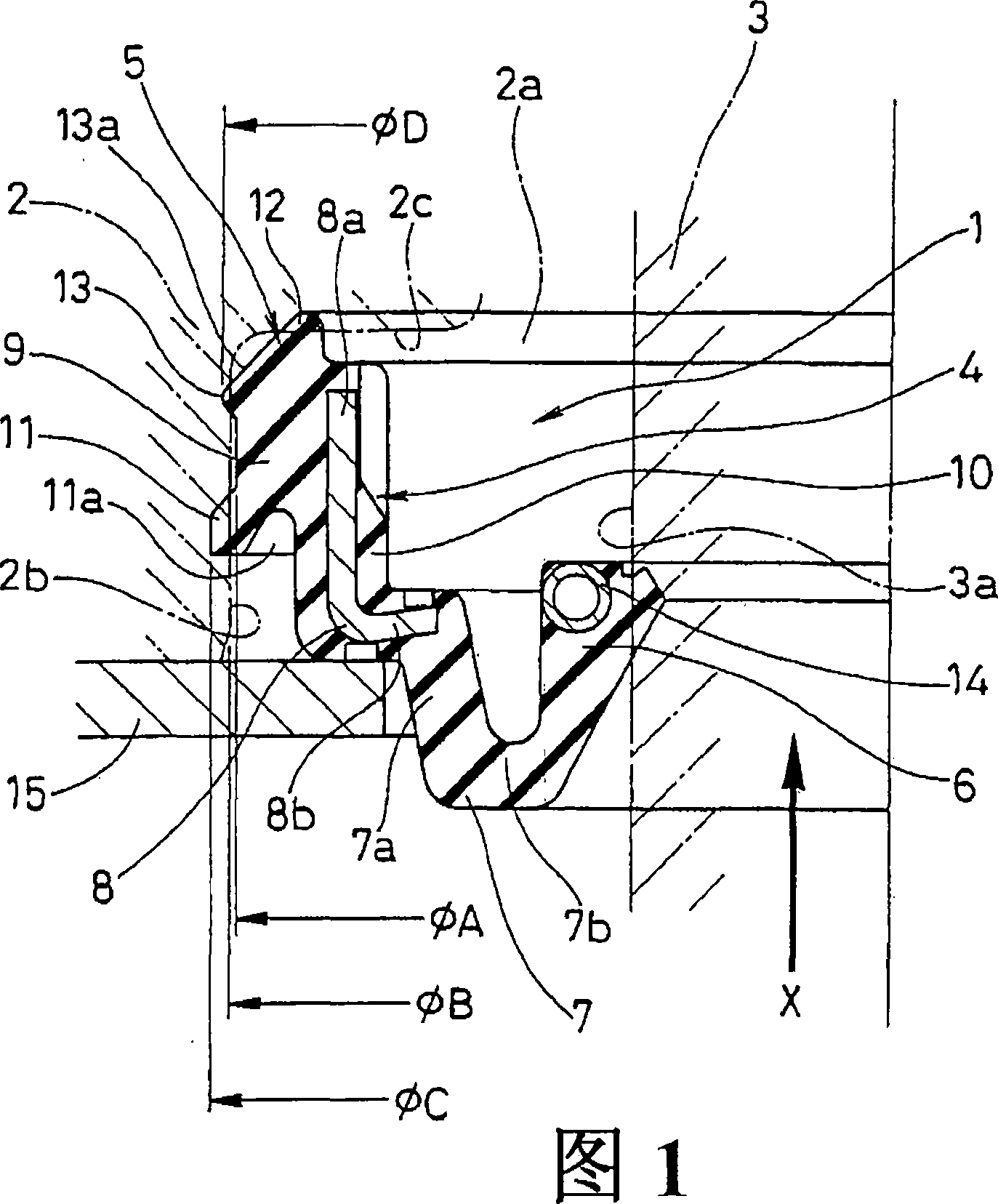

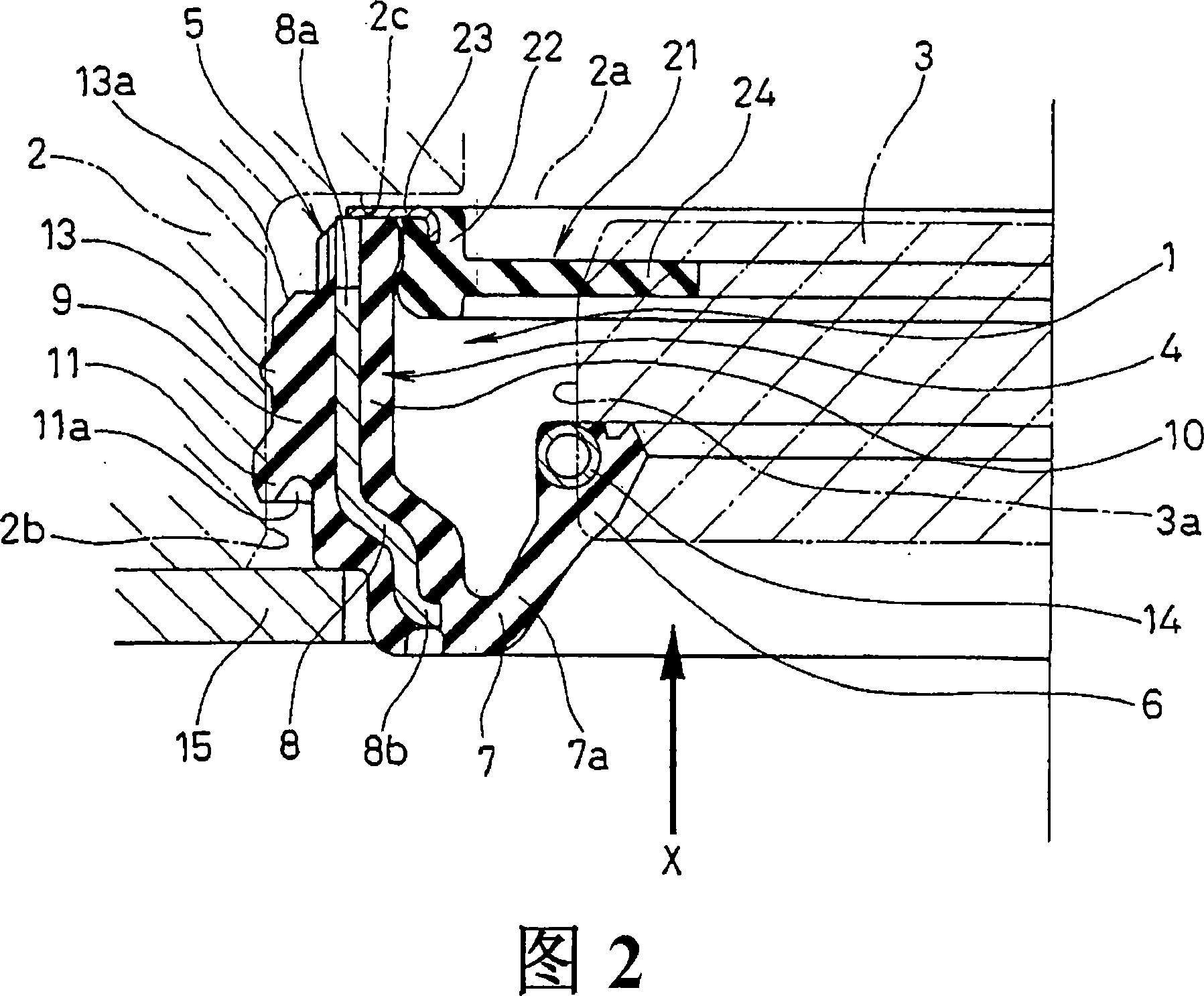

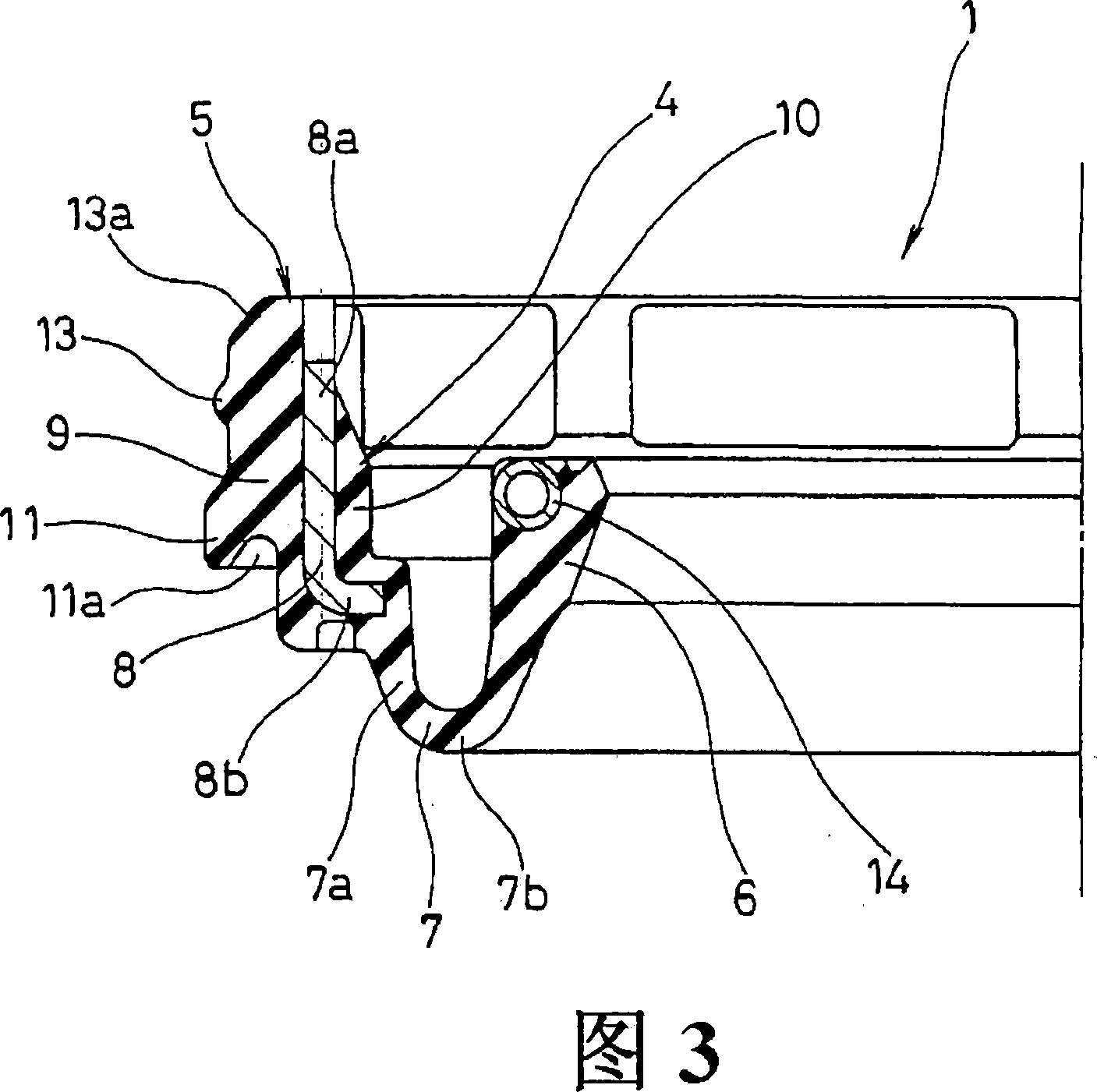

[0068] Fig. 1 is a half-sectional view of the gasket 1 according to the first embodiment of the present invention;

[0069] The gasket 1 described in this embodiment is used to seal between the resin cylinder head 2 and the spark plug barrel 3 in an internal combustion engine, and is installed on the inner peripheral surface 2b of the opening 2a of the cylinder head 2, and it is closely attached to the above-mentioned plug. The outer peripheral surface 3a of the spark plug barrel 3 at the opening 2a is structured as follows. In addition, the gasket 1 is configured to be pushed into the opening 2 a of the cylinder head 2 from the inner side of the cylinder head 2 (lower side in the figure) (arrow X direction).

[0070] First, this gasket (spark plug gasket) 1 is integrally formed with: an outer peripheral mounting portion 5 which is annular and fits on the inner peripheral side of the cylindrical inner peripheral surface 2b of the opening 2a in the cylinder head 2; 6, which is...

no. 4 example

[0083]In the above-mentioned first to third embodiments (FIGS. 1 to 3), the gasket 1 is configured to be pressed into the opening 2a of the cylinder head 2 from the inside (downward in the figure) of the cylinder head 2, but the structure is also The opening 2 a of the cylinder head 2 may be pushed in from the outside (upper in the figure) instead of the inside of the cylinder head 2 . At this time, as shown in FIG. 4 , the lip-shaped interference amount setting member 11 is arranged to face the reverse of the push-in direction (direction of arrow X), that is, upward in the figure. In addition, a radial position determining element 13 is provided below the drawing of the lip-shaped interference amount setting element 11. The radial position determining element 13 is not in the shape of a protrusion, but corresponds to the inner peripheral surface 2b of the opening of the cylinder head 2. The tapered object that is provided and is in close contact with the tapered radial positi...

no. 5 example

[0085] Moreover, as shown in FIG. 5, the flange part 8b may be provided in the rear end part of the metal ring 8 in the pushing direction of the cylindrical part 8a.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com