Drain pump

A technology for drainage pumps and vanes, which is applied in the direction of pumps, axial flow pumps, pump components, etc., and can solve problems such as noise, rotation balance deterioration, and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

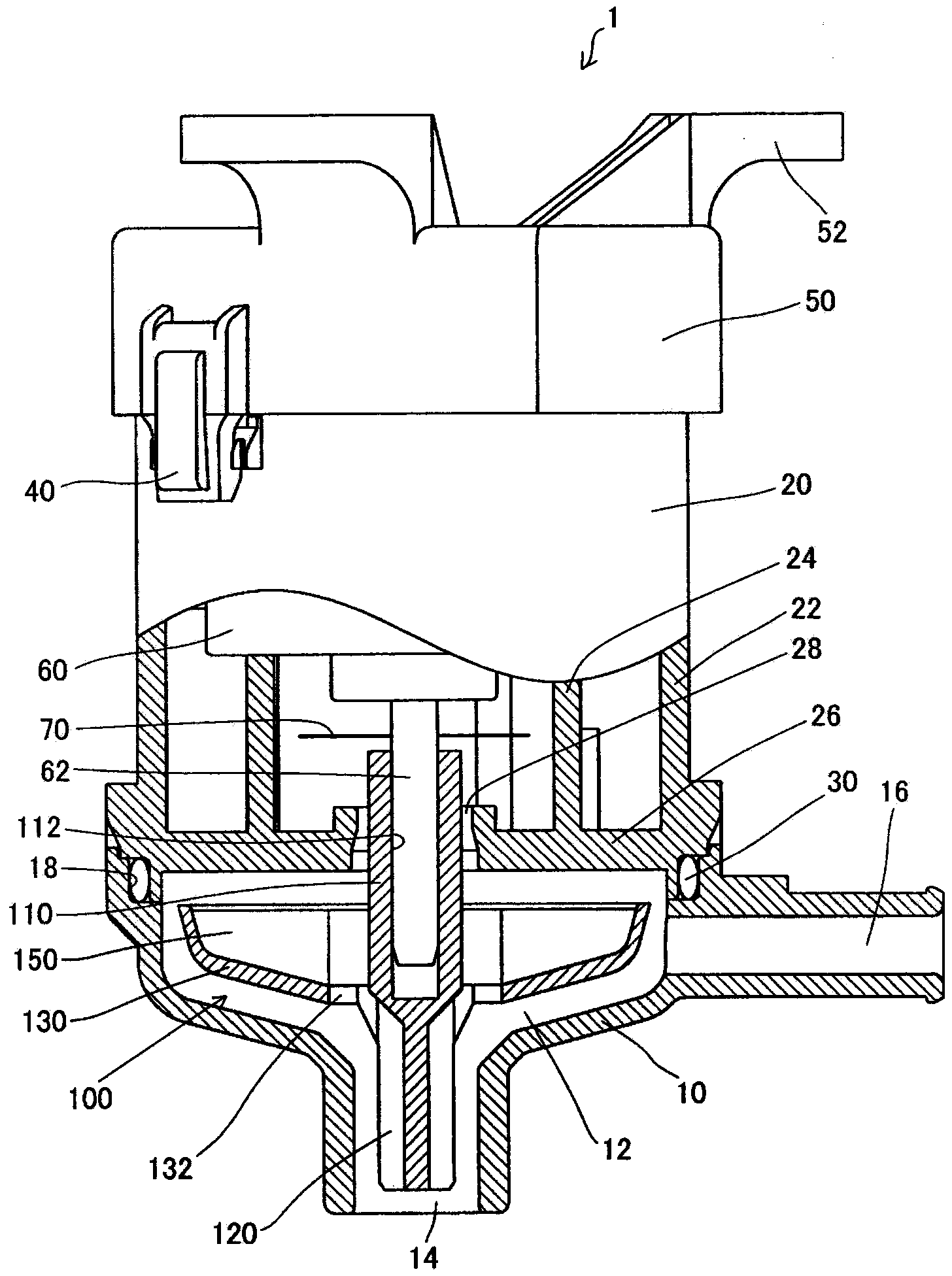

[0036] figure 1 A drain pump according to one embodiment of the present invention is shown.

[0037] The drain pump 1 has a resin casing 10 , and the casing 10 has a suction port 14 and a discharge port 16 communicating with a pump chamber 12 . The cover portion 26 of the cover body 20 is fitted into the housing 10 by a snap-fit mechanism.

[0038] The cover body 20 has an outer cylindrical portion 22 and an inner cylindrical portion 24 , and a bracket 50 is attached to the upper portion of the cover body 20 via a locking portion 40 . The bracket 50 has an attachment portion 52 for attaching the drain pump 1 to other equipment.

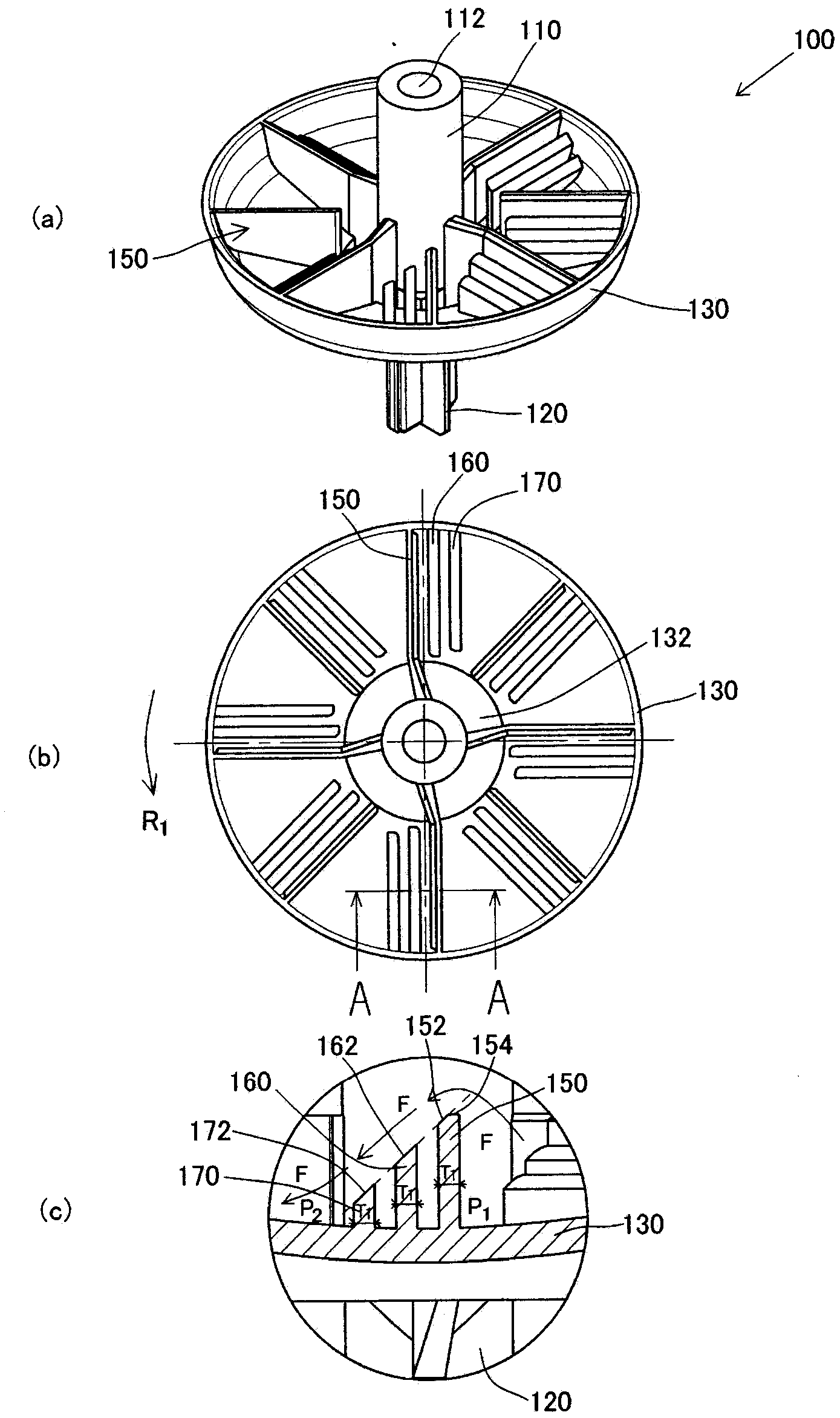

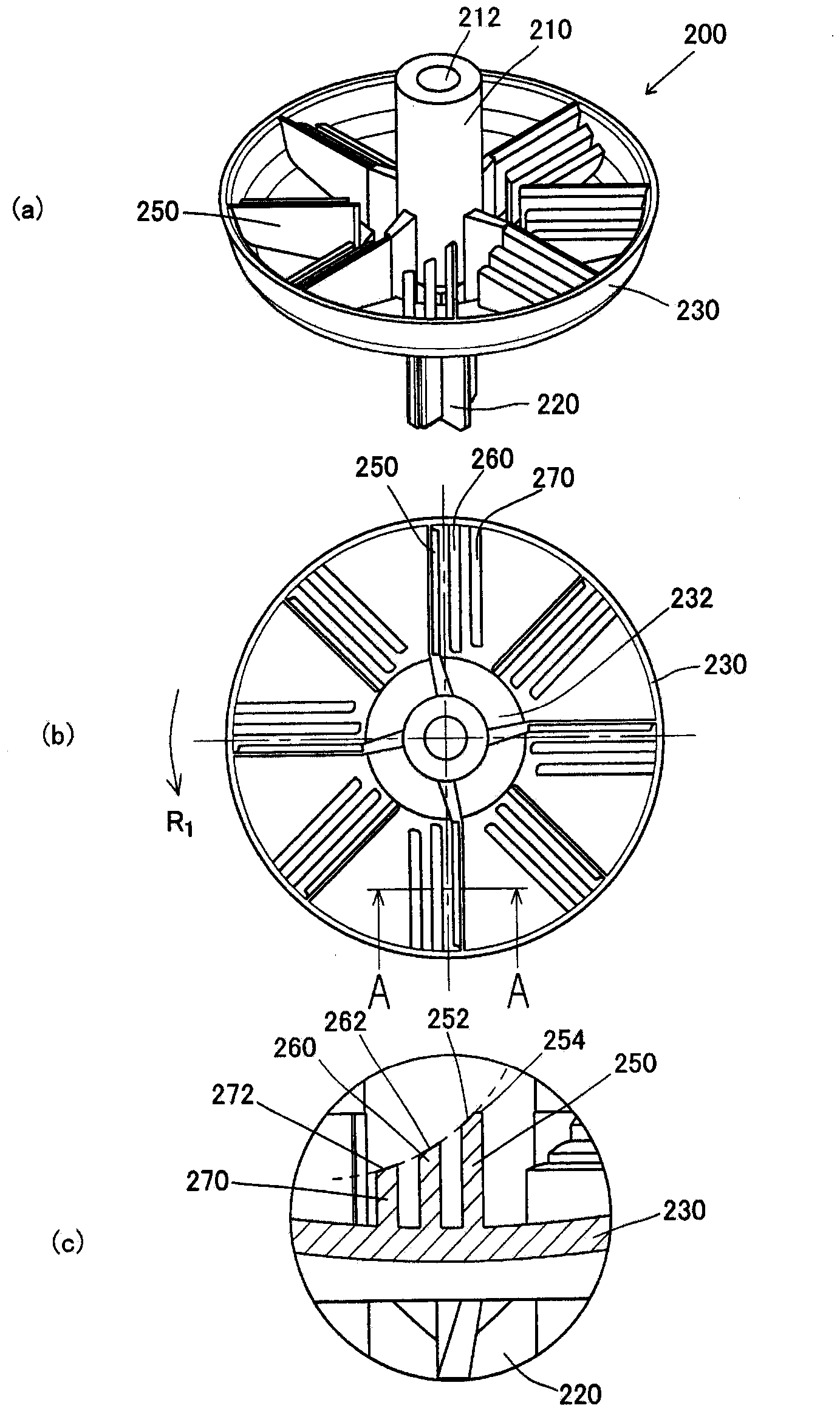

[0039] The inner cylinder portion 24 of the cover 20 supports the motor 60, and the drive shaft 62 of the motor 60 is inserted into the insertion hole 112 of the mounting shaft 110 of the rotary blade 100, thereby supporting the rotary blade 100, which is arranged on Inside the pump chamber 12 of the casing 10 . The mounting shaft 110 of the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com