Method for manufacturing a pad for a touch panel, and pad for a touch panel manufactured by same

A technology for touch panels and manufacturing methods, applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., to achieve the effects of increasing concentration, uniform surface resistance, and eliminating bad residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings.

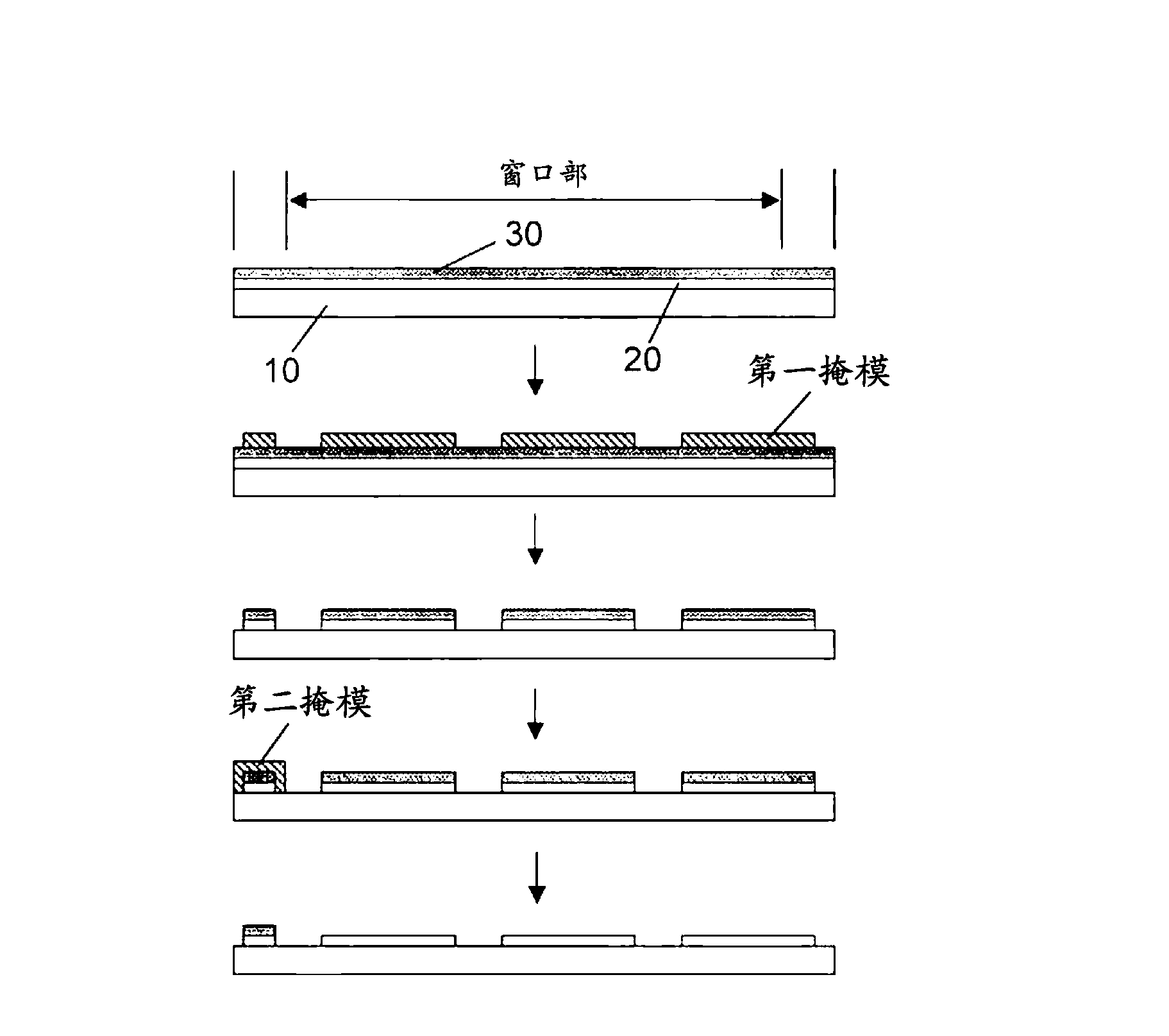

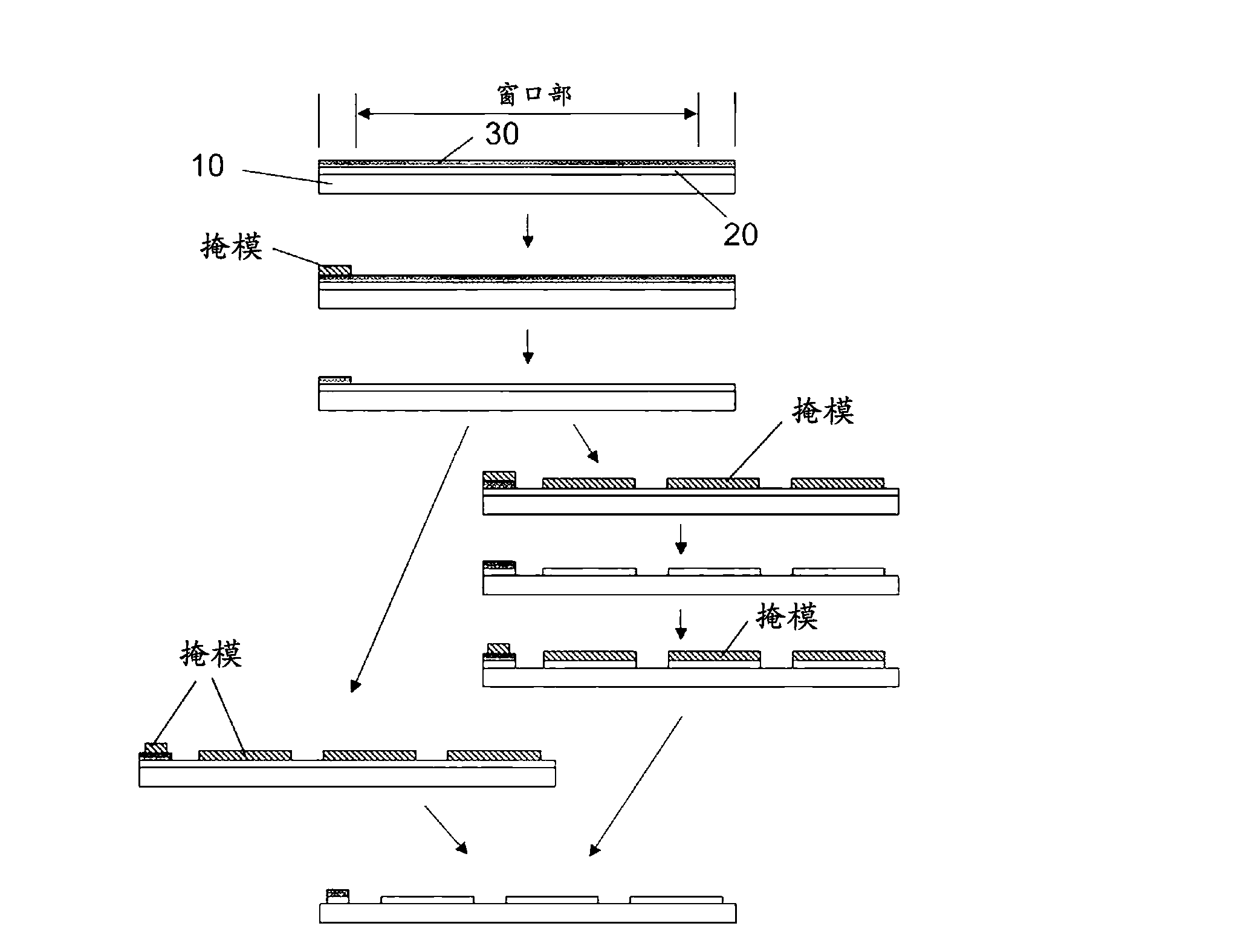

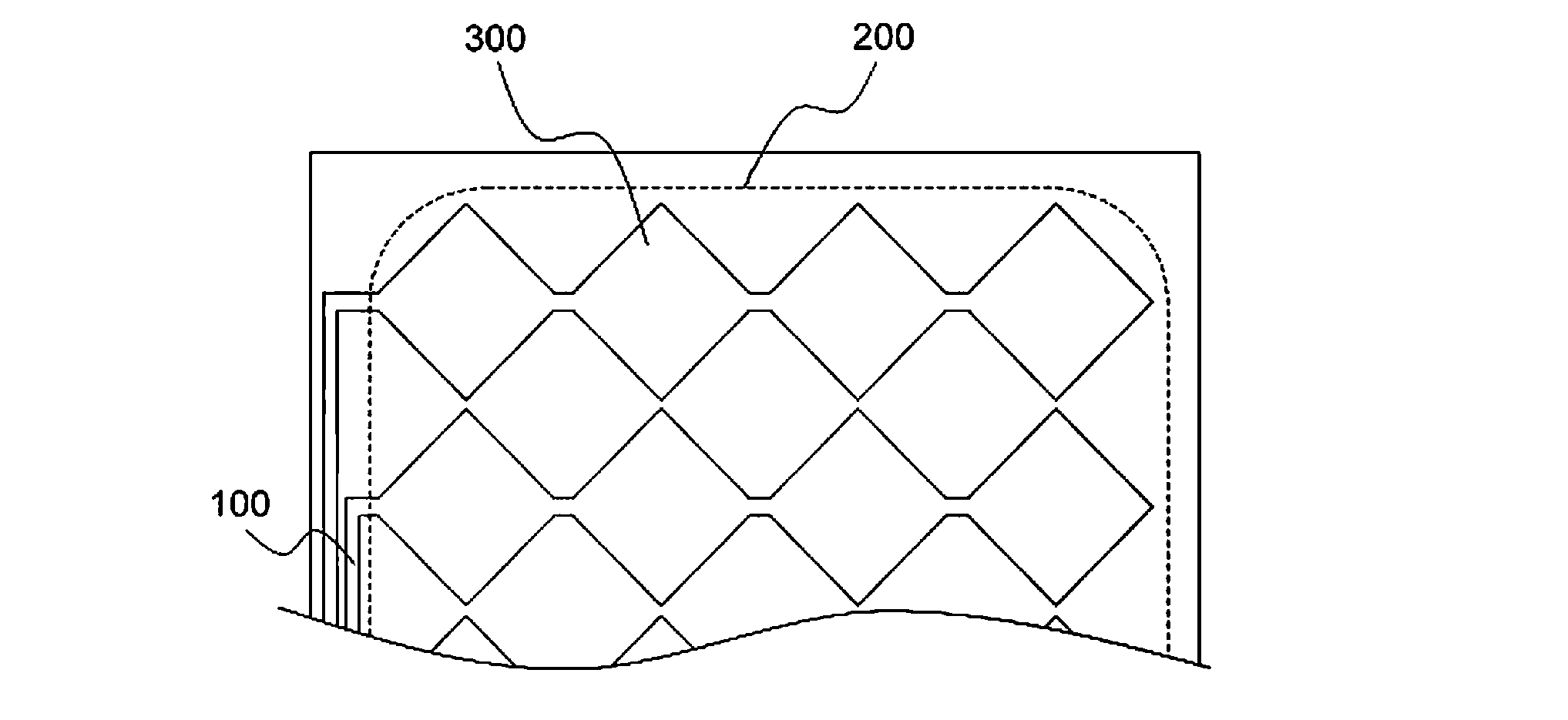

[0021] The present invention relates to a method for manufacturing a sheet for a touch panel, comprising: a step of preparing a sheet for manufacturing a touch panel, the sheet for manufacturing a touch panel including a light-transmitting insulator layer 10 made of an organic insulator or an inorganic insulator; 10, the light-transmitting conductive material coating 20 formed on the upper surface, and the metal coating 30 formed on the upper surface of the light-transmitting conductive material coating 20; the step of etching the metal coating 30, so that the touch In the metal coating 30 of the sheet for panel manufacturing, the metal coating 30 of the corresponding portion 100 of the lead is retained, and at least the metal coating 30 of the corresponding portion 200 of the window is etched; and etching is carried out on the sheet for manufacturing the touch panel af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com