Extraction device and method for extracting resin molded article

A technology of resin forming and taking out device, applied in the field of preventing taking out, can solve problems such as uneven temperature change, bad influence on product quality, etc., and achieve the effect of good adhesion and damage prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

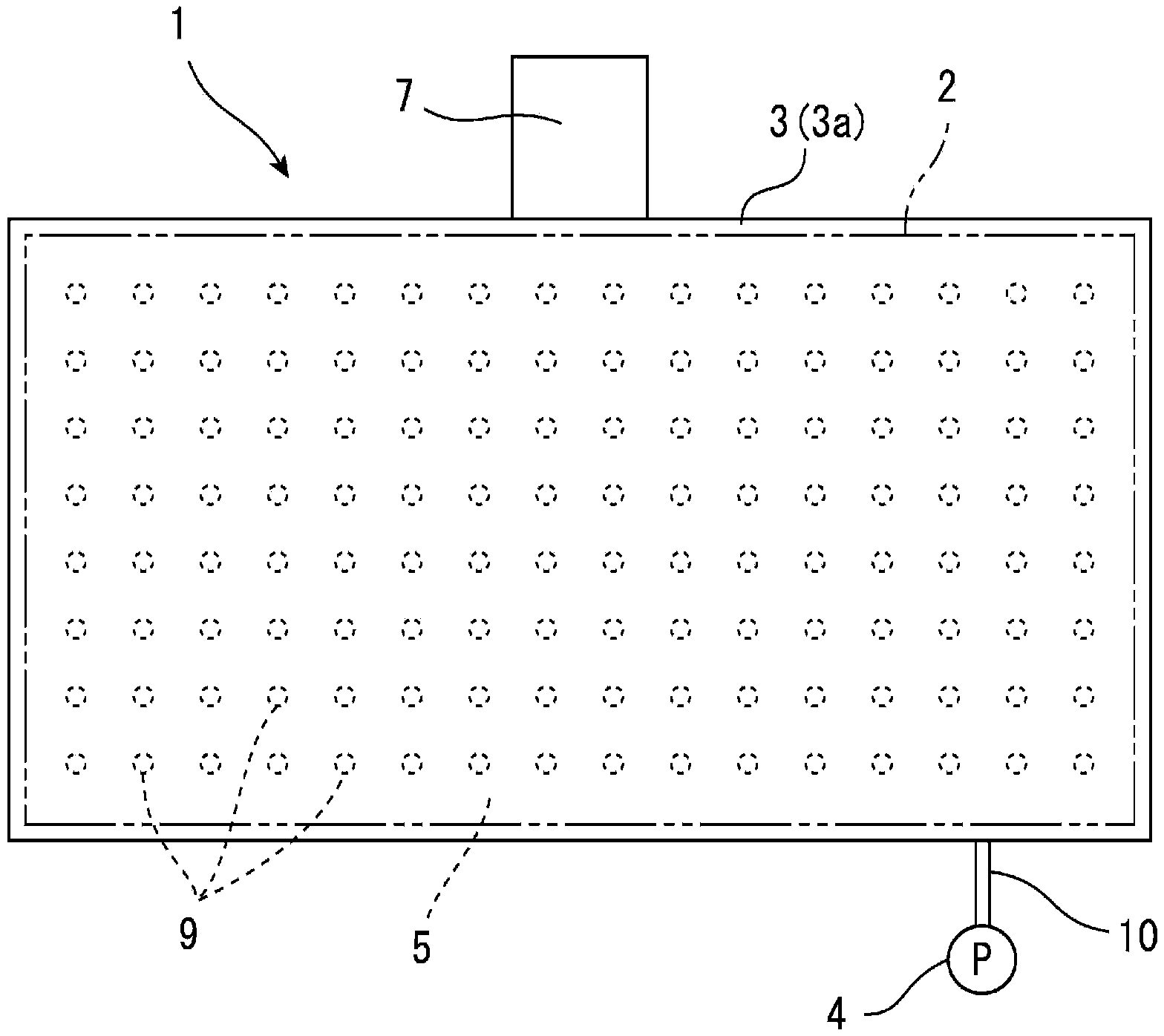

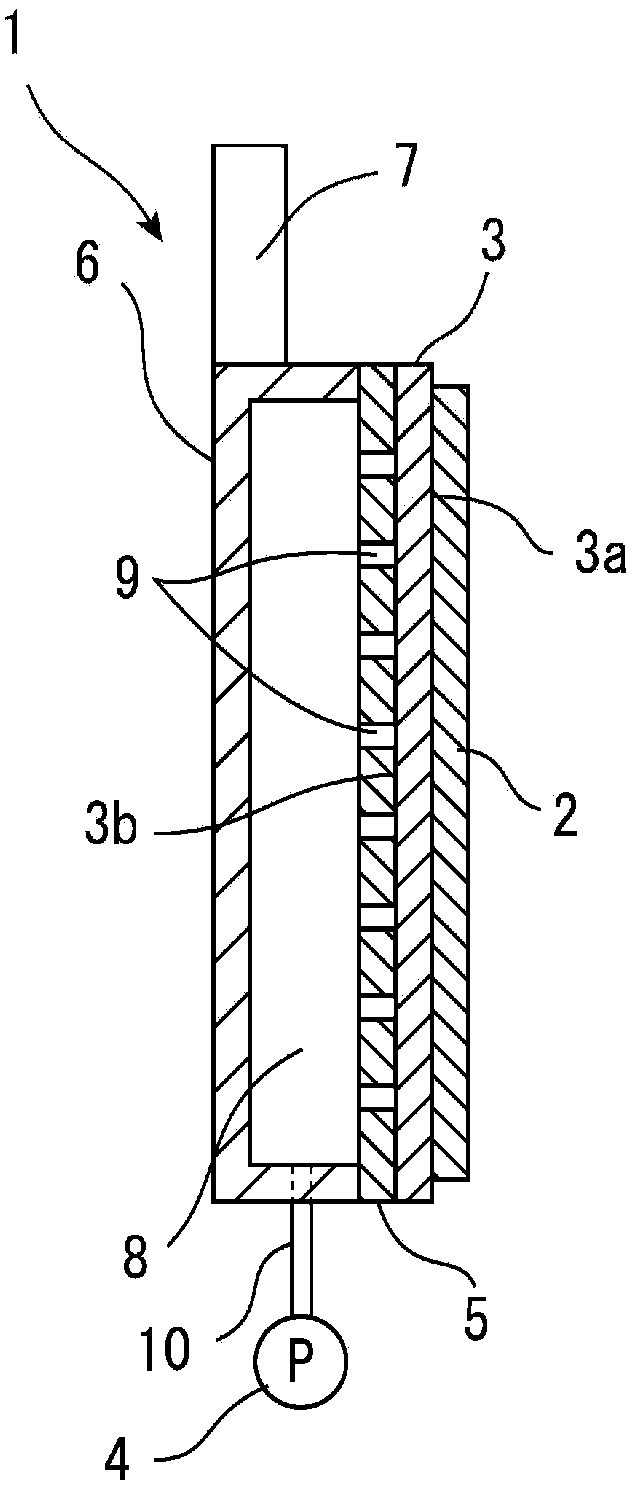

[0037] figure 1 and figure 2 The take-out device 1 of Example 1 shown is used as a resin molded product that is attached to the mold of the injection molding machine and has a flat plate shape at 60°C to 70°C and has a relatively thin wall thickness (about 0.1mm to 0.5mm). Used when the light guide plate 2 is taken out (released from the mold).

[0038] The take-out device 1 includes: an adsorber 3 that adsorbs the entire surface of one side of the flat light guide plate 2; a vacuum pump 4 as a negative pressure generating unit that generates suction when the absorber 3 adsorbs the light guide plate 2; The suction block member 5 holding the suction body 3 ; the base body 6 holding the suction block member 5 ; and the arm 7 .

[0039] On one surface, the absorbing body 3 has an absorbing surface 3a capable of abutting against the entire one surface of the light guide plate 2 to absorb it, and the edge of the other surface 3b side on the opposite side is integrally fixed to ...

Embodiment 2

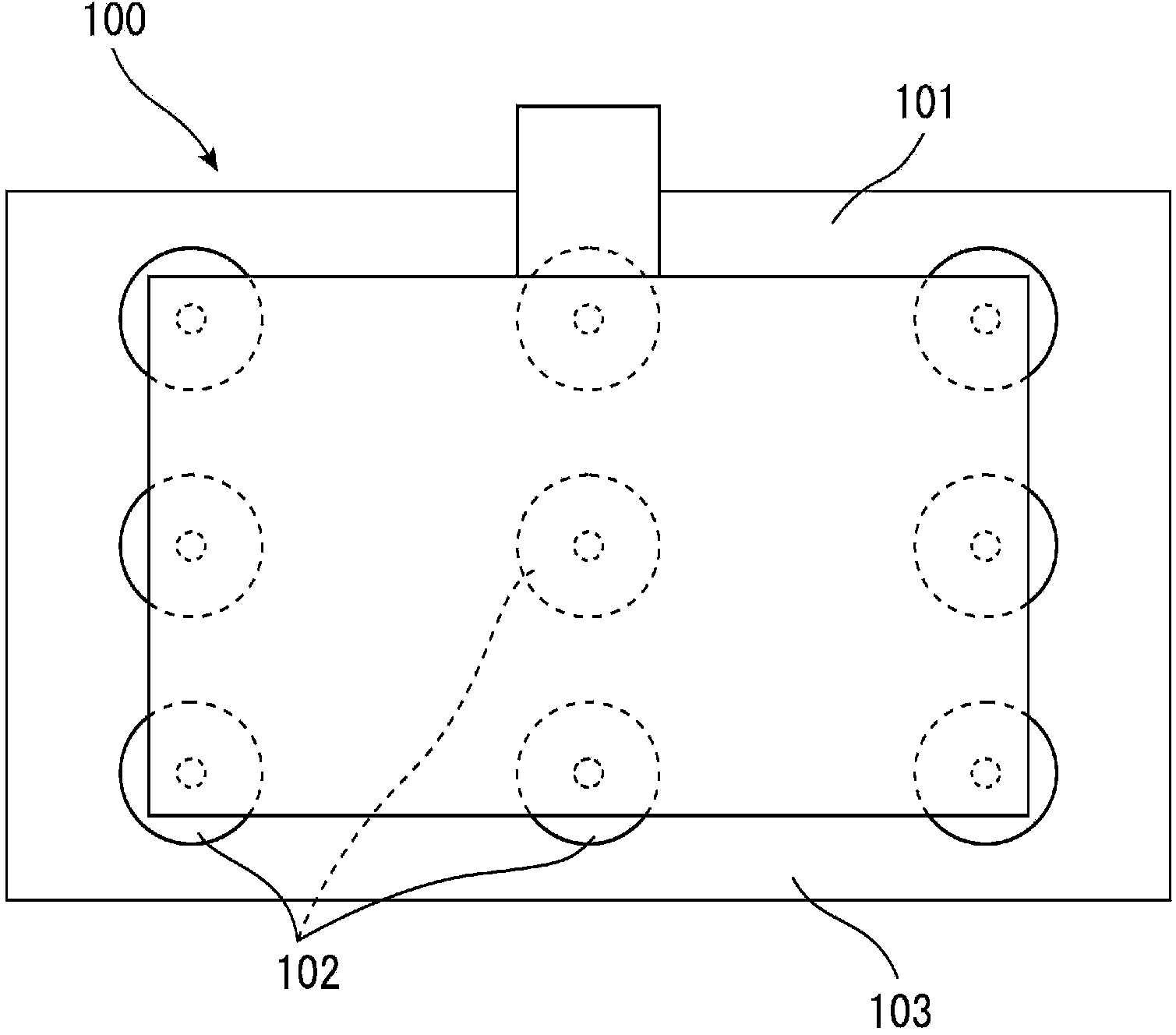

[0047] Figure 5 and Figure 6 The take-out device 51 of Example 2 shown is used as a resin molded product that is attached to the mold of the injection molding machine and has a flat plate shape at 60°C to 70°C and has a relatively thin wall thickness (about 0.1mm to 0.5mm). It is used when the light guide plate 52 is taken out (released from the mold).

[0048] The take-out device 51 is equipped with: an elastic absorber 53 that absorbs one side of the flat light guide plate 52; a vacuum pump 54 that generates suction as a negative pressure generating unit when utilizing the absorber 53 to absorb the light guide plate 52; Body 53 holds base 56; arm 57. It should be noted that the material of the adsorbent 53 is silicone rubber, and the surface thereof is coated with fluorine in a non-vacuum state to form fine unevenness (so-called rough state).

[0049] In the adsorption body 53, one surface has an adsorption surface 53a that is in contact with one side of the light guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com