Tape expansion device

A technology of expansion device and cutting tape, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve problems such as job interruption, cutting tape breakage, and scattered devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

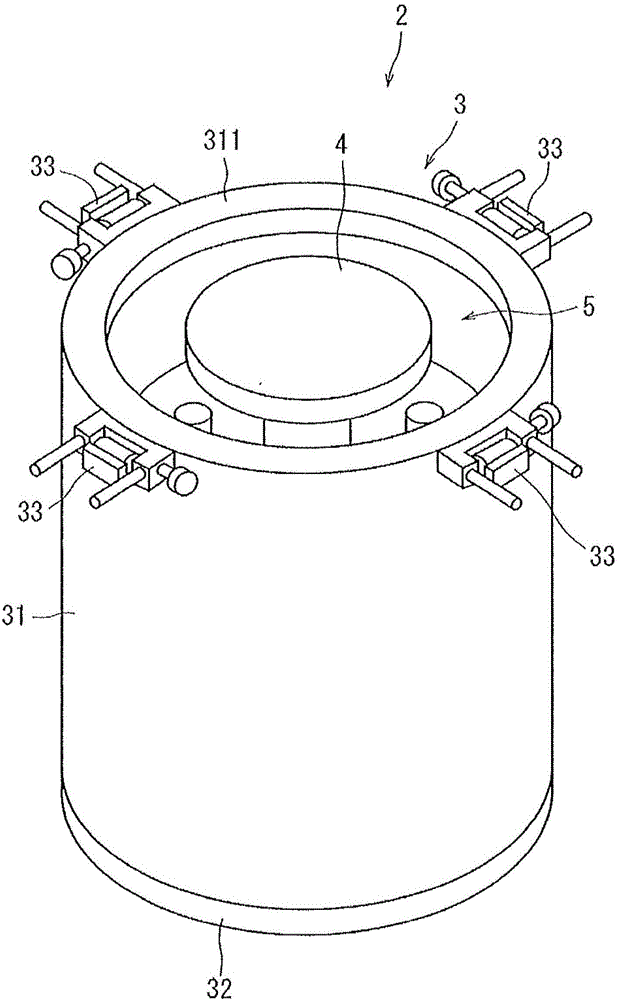

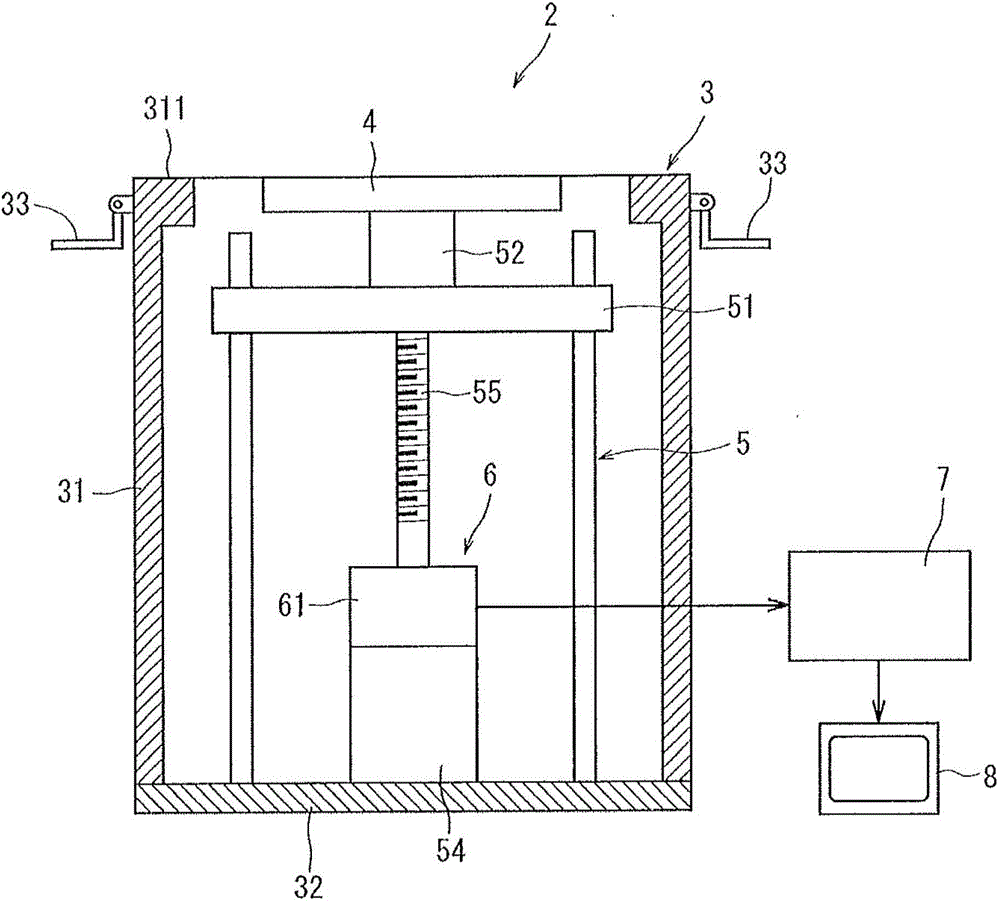

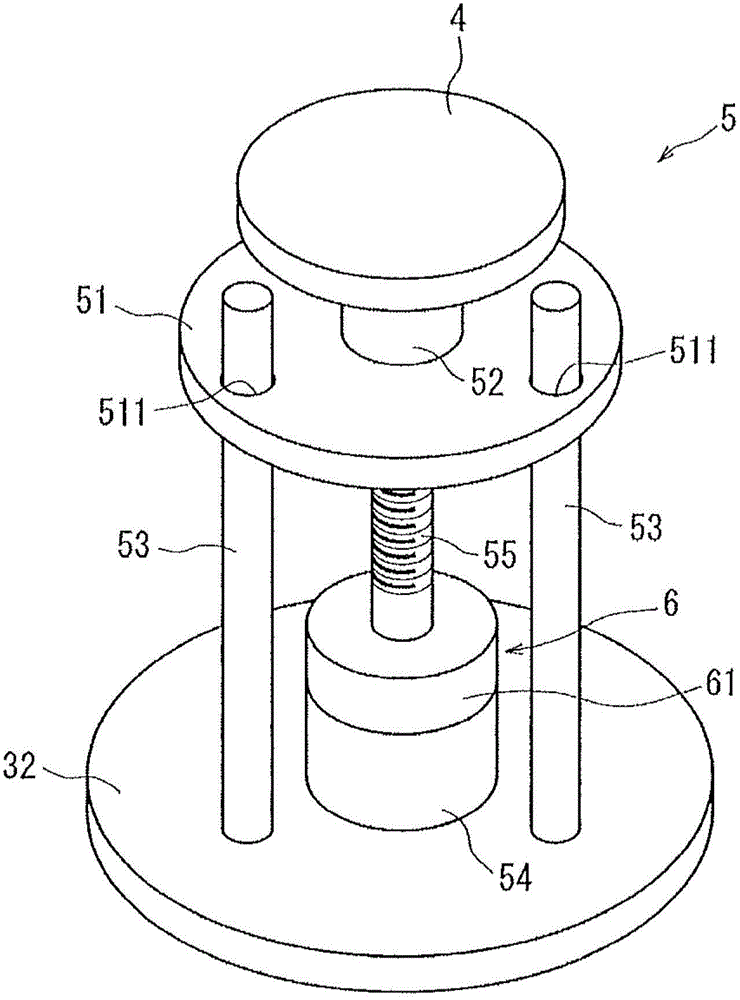

[0027] Hereinafter, preferred embodiments of the band expansion device according to the present invention will be described in detail with reference to the accompanying drawings.

[0028] Image 6 A wafer 10 attached to an upper surface of a dicing tape T made of a synthetic resin film mounted on a ring frame F is shown. In this wafer 10 , a plurality of lines to divide 101 are formed in a grid pattern on a surface 10 a , and devices 102 are formed in a plurality of regions divided by the lines to divide 101 . Positioning the converging point of the pulsed laser light with a wavelength that is transparent to the wafer 10 inside the wafer 10, and irradiating the laser light to the wafer 10 along the planned dividing line 101, the inside of the wafer along the planned dividing line 101. The modified layer 103, which is the starting point of breakage, is continuously formed on the wire. In addition, the modified layer 103 can be formed by the laser processing method disclosed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com