Moving belt type conveying loading and unloading machine

A technology for conveyors and loading and unloading machines, which is applied in the direction of conveyors, conveyor objects, loading/unloading, etc., and can solve the problems of multiple loading and unloading, which cannot meet the needs of economical and fast loading and unloading, convenience and safety, and difficulty in personnel organization, so as to avoid secondary Loading and unloading and handling, moving and transition are convenient and fast, reducing the effect of manual assisted handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

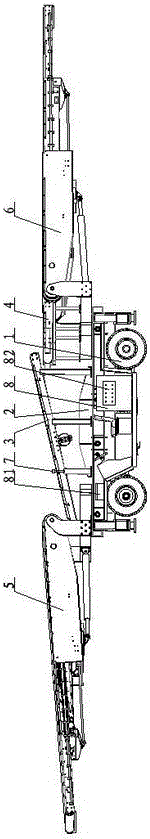

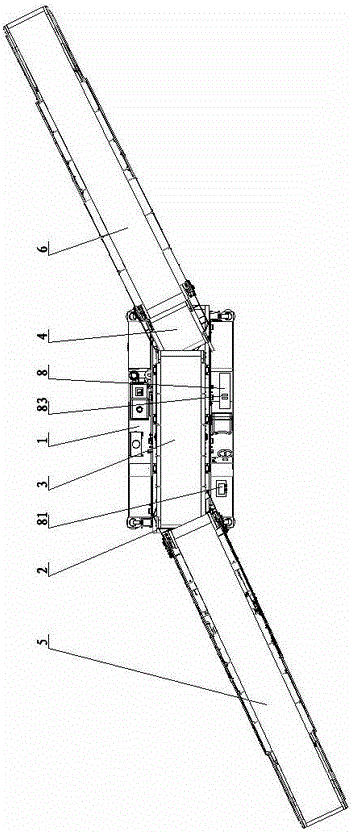

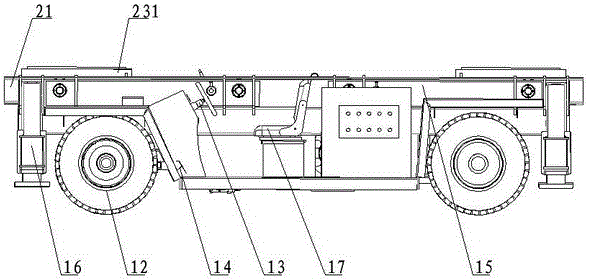

[0045] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 As shown, the present invention includes a load-carrying vehicle 1 with the functions of walking and racking, a skid trolley 2 with a sliding function, an intermediate conveyor 3 and a transition conveyor 4 for intermediate transition transportation, and has telescopic, amplitude and Loading conveyor 5 and unloading conveyor 6 with swing function, metering device 7 with metering, display, storage and printing functions and its manipulation control system 8;

[0046] The sliding trolley 2 is located on the carrying vehicle 1, and is clamped in the sliding track 18 of the vehicle frame 15 of the carrying vehicle 1 through the supporting rollers 19; the two ends of the sliding trolley 2 are symmetrically installed with the feeding conveyor 5 and the unloading conveyor. Conveyor 6, the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com