Patents

Literature

58 results about "Resin dispensing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A resin dispensing system is a technical installation to process casting resin for the purpose of filling, sealing, covering or soaking technical parts, especially in the field of electricity and electronics like transformers, LCDs and other devices of various size.

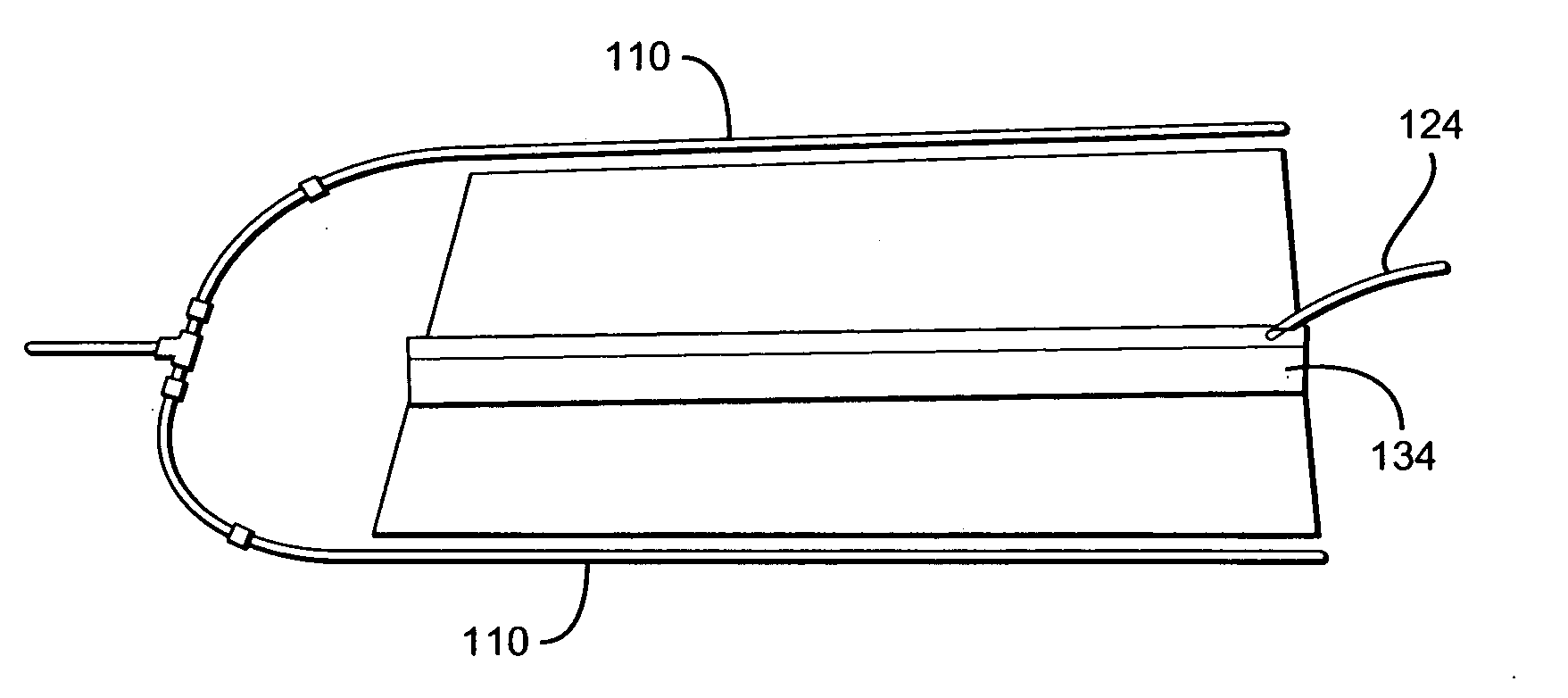

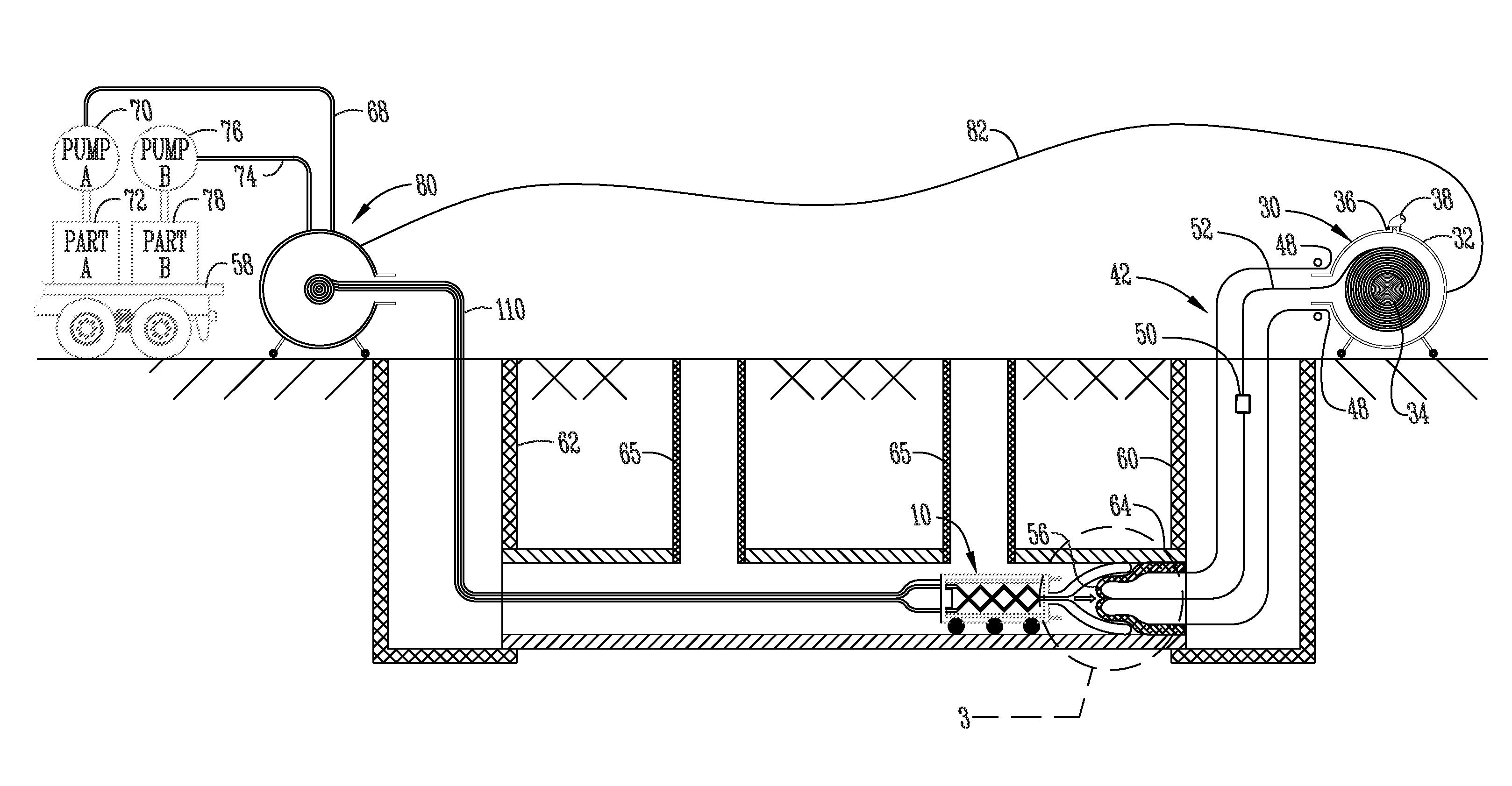

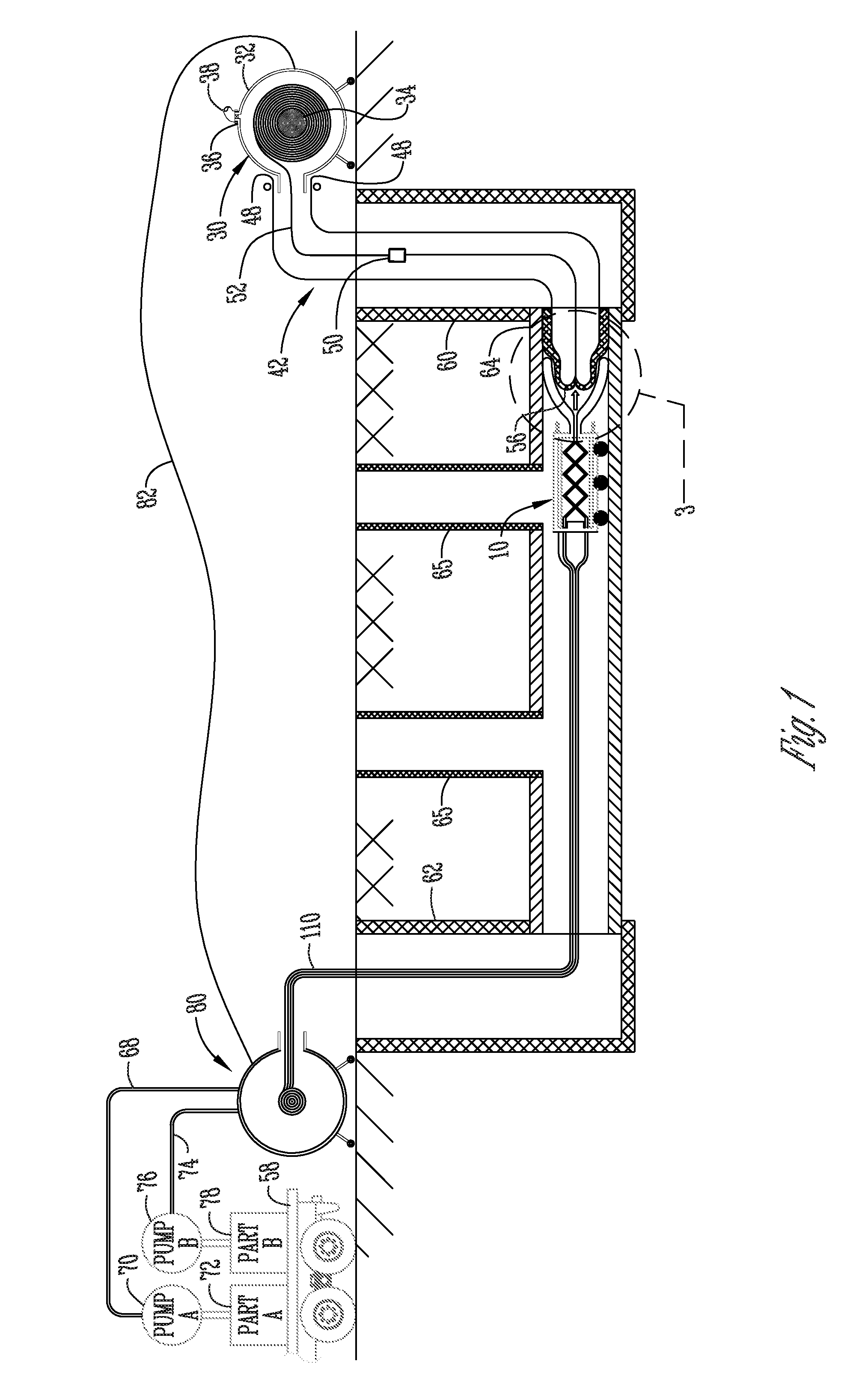

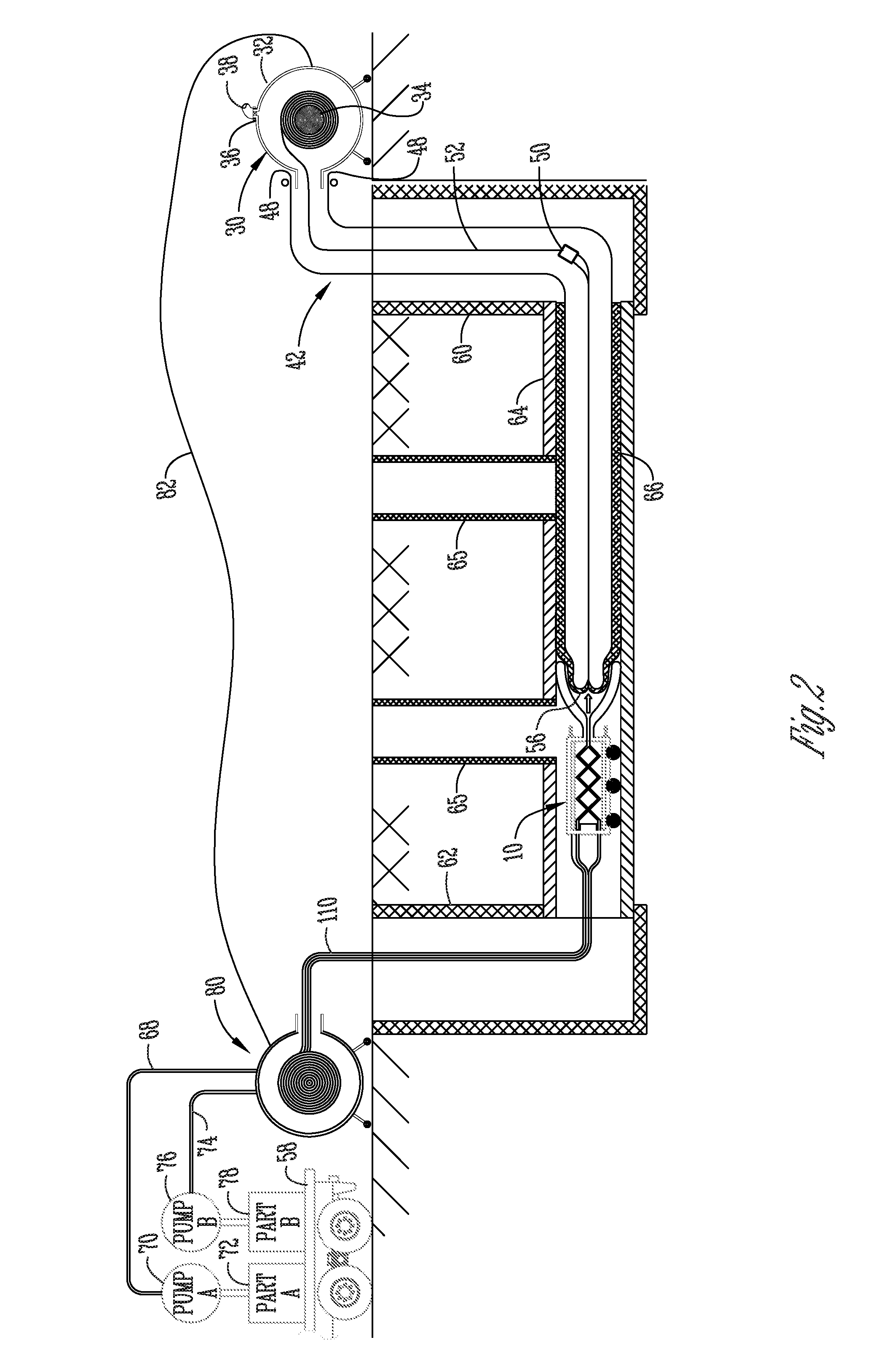

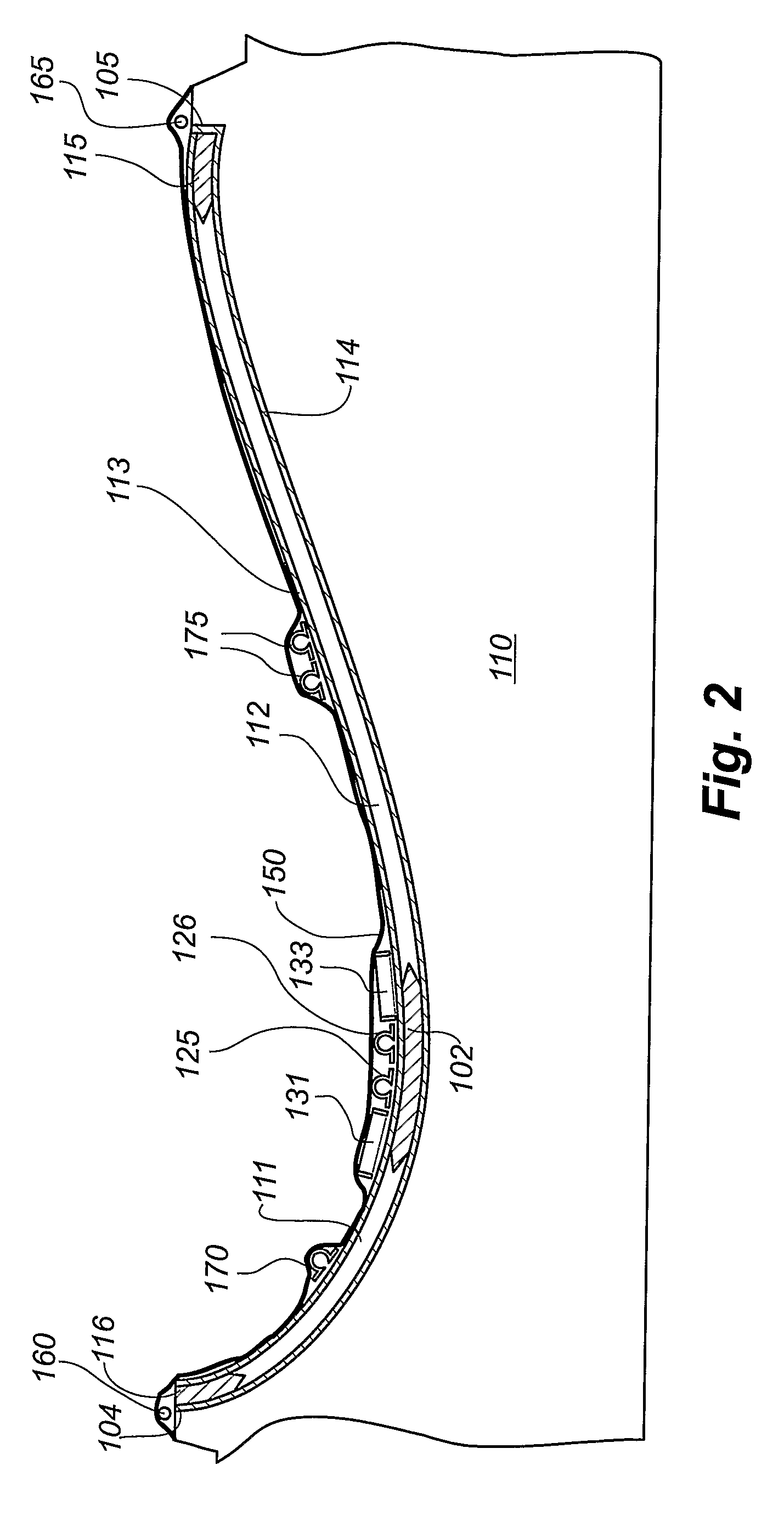

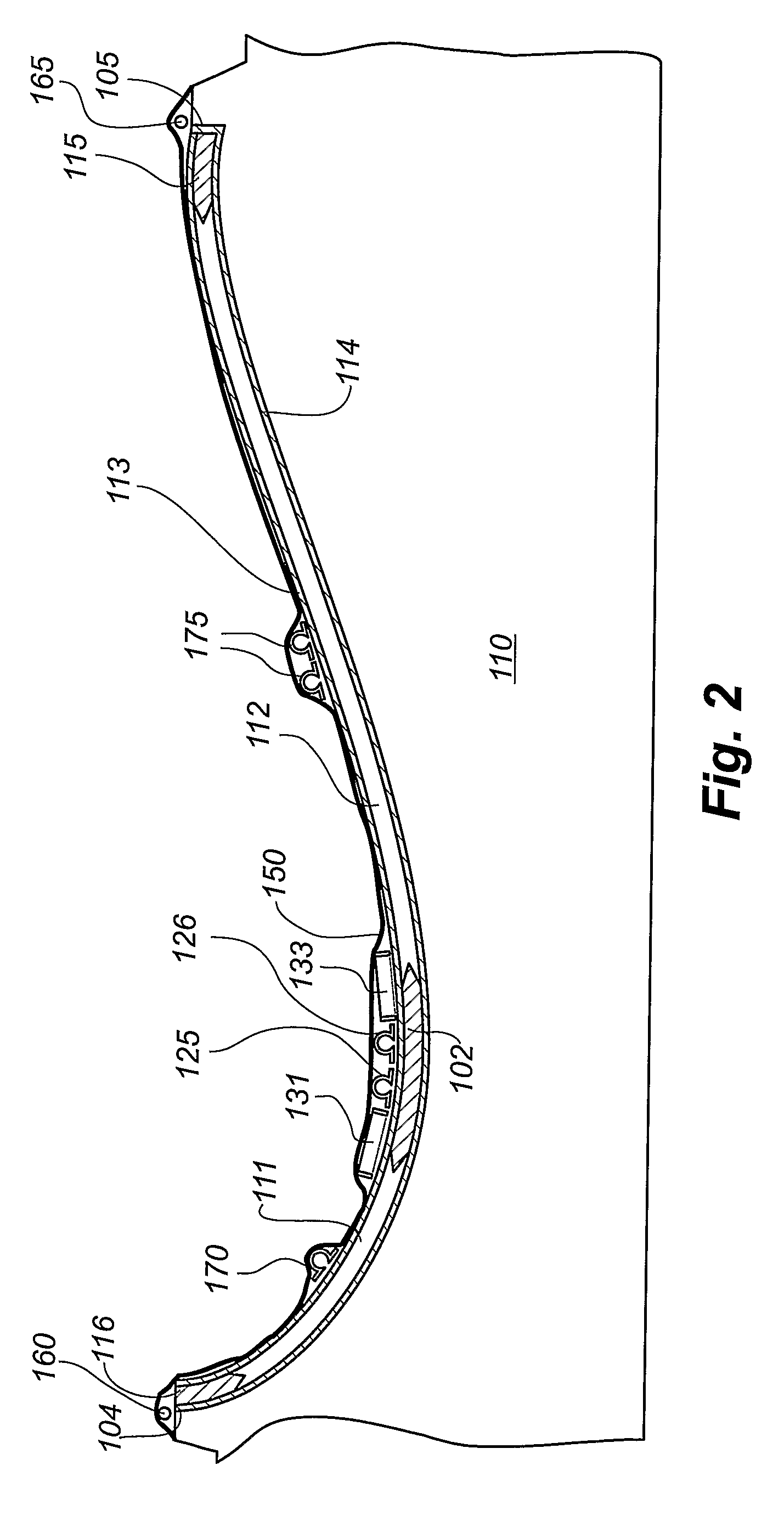

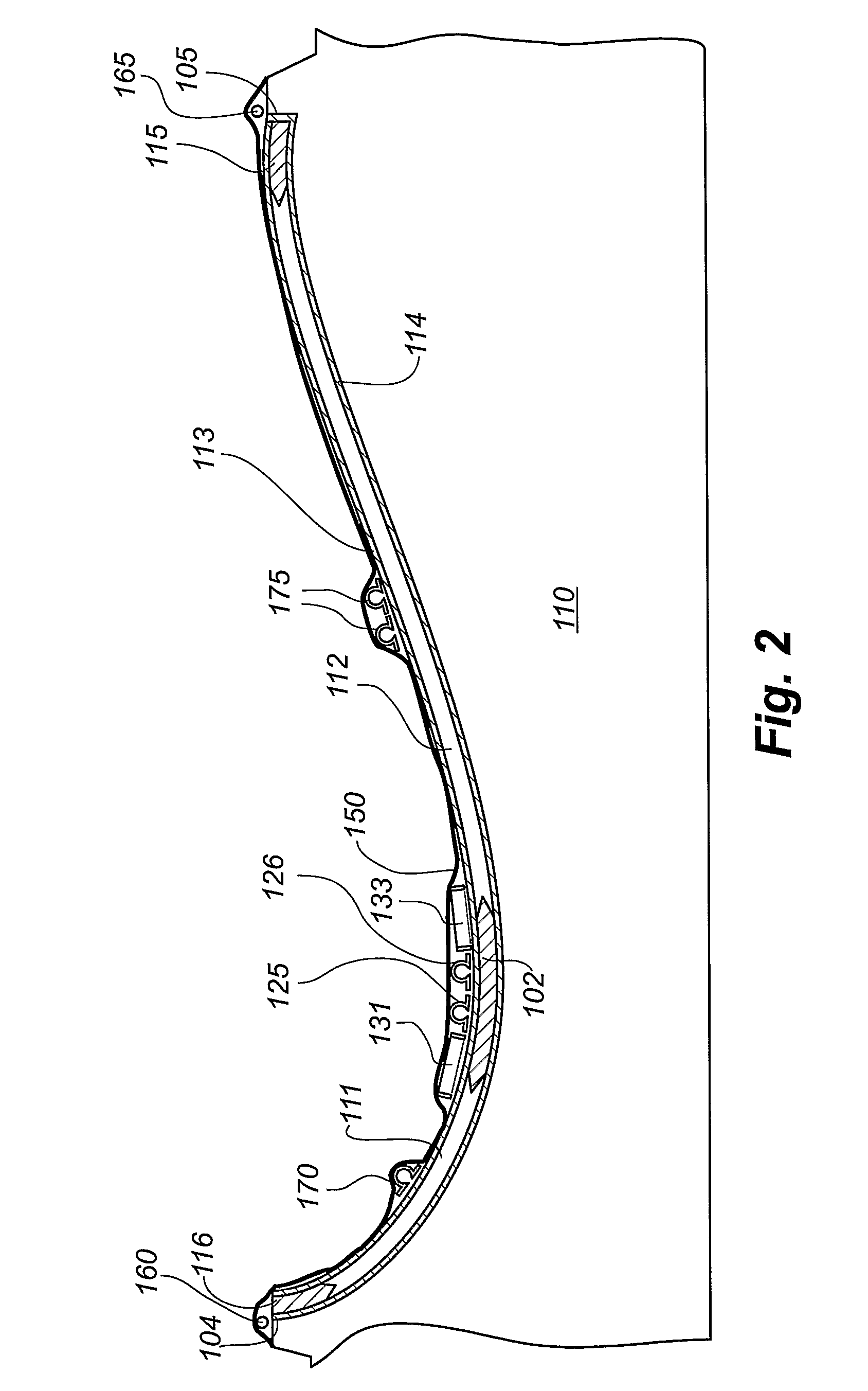

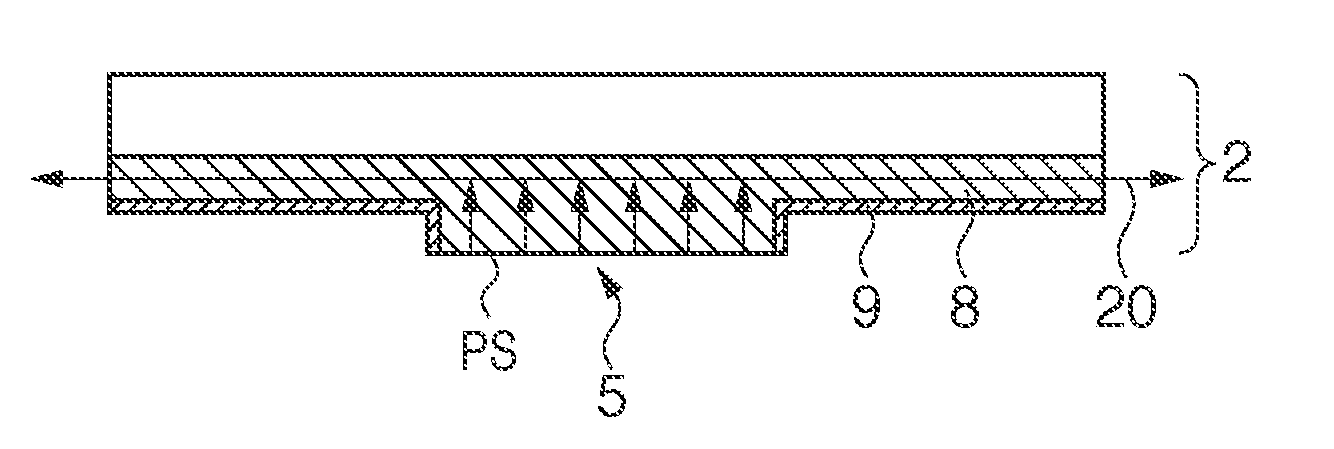

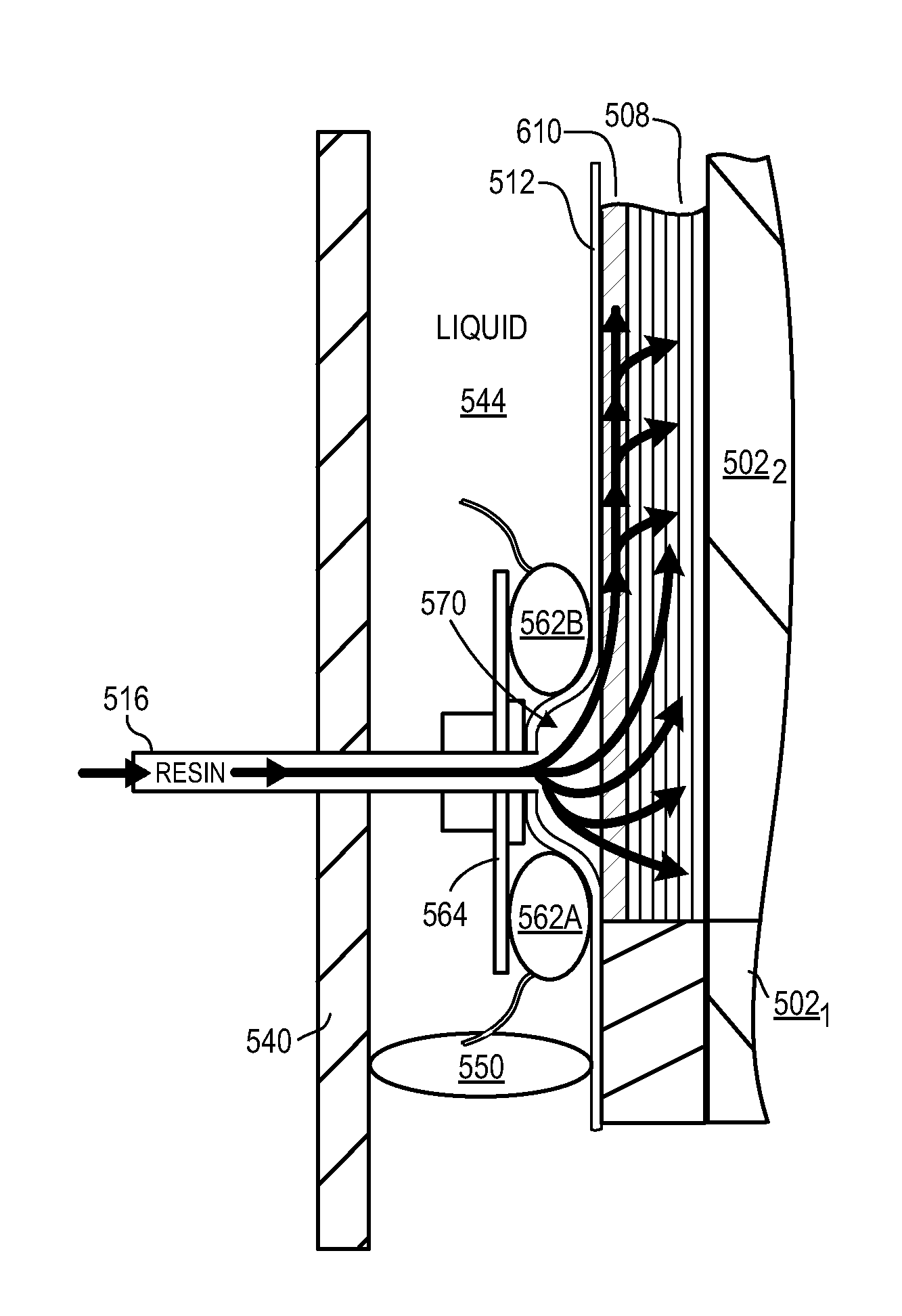

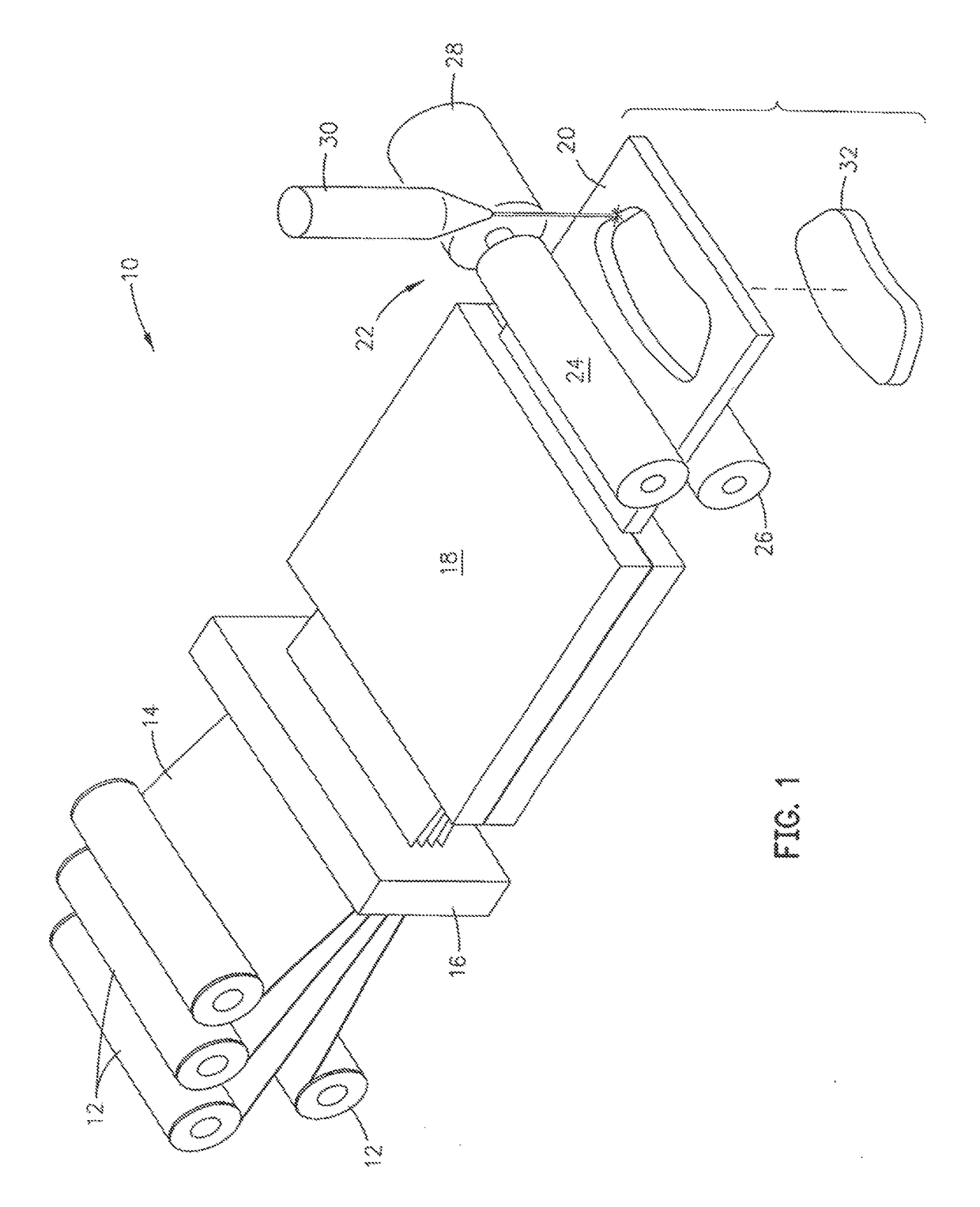

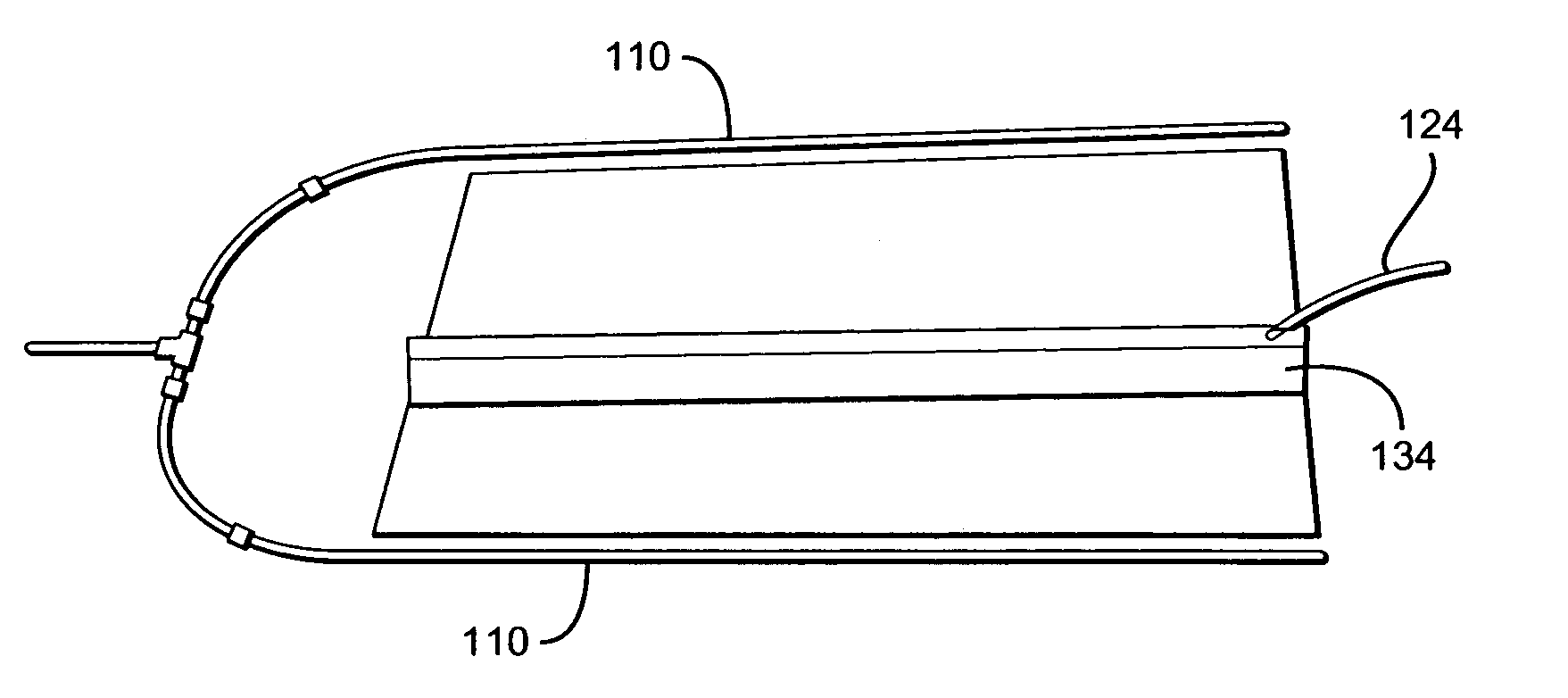

Vacuum-Assisted Resin Transfer Molding Process with Reusable Resin Distribution Line

ActiveUS20110169190A1Reduce deliveryConfectioneryWood working apparatusResin dispensingShell molding

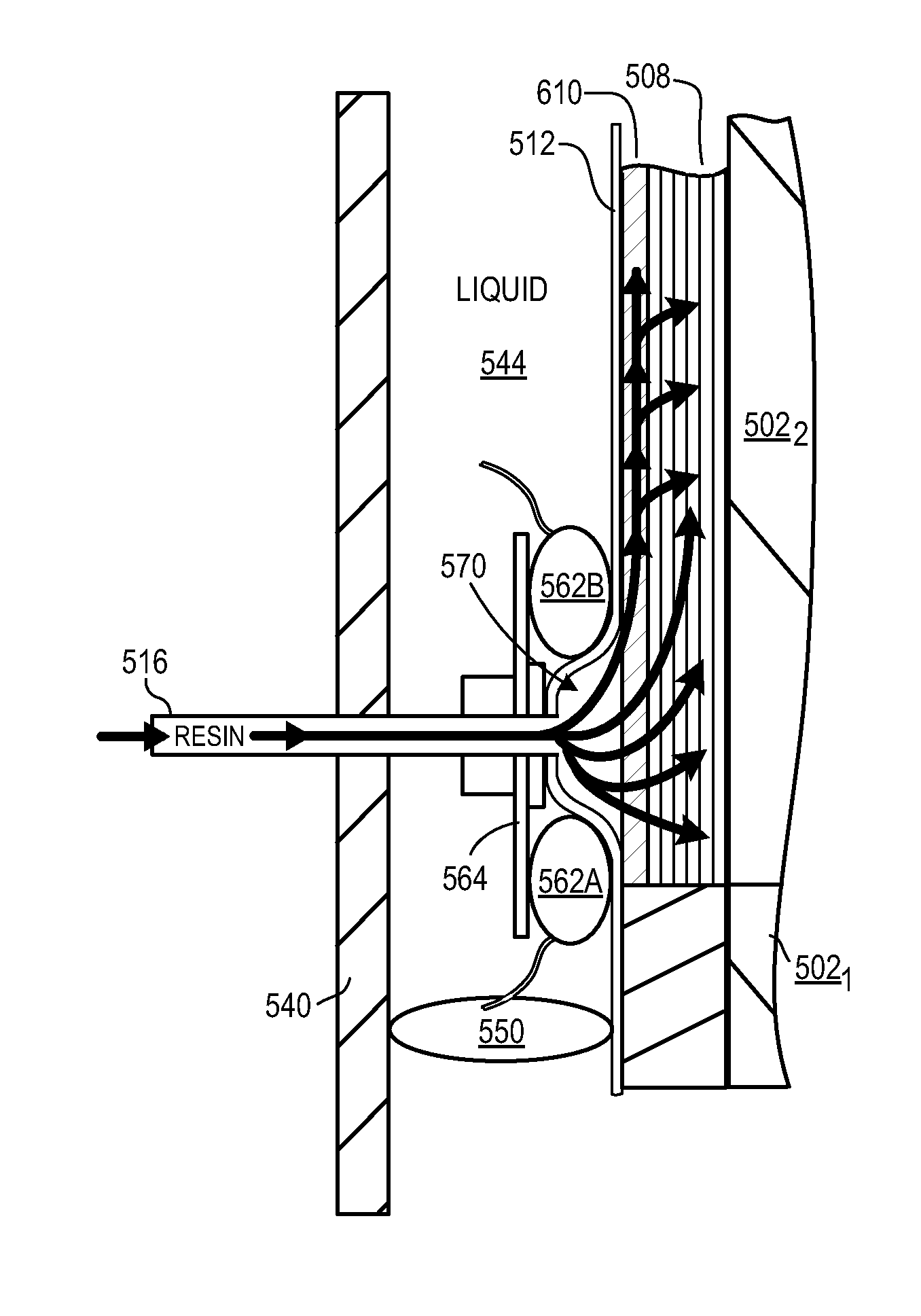

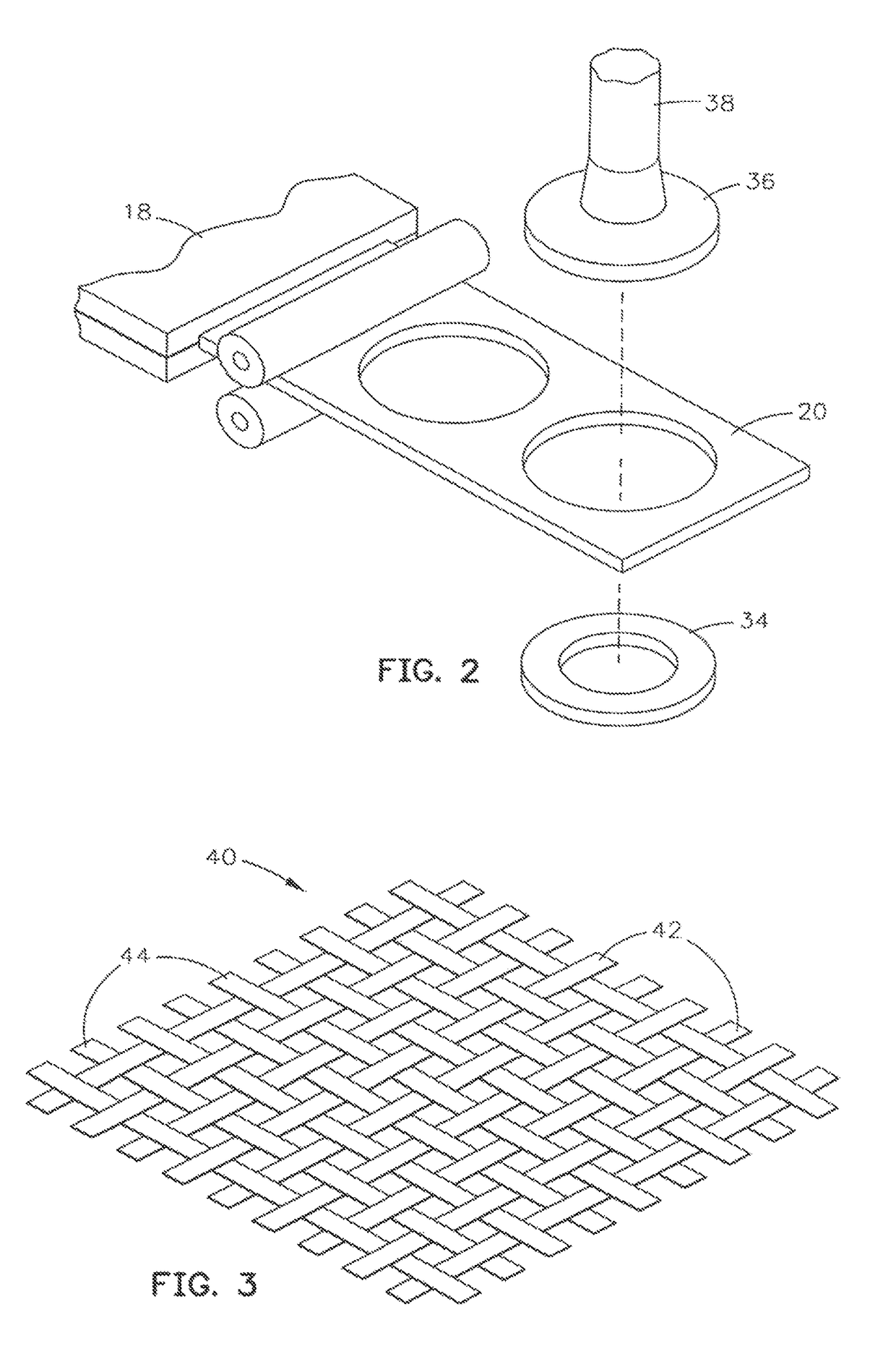

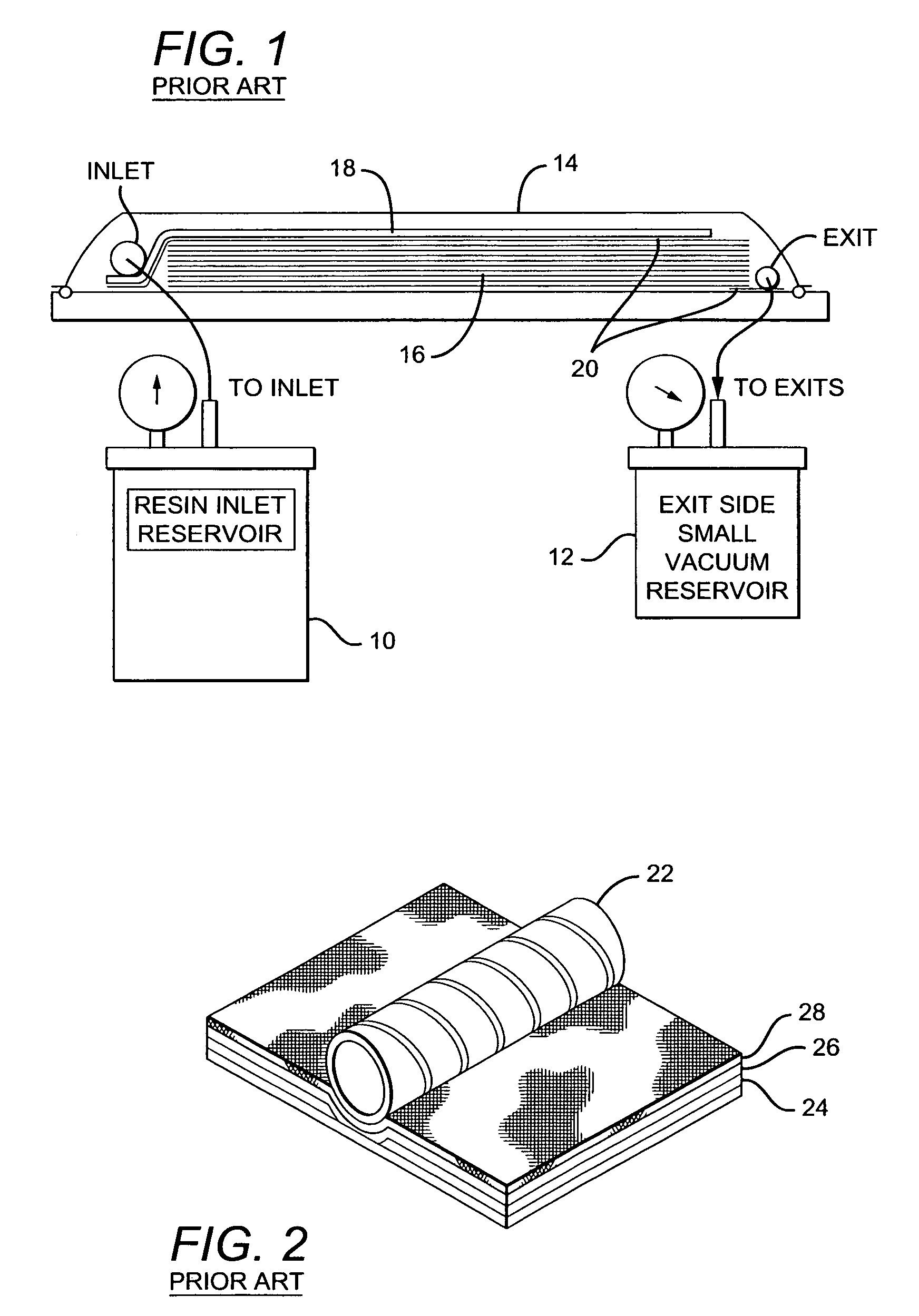

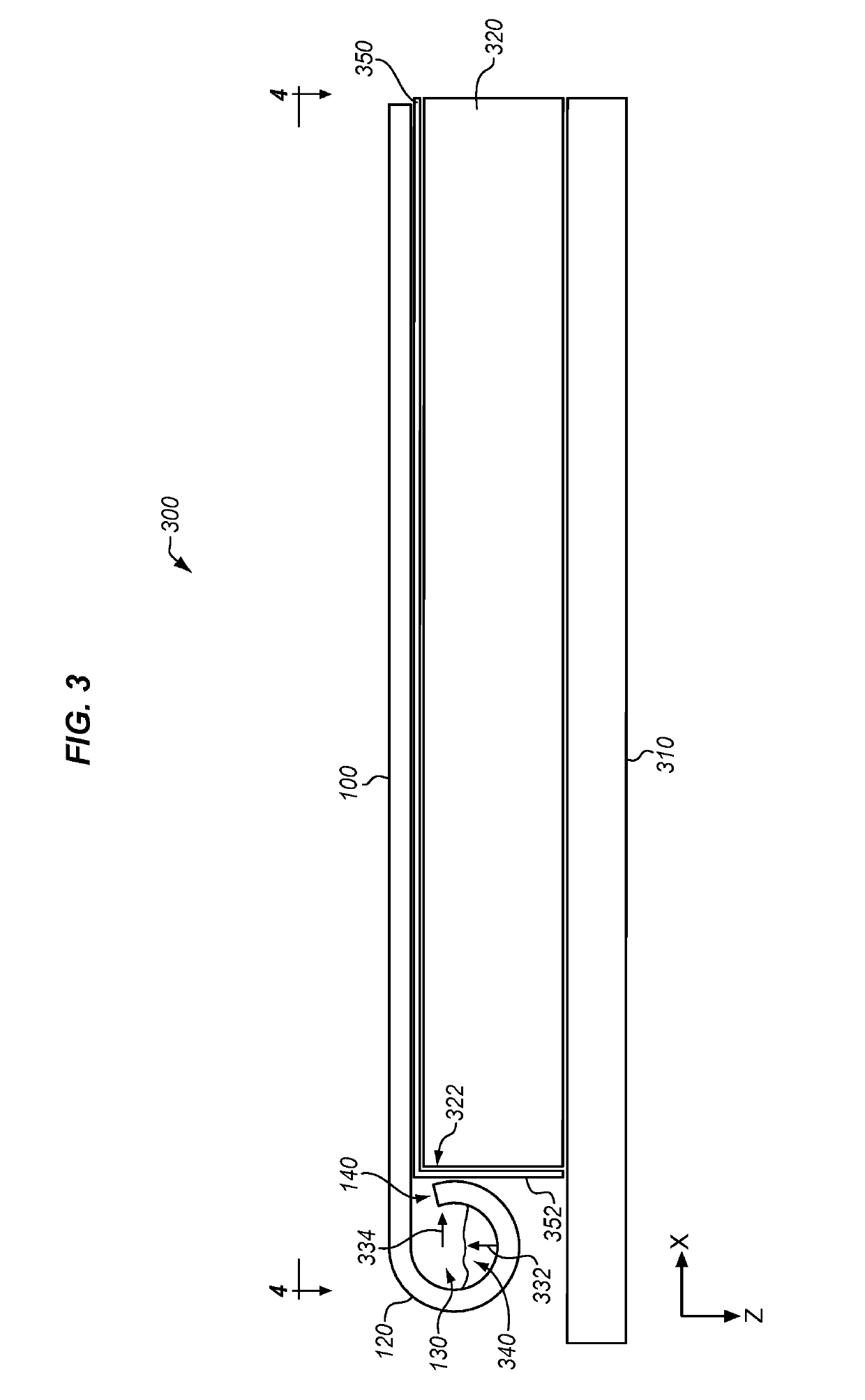

A method and apparatus for a reusable resin distribution line for use in conjunction with a resin transfer molding apparatus is disclosed. The apparatus includes a soft tool and a hard tool (i.e., mold). In the illustrative embodiment, two inflatable bladders are disposed on a side of the soft tool, wherein a bridge spans the bladders. The soft tool is coupled to the bridge. When the bladders are inflated, the bridge moves away from the hard tool, drawing the soft tool away from the hard tool in the region between the bladders. This creates a temporary passage or reusable resin distribution line for distributing resin to a reinforcement constituent disposed between the soft tool and the hard tool.

Owner:LOCKHEED MARTIN CORP

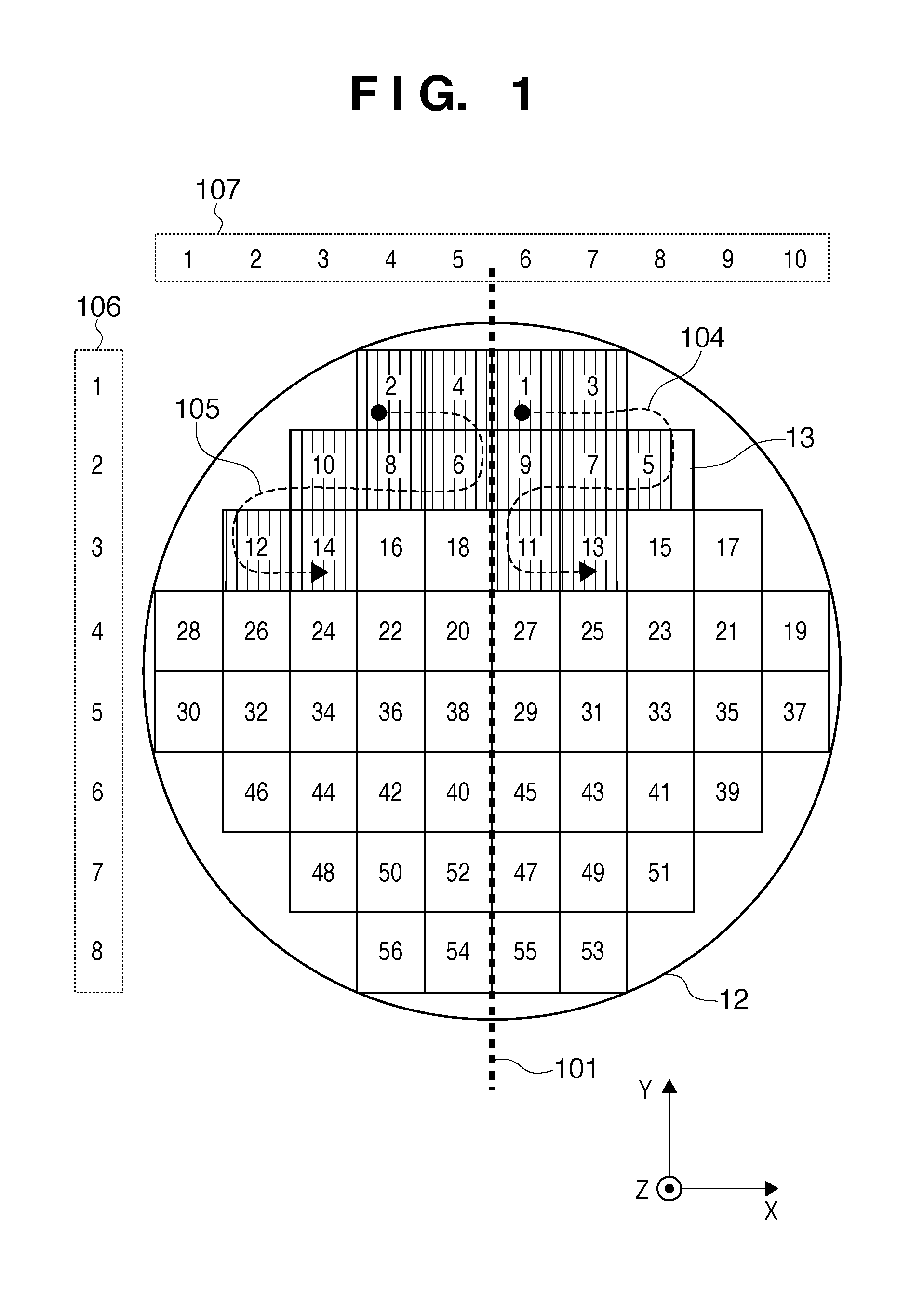

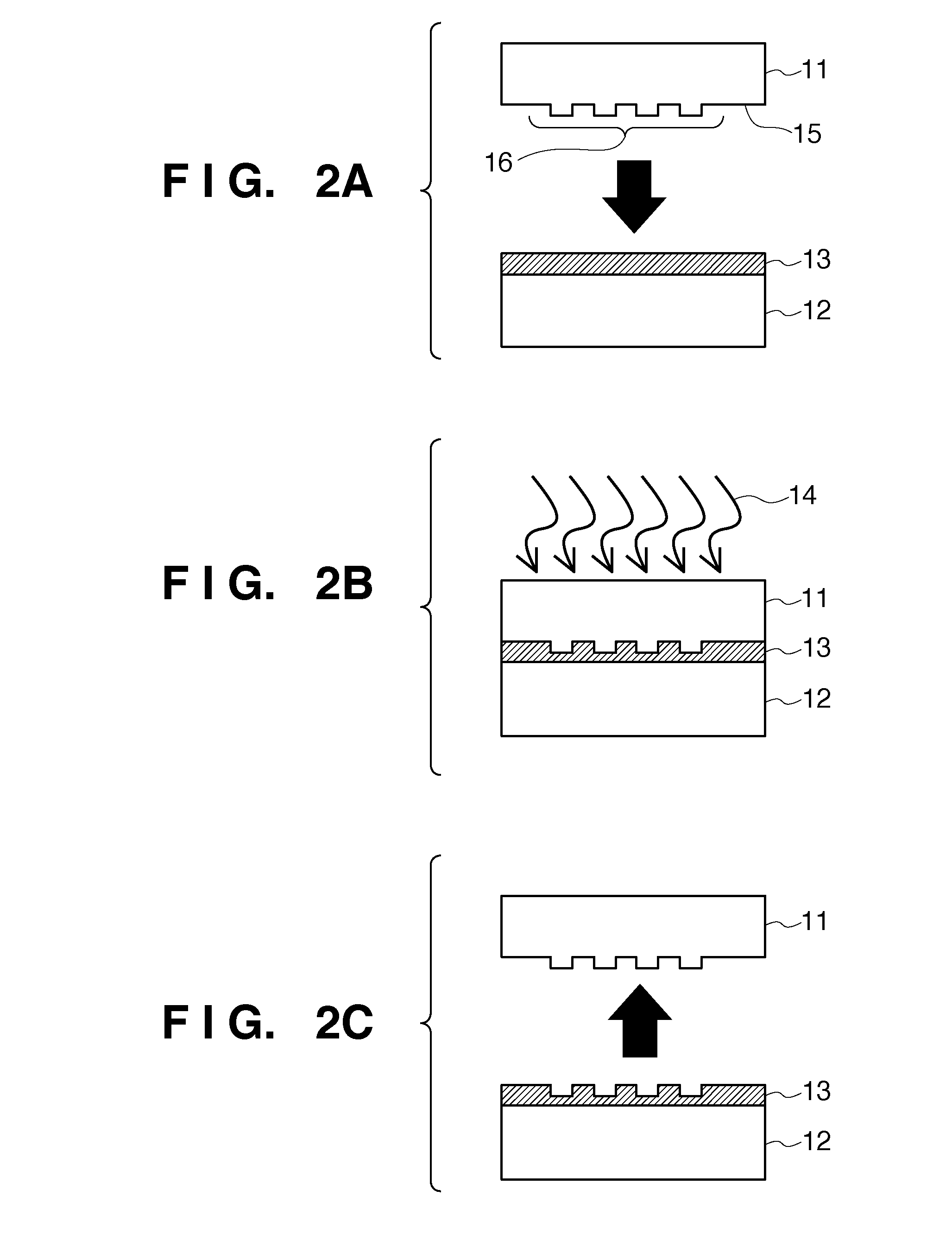

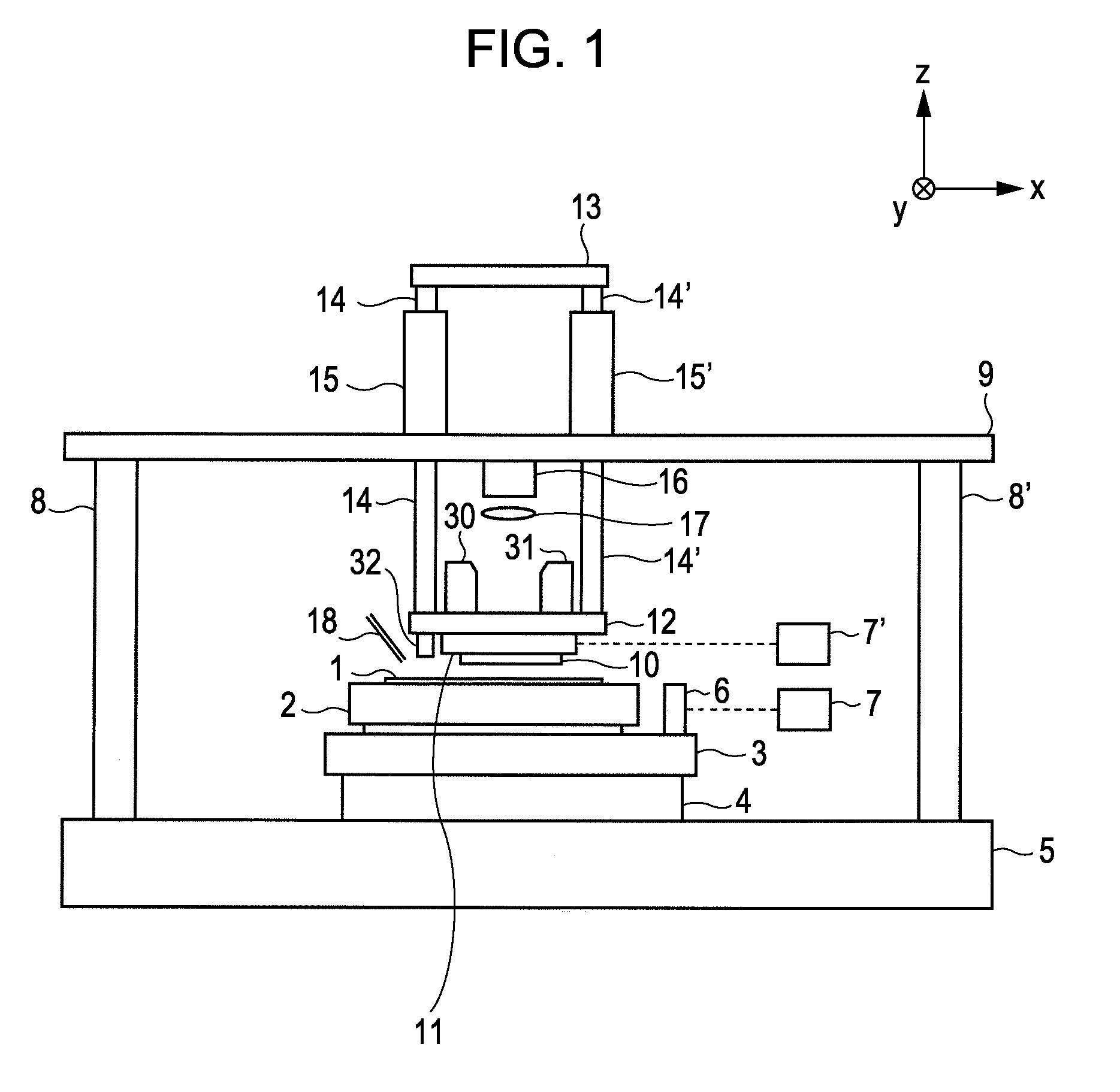

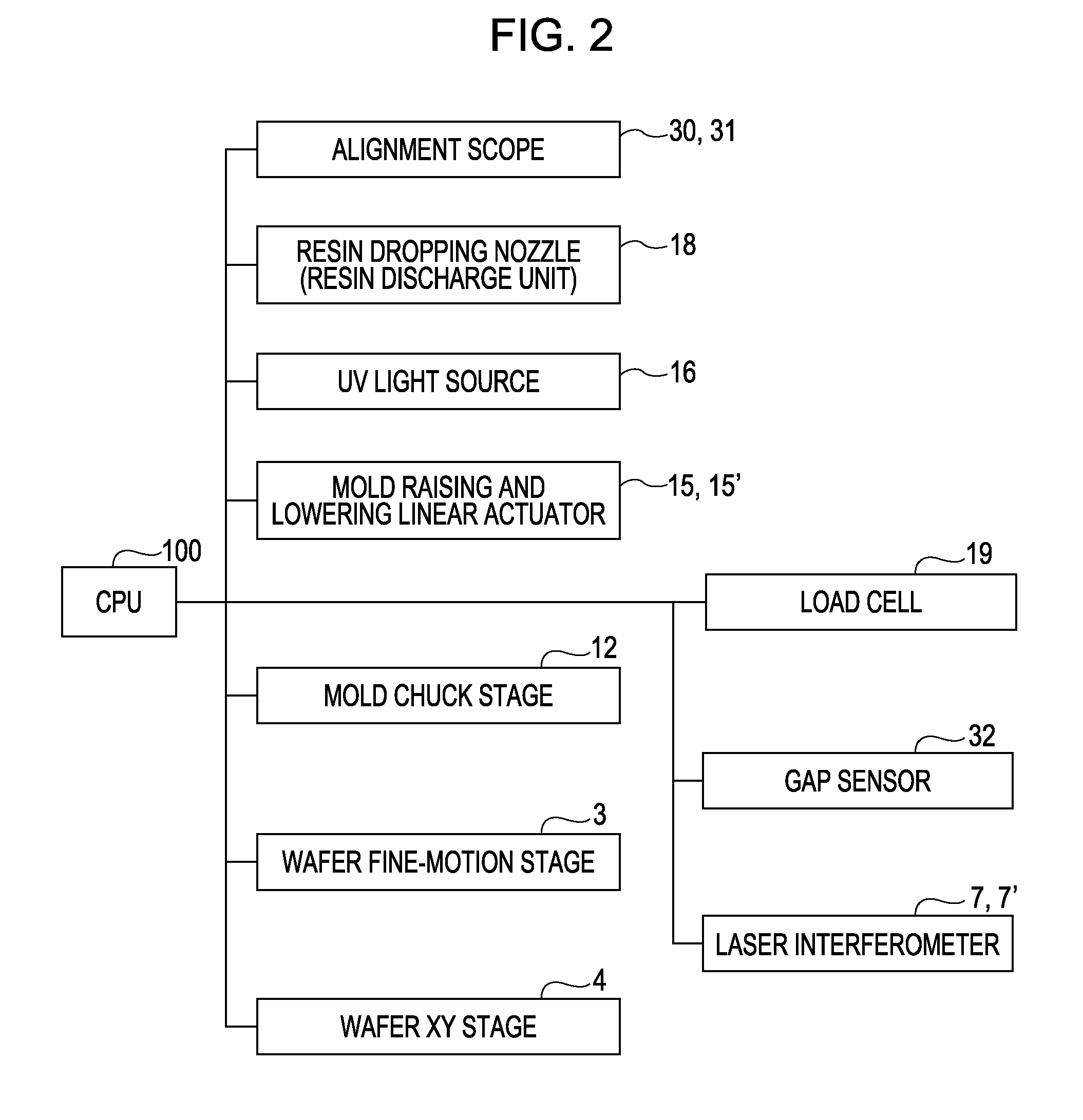

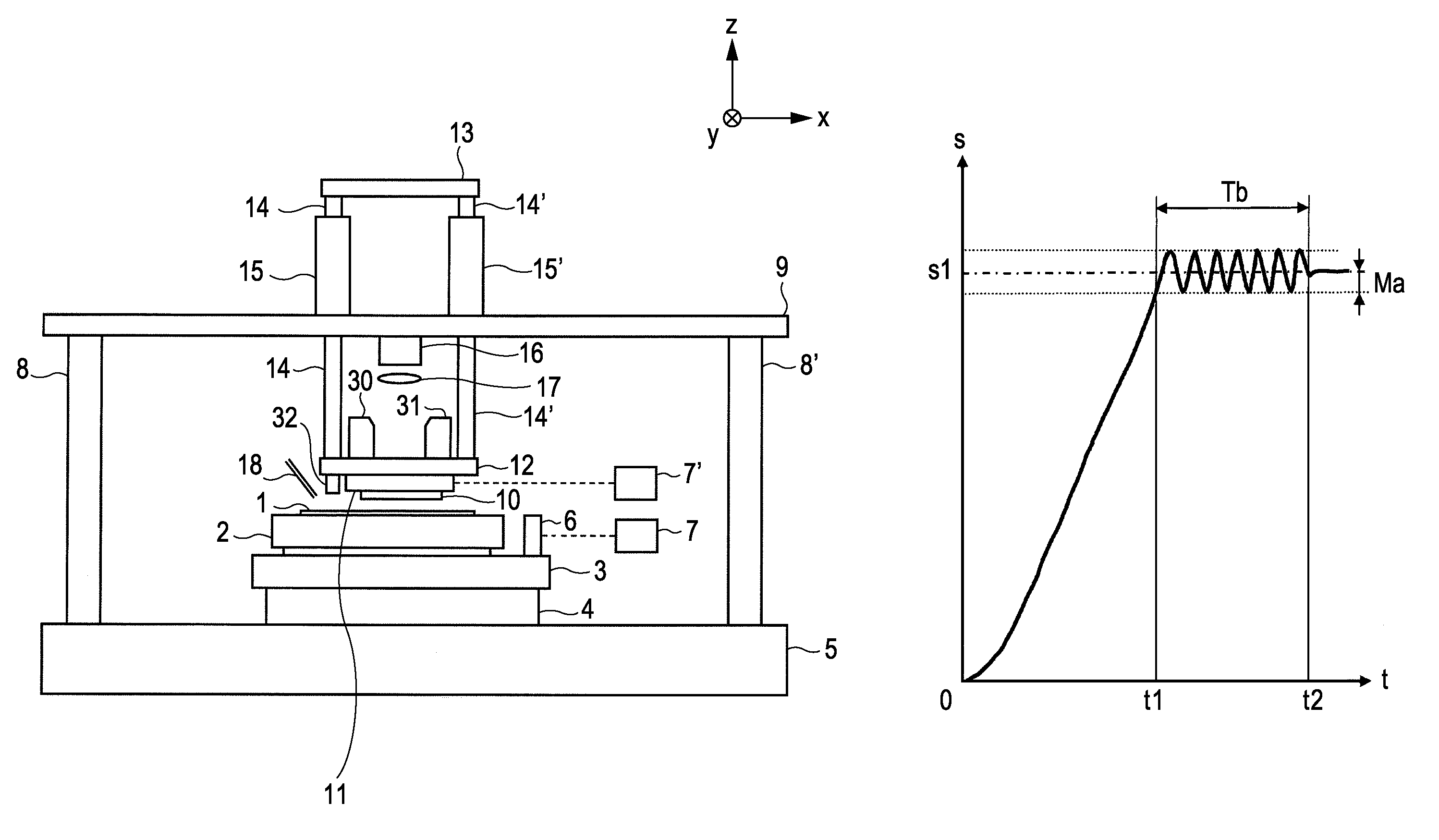

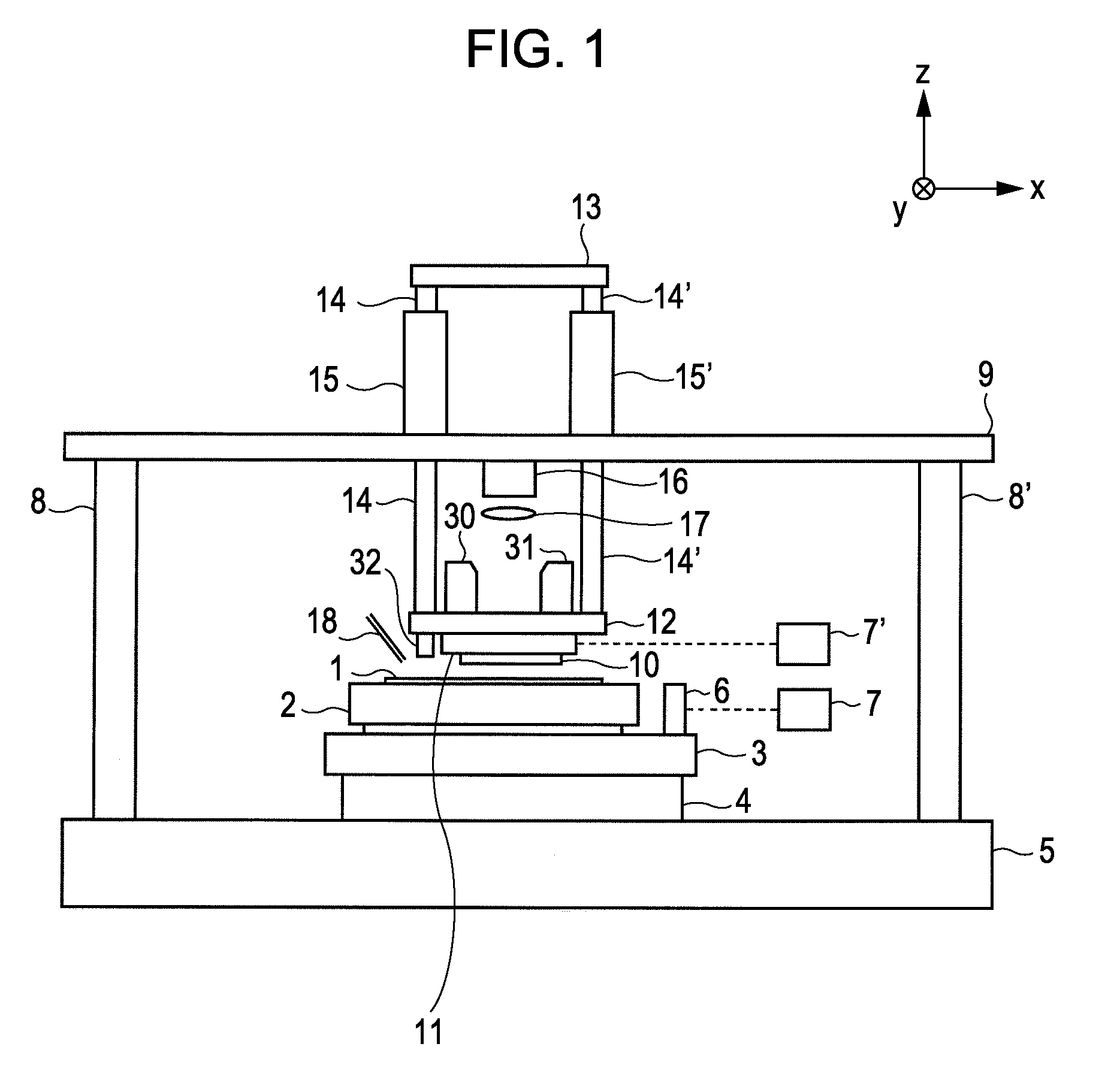

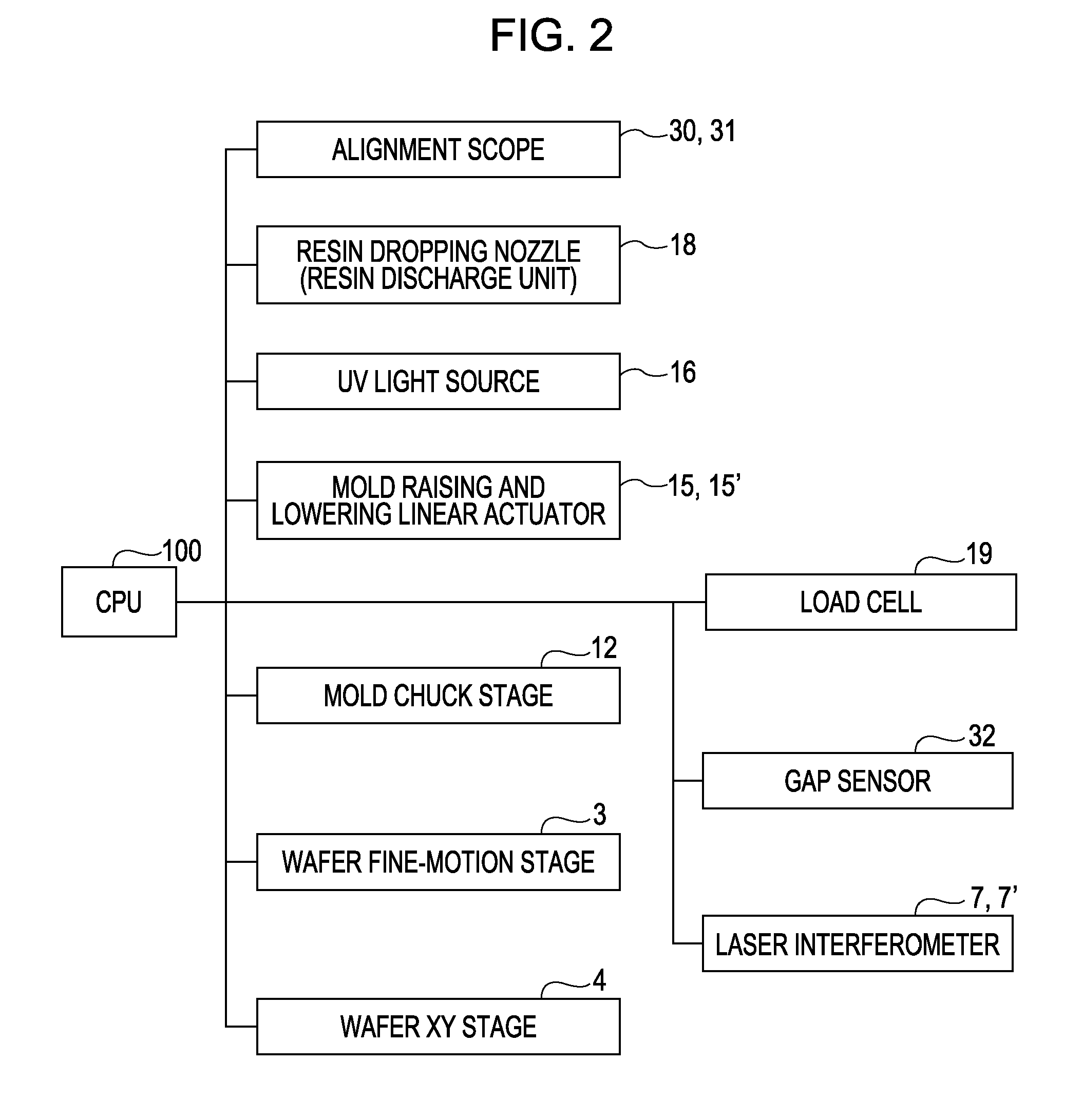

Imprint apparatus and method

Owner:CANON KK

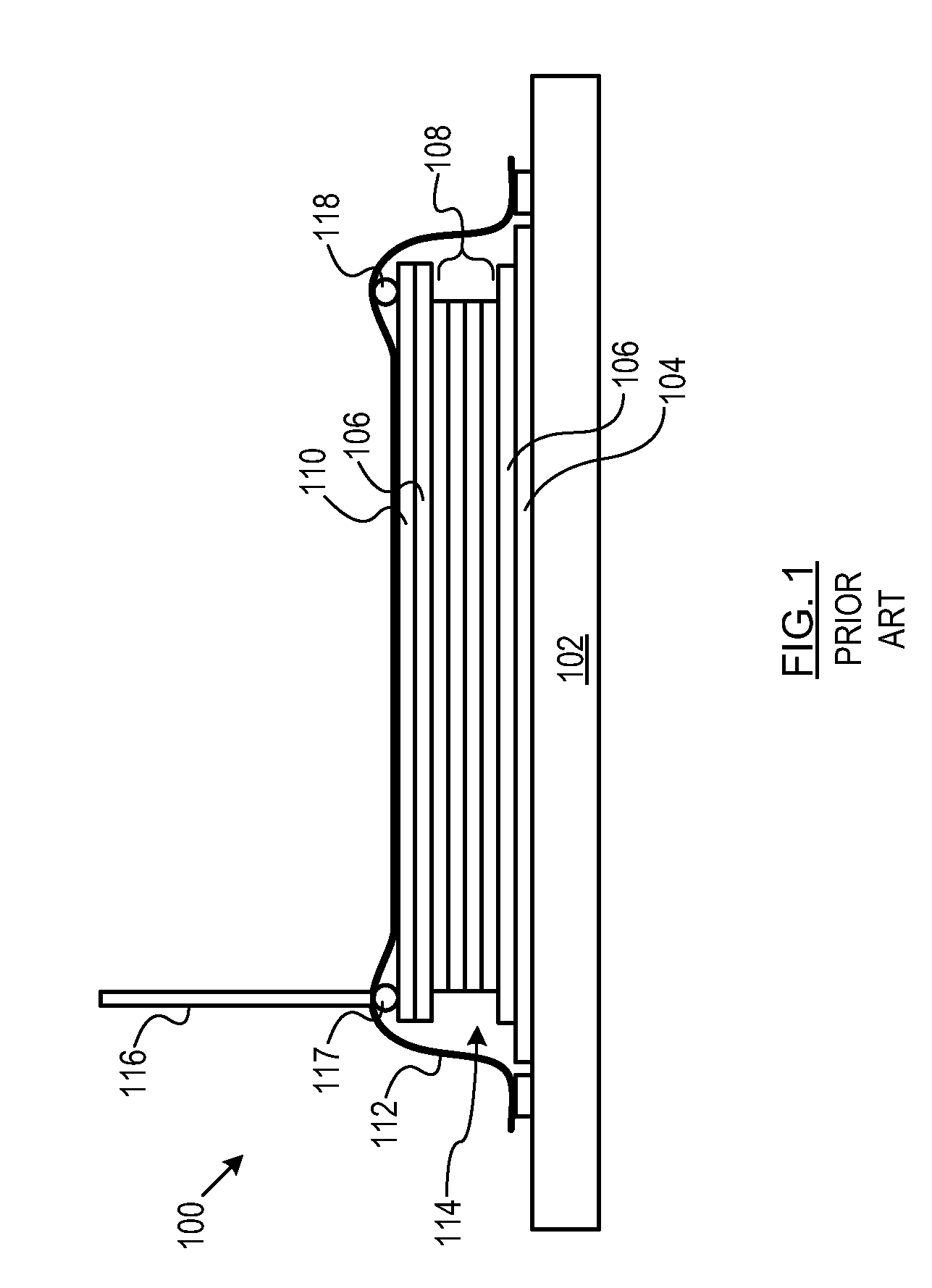

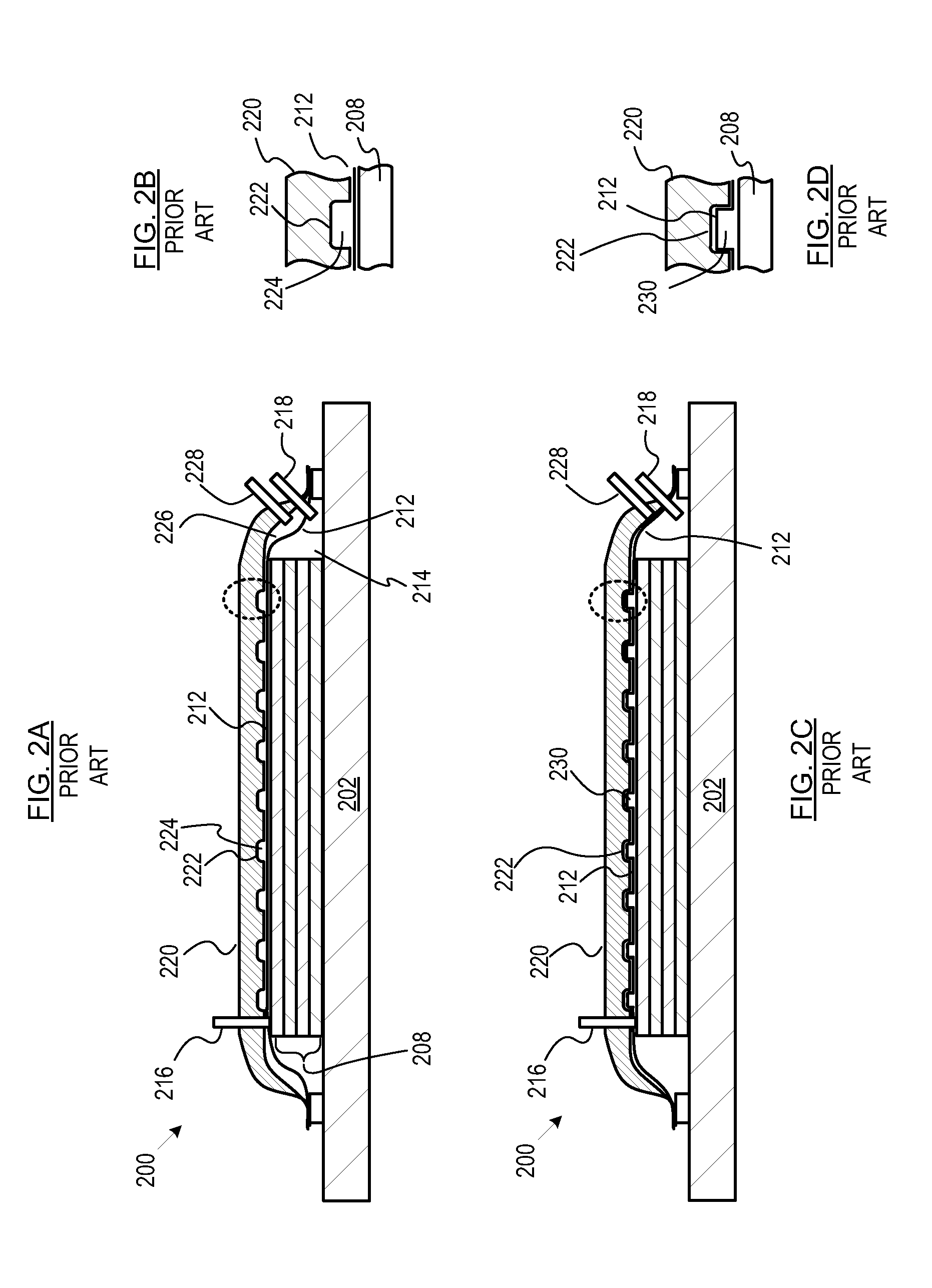

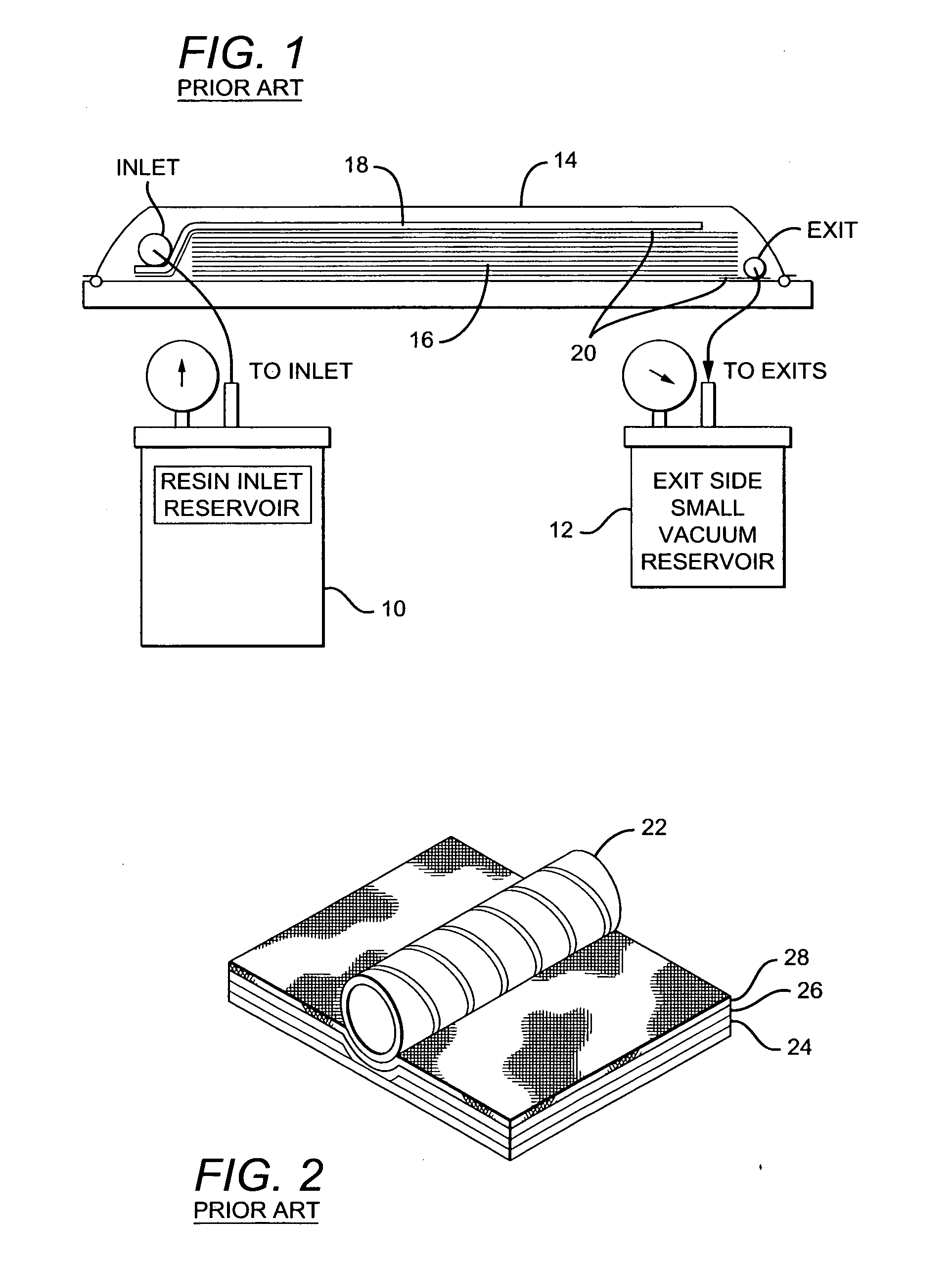

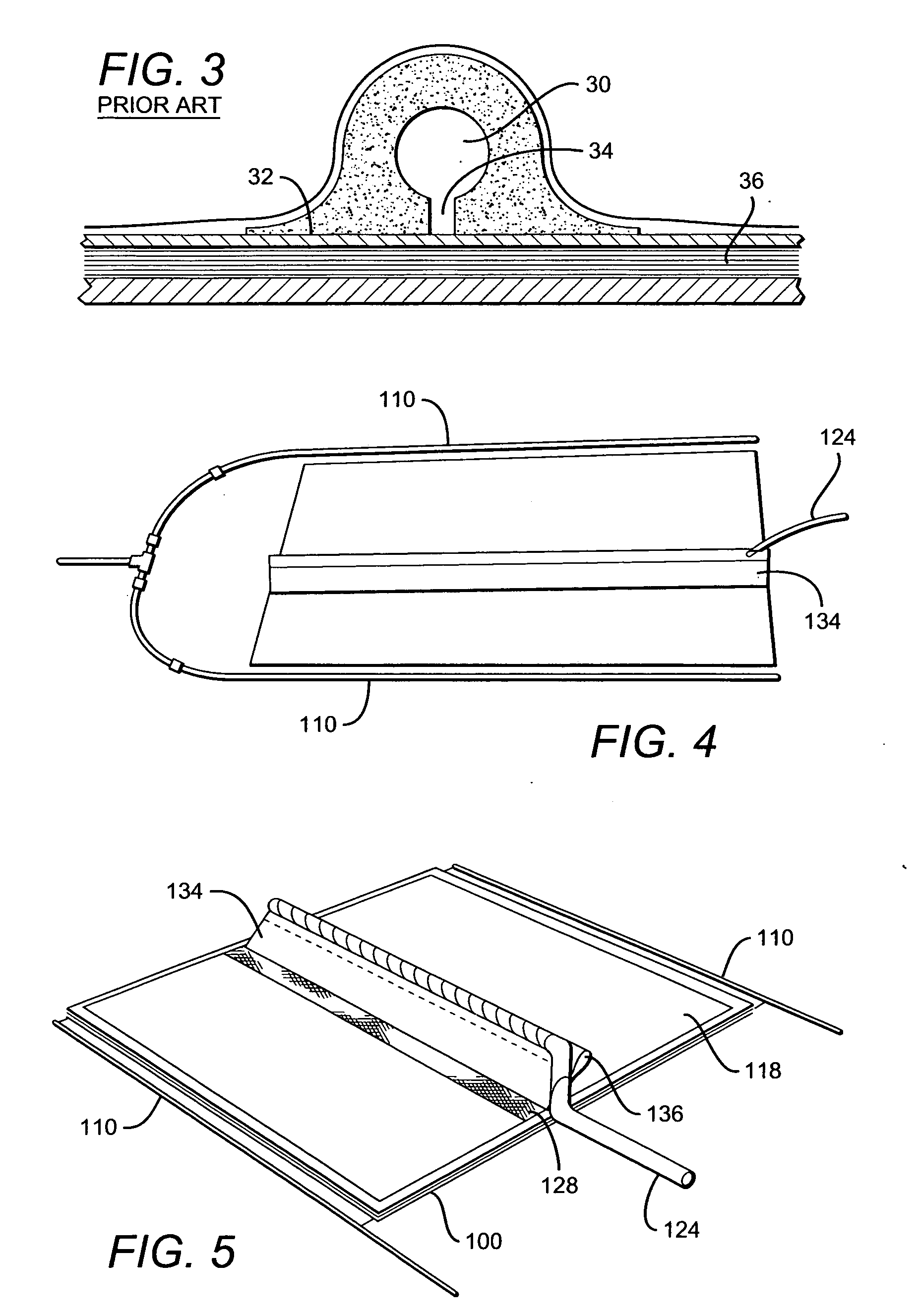

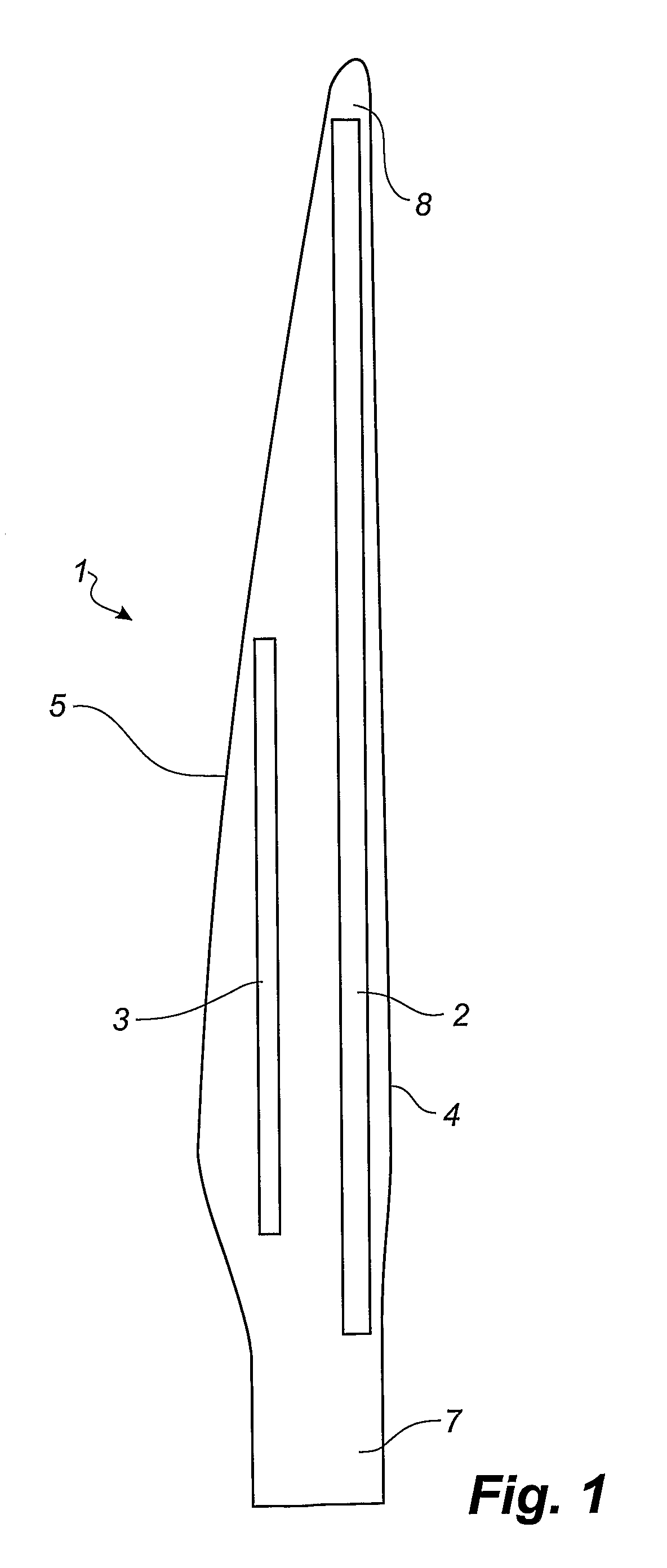

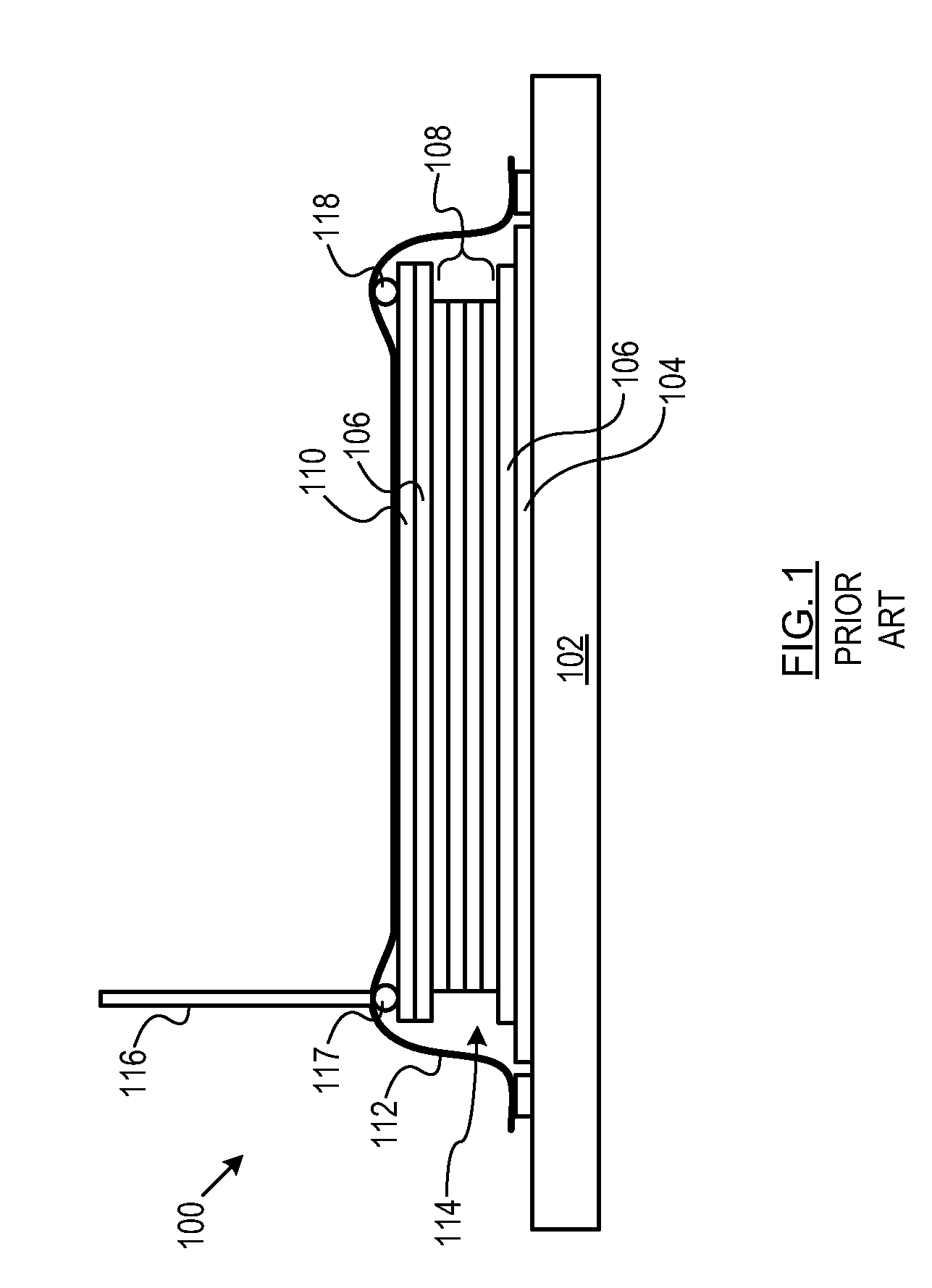

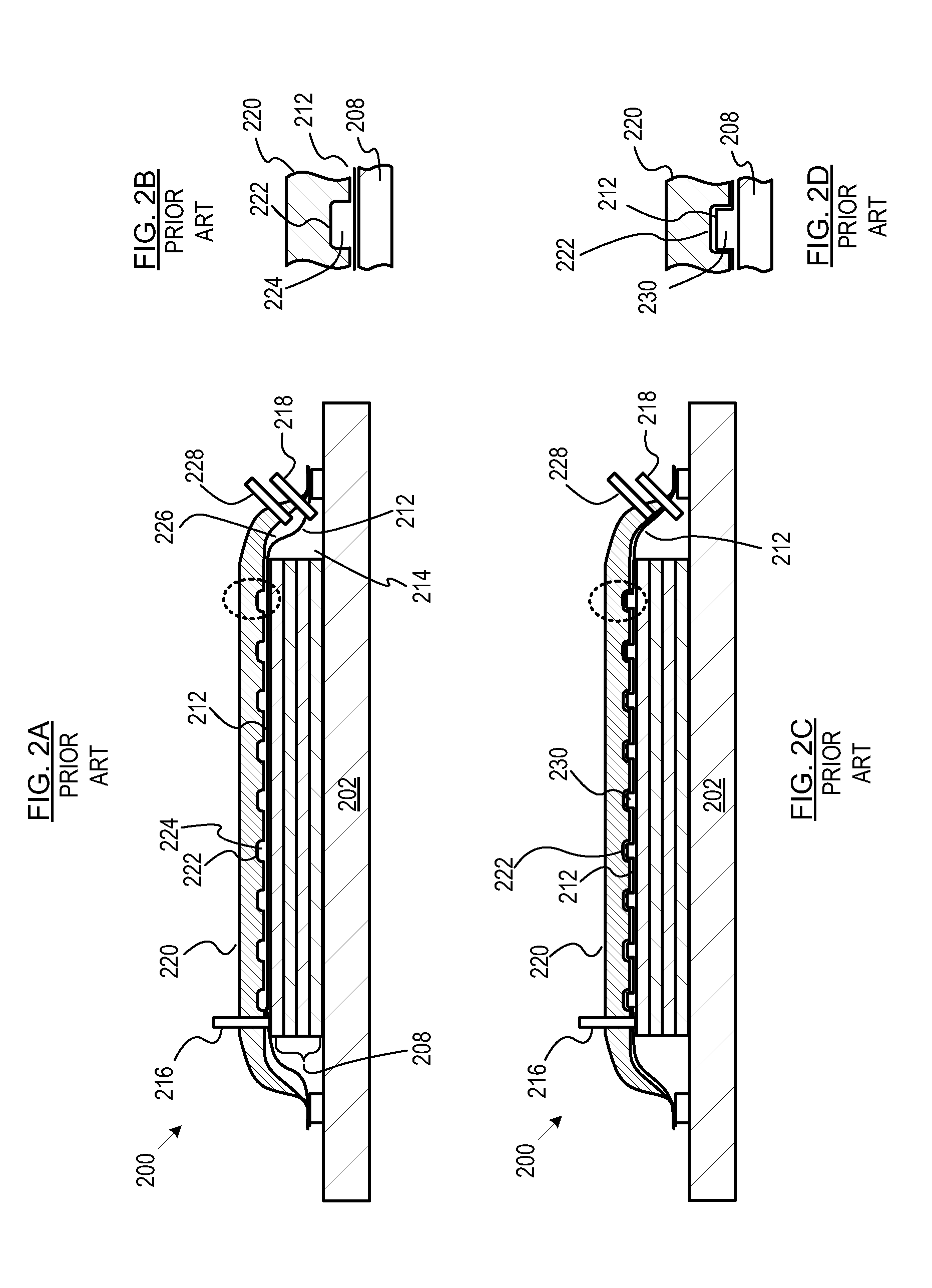

Tube induced deformity elimination proccess

ActiveUS20080079193A1Reduces and eliminates deformationEliminate deformationLaminationWood working apparatusResin dispensingEngineering

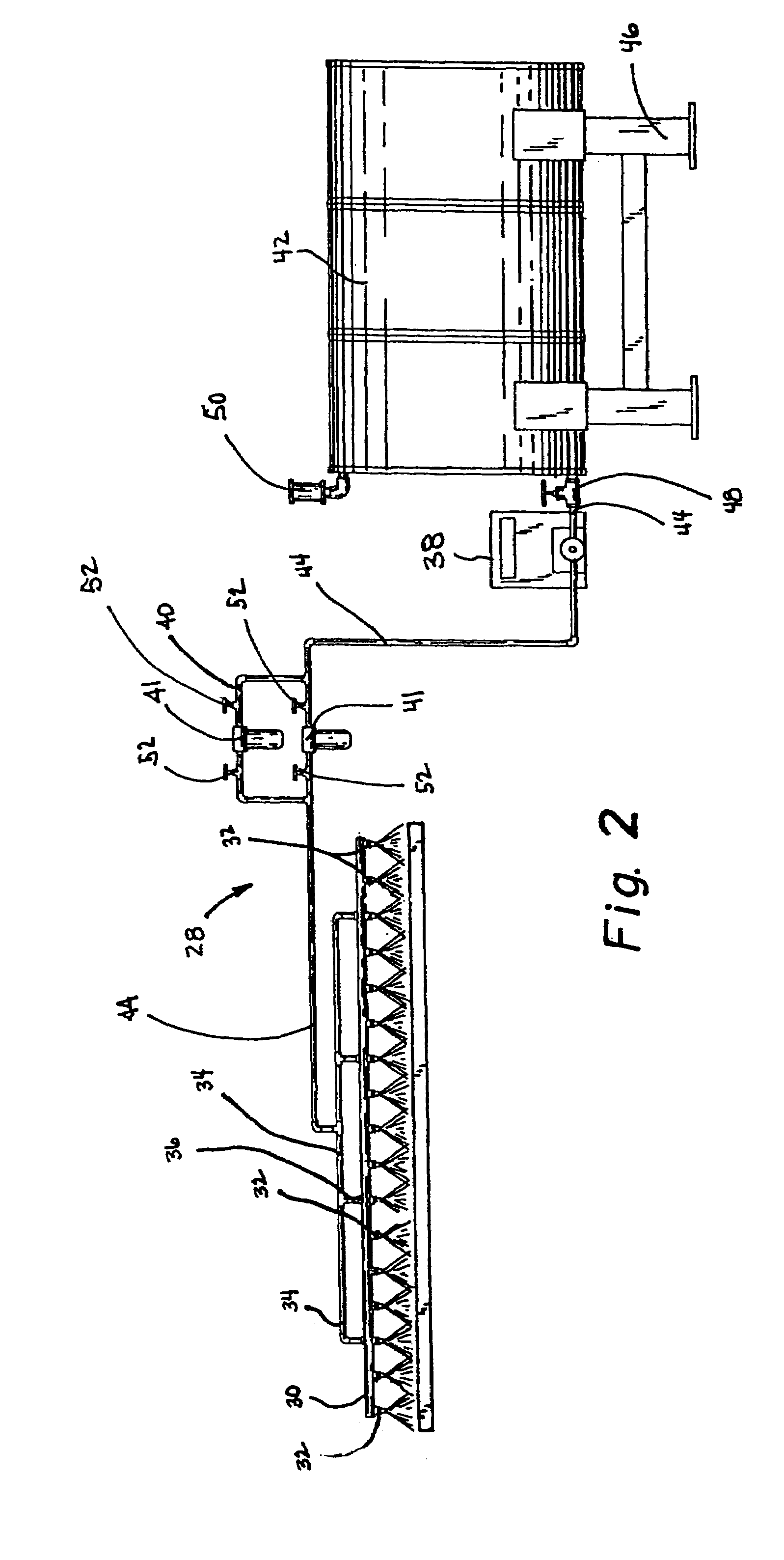

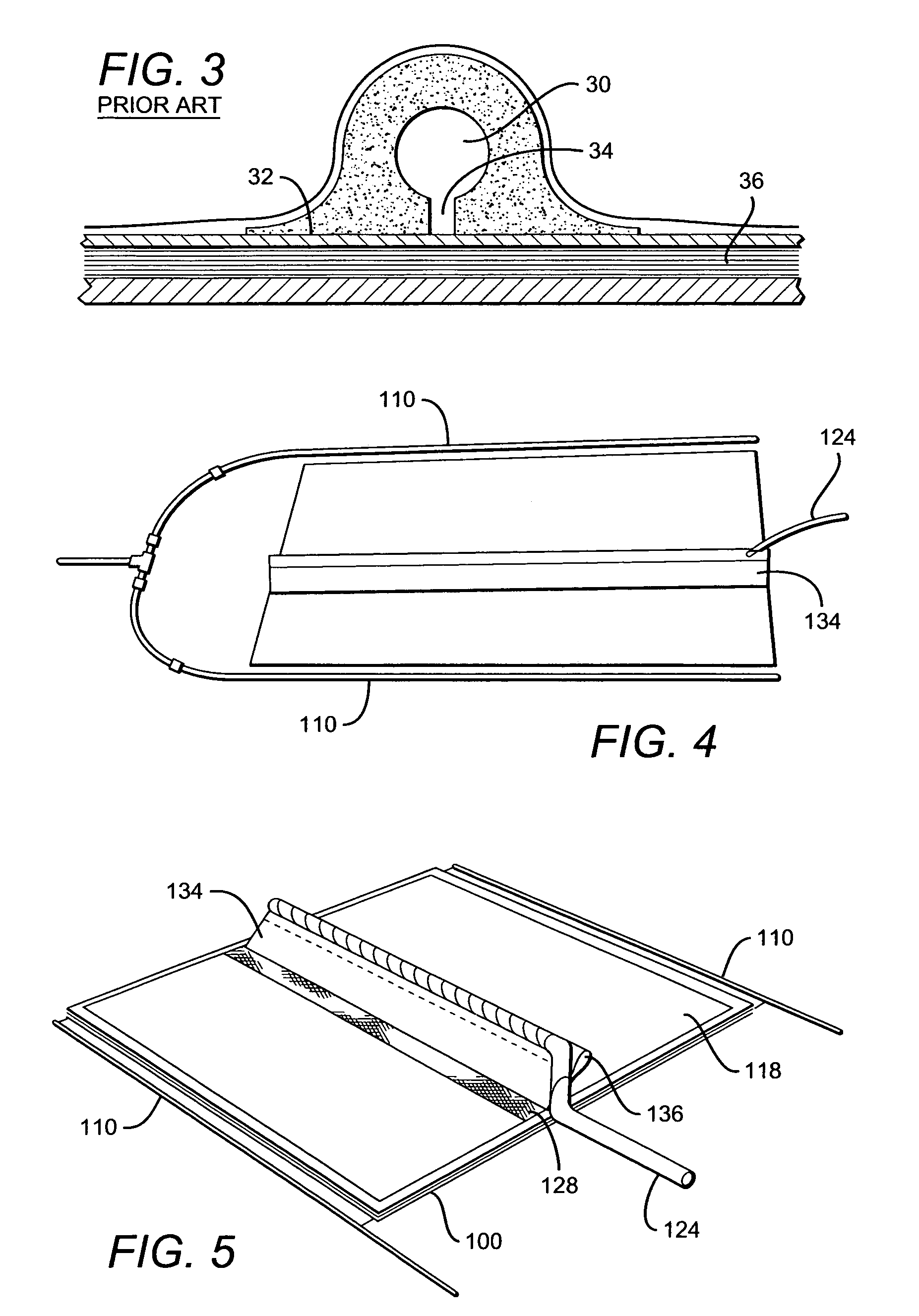

The invention is directed to a process for elimination of deformations on resin infused composite parts in which the resin distribution tube used in a resin vacuum infusion process is positioned above the surface of a preform and is not in contact with the preform. Flow media indirectly connects the resin distribution tube to the preform which allows for free movement of resin without direct contact of the resin distribution tube to the perform, and thus, this eliminates deformations that are caused by direct contact of the resin distribution tube to the preform.

Owner:THE BOEING CO

Apparatus and method for lining a pipe

InactiveUS20100295198A1Simple methodLiquid surface applicatorsLayered productsResin dispensingMechanical engineering

An apparatus and method for lining a damaged portion of a pipeline is disclosed. An inverting tubular liner is resin impregnated while in the pipeline in need of repair. An inverting end of the liner is received by a dispensing unit that dispenses resin under pressure to the inverting face of the liner. The liner is then pressed against the damaged section of the pipe until the resinous material cures and hardens.

Owner:LMK TECH LLC

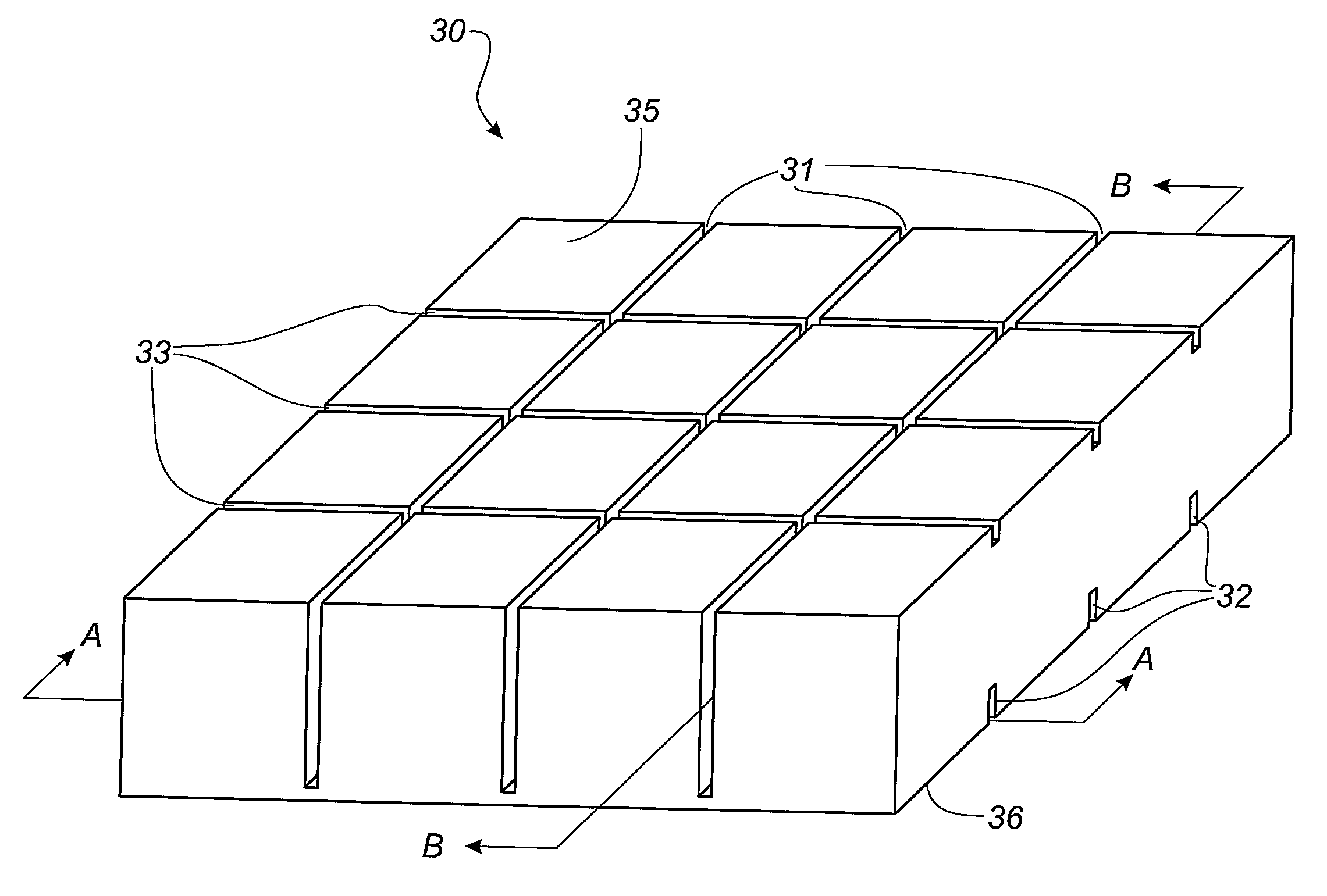

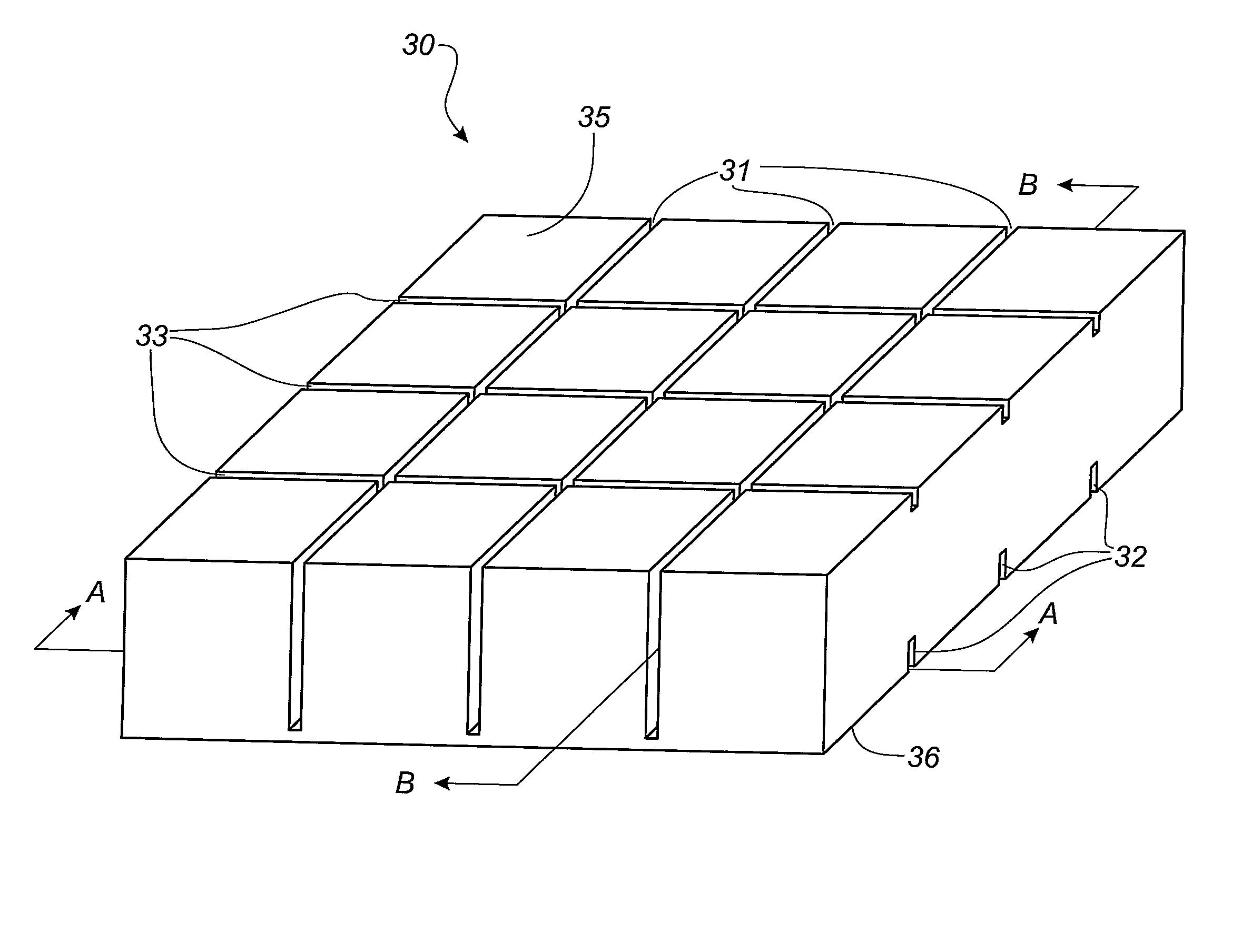

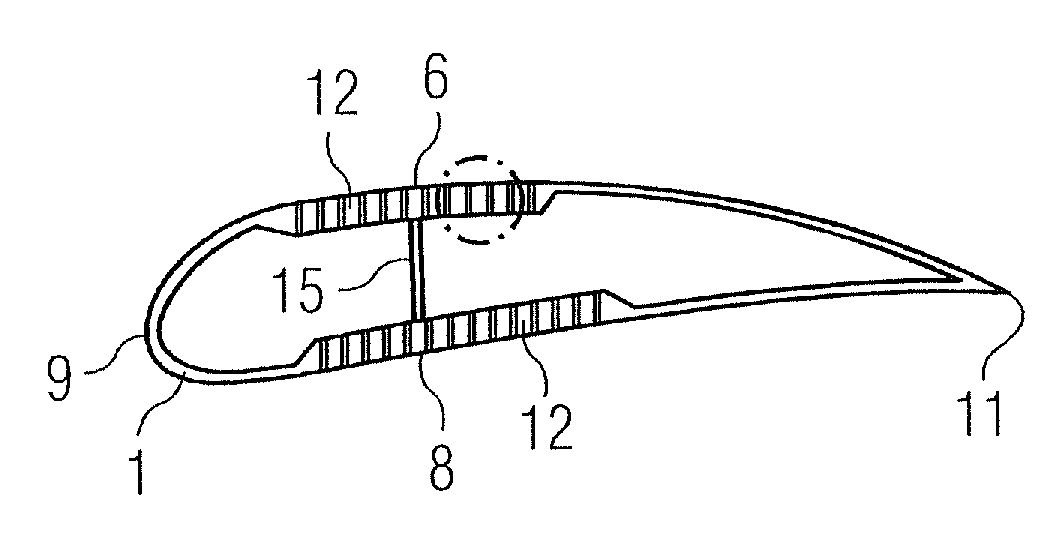

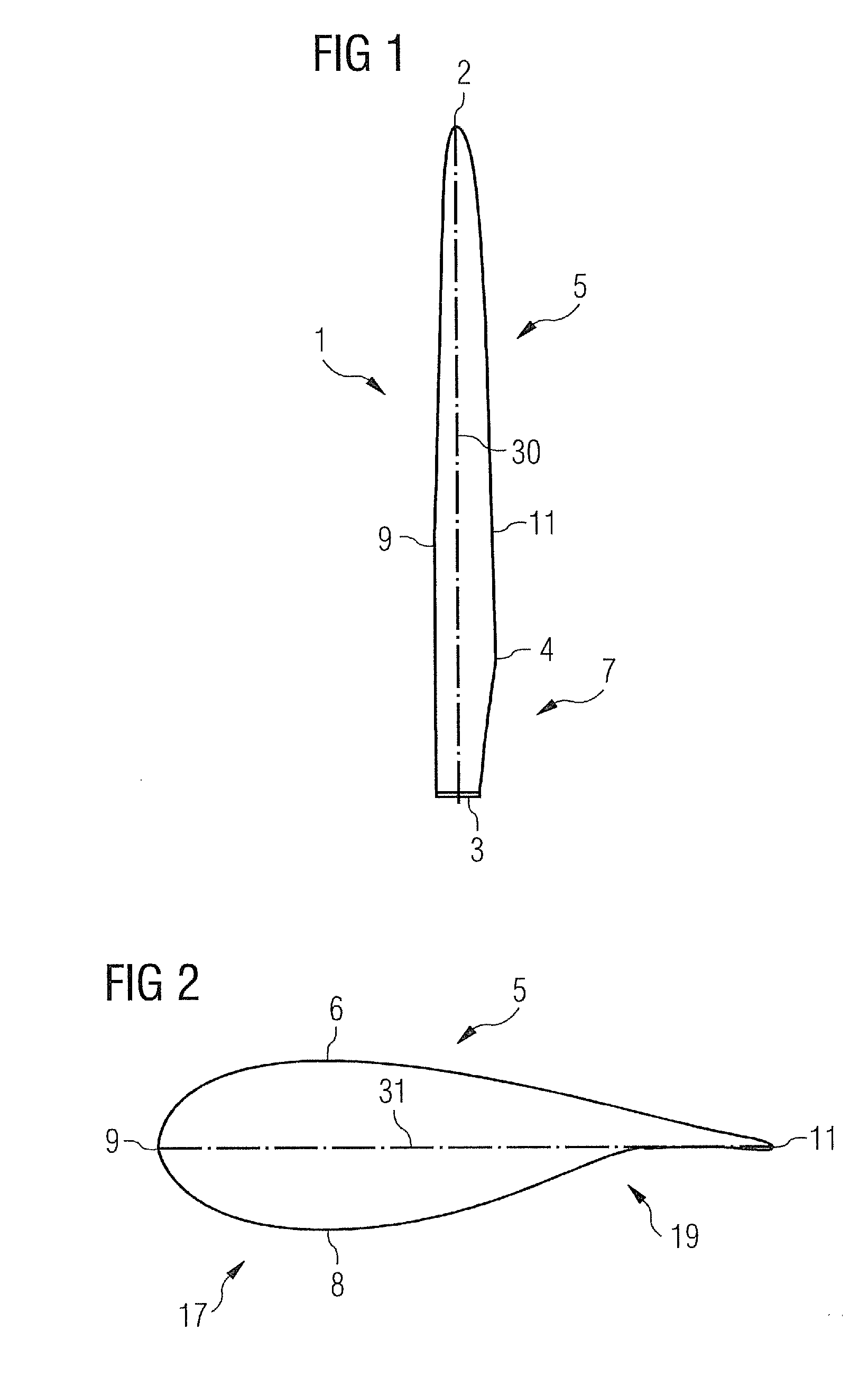

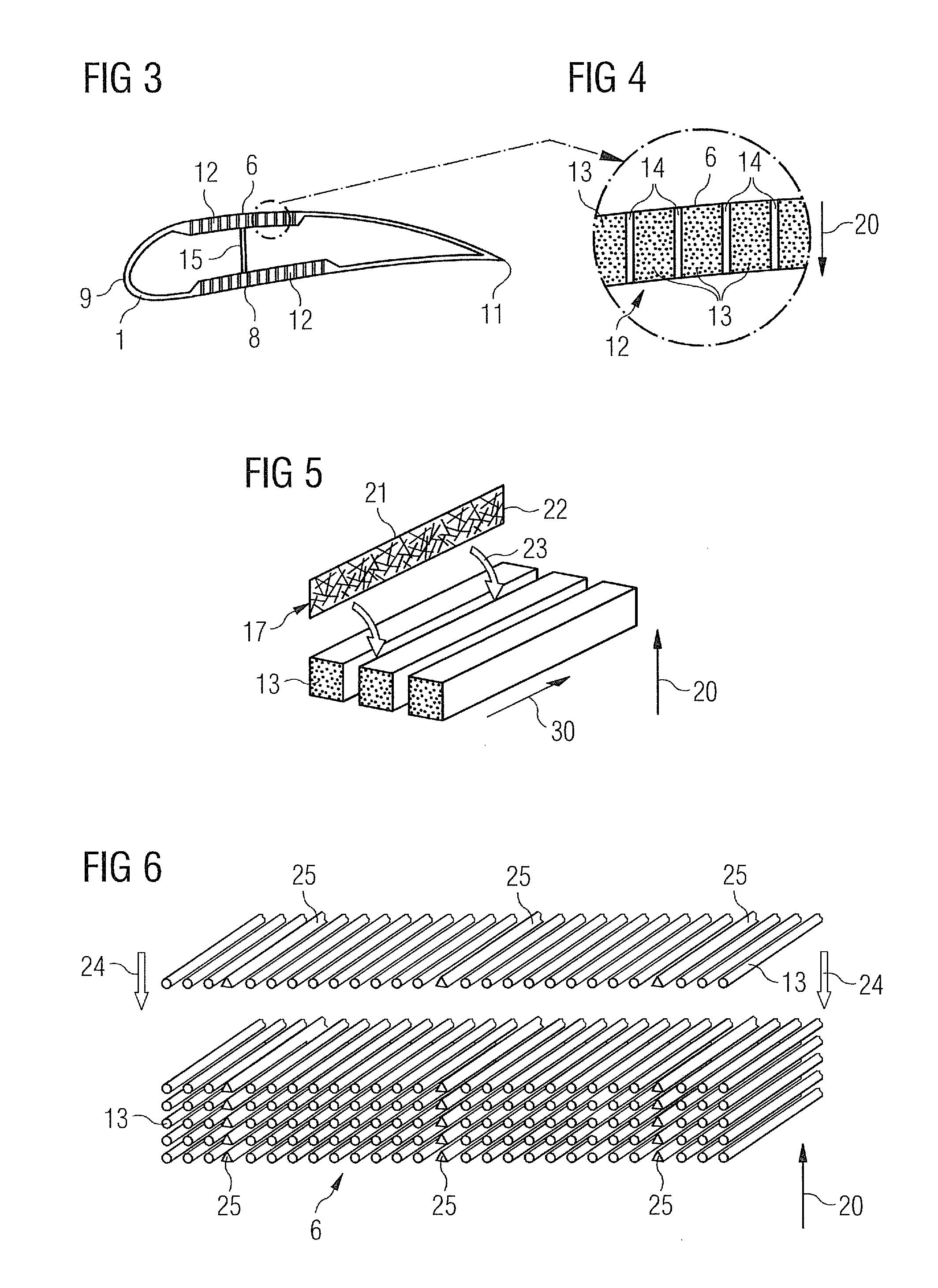

Method of Using a Formable Core Block for a Resin Impregnation Process

ActiveUS20100189973A1Easy to disassembleAvoid handlingFinal product manufactureMovable spraying apparatusResin dispensingEngineering

A use of a core block for an impregnation process as well as a composite structure comprising such a core block is described. The core block has a first surface and a second surface, and a number of first grooves is formed in the first surface of the core. Furthermore, a number of second grooves is formed in the second surface of the core. The first grooves have a first height (h1) and a bottom, and the first grooves and the second grooves are part of a resin distribution network formed in the core block. The distance (t) between the bottom of the first grooves and the second surface of the core block is of such a size that the core block is flexible along the first grooves. Additionally, the sum of the first height and the second height is larger than the thickness of the core block, and at least one of the first grooves in the first surface of the core block crosses at least one of the second grooves in the second surface of the core block.

Owner:LM GLASSFIBER

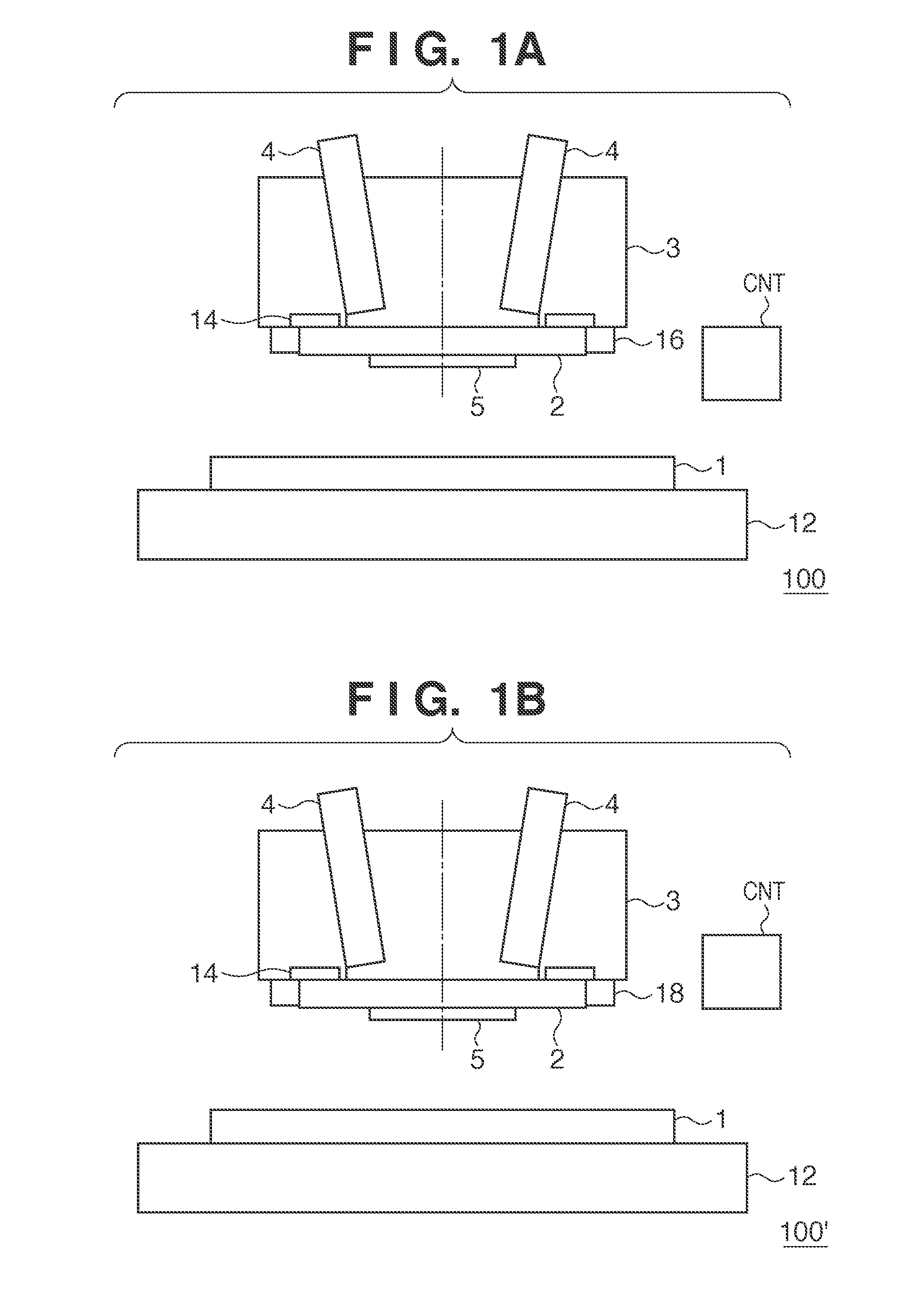

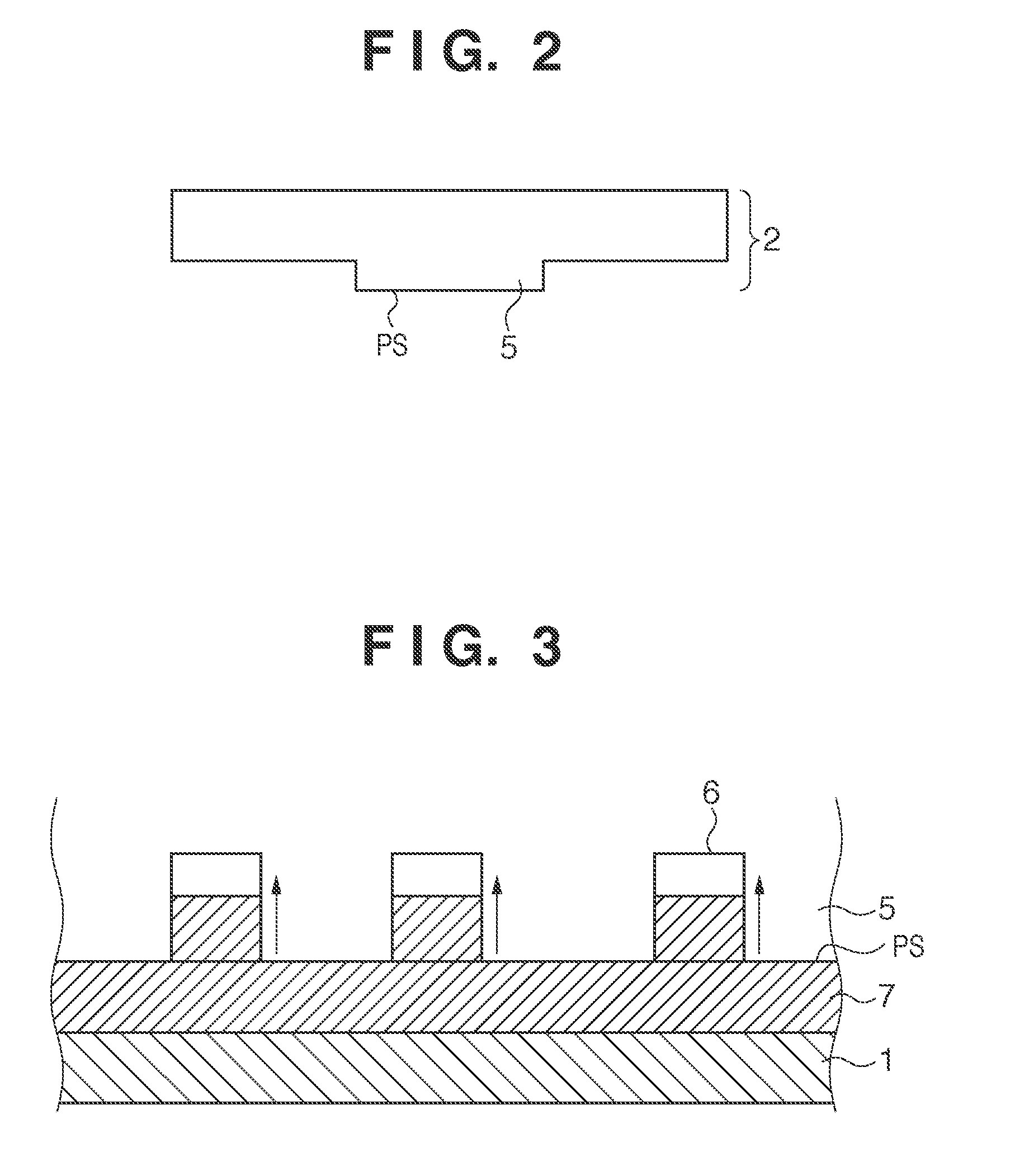

Imprint apparatus and article manufacturing method

InactiveUS20100072649A1Improve throughputConfectioneryNanoinformaticsResin dispensingMechanical engineering

Owner:CANON KK

Method of using a formable core block for a resin impregnation process

ActiveUS8440120B2Avoid handlingAvoid layeringFinal product manufactureMovable spraying apparatusResin dispensingEngineering

A use of a core block for an impregnation process as well as a composite structure comprising such a core block is described. The core block has a first surface and a second surface, and a number of first grooves is formed in the first surface of the core. Furthermore, a number of second grooves is formed in the second surface of the core. The first grooves have a first height (h1) and a bottom, and the first grooves and the second grooves are part of a resin distribution network formed in the core block. The distance (t) between the bottom of the first grooves and the second surface of the core block is of such a size that the core block is flexible along the first grooves. Additionally, the sum of the first height and the second height is larger than the thickness of the core block, and at least one of the first grooves in the first surface of the core block crosses at least one of the second grooves in the second surface of the core block.

Owner:LM GLASSFIBER

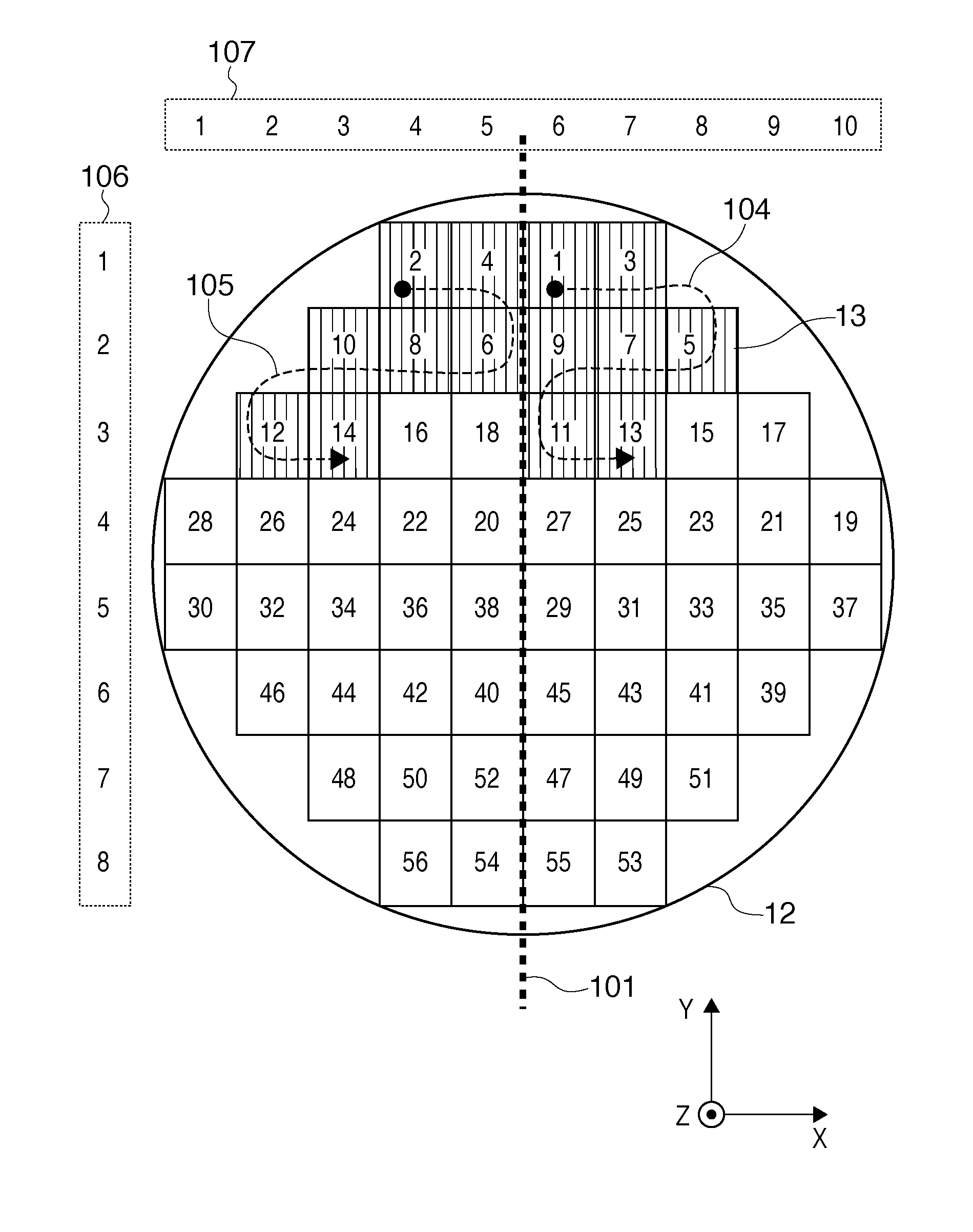

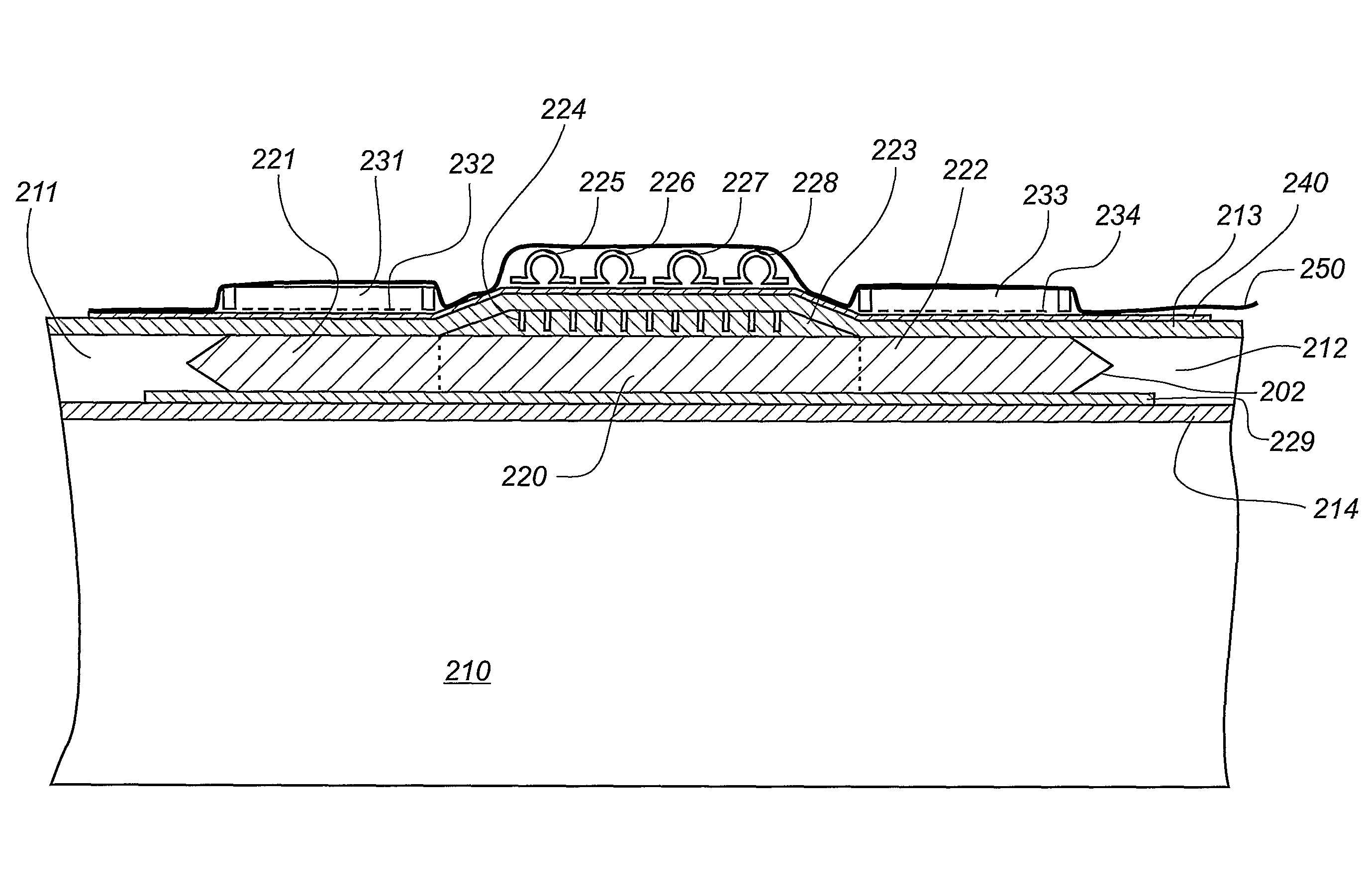

Composite structure and method for producing a composite structure

ActiveUS8221666B2Increase flow rateDistribute quicklyFinal product manufactureConfectioneryResin dispensingInlet channel

A method for producing a composite structure and a composite structure obtained by the method is described. The method comprises the following steps: a) providing a mold comprising a rigid mold part and a flexible vacuum bag, b) placing a fiber insertion in the mold part, the fiber insertion including a plurality of fiber layers and, when placed in the mold part, having an upper surface and a lower surface as well as a first side and a second side, the fiber insertion including a first zone at the first side and a second zone at the second side, the first zone and the second zone being separated by an intermediate zone, c) placing an upper distribution medium above the intermediate zone of the fiber insertion, the distribution medium comprising a resin distribution network for distributing resin along the upper distribution medium, d) placing a number of resin inlet channels above the upper distribution medium for supplying liquid resin to the resin distribution network, e) placing a first vacuum outlet at least partially overlapping the first zone of the fiber insertion and a second outlet at least partially overlapping the second zone of the fiber insertion, f) placing the vacuum bag on top of the mold part, thus sealing the vacuum bag against the mold part to define a mold cavity, g) evacuating the mold cavity, h) connecting a source of uncured fluid resin to the resin inlet channels so as to feed uncured resin to the resin distribution network in order to fill the mold cavity and to impregnate at least the fiber insertion and the upper distribution medium with uncured resin, and i) allowing the resin to cure in order to form the composite structure.

Owner:LM GLASSFIBER

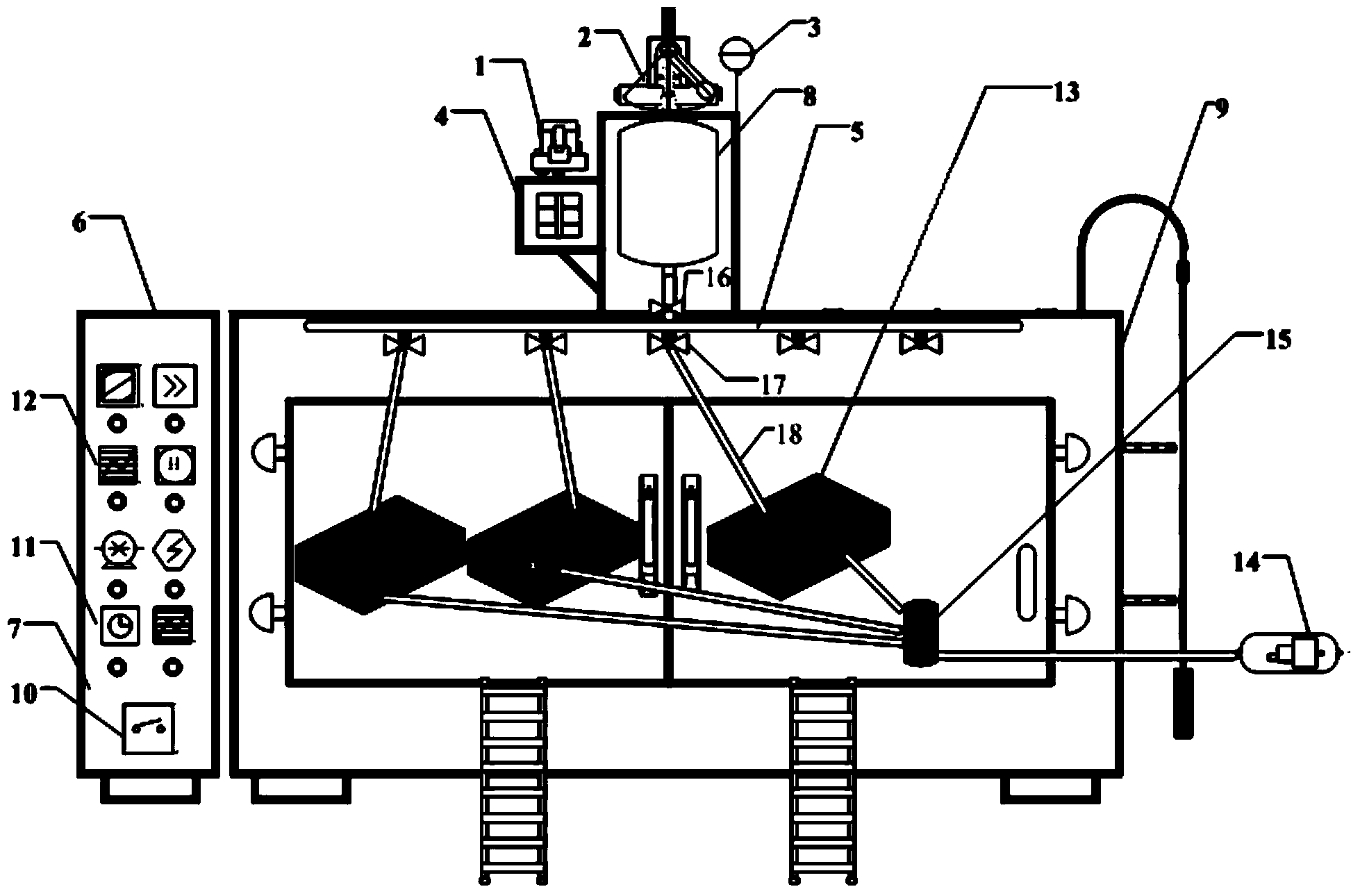

High-temperature RTM (resin transfer molding) integrated molding equipment

The invention provides high-temperature RTM (resin transfer molding) integrated molding equipment. The equipment comprises a resin tank, a high-temperature resin distributing pipeline and a curing tank, wherein the resin tank is arranged at the top of the curing tank in an integrated manner, the high-temperature resin distributing pipeline is arranged at the top part in the curing tank to meet the requirements of heat preservation property of the high-temperature resin distributing pipeline and the flowing property of the rein injection runners, the top part of the curing tank is provided with an opening at a glue outlet of the resin tank, three or more product molds can be placed in the curing tank, a mold vacuum pipeline is arranged outside the curing tank, the glue outlet of the resin tank is connected with the high-temperature resin distributing pipeline by a discharging valve, the high-temperature resin distributing pipeline is provided with three or more outlets, each outlet is connected with one mold through a resin distributing valve and a resin flowing pipeline, and each mold is connected with the mold vacuum pipeline by a liquid storage tank. According to the invention, high-temperature resin can be ensured to be fully poured and fed, the molding operation is convenient and the production efficiency is improved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Imprint apparatus and method of manufacturing article

ActiveUS20110236579A1Improve throughputHigh yieldNanoinformaticsPhotomechanical apparatusResin dispensingEngineering

Owner:CANON KK

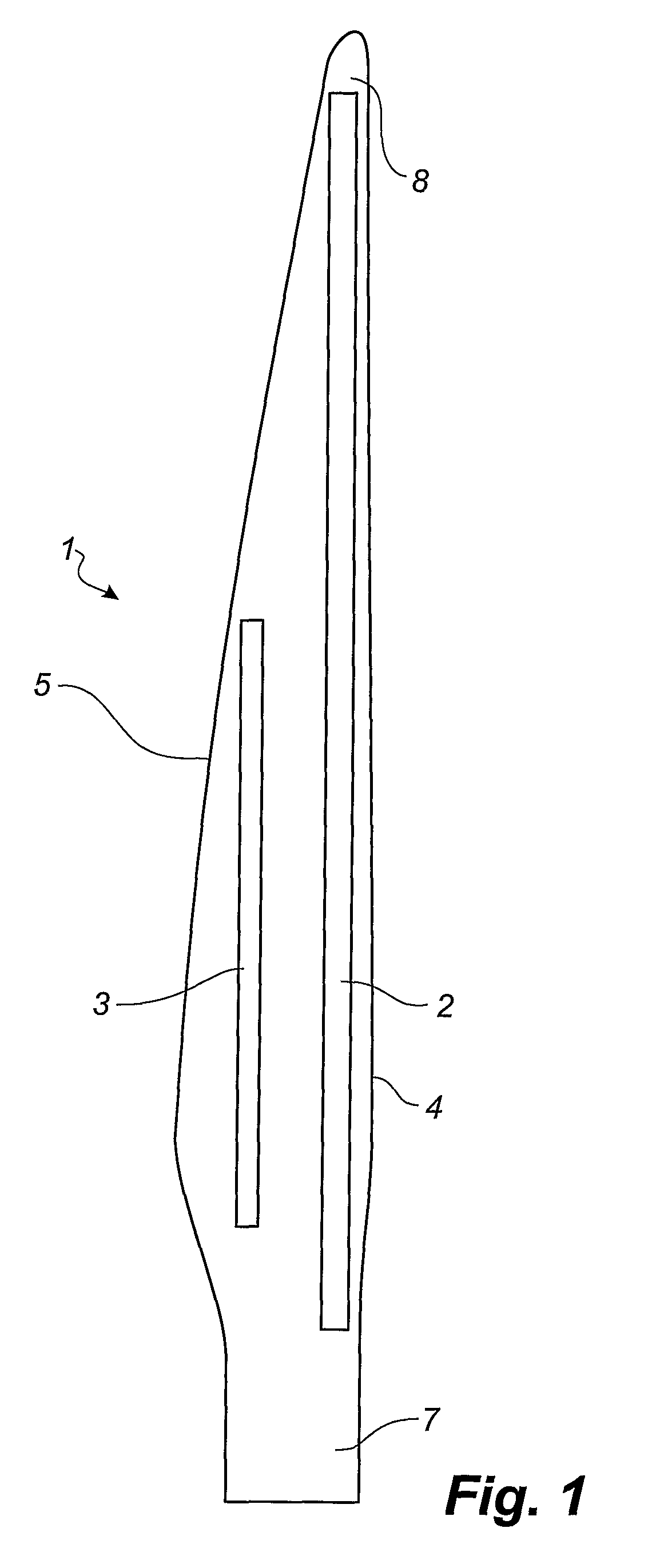

Method for manufacturing a work piece by vacuum assisted resin transfer moulding

InactiveUS20120263600A1Reduce manufacturing costLow costFinal product manufactureLayered productsFiberVacuum assisted

A method for manufacturing a work piece by Vacuum Assisted Resin Transfer Moulding is includes the steps of placing fibre rovings in a mould of a closed mould system which comprises a mould cavity, placing at least one resin distribution device between the fibre rovings, and applying vacuum to the closed mould system and injecting resin into the mould cavity.

Owner:SIEMENS AG

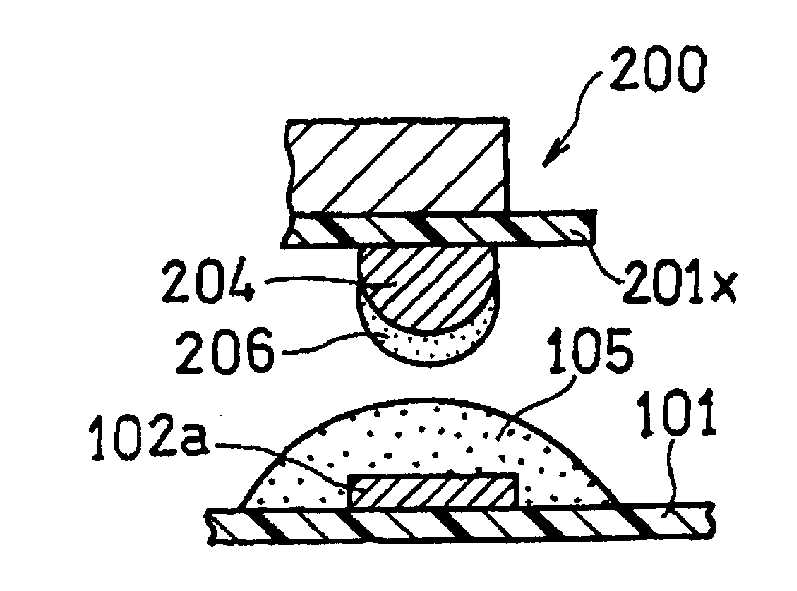

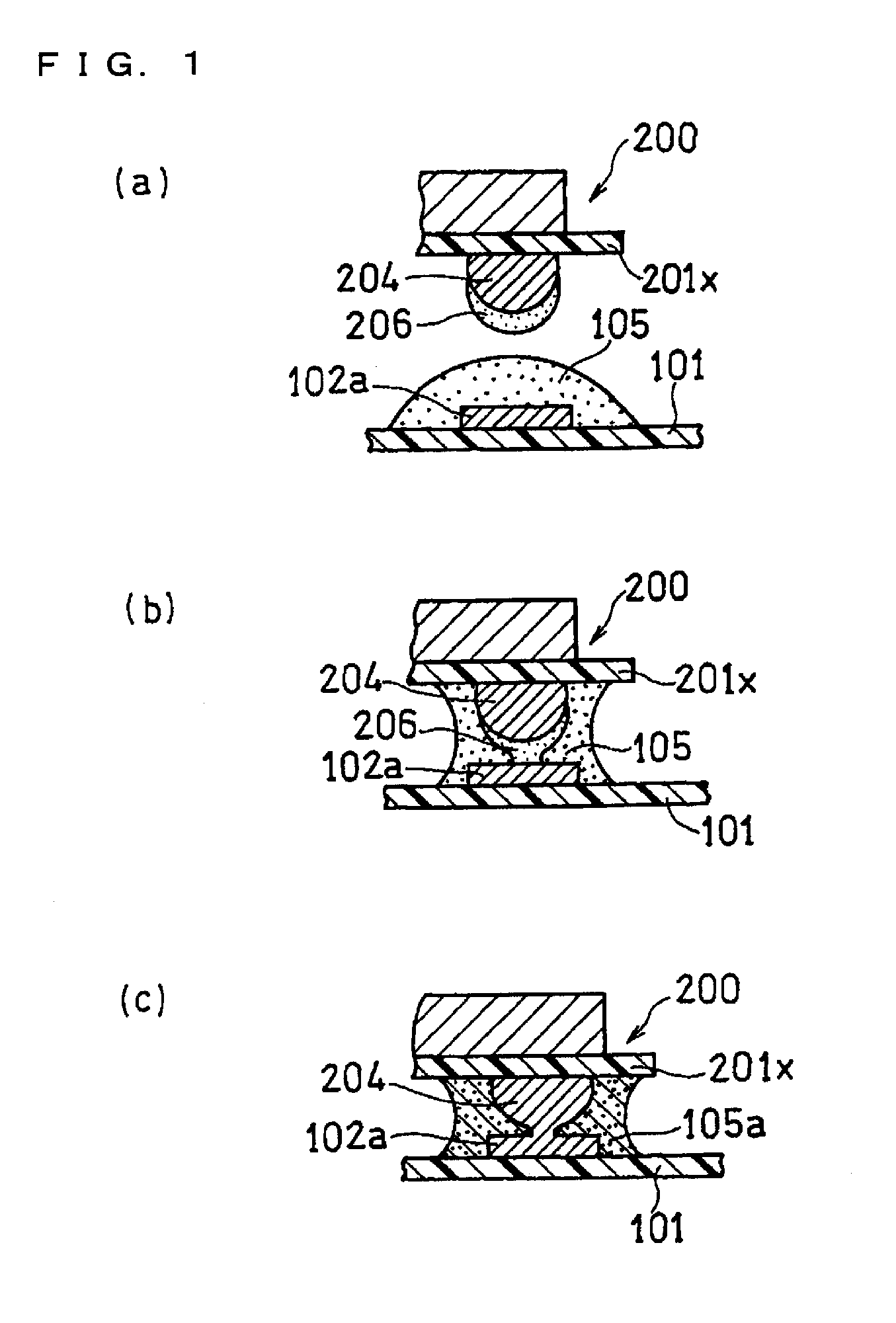

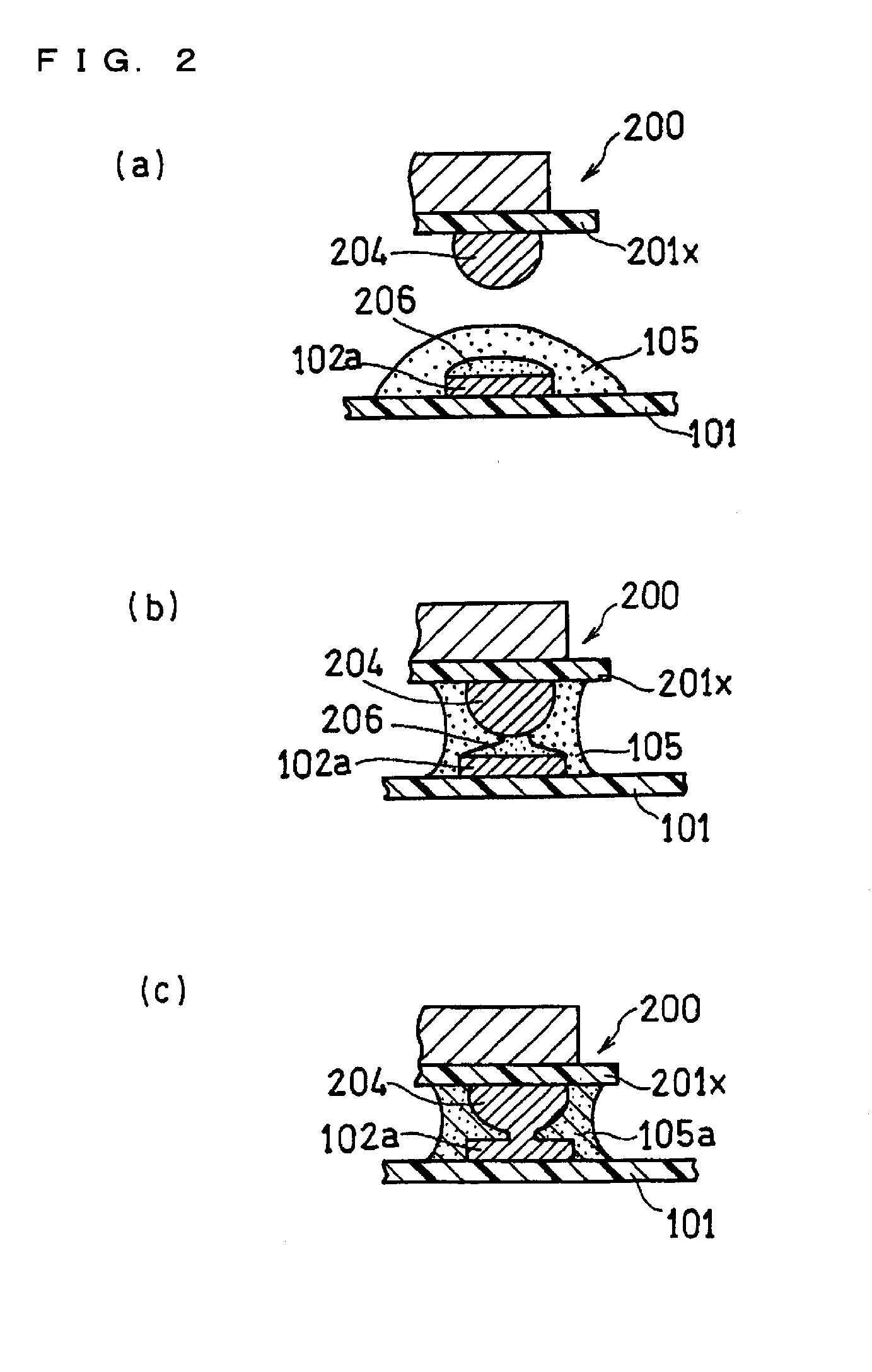

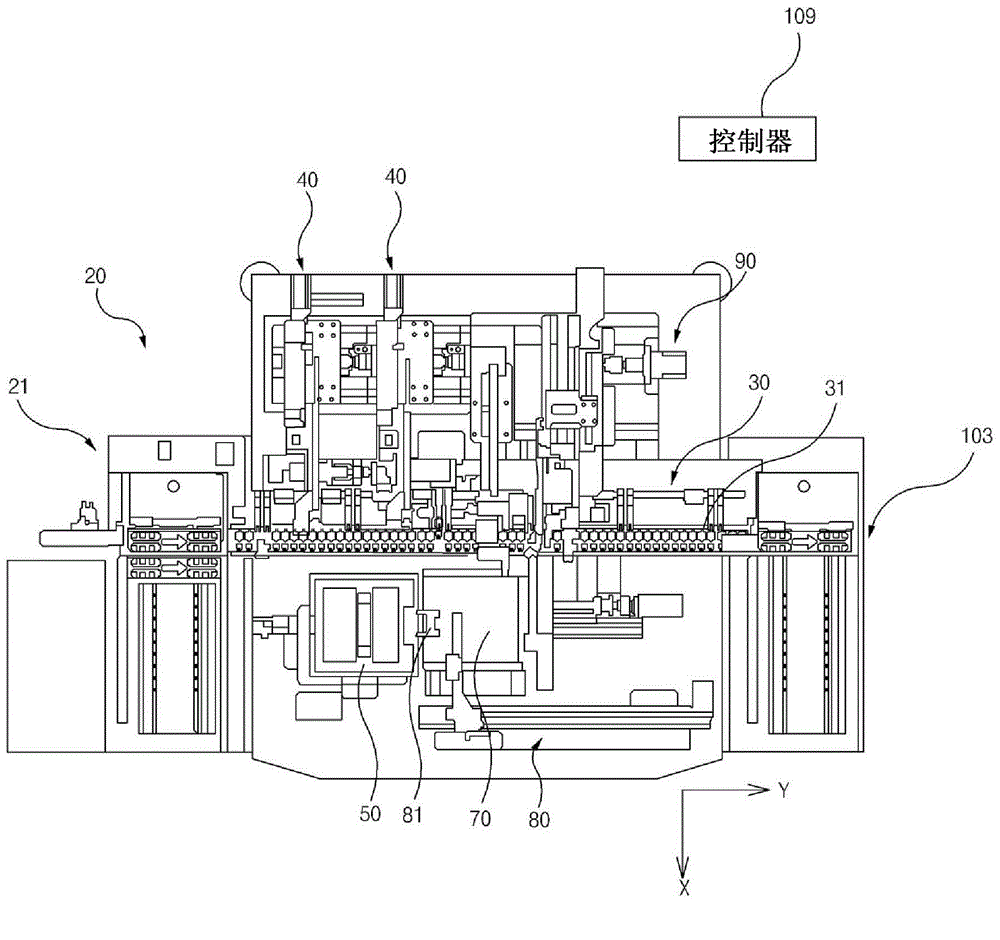

Electronic component mounting method, electronic component placement machine, and electronic component mounting system

ActiveUS20140096379A1Poor junction at the solder joints can be preventedFully moistenedPrinted circuit assemblingFinal product manufactureResin dispensingEngineering

An electronic component mounting method including the steps of: providing a first electronic component having a principal surface provided with a plurality of bumps; providing a substrate having a placement area provided with a plurality of first electrodes corresponding to the plurality of bumps; applying flux to the plurality of bumps; applying flux to at least one of the first electrodes adjacent to at least one reinforcement position set on a peripheral portion of the placement area; dispensing a thermosetting resin onto the reinforcement position, and at least partially coating the first electrode adjacent to the reinforcement position, with the thermosetting resin; placing the first electronic component on the substrate such that the bumps land on the corresponding first electrodes, and thus bringing the thermosetting resin into contact with a peripheral edge portion of the first electronic component; and heating the substrate with the first electronic component placed thereon.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

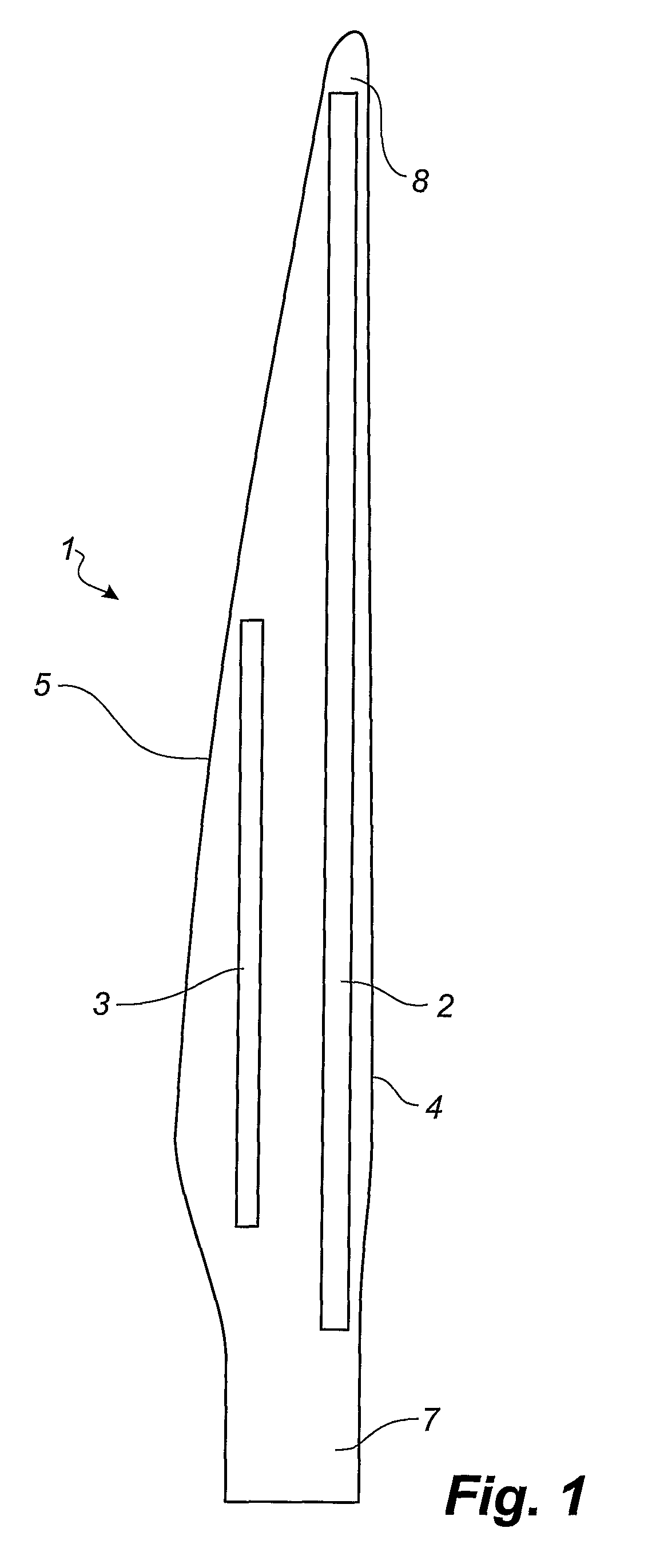

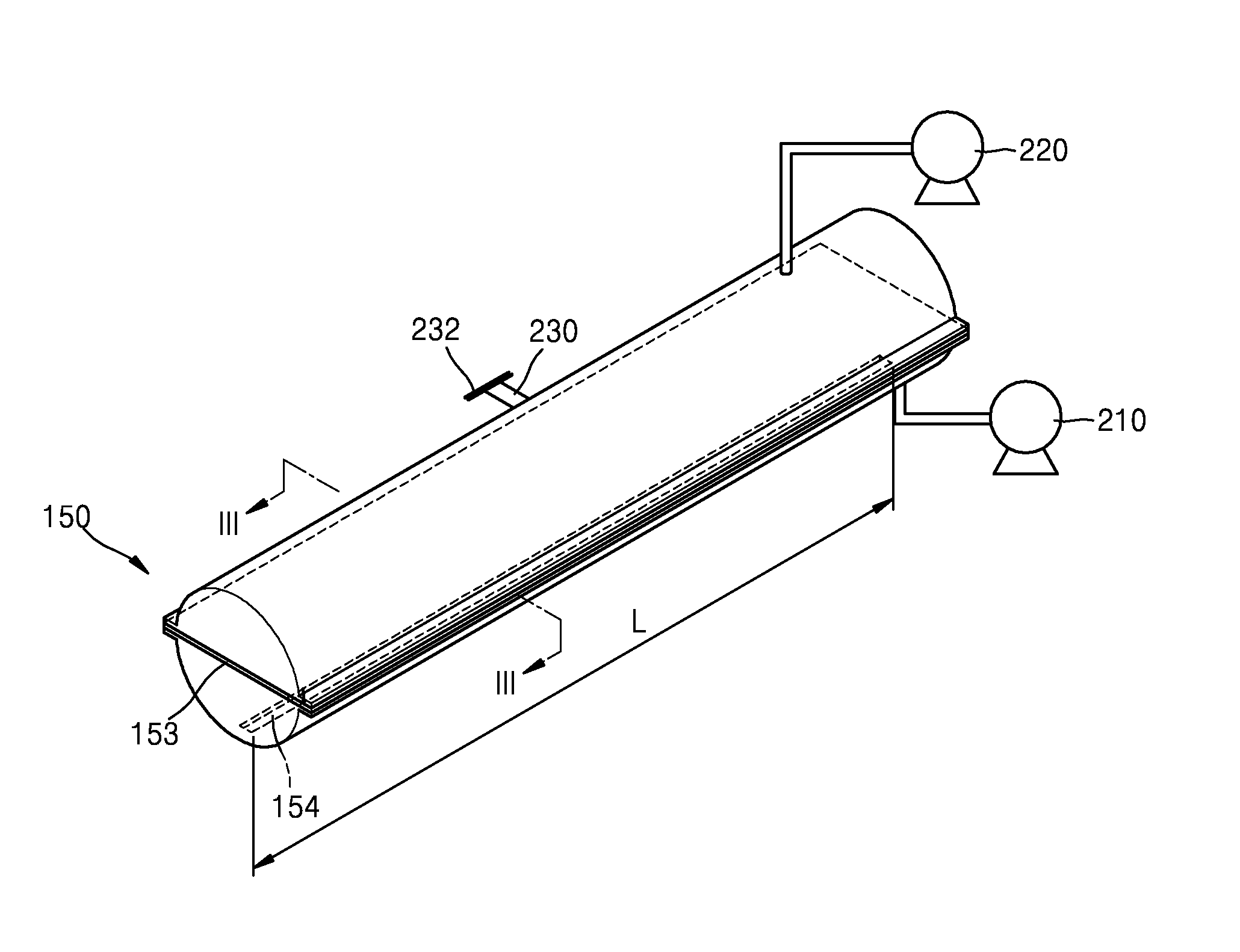

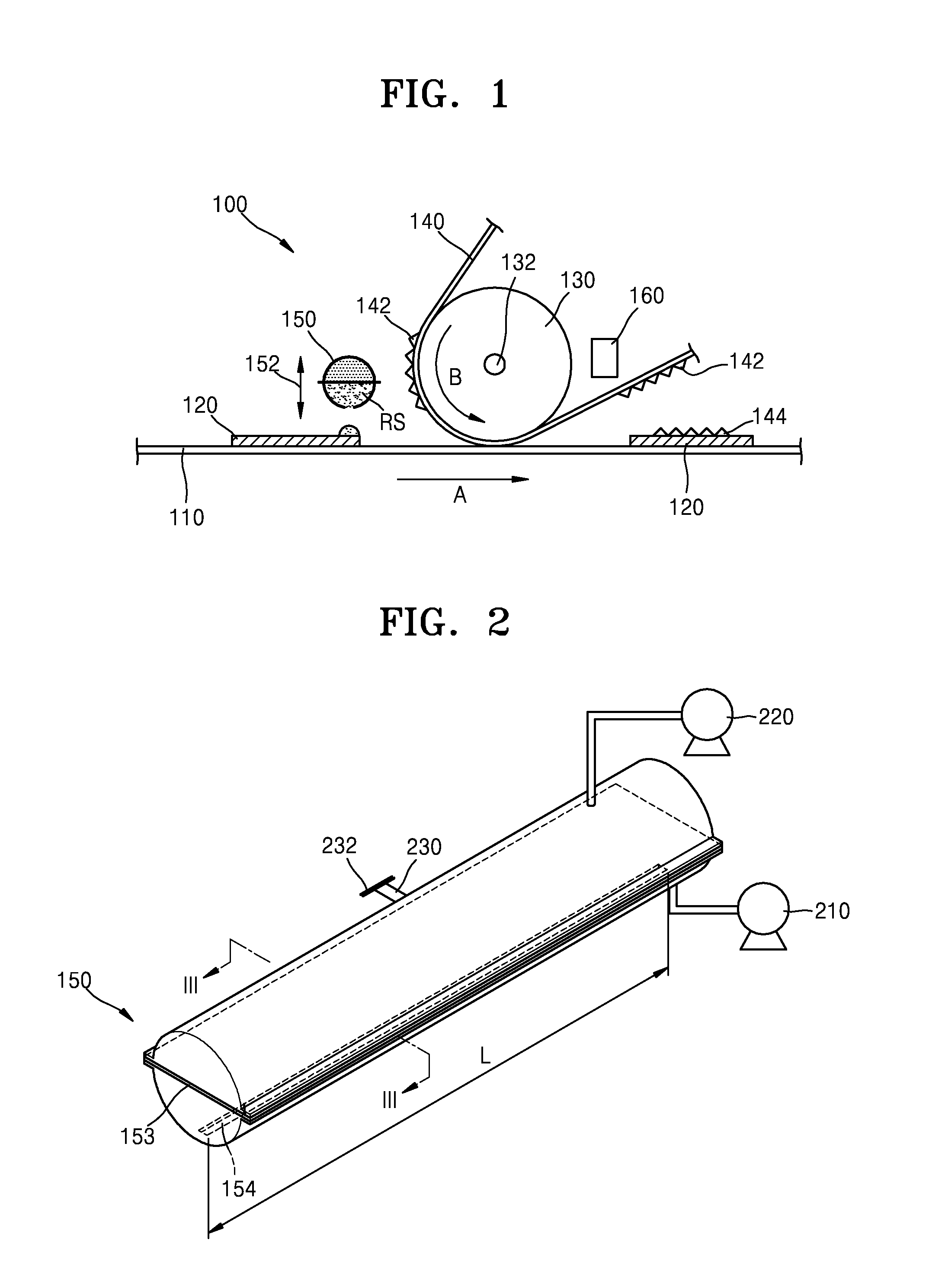

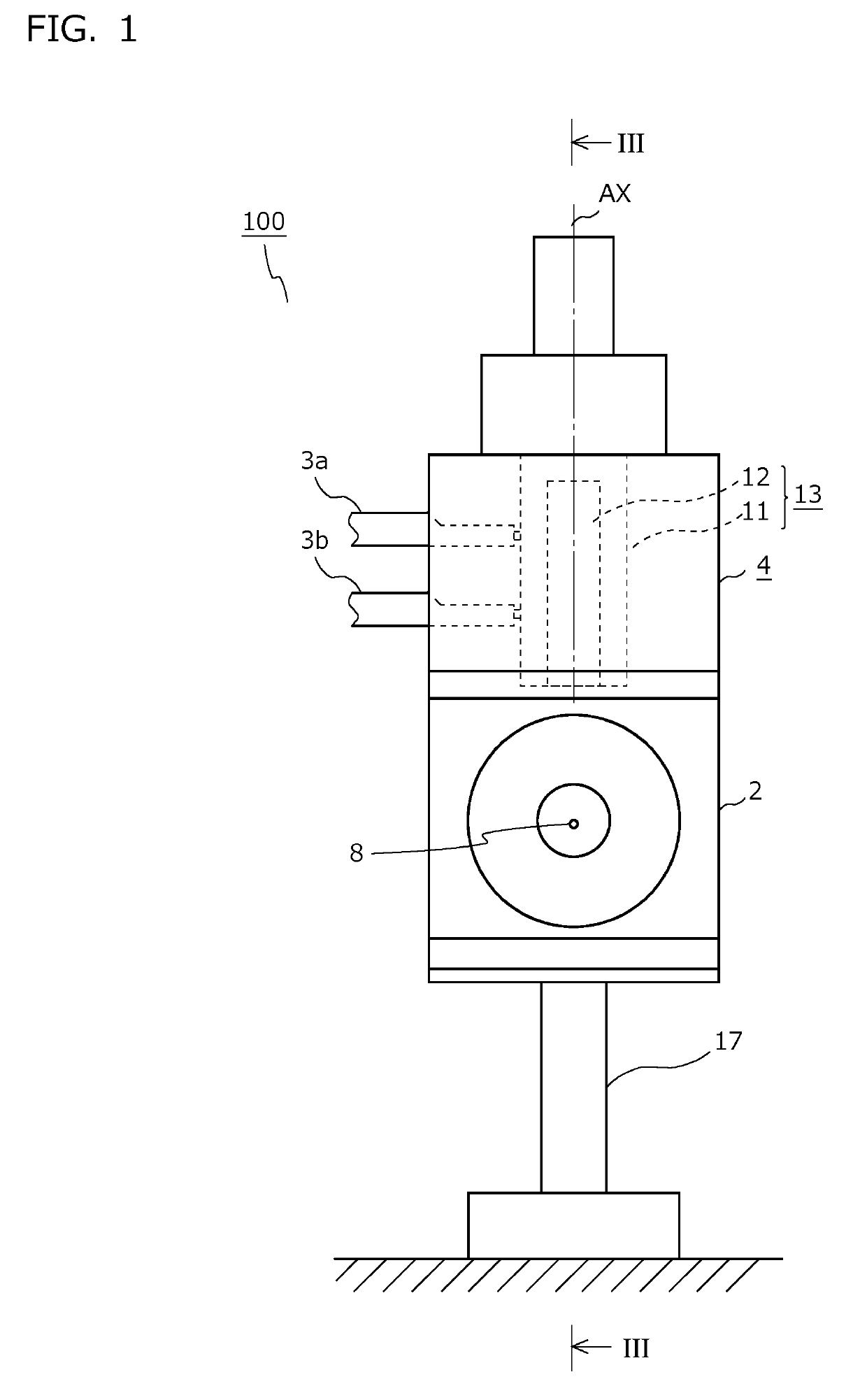

Flexible tube and production apparatus therefor

Provided is a production apparatus capable of producing a flexible tube whose hardness is naturally varied along the length direction thereof. This mixing valve includes: a first valve configured to distribute a first resin to a resin supply path and a resin discharge path; and a second valve configured to distribute a second resin to the resin supply path and the resin discharge path. In the mixing valve, the mixing proportion between the first resin and the second resin is increased or decreased in association with molding of the flexible tube, by changing a distribution ratio of the first resin in the first valve and a distribution ratio of the second resin in the second valve while keeping constant the total of the supply mounts of the first resin and the second resin supplied to a die.

Owner:PLA GIKEN

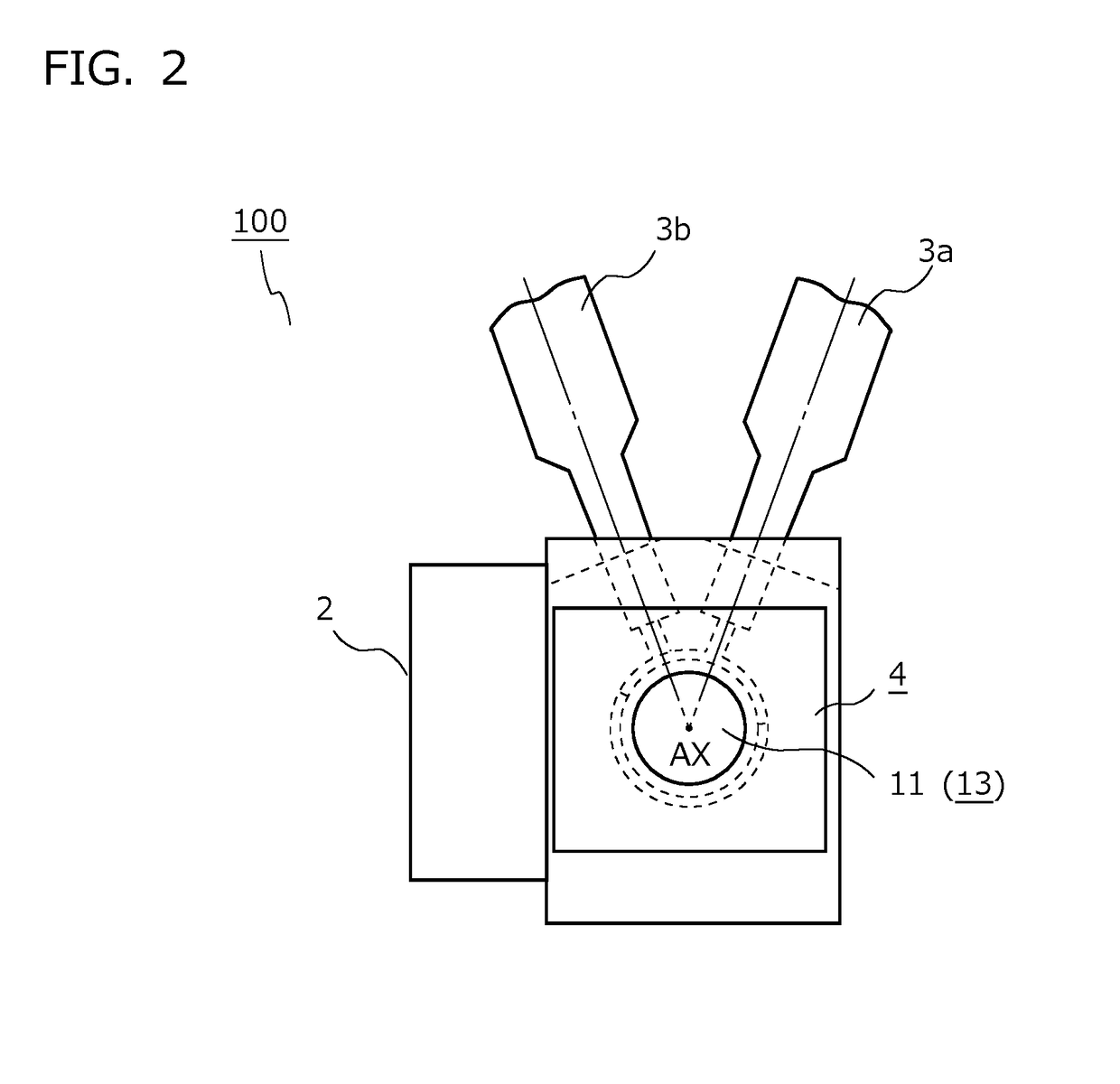

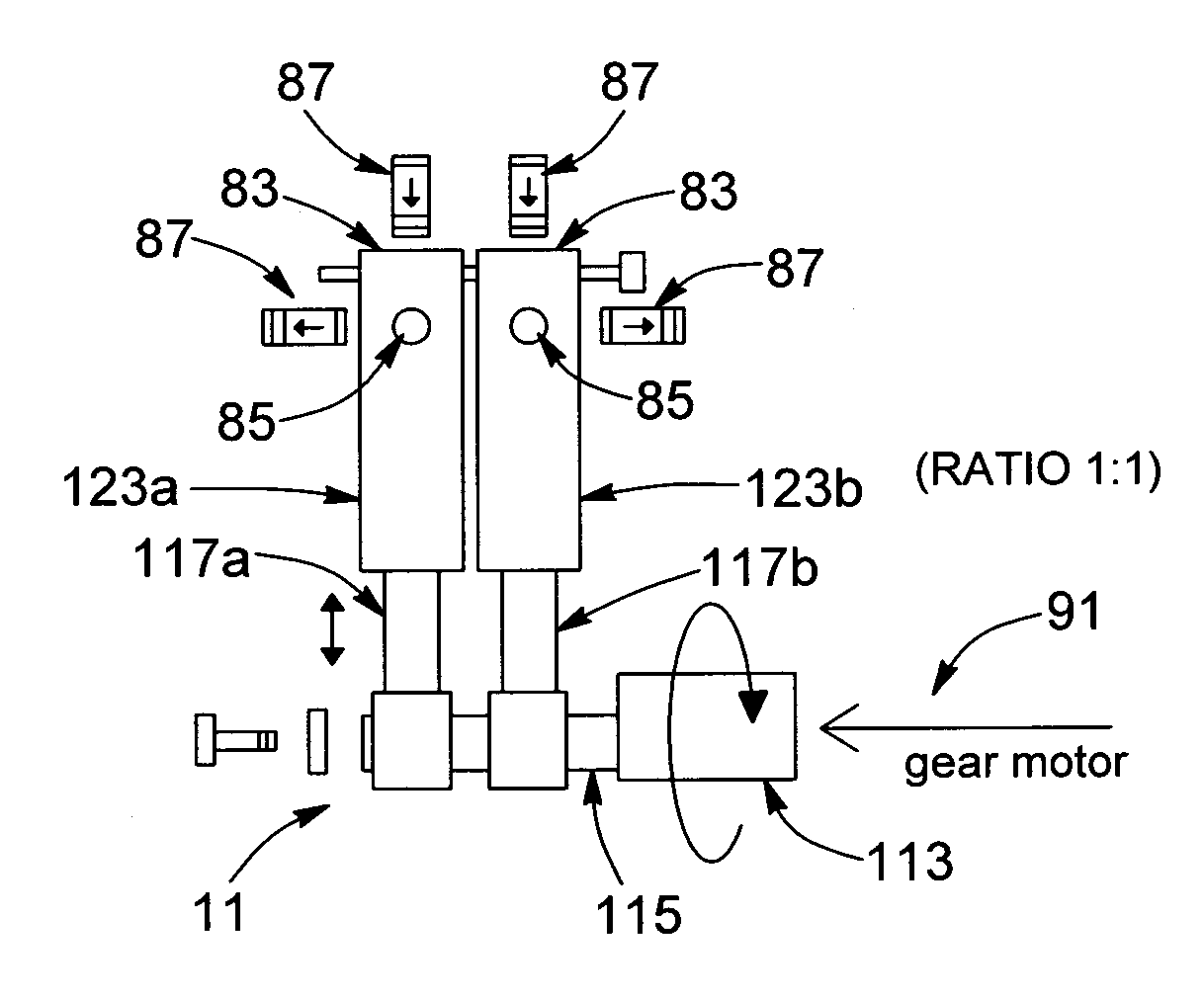

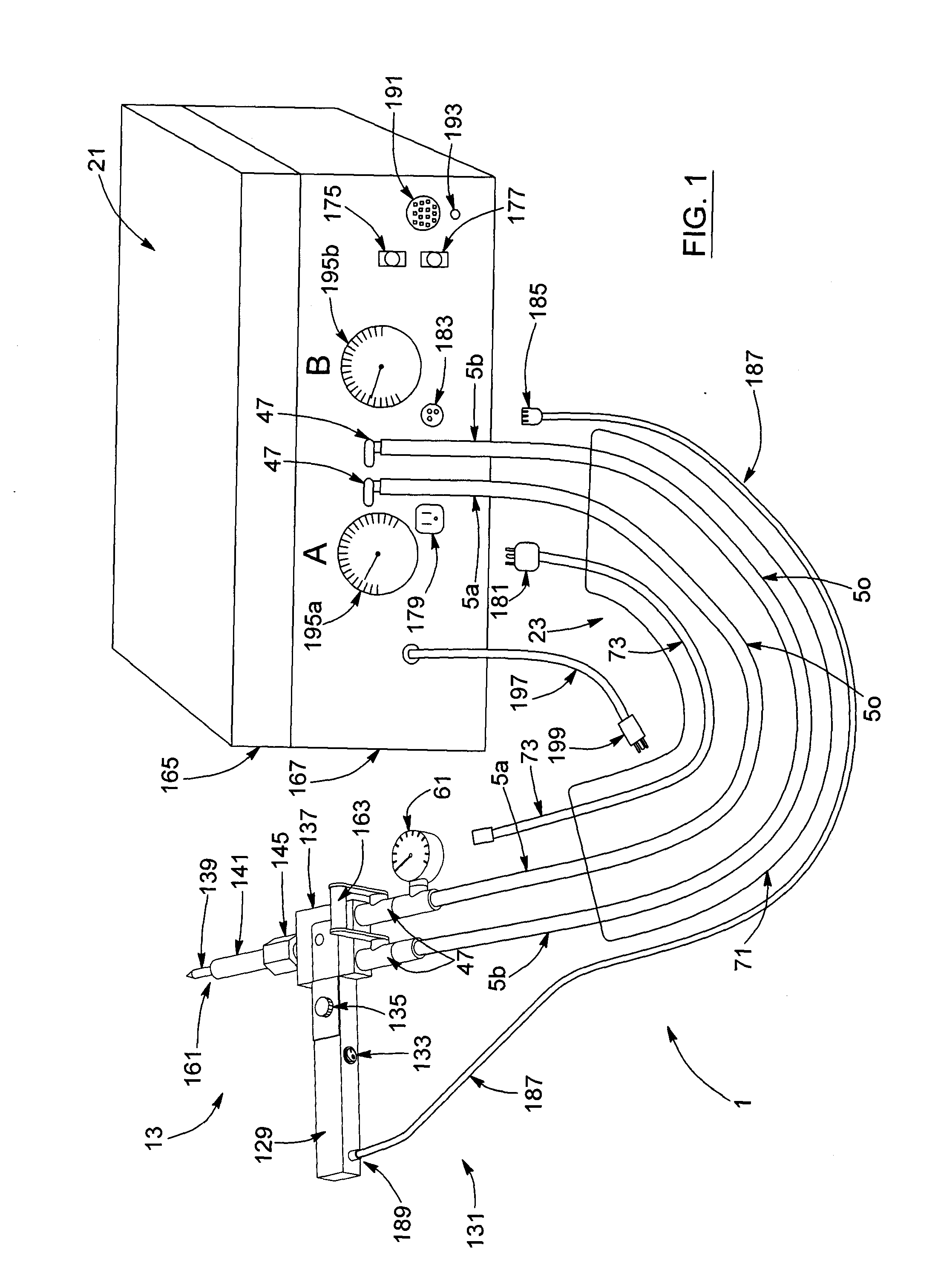

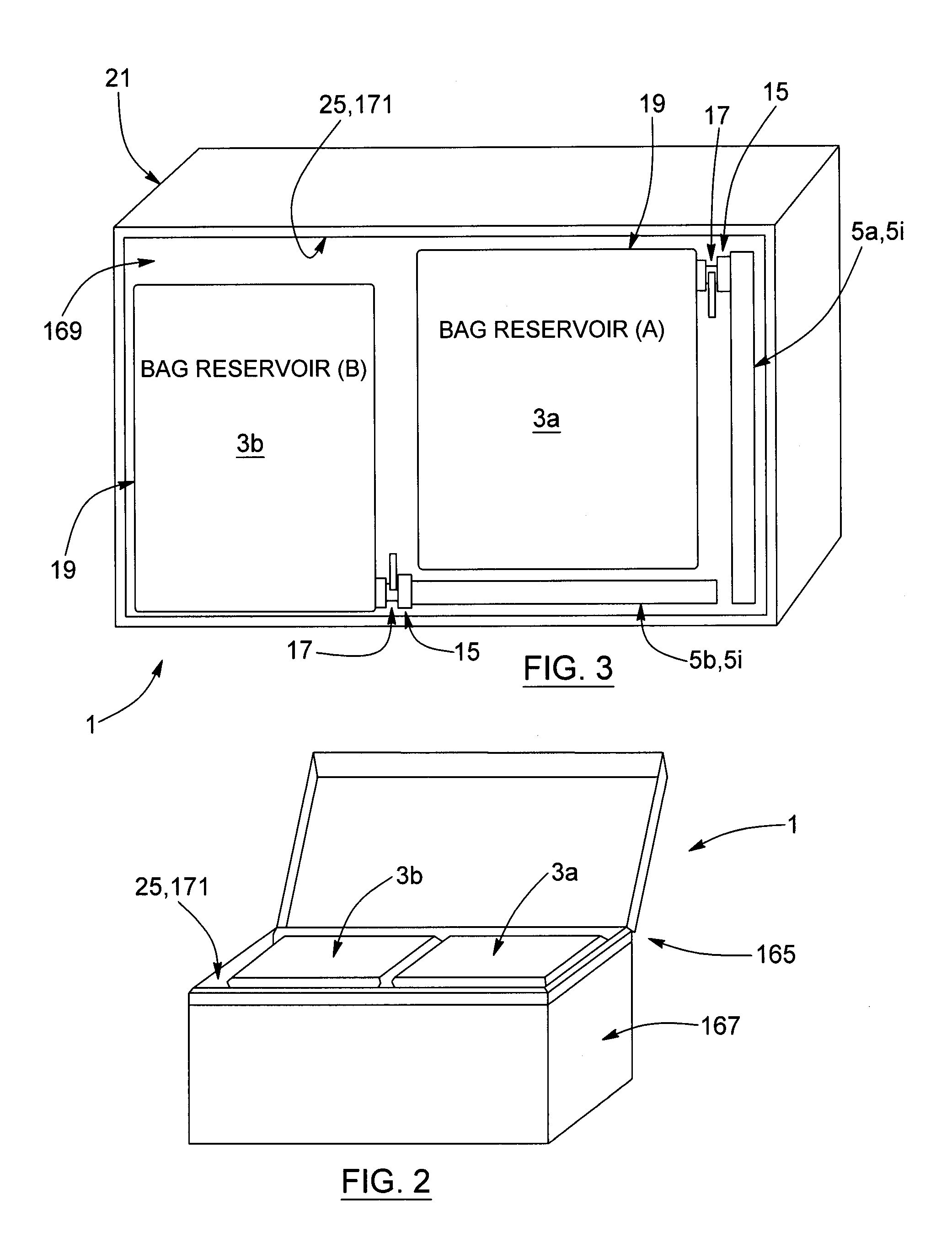

Resin distributor, reservoir bag to be used therewith, vehicle provided with such a system, kit for assembling the same, and methods of assembling and of operating associated thereto

InactiveUS20130025699A1Less clean upLess pressedRatio controlThin material handlingReservoir bagResin dispensing

A system for distributing resin, the system including at least one supply of resin, at least one conduit operatively connectable to a corresponding supply of resin, and at least one pump operatively connectable to each conduit for pumping resin from the corresponding supply of resin. The system also includes a driving assembly operatively connectable to each pump for driving the same, the driving assembly including a transmission assembly being adjusted specifically depending on the nature of resin to be pumped through each conduit by means of an appropriate transmission ratio. The system also includes a discharging assembly separate from the driving assembly and operatively connectable to each conduit for discharging resin out from the discharging assembly, the discharging assembly being also operatively connectable to the driving assembly for selectively and adjustably controlling operating parameters of each pump. Also described is a resin reservoir bag to be used for with the resin distributing system.

Owner:KIMCO PTE

Imprint apparatus and article manufacturing method

Owner:CANON KK

Vacuum-assisted resin transfer molding process with reusable resin distribution line

A method and apparatus for a reusable resin distribution line for use in conjunction with a resin transfer molding apparatus is disclosed. The apparatus includes a soft tool and a hard tool (i.e., mold). In the illustrative embodiment, two inflatable bladders are disposed on a side of the soft tool, wherein a bridge spans the bladders. The soft tool is coupled to the bridge. When the bladders are inflated, the bridge moves away from the hard tool, drawing the soft tool away from the hard tool in the region between the bladders. This creates a temporary passage or reusable resin distribution line for distributing resin to a reinforcement constituent disposed between the soft tool and the hard tool.

Owner:LOCKHEED MARTIN CORP

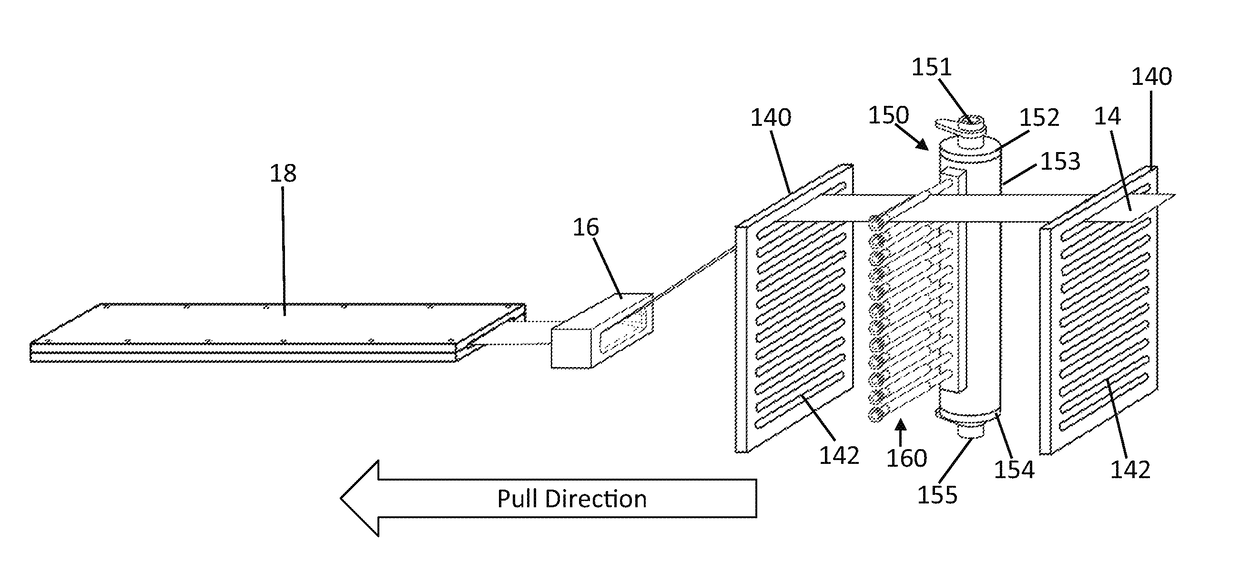

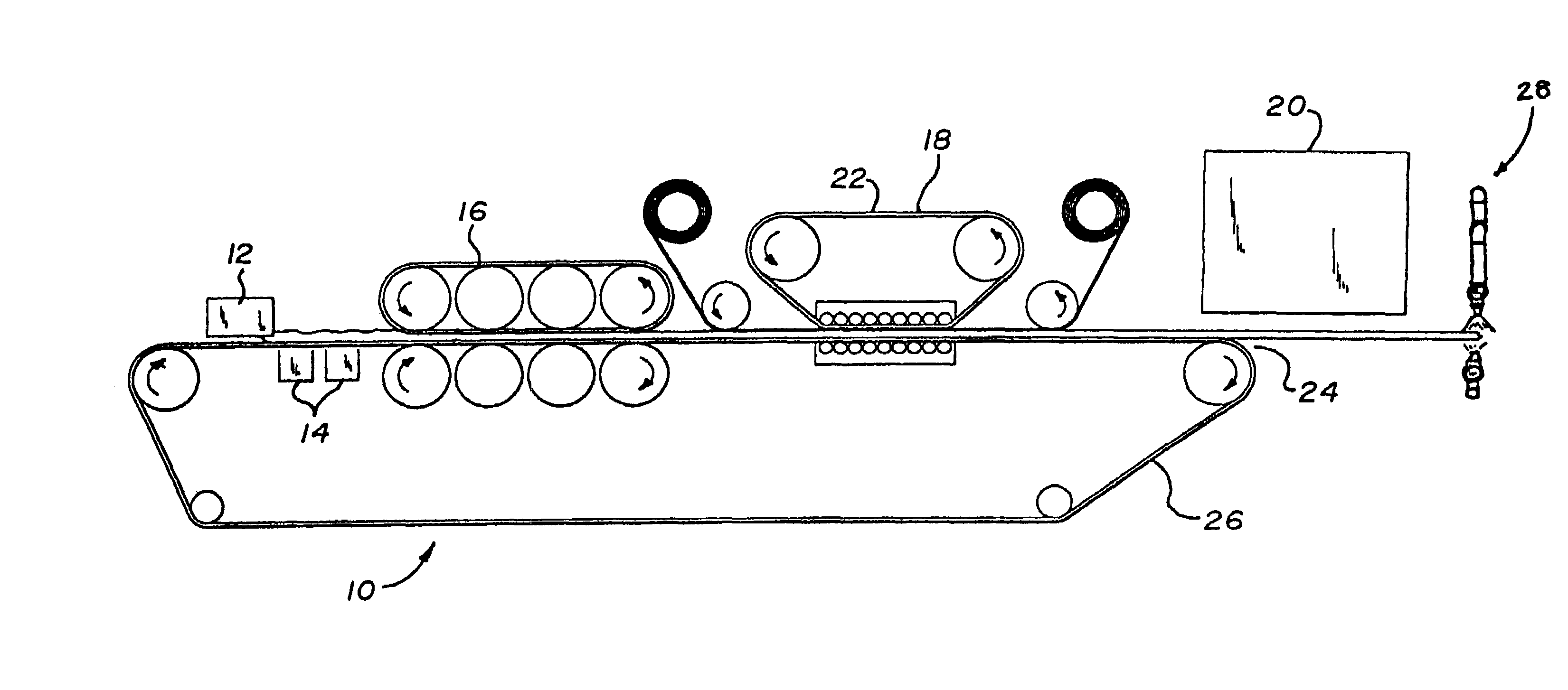

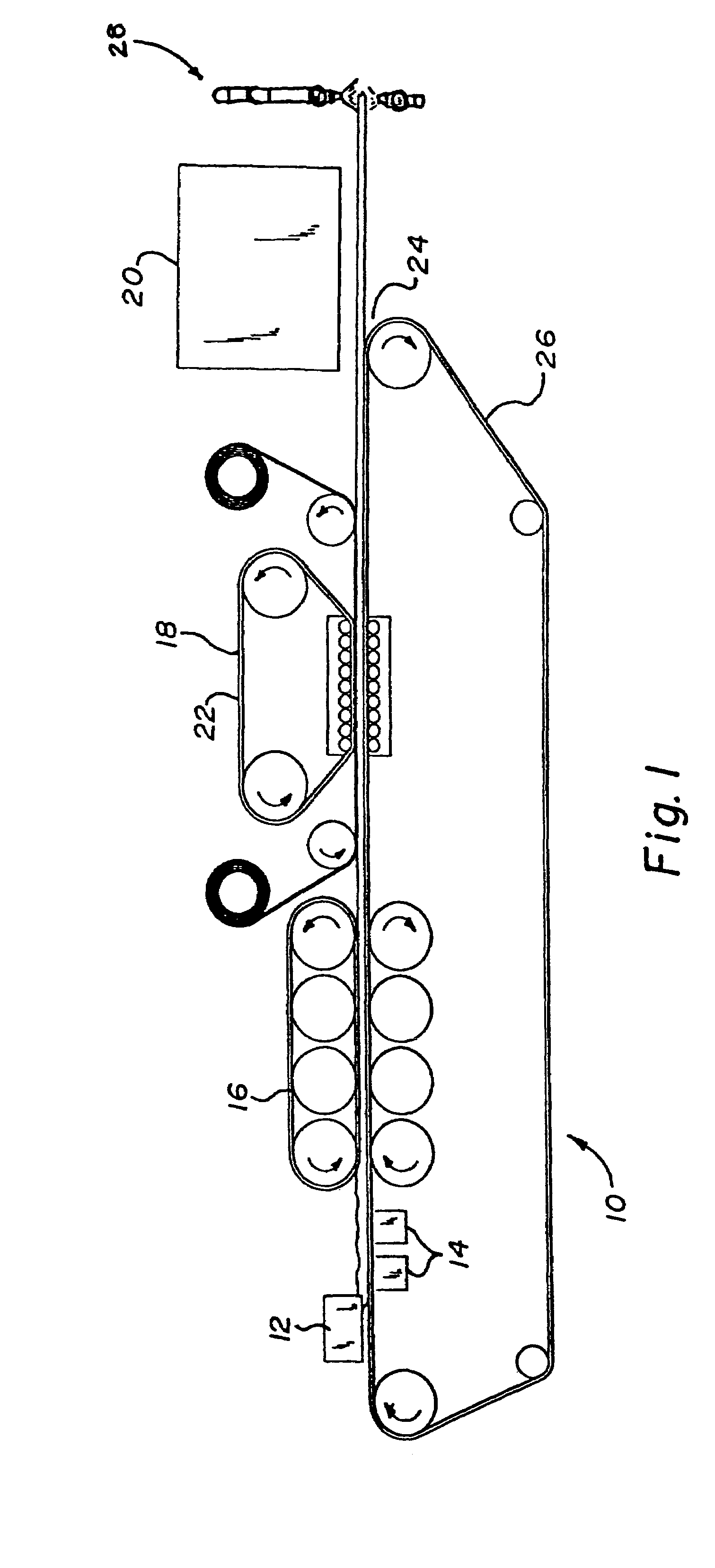

Composite friction elements and pultrusion method of making same

A system for continuous process manufacturing of composite friction units uses one or more array gates with a plurality of cutouts each sized to receive one of a plurality of reinforcing fiber fabric therethrough. The system also uses a resin plenum with plenum chamber and a plurality of dispensing tube assemblies. Each of the plurality of dispensing tube assemblies corresponds to a different cutout and includes dispensing bores positioned to dispense resin onto one of the reinforcing fiber fabrics. The system also uses a forming die that receives the reinforcing fiber fabrics with the resin to form a composite panel as they pass through the forming die.

Owner:BOOHER BENJAMIN V

Cellulose gypsum based substrate with increased water resistance and strength by surface application of polymeric diphenylmethane diisocyanate

InactiveUS7309516B2Increase resistanceHigh strengthPretreated surfacesCleaning machinesCelluloseResin dispensing

The disclosed invention consists of an improved gypsum based, cellulosic containing board and method for applying a resin to an untreated board at a spray station where pMDI resin is sprayed onto the front and back side of the board. A resin distribution system is used to supply the spray nozzles with pMDI. Optionally, a second spray station is included, if desired, to add additional pMDI resin over the surface of the board to achieve complete coverage. The improvement is an increased water resistance and flexural strength.

Owner:UNITED STATES GYPSUM CO

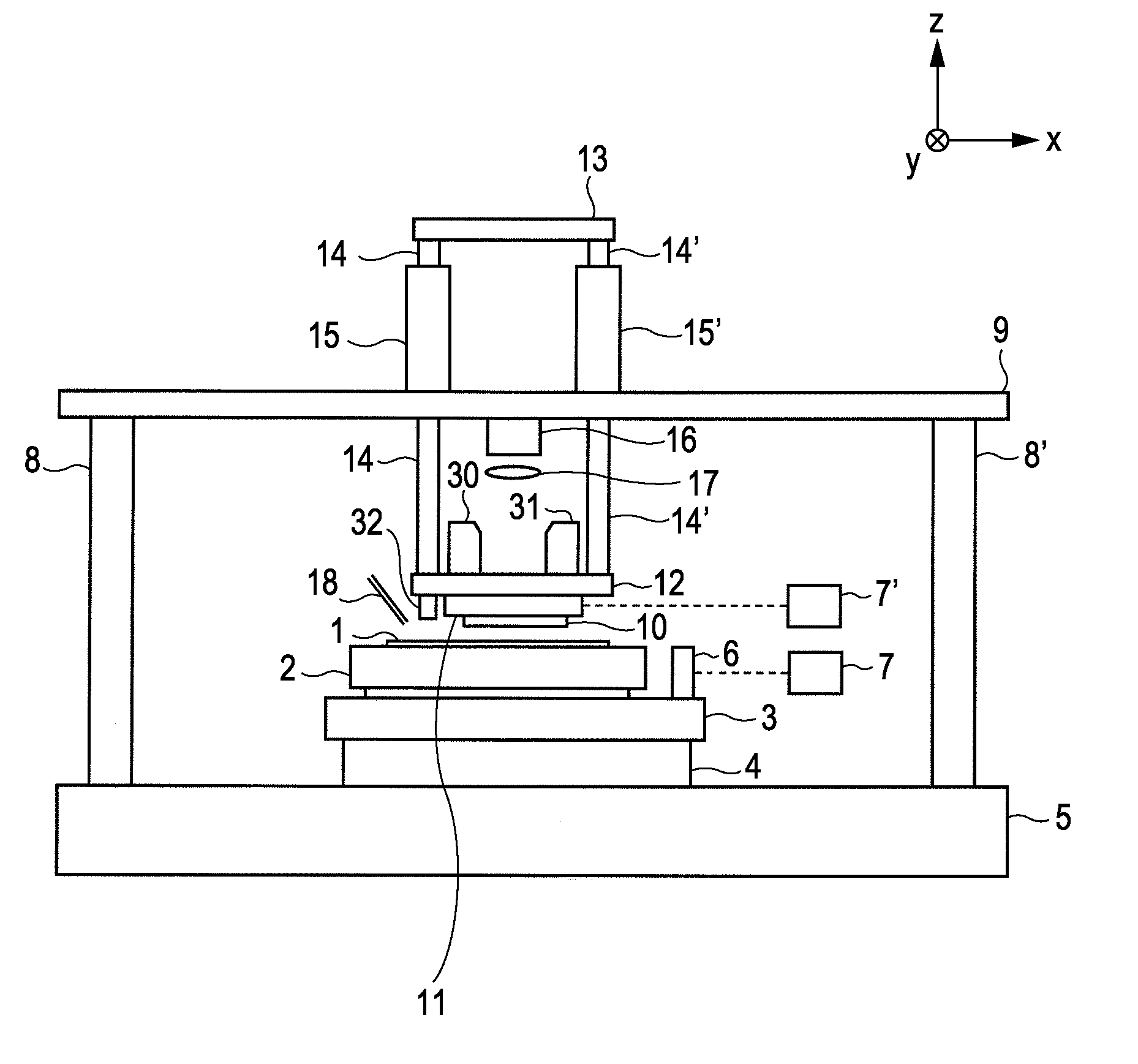

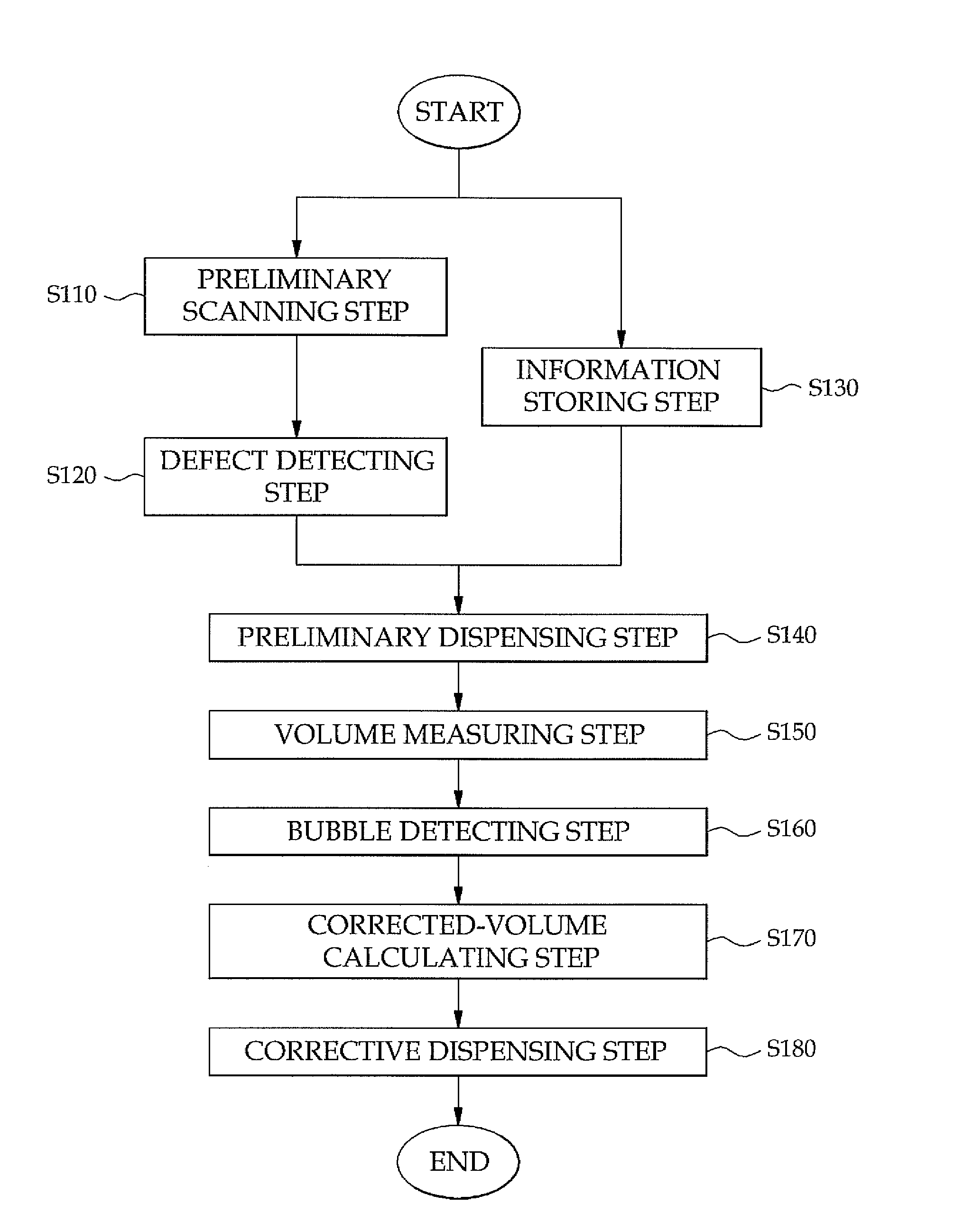

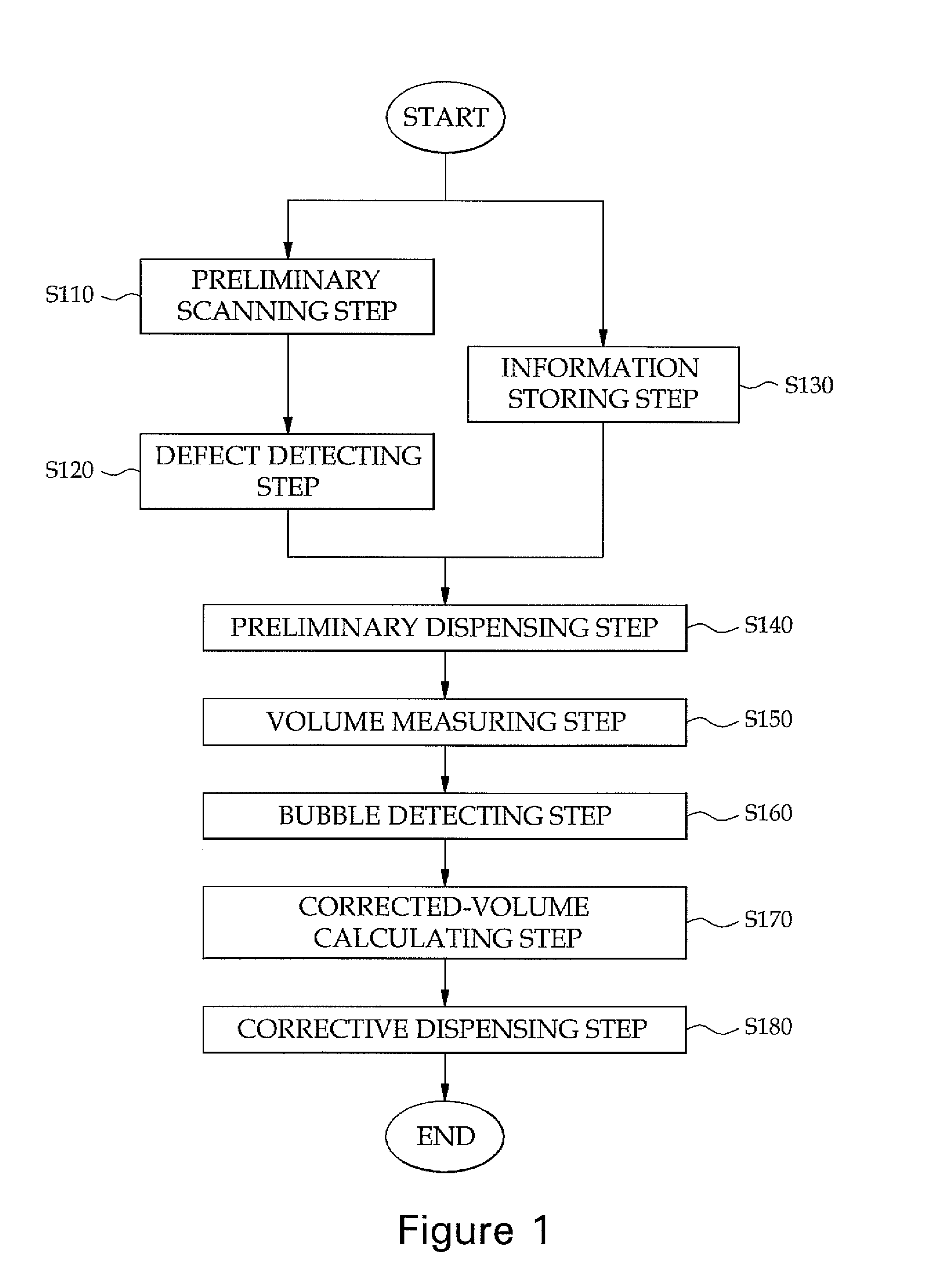

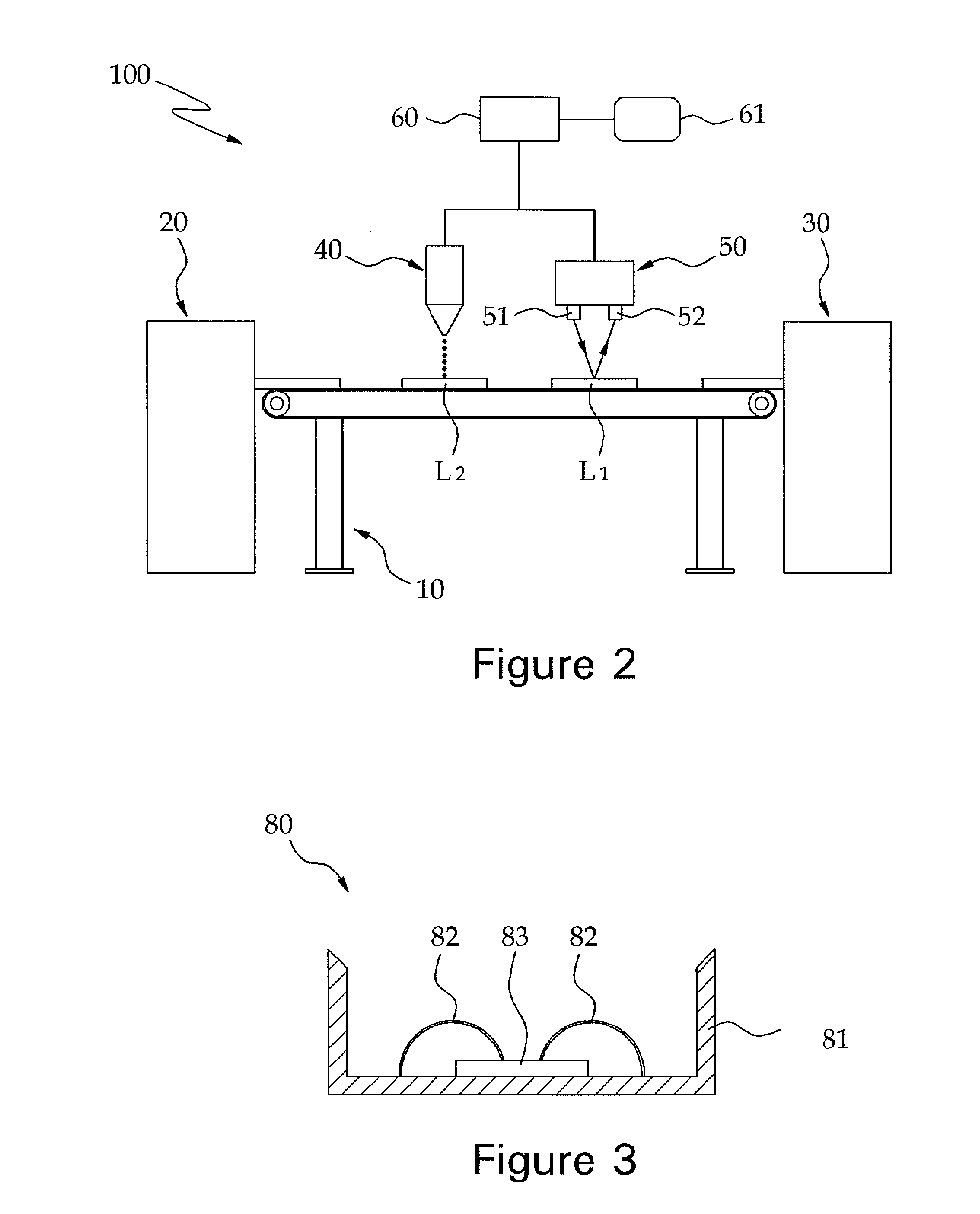

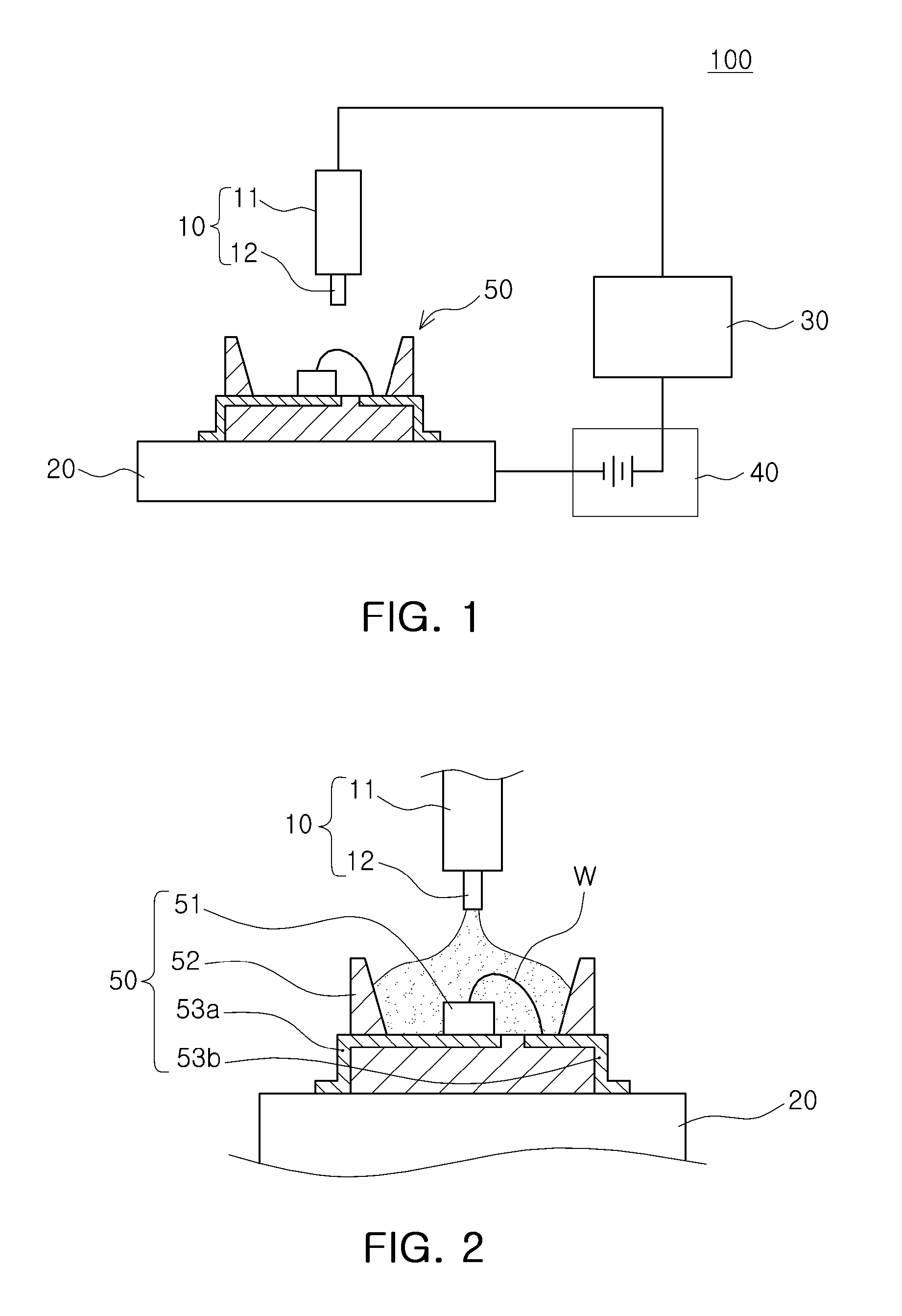

Volume-based dispensing control method

ActiveUS20100327468A1Easy to controlQuick measurementSemiconductor/solid-state device detailsSolid-state devicesResin dispensingDistribution control

A volume-based dispensing control method is capable of enabling a pump to dispense a resin with greatly increased accuracy. The method includes: a preliminary dispensing step in which a resin is dispensed on one or more workpieces with a pump; a volume measuring step in which the workpieces passed through the preliminary dispensing step is scanned by an optical scanner to measure a dispensed resin volume; a corrected-volume calculating step in which a corrected volume of the resin to be additionally dispensed is calculated by using a difference between the dispensed resin volume measured in the volume measuring step and a predetermined dispensing volume; and a corrective dispensing step in which the resin is dispensed on the workpieces in light of the corrected volume calculated in the corrected-volume calculating step.

Owner:PROTEC CO LTD

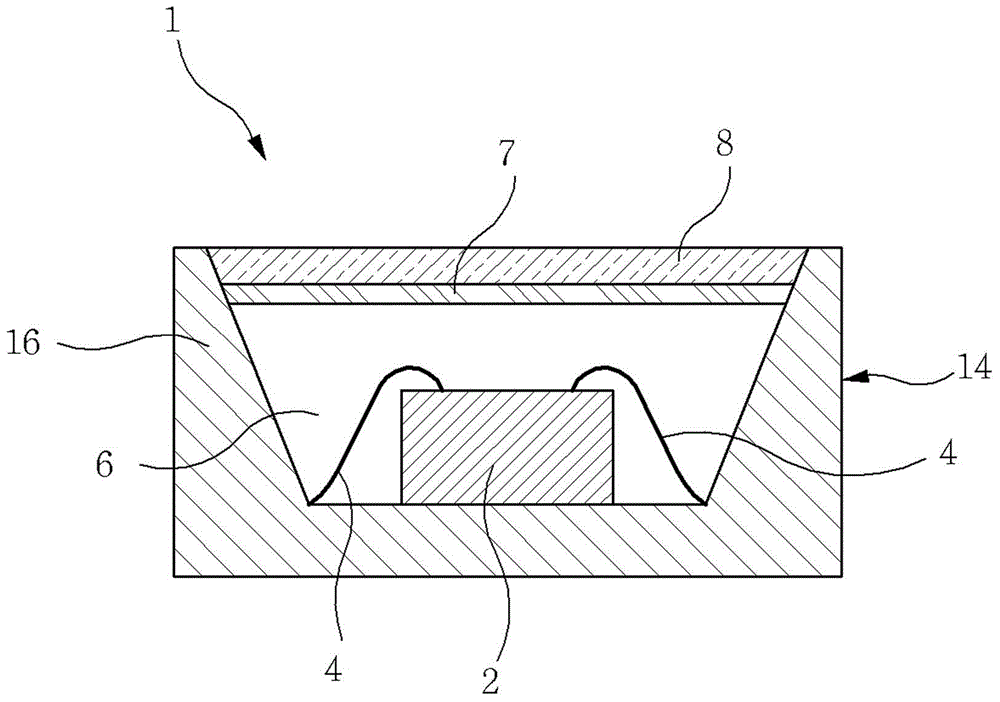

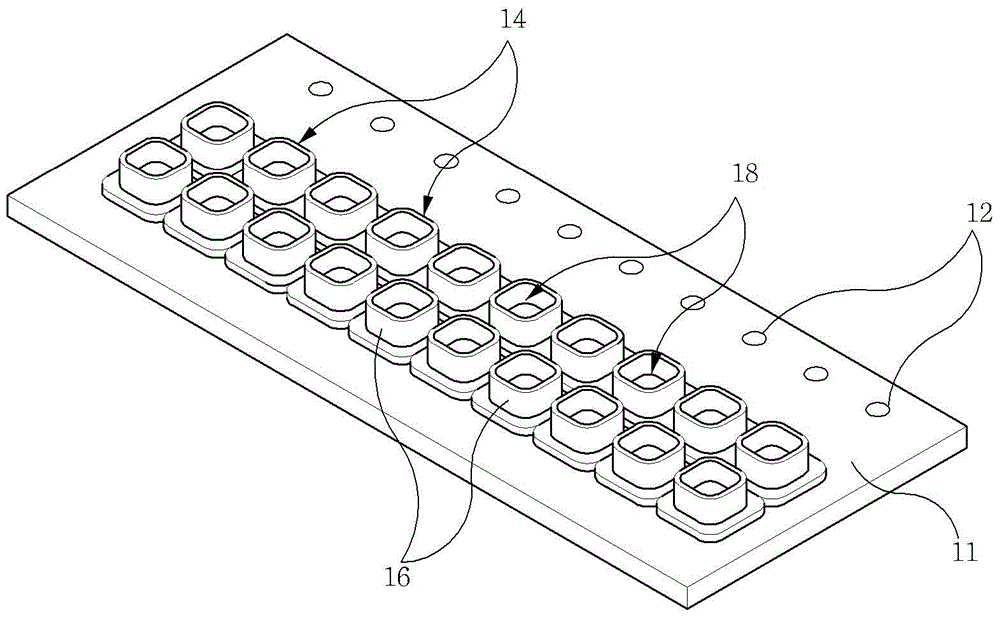

Apparatus and method for fabricating semiconductor chip package with film attached on

InactiveCN104377277AIncrease production capacityImprove yieldSemiconductor/solid-state device detailsSolid-state devicesResin dispensingSemiconductor chip

The invention relates to an apparatus and a method for fabricating a semiconductor chip package with a film attached on. In particular, the invention provides an LED package with a fluorescent film attached on, an apparatus for fabricating the semiconductor chip package with a film attached on and a method for fabricating the semiconductor chip package. The apparatus comprises a lead frame loading unit for loading lead frames sequentially, resin dispensing units for sealing, a thin film stage, a thin film attaching unit and a lead frame unloading unit. The resin dispensing units are used for injecting sealing resin on the lead wire frameworks and formed on chip receiving parts of the lead frames in a sealed manner. In a thin film stage, fluorescent film slices are moved to a pickup position in order. Via the thin film attaching unit, after being absorbed, the fluorescent film slices in a material receiving position are attached to the resin for sealing of the lead frames. After the lead frames passing through the thin film are unloaded, the lead frame unloading unit recovers the action.

Owner:人科机械有限公司

Resin dispenser for nano-imprint

InactiveUS20150108688A1Reduce dispensing timeLiquid surface applicatorsPhotomechanical apparatusResin dispensingEngineering

Owner:SAMSUNG ELECTRONICS CO LTD +1

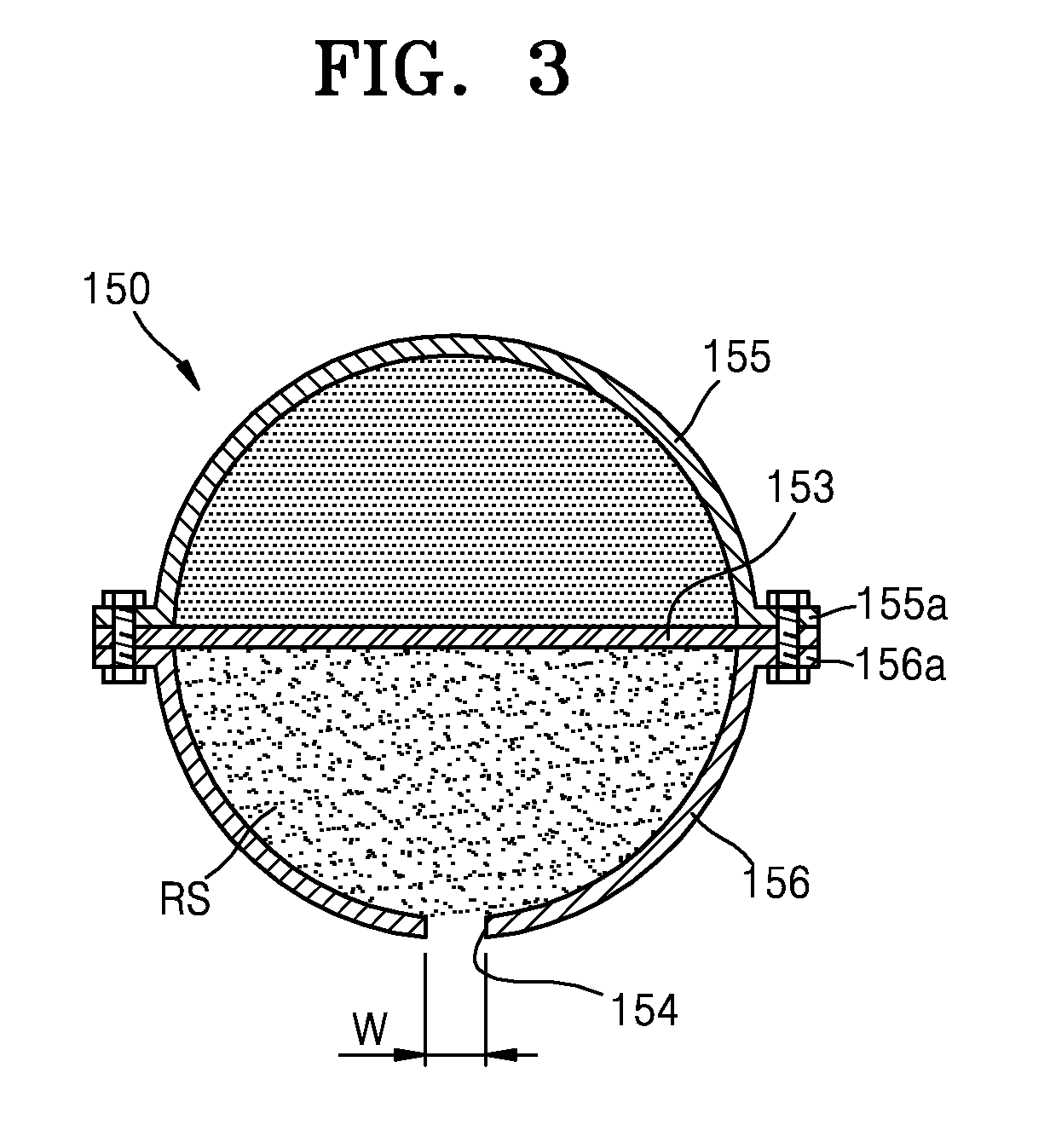

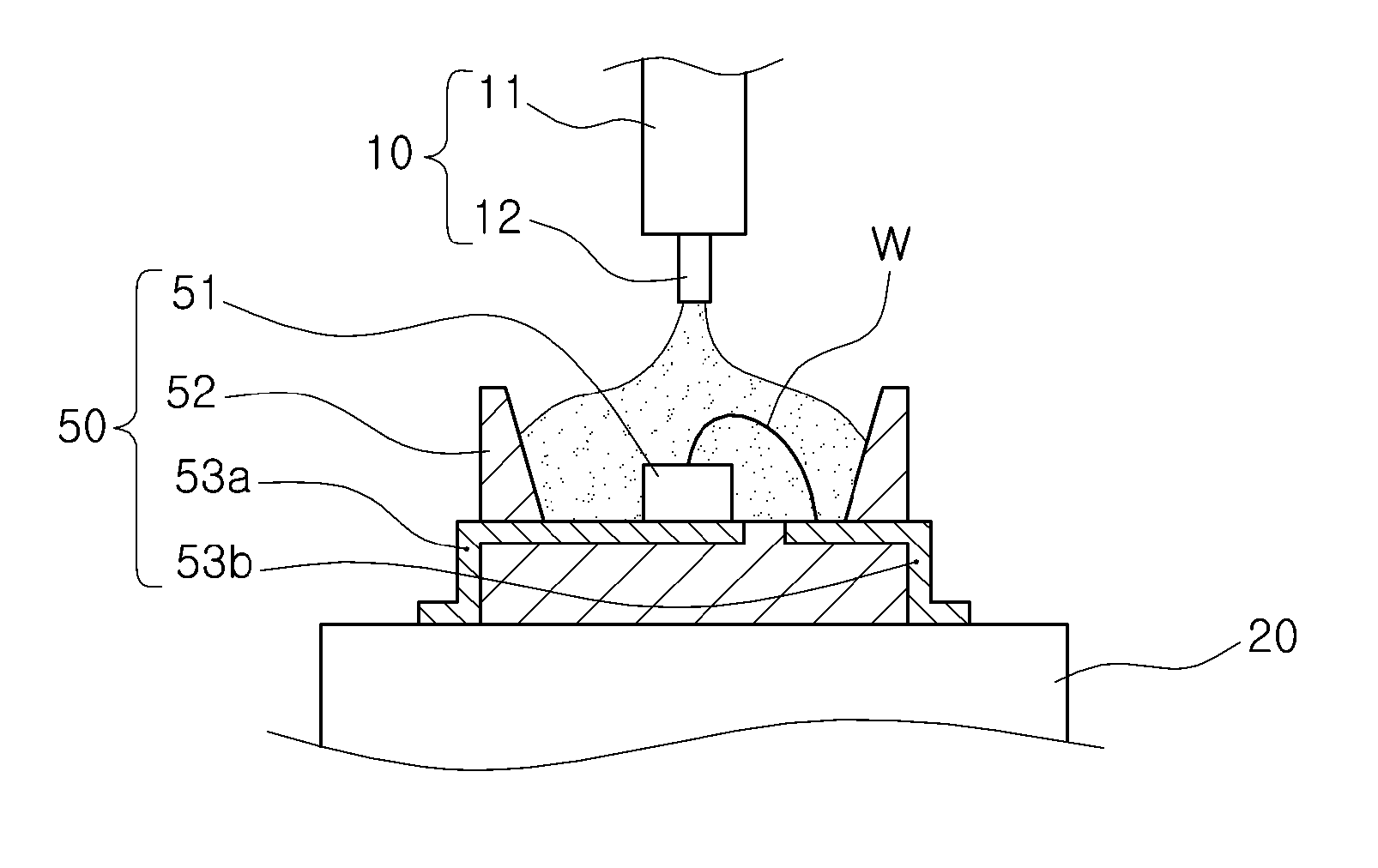

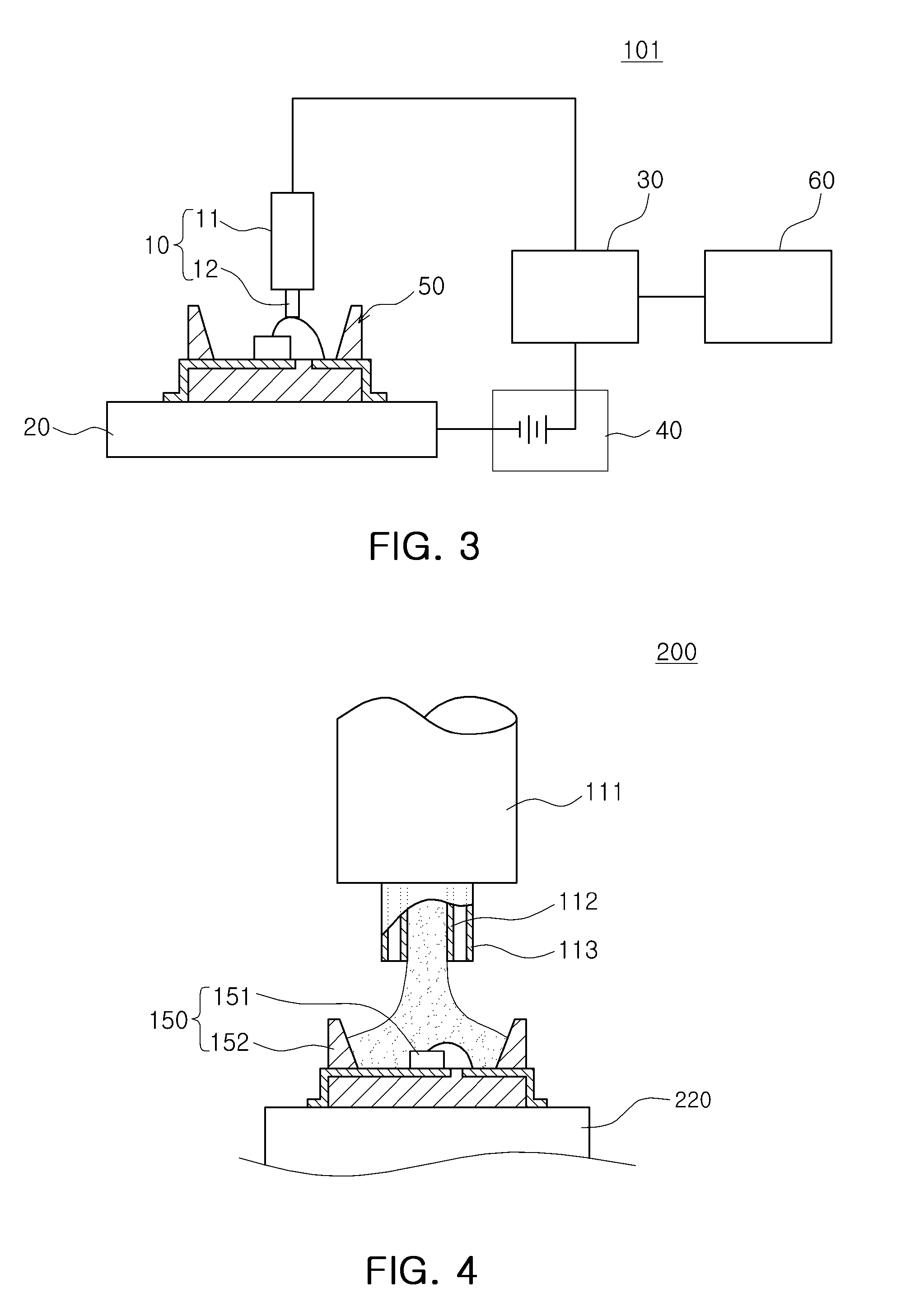

Resin dispensing apparatus for light emitting device package and method of manufacturing light emitting device package using the same

ActiveUS20120129281A1Improve reliabilitySemiconductor/solid-state device testing/measurementSolid-state devicesResin dispensingEngineering

There is provided a resin dispensing apparatus for a light emitting device package and a method of manufacturing a light emitting device package using the same. The resin dispensing apparatus includes a resin dispensing part including a resin storage portion filled with a resin therein and a resin discharge portion combined with the resin storage portion and discharging the resin therefrom; a supporting part having a light emitting device package disposed on an upper surface thereof and electrically connected to the light emitting device package; a voltage applying part having both terminals respectively connected to the resin dispensing part and the supporting part to apply a voltage thereto; and a sensing part electrically connected to the resin dispensing part and the supporting part individually and sensing a contact between the resin dispensing part and the light emitting device package with an electrical signal.

Owner:SAMSUNG ELECTRONICS CO LTD

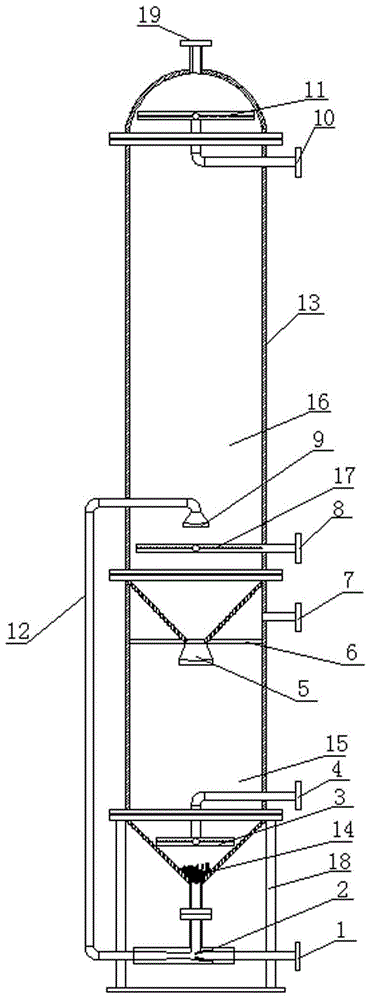

Continuous synchronous adsorption-regeneration softener

InactiveCN105692769AEmission reductionReduce pollutionWater/sewage treatment by ion-exchangeWater/sewage treatment apparatusWater softeningContinuous/uninterrupted

The invention discloses a continuous synchronous adsorption and regeneration softener, which comprises a cylinder body with ion exchange resin inside, legs are arranged at the bottom of the cylinder body, the upper part of the inner chamber of the cylinder is an adsorption chamber, and the lower part is a regeneration chamber; The upper part is connected with a soft water collecting device; the lower part of the adsorption chamber is provided with a resin distribution device 1, and the bottom of the adsorption chamber communicates with the regeneration chamber below the adsorption chamber through the resin distribution device 2; the upper side of the regeneration chamber communicates with the hard water outlet; the regeneration chamber The lower part is provided with a regeneration agent distribution device; the bottom of the regeneration chamber communicates with the resin mixing device through a pipeline; one end of the resin mixing device communicates with the hard water inlet through a pipeline, and the other end communicates with the resin delivery pipeline outside the cylinder, and the top of the resin delivery pipeline is connected with the The resin distribution device is connected. The invention can realize simultaneous resin adsorption and resin regeneration for water with high hardness, can continuously and uninterruptedly soften the incoming water, and can greatly save the amount of ion exchange resin.

Owner:SHANDONG AMS ENVIRONMENTAL

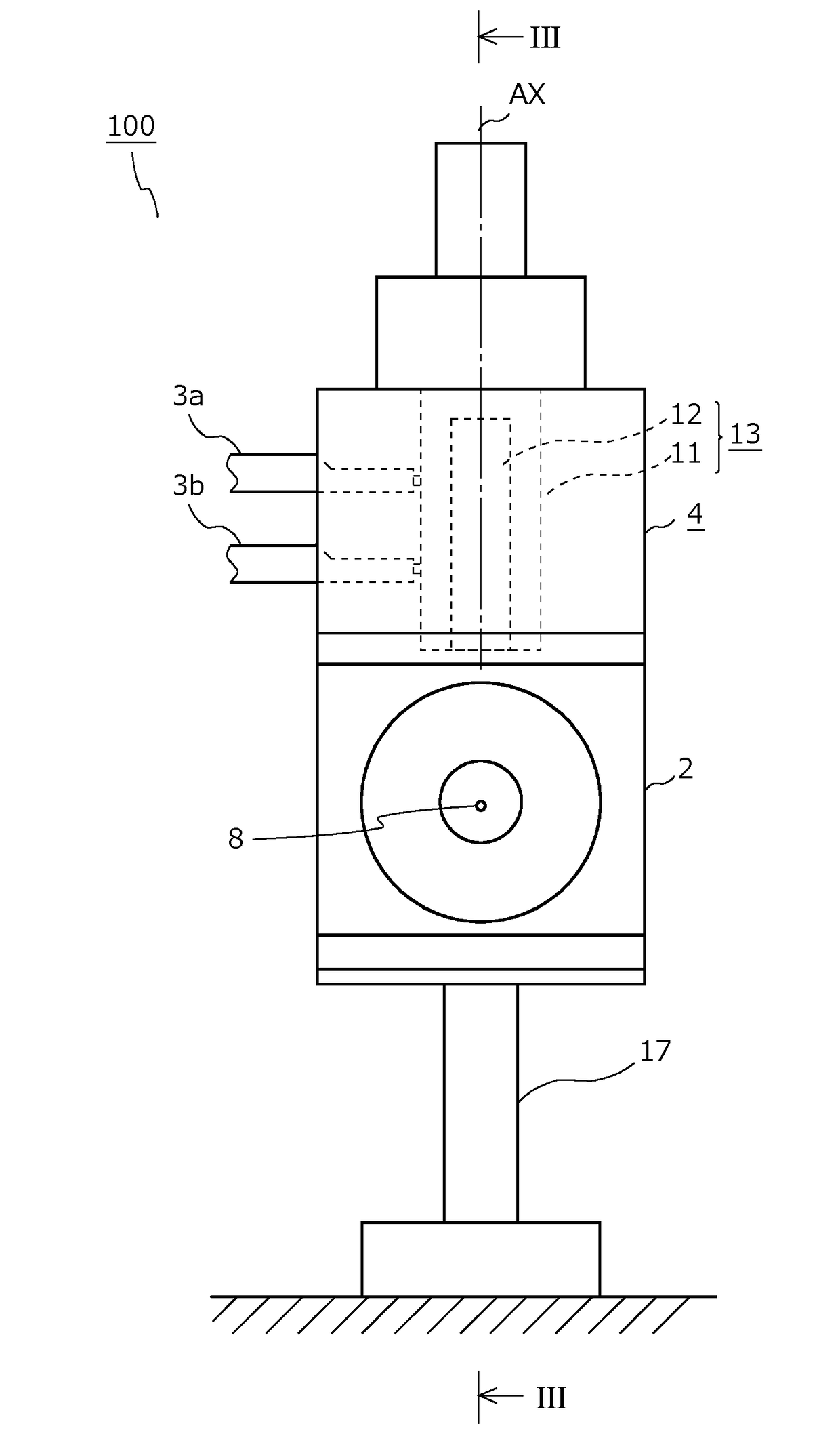

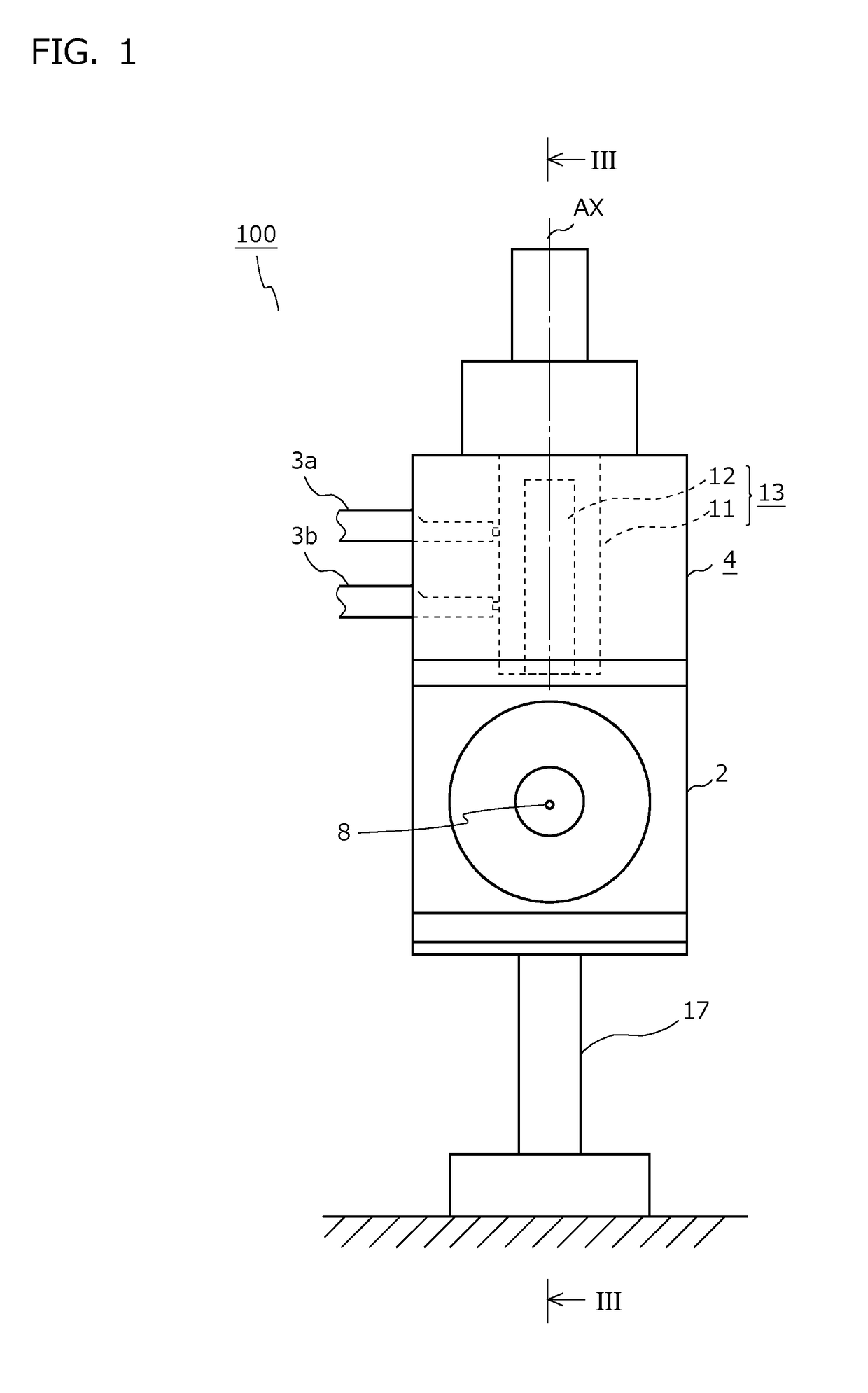

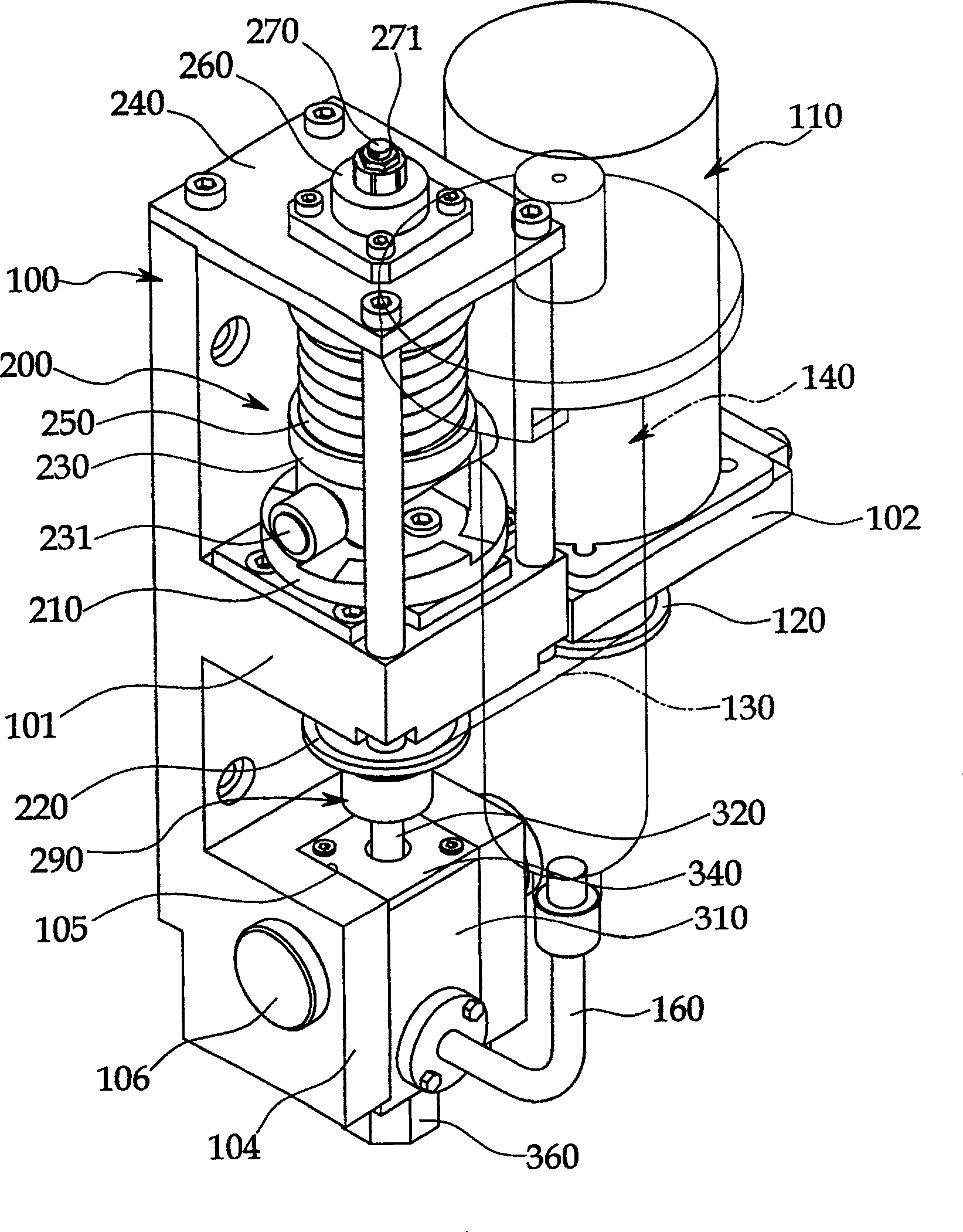

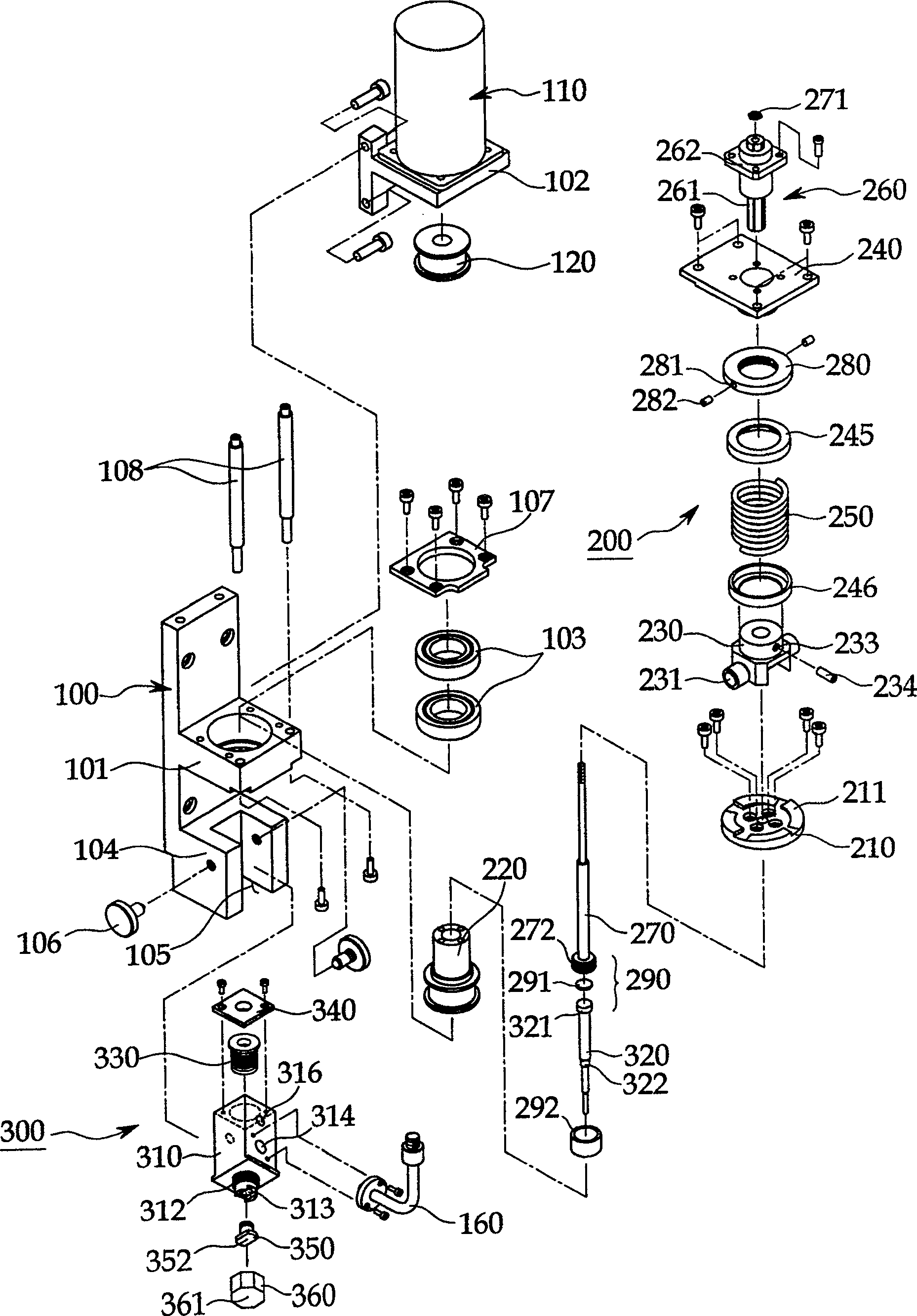

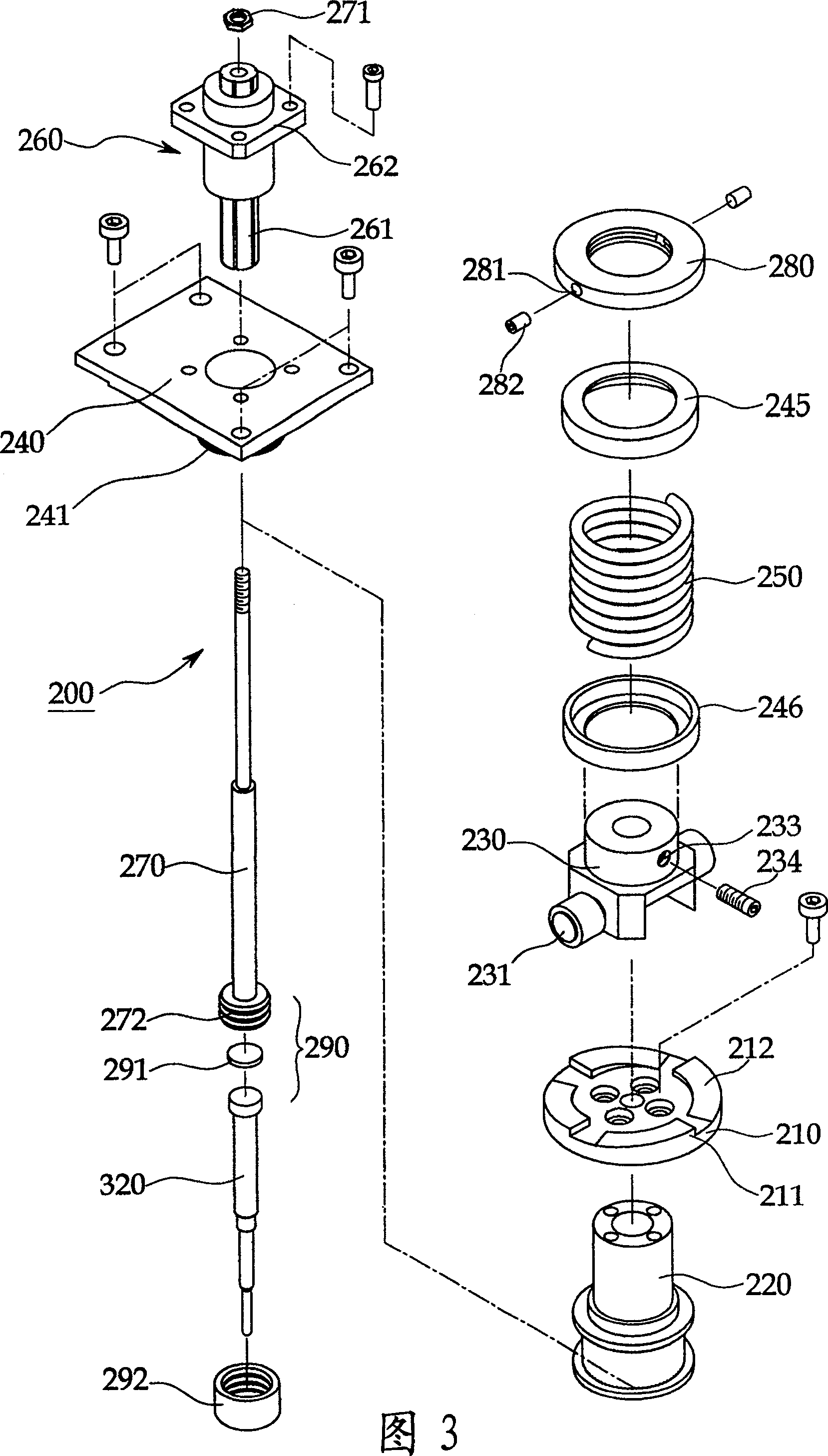

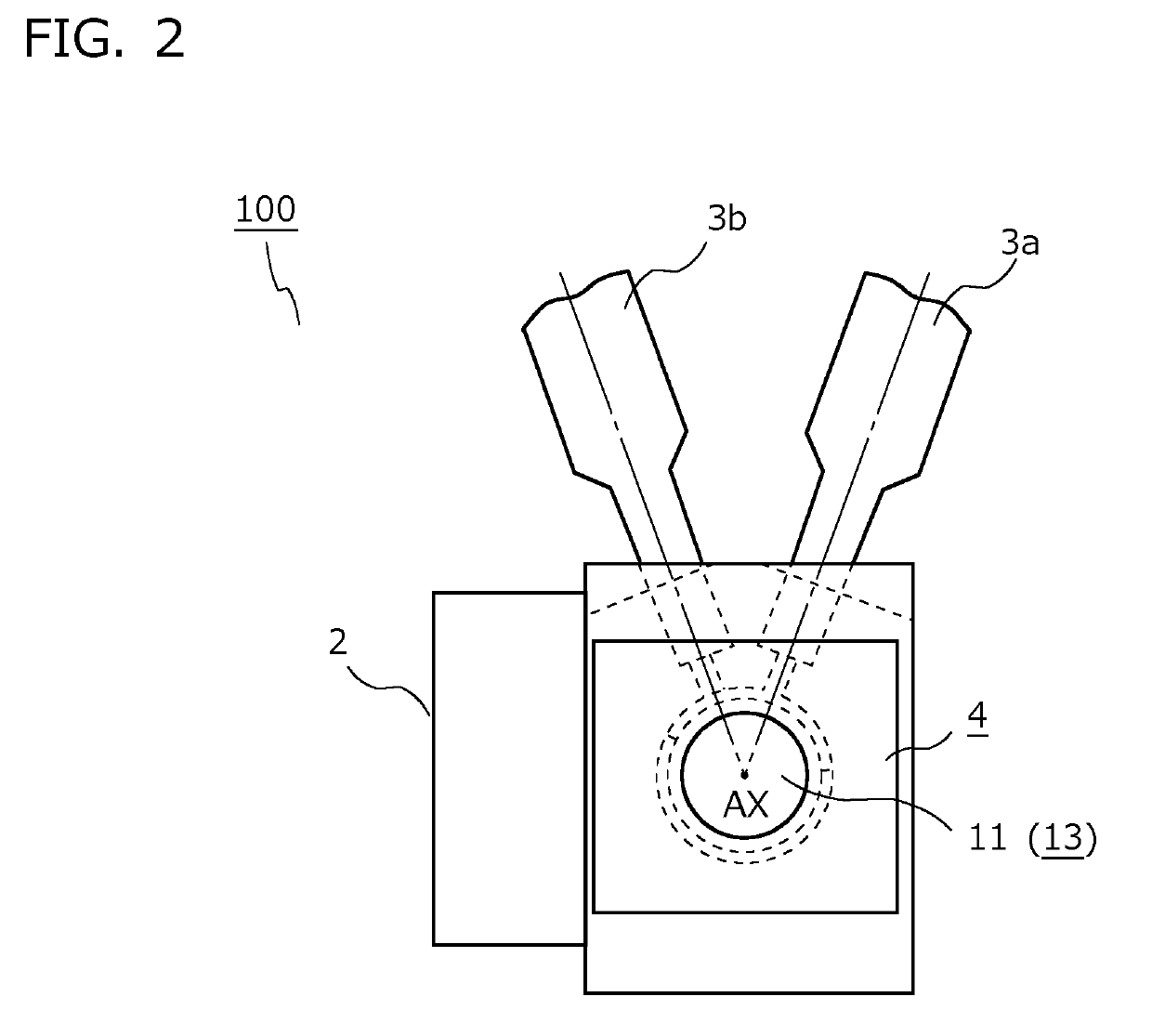

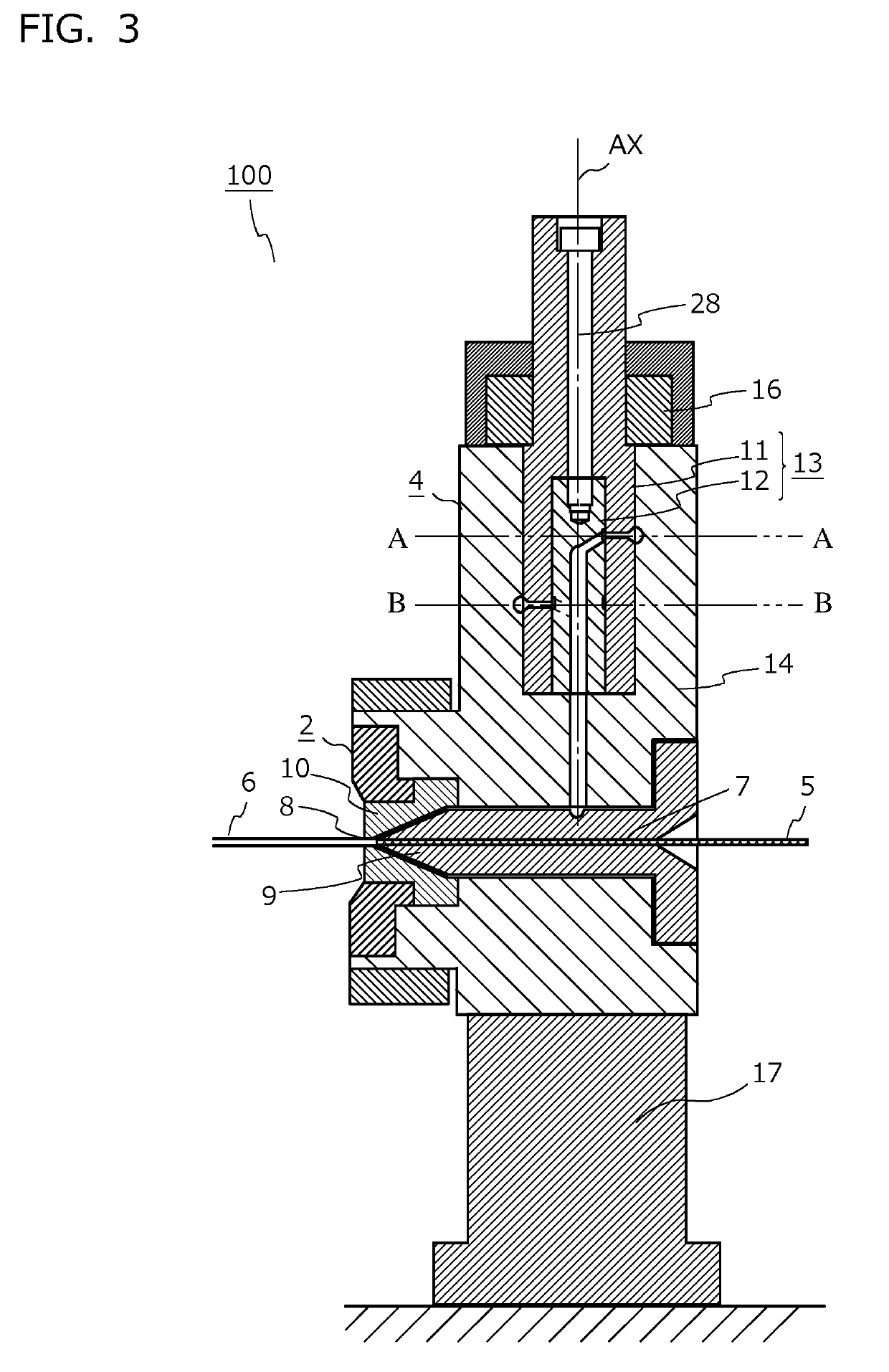

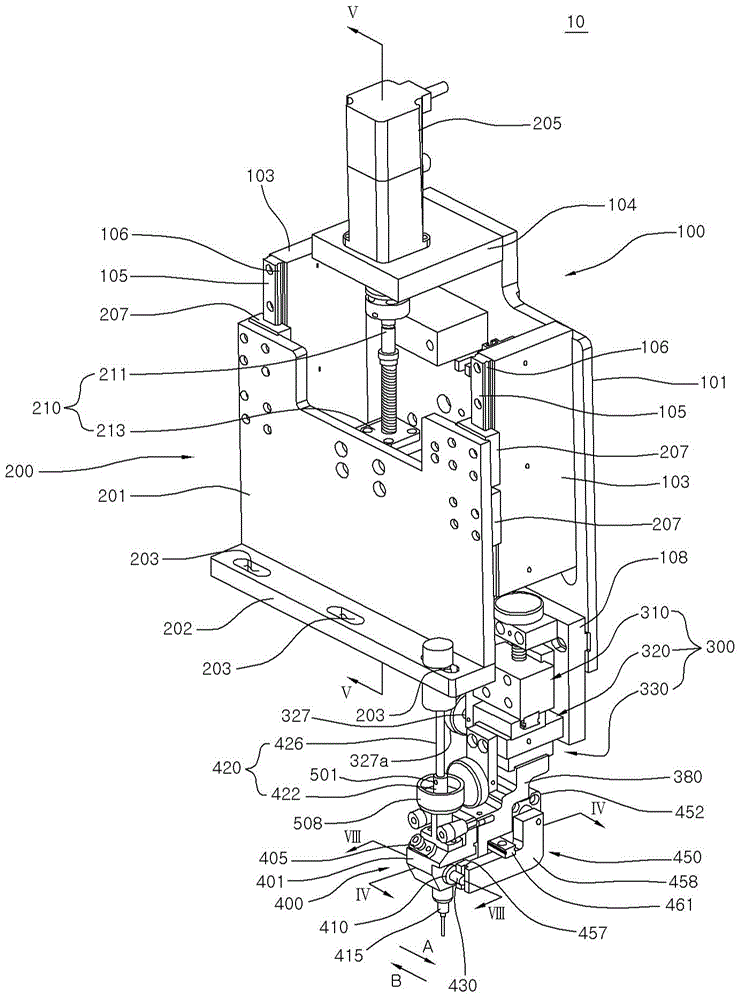

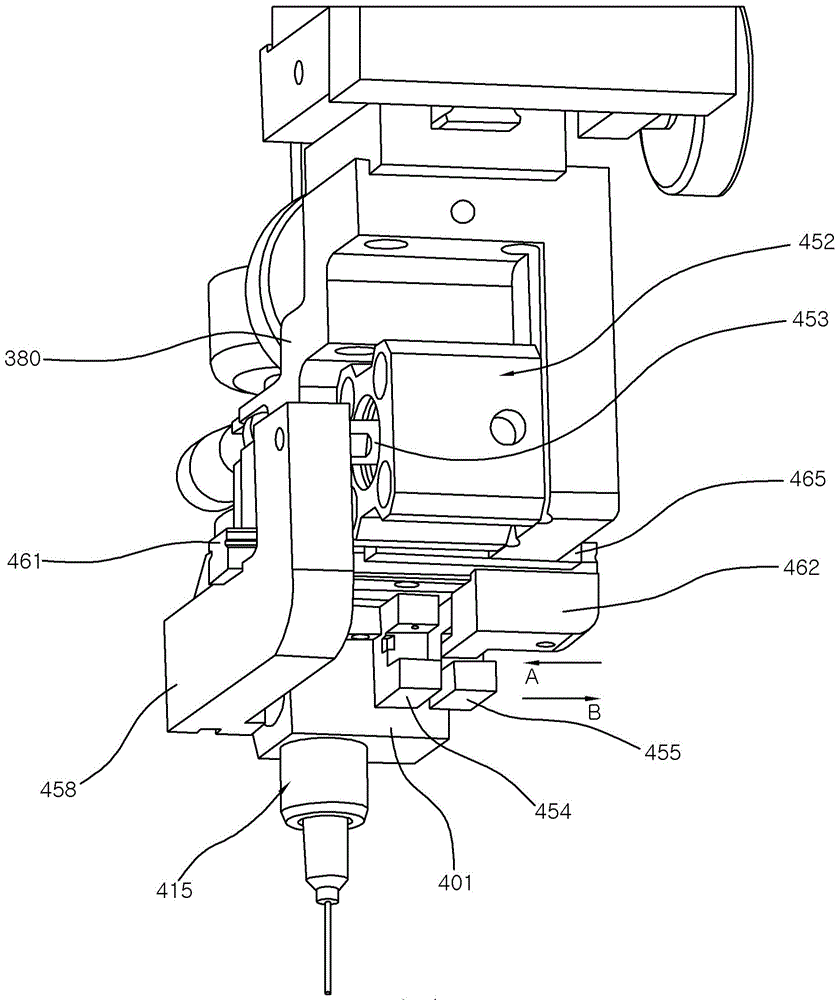

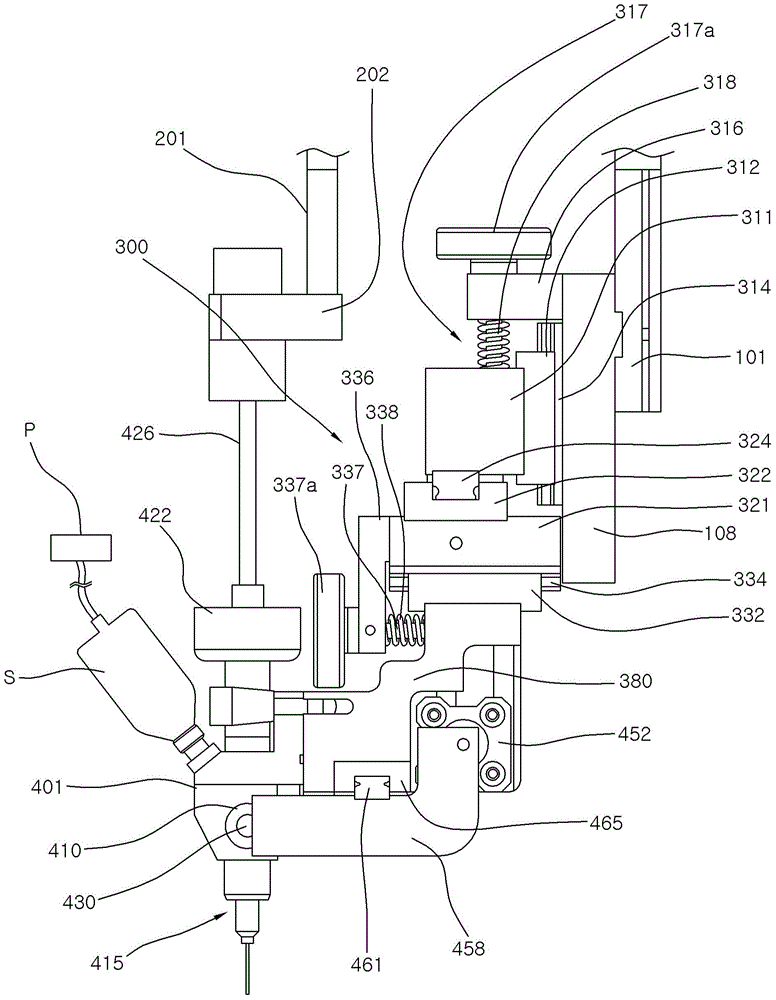

Resin distributing device

ActiveCN100502620CPromote decompositionEasy to assemblePrinted circuit assemblingLiquid surface applicatorsResin dispensingEngineering

Providing a resin dispensing device with a simple structure and to be adapted in various fields of applications, which allows easy assembly and integration with maintenance, replacement and component cleaning equipment, reduction of replacement cost, applications not related to resin and easy inspection of nozzle state, thereby optimizing reliability of the device. A resin dispensing device consisting of: a robotic assembly with conventional driving heads capable of moving along X-Y-Z axes; resin storage injection heads mounted to the driving heads of the robotic assembly so as to construct a resin dispensing device of configuration allowing dispensing of resin from the injection heads, characterized in: a top and a bottom adjustment means, the top and bottom adjustment means sustaining rotating forces of servo motor of a driving source provided at a side of the machine bed of the driving heads, converting the rotating forces into linear ascending and descending motions via camming effects, and causing variations in dispensing speed and route of the contact poles.

Owner:PROTEC CO LTD

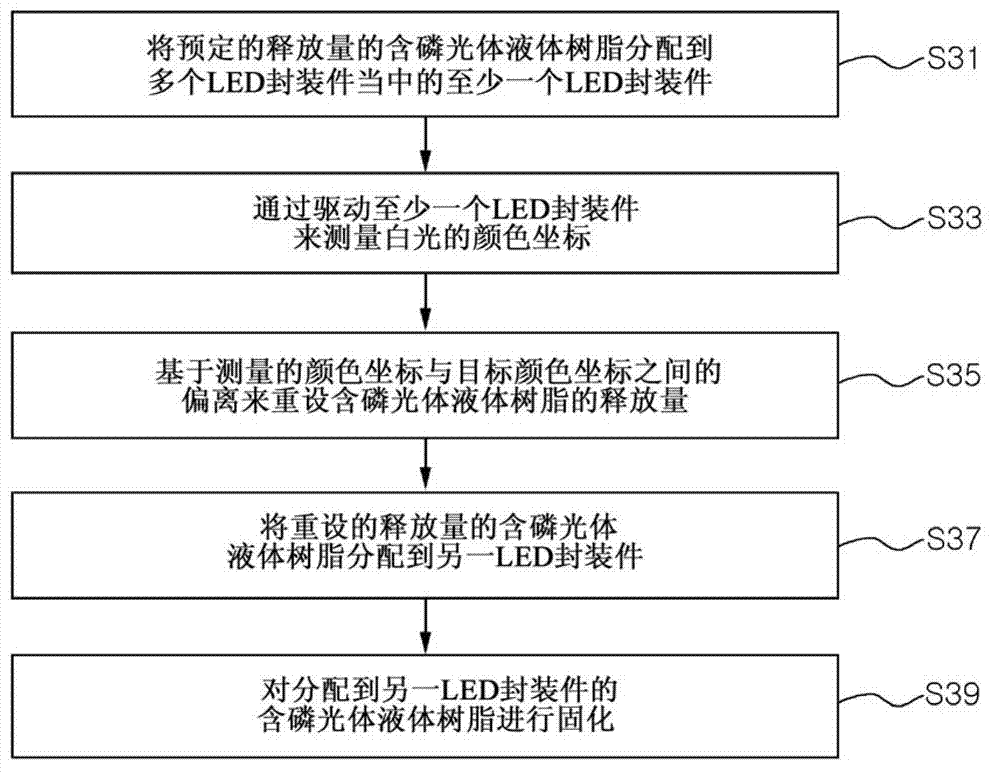

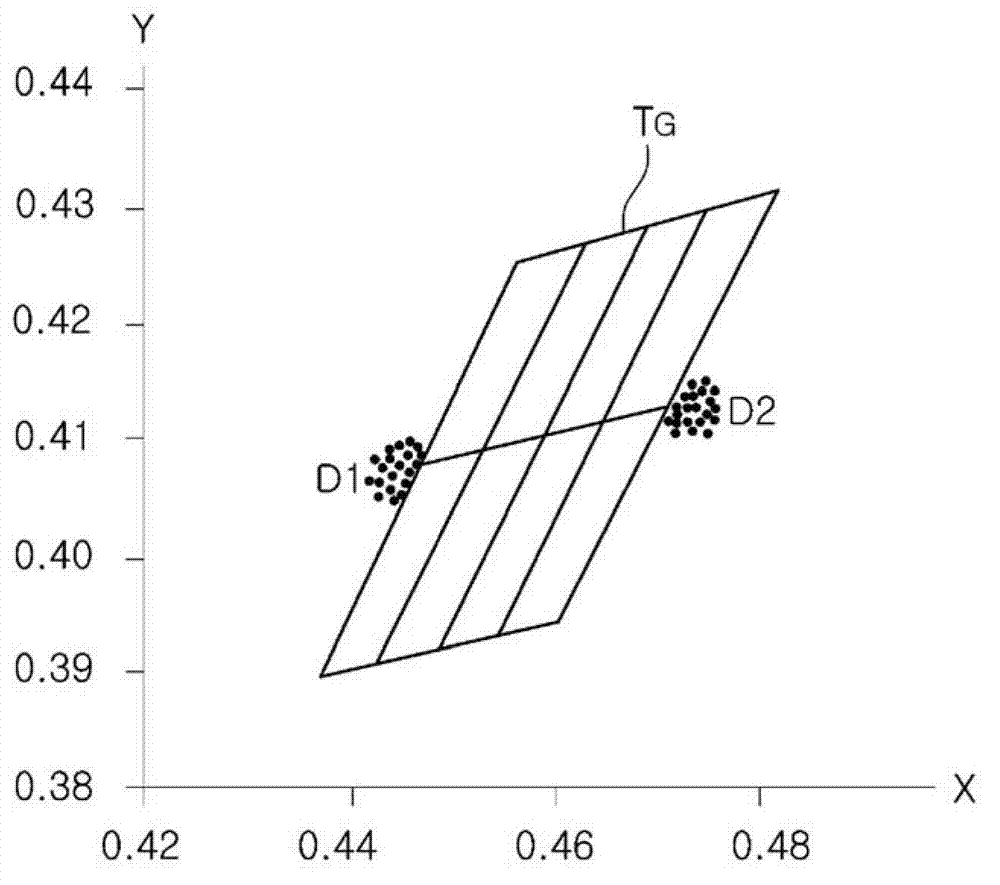

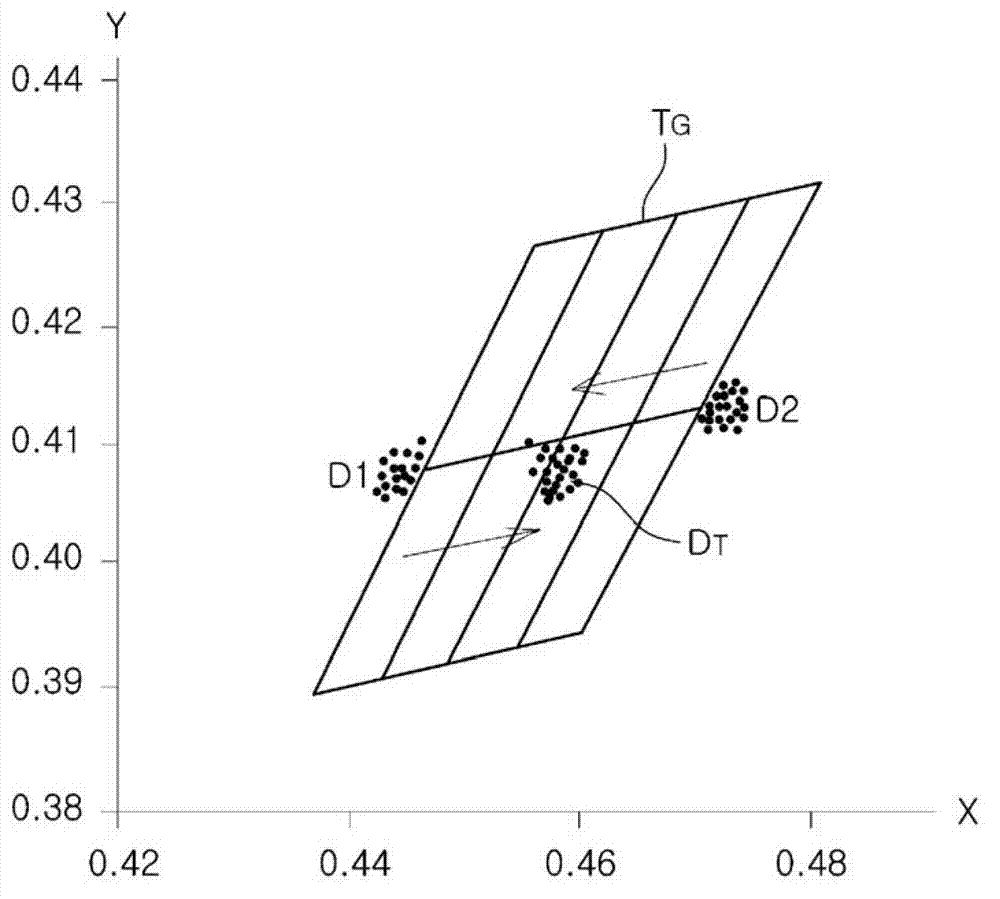

Method of manufacturing light emitting device and phosphor-containing fluid resin dispensing apparatus

InactiveCN103199175ASemiconductor/solid-state device testing/measurementSolid-state devicesResin dispensingPhosphor

There is provided a method of manufacturing a light emitting diode (LED) package, including discharging a predetermined discharge amount of a phosphor-containing fluid resin to at least one LED package, and measuring color coordinates of white light emitted from the at least one LED package. The method also includes adjusting a discharge amount of the phosphor-containing fluid resin, based on a deviation between the measured color coordinates and target color coordinates, so as to obtain the target color coordinates. The method further includes discharging the adjusted discharge amount of the phosphor-containing fluid resin to another LED package; and curing the phosphor-containing fluid resin dispensed to the another LED package.

Owner:SAMSUNG ELECTRONICS CO LTD

Tube induced deformity elimination process

ActiveUS7585448B2Eliminate deformationImprove structural performanceLaminationWood working apparatusResin dispensingEngineering

The disclosure is directed to a process for producing resin infused composite parts having improved structural performance and improved surface appearance. The process comprises the steps of positioning a dry composite preform on a forming tool component, arranging resin exit lines in close proximity to the perform, placing a permeable release material on the perform, and placing a first piece of flow media over the release material. The process further comprises the steps of wrapping a resin distribution tube with a second piece of flow media, placing a vacuum bag layer over the forming tool component, preform, release material, first and second pieces of flow media and resin distribution tube, such that the resin distribution tube is retained in a pleat formed in the vacuum bag layer and such that a bagged preform is formed, and positioning the resin distribution tube above the bagged preform.

Owner:THE BOEING CO

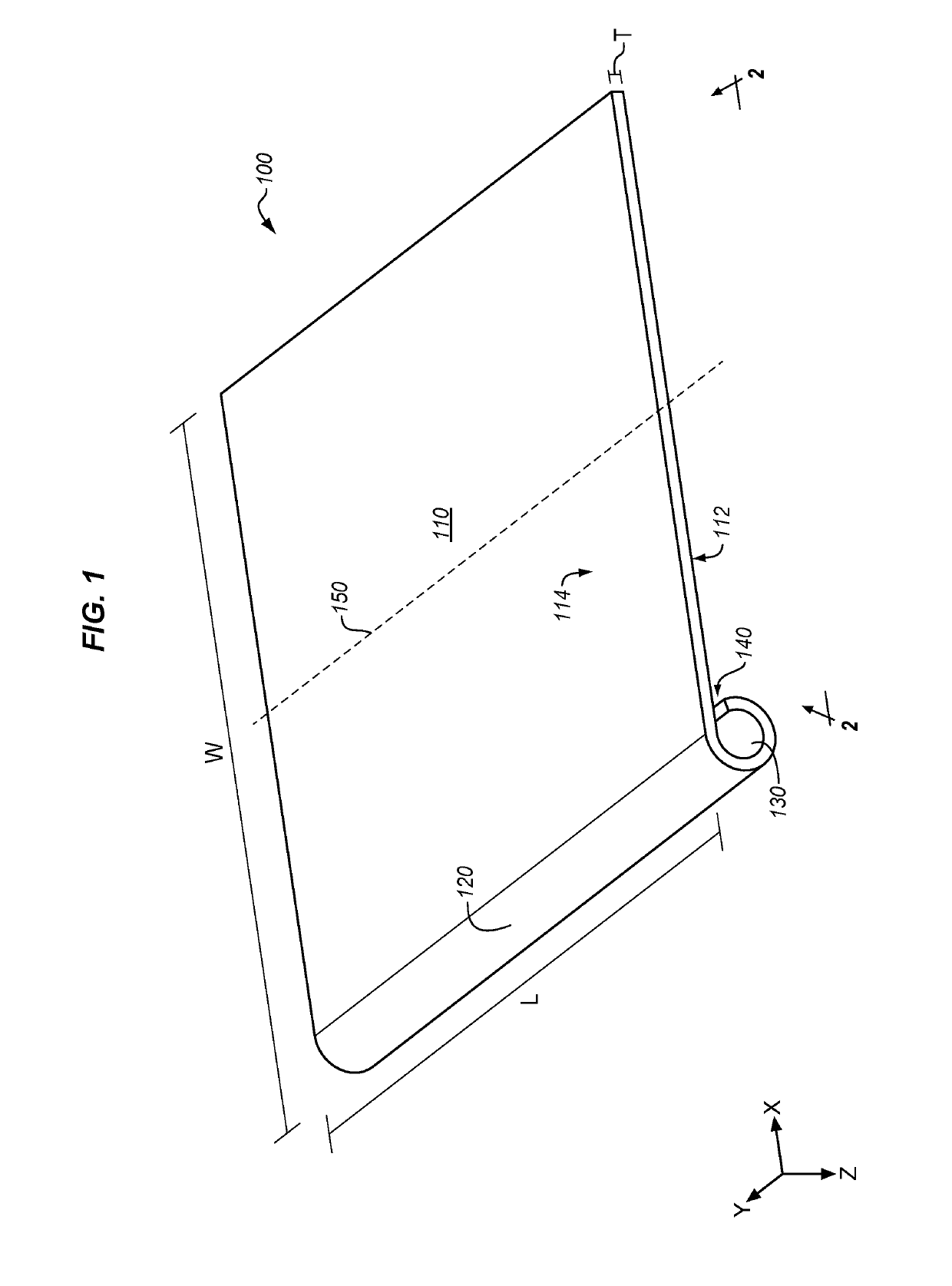

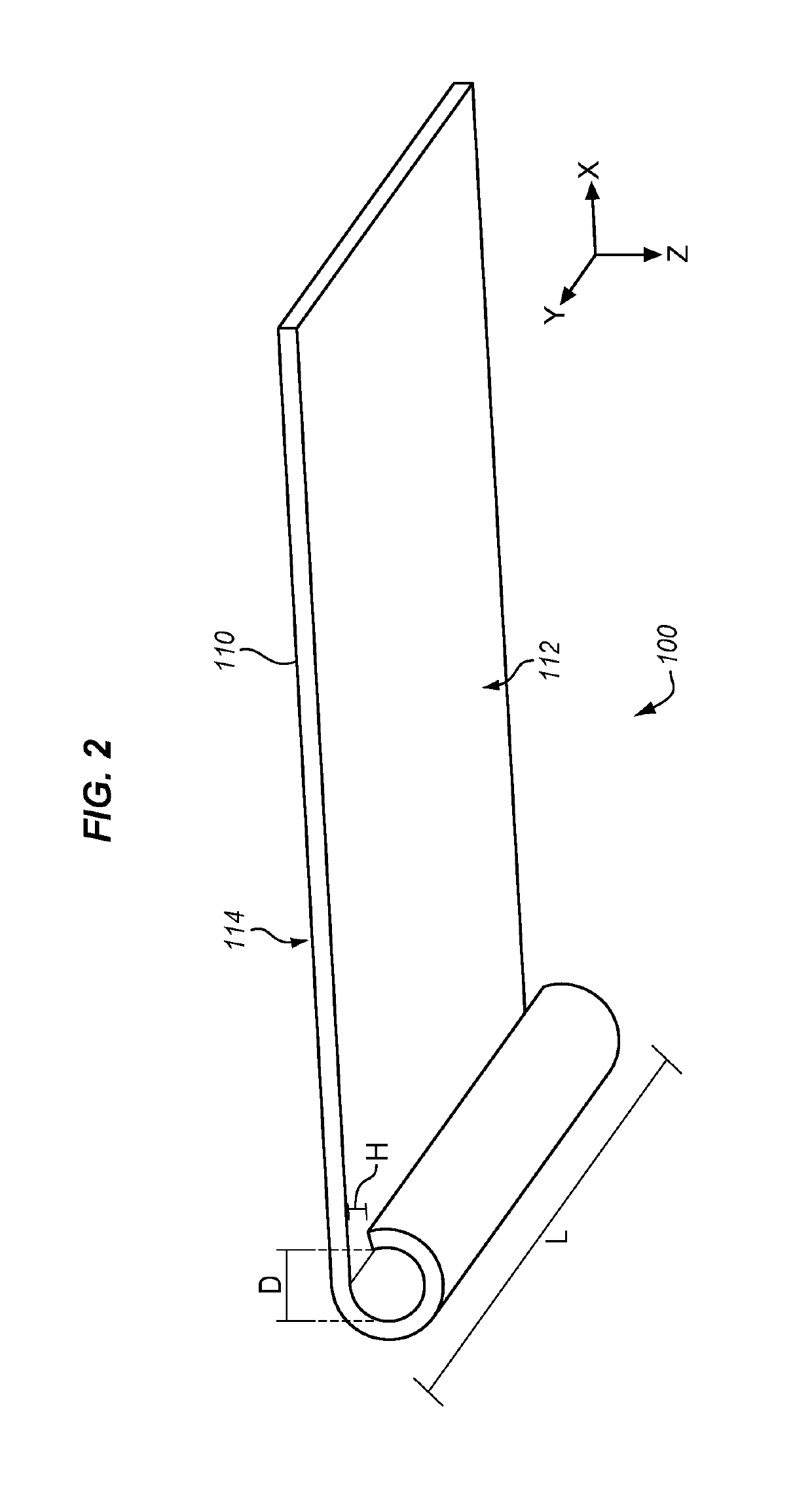

Caul plates that define channels for distributing resin to composite parts

Systems and methods are provided for fabricating composite parts. One embodiment is a method that includes selecting a caul plate having a body and a trough disposed at a side of the body which defines a channel that hangs beneath the body, the caul plate further having an opening disposed between the trough and the lower surface to form a fluid pathway for resin within the channel to exit into a preform. The method also includes placing the caul plate atop a preform of dry fiber and aligning the channel with a periphery of the preform, placing resin into the trough, and impregnating the preform with resin from the trough.

Owner:THE BOEING CO

Flexible tube and production apparatus therefor

Provided is a production apparatus capable of producing a flexible tube whose hardness is naturally varied along the length direction thereof. This mixing valve includes: a first valve configured to distribute a first resin to a resin supply path and a resin discharge path; and a second valve configured to distribute a second resin to the resin supply path and the resin discharge path. In the mixing valve, the mixing proportion between the first resin and the second resin is increased or decreased in association with molding of the flexible tube, by changing a distribution ratio of the first resin in the first valve and a distribution ratio of the second resin in the second valve while keeping constant the total of the supply mounts of the first resin and the second resin supplied to a die.

Owner:PLA GIKEN

Resin dispensing device

The invention provides a resin dispensing device having a dispensing head unit. The abovementioned dispensing head unit includes: a dispensing head main body; a needle component; a resin injection portion; an injector; and a flow path changer lever arranged to be able to slide inside the abovementioned dispensing head main body and to selectively communicate the abovementioned resin filling cylinder and the abovementioned needle component or communicate the abovementioned resin filling cylinder and the abovementioned injector, when the abovementioned resin filling cylinder is communicated with the abovementioned injector, resin housed in the abovementioned injector is filled in the abovementioned resin filling cylinder, and when the abovementioned resin filling cylinder is communicated with the abovementioned needle component, resin filled in the abovementioned resin filling cylinder is discharged through the abovementioned needle component, the abovementioned resin injection portion includes a piston component which is slidably arranged inside the abovementioned resin filling cylinder and pushes resin filled in the abovementioned resin filling cylinder towards a lower part, and an exhaust vent which discharges air outwards when resin is filled is formed at one side of an upper end part of the abovementioned resin filling cylinder.

Owner:株式会社头梧择

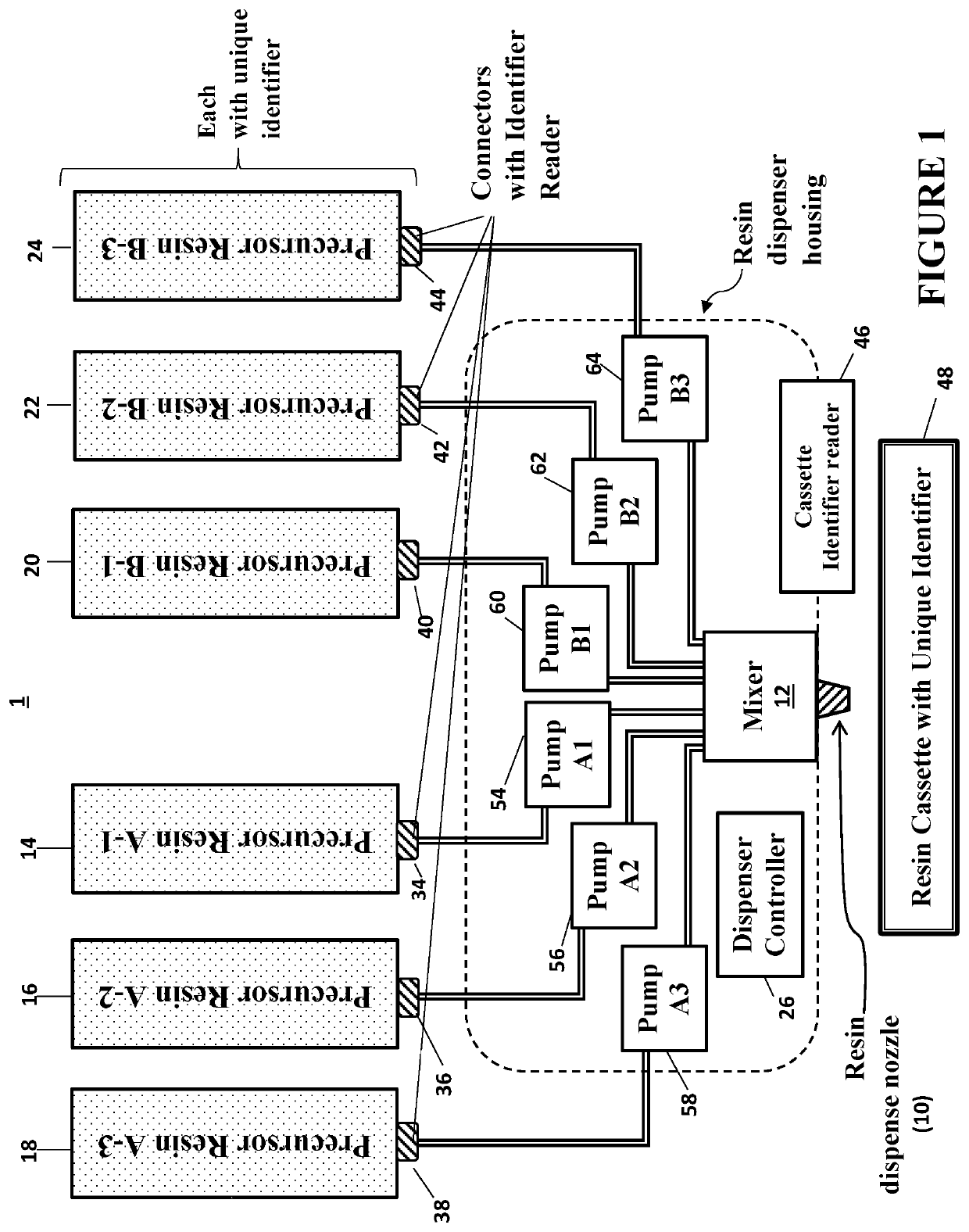

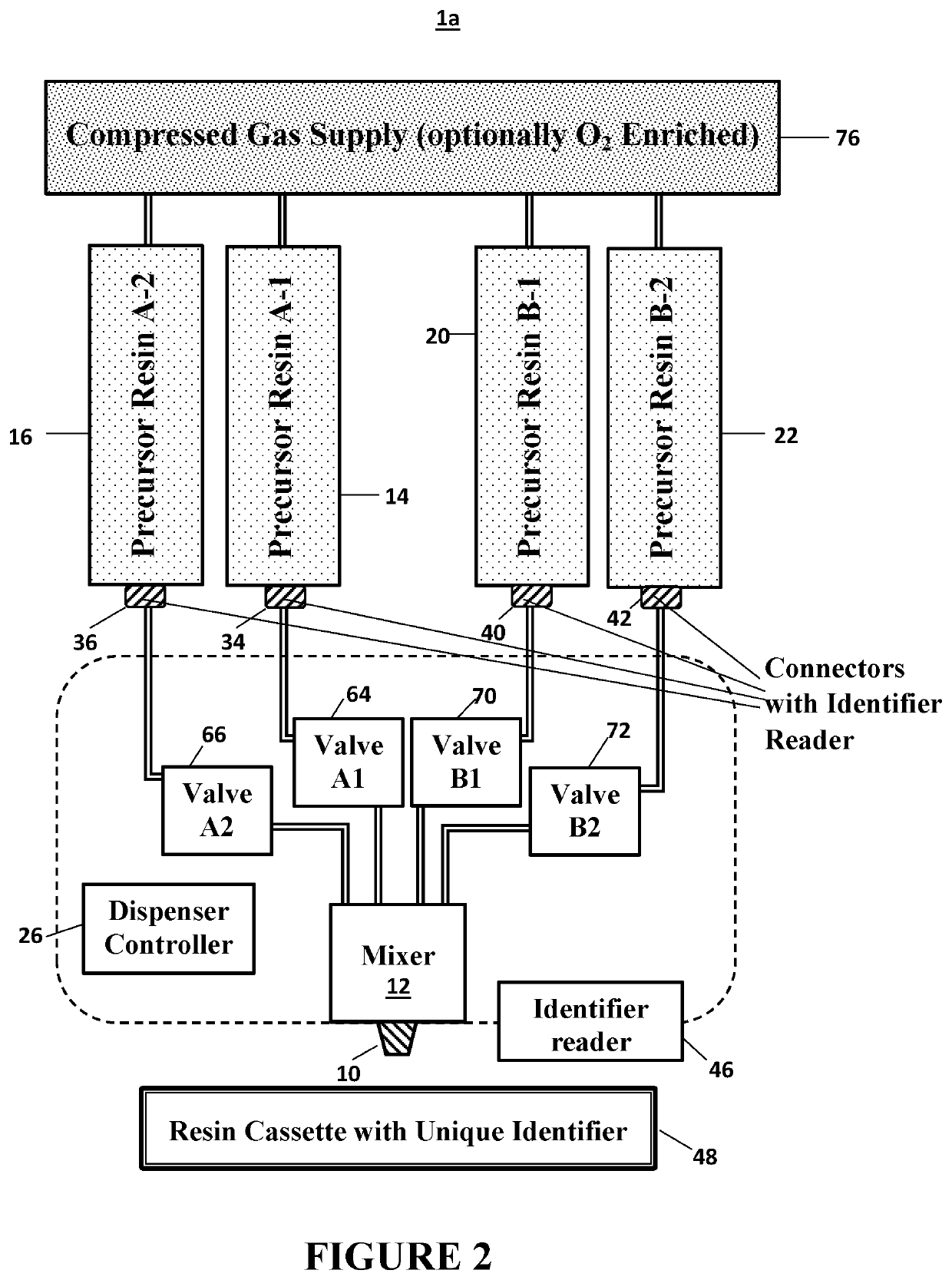

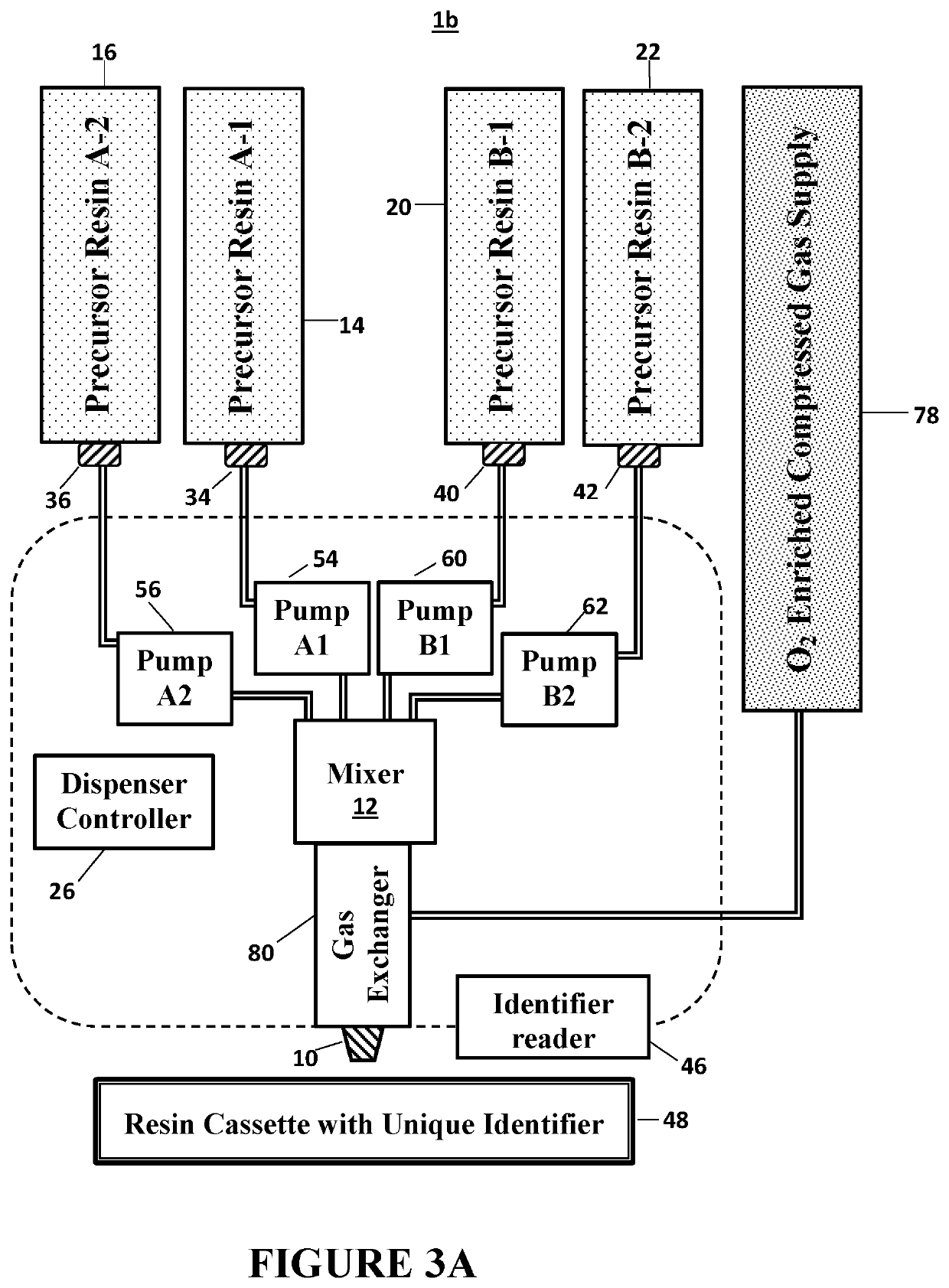

Resin dispenser for additive manufacturing

ActiveUS11458673B2Manufacturing platforms/substratesManufacturing enclosuresDual curePolymer science

A method of making a three-dimensional object by additive manufacturing from a blended resin (e.g., a blended dual cure resin), the blended resin including (i) at least one light polymerizable first component and, (ii) optionally but preferably, at least one, or a plurality of, second solidifiable components that are different from said first component, the method including one or more of the steps of: (a) providing a first resin and a second resin, where the resins produce three-dimensional objects having different mechanical properties from one another when all are produced under the same process conditions; (b) mixing the first and second resins with one another to produce the blended resin, the blended resin producing a three-dimensional object having mechanical properties intermediate between that of objects produced by the first and second resins when all are produced under the same process conditions; and (c) dispensing the blended resin to the build region of an additive manufacturing apparatus; and then (d) optionally but preferably producing a three-dimensional object from the blended resin in the apparatus.

Owner:CARBON INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com