Method of manufacturing light emitting device and phosphor-containing fluid resin dispensing apparatus

A liquid resin, phosphor technology, applied in the direction of liquid distribution, transportation or transfer device, distribution device, electric solid device, etc., can solve the problems of reduced output, defective LED packages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the following detailed description, many specific details are explained by way of examples in order to provide a thorough understanding of relevant teachings. However, those skilled in the art should understand that this teaching can be implemented without these details. In other instances, well-known methods, procedures, components, and / or circuits are described at a relatively high level without involving details, so as not to unnecessarily obscure aspects of the teachings.

[0027] In addition, the same or similar reference numerals in all the drawings represent parts that perform similar functions and actions.

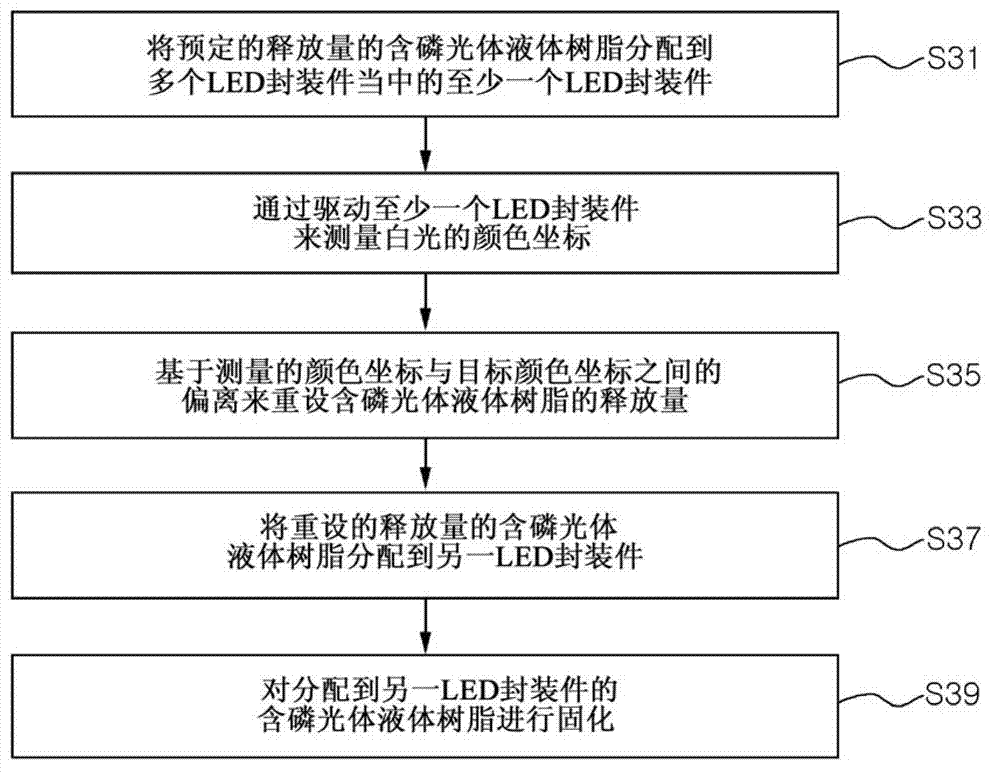

[0028] figure 1 It is a flowchart showing a method of manufacturing a light emitting device according to an embodiment of the present disclosure.

[0029] The method of manufacturing a light emitting device according to an embodiment of the present disclosure may be started in operation S31, which dispenses a predetermined release amount of phosphor-containing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com