Resin dispensing device

A coating device and resin technology, which is applied to devices and coatings that apply liquid to surfaces, can solve problems such as inability to continuously discharge resin, inability to discharge resin, and differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

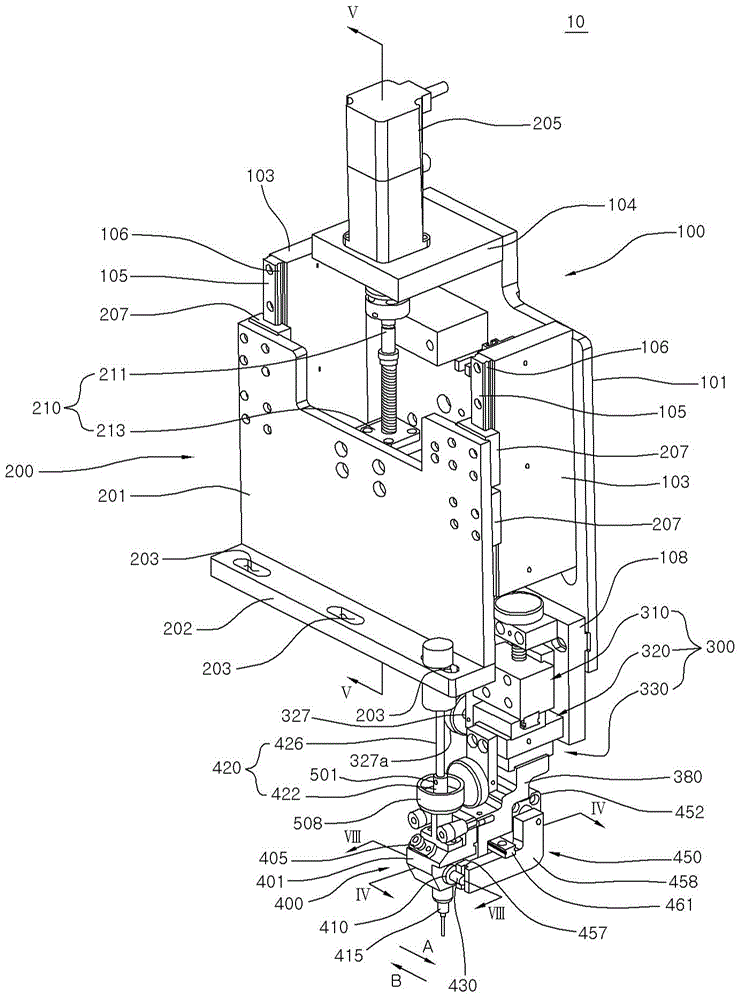

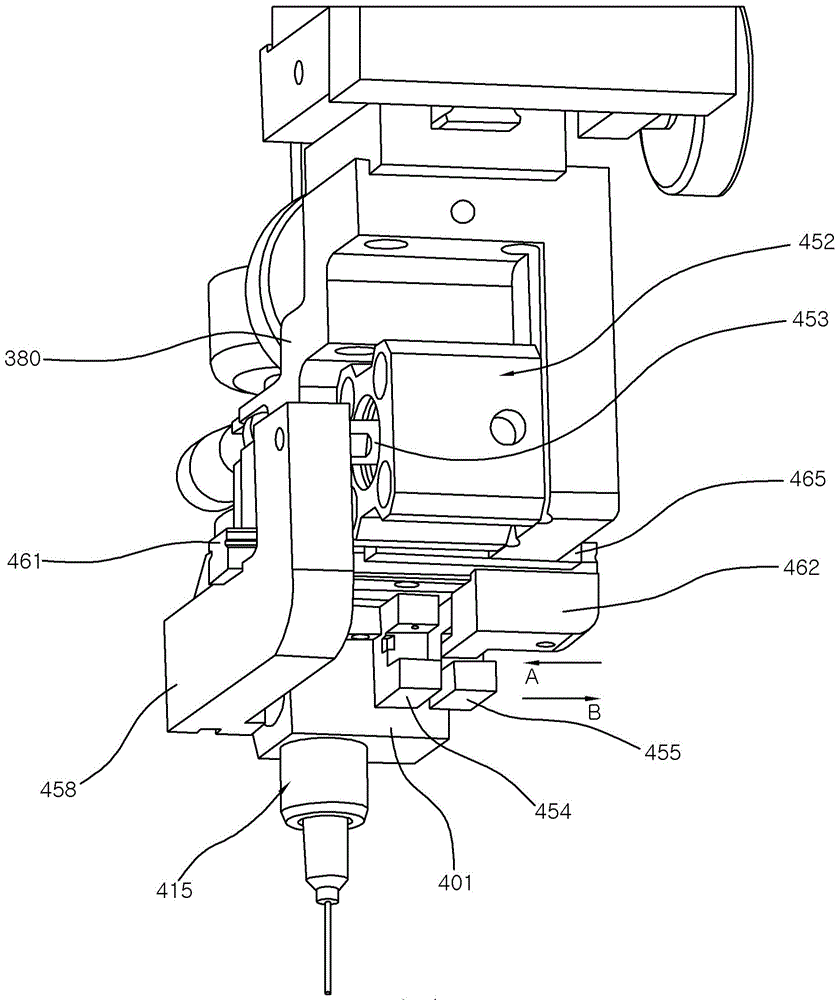

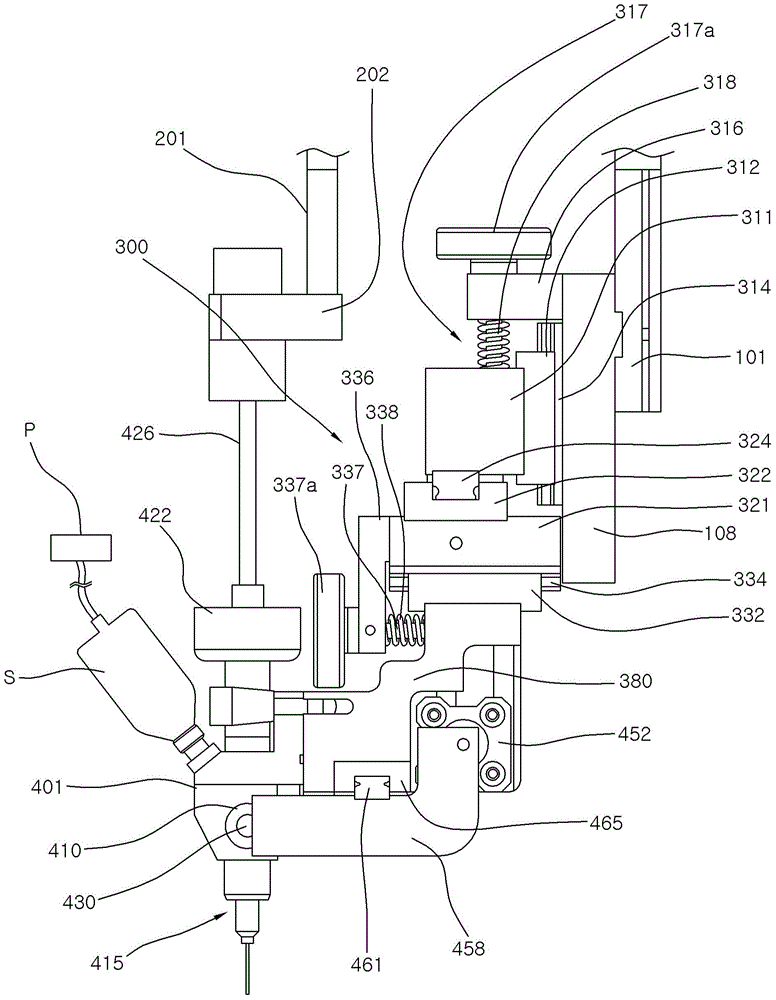

[0028] Next, a resin coating device 10 according to an embodiment of the present invention will be described with reference to the drawings. in addition, figure 1 is a perspective view of a resin coating device according to an embodiment of the present invention except for a syringe, figure 2 is viewed from the back figure 1 A perspective view of a part of the resin coating apparatus shown, image 3 yes figure 1 A schematic view of the right part of the syringe provided in the resin coating apparatus shown.

[0029] The resin coating device 10 includes a base part 100 , a vertical movement part 200 , a position adjustment unit 300 , and a coating head unit 400 .

[0030] For the base 100, the base plate 101 is installed on a common robot unit and is connected to a drive head that can move along the X-Y-Z axis. On both sides of the base plate 101, a pair of guide rails are connected along the upper and lower length directions in a manner protruding forward. Bracket 103. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com