Apparatus and method for fabricating semiconductor chip package with film attached on

A technology for chip packaging and manufacturing devices, applied in semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve the problems of low luminous quality and yield of LED packaging, unusable sealing resin, and low luminous efficiency, etc. Achieve the effect of improving production performance, reducing usage, and low calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The manufacturing equipment and manufacturing method of the film-bonded semiconductor chip chip package will be described in detail according to the implementation of the invention with reference to the attached drawings below. The terms (terminology) used in this specification are used to properly express the implementation of this invention, and have different effects depending on the user or the user's intention or language habits in the field to which this invention belongs. Therefore, the definitions of these terms can only be understood by understanding the contents of this specification as a whole.

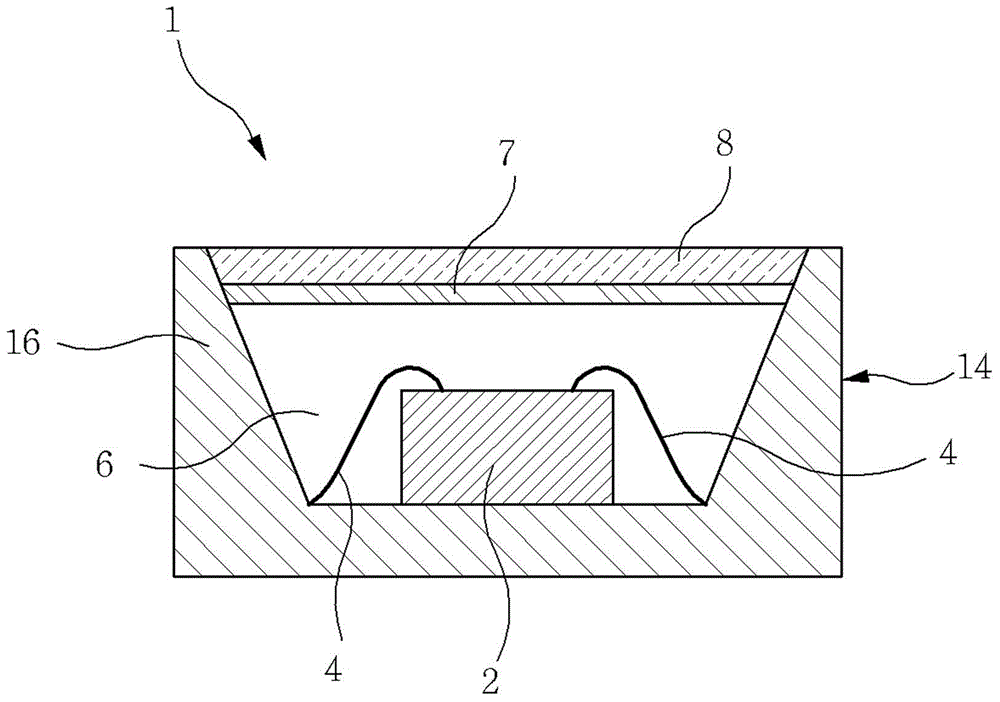

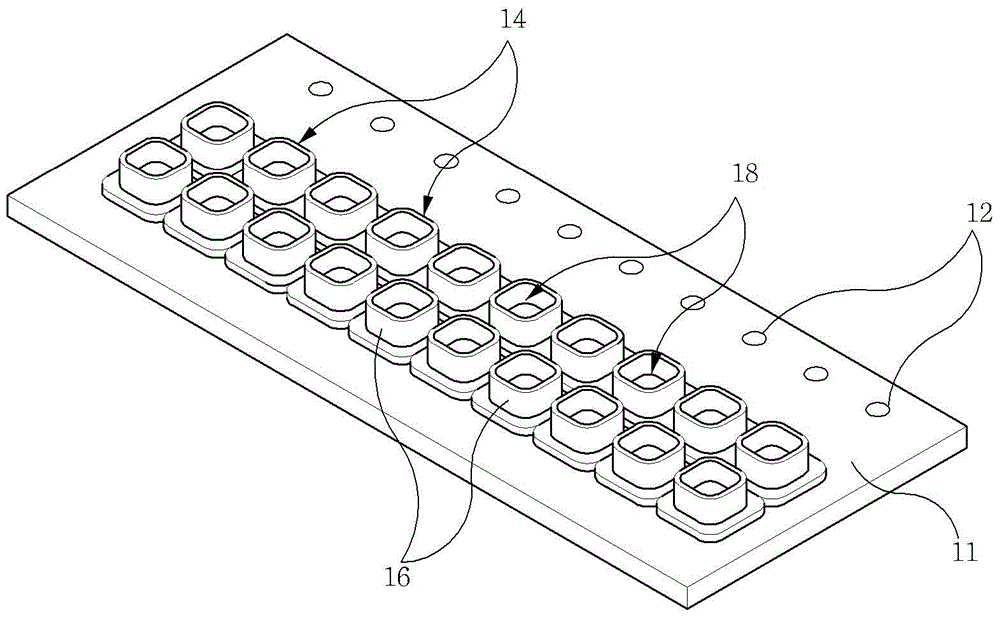

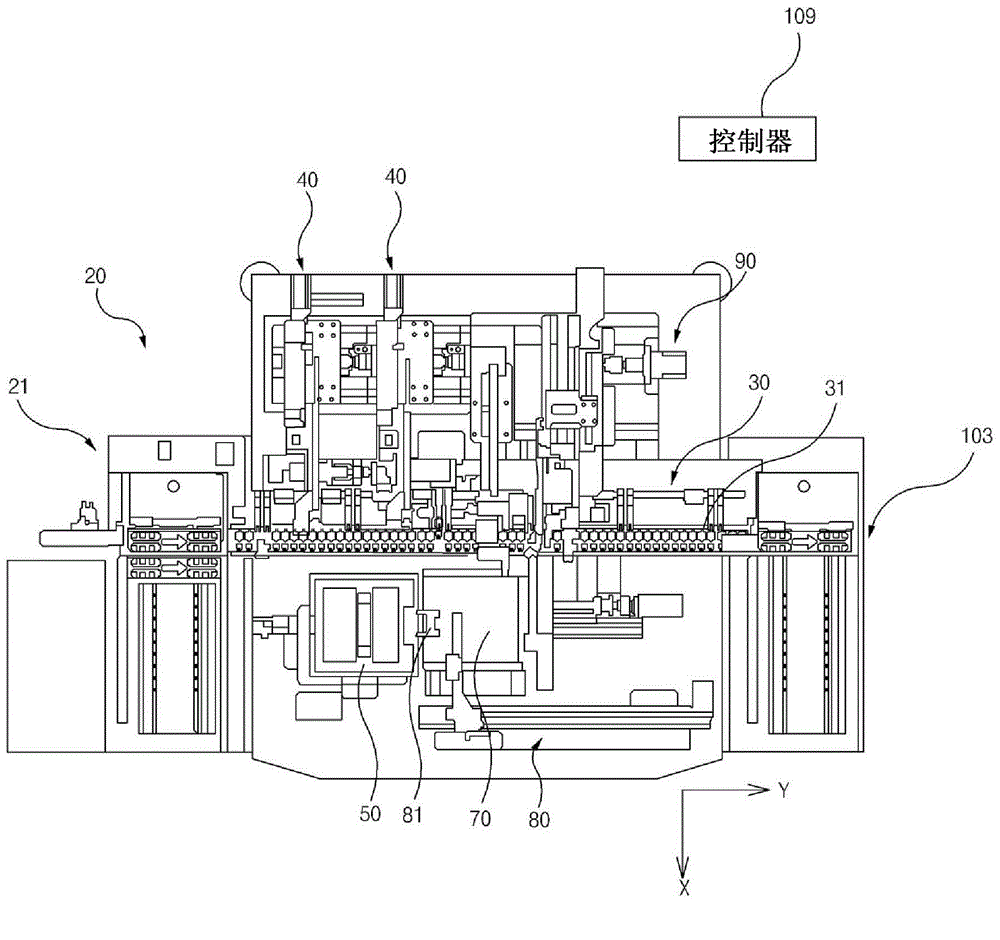

[0070] First of all, use the semiconductor chip chip package manufacturing equipment of this invention to manufacture a kind of semiconductor chip chip, as an example figure 1 It is a one-sided view showing that the fluorescent film is attached to the LED package, figure 2 It is an instruction diagram showing a form in which a lead frame (lead frame) used for manuf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com