Continuous synchronous adsorption-regeneration softener

A softener and adsorption chamber technology, applied in chemical instruments and methods, adsorption water/sewage treatment, ion exchange water/sewage treatment, etc., can solve problems such as increasing salt content, environmental pollution, short adsorption cycle, etc., to reduce Discharge of waste water, reduce environmental pollution, improve the effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

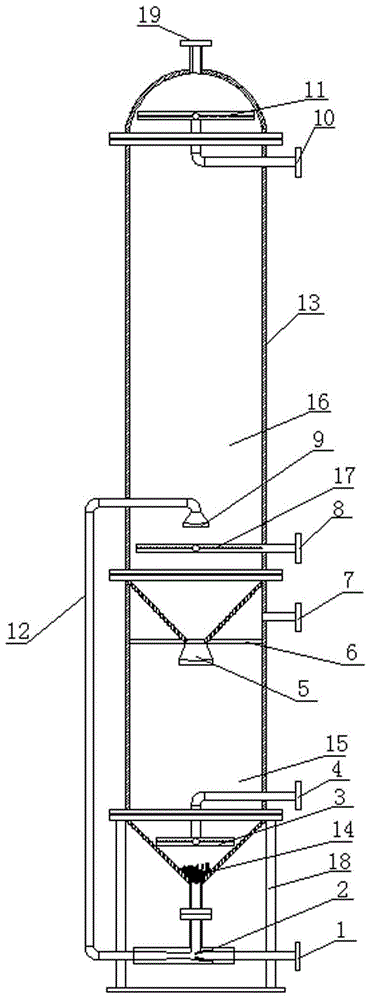

[0012] The continuous synchronous adsorption and regeneration softener includes a cylinder 13 with ion exchange resin 14 inside, an exhaust port 19 is provided on the top of the cylinder 13, and a leg 18 is provided on the bottom of the cylinder 13. The cylinder 13 The upper part of the inner cavity is the adsorption chamber 16, and the lower part is the regeneration chamber 15; the upper part of the adsorption chamber 16 is equipped with a soft water collection device 11, and the soft water collection device 11 communicates with the softened water outlet 10 on the cylinder 13; the lower part of the adsorption chamber 16 is installed There is a resin distribution device one 9, and the bottom of the adsorption chamber 16 communicates with the regeneration chamber 15 below the adsorption chamber 16 through the resin distribution device two 5; an auxiliary distribution device 17 is installed between the resin distribution device one 9 and the resin distribution device two 5 , the ...

Embodiment 2

[0014] The continuous synchronous adsorption and regeneration softener includes a cylinder 13 with ion exchange resin 14 inside, an exhaust port 19 is provided on the top of the cylinder 13, and a leg 18 is provided on the bottom of the cylinder 13. The cylinder 13 The upper part of the inner cavity is the adsorption chamber 16, and the lower part is the regeneration chamber 15; the upper part of the adsorption chamber 16 is equipped with a soft water collection device 11, and the soft water collection device 11 communicates with the softened water outlet 10 on the cylinder 13; the lower part of the adsorption chamber 16 is installed There are two resin distribution devices one 9, the bottom of the adsorption chamber 16 communicates with the regeneration chamber 15 below the adsorption chamber 16 through the resin distribution device two 5; two auxiliary distribution devices are installed between the resin distribution device one 9 and the resin distribution device two 5 Device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com