Resin distributing device

A dispensing device and resin technology, applied in the direction of suspension devices, packaging, and devices for coating liquid on the surface, etc., can solve the problems of large maintenance, complex structure, etc., to ensure the reliability of the device, realize the attenuation function, The effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, embodiments of the present invention will be described in detail based on the drawings.

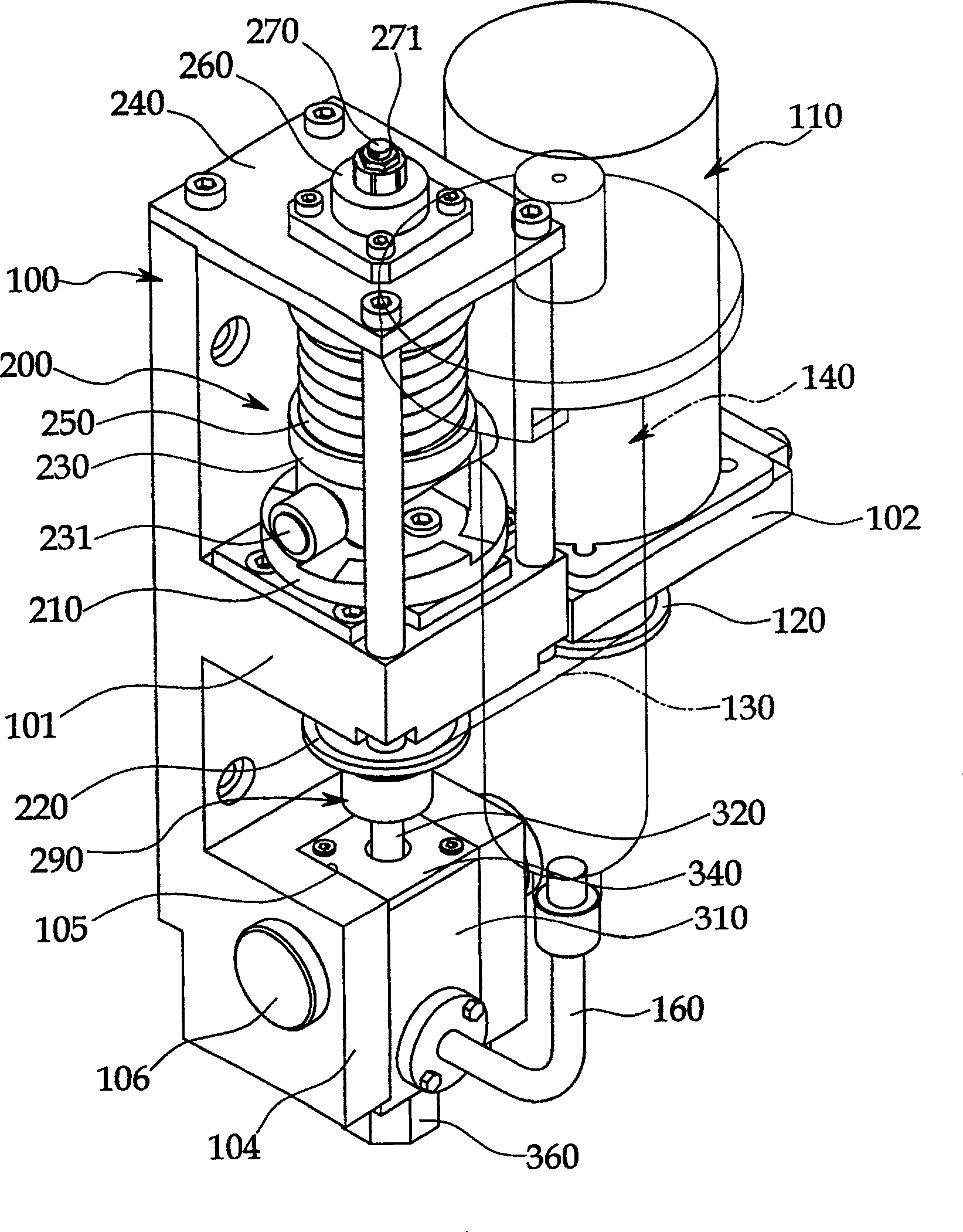

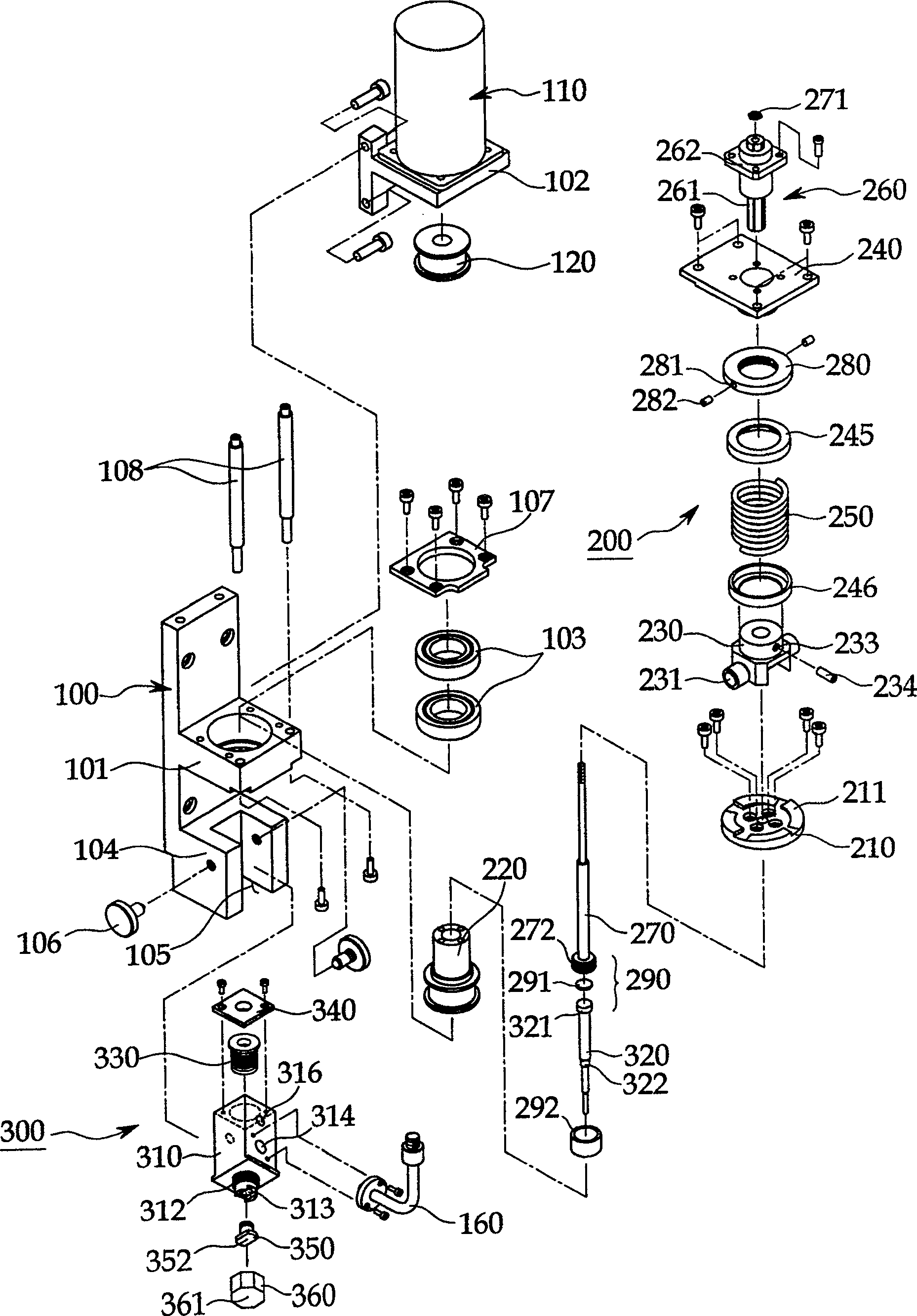

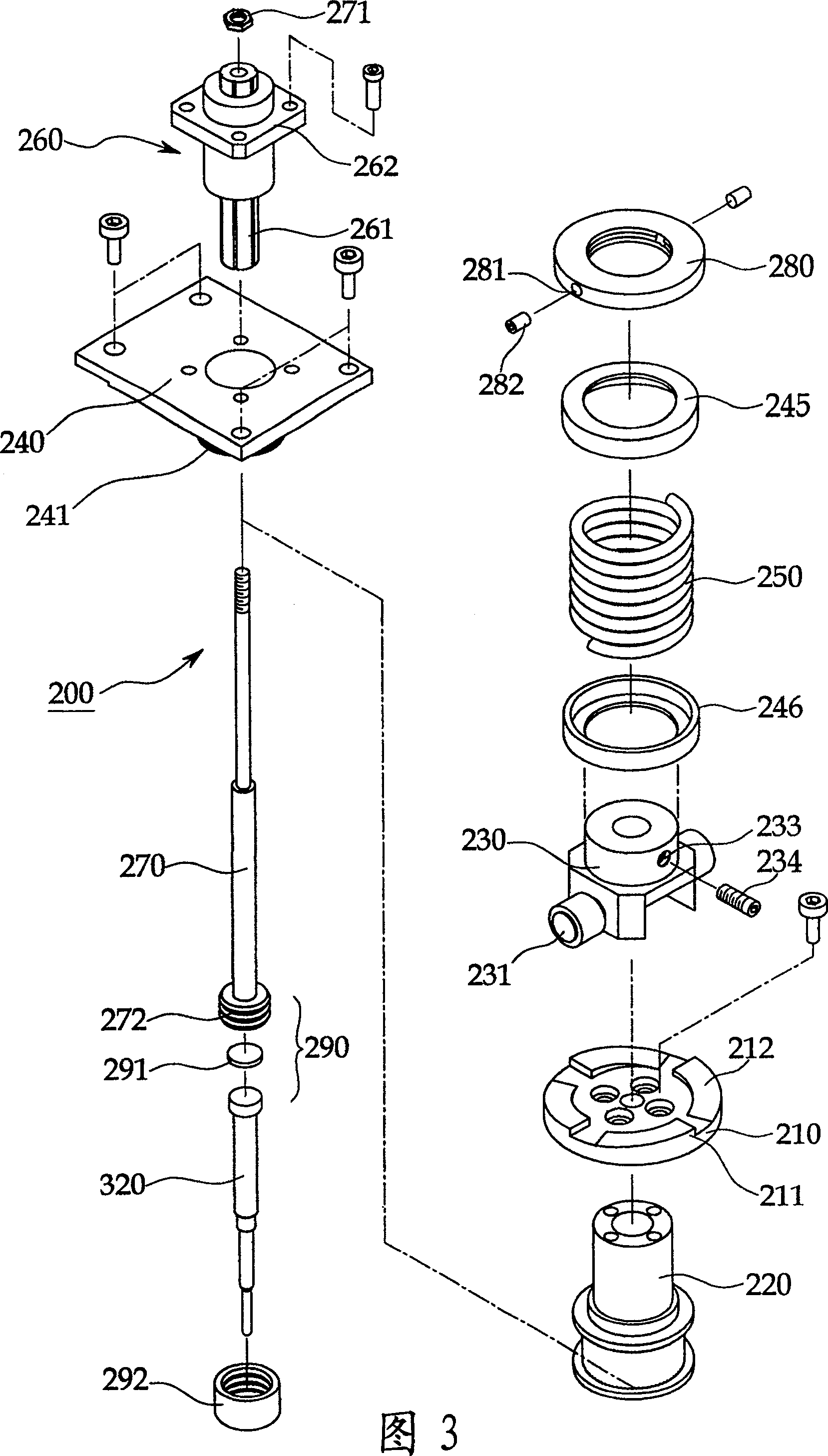

[0044] Such asfigure 1 ~As shown in Figure 6, the resin distributing device according to the present invention is installed on a common robot unit, including: a drive head main body 100 that can move along the X—Y—Z axis; A syringe 140 for resin storage; a servo motor 110 installed on one side of the main body 100; a vertical adjustment device 200 that receives the rotational force of the servo motor through a timing belt 130 and converts the rotational motion into a linear lifting motion; and has The dotting nozzle (dotting nozzle) 300 of the dotting rod 320 connected with the above-mentioned up and down adjustment device.

[0045] The drive head main body 100 is provided with a support bracket 102 on one side of the support platform 101 protruding from the middle, and the servo motor 110 is mounted on the support bracket 102 by bolts.

[0046] The structure of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com