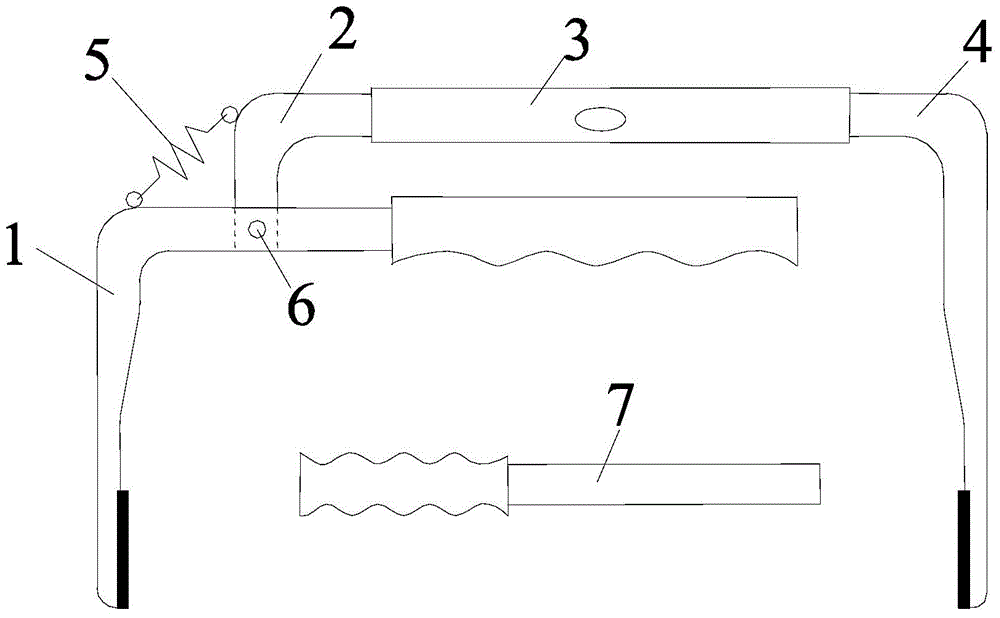

Two-way extending assembly brick clamp for shale-sintered thermal-insulating blocks

A technology for thermal insulation blocks and shale, which is applied in construction, building structure, construction material processing, etc., can solve the problem that ordinary bricks cannot be applied, and achieves the effect of increasing reliability, safe handling process and reducing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

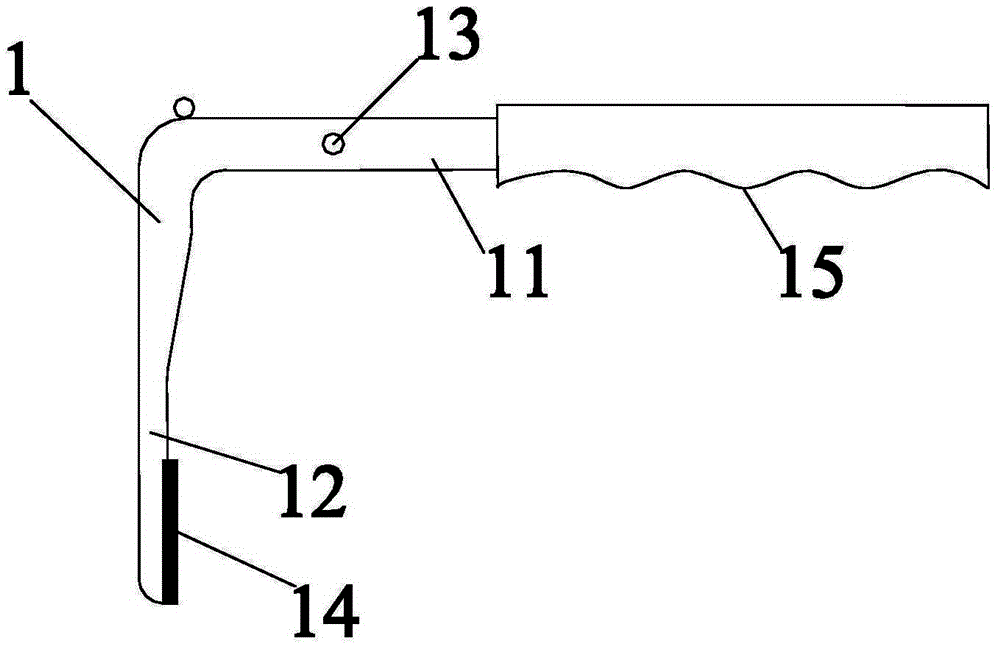

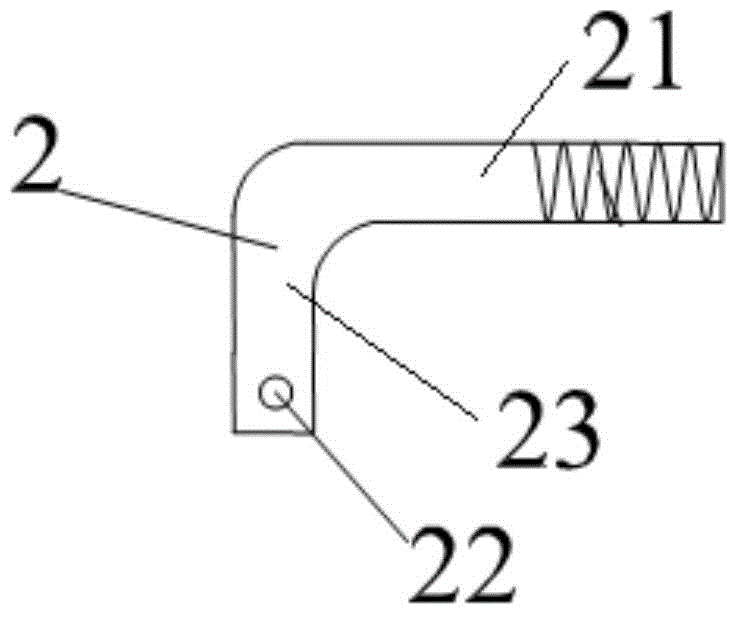

[0026] This embodiment follows the technical solution of the present invention, and the round steel material used for the main body is Q235 with a diameter of 15mm. The lengths of the screw threads provided on the sleeve connecting screw rod 21 and the screw rod 41 are both 10 cm. The wall thickness of the sleeve 3 is 5 mm, the inner diameter is 15 mm, and the diameter of the circular hole 31 in the middle of the sleeve 3 is 12 mm. The diameters of the round hole 13 on the handle 11 and the round hole 22 of the clamping rod connecting rod 23 are 8 mm, and the diameter of the rotating shaft 6 is 7.5 mm. The stiffness coefficient of the reaction force spring 5 is k=1-5N / mm. The size of the rubber spacer 14 on the first brick clamp 12 and the rubber spacer 43 on the second brick clamp 42: the length is 80mm, the width is 30mm, and the thickness is 5mm. Both the first brick clamp 12 and the second brick clamp 42 are forged from circular rods, both have a length of 100 mm and a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com