Foam-dispensing pump container

一种泡沫、泵式的技术,应用在喷射装置、液体喷射装置、关闭等方向,达到减少逆流、改善使用性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

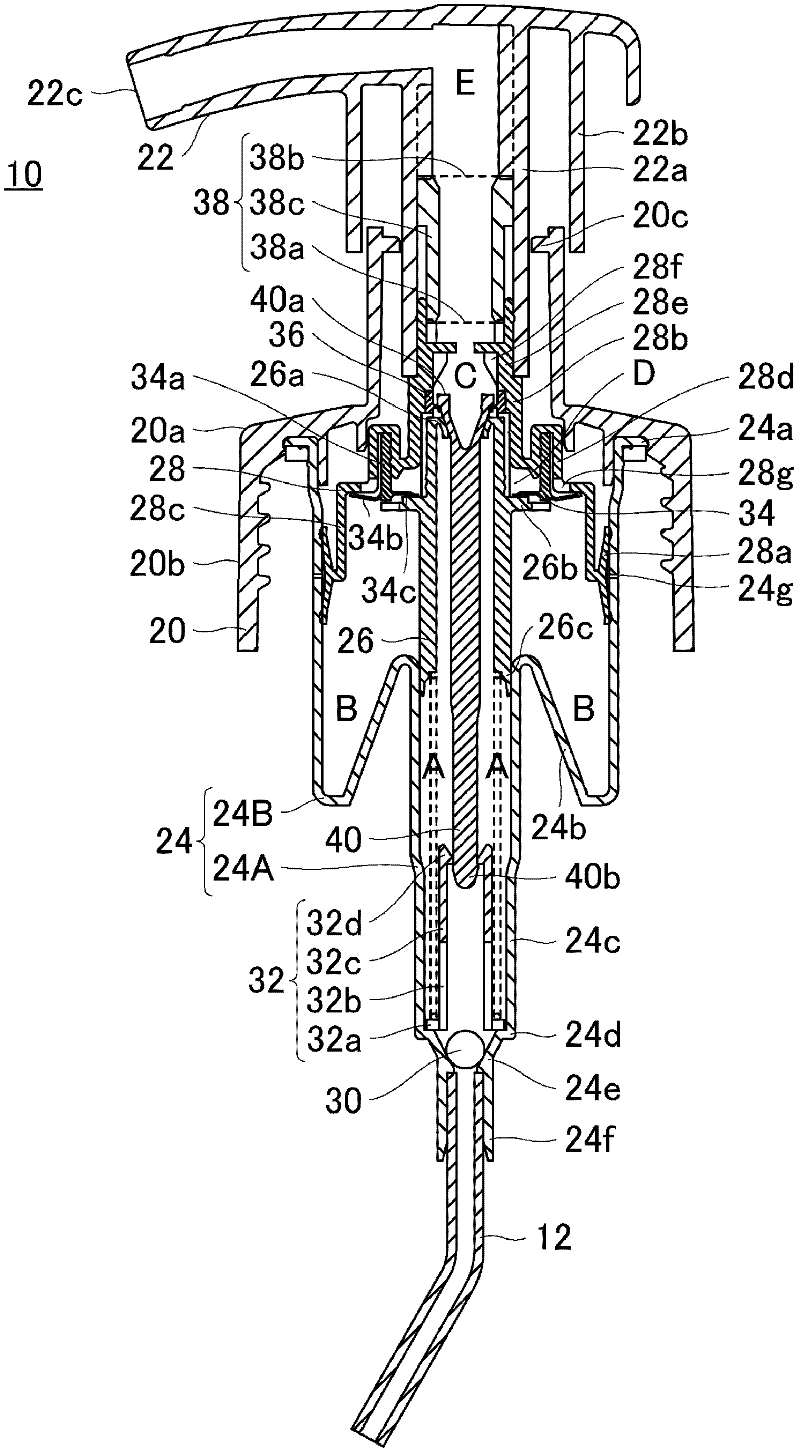

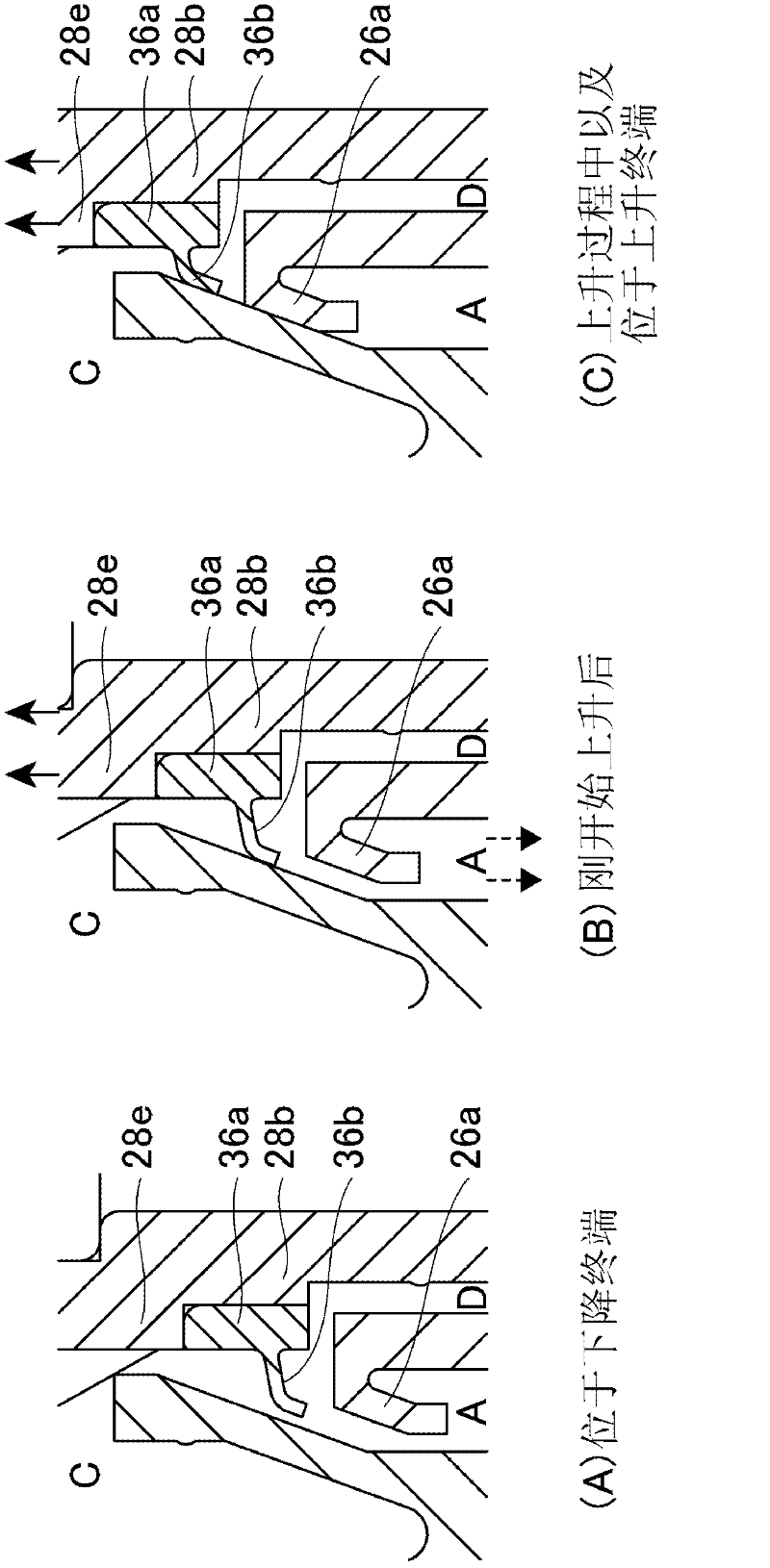

[0036] Next, preferred embodiments of the present invention will be described with reference to the drawings.

[0037] Structure of the pump foam ejection container

[0038] The pump-type foam spray container of this embodiment includes: a container body, which is used to accommodate liquid; a spray pump body, which is detachably installed on the mouth of the upper end of the container body; a pipe body, which is connected with the spray pump The body is connected and extends to the interior of the container body.

[0039] figure 1 It is a sectional view showing the discharge pump body 10 of the pump-type foam discharge container according to one embodiment of the present invention (a front sectional view in a state where the nozzle head is located at the terminal end of the rise).

[0040] A base cap (base cap) portion 20 is provided below the discharge pump body 10 of the present embodiment and has a skirt shape, and internal threads are formed on the inner peripheral su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com