Shower plate, method for manufacturing the shower plate, plasma processing apparatus using the shower plate, plasma processing method and electronic device manufacturing method

A plasma and processing device technology, applied in the field of plasma processing devices, can solve problems such as poor surface flatness, and achieve the effects of preventing electric field concentration, preventing ignition phenomenon, and preventing backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

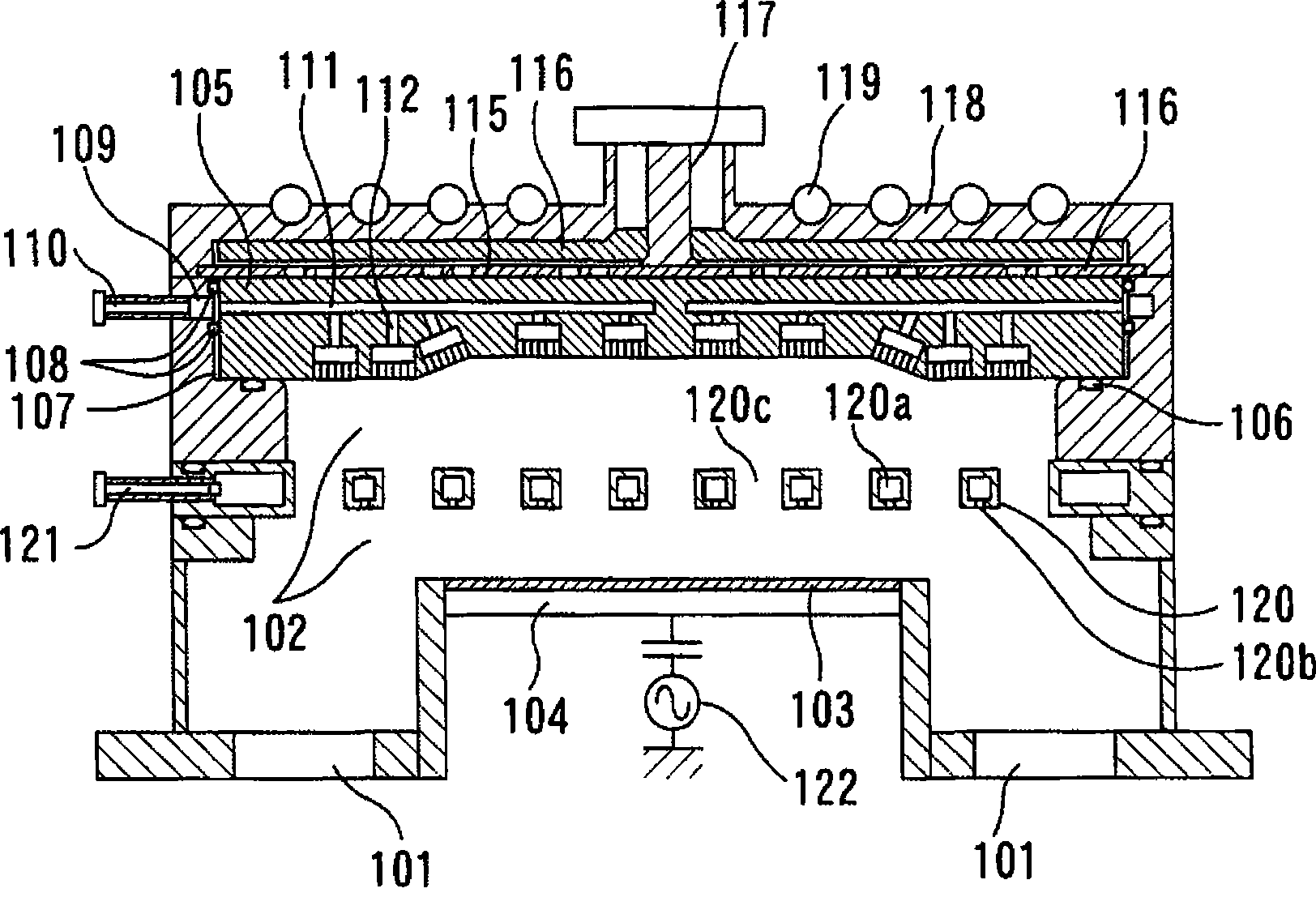

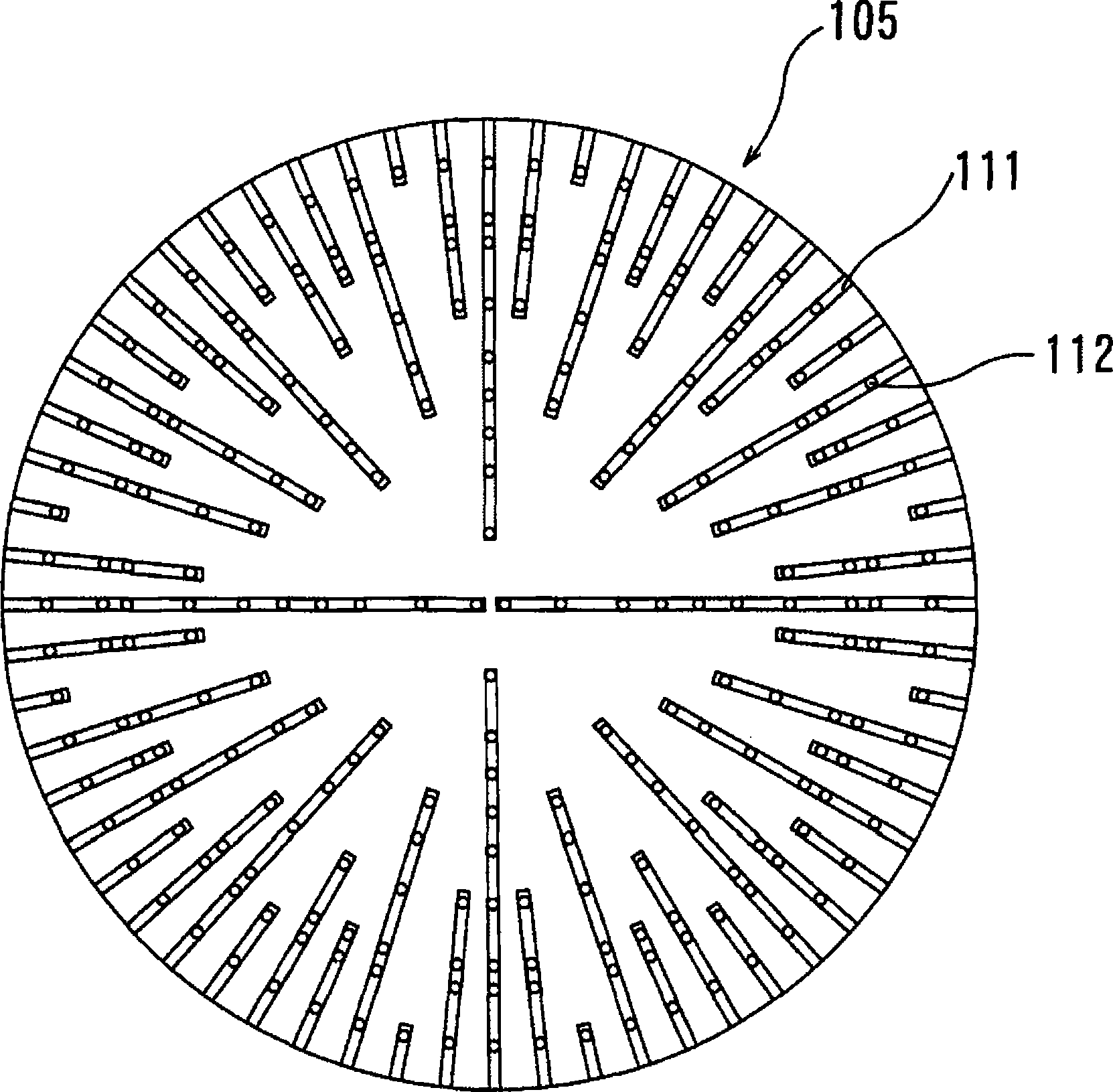

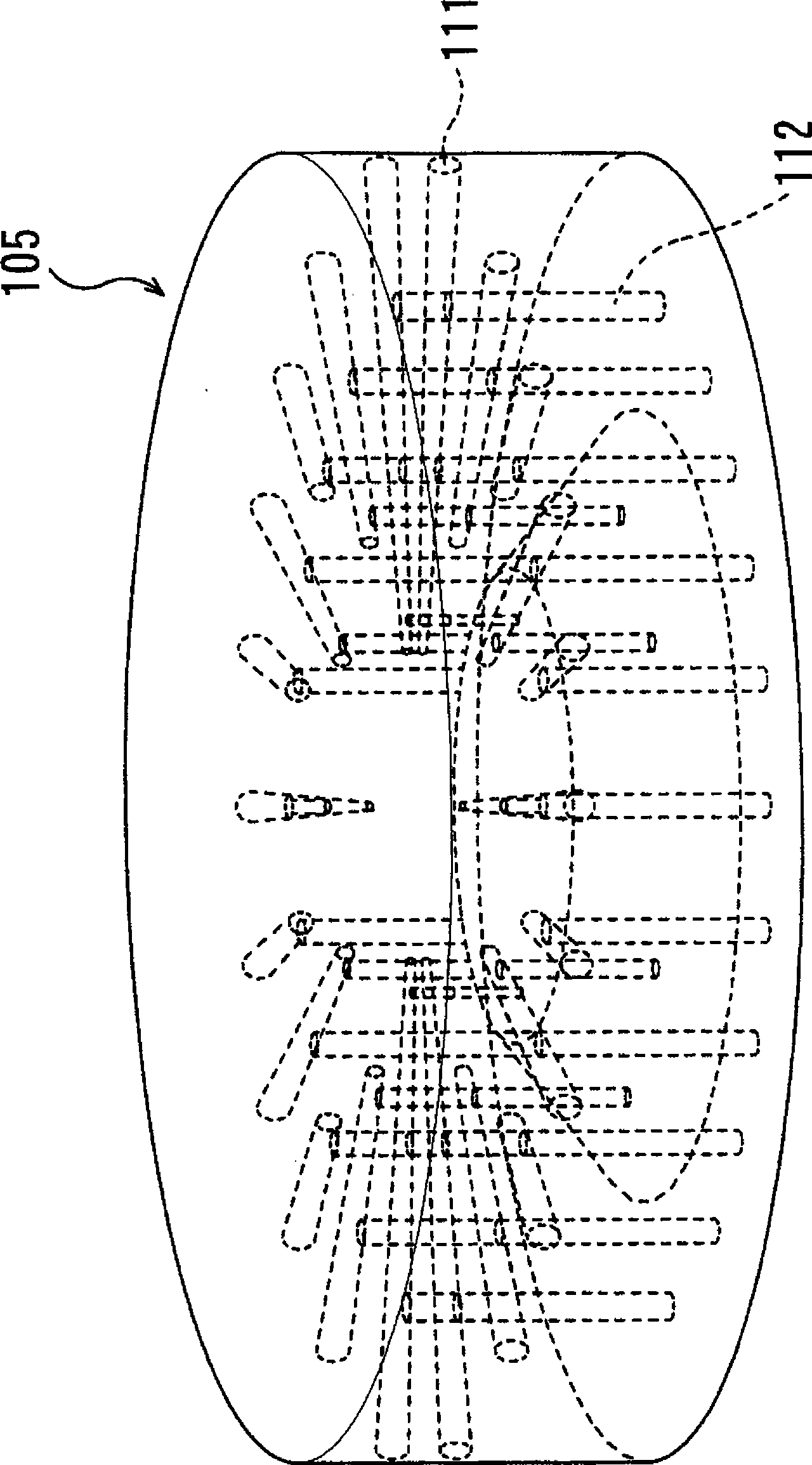

[0064] figure 1 Shows the first embodiment of the present invention. refer to figure 1 , represents a microwave plasma processing device. The illustrated microwave plasma processing apparatus has a processing chamber 102 exhausted through a plurality of exhaust ports 101 , and a holding table 104 for holding a substrate 103 to be processed is arranged in the processing chamber 102 . In order to exhaust the inside of the processing chamber 102 uniformly, the processing chamber 102 defines an annular space around the holding table 104, and a plurality of exhaust ports 101 are equally spaced in a manner communicating with the space, that is, relative to the substrate to be processed. 103 are arranged axially symmetrically. With the arrangement of the exhaust ports 101 , the processing chamber 102 can be uniformly exhausted from the exhaust ports 101 .

[0065] On the upper part of the processing chamber 102, an O-ring 106 for sealing is installed at a position corresponding...

Embodiment 2

[0099] Figure 5 Shows the second embodiment of the present invention. refer to Figure 5 , represents a microwave plasma processing device. The same reference numerals are assigned to the same reference numerals as those in the first embodiment, and description thereof will be omitted.

[0100] In this embodiment, an O-ring 106 for sealing is installed on the upper part of the processing chamber 102 as a part of the outer wall of the processing chamber 102 at a position corresponding to the substrate 103 to be processed on the holding table 104 as a relative medium. The electric constant is 9.8, and low microwave dielectric loss (dielectric loss is 1×10 -4 The plate-shaped shower plate 201 made of alumina and formed with a plurality of (230) openings, that is, vertical holes 200 , is a dielectric. And, in the processing chamber 102, an O-ring 203 for sealing is installed on the upper surface side of the shower plate 201, that is, on the opposite side to the holding table ...

Embodiment 3

[0110] Figure 10 A third embodiment of the present invention is shown. Referring to the figure, a microwave plasma processing apparatus is shown. The same reference numerals are assigned to the parts that overlap with those of the first and second embodiments, and description thereof will be omitted. The longitudinal hole 300 of the shower plate 301 in the present embodiment is Figure 11 construction shown. That is, a gas discharge hole 300a with a diameter of 0.05mm and a length of 0.5mm is opened on the side of the processing chamber 102 for exciting plasma, and the gas introduction side of the gas discharge hole 300a is connected to a hole 300b with a diameter of 1mm. In addition, in order to avoid electric field concentration of microwaves, chamfering 303 is performed on the corner portion of the hole 300 b on the gas introduction side. Then, a cylindrical porous ceramic sintered body 302 having a height of 5 mm and having pores communicating in the gas flow directio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com