Treatment method for wastewater with high ammonia nitrogen content

A technology for wastewater treatment and high ammonia nitrogen, which is applied in multi-stage water treatment, biological water/sewage treatment, light water/sewage treatment, etc. Nitrogen sensitivity and other problems, to achieve the effect of good effluent quality, superior denitrification effect, and stable effluent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

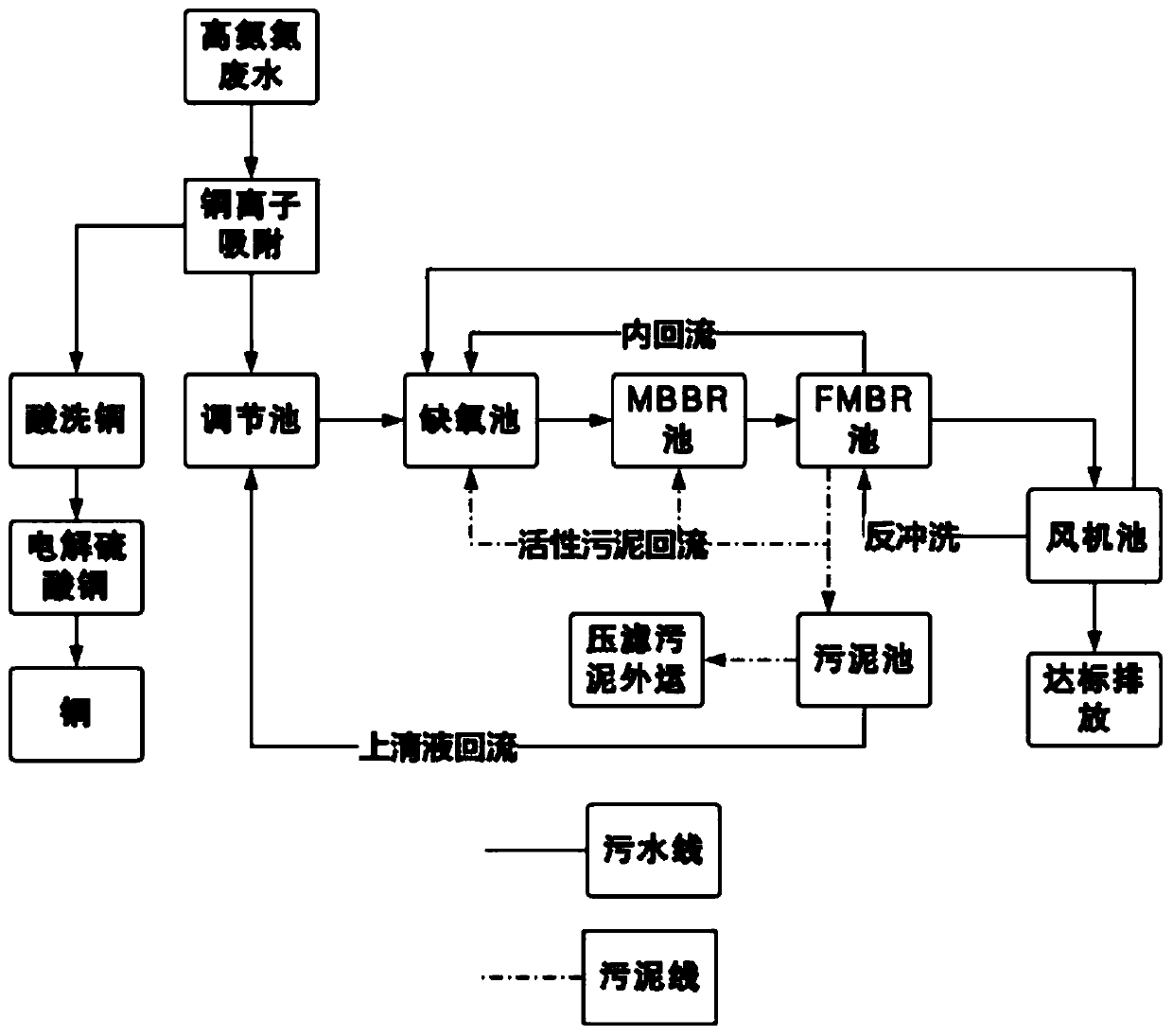

[0041] Combine below figure 1 A kind of high ammonia nitrogen wastewater treatment method of the present invention is specifically described, a kind of high ammonia nitrogen wastewater treatment method of the present invention comprises the following steps:

[0042] S1. Adsorb copper ions to adjust the pH of the high ammonia nitrogen wastewater to be treated to 5.25, then flow the high ammonia nitrogen wastewater to be treated into a resin column through a self-suction pipe, and the resin column adsorbs copper ions to obtain ammonia nitrogen content of 1500 mg / L and CODcr content It is 200mg / L primary treatment of high ammonia nitrogen wastewater, in which the resin column is filled with LSC-100 resin, and the copper ions adsorbed in the resin column are pickled with sulfuric acid to regenerate the resin filled in the resin column to regenerate copper sulfate, and then electrolyze copper sulfate to generate metal Copper, metal copper recycling;

[0043] S2. Regulating pond ad...

Embodiment 2

[0063] Combine below figure 1 A kind of high ammonia nitrogen wastewater treatment method of the present invention is specifically described, a kind of high ammonia nitrogen wastewater treatment method of the present invention comprises the following steps:

[0064] S1. Adsorb copper ions: adjust the pH of the high ammonia nitrogen wastewater to be treated to be 5, then flow the high ammonia nitrogen wastewater to be treated into a resin column through a self-suction pipe, and the resin column adsorbs copper ions to obtain ammonia nitrogen content of 1000mg / L, CODcr The first-stage treatment of high ammonia nitrogen wastewater with a content of 150mg / L, in which the resin column is filled with LSC-930 resin, the copper ions adsorbed in the resin column are pickled with sulfuric acid to regenerate the resin filled in the resin column to regenerate copper sulfate, and then electrolyze copper sulfate to generate Copper metal, copper recycling.

[0065] S2. Regulating pond adjust...

Embodiment 3

[0083] Combine below figure 1 A kind of high ammonia nitrogen wastewater treatment method of the present invention is specifically described, a kind of high ammonia nitrogen wastewater treatment method of the present invention comprises the following steps:

[0084] S1. adjust the pH of the high ammonia nitrogen wastewater to be treated to be 5.5, then the high ammonia nitrogen wastewater to be treated flows into the resin column through the suction pipe, and the resin column absorbs copper ions, so that the ammonia nitrogen content is 2000mg / L, and the CODcr content is 200mg / L. L’s primary treatment of high ammonia nitrogen wastewater, in which the resin column is filled with LSC-930 resin, the copper ions adsorbed in the resin column are pickled with sulfuric acid to regenerate the resin filled in the resin column to regenerate copper sulfate, and then the copper sulfate is electrolyzed to generate metallic copper.

[0085] S2. Regulating pond adjustment: the primary treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com