Patents

Literature

41results about How to "Won't pour back" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Indoor drainage system capable of prevention sewage from pouring

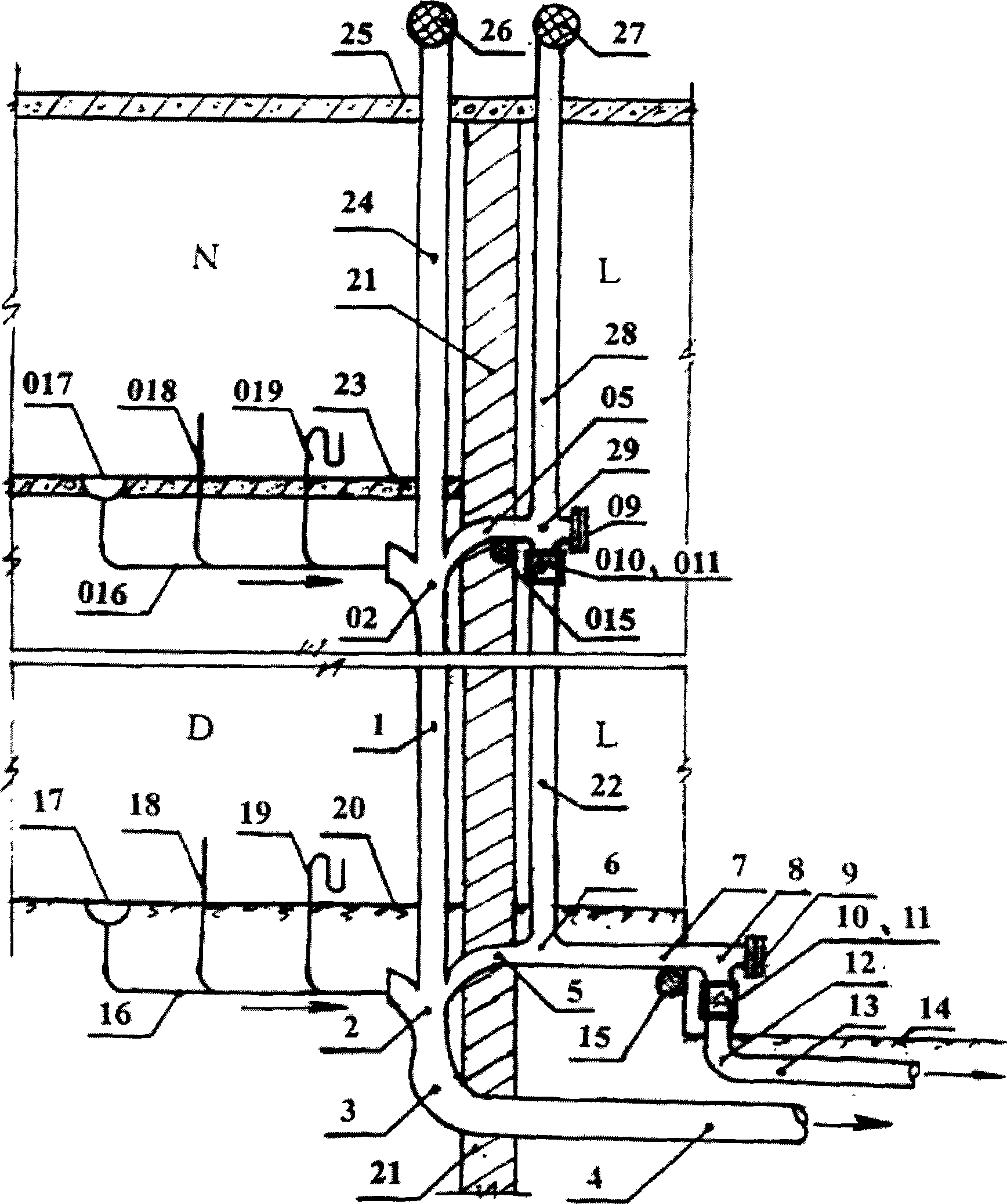

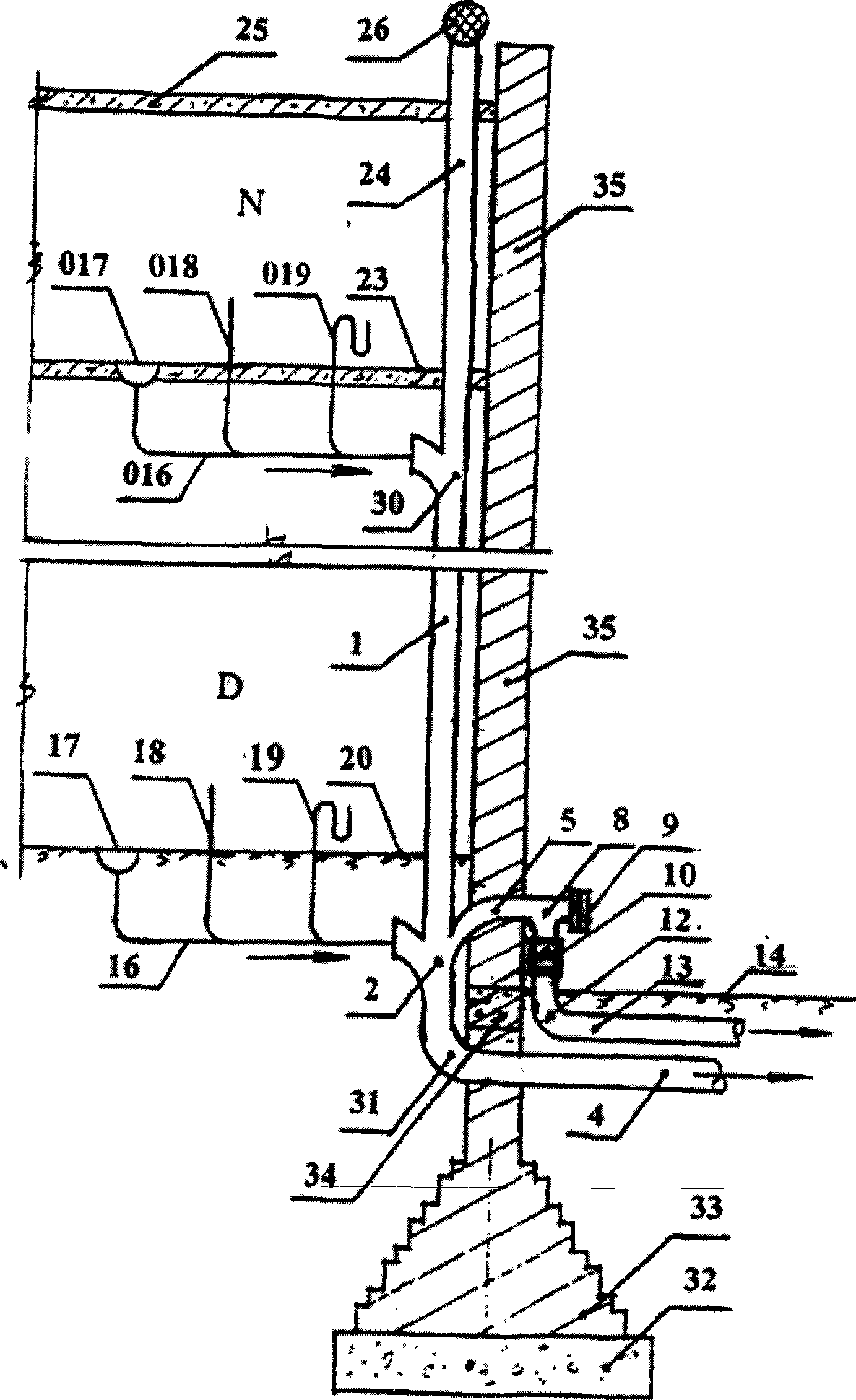

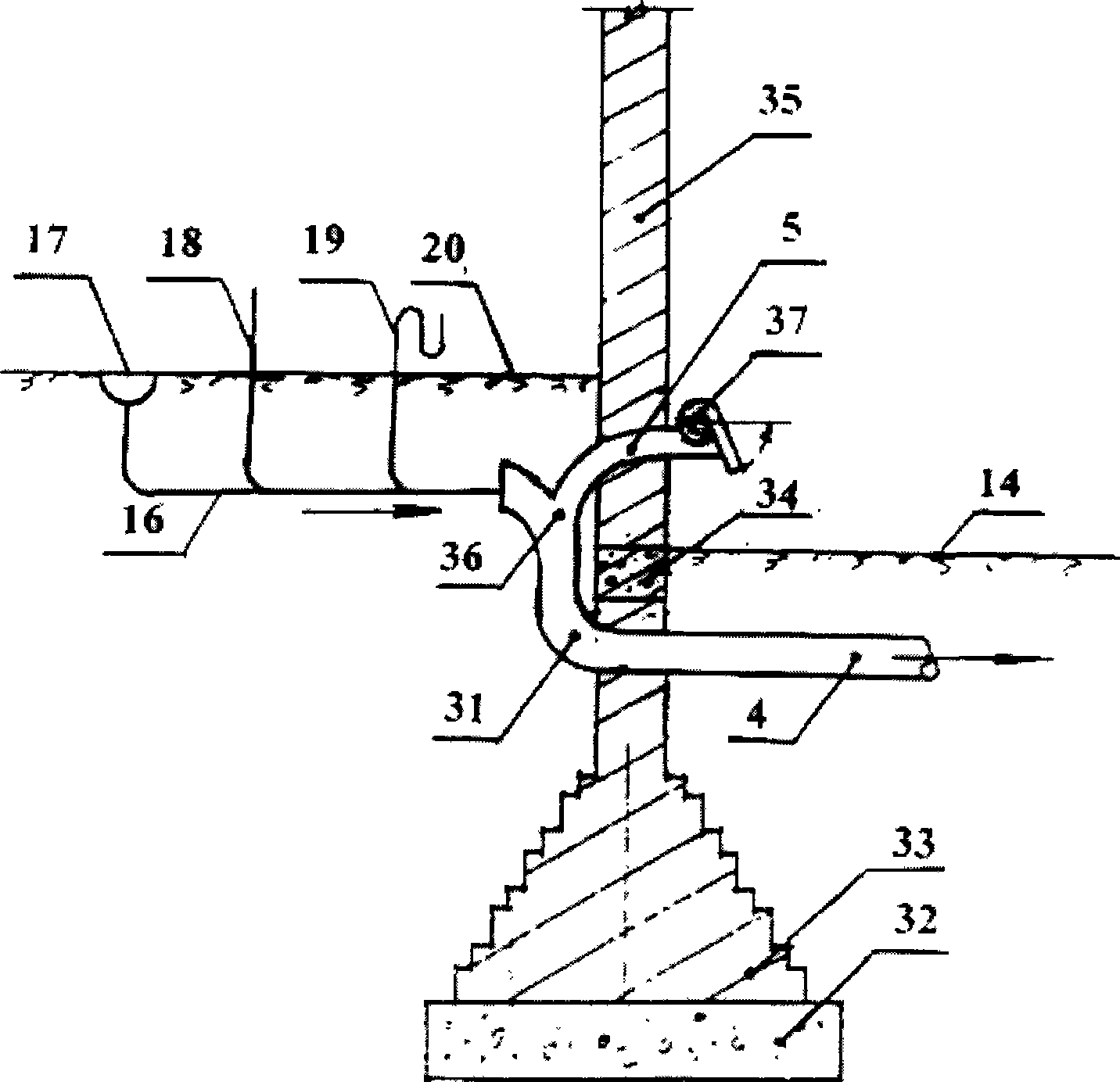

The invention discloses an indoor drainage system for preventing back flow of sewage, which is applicable to residential buildings, office buildings, commercial buildings, hotels, auditoriums, etc. The indoor drainage system mainly comprises a drainage stand pipe and a stack vent thereof, a cross junction, a drainage elbow of 90 degrees, a discharge pipe, an overflow pipe (the pipe bottom is about 150mm lower than the indoor ground level), an indoor overflow horizontal pipe, an overflow drainage tee, a blind flange (positioned at staircases or outdoors), a transparent observation pipe, an overflow telemetering light control probe, an electrical control probe, an overflow discharge pipe, a horizontal drainage branch pipe, sanitary ware, an overflow stand pipe and a stack vent thereof. When some place of the drainage stand pipe or the discharge pipe is blocked, the sewage is automatically discharged from the overflow pipe and not returned indoors. When the pipe is cleared, the blind flange is taken off, a spring soft shaft of an electric cleaning machine is rotatably inserted into the pipe mount and the pipe can be cleaned in short time. As the cleaning machine is not arranged indoors, the pipe can be periodically cleaned for blockage prevention. The telemetering device can timely discover blockage of the drainage pipe.

Owner:刘宪武 +2

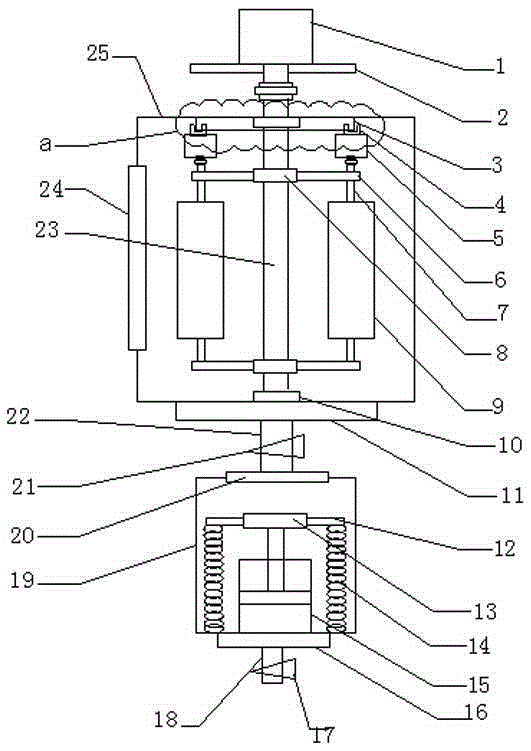

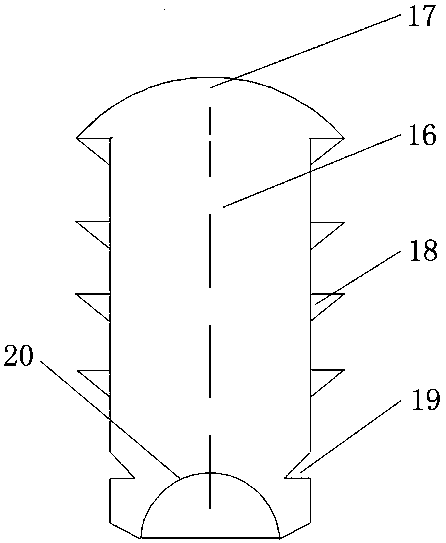

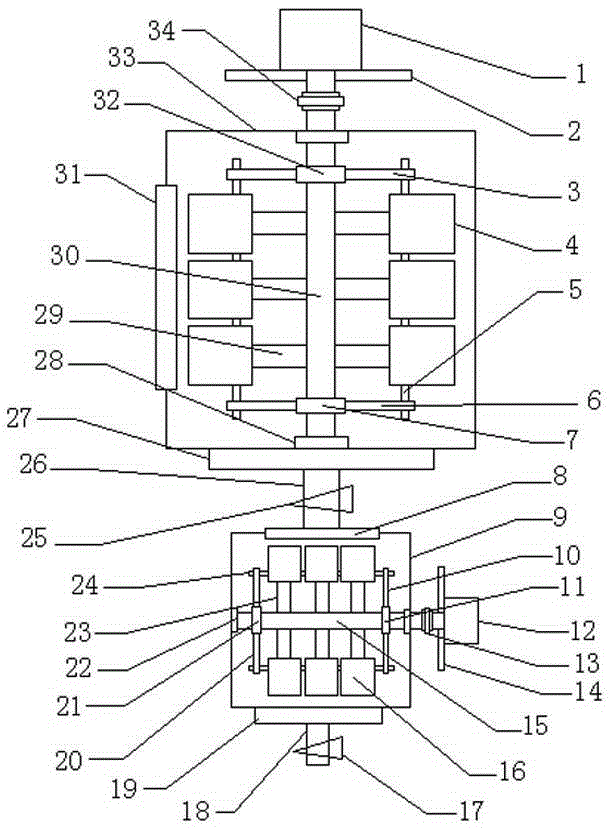

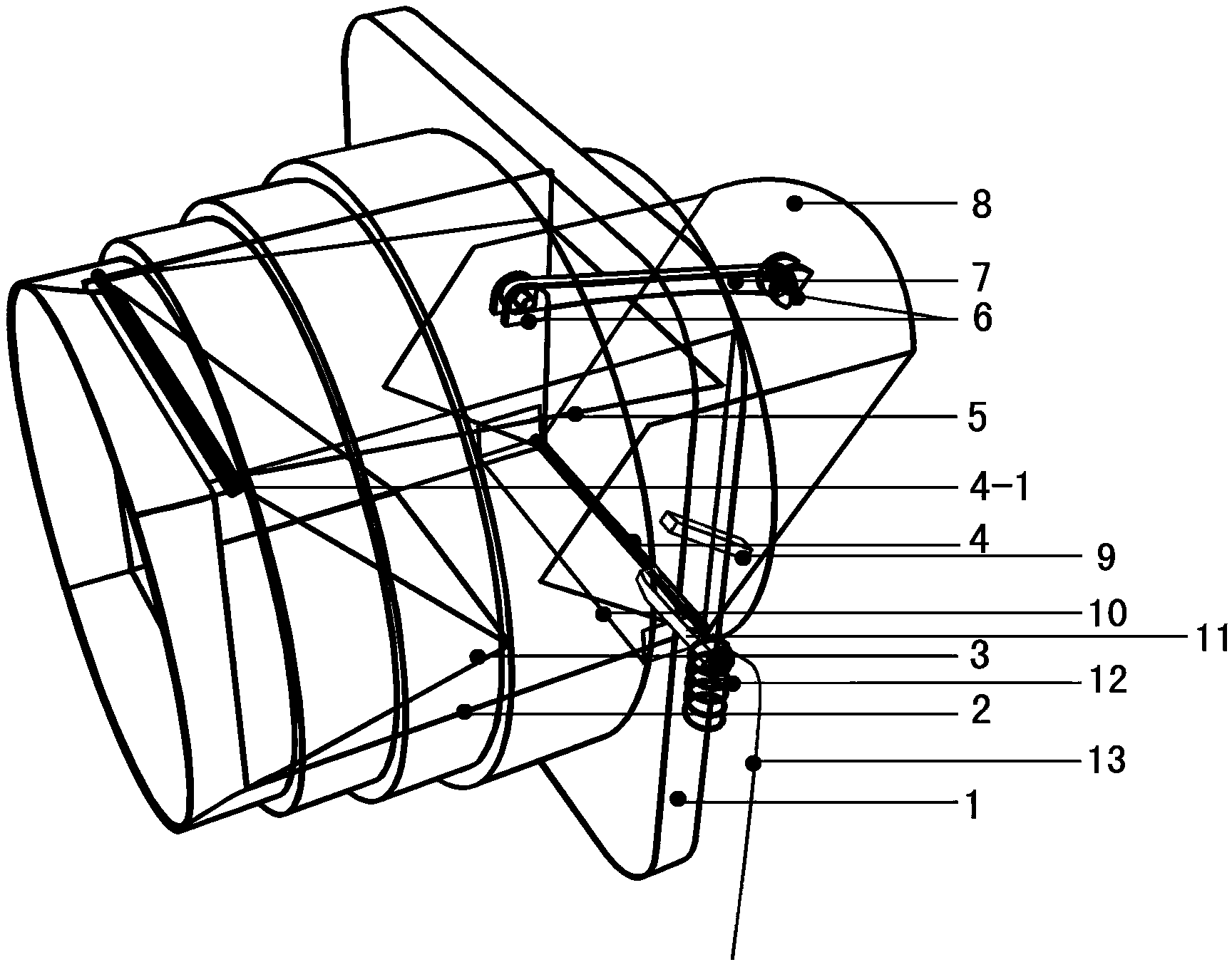

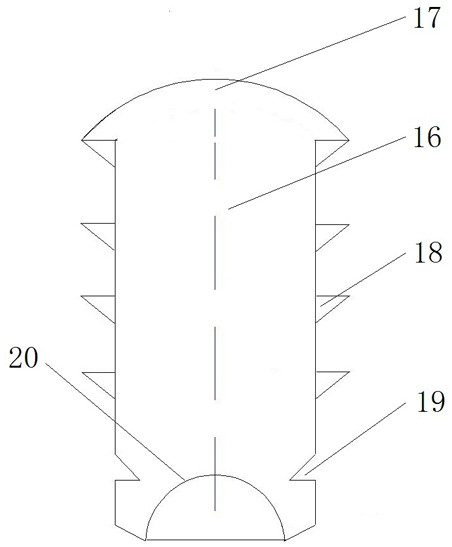

Integrated vertical-axis tidal current energy power generation device

InactiveCN105317622AWon't pour backAchieve conversionMachines/enginesEngine componentsEngineeringDynamo

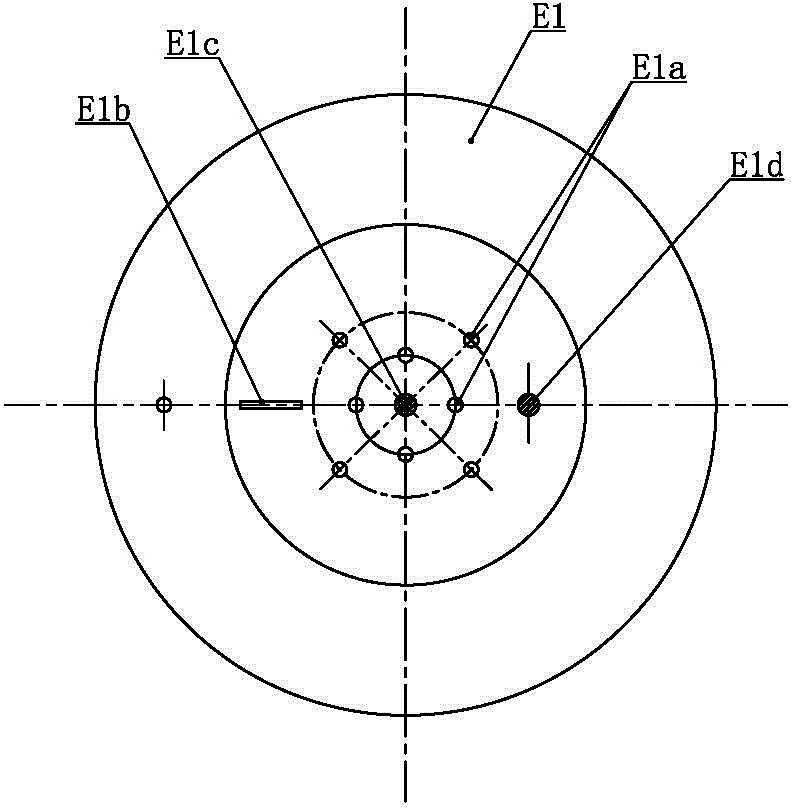

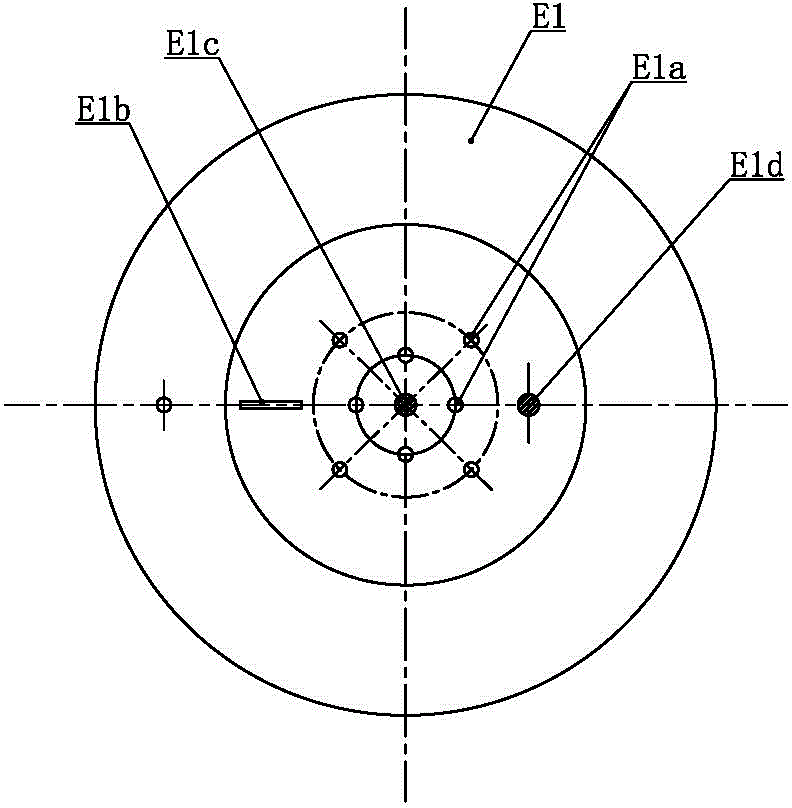

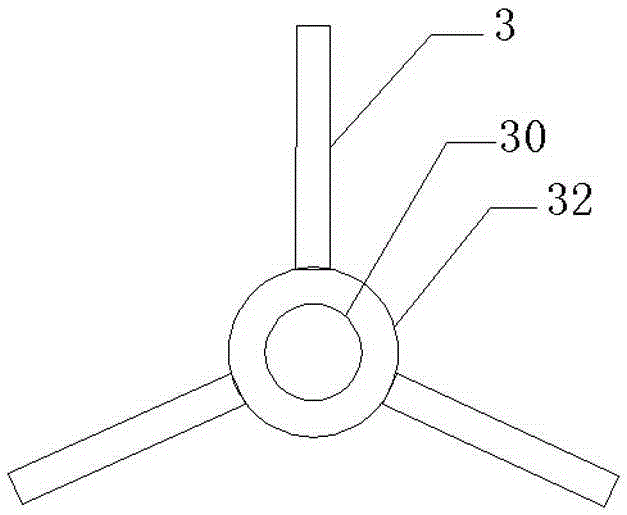

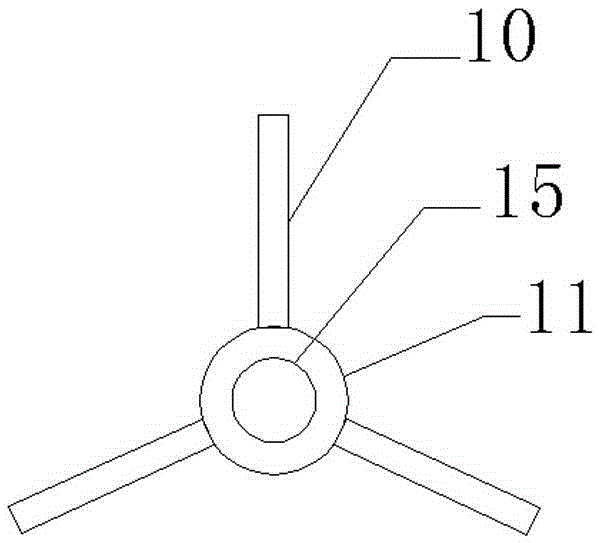

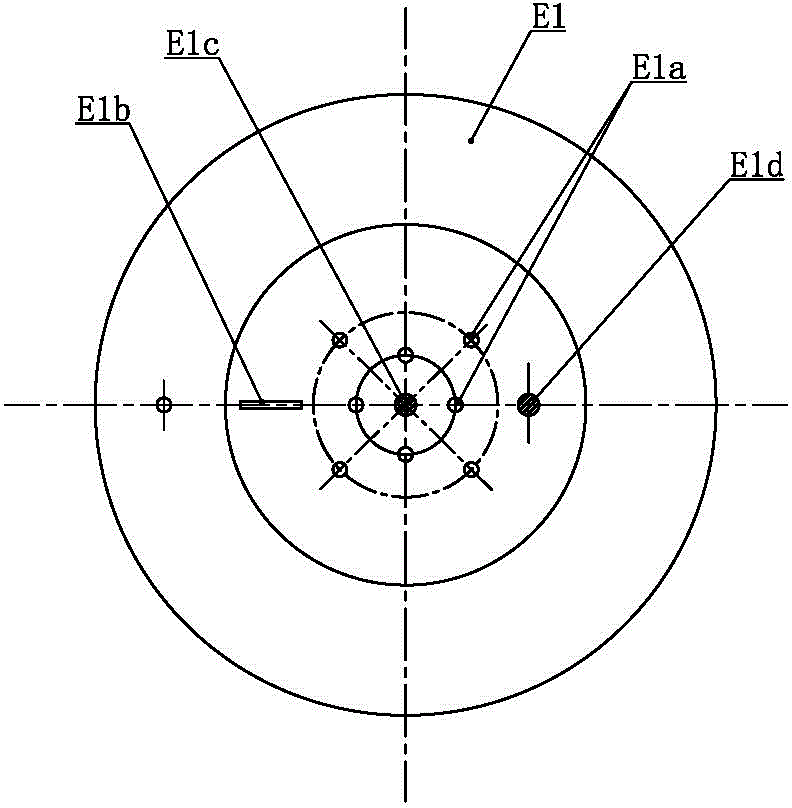

The invention relates to an integrated vertical-axis tidal current energy power generation device and belongs to the technical field of tidal current energy power generation. The integrated vertical-axis tidal current energy power generation device comprises a first generator, a rack, a sliding rail, sliding blocks, second generators, supports, blade shafts, a shaft sleeve, blades, flange bearings, a first flow outlet, a connecting plate, a pushing plate, springs, oil cylinders, a second flow outlet, a second piston type one-way valve, a second outflow pipe, a second housing, a second flow inlet, a first piston type one-way valve, a first outflow pipe, a rolling shaft, a first flow inlet and a first housing. The first flow inlet is formed in the left side of the first housing. The flange bearings are mounted at the upper end and the lower end of the interior of the first housing respectively. The rolling shaft is mounted on the flange bearings. The upper end of the rolling shaft stretches out of the first housing. The integrated vertical-axis tidal current energy power generation device has the advantage of being high in power generation efficiency.

Owner:ZHEJIANG OCEAN UNIV

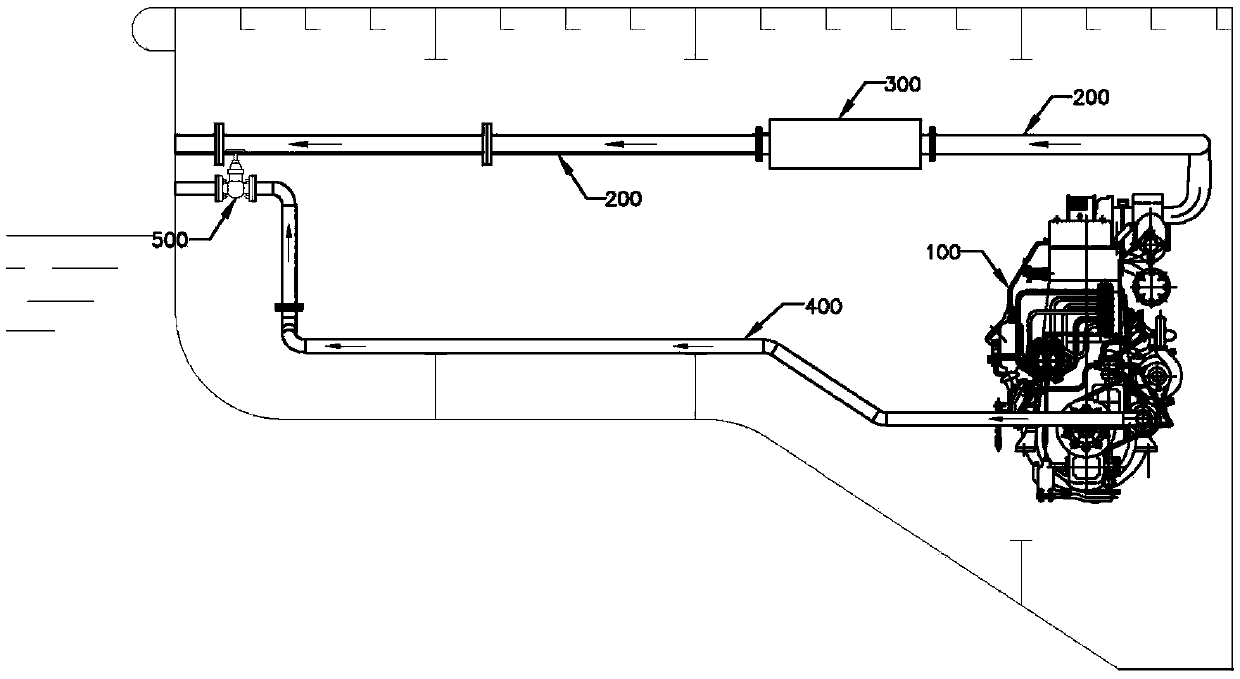

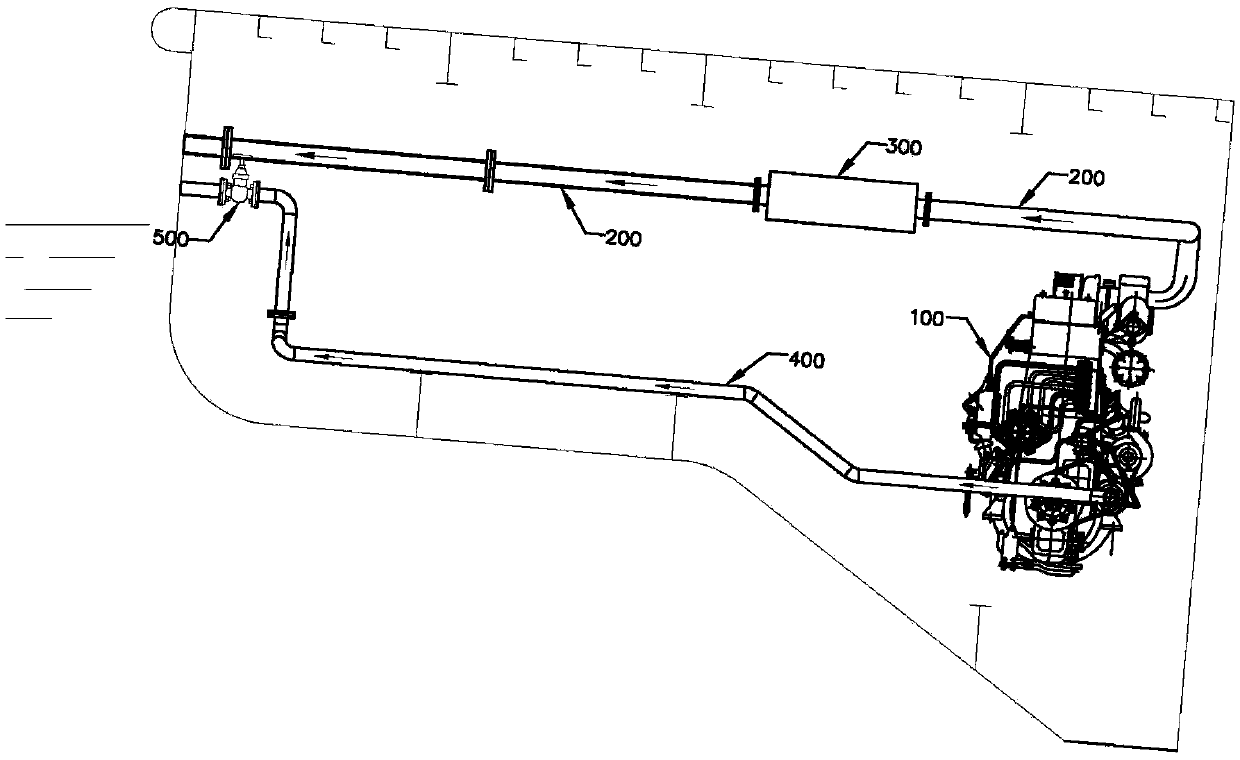

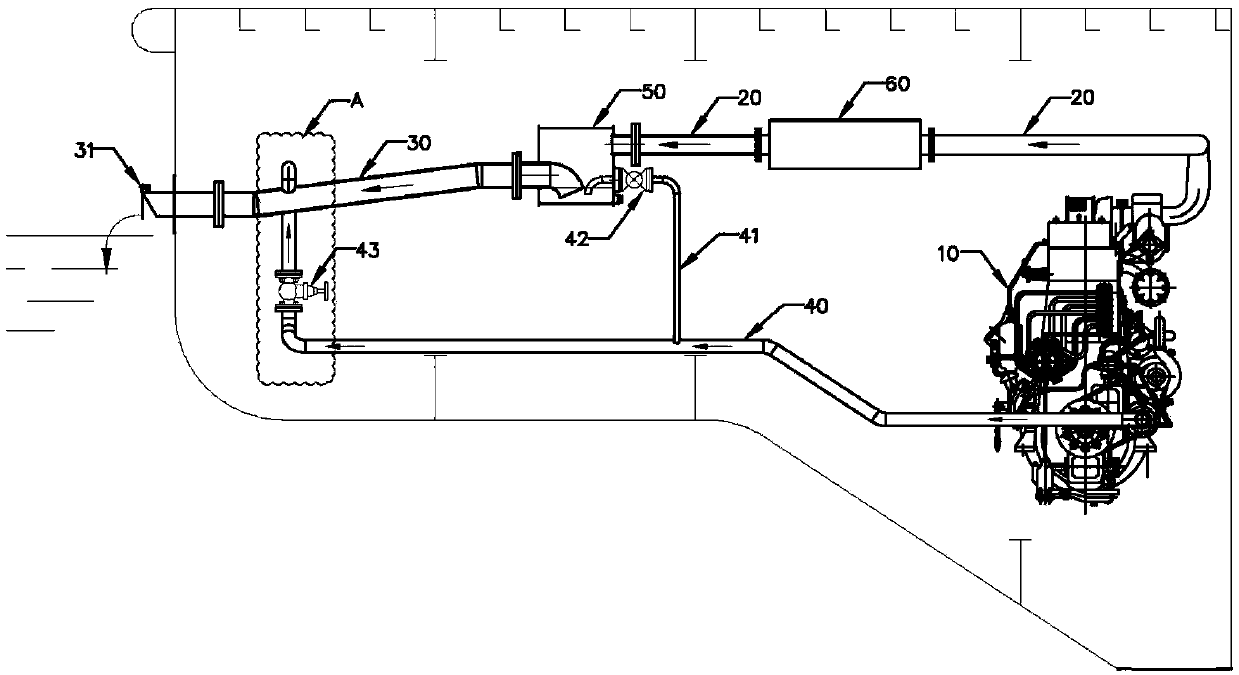

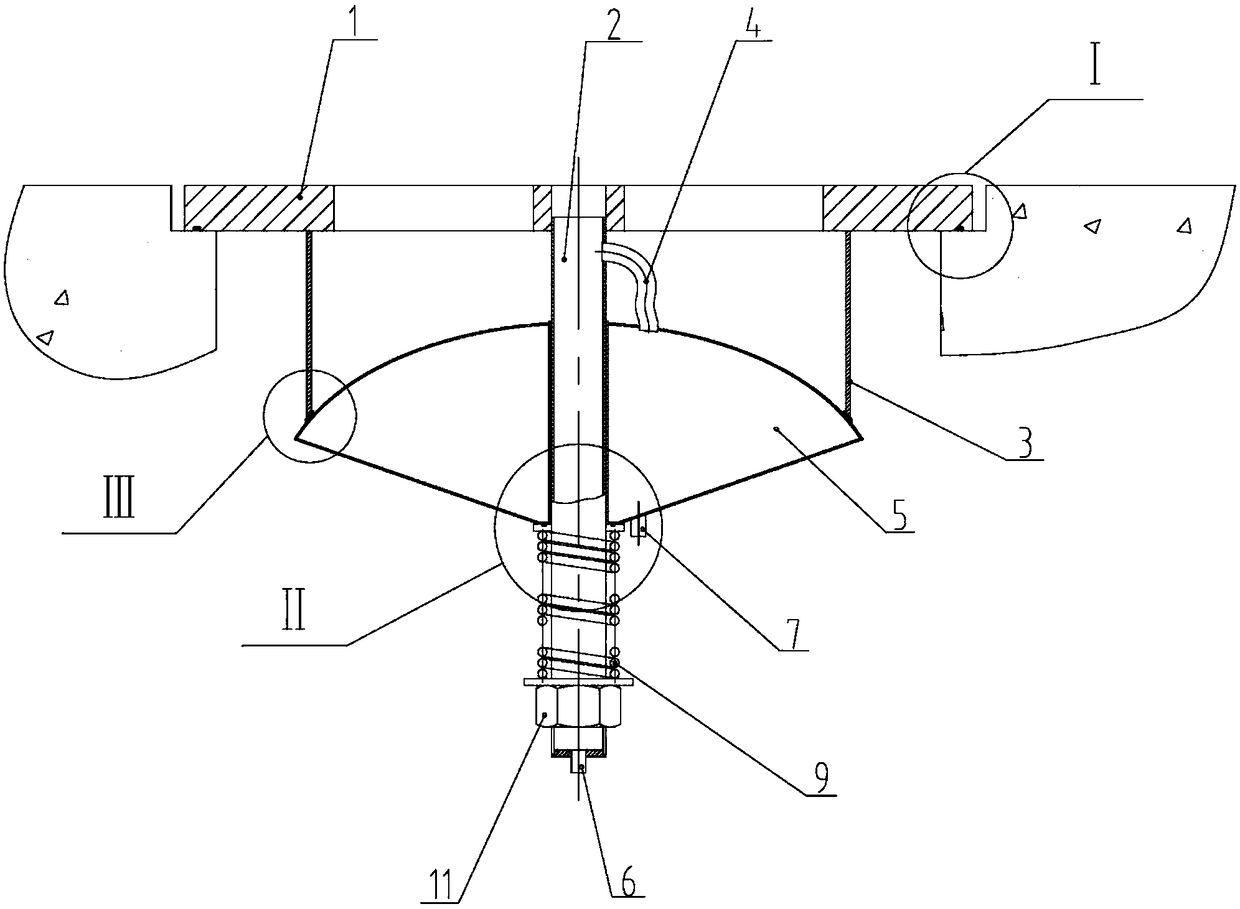

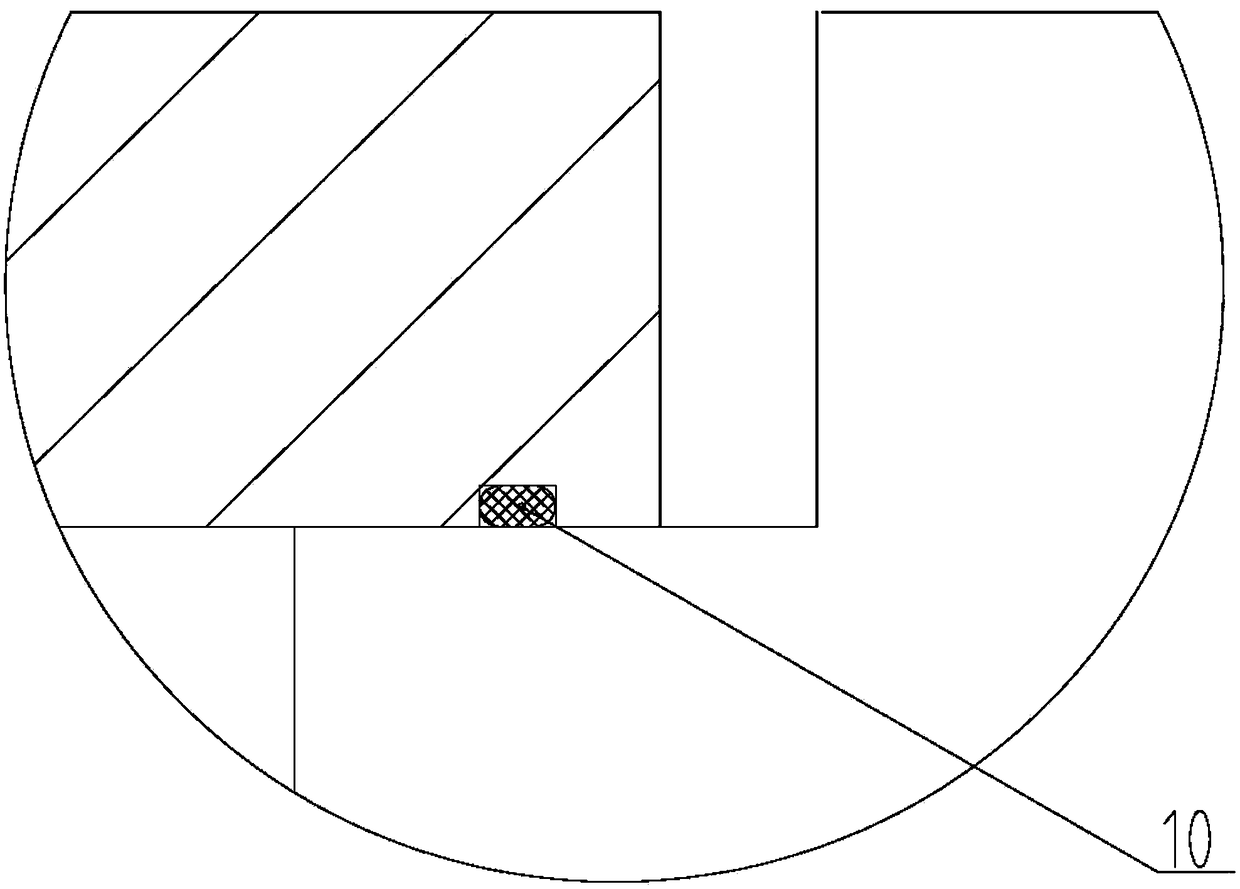

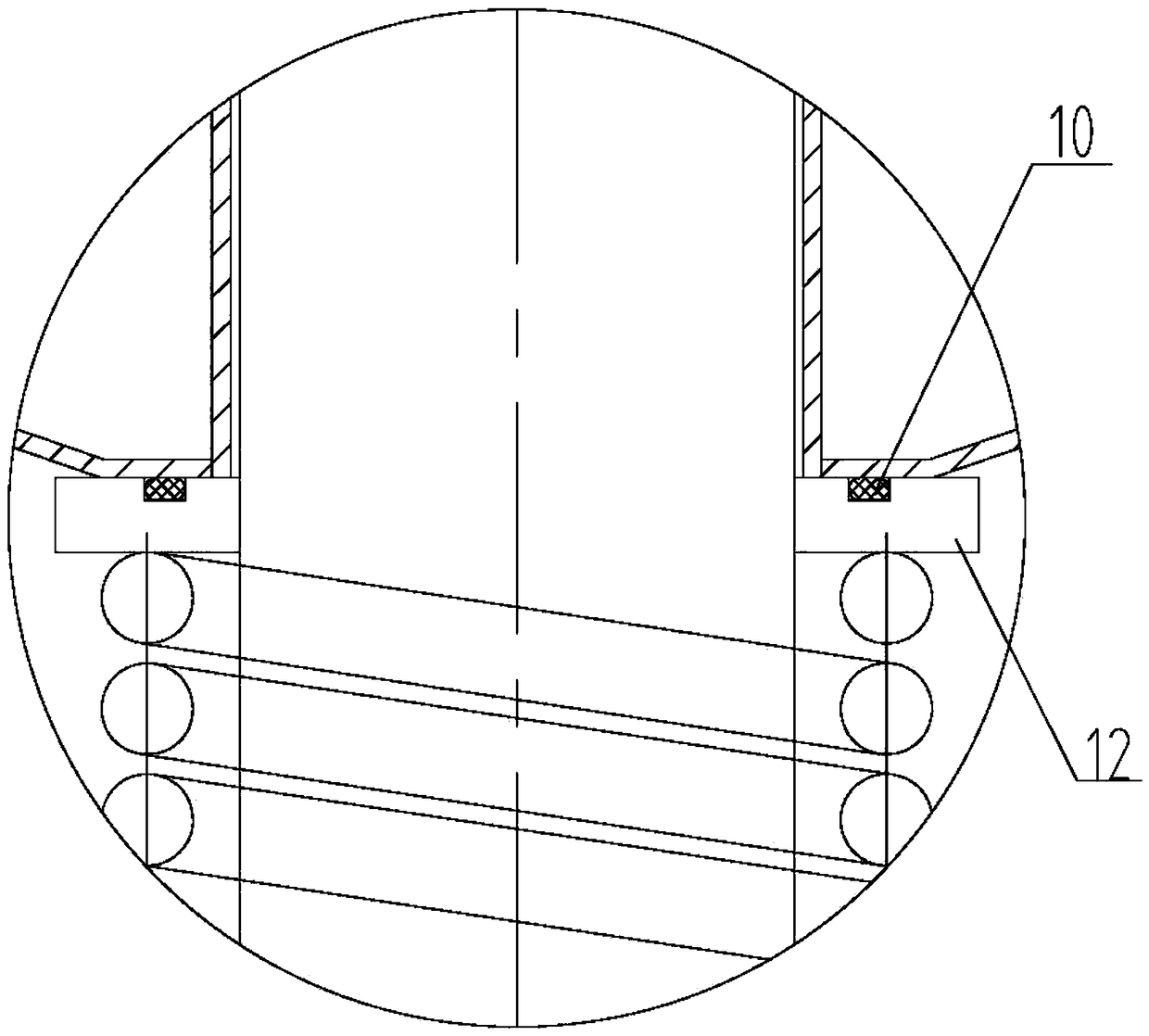

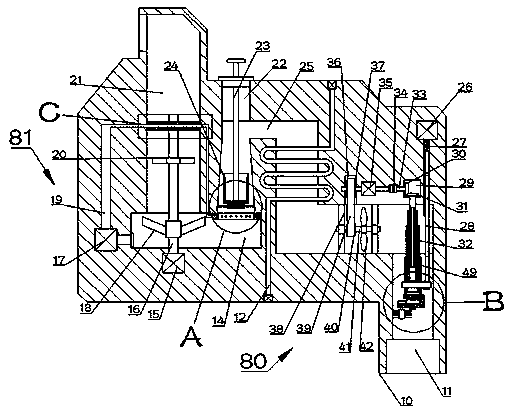

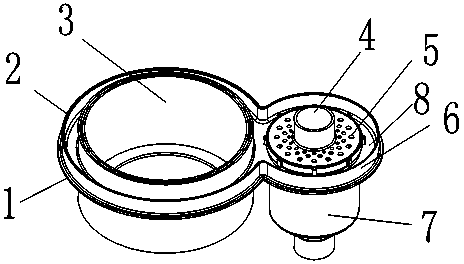

Ship exhaust system and wet exhaust apparatus thereof

ActiveCN108678848AReduce the temperatureWon't pour backExhaust apparatusSilencing apparatusEngineeringSulfide

The invention discloses a ship exhaust system and a wet exhaust apparatus thereof. The wet exhaust apparatus is connected in the ship exhaust system, and comprises a main body pipe, a gas inlet pipe,a water inlet pipe and a gas exhaust pipe, wherein the gas inlet pipe and the water inlet pipe are disposed at a first end surface of the main body pipe, the gas exhaust pipe is disposed at a second end surface of the main body pipe; the gas inlet pipe is connected to an outlet end of a first smoke exhaust pipe, the water inlet pipe is connected to a first outlet end of a seawater discharge pipe;the gas exhaust pipe is connected to an inlet end of a second smoke exhaust pipe, a first elbow is connected to the gas exhaust pipe; and the first elbow is disposed in the main body pipe, and the endopening of the first elbow is disposed downward, wherein the distance between the bottommost position at the end opening of the first elbow and a centerline of the gas exhaust pipe is between a radius of the gas exhaust pipe and a half of the exhaust backpressure of a diesel generator. According to the ship exhaust system and the wet exhaust apparatus thereof, the discharge of black smoke is effectively reduced, the emission of atmospheric sulfides is reduced, and waves are effectively prevented from flowing backwards to influence the diesel generator.

Owner:CHINA MERCHANTS HEAVY IND SHENZHEN +1

Downward open type automatic drainage well lid

InactiveCN108179802ALow costThere will be no backflow phenomenonSewerage structuresWater storageTerrain

The invention belongs to the field of urban drainage systems, and particularly relates to a downward open type automatic drainage well lid. The well lid comprises a well lid body, an outer ring of thewell lid body is a solid part, an inner ring of the well lid body is a hollowed-out part, and a drainage hole is formed in the center of the well lid body; a supporting ring is arranged on the lowersurface of the well lid body in the circumferential direction; a drainage pipe communicated with the drainage hole is arranged below the well lid body, and a water storage bin is movably arranged on the drainage pipe; a plurality of water inlets are uniformly formed in the top of the water storage bin in the circumferential direction, and a water outlet is formed in the bottom of the water storagebin; the water storage bin is tightly attached to the edge of the supporting ring through an elastic device. The water storage bin and the supporting ring are tightly attached through the elastic device, so that the well lid device is especially suitable for road sections low in terrain, and no backward flowing phenomenon is caused. In addition, the well lid is simple in structure and low in cost, and a worker does not need to watch the well lid during use, no other peripheral equipment is used, and the application range is wide.

Owner:陈年康

Vertical-axis tidal current energy hydraulic turbine set with seaworthiness adjusting device

InactiveCN105179145AWon't pour backHydro energy generationMachines/enginesWater flowPulp and paper industry

The invention belongs to the technical field of ship accessories, and relates to a vertical-axis tidal current energy hydraulic turbine set with a seaworthiness adjusting device. The vertical-axis tidal current energy hydraulic turbine set comprises a rack, a first generator, a first coupler, a machine shell, a first connecting rod, first blades, connecting columns, second rollers, second blades, second couplers, second generators, a first support, a second support, a third generator, a third coupler, third blades, a third roller, a piston type one-way valve, a third support, a water outlet pipe, a second connecting rod, supporting frames, water inlet pipes, water suction pumps, water outlet pipes, a first roller and flange bearings. The flange bearings are arranged at the upper end and the lower end in the machine shell. The first roller is installed on the two flange bearings, and the upper end of the first roller extends out of the machine shell. The vertical-axis tidal current energy hydraulic turbine set has the beneficial effects that water flowing down from the blades can be used, and water flowing out of a flowing-out pipe of a hydraulic turbine can be secondarily utilized.

Owner:ZHEJIANG OCEAN UNIV

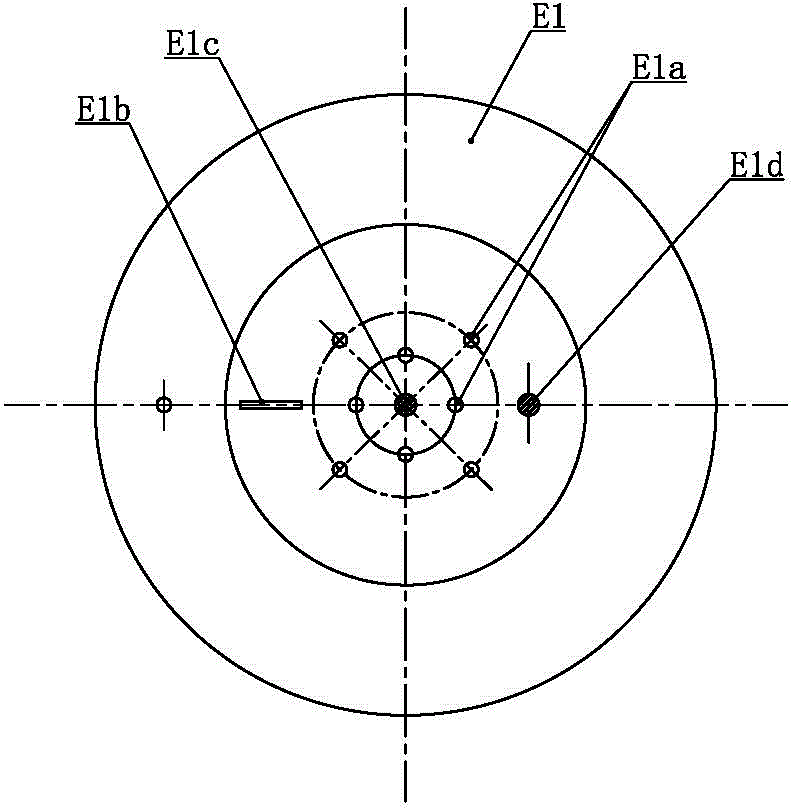

Electromagnetic check valve of common flue

InactiveCN104089075AAvoid odorSolve the odorOperating means/releasing devices for valvesCheck valvesFlueAirflow

The invention discloses an electromagnetic check valve of a common flue. The electromagnetic check valve comprises a base, a barrel body, a valve element, a one-way valve block and a reducing ring, wherein the valve element and the one-way valve block are arranged in the barrel body. The electromagnetic check valve is characterized in that an electromagnetic device is arranged on the valve element, and an iron sheet is arranged at the position, corresponding to the electromagnetic device, of the one-way valve block; the electromagnetic device comprises an electromagnet, and a common magnet is fixed at the top of the electromagnet. When a smoke exhaust starts to work, the electromagnetic device is in the power-on state, magnetic fields of the electromagnet and the common magnet are offset, magnetic force of the electromagnetic device is lost, and the one-way valve block can be freely opened. Air flow with cooking fumes passes through an air inlet and a cooking fume channel to push the one-way valve block open, and the cooking fumes are discharged into the common flue. When the smoke exhaust stops working, the electromagnetic device is in the power-off state, the magnetic force of the electromagnetic device is recovered, the electromagnetic device and the iron sheet on the one-way valve block are attracted, the one-way valve block falls to the position of a circular stopping ring of the barrel body under the effects of suction force of the magnet and the gravity of the one-way valve block, the cooking fume channel smoke channel and the common flue are separated to form complete sealing.

Owner:HANGZHOU SIMTONE ELECTRICAL APPLIANCE EQUIP

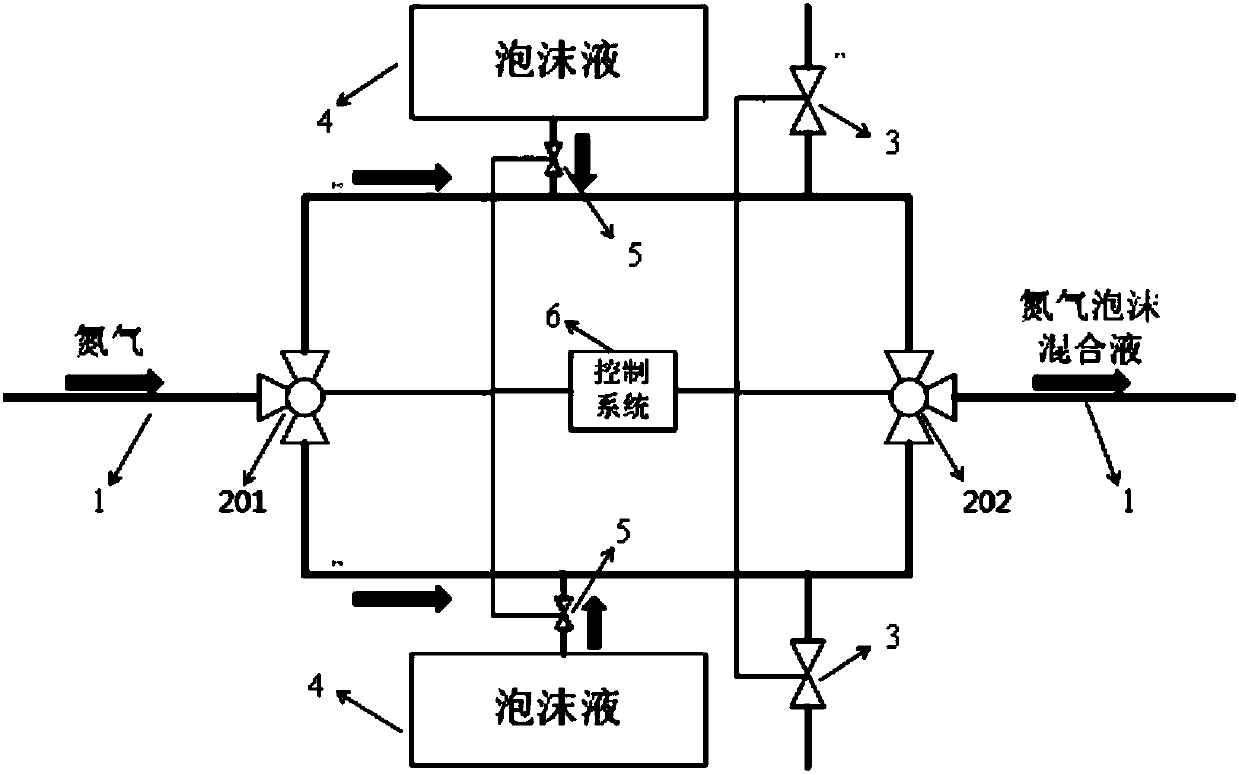

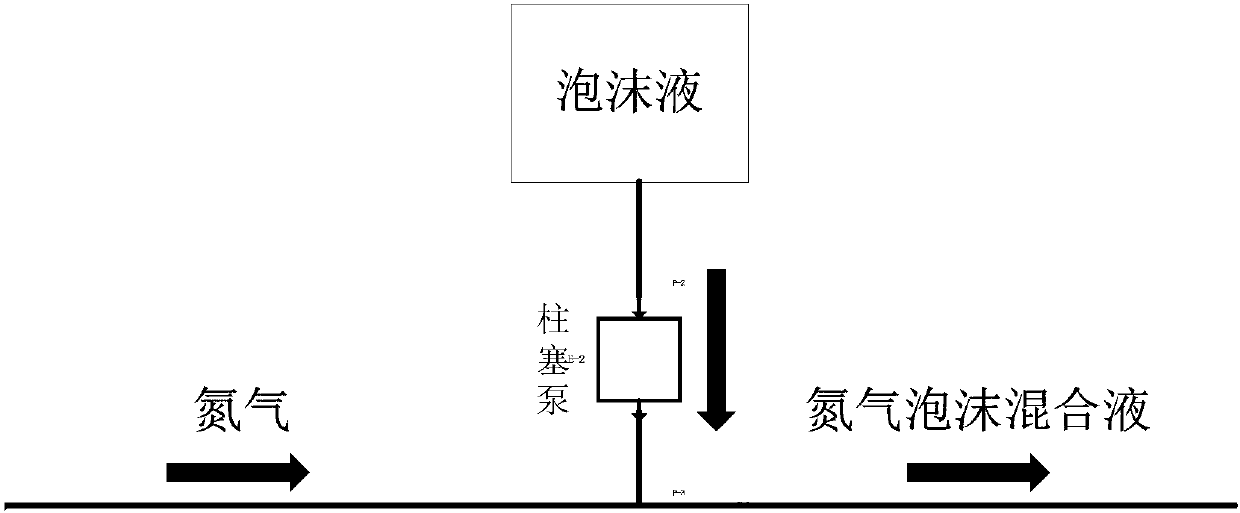

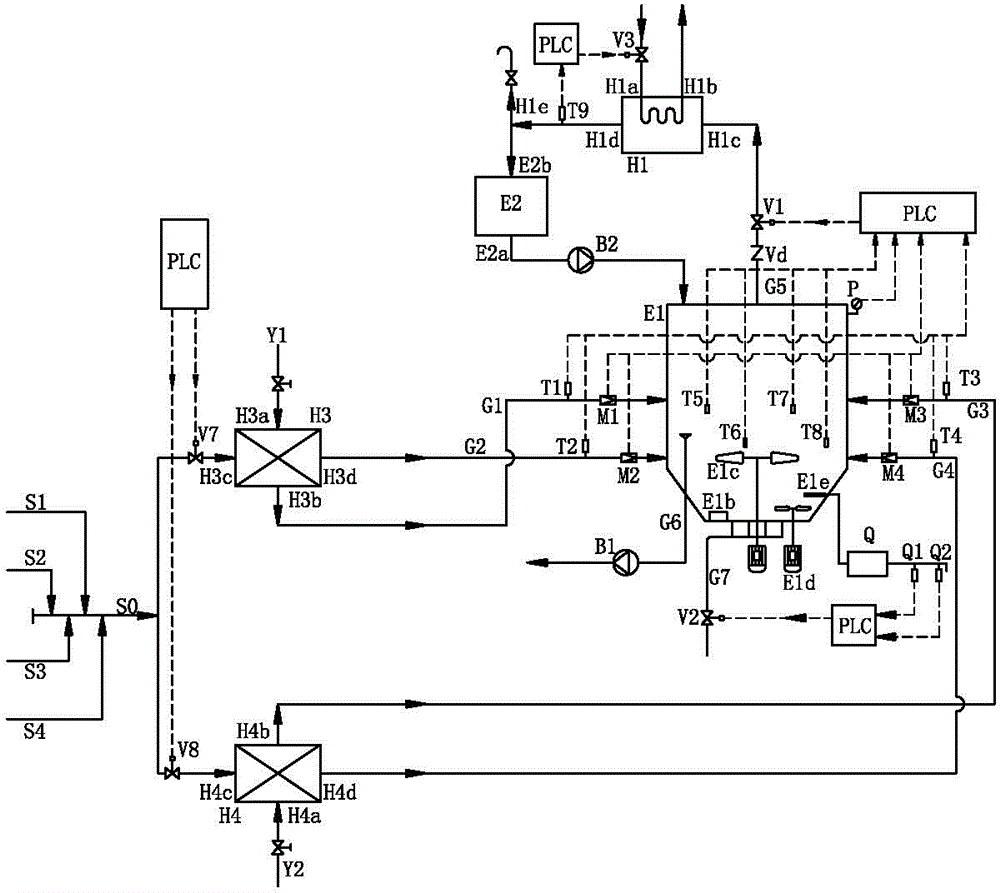

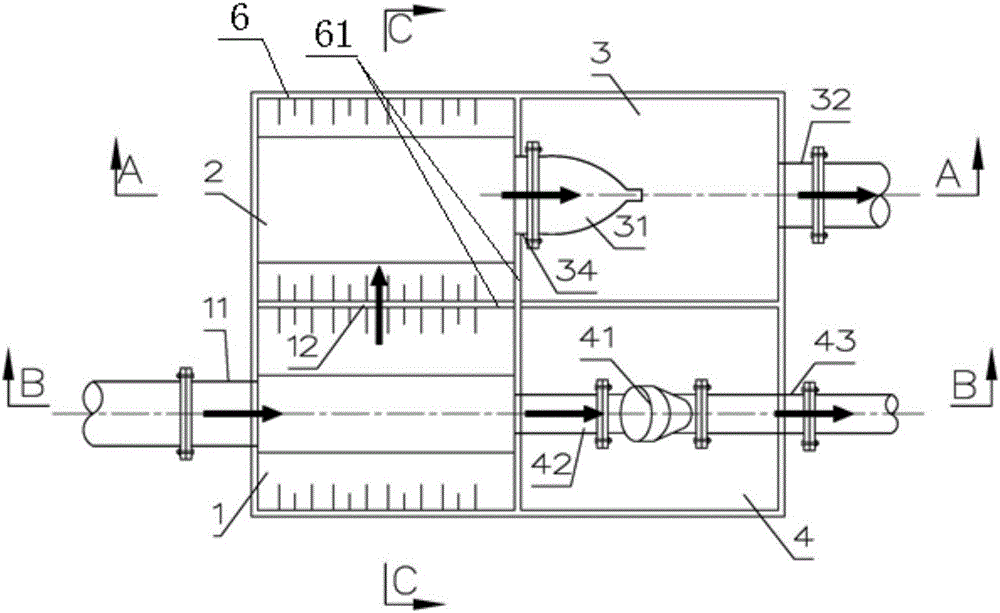

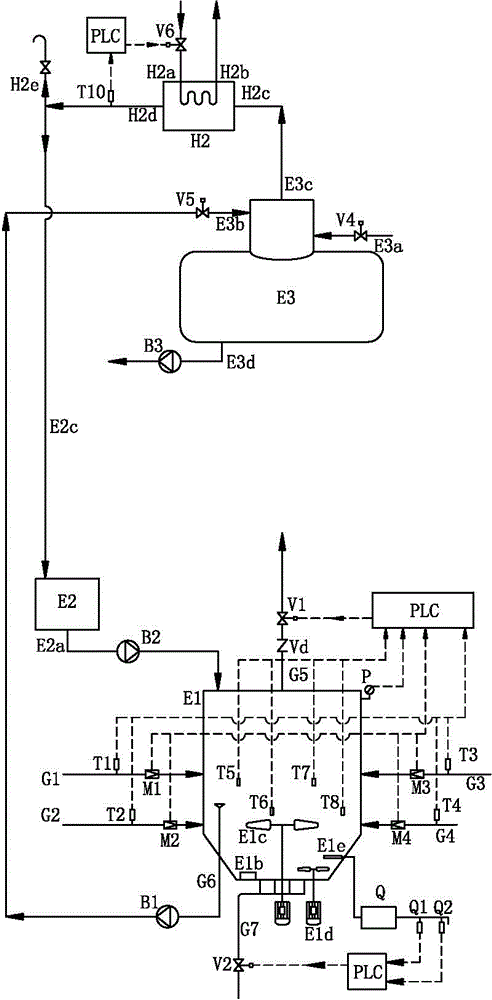

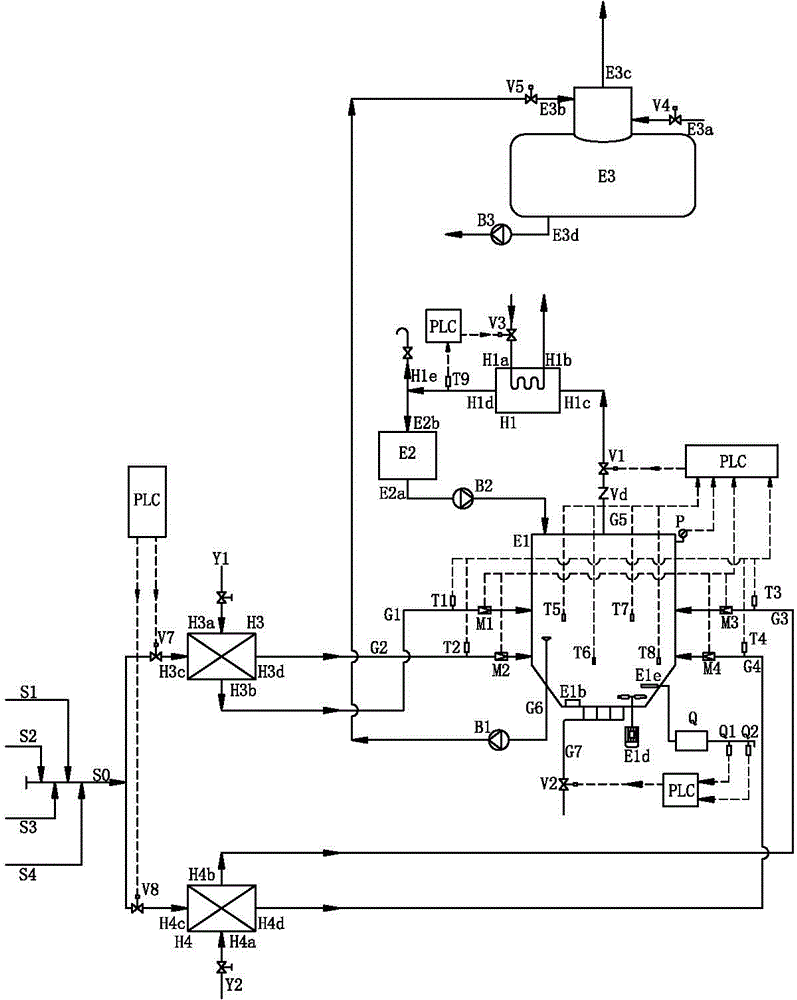

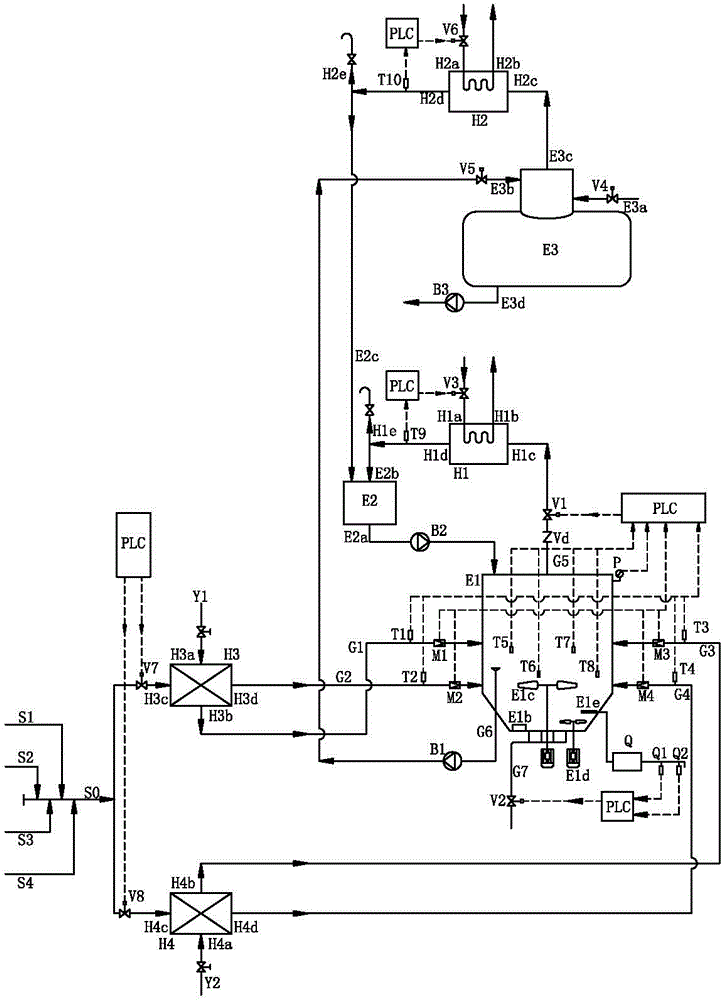

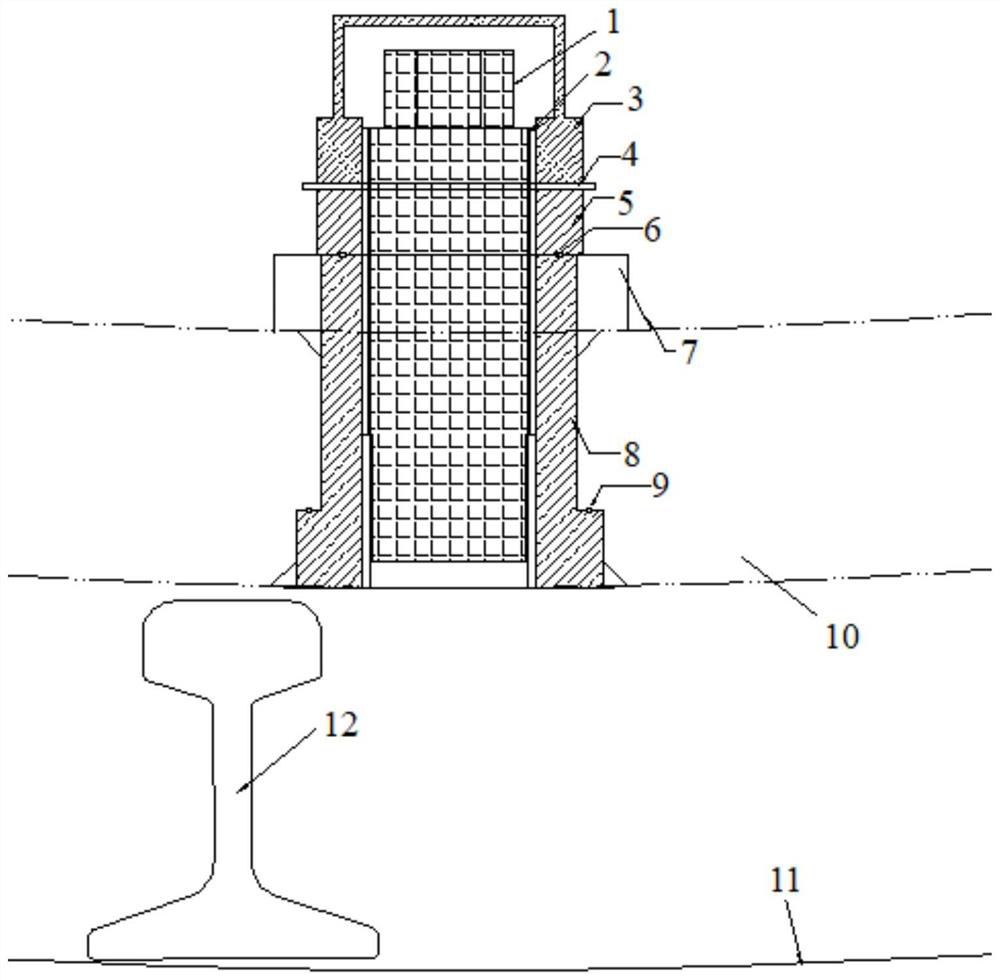

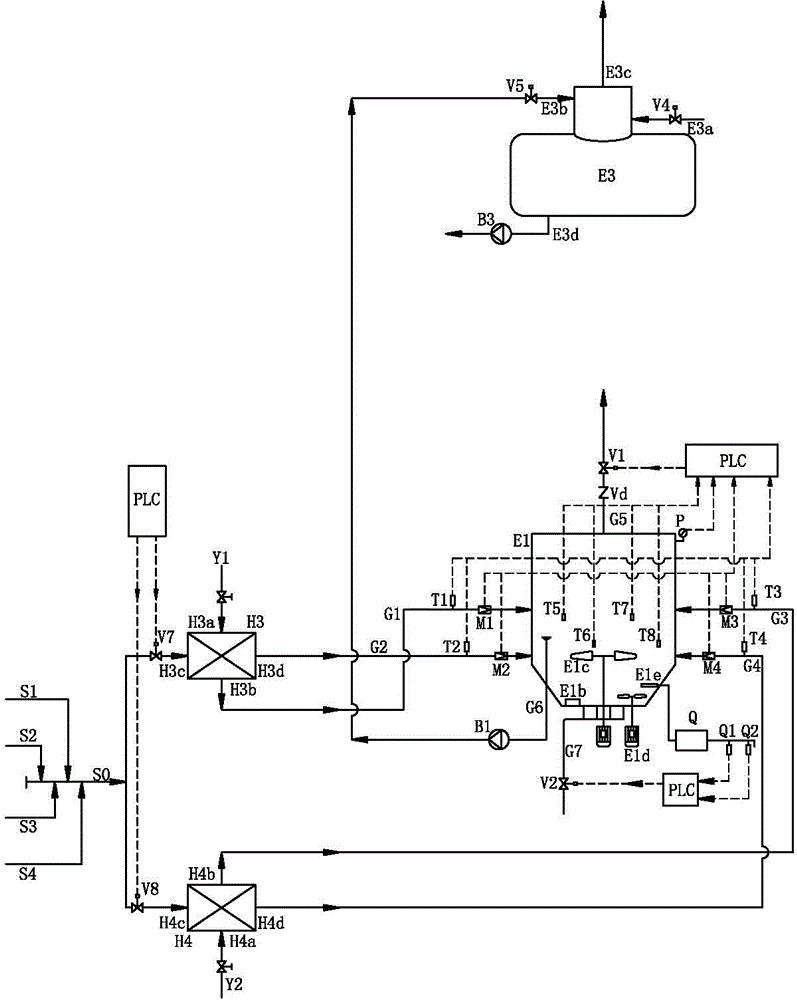

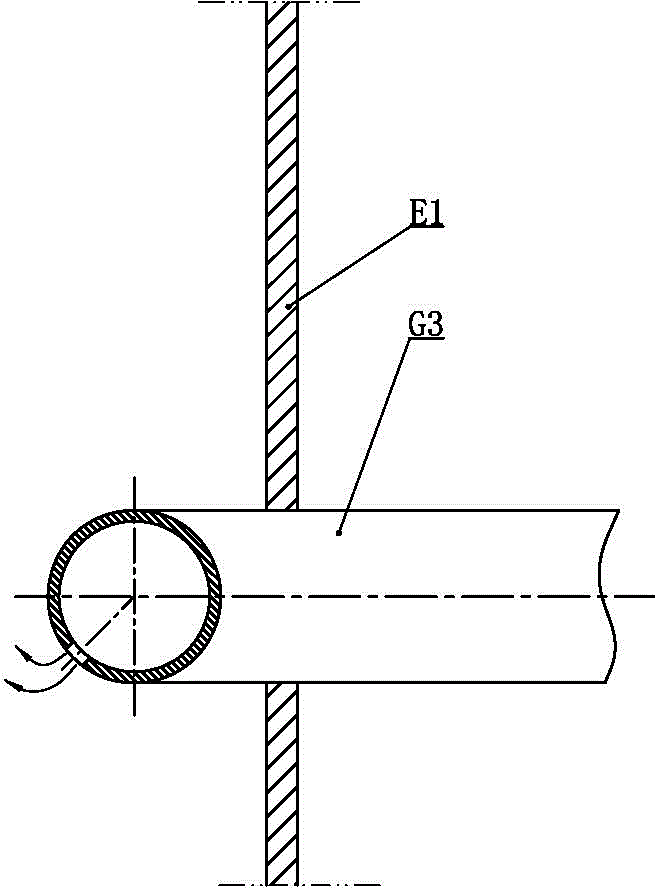

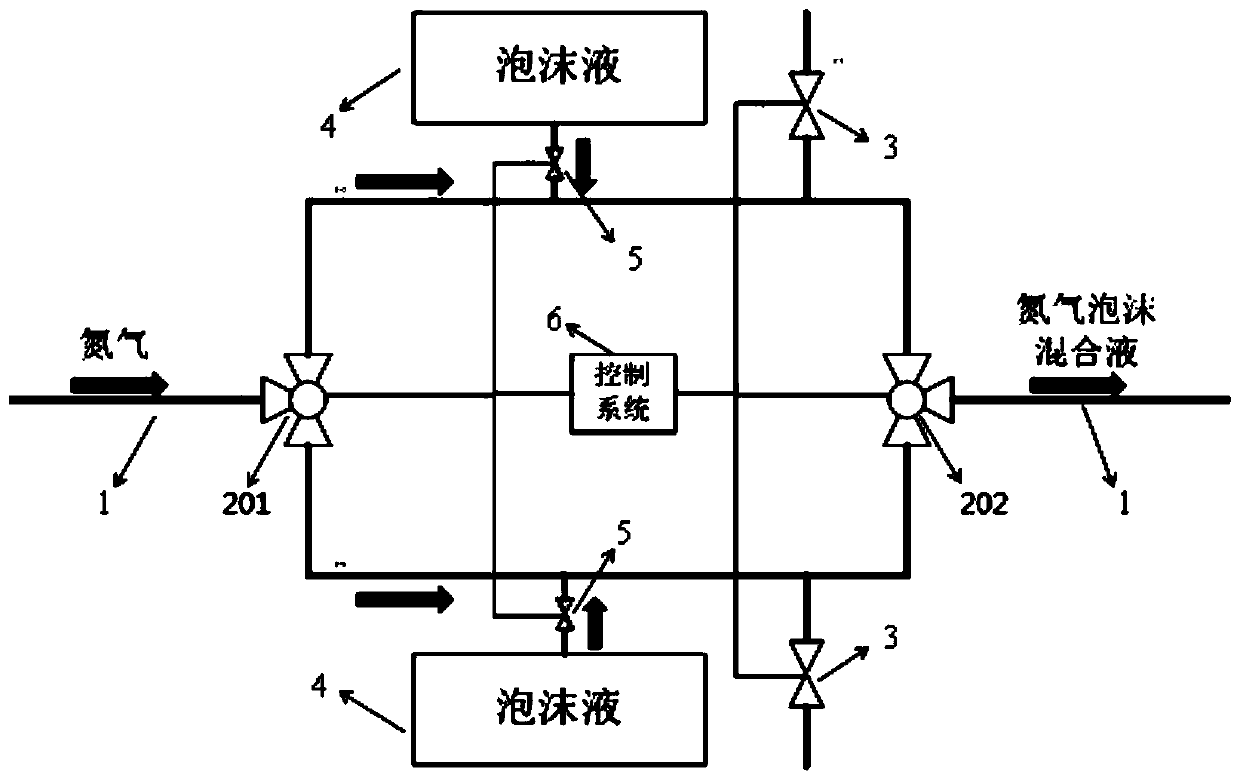

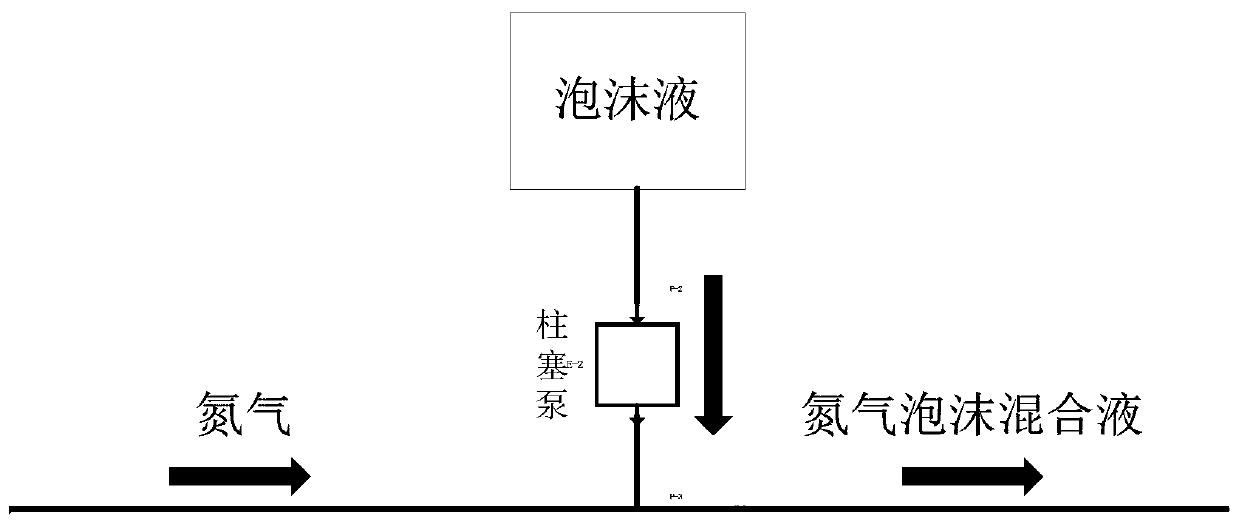

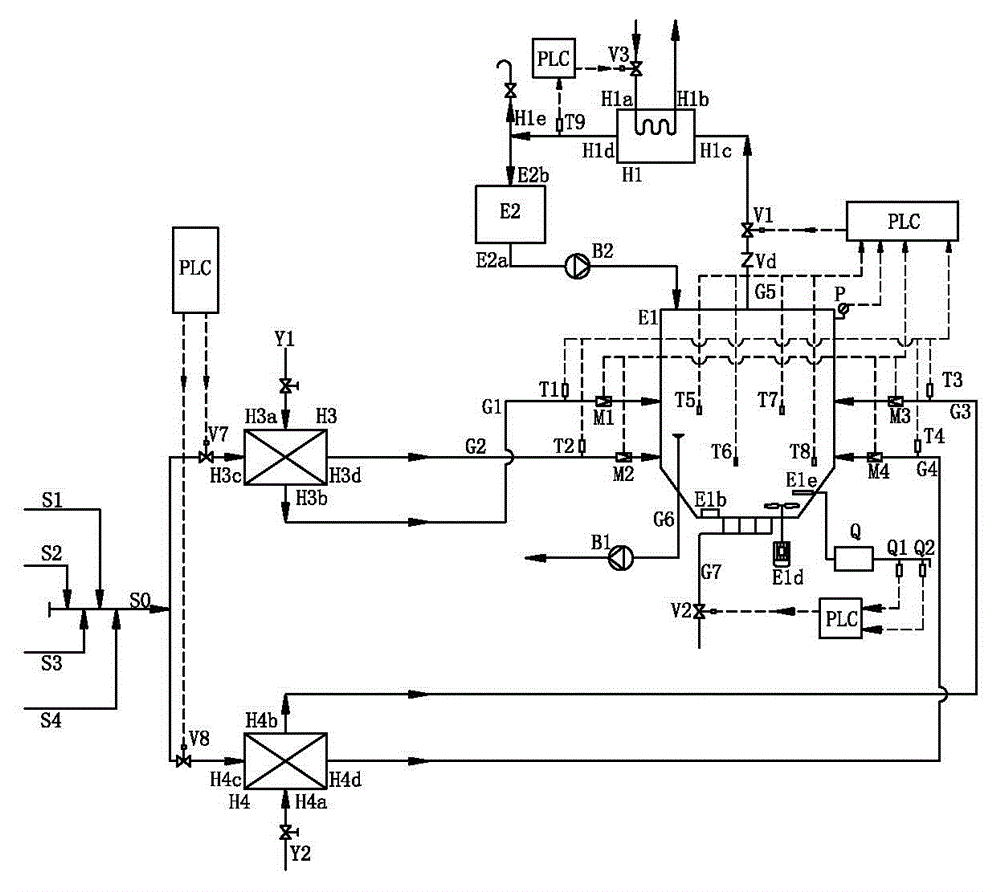

Novel foam liquid injecting system

The invention discloses a novel foam liquid injecting system. The novel foam liquid injecting system comprises a nitrogen pipeline and a PLC control system; a first tee ball valve is mounted on the nitrogen pipeline and is used for dividing the certain section of the nitrogen pipeline into two branch pipelines, a foam liquid storage tank is arranged on each branch pipeline, then the two branch pipelines are combined into one pipeline, and opening and closing of the first tee ball valve is automatically controlled through the PLC control system. According to the novel foam liquid injecting system, kinetic energy of nitrogen during flowing in the pipeline, pressure of the foam liquid storage tanks and gravitational potential energy of foam liquid are fully utilized, so that the mixed foam liquid is injected and carried without using extra power, a plunger pump is successfully replaced, and the problems of high energy consumption, high cost and poor stability generated by using an original plunger pump are effectively solved; and the novel foam liquid injecting system has the characteristics of low cost, low energy consumption, good running stability, simple operation, easy arrangement and easy maintenance, and has very important practical value in the field of petroleum exploitation.

Owner:XI AN JIAOTONG UNIV

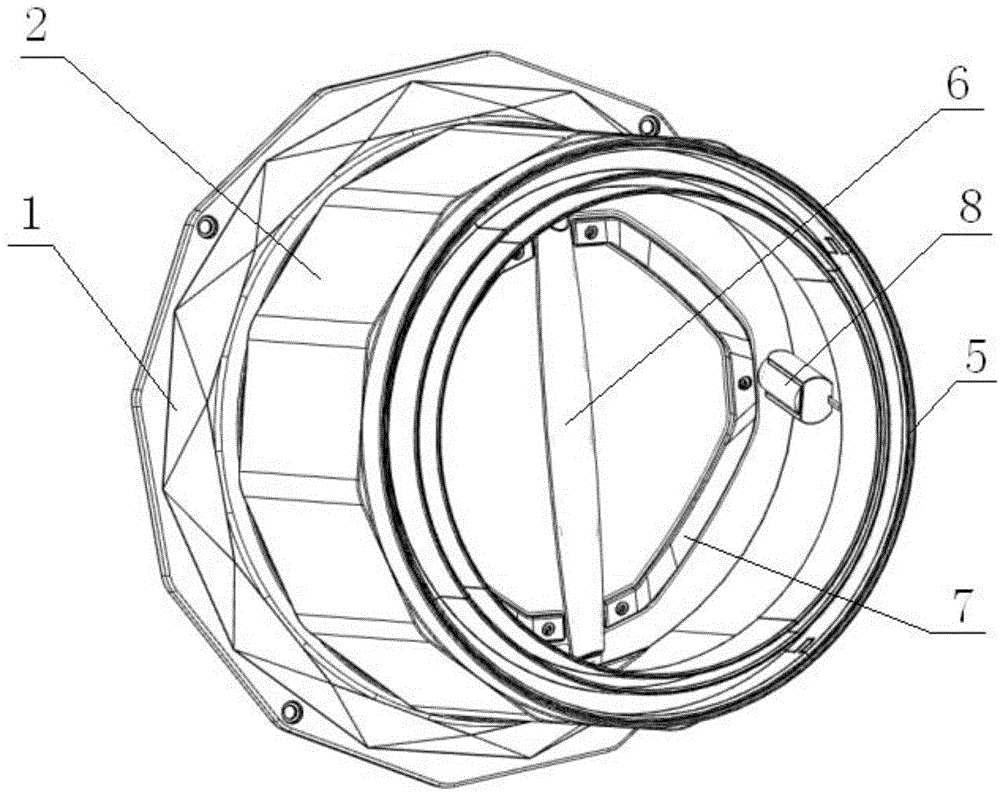

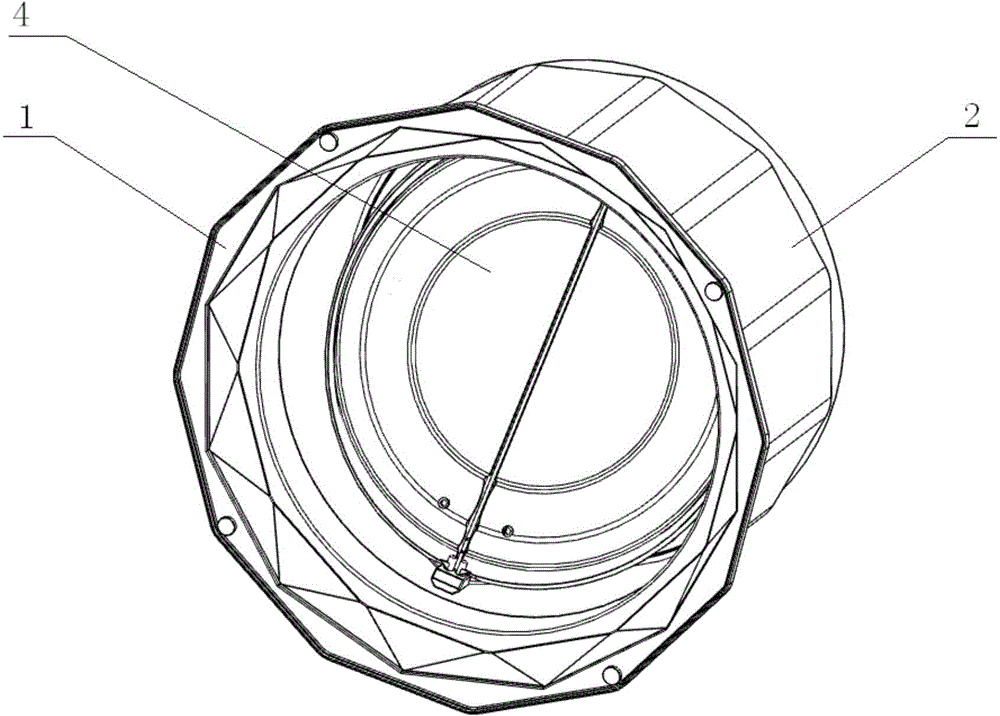

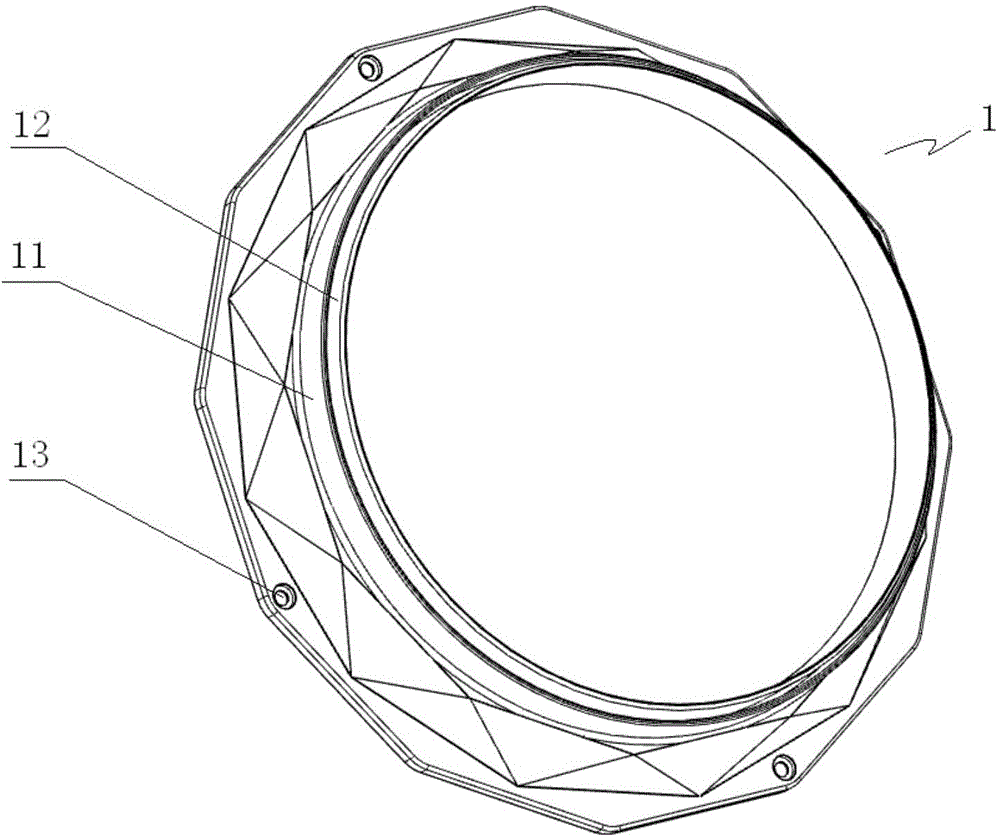

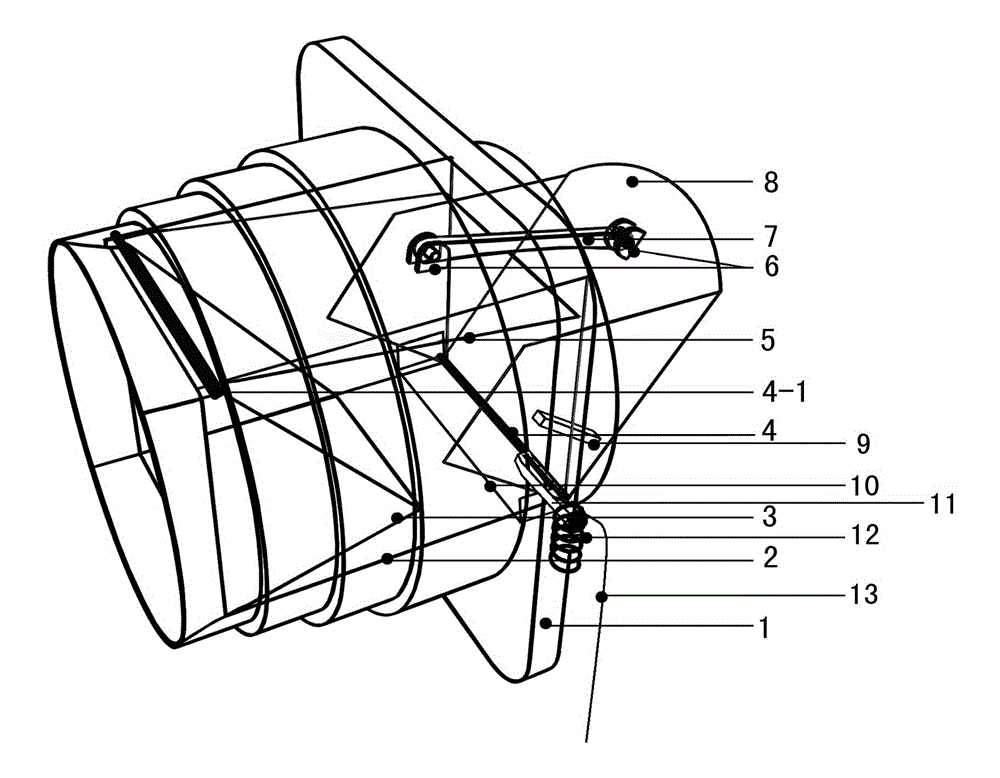

Check valve with double fireproof valves for smoke flue

The invention discloses a check valve with double fireproof valves for a smoke flue, which comprises a valve body, a sealing valve and a spring and is characterized in that the valve body is divided into a main valve body and an auxiliary valve body; and the auxiliary valve body is placed in the main valve body and is assembled with the main valve body in a matching manner. The check valve has the advantages that the fireproof valves of the check valve have the function of leading smoke upwards, no smoke backflow can be generated, and the smoke-blocking and fireproof effects are good; and moreover, the big flue is not required, so that the building weight can be reduced, the kitchen space is enlarged, and the construction cost is reduced.

Owner:黄加丰

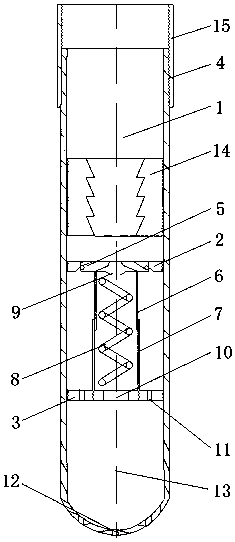

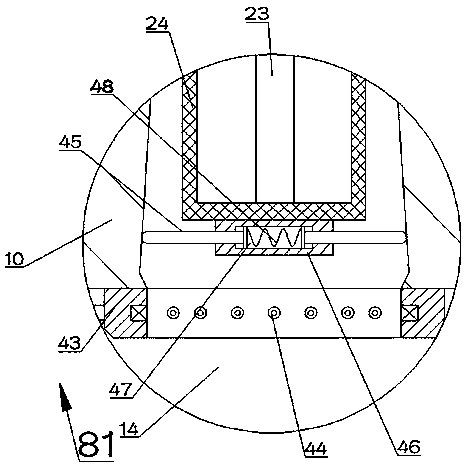

Automatic grouting device for well cementing sleeve

ActiveCN108119093AWon't pour backTo achieve the role of cementingConstructionsWell/borehole valve arrangementsWell cementingEngineering

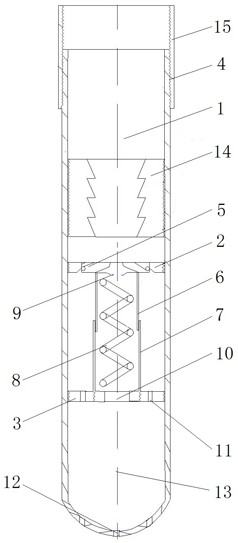

The invention relates to the technical field of oil and gas well cementing devices, and provides an automatic grouting device for a well cementing sleeve. The automatic grouting device for the well cementing sleeve includes a tubular device main body, a single-flow valve assembly is arranged in the device main body, the single-flow valve assembly includes a spring seat, and the spring seat is provided with a spring for abutting against a valve ball to a valve port of the single-flow valve assembly, the valve port is formed by a one-way movable valve seat disposed in the device main body, the one-way movable valve seat includes two or more valve blocks swinging up and down, and the valve blocks have a closed state in which the valve port is formed by mutual closing and an open state for thevalve ball to pass from top to bottom, the top of the spring is provided with a valve ball seat for supporting the valve ball, and the valve ball seat is provided with a ball seat circulating hole communicated with the valve port. The device does not need intermittent operation and has a stable working state during grouting and can reduce the amount of work, improve the work efficiency of the well cementing operation, reduce parts needed during the grouting process and reduce the production cost.

Owner:PETROLEUM ENG TECH RES INST CHINA PETROLEUM & CHEM CORP NORTH CHINA OIL & GAS CO +1

Combustion boiler flue gas treatment equipment for thermal power plant

InactiveCN111085099AWon't pour backGuaranteed service lifeCombination devicesGas treatmentPower stationFlue gas

The invention discloses combustion boiler flue gas treatment equipment for a thermal power plant. The equipment comprises a device box body, wherein an air inlet pipeline is arranged in the device boxbody. According to the invention, when a first motor is started, the first motor drives fan blades to rotate, and the fan blades rotate to suck flue gas generated in a power generation boiler into the air inlet pipeline so as to suck the flue out of the burning boiler, so that the flue gas cannot flow backward, and can be subjected to medicated bath and waste heat recovery treatment, the finallydischarged flue gas can meet the requirement of environmental protection, good resource utilization efficiency can be achieved, carbon deposited on the inner wall of the pipeline can be cleaned, and the service life of the equipment is ensured.

Owner:TAIZHOU LUQIAO BOREN ENVIRONMENTAL PROTECTION EQUIP CO LTD

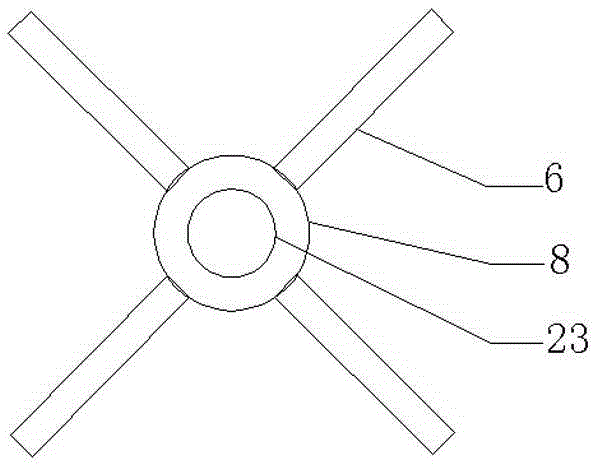

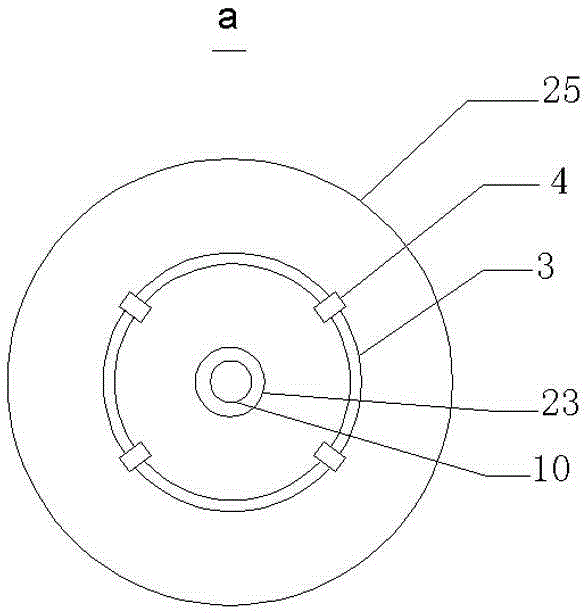

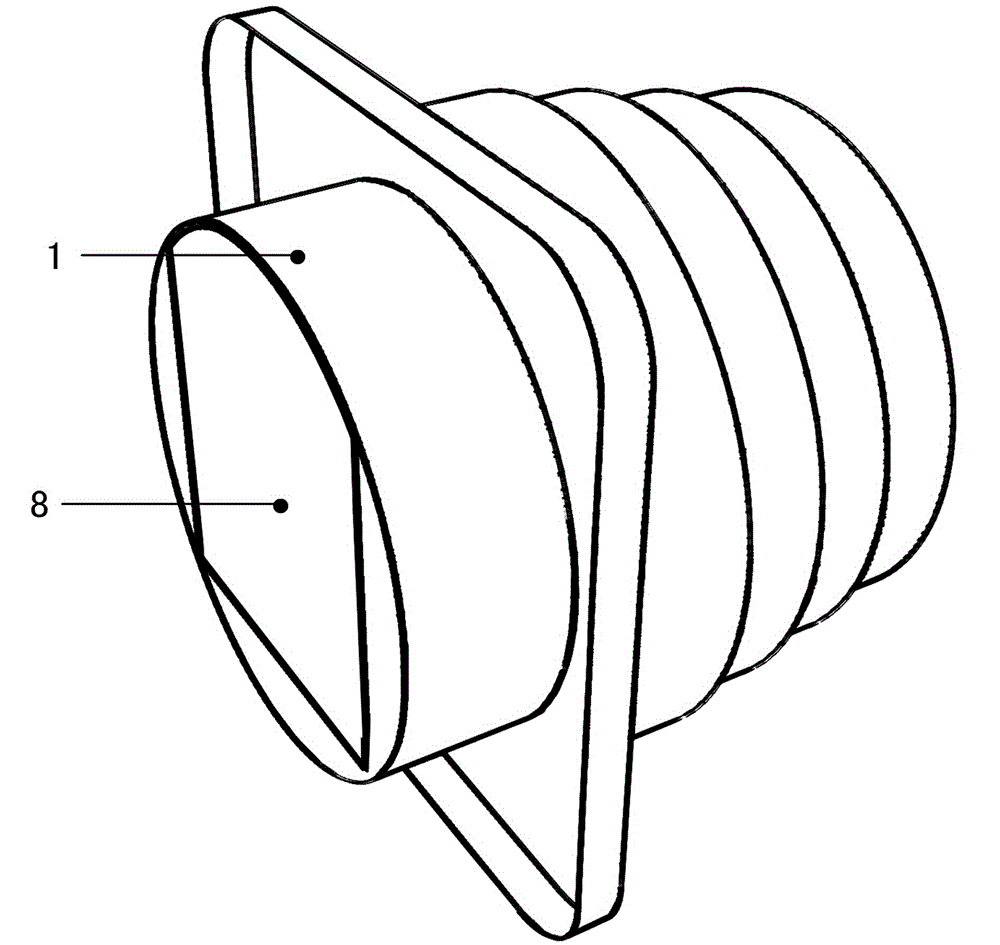

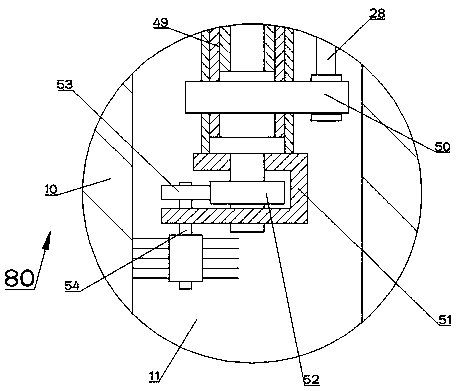

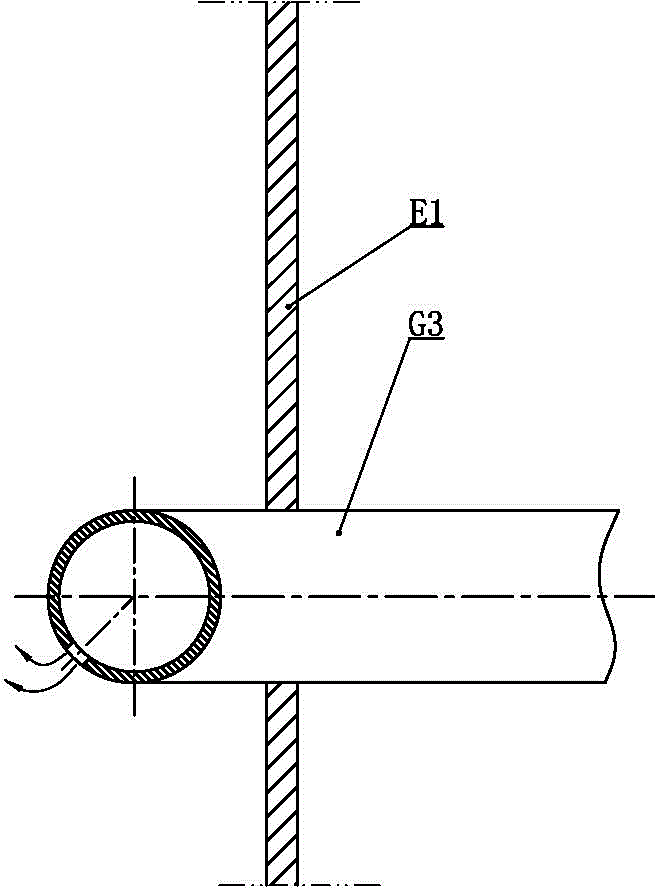

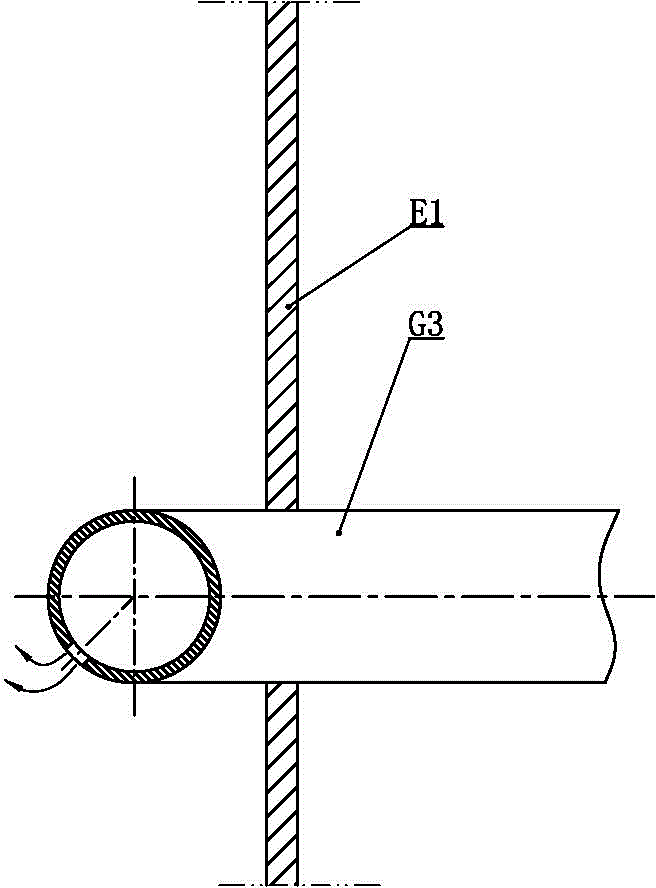

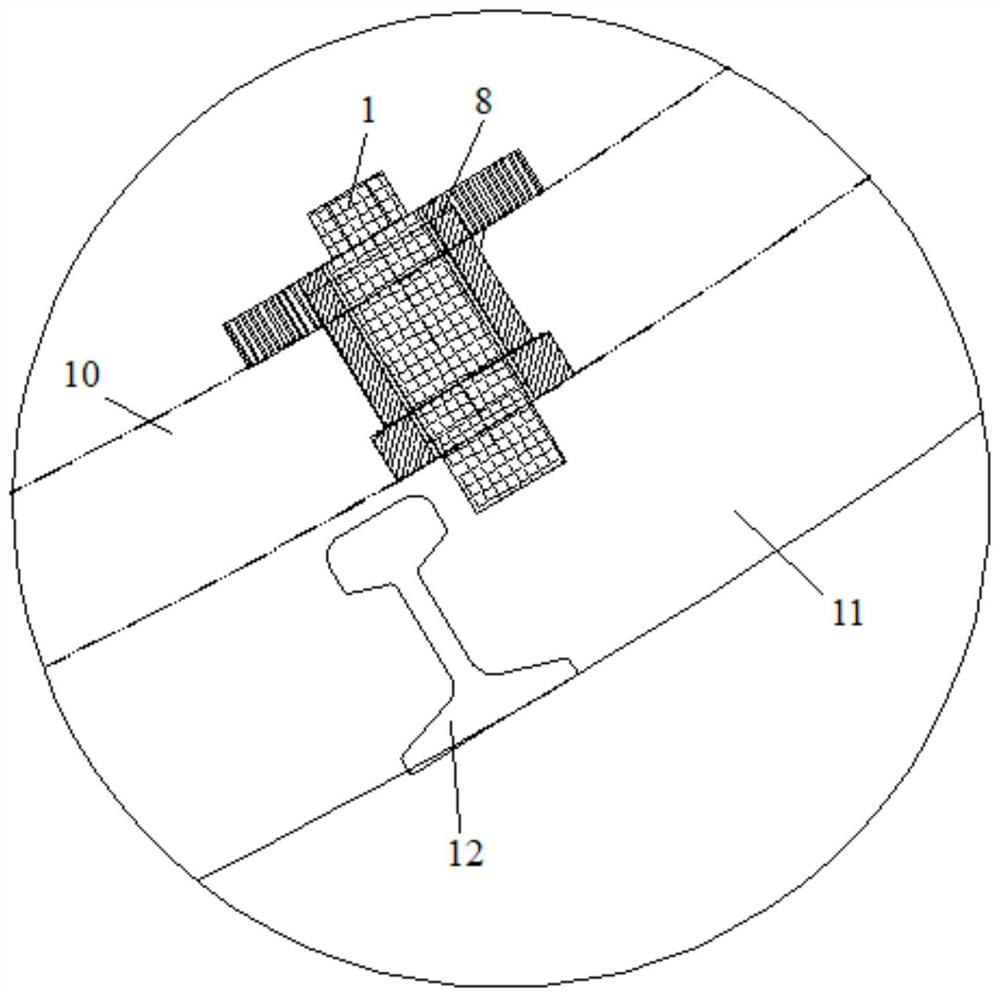

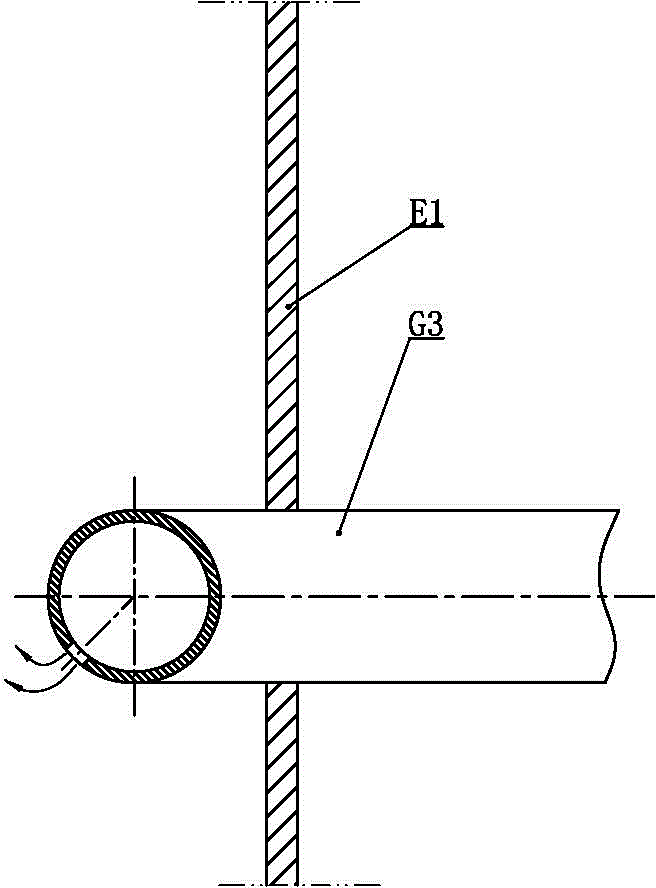

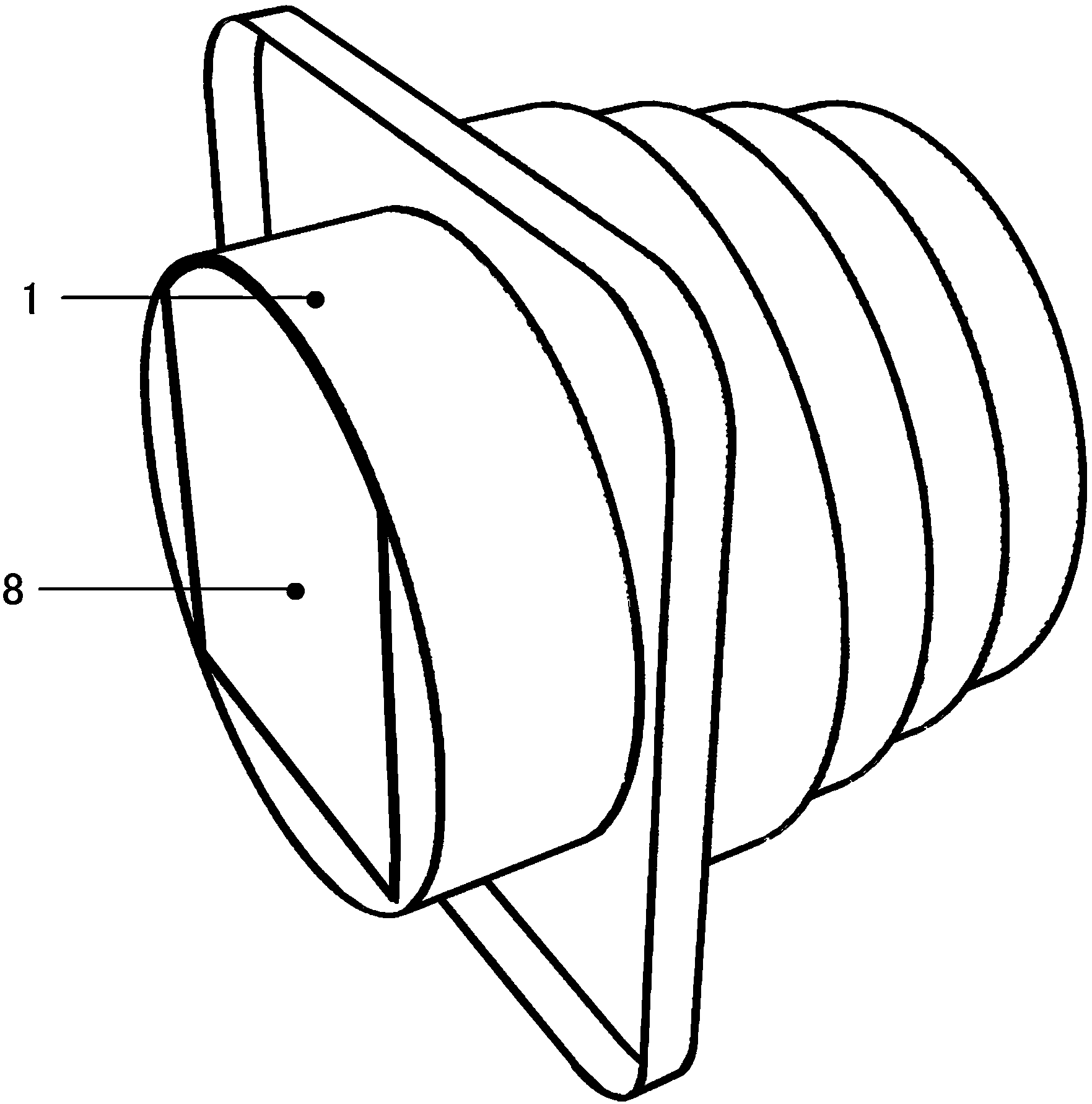

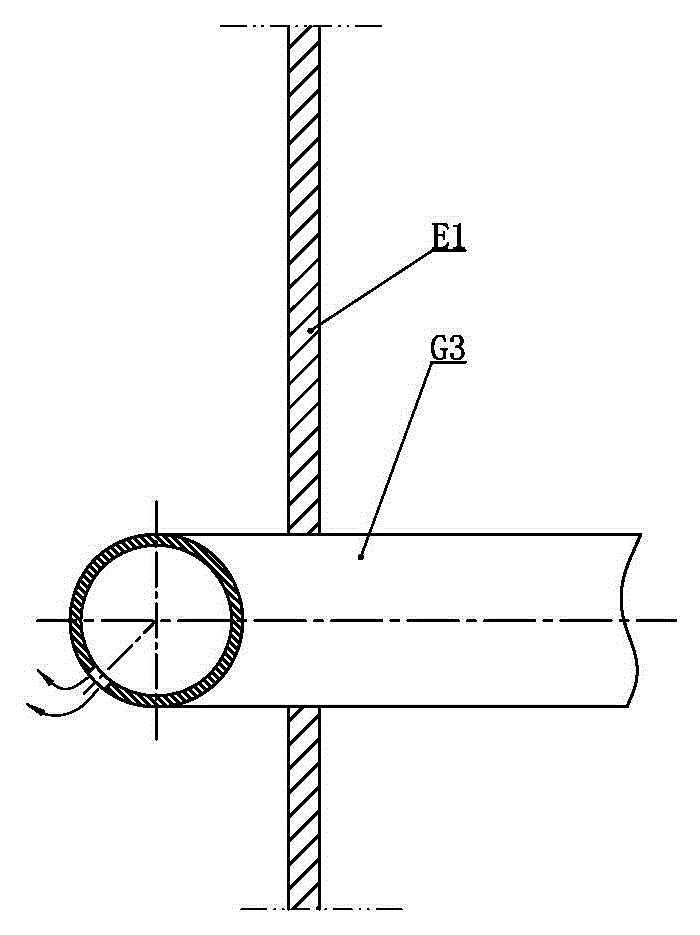

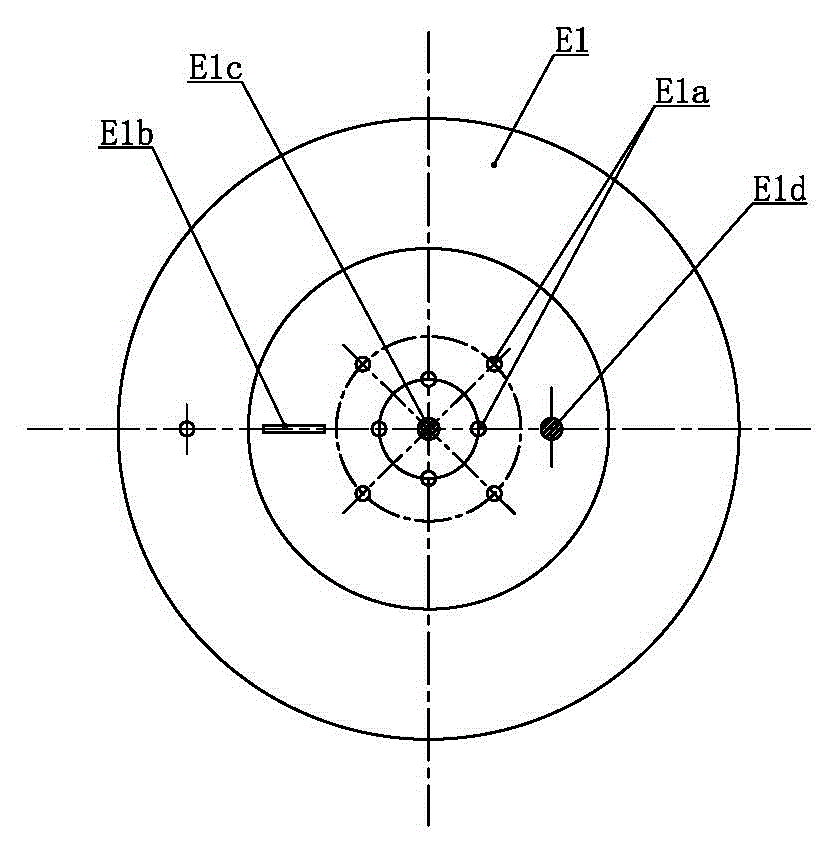

Building water discharge vertical pipe table opening

ActiveCN104047355AWon't pour backInflux will not causeSewerage structuresWater dischargeEnvironmental engineering

The invention relates to a building water discharge vertical pipe table opening, which comprises a sleeve pipe and an accumulated water discharge pipe element, wherein the sleeve pipe can be sheathed on a water discharge vertical pipe, the sleeve pipe and the pipe element are connected into a whole through a connecting element arranged at the outer sides of the sleeve pipe and the pipe element, in addition, at least one waterproof wall which is basically vertical to the connecting element and surrounds the sleeve pipe and the pipe element is arranged around the outer sides of the sleeve pipe and the pipe element, and an accumulated water discharge hole is formed in the connecting element and is communicated with an internal passage of the pipe element. The internal passage of the sleeve pipe is not communicated with an internal passage of the accumulated water discharge pipe element, so all accumulated water in a pad layer of a water discharge system arranged at the same floor can be discharged out from the accumulated water discharge pipe element; during the water filling test of a water discharge vertical pipe, the water in the sleeve pipe cannot backwards flow out of the accumulated water discharge pipe element, so the water filling test of the water discharge vertical pipe can be normally carried out, and the backward flowing of gas in the water discharge vertical pipe cannot be caused.

Owner:关文民 +1

One-stage deoxidizing device for indirect heat-exchange forcible mixed exhaust steam recovery of condensate water and desalted water

InactiveCN104089271ADoes not affect normal operationAvoid pressure suffocation and poor drainage of condensateLiquid degasificationImpellerBuffer tank

The invention relates to a one-stage deoxidizing device for indirect heat-exchange forcible mixed exhaust steam recovery of condensate water and desalted water. A first water inlet pipe, a second water inlet pipe, a third water inlet pipe and a fourth water inlet pipe are connected onto a pressure-bearing buffer tank, wherein the first water inlet pipe and the third water inlet pipe are located on the upper layer, and the second water inlet pipe and the fourth water inlet pipe are located on the lower layer; mixed condensate water is introduced into the second water inlet pipe and the fourth water inlet pipe respectively after subjected to heat exchange with synthesis ammonia desalted water and conversion desalted water through a third heat exchanger and a fourth heat exchanger, the synthesis ammonia desalted water and the conversion desalted water are introduced into the first water inlet pipe and the third water inlet pipe respectively after subjected to heat exchange through the third heat exchanger and the fourth heat exchanger; buffer tank exhaust steam is cooled into buffer tank exhaust steam condensate water by a first heat exchanger, the buffer tank exhaust steam condensate water is injected into the pressure-bearing buffer tank by a condensate water collecting tank and a second water pump, and non-condensable gas is discharged simultaneously; a water outlet pipe of the buffer tank is connected with an inlet of a first water pump, and an outlet of the first water pump is connected to a boiler water replenishing pipe; and a forcible mixing impeller is mounted at the middle-lower part of the inner cavity of the pressure-bearing buffer tank, and a blow-down pipe is connected to a bottom plate of the pressure-bearing buffer tank. According to the device, the utilization rate of condensate water waste heat is high, and the operation is reliable.

Owner:江苏安众环保技术有限公司

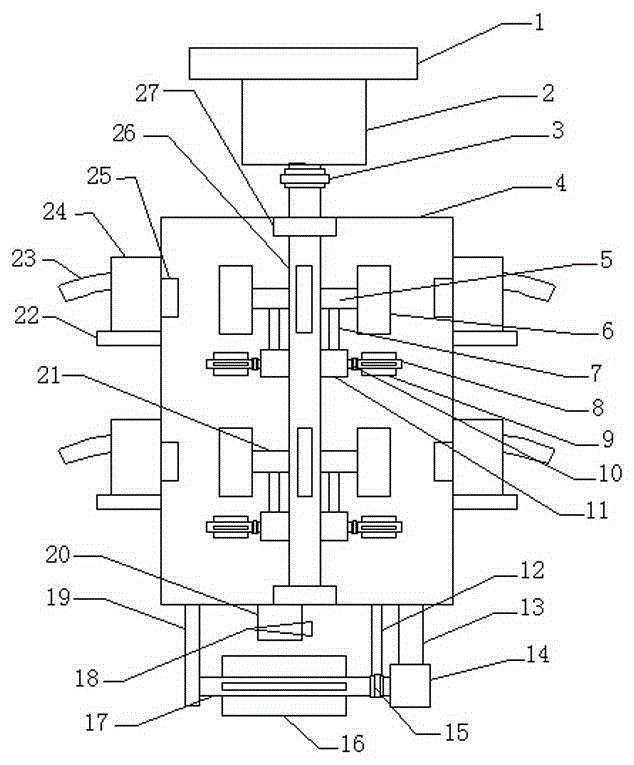

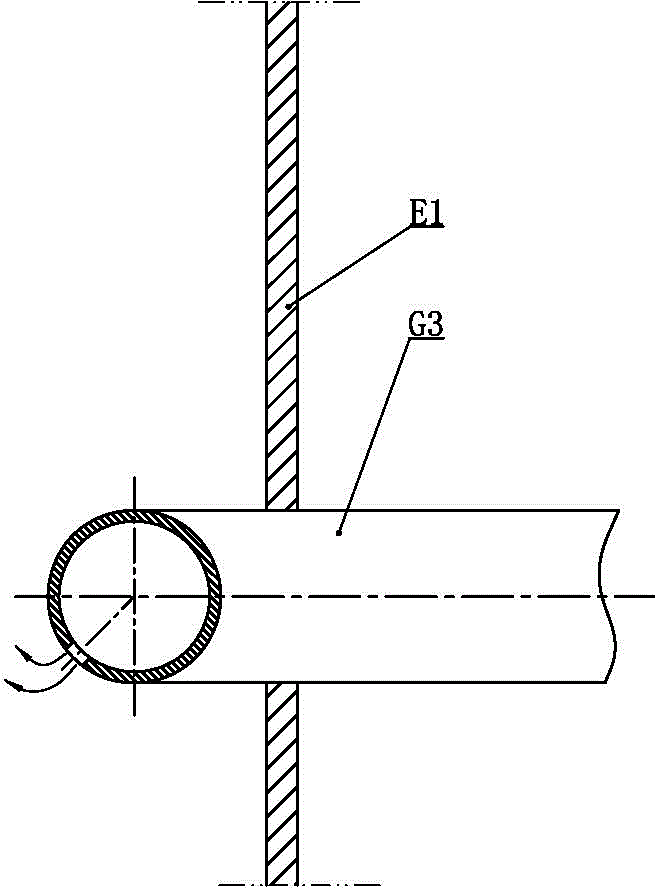

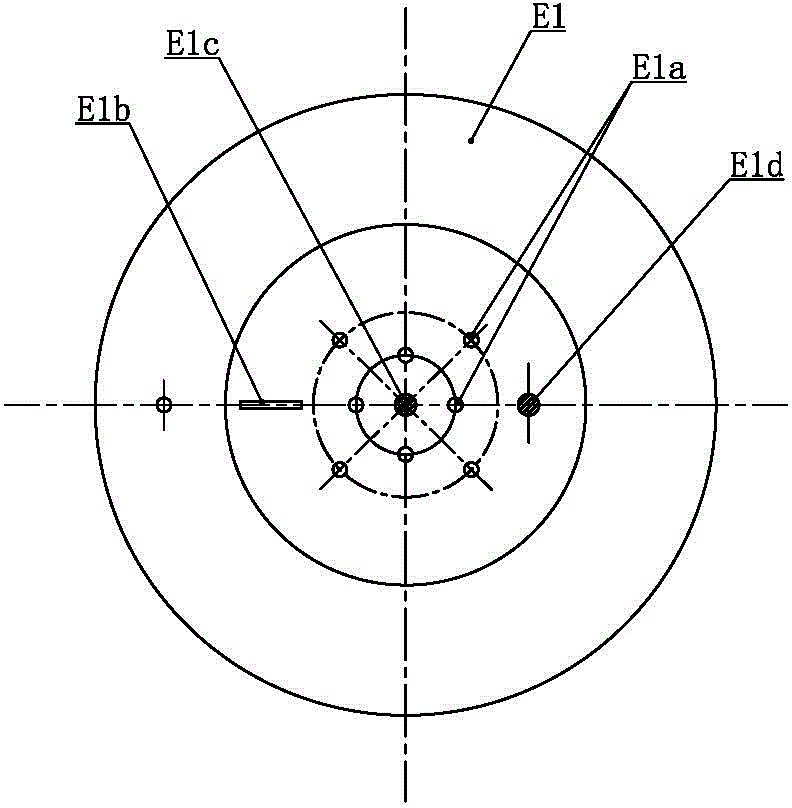

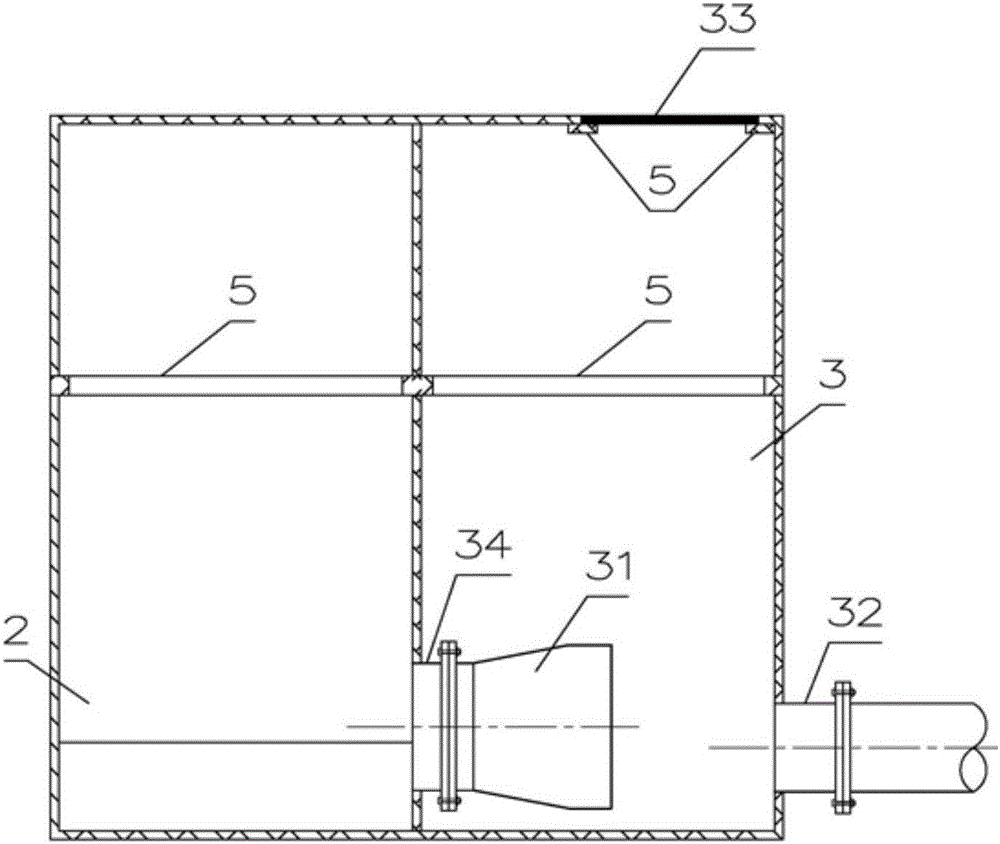

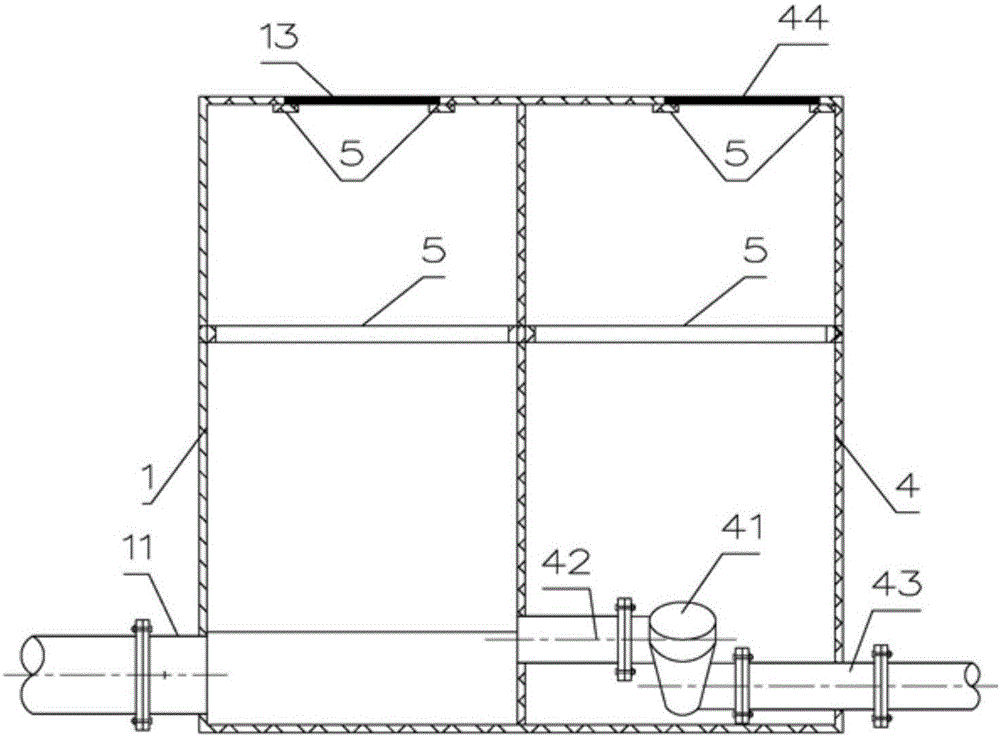

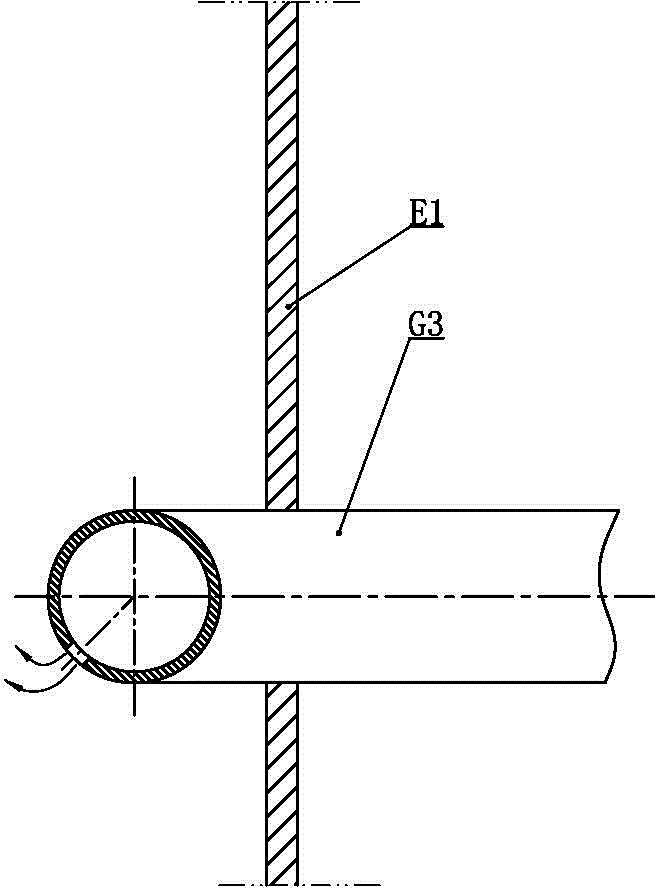

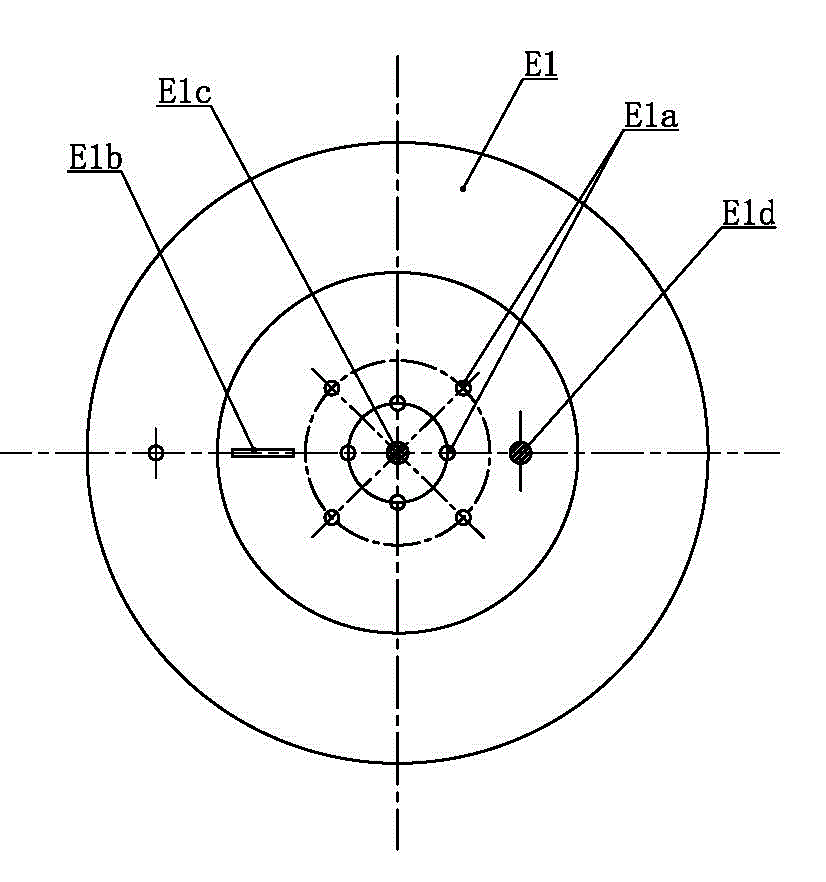

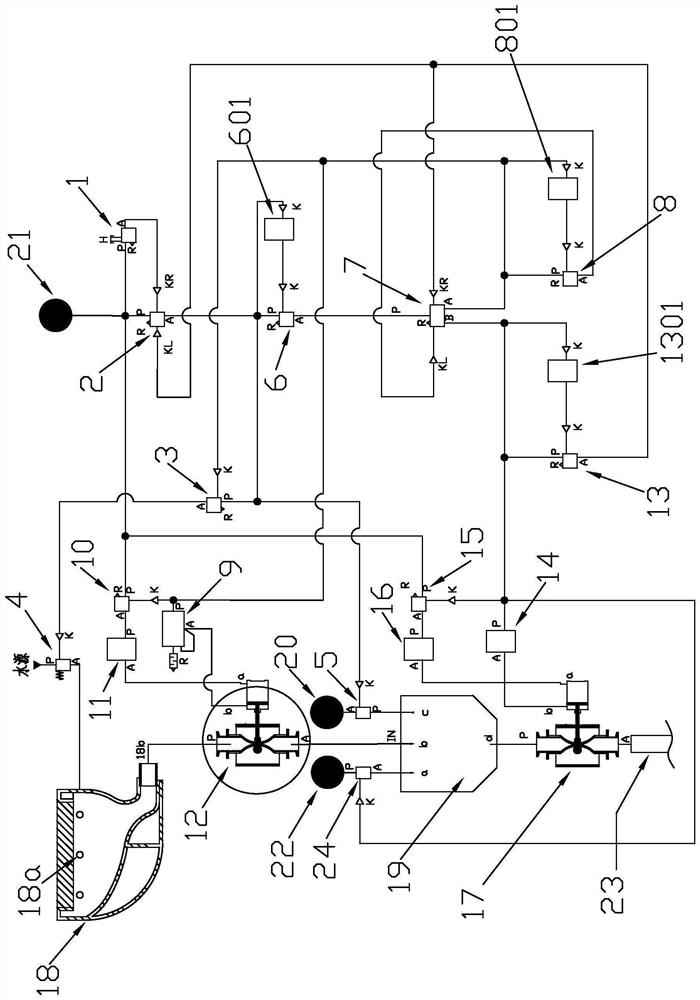

Integrated automatic flow adjusting and intercepting well equipment and intercepting process thereof

InactiveCN105672452AAvoid cycleAvoid the difficulty of precisely controlling the amount of intercepted sewageSewerage structuresGlass fiberPlastic materials

The invention discloses an integrated automatic flow regulating and intercepting well equipment, which includes an equipment box, the equipment box is made of glass fiber reinforced plastic, and the inside of the equipment box is divided into four parts by cross-shaped glass fiber reinforced plastic partitions, and the four parts are divided into four parts according to Confluent sewage wells, overflow sewage wells, anti-sewage backflow wells and valve wells are arranged clockwise. The integrated automatic flow regulating and intercepting well equipment of the present invention adopts structural equipment, and introduces a swirl flow limiting valve and a duckbill valve at the same time, avoiding the long construction period of traditional intercepting wells, the difficulty of accurately controlling the amount of intercepted sewage, and the inability to prevent backflow Defects. The invention also discloses a flow closure process of the integrated automatic flow regulation and closure well equipment.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

Deoxidized exhaust steam condensing device for mixed recovery of condensate water and desalted water

InactiveCN104089274AExacerbating waste heat emissionsDoes not affect normal operationLiquid degasificationPipingSaline water

The invention relates to a deoxidized exhaust steam condensing device for mixed recovery of condensate water and desalted water. A first water inlet pipe, a second water inlet pipe, a third water inlet pipe and a fourth water inlet pipe are connected onto the circumference of a pressure-bearing buffer tank, wherein the first water inlet pipe and the third water inlet pipe are located on the upper layer, and the second water inlet pipe and the fourth water inlet pipe are located on the lower layer; synthesis ammonia cooled desalted water and conversion cooled desalted water are introduced into the first water inlet pipe and the third water inlet pipe respectively, and calcining furnace condensate water and fluidized bed condensate water are introduced into the second water inlet pipe and the fourth water inlet pipe respectively; the top of the pressure-bearing buffer tank is connected with a buffer tank steam discharge pipe; a buffer tank water outlet pipe is connected with a first water pump, an outlet of the first water pump is connected to a deaerator head water inlet pipe of a high-pressure deaerator, a deaerator tank drain pipe is connected to a boiler water replenishing pipe through a third water pump, the deoxidized exhaust steam becomes deoxidized exhaust steam condensate water after condensed by a second heat exchanger, and the deoxidized exhaust steam condensate water enters a condensate water collecting tank and is sent to the pressure-bearing buffer tank by a second water pump; and drain outlets are formed in a bottom plate of the pressure-bearing buffer tank and connected with a blow-down pipe, and a second control valve is mounted on the blow-down pipe. According to the device, the utilization rate of condensate water waste heat is high, and the operation is reliable.

Owner:江苏安众环保技术有限公司

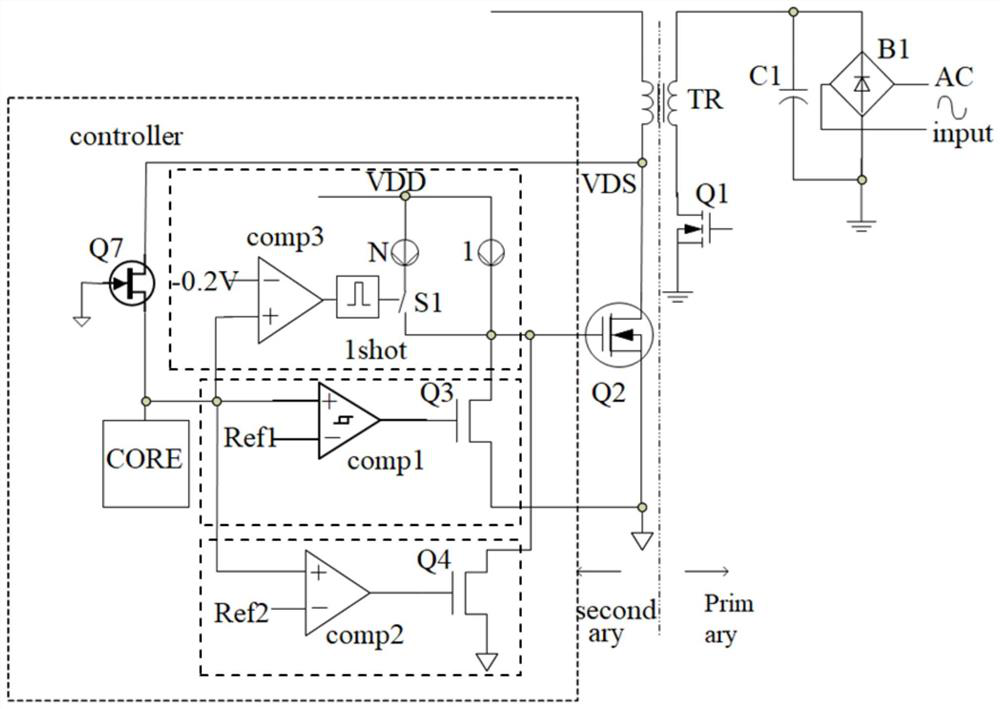

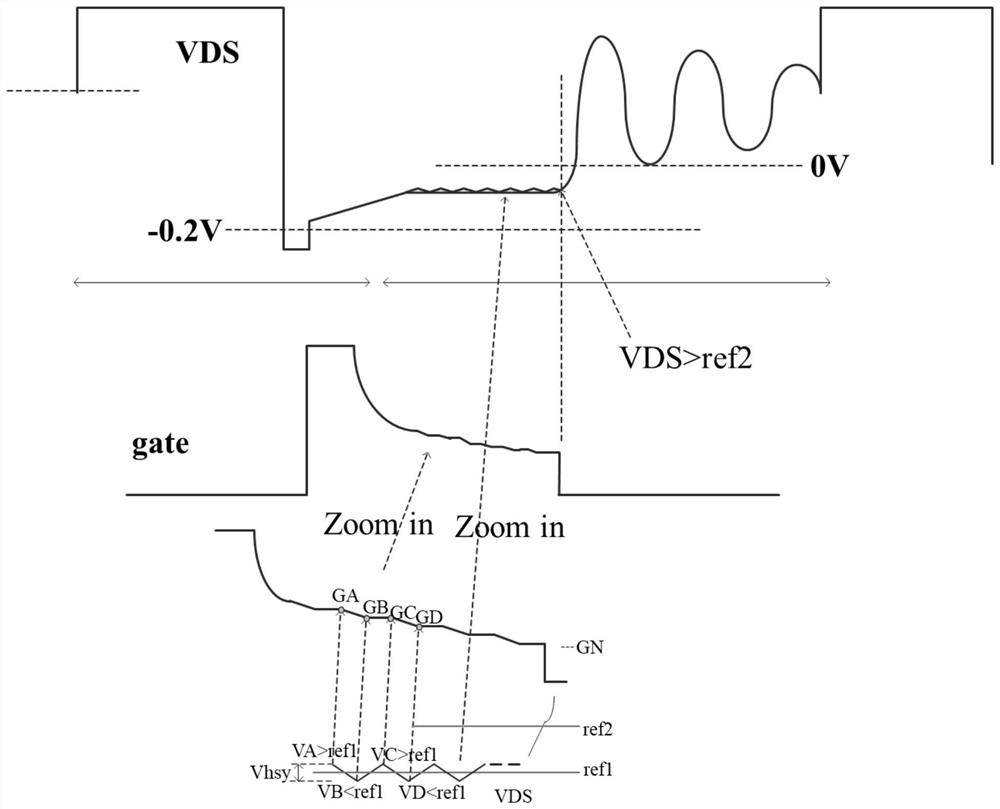

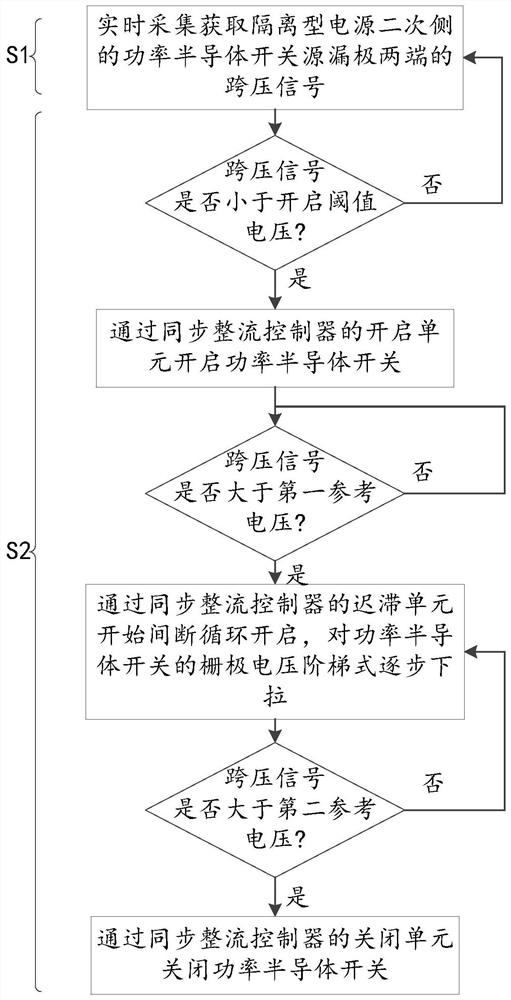

Synchronous rectification device and method for isolated power supply

PendingCN111953184AImprove efficiencyReduce conduction lossEfficient power electronics conversionAc-dc conversionPhysicsGate voltage

The invention discloses a synchronous rectification device and method for an isolated power supply, and the device comprises a power semiconductor switch and a synchronous rectification controller, and a reference grounding end of the isolated power supply is connected with a reference ground through the source and drain electrodes of the power semiconductor switch. In the synchronous rectification controller, a control unit receives the voltage-crossing signals at the two ends of the source electrode and the drain electrode of the power semiconductor switch, separately controls a switching-onunit and a switching-off unit to switch on and off the power semiconductor switch according to the voltage-crossing signals, and controls a hysteresis unit to be switched on discontinuously and circularly so as to gradually pull down the grid voltage of the power semiconductor switch in a stepped mode. According to the present invention, the technical problems of low conversion efficiency, current backflow and short circuit of the isolated power supply are solved, the power semiconductor switch can be quickly turned on and turned off, the gate voltage of the power semiconductor switch is gradually reduced in a stepped manner, and the switch is directly turned off when the gate voltage approaches to a cut-off threshold voltage, so that the current backflow is reduced, and the opportunity of primary / secondary side short circuit is reduced.

Owner:SHANGHAI BAIGONG SEMICON CO LTD

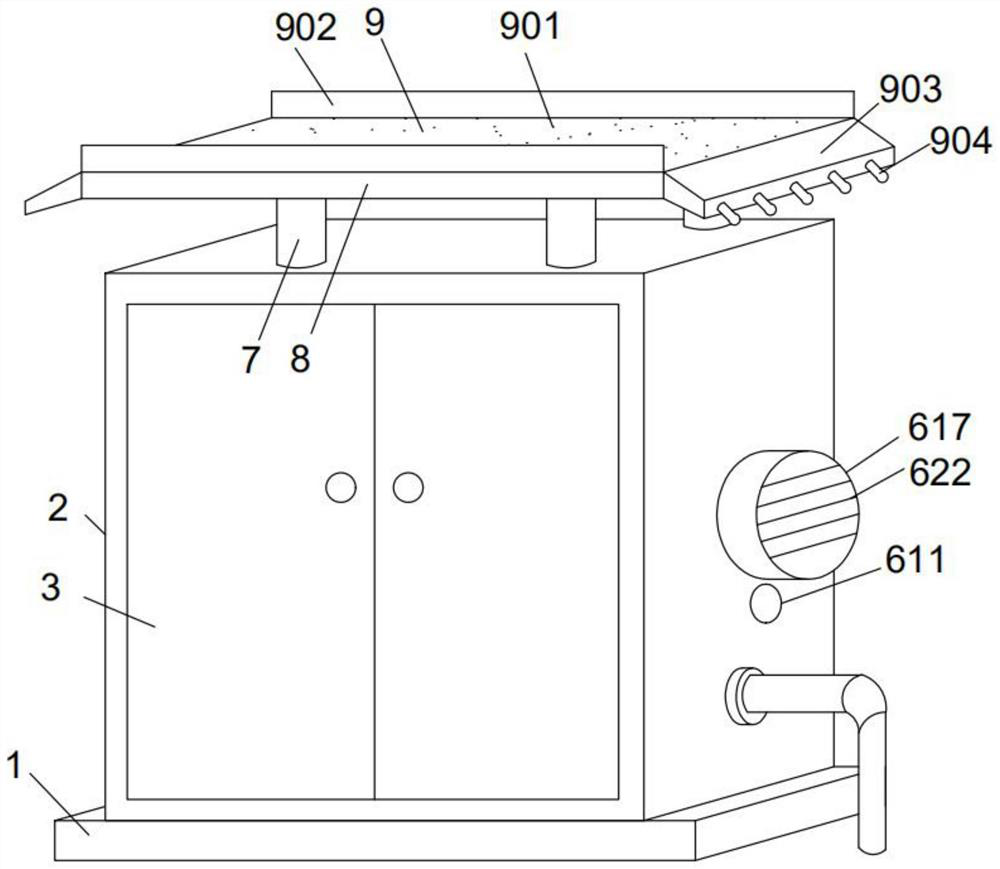

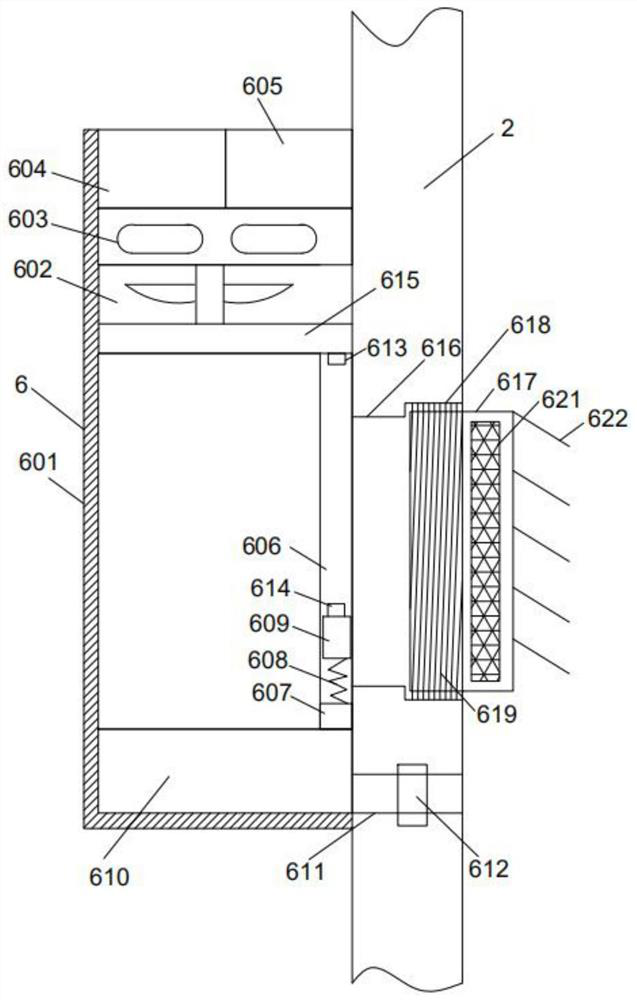

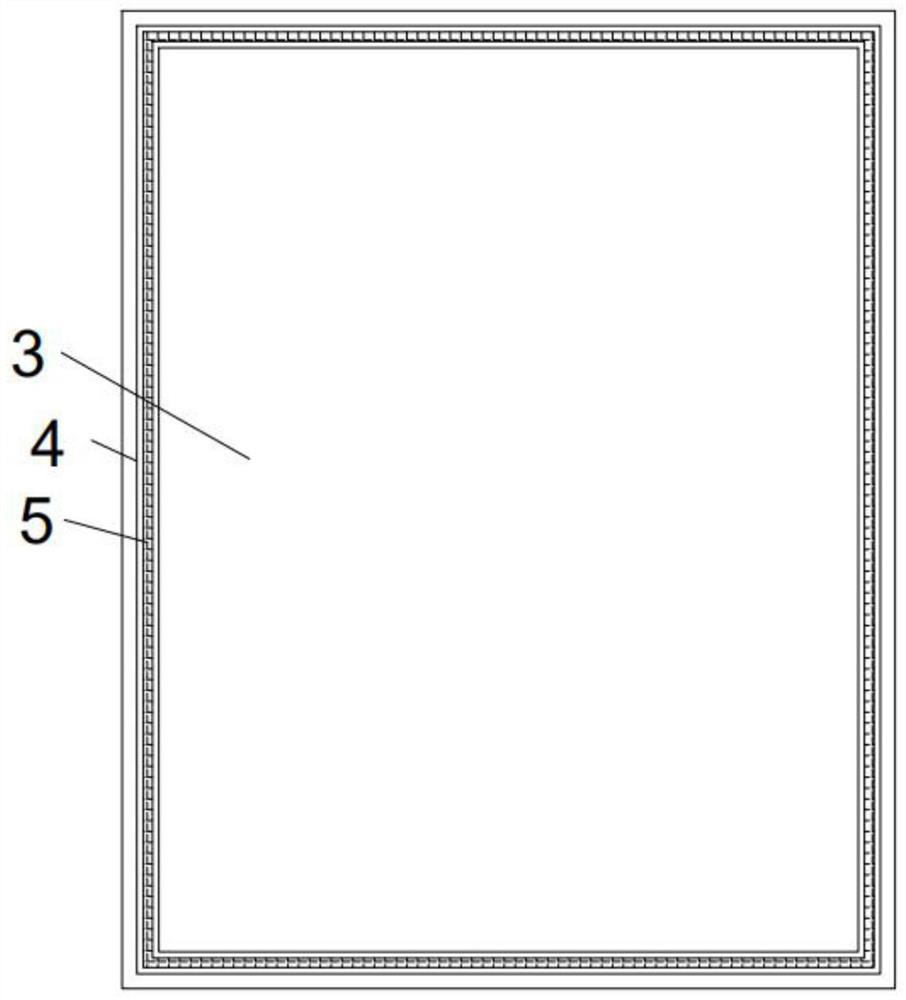

Temperature control monitoring system for power distribution cabinet and power distribution cabinet

InactiveCN112582894AWon't splashReduce fallsBoards/switchyards circuit arrangementsSubstation/switching arrangement cooling/ventilationTemperature controlControl theory

The invention aims to provide a power distribution cabinet with rainwater draining and blocking functions. Thepower distribution cabinet can drain and block the rainwater entering from a heat dissipation exhaust pipe, thereby ensuring the safe operation of internal electrical devices. The power distribution cabinet comprises a mounting base, and a cabinet body is fixedly connected to the top of the mounting base. Thepower distribution cabinet is characterized in that a heat dissipation device is fixedly mounted at the right side of the cabinet body, the heat dissipation device comprises the heat dissipation exhaust pipe, and a sliding rail is fixedly installed at the right side of the heat dissipation exhaust pipe; a fixing block is fixedly connected to the bottom end of the interior of the sliding rail, a sealing belt is fixedly connected to the top of the fixing block, and a floating block is fixedly connected to the top of the sealing belt; a pressing block is fixedly connected to the top of the floating block, the floating block slides in the sliding rail, and a waterproof button is fixedly installed at the top end of the interior of the sliding rail; a switch valve is fixedlyinstalled at the top of the waterproof button, is electrically connected with the waterproof button through a wire, and is electrically connected with a main power supply of the cabinet body through awire.

Owner:王汝佳

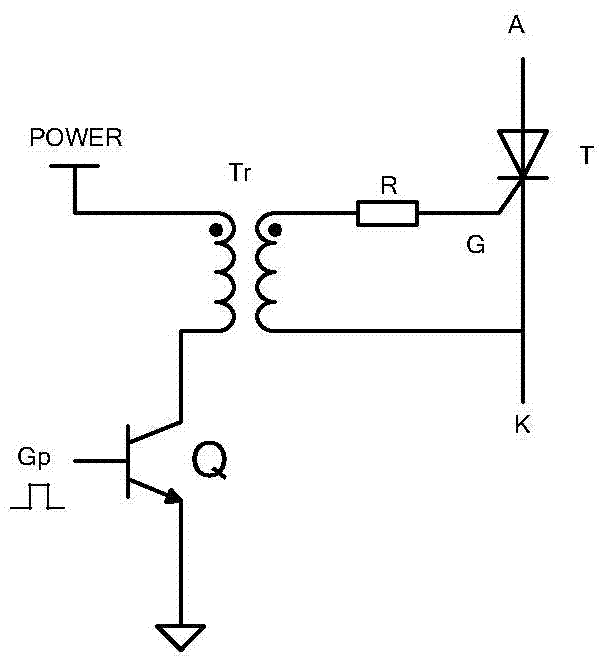

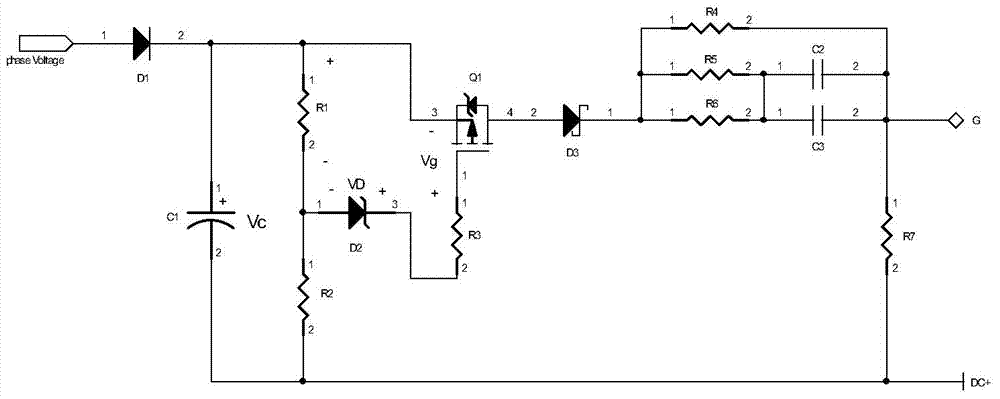

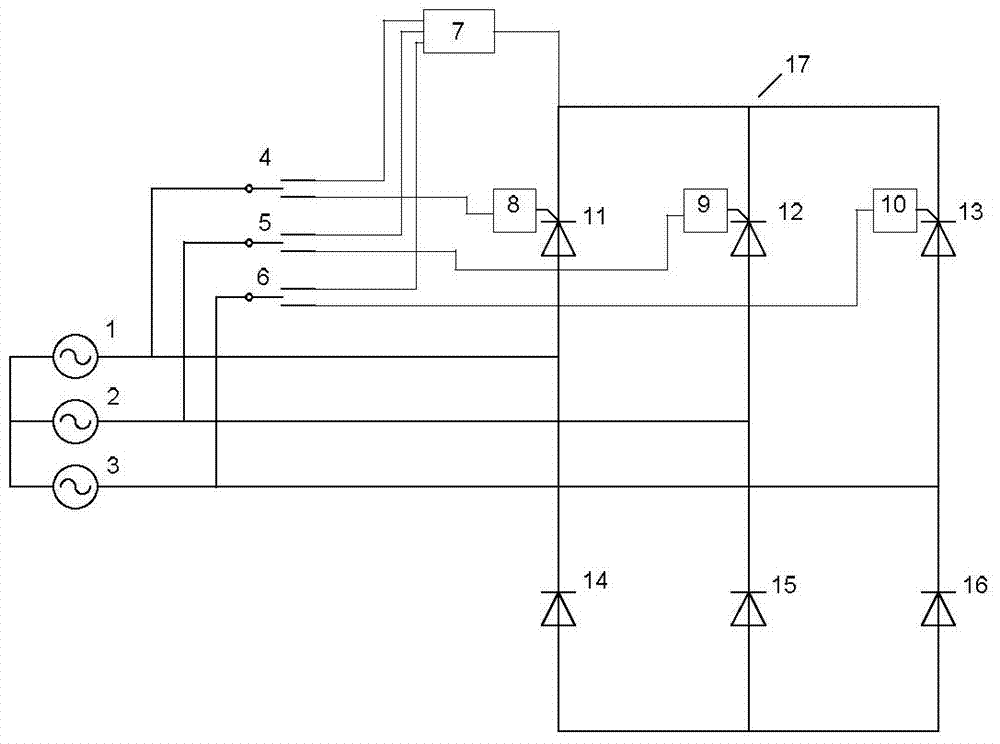

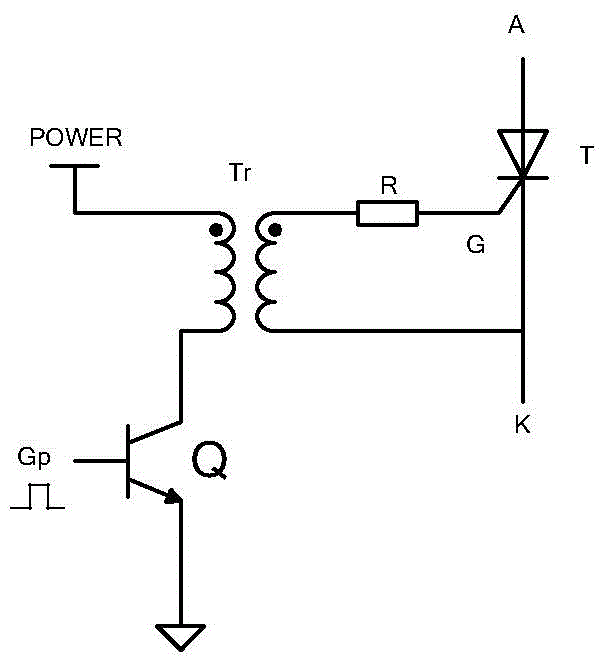

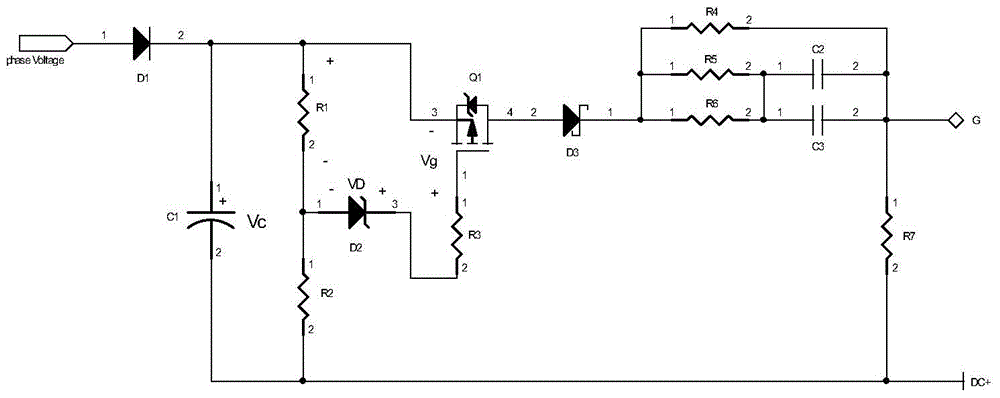

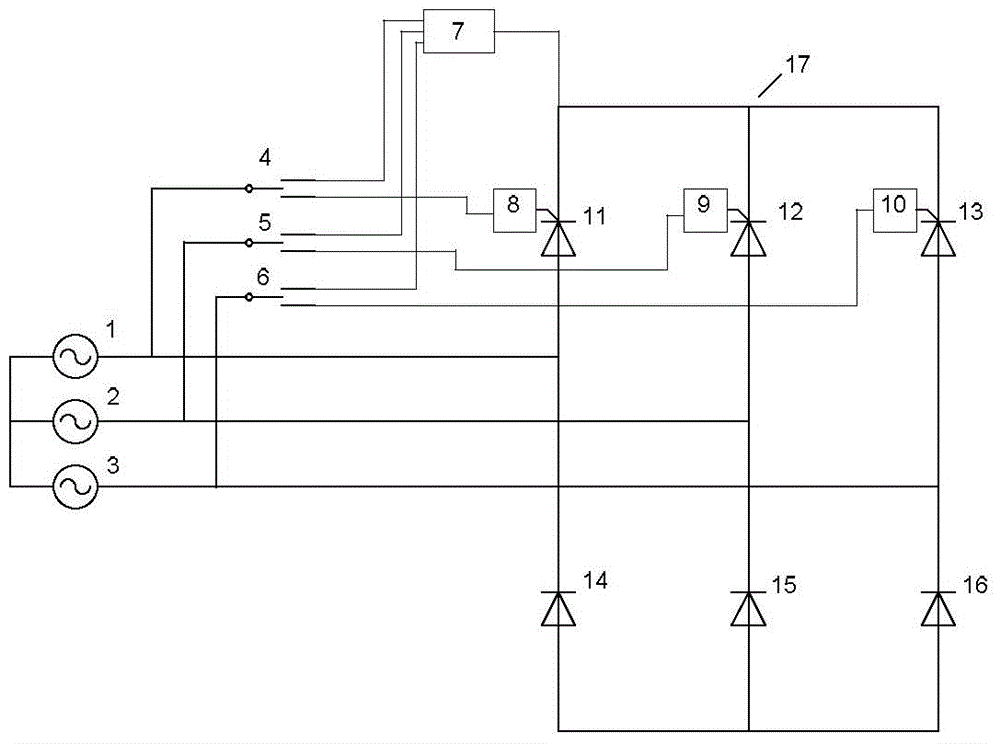

Thyristor trigger circuit for three-phase input rectifying circuit of frequency converter

The invention provides a thyristor trigger circuit for a three-phase input rectifying circuit of a frequency converter. The thyristor trigger circuit comprises a fast recovery diode, a charging capacitor, an MOSFET (Metal-Oxide-Semiconductor Field Effect Transistor), an MOSFET grid drive adjusting circuit and a thyristor driving circuit. A phase voltage is input at the input end of the trigger circuit, the phase voltage is connected with an anode of the charging capacitor after passing through the fast recovery diode, the anode of the charging capacitor is connected with a source electrode of the MOSFET, a drain electrode of the MOSFET is connected with a door electrode of a thyristor to be triggered through the thyristor driving circuit, a cathode of the charging capacitor is respectively connected with a cathode of the thyristor to be triggered and a positive bus of the rectifying circuit of the frequency converter, and the MOSFET grid drive adjusting circuit is arranged between the charging capacitor and a grid electrode of the MOSFET. The thyristor trigger circuit disclosed by the invention is used for the three-phase input rectifying circuit, so that the scheme is more simple and practical, and the cost is reduced.

Owner:WISDRI WUHAN AUTOMATION

Condensate water and demineralized water indirect heat-exchange exhaust steam recovery two-stage deoxygenization device

ActiveCN104085943AExacerbating waste heat emissionsDoes not affect normal operationFeed water supplyWater/sewage treatment by degassingPipingRecuperator

The invention relates to a condensate water and demineralized water indirect heat-exchange exhaust steam recovery two-stage deoxygenization device. According to the invention, a pressure-bearing buffering tank is provided with a first water inlet pipe and a third water inlet pipe positioned on an upper level, and a second water inlet pipe and a fourth water inlet pipe positioned on a lower level. Mixed condensate water is respectively subjected to indirect heat-exchange with synthetic ammonia demineralized water and transformation demineralized water through a third heat exchanger and a fourth heat exchanger, and is then respectively connected into the second water inlet pipe and the fourth water inlet pipe. After the heat-exchange process through the third and fourth heat exchangers, the synthetic demineralized water and the transformation demineralized water are respectively connected into the first water inlet pipe and the third water inlet pipe. Buffering tank exhaust steam enters a first heat exchanger and is cooled into buffering tank exhaust steam condensate water, and the buffering tank exhaust steam condensate water is replenished into the pressure-bearing buffering tank through a condensate water collection tank and a second water pump. Non-condensible gas is discharged at the same time. Buffering tank discharged water is delivered into a high-pressure deoxygenization device through a first water pump. A deoxygenization tank water discharge pipe is connected into a boiler water replenishing pipe through a third pump. A sewage discharge pipe is connected to a bottom plate of the pressure-bearing buffering tank. The device provided by the invention has the advantages of high condensate water residual heat utilization rate and reliable operation.

Owner:云南能投有能科技股份有限公司

Flexible blade type vertical shaft tide energy water turbine

A flexible blade type vertical shaft tide energy water turbine comprises a first power generator, a first machine frame, a first upper support, first blades, a first blade shaft, a first lower support, a first lower shaft sleeve, a second flow inlet, a second machine case, a second upper support, a second upper shaft sleeve, a second power generator, a second coupling, a second machine frame, a second roller, second blades, a second piston type one-way valve, a second flow-out pipe, a second flow outlet, a second lower support, a second lower shaft sleeve, second flange bearings, a second connecting piece, a second blade shaft, a first piston type one-way valve, a first flow-out pipe, a first flow outlet, first flange bearings, a first connecting piece, a first roller, a first flow inlet, a first upper shaft sleeve, a first machine case and a first coupling. The first flow inlet is formed in the left side of the first machine case. The first flange bearings are installed at the upper end and the lower end inside the first machine case respectively. The flexible blade type vertical shaft tide energy water turbine has the advantages that the multiple blades are arranged on the blade shafts, and water which flows out of the flow out pipes of the water turbine can be reused.

Owner:ZHEJIANG OCEAN UNIV

Condensate water desalination heat exchange mixed exhaust steam recovery secondary deoxygenation exhaust steam condensing device

ActiveCN104089272BDoes not affect normal operationAvoid pressure suffocation and poor drainage of condensateLiquid degasificationImpellerPlate heat exchanger

The invention relates to a two-stage deoxidized exhaust steam condensing device for heat-exchange mixed exhaust steam recovery of condensate water and desalted water. A pressure-bearing buffer tank is provided with a first water inlet pipe, a second water inlet pipe, a third water inlet pipe and a fourth water inlet pipe, wherein the first water inlet pipe and the third water inlet pipe are located on the upper layer, and the second water inlet pipe and the fourth water inlet pipe are located on the lower layer; mixed condensate water is introduced into the second water inlet pipe and the fourth water inlet pipe respectively after subjected to indirect heat exchange by a third heat exchanger and a fourth heat exchanger, and synthesis ammonia desalted water and conversion desalted water are introduced into the first water inlet pipe and the third water inlet pipe respectively after subjected to indirect heat exchange of the third heat exchanger and the fourth heat exchanger; buffer tank exhaust steam is cooled into buffer tank exhaust steam condensate water by a first heat exchanger; buffer tank outlet water is sent into a high-pressure deaerator by a first water pump, and drained water of a deaerator tank is sent to a boiler water replenishing pipe by a third water pump; the deoxidized exhaust steam is cooled into deoxidized exhaust steam condensate water by a second heat exchanger, the buffer tank exhaust steam condensate water and the deoxidized exhaust steam condensate water are injected into the pressure-bearing buffer tank by a condensate water collecting tank and a second water pump, and meanwhile, gas is discharged; and a forcible mixing impeller is mounted at the middle-lower part of the pressure-bearing buffer tank. According to the device, the utilization rate of condensate water waste heat is high, and the operation is reliable.

Owner:云南能投有能科技股份有限公司

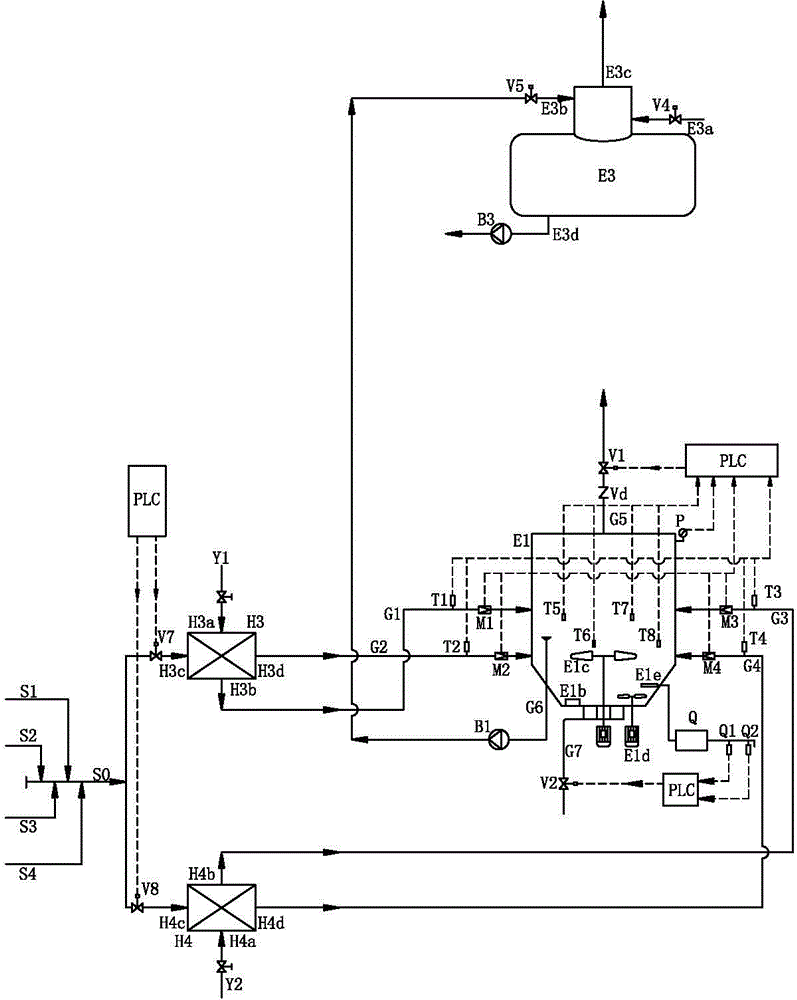

The construction method used for the anti-rotation at the start of the shield machine

The invention discloses a starting anti-rotation device for a shield machine and a construction method thereof. A pair of rails are arranged at intervals in the lower part of the steel sleeve, which includes the following steps: Step 1. A pair of inner and outer through holes are arranged symmetrically on the shield body. jacks, and the distance between a pair of jacks is set so that they can be located on both sides of a pair of rails; Step 2, seal and fix the sleeve in the jack, and set threads on the inner wall of the sleeve; Step 3, A pair of screw rods are threadedly connected in a pair of sockets respectively, and can extend or retract into the outer wall of the shield. The invention has the advantages of simple structure, convenient use, good sealing effect and the like.

Owner:CCCC SECOND HARBOR ENG

Condensed water desalination indirect heat exchange forced mixed secondary deaeration device

InactiveCN104085937BDoes not affect normal operationAvoid pressure suffocation and poor drainage of condensateFeed water supplyWater/sewage treatment by degassingImpellerBuffer tank

The invention relates to a secondary deoxidizing device for performing indirect heat exchange and forced mixing on condensed water and desalted water. A pressure-bearing buffer tank is connected with first and third water inlet pipes positioned on an upper layer as well as second and fourth water inlet pipes positioned on a lower layer; mixed condensed water is introduced into the second and fourth water inlet pipes respectively after undergoing indirect heat exchange with synthetic ammonia desalted water and transformed desalted water through third and fourth heat exchangers respectively; the synthetic ammonia desalted water and transformed desalted water are introduced into the first and third water inlet pipes respectively after undergoing heat exchange through the third and fourth heat exchangers; the middle part of the top wall of the pressure-bearing buffer tank is connected with a buffer tank exhaust pipe; buffer tank output water is pumped into a high-pressure deoxidizer through a first water pump; deoxidizing box drainage water is pumped into a water replenishing pipe of a boiler through a third water pump; the top of a deoxidizing head of the high-pressure deoxidizer is connected with a deoxidizing head exhaust pipe for exhausting deoxidizing exhaust steam and non-condensable gas; a forced mixing impeller is arranged on the middle lower part of the inner cavity of the pressure-bearing buffer tank; and a bottom plate of the pressure-bearing buffer tank is connected with a blow-off pipe. The device is high in residual heat utilization ratio of condensed water, and runs reliably.

Owner:YIHENG ENERGY SAVING TECH JIANGSU

Check valve with double fireproof valves for smoke flue

The invention discloses a check valve with double fireproof valves for a smoke flue, which comprises a valve body, a sealing valve and a spring and is characterized in that the valve body is divided into a main valve body and an auxiliary valve body; and the auxiliary valve body is placed in the main valve body and is assembled with the main valve body in a matching manner. The check valve has the advantages that the fireproof valves of the check valve have the function of leading smoke upwards, no smoke backflow can be generated, and the smoke-blocking and fireproof effects are good; and moreover, the big flue is not required, so that the building weight can be reduced, the kitchen space is enlarged, and the construction cost is reduced.

Owner:黄加丰

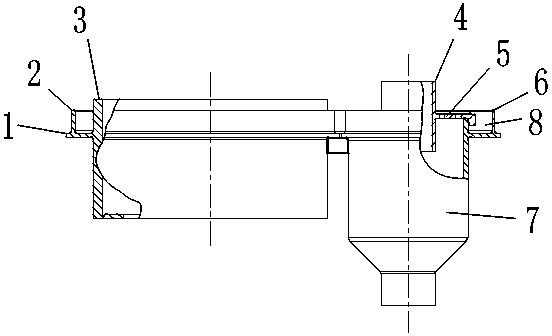

a filling valve

ActiveCN104163395BWon't pour backAvoid the phenomenon of stuck particlesSlide valveLiquid bottlingEngineeringExhaust pipe

The invention provides a loading valve. The loading valve comprises a valve body, a valve sleeve, and an exhaust pipe; the valve body is provided with a valve cavity, the valve sleeve is provided with an axial through hole, the top end of the valve sleeve stretches into the valve cavity, the bottom end of the valve sleeve is arranged outside the valve body, a spring which can drive the valve sleeve to move in the opposite direction relative to the valve body is arranged between the valve sleeve and the valve body; an anti-separation structure for preventing the valve sleeve from being separated from the valve body is arranged between the valve body and the valve sleeve; the loading valve also comprises a liquid feeding pipe, a first gap is arranged between the liquid feeding pipe and the valve body, a second gap is arranged between the liquid feeding pipe and the valve cover, the bottom end of the liquid feeding pipe is connected to a liquid discharge part, the outer diameter of the liquid discharge part is larger than the outer diameter of the liquid feeding pipe, the joint part between the liquid feeding pipe and the liquid discharge part forms an end face of shaft shoulder, and the side wall of the liquid discharge part is provided with a liquid outlet. The loading valve is especially suitable for loading liquid containing particles, the valve sleeve will not be separated from the valve body, the particles cannot be easily left, and the installation and disassembly of the loading valve are both convenient.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

Thyristor trigger circuit for inverter three-phase input rectification circuit

The invention provides a thyristor trigger circuit for a three-phase input rectification circuit of a frequency converter, including a fast recovery diode, a charging capacitor, a MOSFET, a MOSFET gate drive adjustment circuit and a thyristor drive circuit; the input terminal of the trigger circuit inputs phase voltage, phase voltage After the fast recovery diode is connected to the positive pole of the charging capacitor, the positive pole of the charging capacitor is connected to the source of the MOSFET, the drain of the MOSFET is connected to the gate of the thyristor to be triggered through the thyristor drive circuit, and the negative pole of the charging capacitor is connected to the thyristor to be triggered The cathode is connected to the positive bus bar of the inverter rectifier circuit, and a MOSFET gate drive adjustment circuit is provided between the charging capacitor and the gate of the MOSFET. The thyristor trigger circuit of the present invention is used in a three-phase input rectifier circuit, which makes the scheme more concise and practical, and reduces the cost.

Owner:WISDRI WUHAN AUTOMATION

Secondary deoxidizing device for performing indirect heat exchange and forced mixing on condensed water and desalted water

InactiveCN104085937ADoes not affect normal operationAvoid pressure suffocation and poor drainage of condensateFeed water supplyWater/sewage treatment by degassingImpellerBuffer tank

The invention relates to a secondary deoxidizing device for performing indirect heat exchange and forced mixing on condensed water and desalted water. A pressure-bearing buffer tank is connected with first and third water inlet pipes positioned on an upper layer as well as second and fourth water inlet pipes positioned on a lower layer; mixed condensed water is introduced into the second and fourth water inlet pipes respectively after undergoing indirect heat exchange with synthetic ammonia desalted water and transformed desalted water through third and fourth heat exchangers respectively; the synthetic ammonia desalted water and transformed desalted water are introduced into the first and third water inlet pipes respectively after undergoing heat exchange through the third and fourth heat exchangers; the middle part of the top wall of the pressure-bearing buffer tank is connected with a buffer tank exhaust pipe; buffer tank output water is pumped into a high-pressure deoxidizer through a first water pump; deoxidizing box drainage water is pumped into a water replenishing pipe of a boiler through a third water pump; the top of a deoxidizing head of the high-pressure deoxidizer is connected with a deoxidizing head exhaust pipe for exhausting deoxidizing exhaust steam and non-condensable gas; a forced mixing impeller is arranged on the middle lower part of the inner cavity of the pressure-bearing buffer tank; and a bottom plate of the pressure-bearing buffer tank is connected with a blow-off pipe. The device is high in residual heat utilization ratio of condensed water, and runs reliably.

Owner:YIHENG ENERGY SAVING TECH JIANGSU

A New Type of Foam Liquid Injection System

The invention discloses a novel foam liquid injecting system. The novel foam liquid injecting system comprises a nitrogen pipeline and a PLC control system; a first tee ball valve is mounted on the nitrogen pipeline and is used for dividing the certain section of the nitrogen pipeline into two branch pipelines, a foam liquid storage tank is arranged on each branch pipeline, then the two branch pipelines are combined into one pipeline, and opening and closing of the first tee ball valve is automatically controlled through the PLC control system. According to the novel foam liquid injecting system, kinetic energy of nitrogen during flowing in the pipeline, pressure of the foam liquid storage tanks and gravitational potential energy of foam liquid are fully utilized, so that the mixed foam liquid is injected and carried without using extra power, a plunger pump is successfully replaced, and the problems of high energy consumption, high cost and poor stability generated by using an original plunger pump are effectively solved; and the novel foam liquid injecting system has the characteristics of low cost, low energy consumption, good running stability, simple operation, easy arrangement and easy maintenance, and has very important practical value in the field of petroleum exploitation.

Owner:XI AN JIAOTONG UNIV

Condensed water desalination water indirect heat exchange exhaust steam recovery primary deaeration device

ActiveCN104085942BDoes not affect normal operationAvoid pressure suffocation and poor drainage of condensateFeed water supplyWater/sewage treatment by degassingSaline waterBuffer tank

The invention relates to a primary deoxidizing device for performing indirect heat exchange on condensed water and desalted water and recovering exhaust steam. A pressure-bearing buffer tank is provided with first and third water inlet pipes positioned on an upper layer as well as second and fourth water inlet pipes positioned on a lower layer; mixed condensed water is introduced into the second and fourth water inlet pipes respectively after undergoing indirect heat exchange with synthetic ammonia desalted water and transformed desalted water through third and fourth heat exchangers respectively; the synthetic ammonia desalted water and the transformed desalted water are introduced into the first and third water inlet pipes respectively after undergoing heat exchange through the third and fourth heat exchangers; buffer tank exhaust steam enters a first heat exchanger to be cooled into buffer tank exhaust steam condensed water, the buffer tank exhaust steam condensed water is replenished into the pressure-bearing buffer tank through a condensed water collecting tank and a second water pump, and meanwhile non-condensable gas is exhausted; a water outlet pipe of the buffer tank is connected with the inlet of a first water pump; the outlet of the first water pump is connected to a water replenishing pipe of a boiler; a bottom plate of the pressure-bearing buffer tank is connected with a blow-off pipe. The device is high in residual heat utilization ratio of condensed water, and runs reliably.

Owner:云南能投有能科技股份有限公司

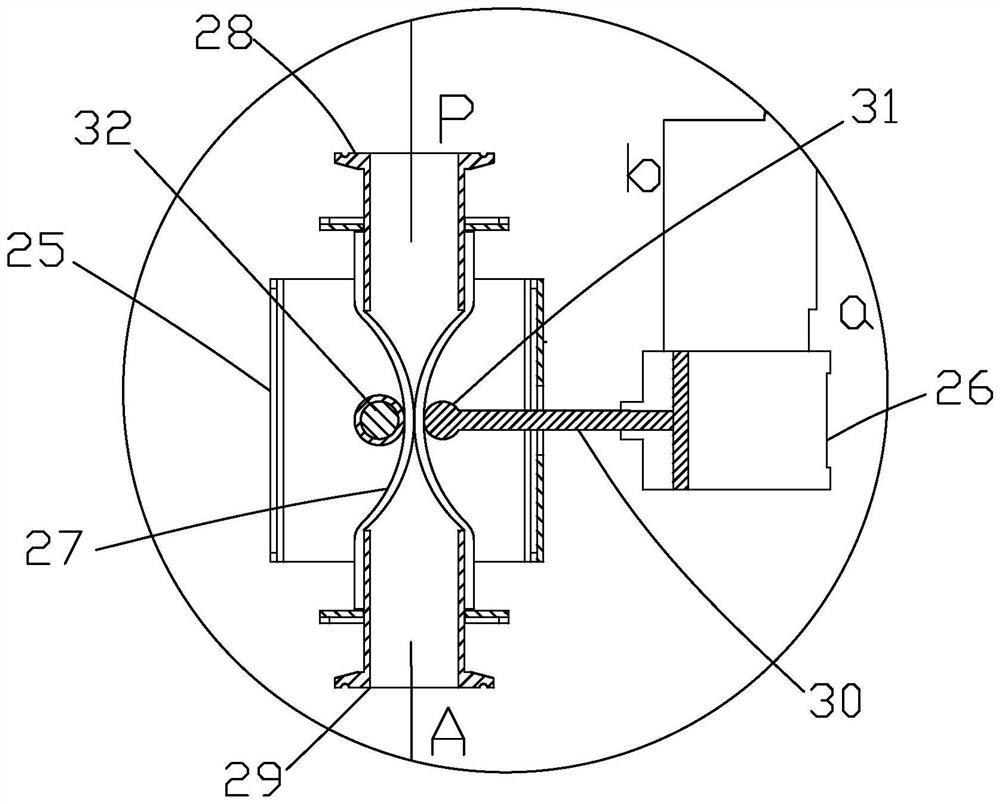

Pure mechanical pneumatic control logic actuator of vacuum toilet

PendingCN114277901AReduce noiseAvoid stickingWater closetsCabin closetsProcess engineeringPneumatic valve

The invention discloses a pure mechanical pneumatic control logic actuator of a vacuum toilet stool, comprising a first pneumatic stop valve which is connected with the toilet stool and a sewage tank; the second pneumatic stop valve is connected with the sewage tank and the sewage discharge pipeline; the pneumatic valve assembly comprises a vacuum tank, a first pressure tank and a second pressure tank; the first pressure tank controls the first pneumatic stop valve and the second pneumatic stop valve through the pneumatic valve assembly, and the suction rate and the discharge rate of the sewage tank are adjusted. According to the device, the opening or closing speed of the first pneumatic stop valve and the second pneumatic stop valve can be increased, noise of the toilet in the suction and pollution discharge process can be reduced, the effect that airflow washes the inner wall of a flow channel can be achieved, the risk of dirt adhesion and clamping is prevented, the pollution discharge efficiency is improved, and the service life of the toilet is prolonged. Meanwhile, sewage and air in the sewage tank cannot flow backwards through the first pneumatic stop valve.

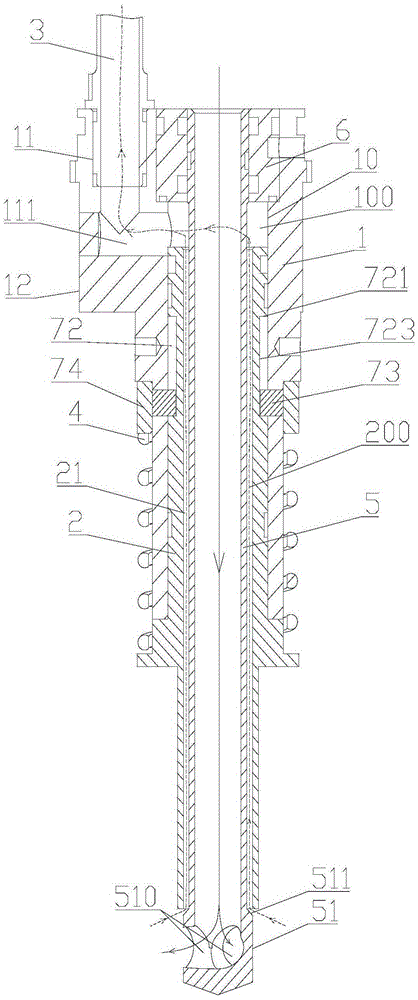

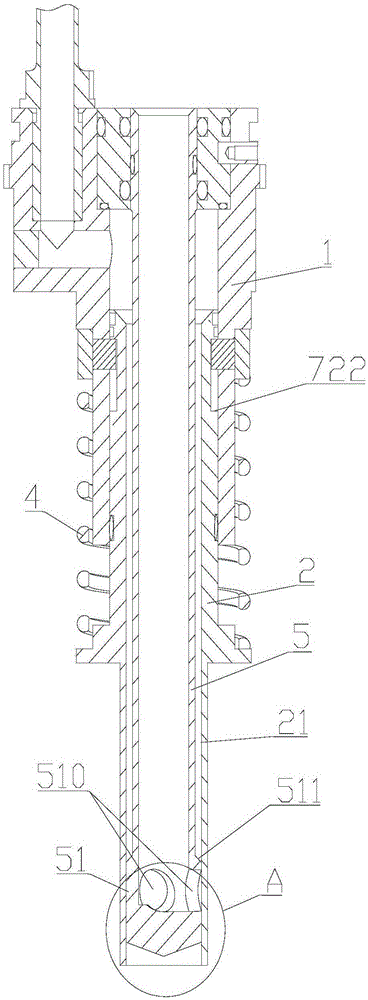

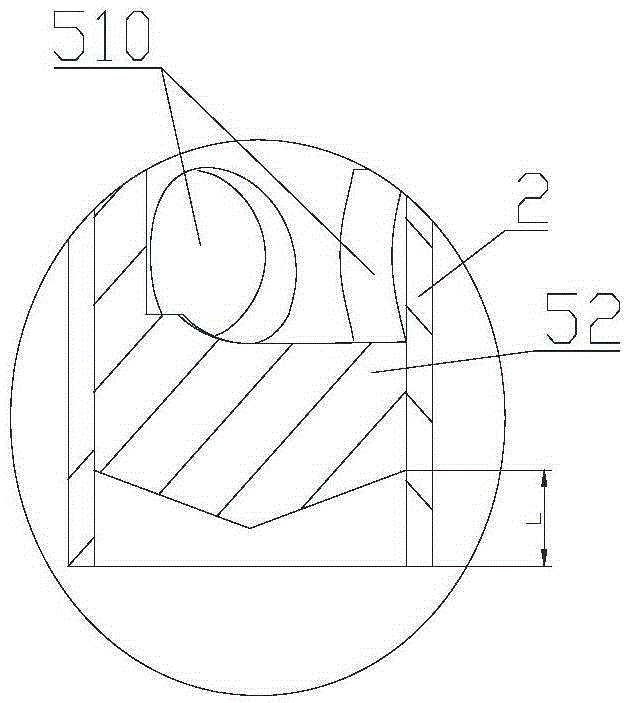

Casing automatic grouting device for well cementing

ActiveCN108119093BWon't pour backTo achieve the role of cementingConstructionsWell/borehole valve arrangementsWell cementingVALVE PORT

The invention relates to the technical field of oil and gas well cementing devices, and provides an automatic grouting device for a well cementing sleeve. The automatic grouting device for the well cementing sleeve includes a tubular device main body, a single-flow valve assembly is arranged in the device main body, the single-flow valve assembly includes a spring seat, and the spring seat is provided with a spring for abutting against a valve ball to a valve port of the single-flow valve assembly, the valve port is formed by a one-way movable valve seat disposed in the device main body, the one-way movable valve seat includes two or more valve blocks swinging up and down, and the valve blocks have a closed state in which the valve port is formed by mutual closing and an open state for thevalve ball to pass from top to bottom, the top of the spring is provided with a valve ball seat for supporting the valve ball, and the valve ball seat is provided with a ball seat circulating hole communicated with the valve port. The device does not need intermittent operation and has a stable working state during grouting and can reduce the amount of work, improve the work efficiency of the well cementing operation, reduce parts needed during the grouting process and reduce the production cost.

Owner:PETROLEUM ENG TECH RES INST CHINA PETROLEUM & CHEM CORP NORTH CHINA OIL & GAS CO +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com