Condensed water desalination indirect heat exchange forced mixed secondary deaeration device

A technology of forced mixing and secondary deoxygenation, applied in degassed water/sewage treatment, preheating, supplementary water supply, etc., can solve the problems of aggravated waste heat discharge, reduced back pressure, large valve opening, etc., to achieve aggravated waste heat the effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

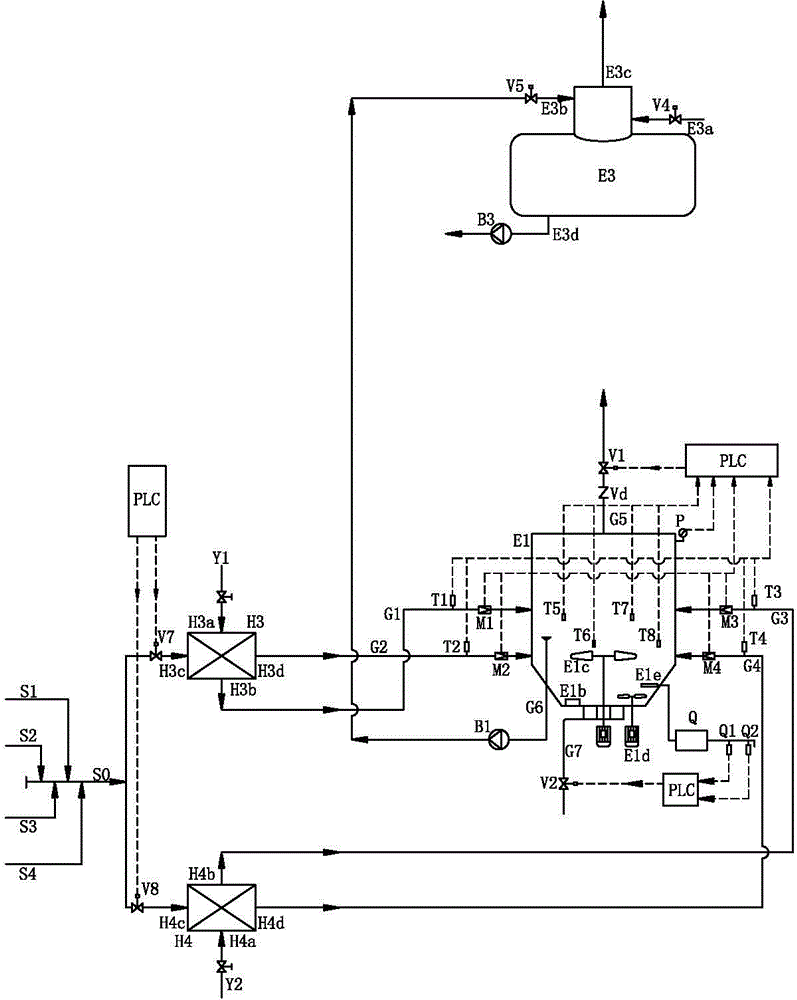

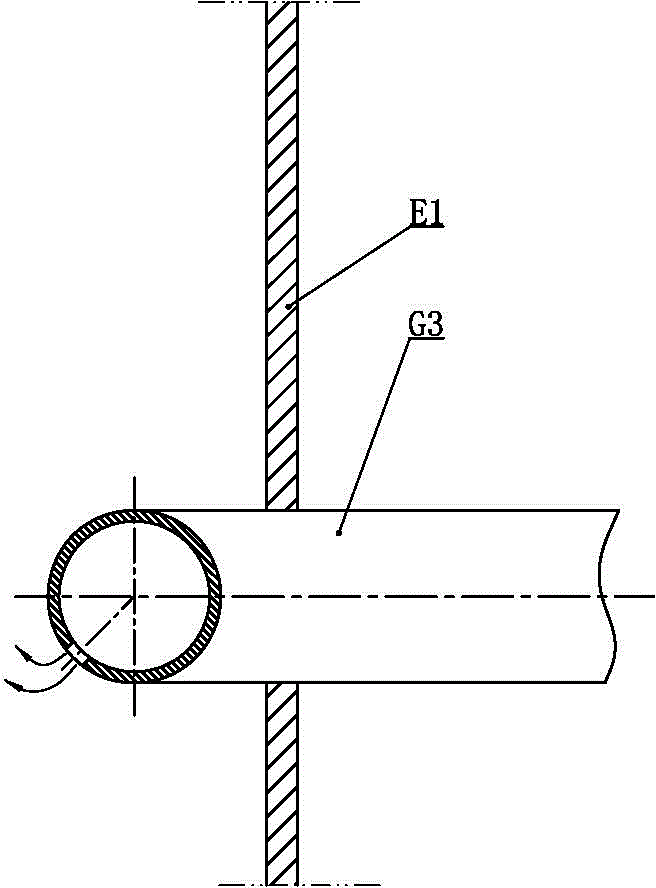

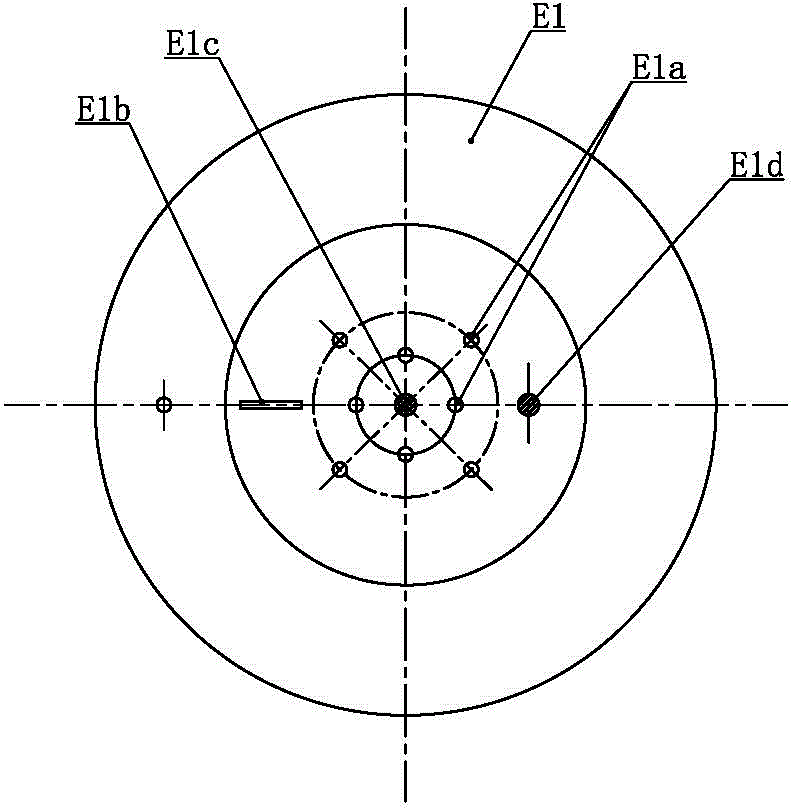

[0029] Such as figure 1 As shown, the condensed water desalination water indirect heat exchange forced mixing secondary oxygen removal device includes a closed pressure buffer tank E1, a third heat exchanger H3 and a fourth heat exchanger H4. Calcination at 135°C to 155°C Furnace condensate enters calciner condensate pipe S1, fluidized bed condensate at 135°C~155°C enters fluidized bed condensate pipe S2, dry ammonium condensate at 135°C~155°C enters dry ammonium condensate pipe, 60°C~80°C The cooling and demineralized water of synthetic ammonia enters the synthetic ammonia demineralized water pipe Y1, the transformation cooling demineralized water of 60℃~95℃ enters the transformation demineralized water pipe Y2, the calciner condensate water pipe S1, the fluidized bed condensate water pipe S2 and the dry ammonium condensate water pipe S3 are connected respectively The condensed water collecting pipe S0 may also connect other condensed water pipes S4 to the condensed water col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com