Novel foam liquid injecting system

A technology of injection system and foam liquid, which is applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., which can solve the problems of high energy consumption, high cost and unstable system operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

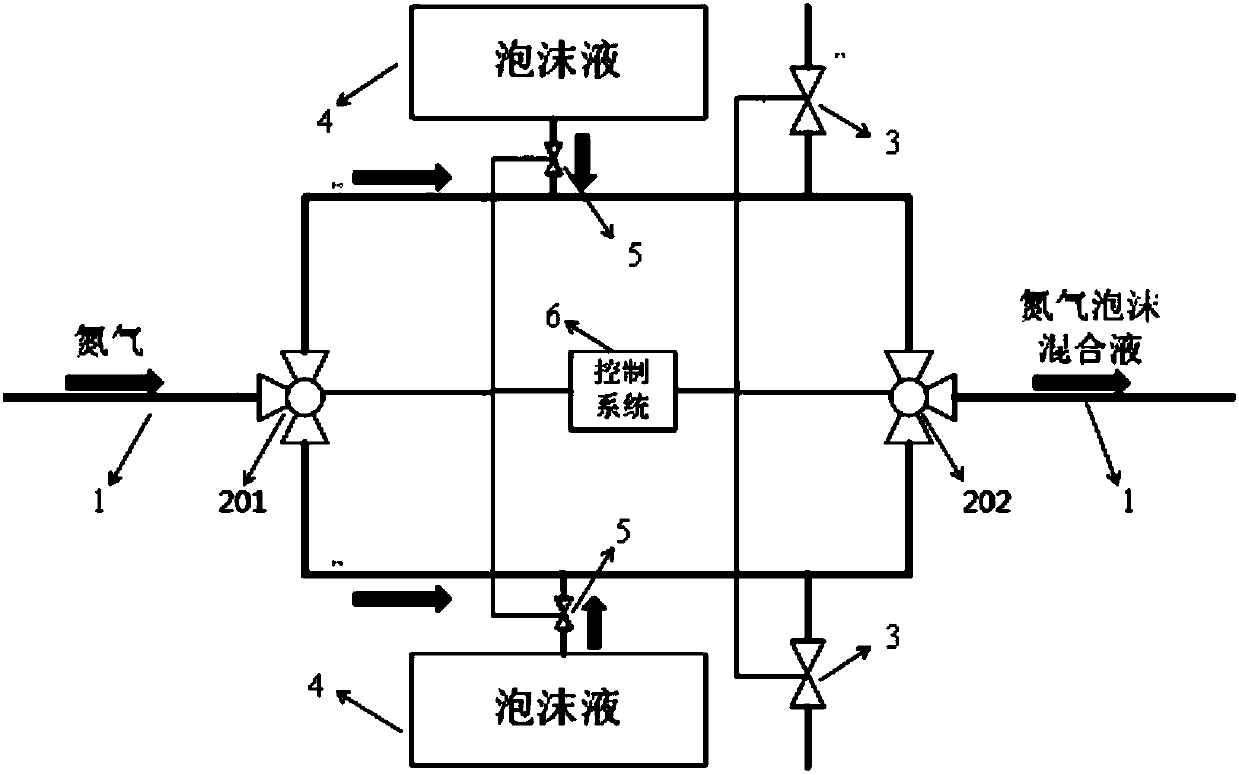

[0024] like figure 1 As shown, the novel foam liquid injection system provided by the present invention includes a nitrogen pipeline 1, two three-way ball valves, a pressure relief valve 3, a foam liquid storage tank 4, a solenoid valve 5 and a PLC control system 6.

[0025] Its specific working process is that the first three-way ball valve 201 divides a certain section of the nitrogen pipeline 1 into two branches, and each branch is connected with a foam liquid storage tank 4 and a pressure relief valve 3, and the foam liquid storage tank 4 And the solenoid valve 5 that controls the flow is also equipped with between the branch. The on-off of each valve is controlled by the PLC control system 6 . After the system is started, the on-off of the valve is controlled by the PLC control system 6 to ensure that only one branch of the two branches...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com