Tubular reactor

A tubular reactor and reaction technology, which is applied in the field of medical machinery and chemical industry, can solve the problems of poor heat exchange effect, large floor area, and too long pipes, etc., to overcome poor heat exchange effect and reduce floor space The effect of improving the area and heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 、 no. 2 approach and no. 3 approach

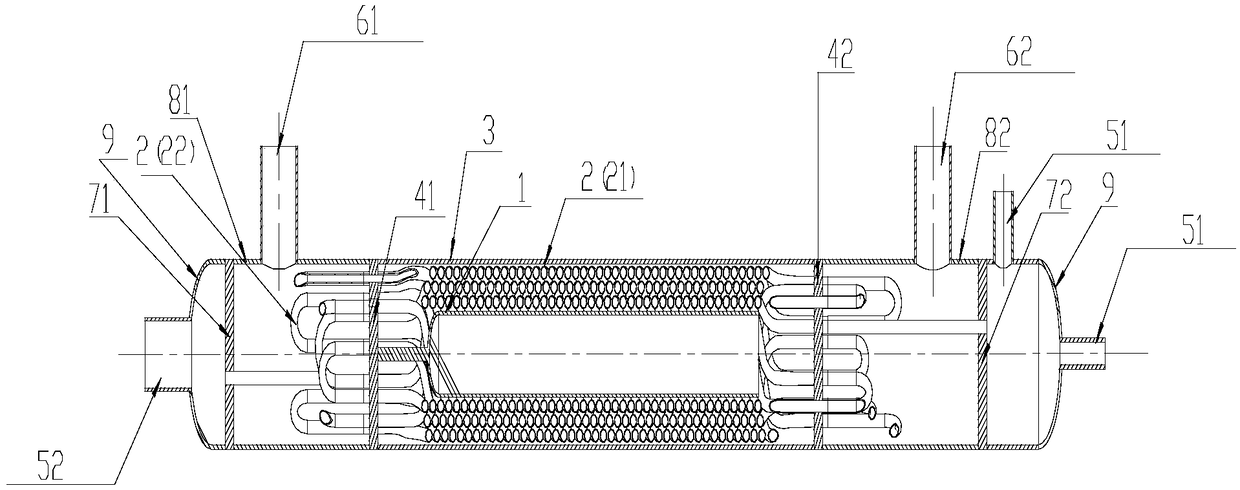

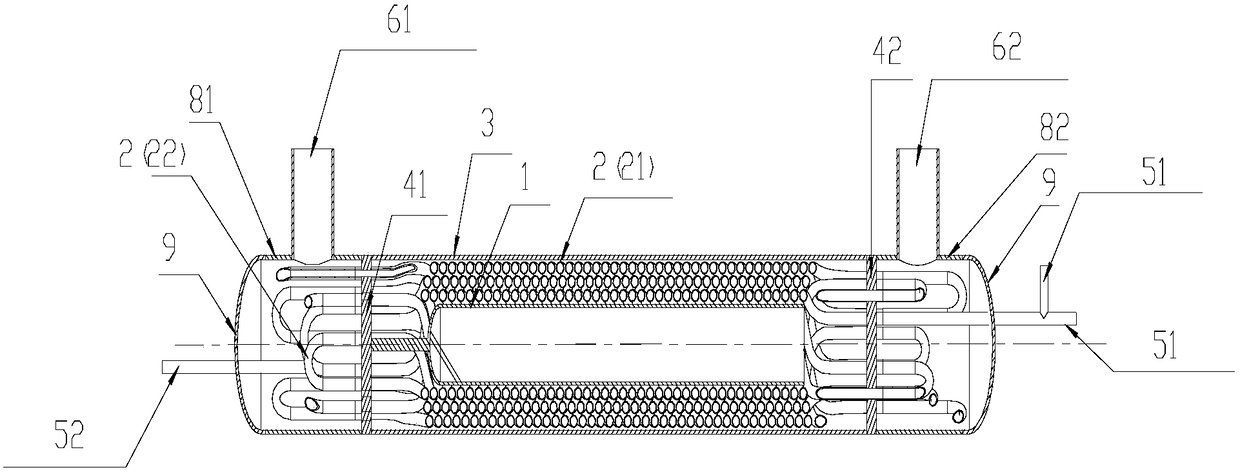

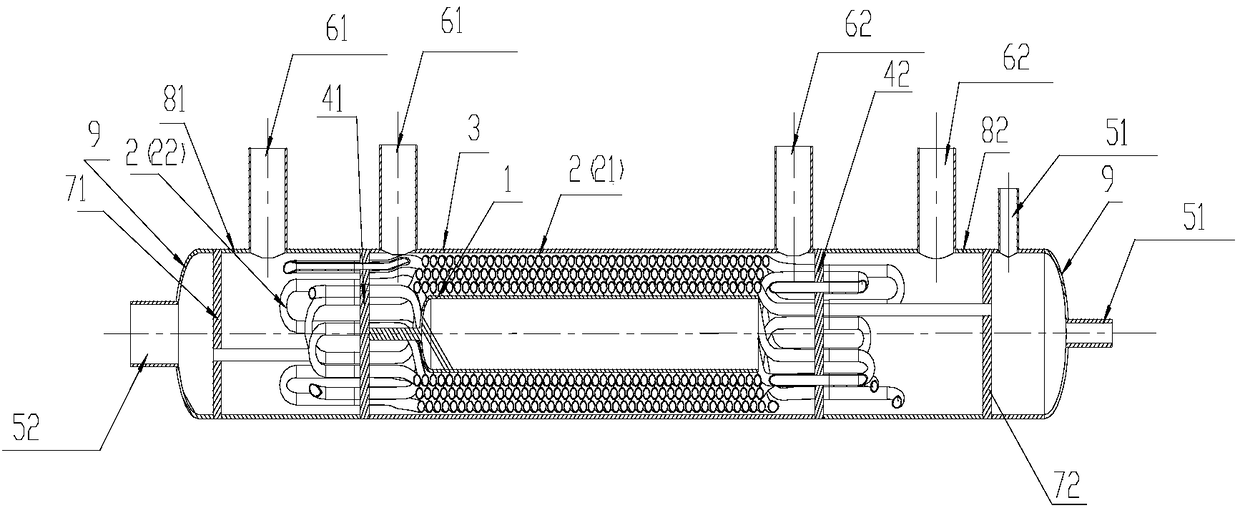

[0082] In the first and second embodiments of the present invention, there are two reactive fluid inlet connectors 51, one reactive fluid outlet connector 52, one heat exchange fluid inlet connector 61, and one heat exchange fluid outlet connector 62, see figure 1 and 2 As shown; and the third embodiment of the present invention has two reaction fluid inlet joints 51, one reaction fluid outlet joint 52, and two heat exchange fluid inlet joints 61 (one of which is arranged on the first tube plate 71 and the first perforated plate 41, and the other is arranged between the first perforated plate 41 and the mandrel 1), and there are two heat exchange fluid outlet joints 62 (one of which is arranged on the second tube plate 72 and the second between the perforated plates 42, and the other is disposed between the second perforated plate 42 and the mandrel 1), as shown in FIG. 3 .

[0083]The reaction fluid can be passed through the reaction fluid inlet connection, especially more t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com