Patents

Literature

40results about How to "Extend the length of the flow path" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

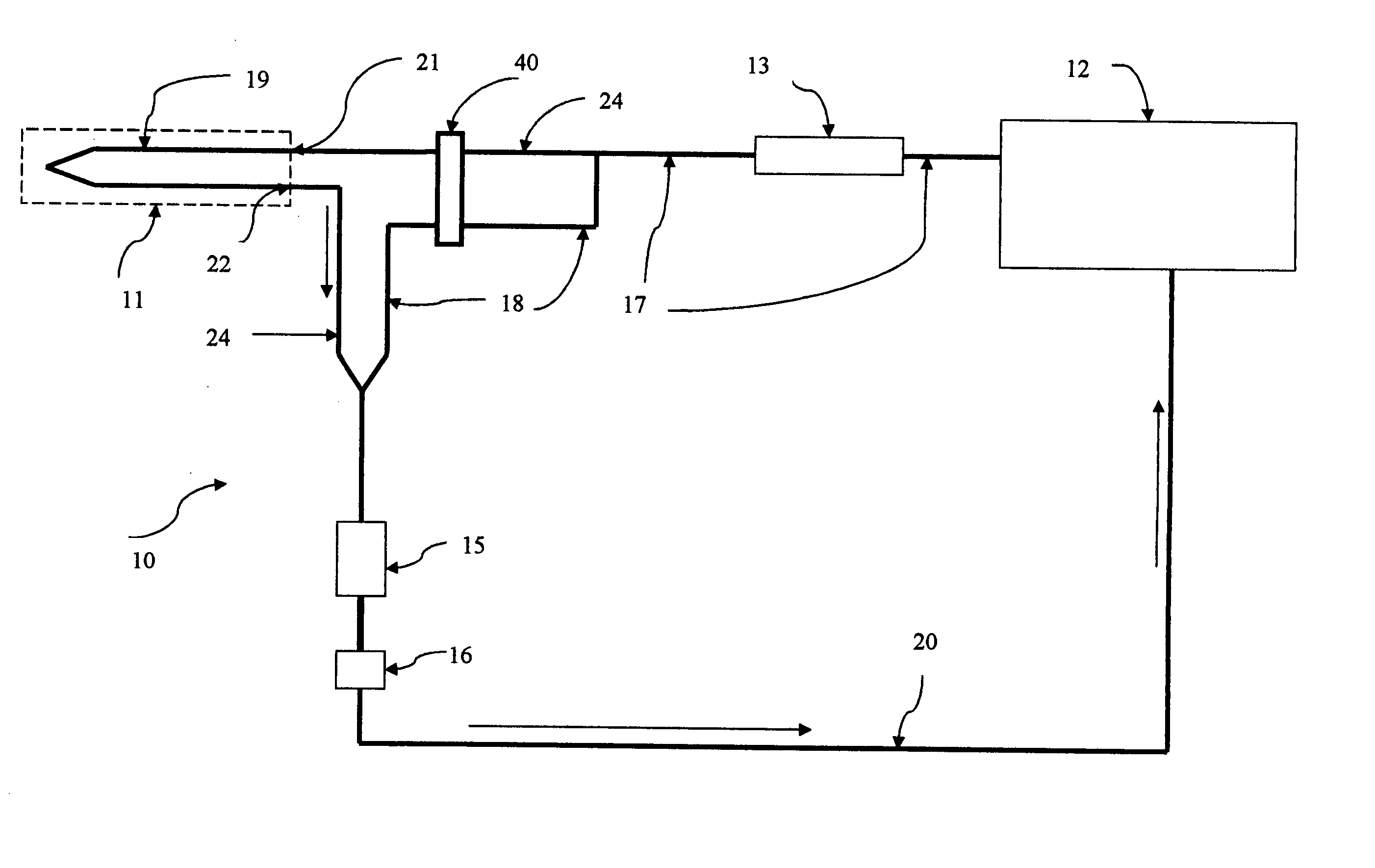

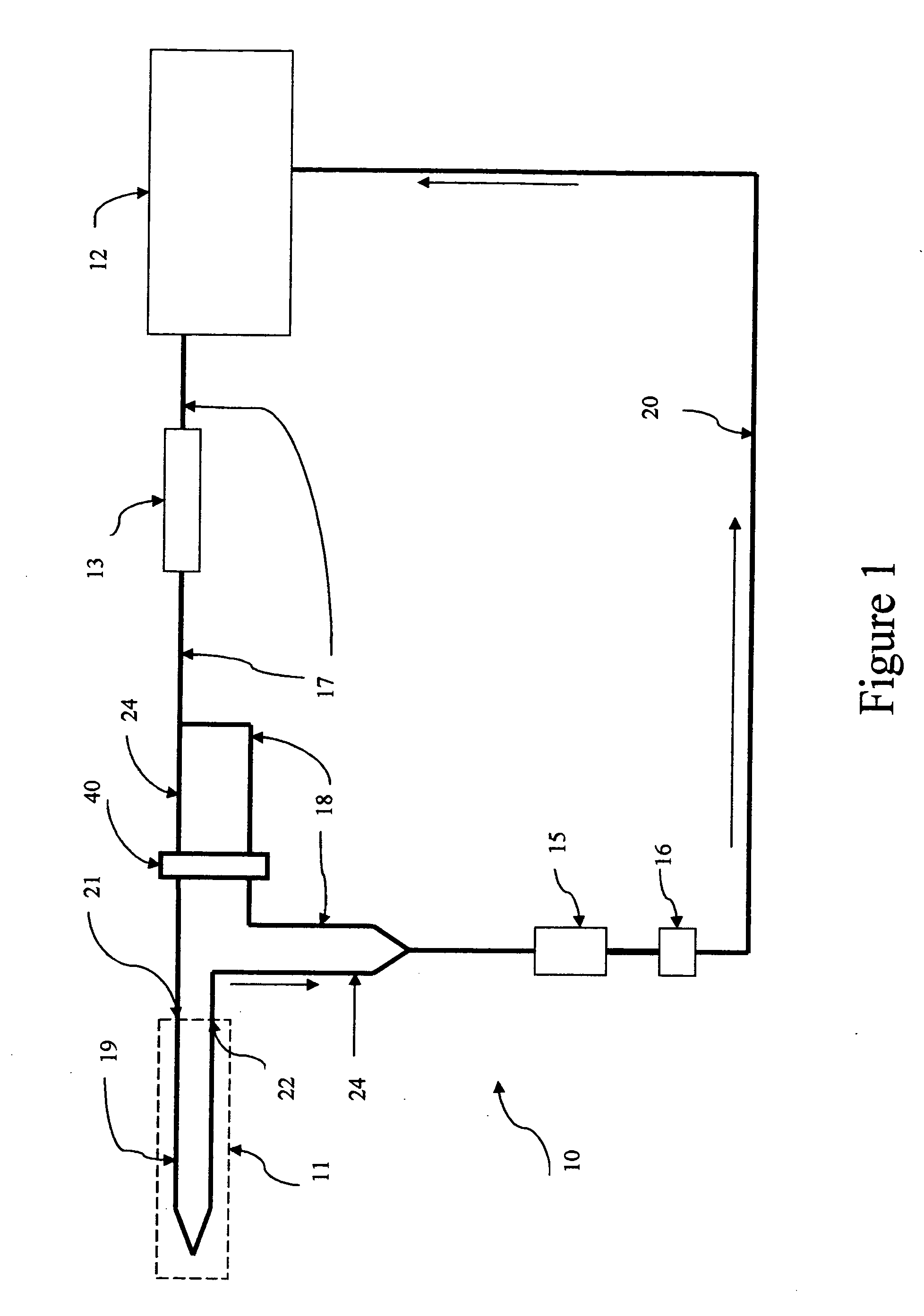

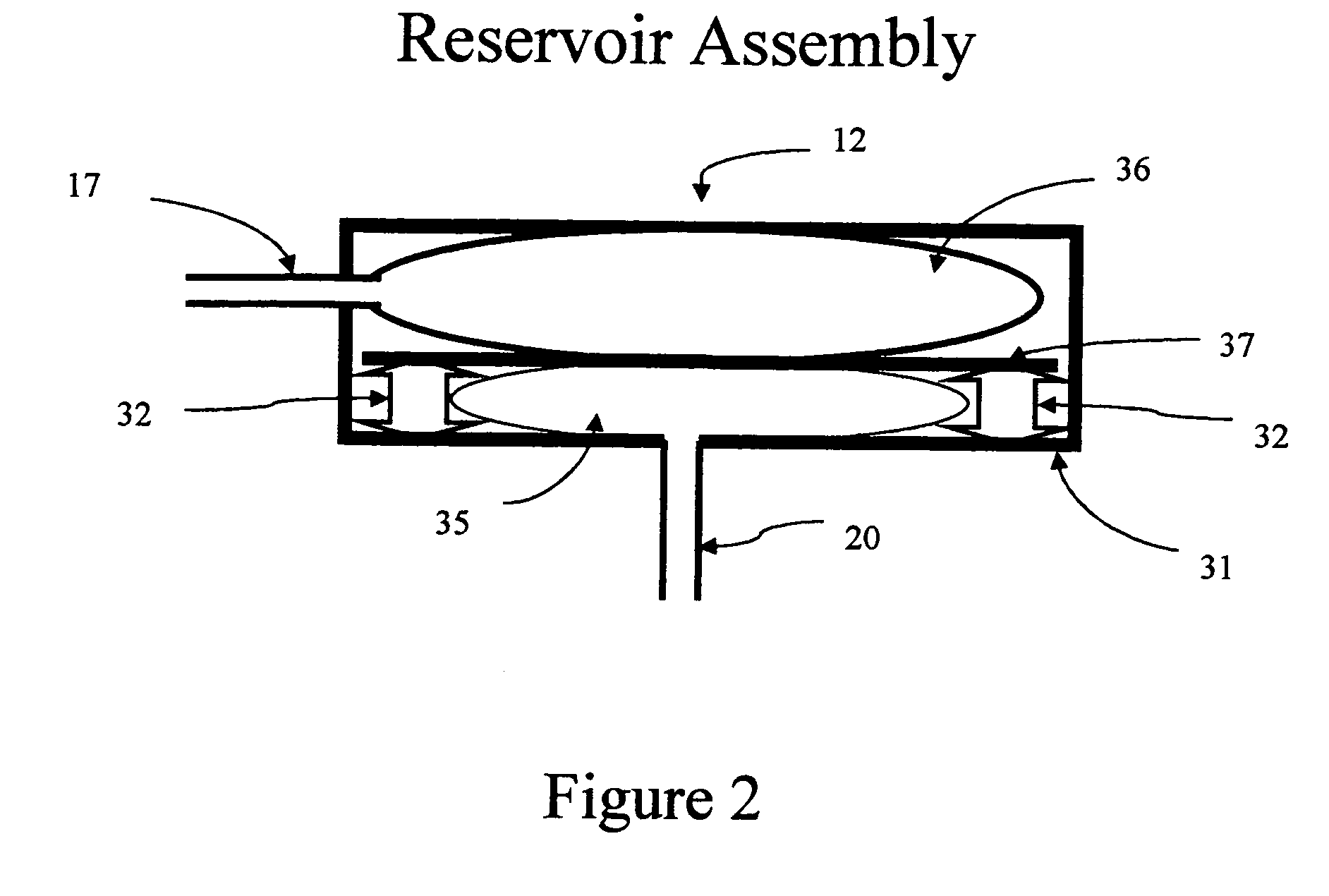

Self-calibrating body analyte monitoring system

InactiveUS20050209518A1Accurate measurementMinimize timeMedical devicesPressure infusionAnalyteMonitoring system

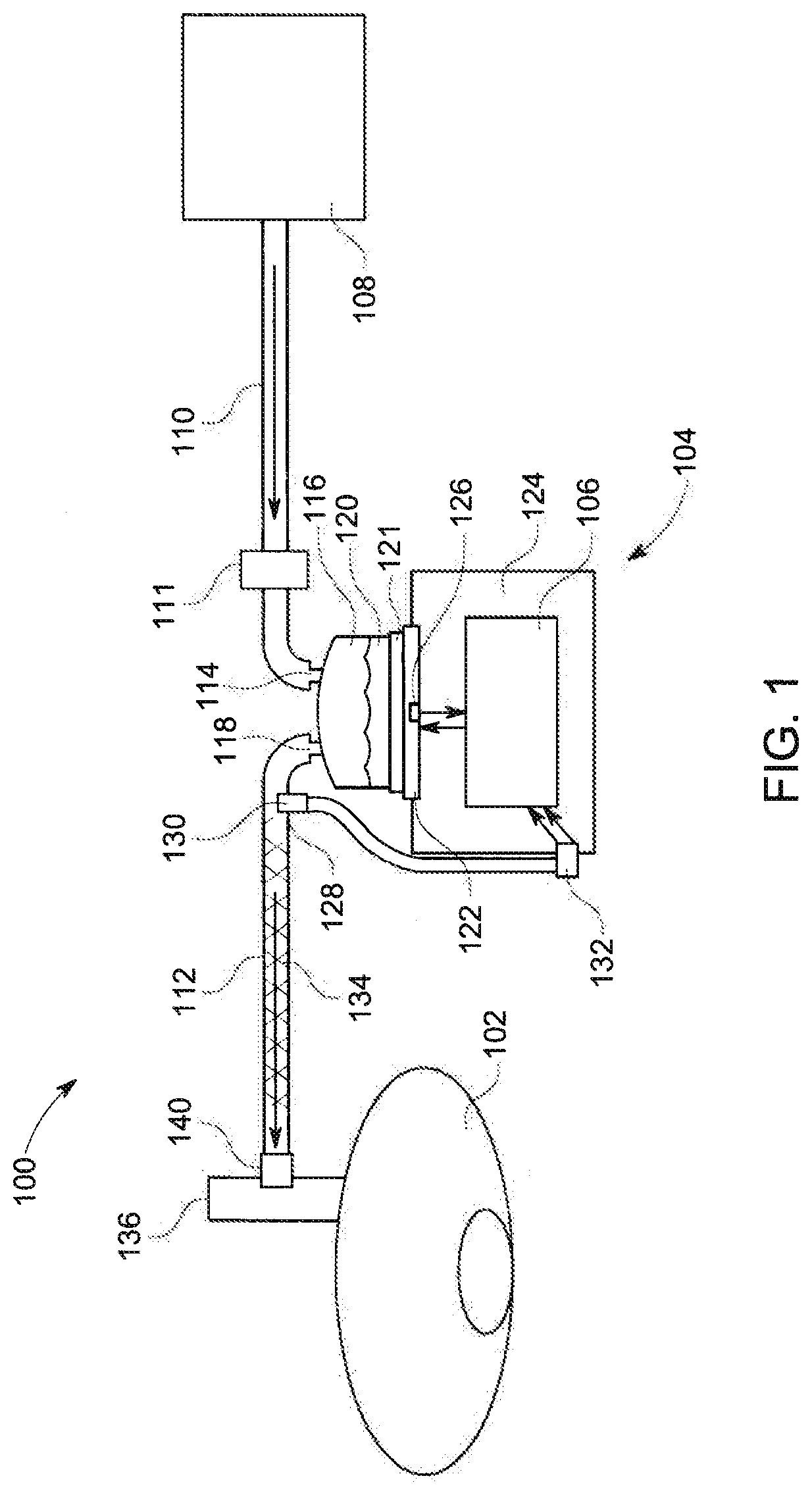

A self-calibrating monitoring system based on microdialysis for measurement of a body analyte is disclosed. In one embodiment, perfusate containing a known concentration of body analyte is mixed with an enzyme solution after passing through a microdialysis needle and instead of passing through the microdialysis needle to measure the body analyte and to calibrate the analysis chamber that measures the body analyte.

Owner:THERAFUSE

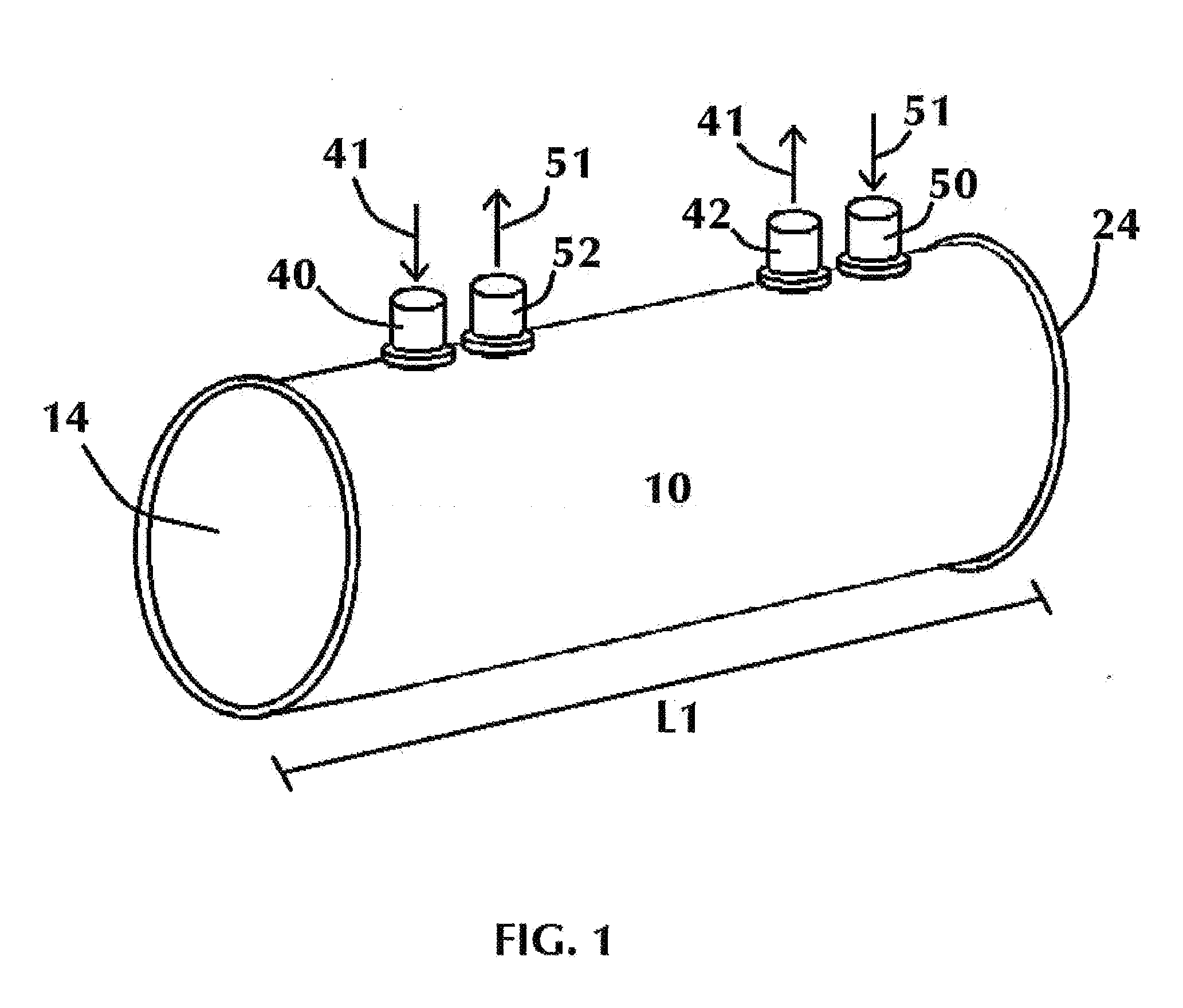

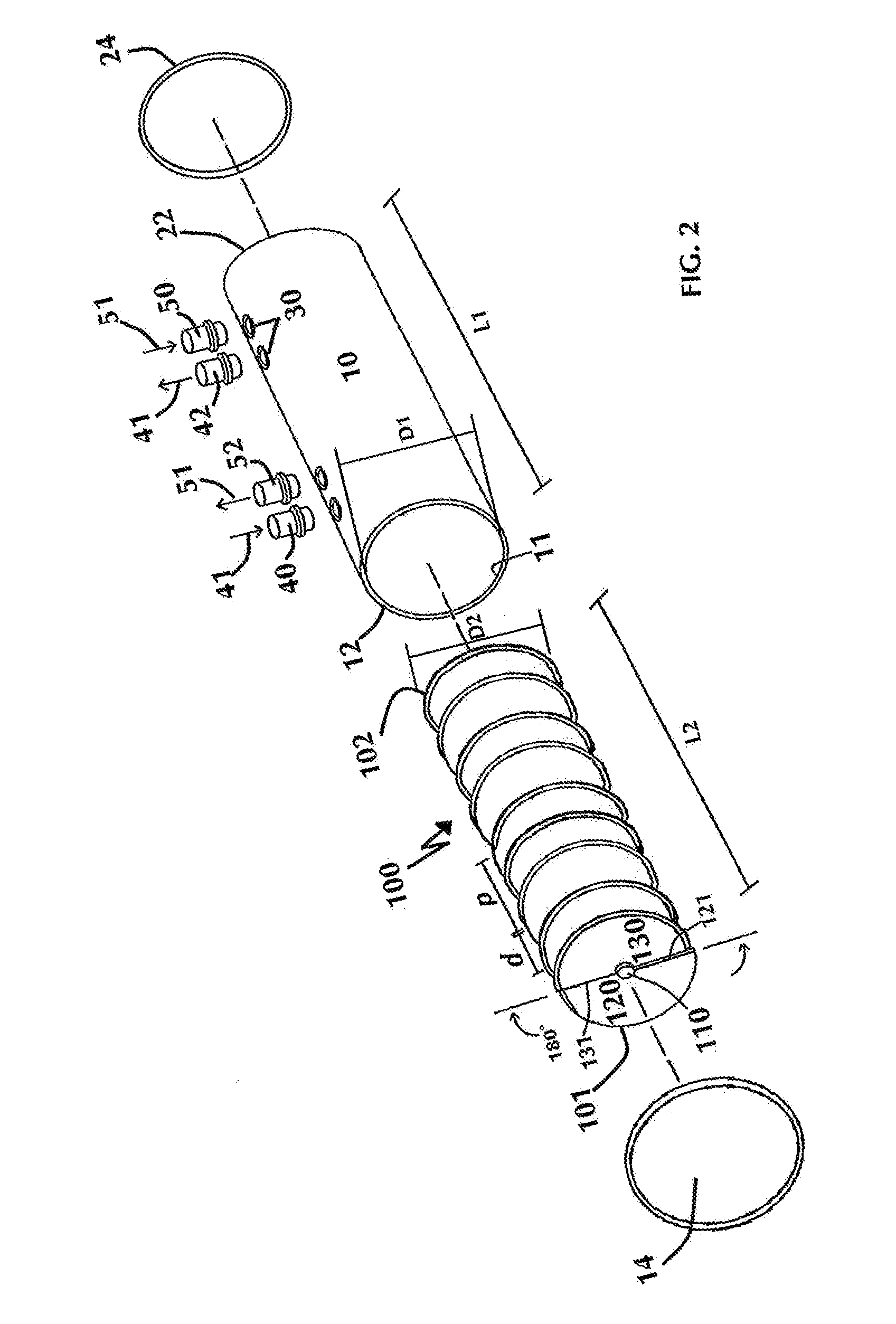

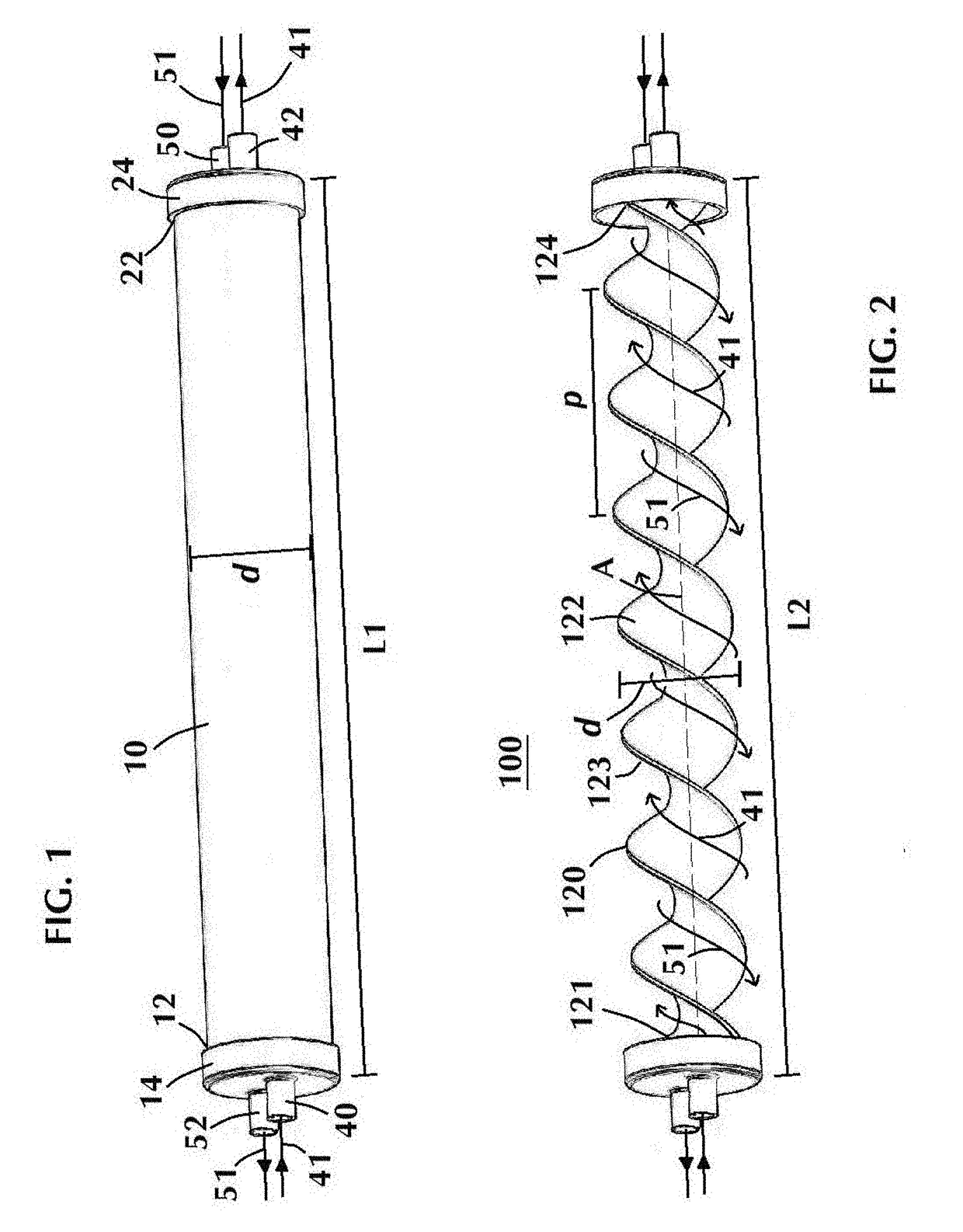

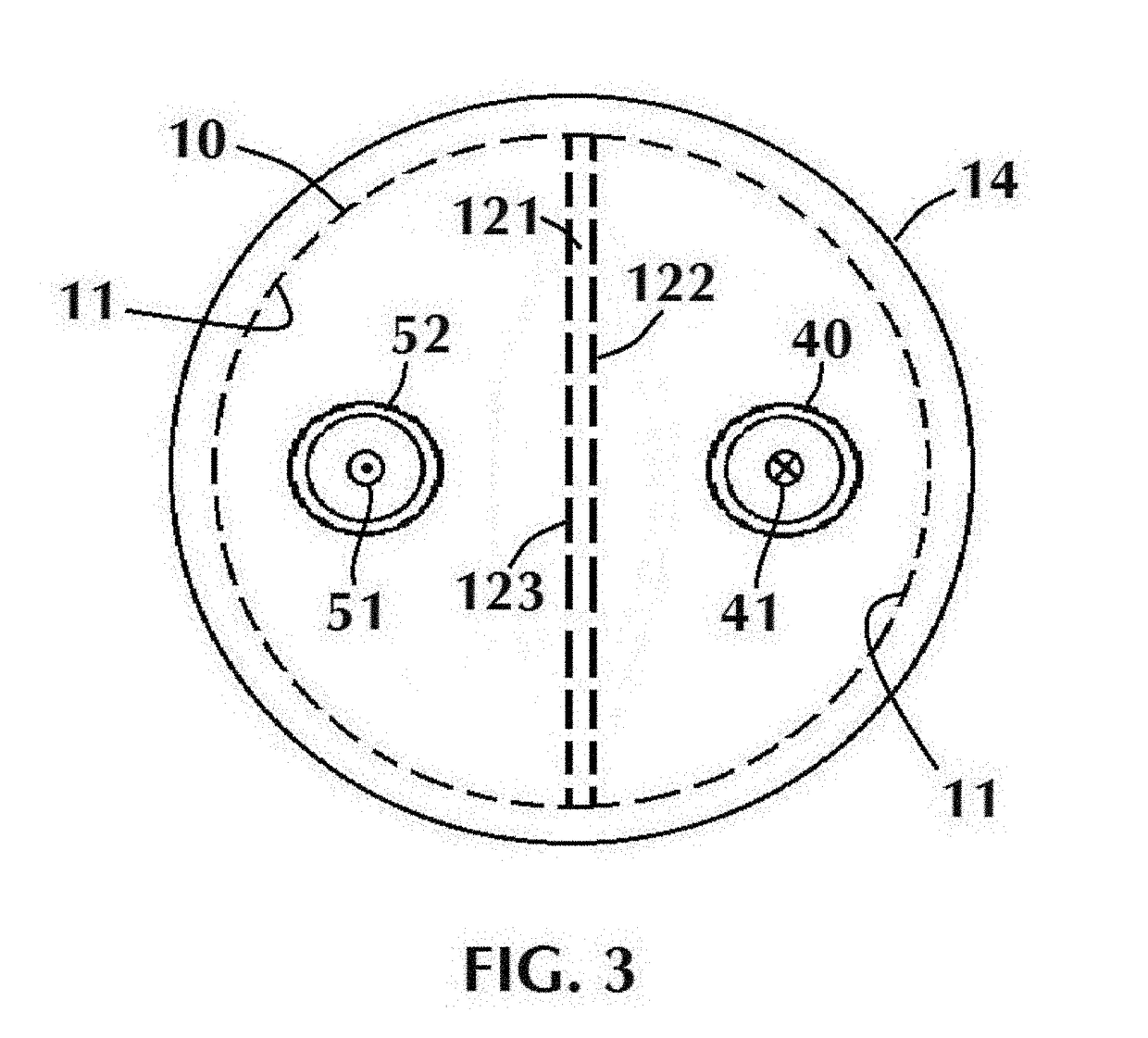

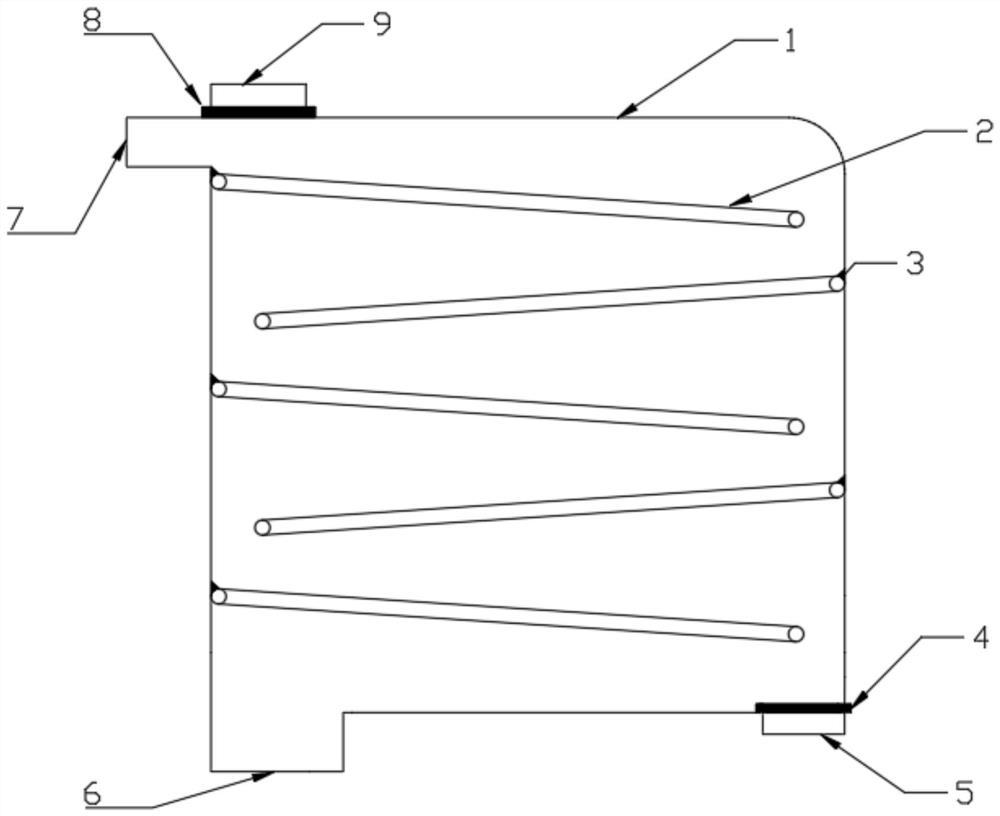

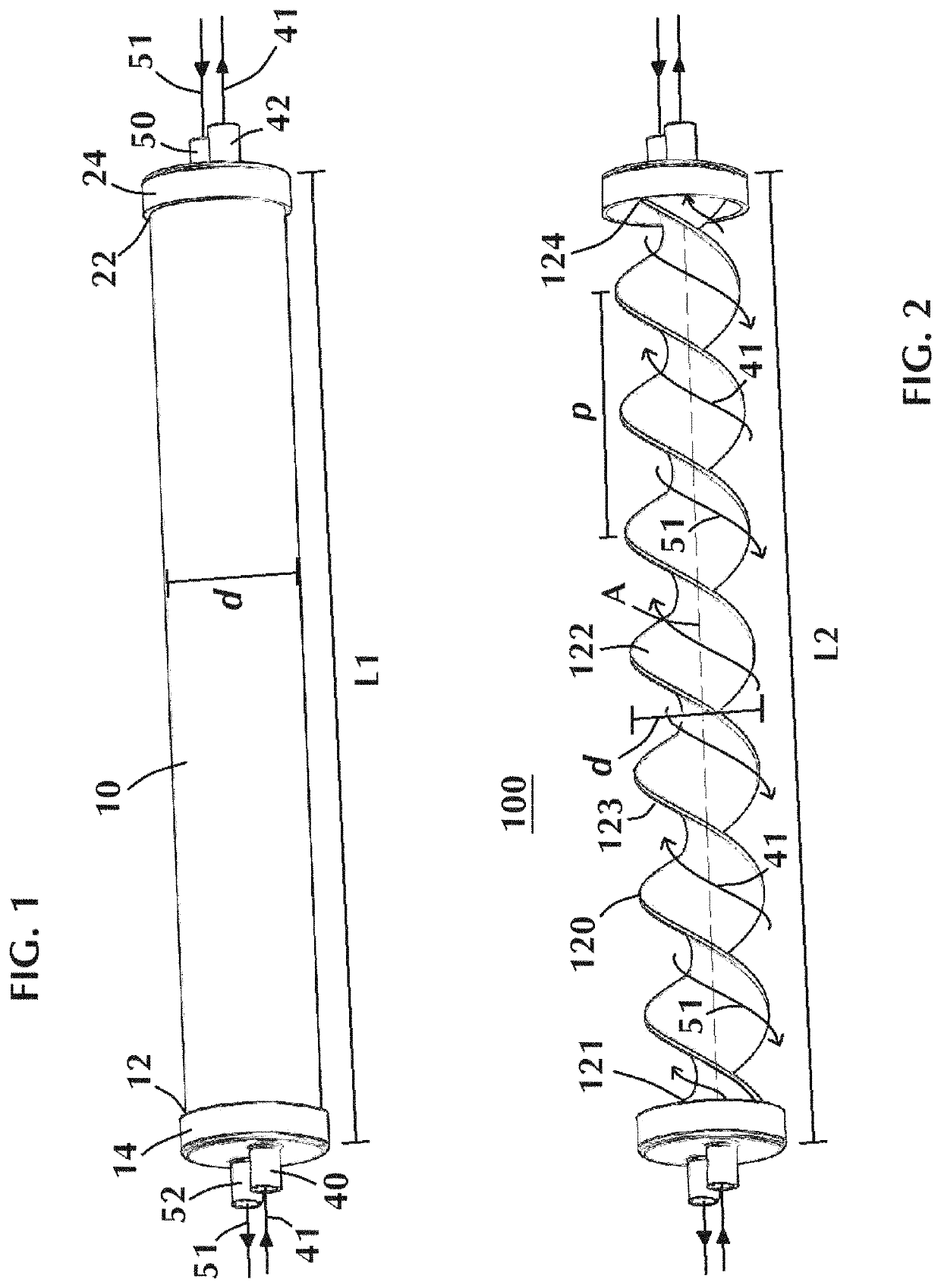

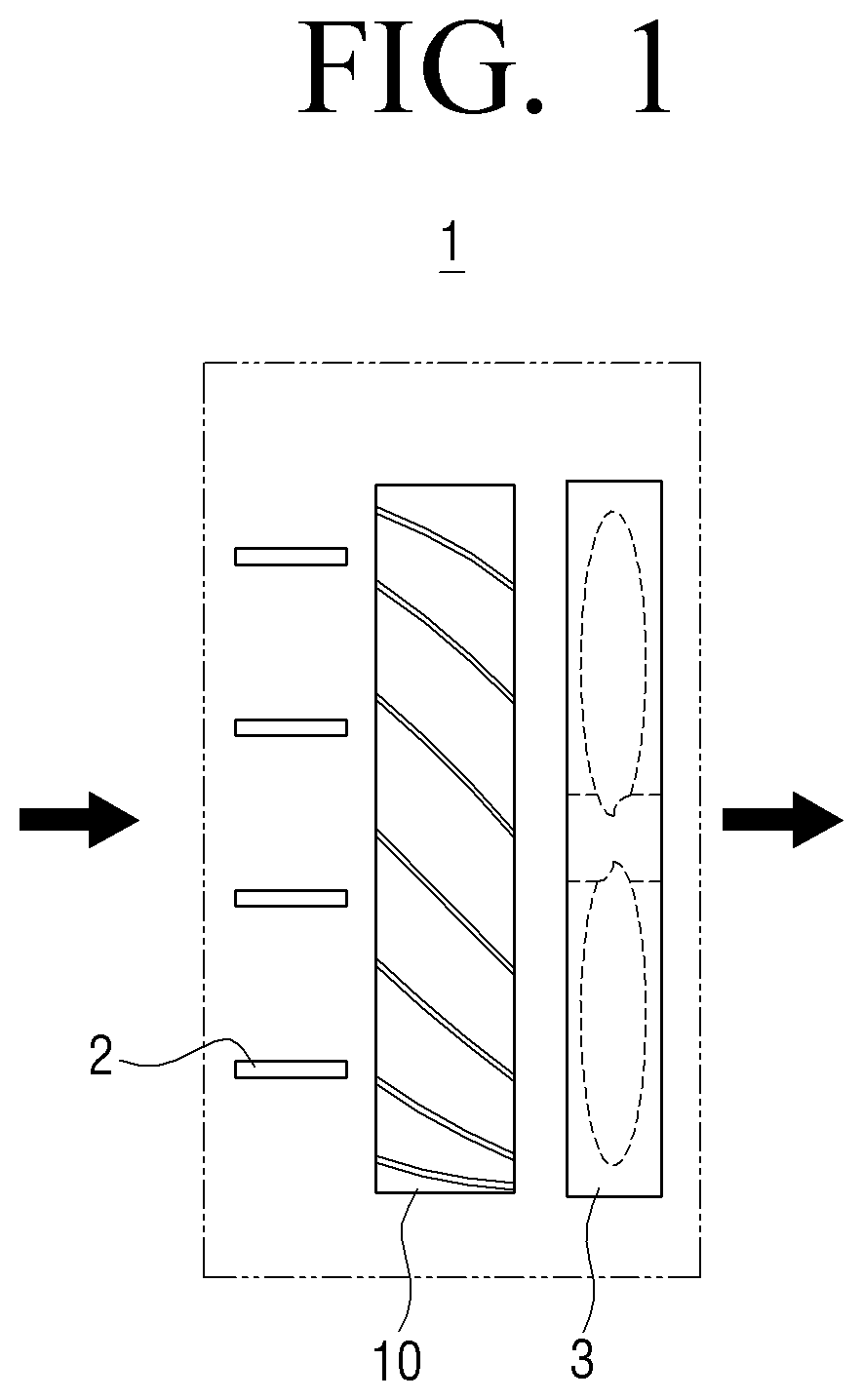

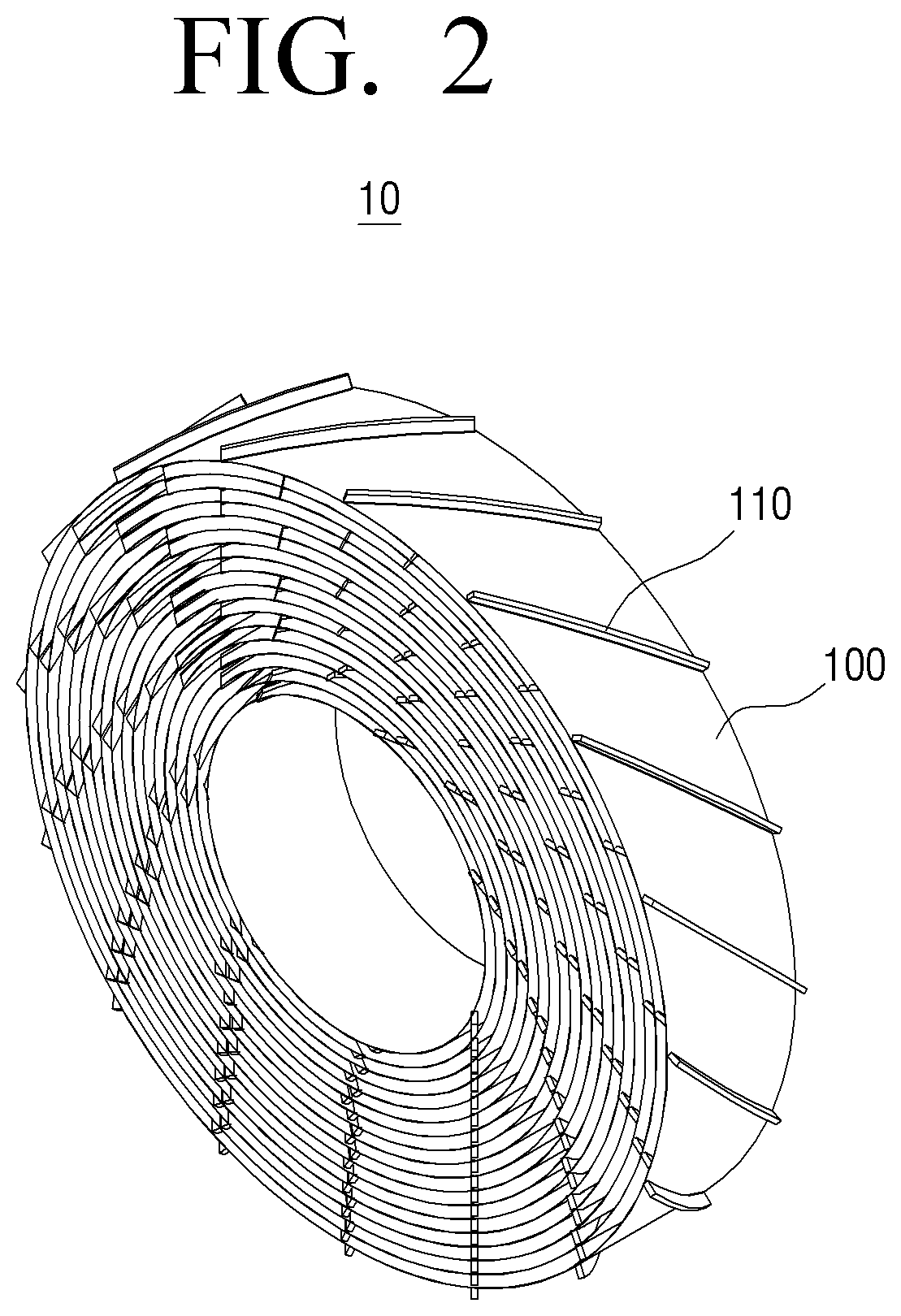

Counterflow helical heat exchanger

InactiveUS20150300745A1Equivalent and superior heat transfer performanceSmall packageHeat exhanger sealing arrangementHeat exchanger casingsEngineeringMechanical engineering

A heat exchanger assembly comprising a tube with a thermally conductive tube insert sealed therein, the tube insert having a substantially similar cross-section to the cross-section of the tube, and a plurality of fluid ports for passage of fluid into and out of the tube, the fluid ports arranged for counterflow operation. The tube insert includes a pair of helices extending along the length of the tube insert, the helices having first and second sides offset from each other by a predetermined distance along the length of the tube insert and first and second ends, each of the first ends offset from the other by a predetermined angle and each of the second ends offset from the other by a predetermined angle. The tube insert is sealed within the tube to form a first fluid flow path and a second fluid flow path, the first fluid flow path defined between the first sides of the helices and the second fluid path defined between the second sides of the helices.

Owner:ENTEREX AMERICA

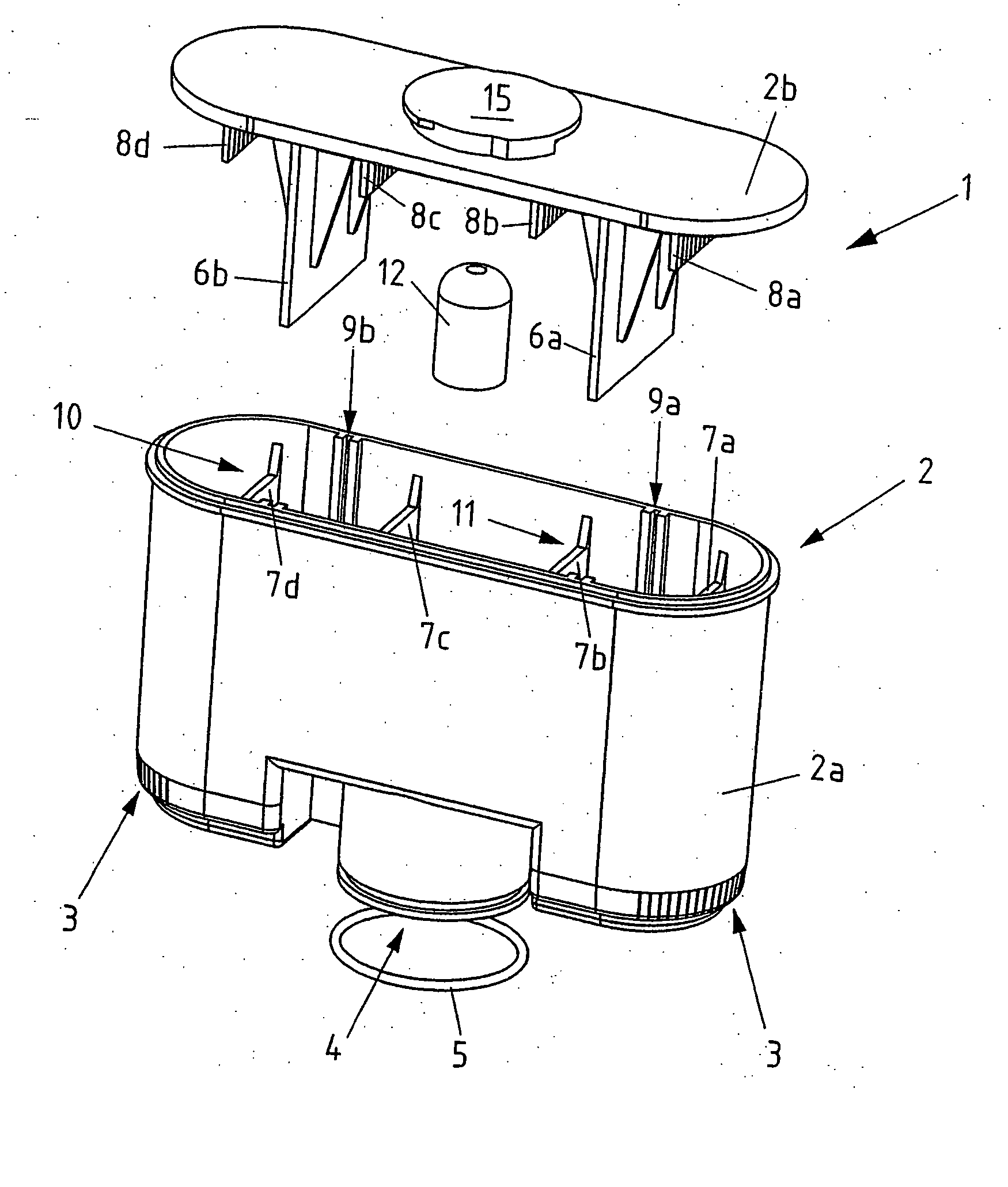

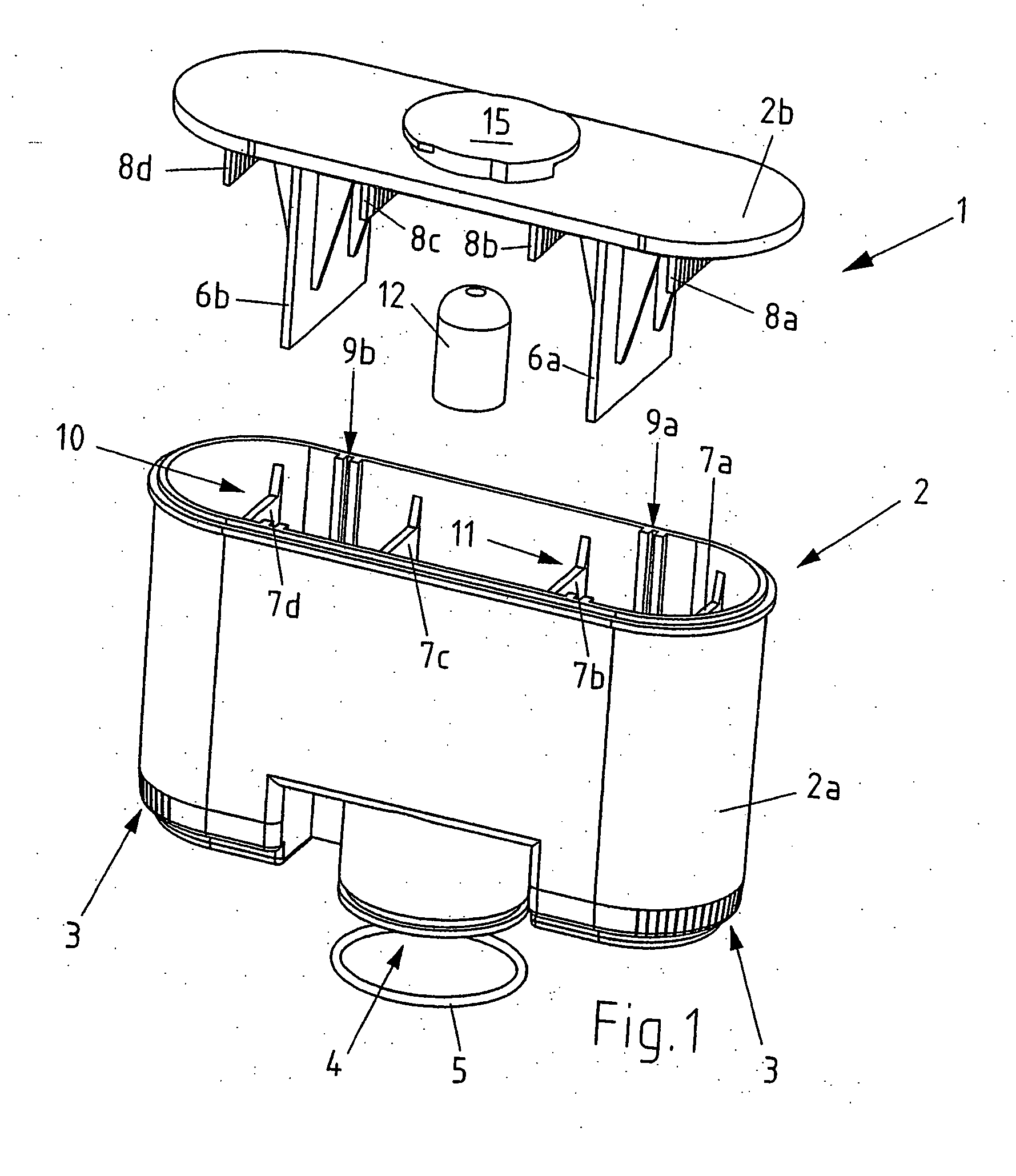

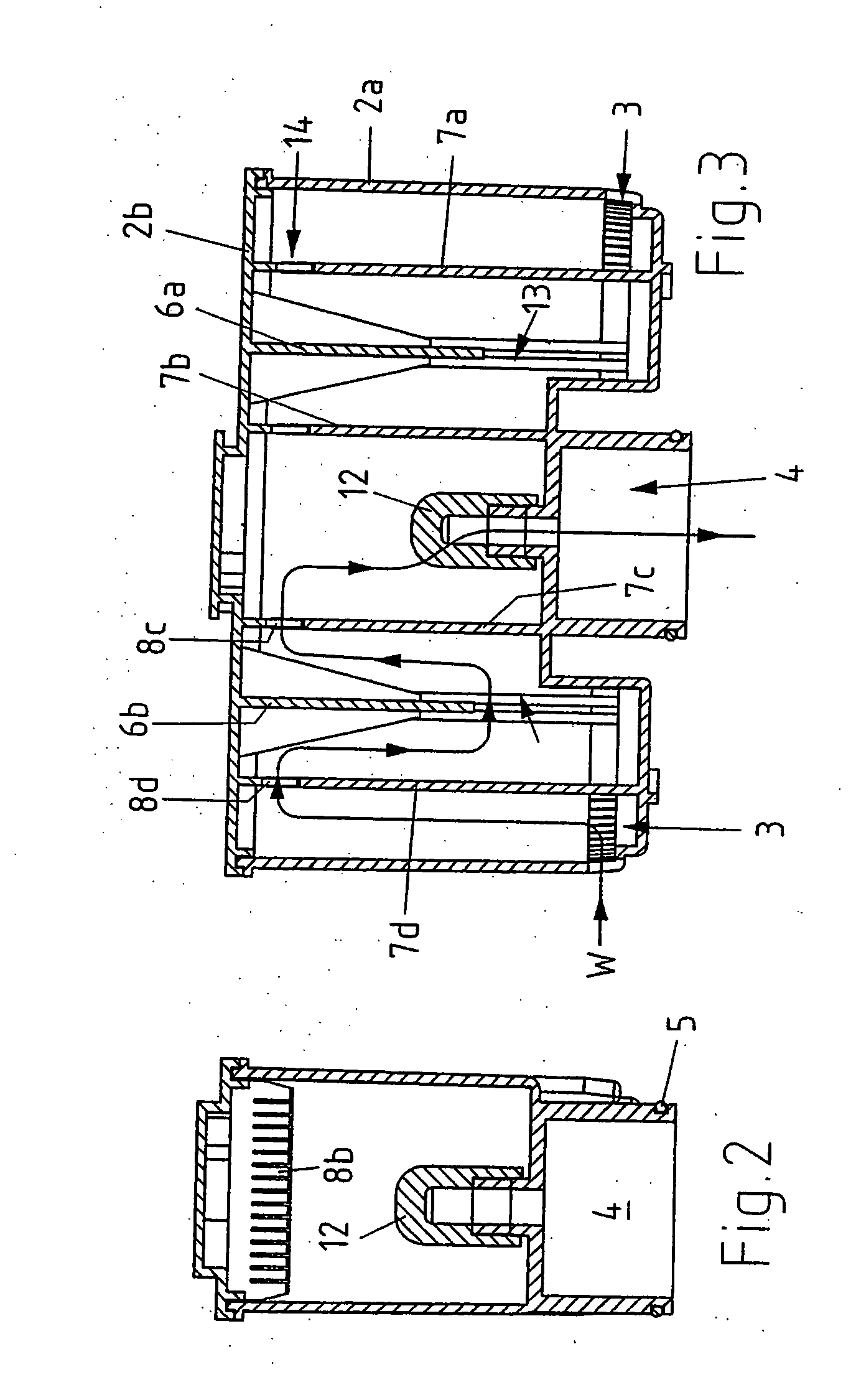

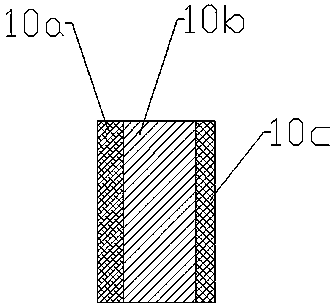

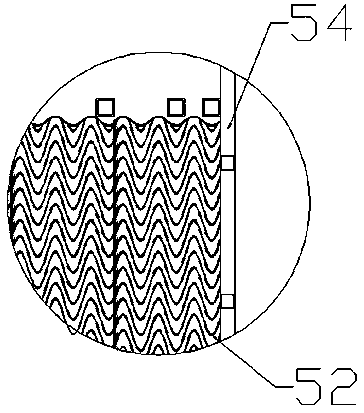

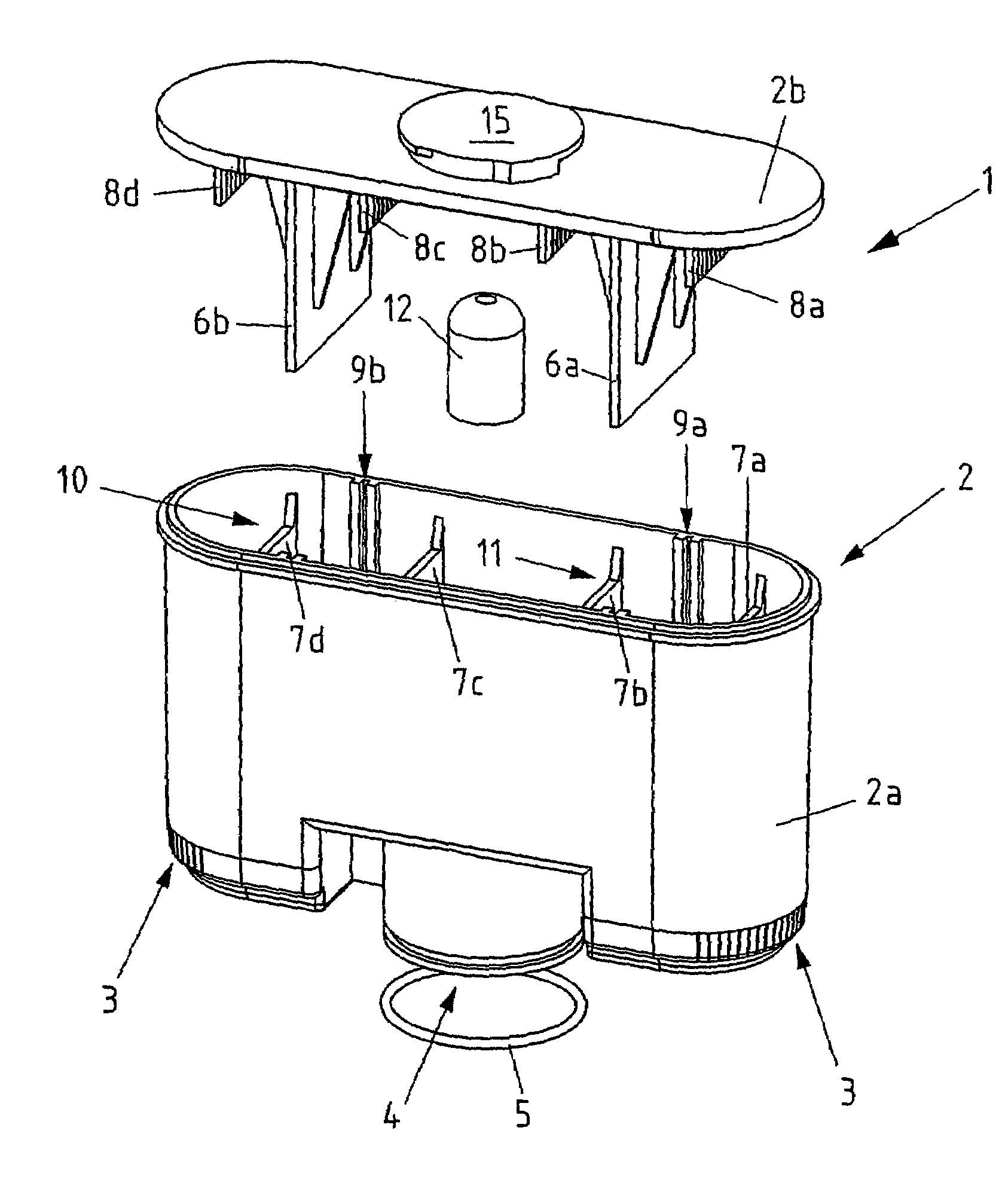

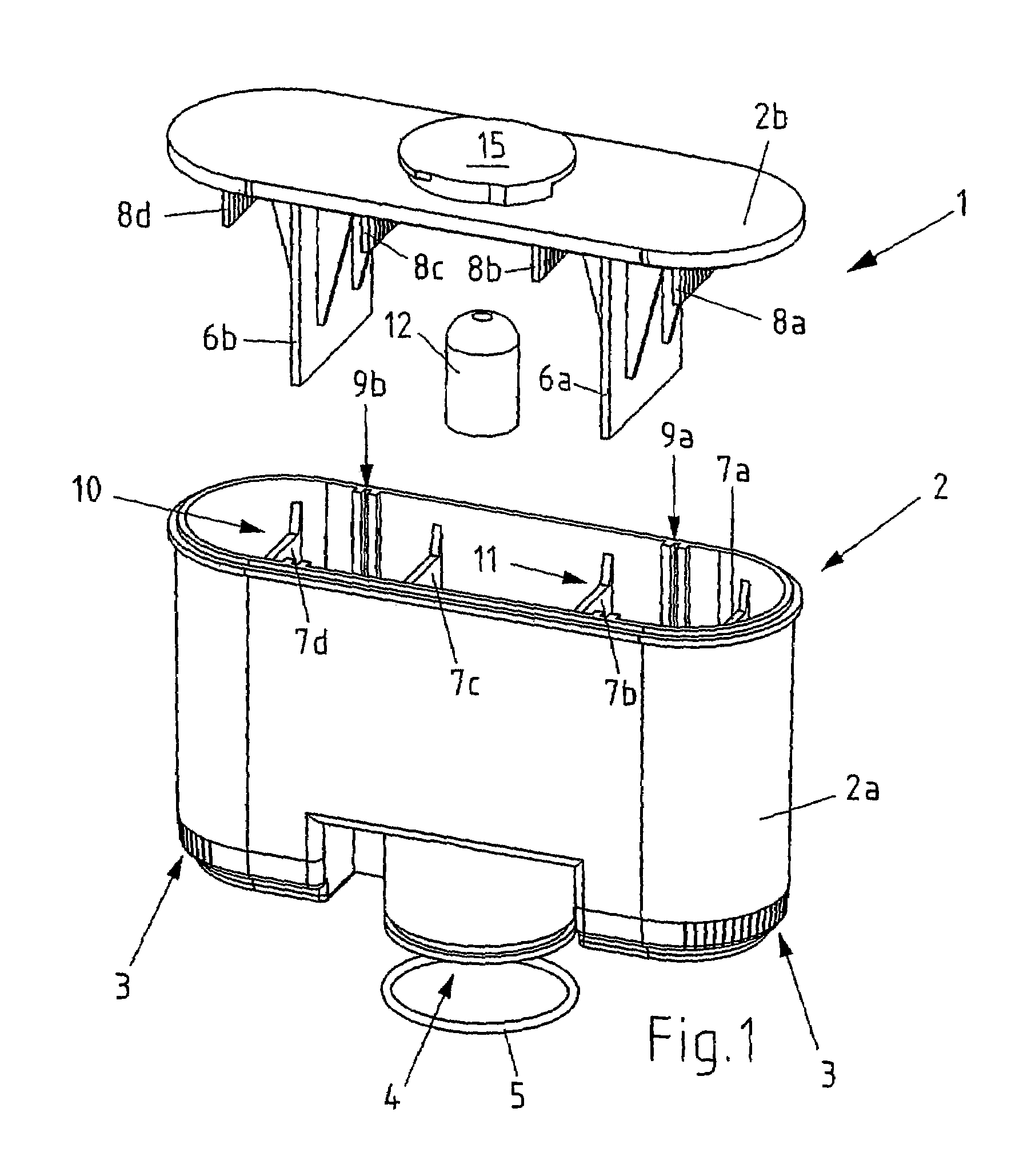

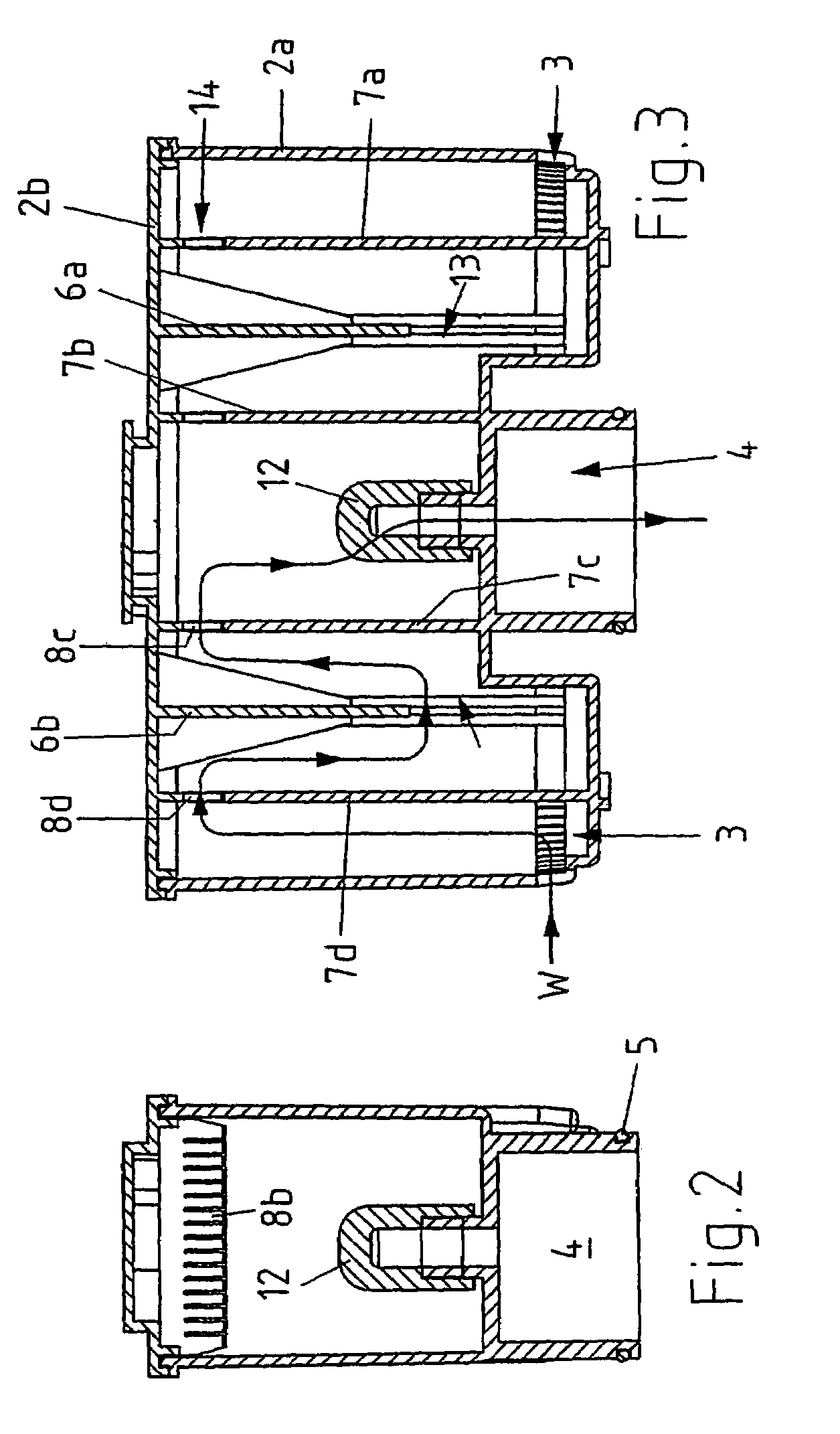

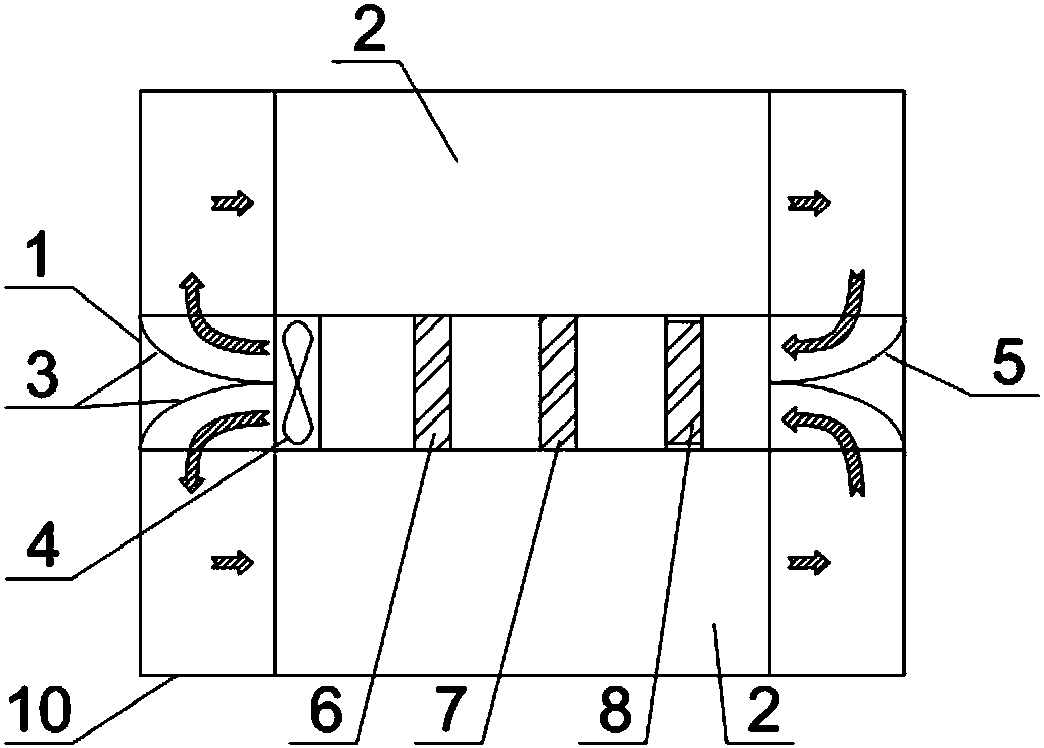

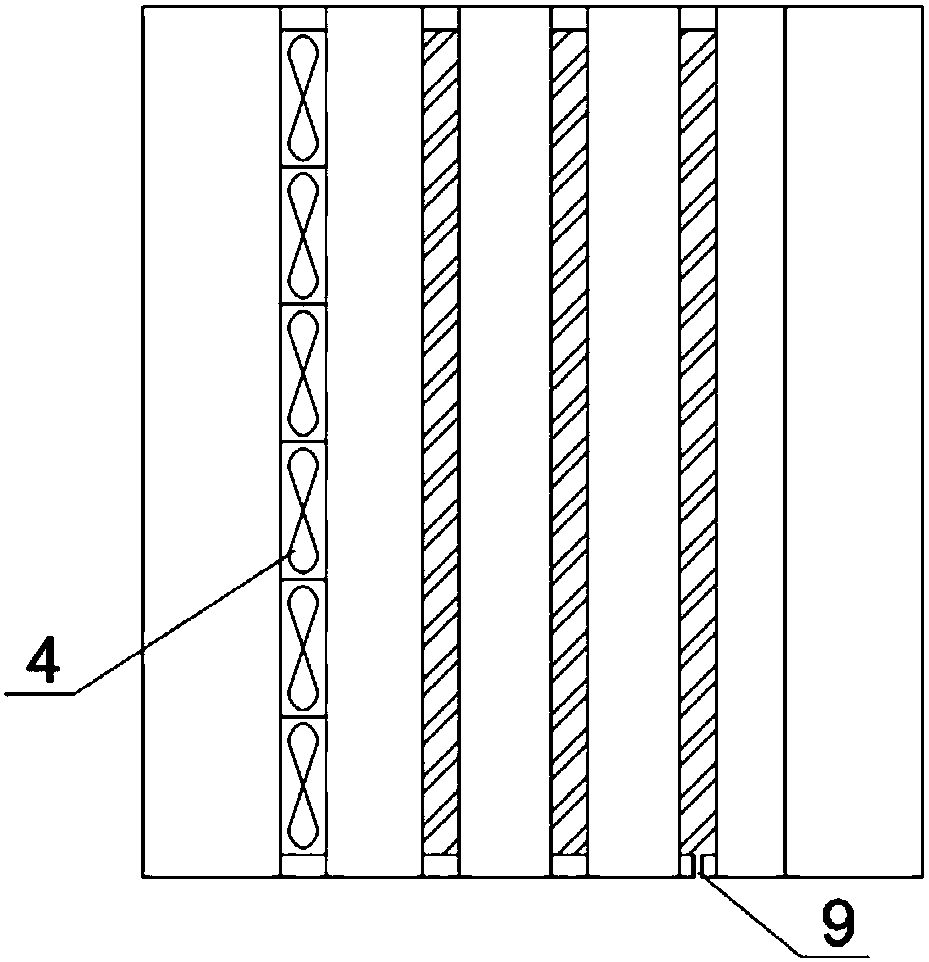

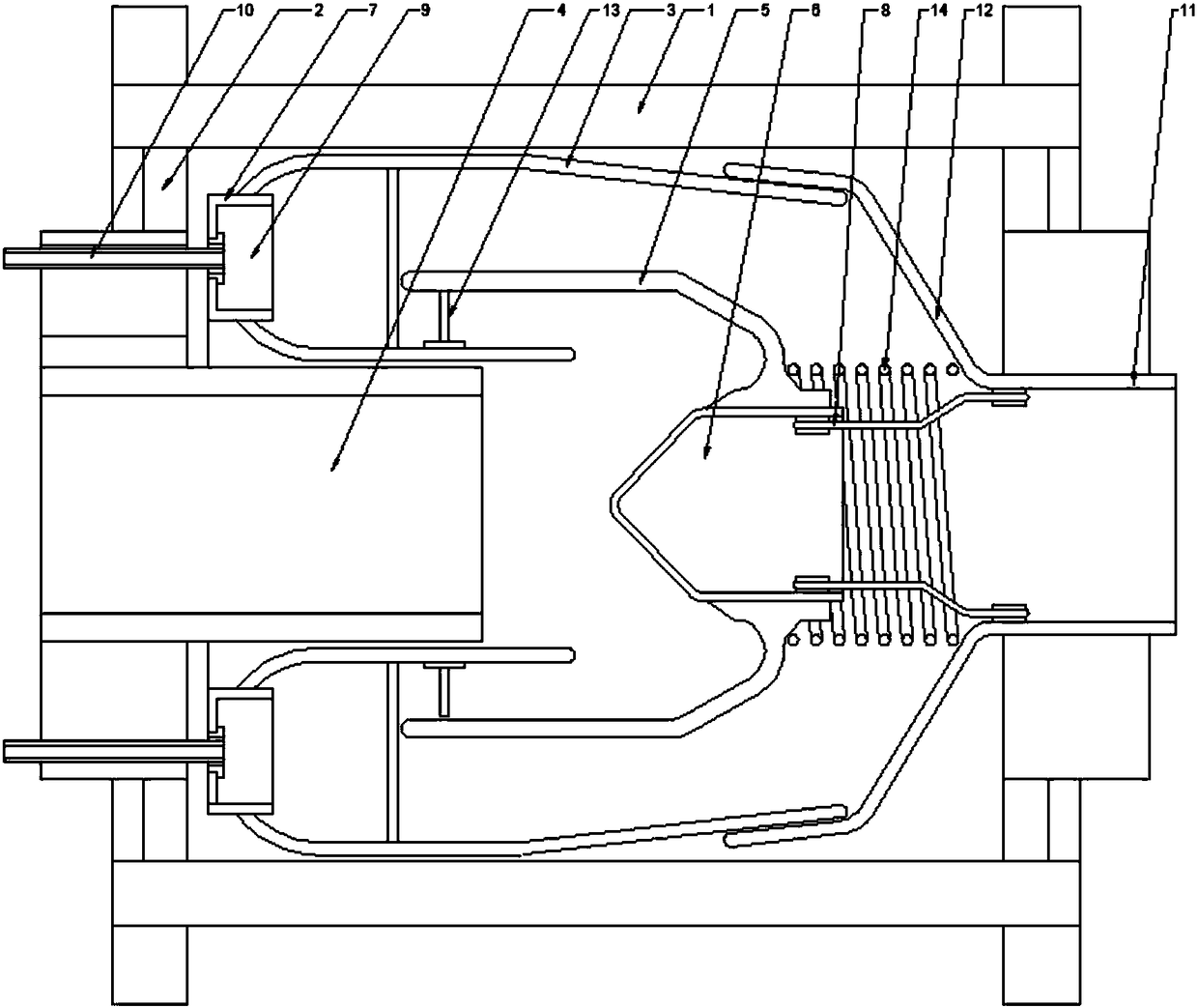

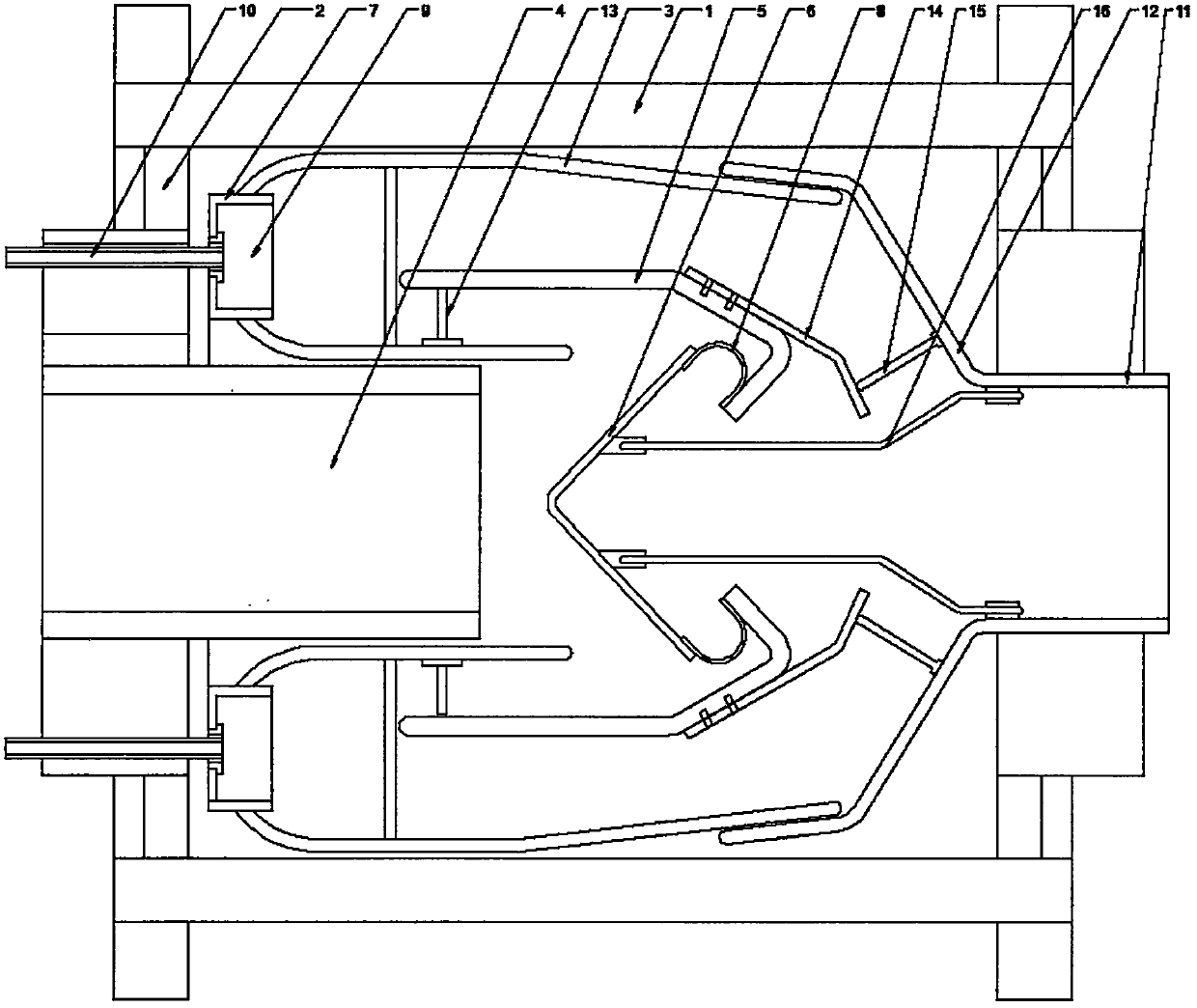

Filter cartridge for a water tank of a coffee machine

ActiveUS20050011824A1Avoid dangerInhibition formationTreatment involving filtrationWater/sewage treatment by ion-exchangeIon-exchange resinWaste management

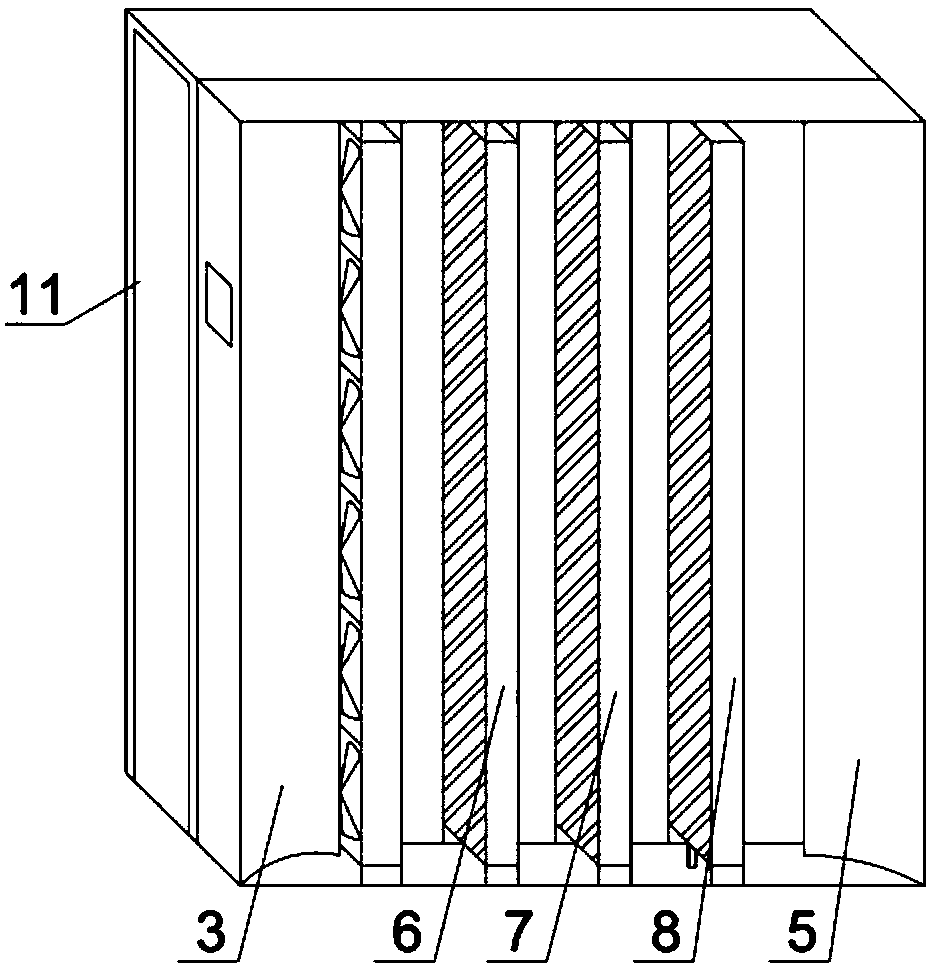

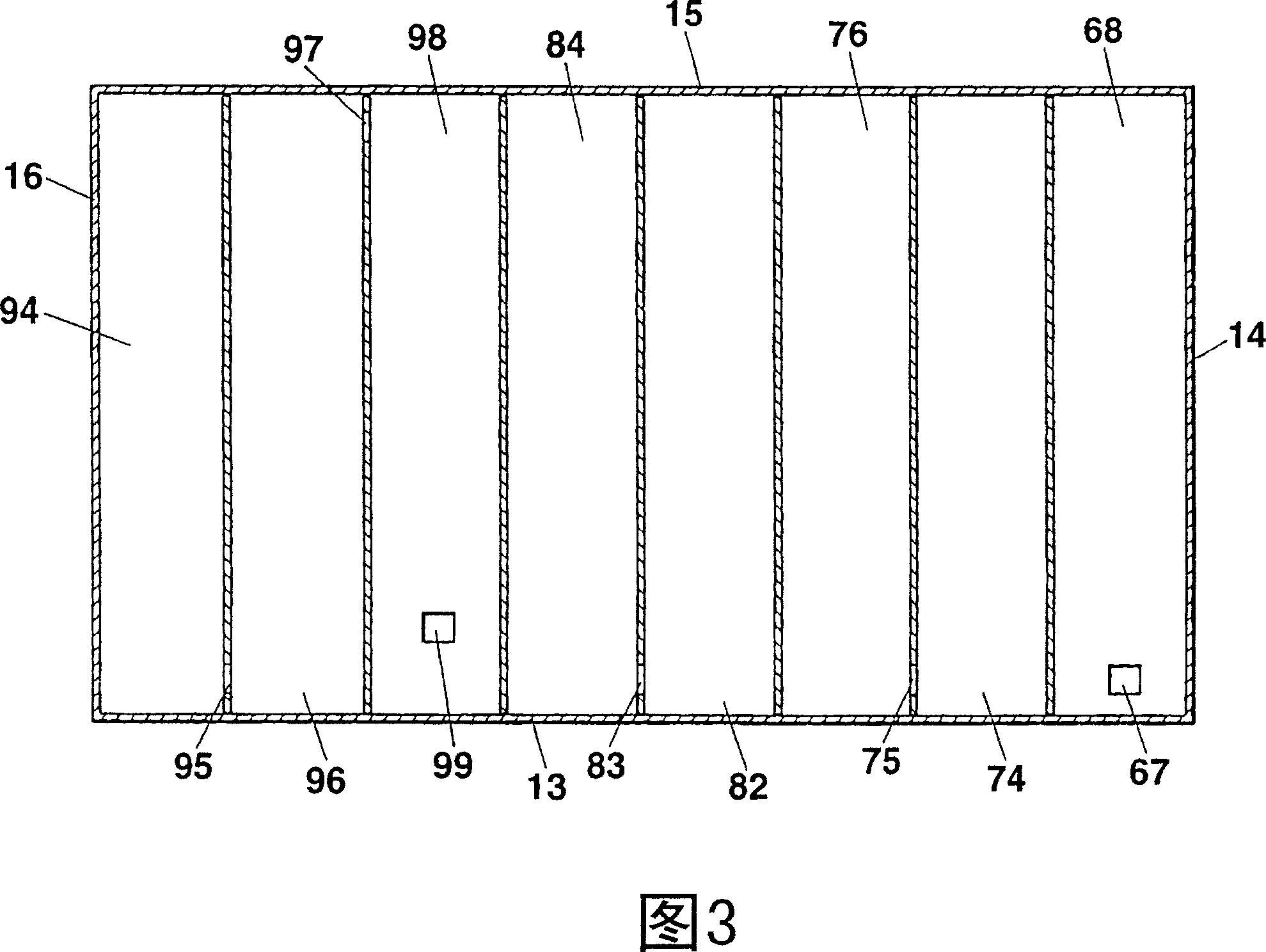

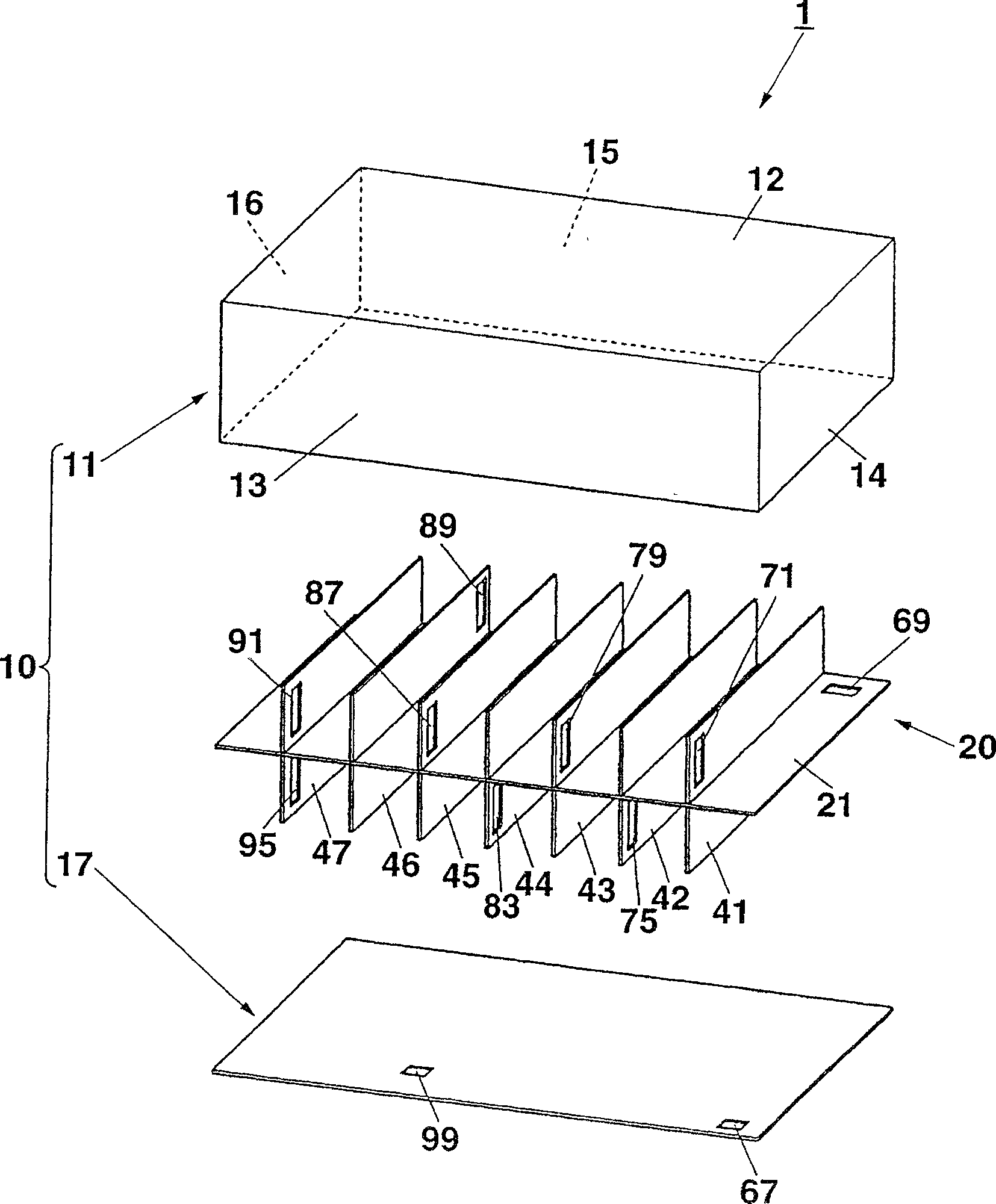

The filter cartridge for the water tank of a coffee machine comprises a housing having on both sides a plurality of slot-shaped openings constituting two inlets. For softening the water, the housing of the filter cartridge contains a ion exchange resin. The bottom of the housing comprises a central outlet. The interior of the housing is provided with a plurality of baffle members increasing the length of the flow path of the water between inlets and outlet. The housing comprises an upper portion and a lower portion, sealingly fixed to each other. The baffle members extend essentially in vertical direction and are alternately fixed to the upper and to the lower housing portion. Water passages are provided between the upper housing portion and the baffle members fixed to the lower housing portion, as well as between the lower housing portion and the baffle members fixed to the upper housing portion. The filter cartridge of the invention requires not much space, but offers high efficiency resulting from the long flowing path of the water through the ion exchange resin between inlets and outlet.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

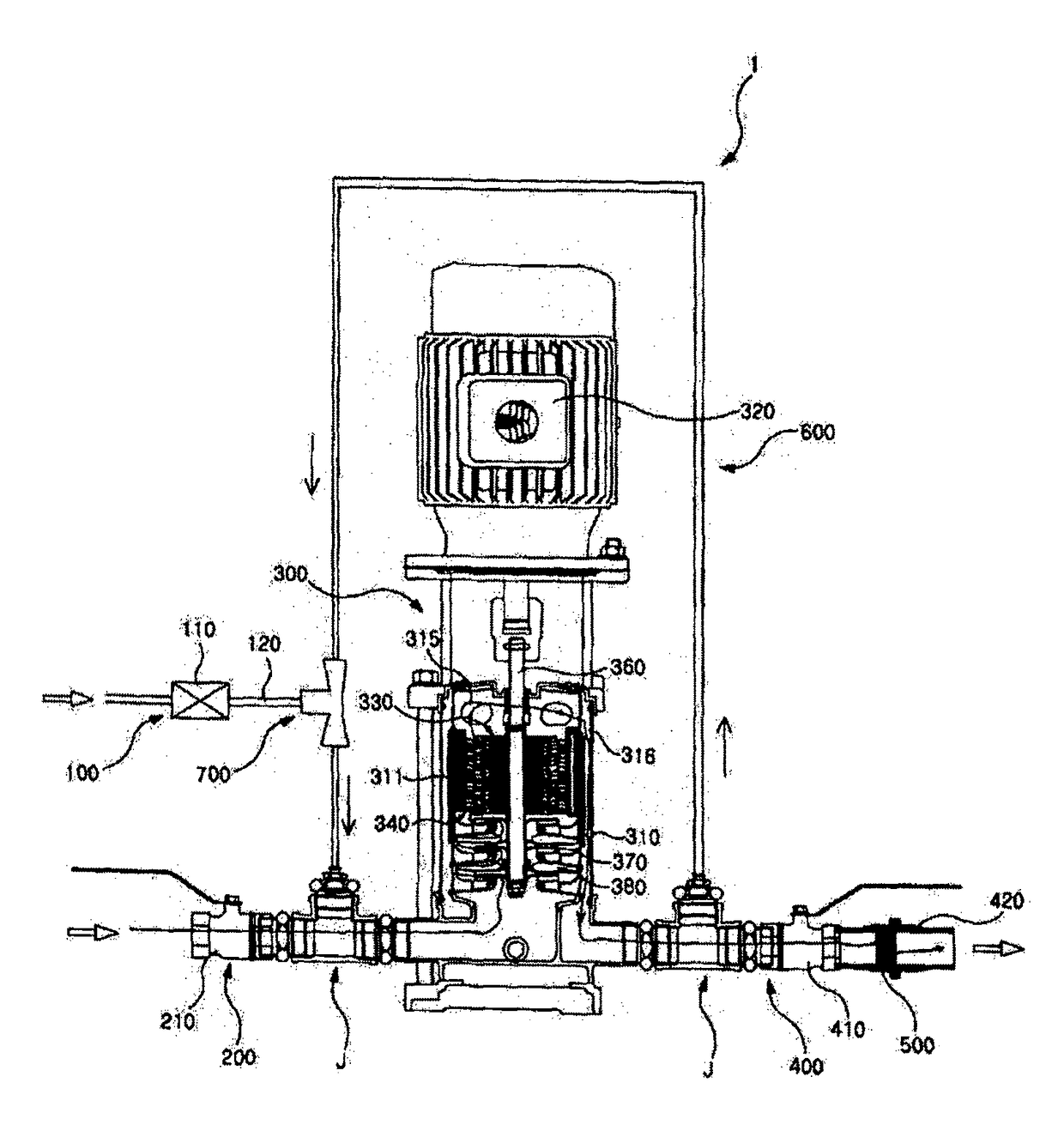

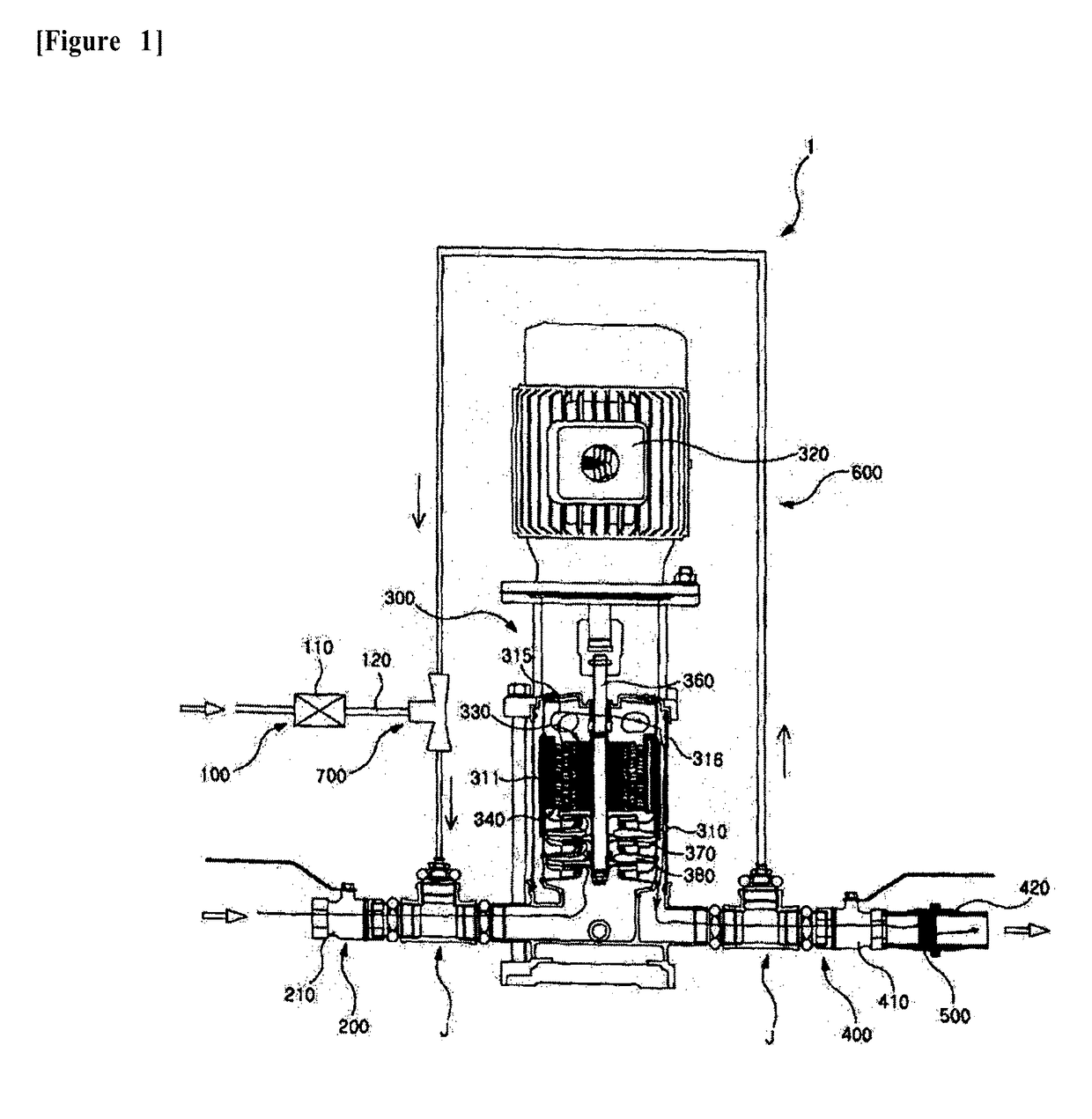

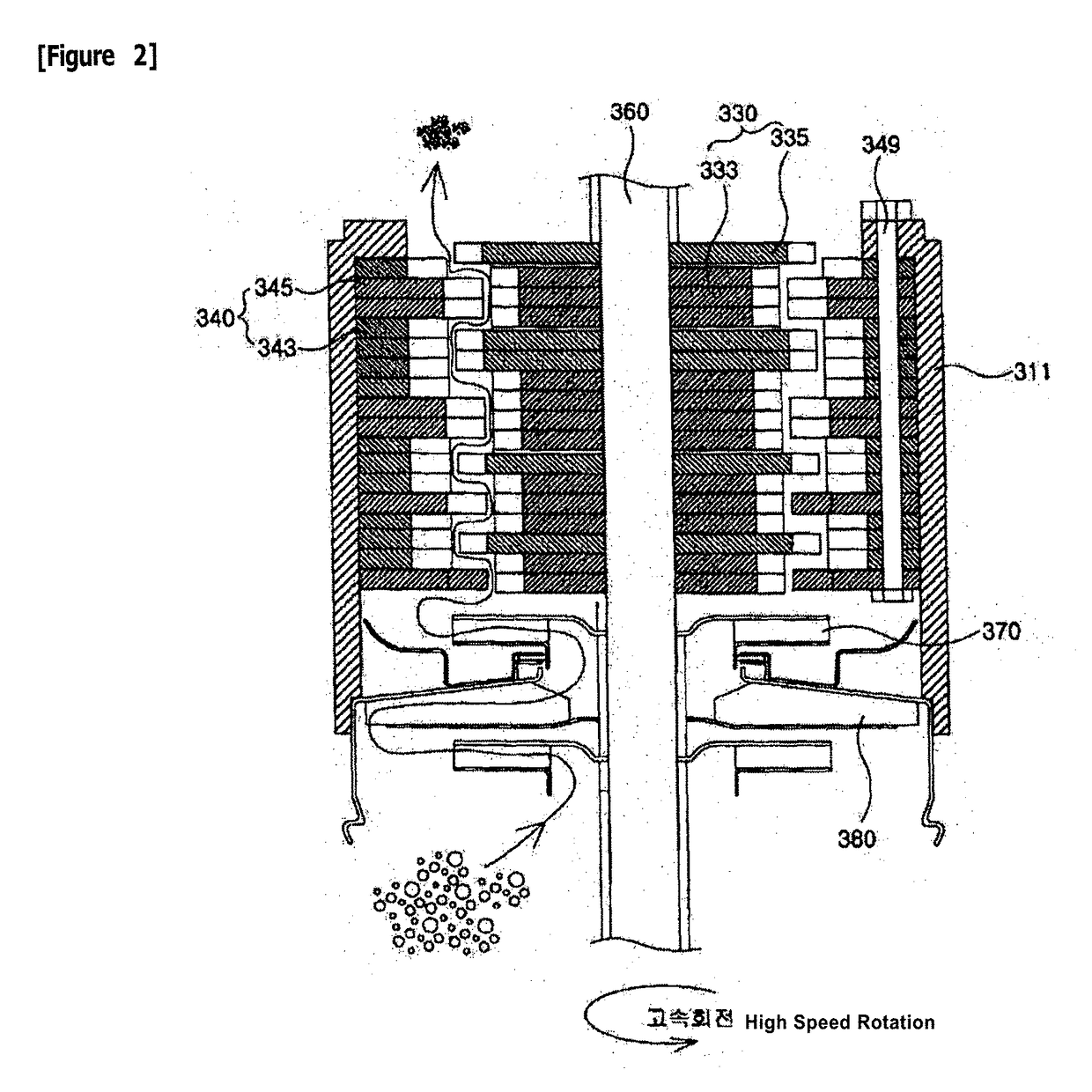

Nano Bubble and Hydroxyl Radical Generator (NBHRG) and Processing System to Decontaminate Water without Chemicals Using NBHRG

PendingUS20180141837A1Improve rate of dissolutionMaximize dissolution rateFlow mixersWater treatment compoundsDrive motorChemical used

This invention is about Nano Bubble and Hydroxyl Radical Generator and has the following detail features;Air inlet part;Inlet pipe for inflowing liquid connected to the above air inlet part;Pump connected to the above inlet pipe;Drive motor connected to the above pump;Rotating blade connected to drive axis of the above drive motor;Fixed blade connected to inside wall of the above pump, and arranged between the above rotating blade;The above rotating blade, the fixed blade or cylindrical blade surfaces of both blades are slanted in a direction.Therefore, this invention proposes Nano Bubble and Hydroxyl Radical Generator which increases dissolving rate of gas by accelerating finization and mix of air and liquid through inducing turbulence of air and liquid by way of constructing slant on surfaces of each blade.

Owner:NABAS GRP INC

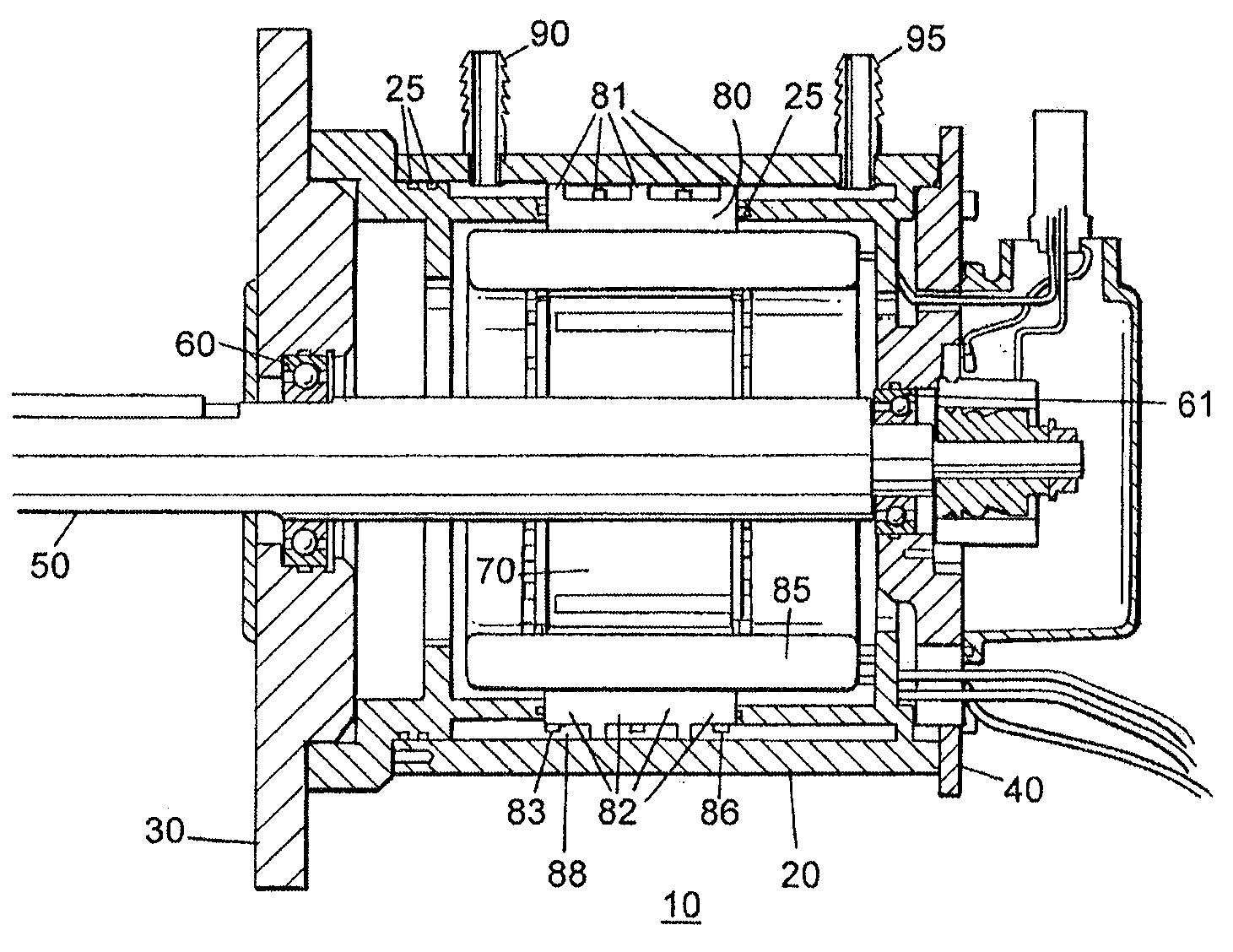

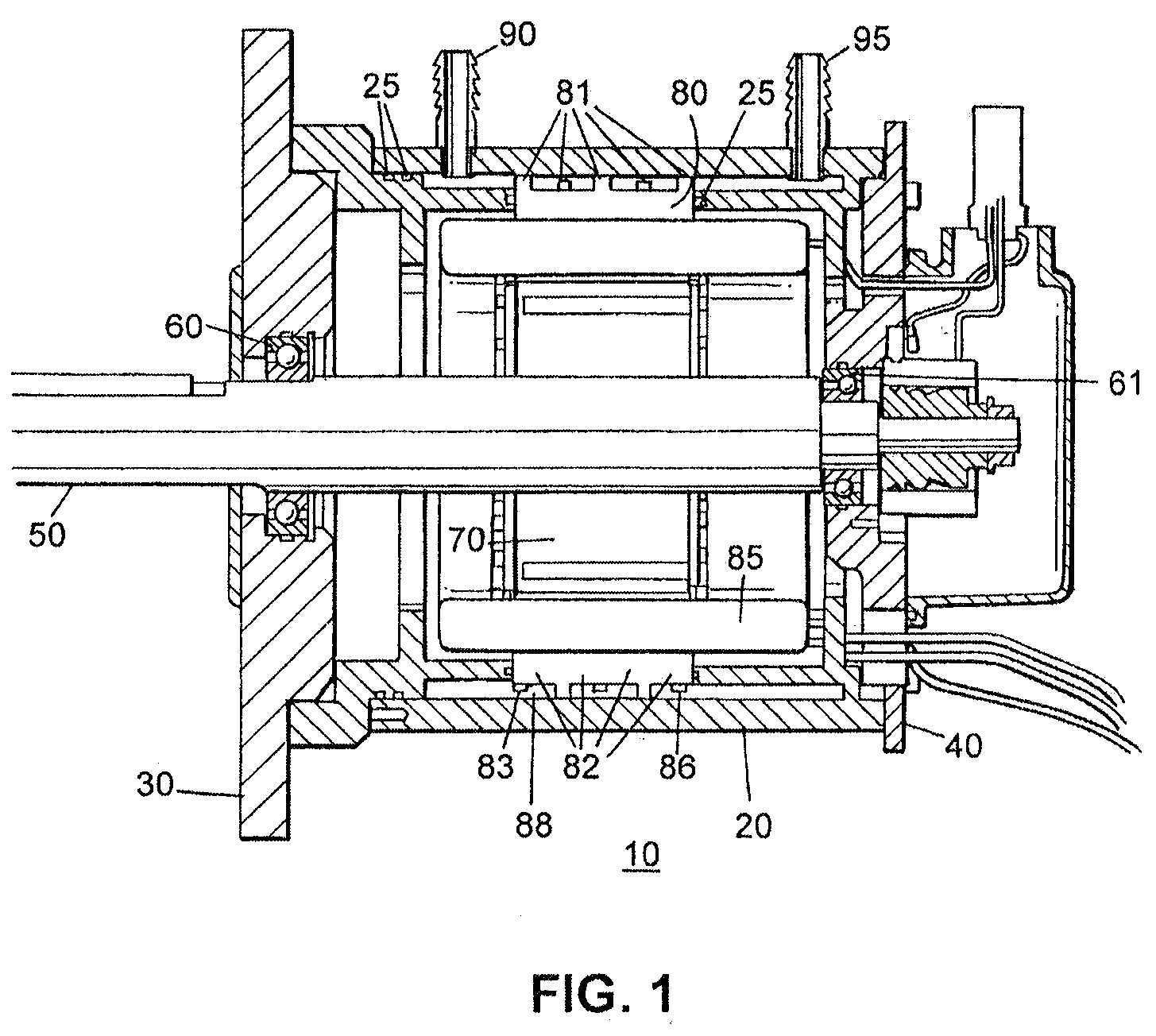

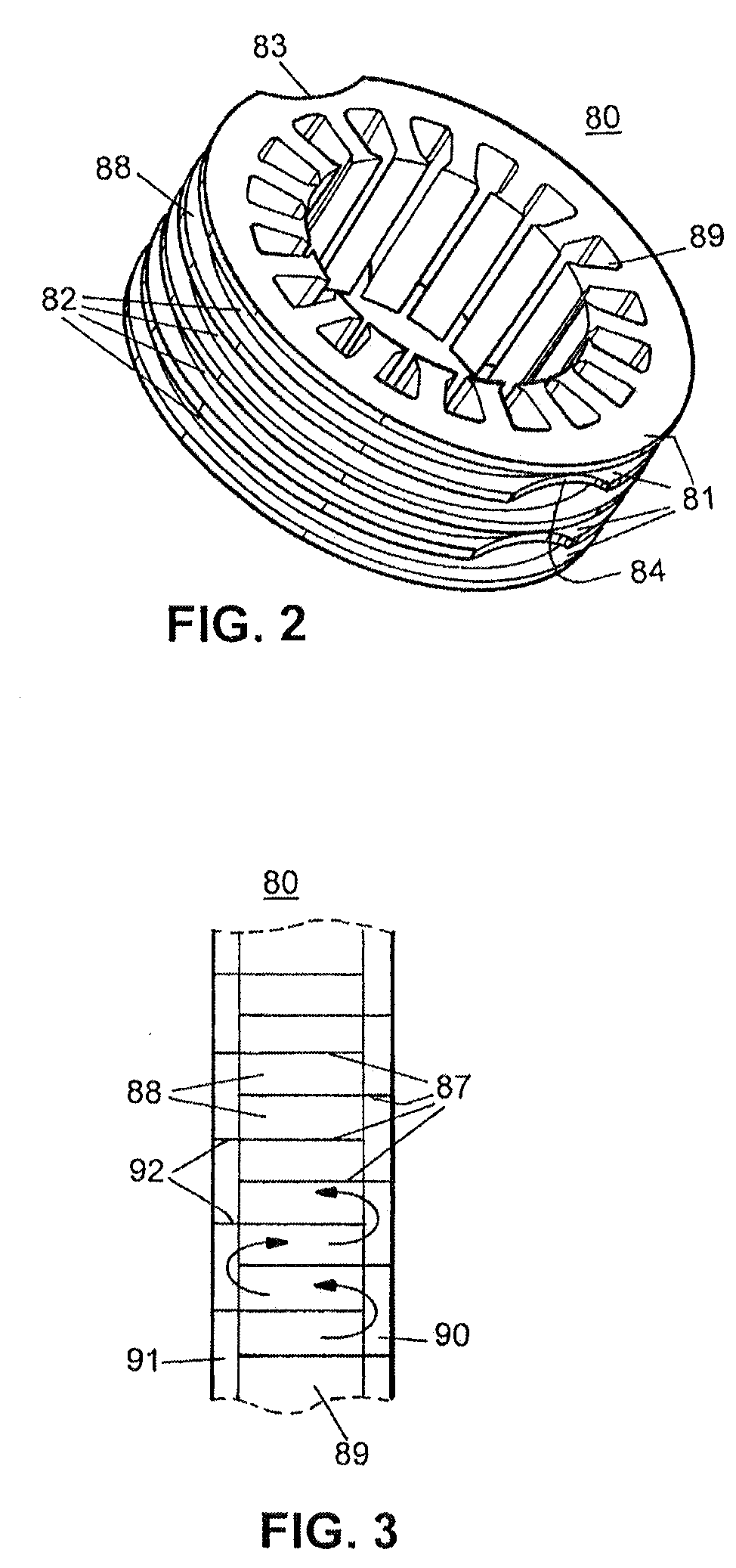

Coolant Flow Channel Arrangement for a Fluid Cooled Electric Motor

InactiveUS20120267970A1Improve thermal conductivityImprove sealingMagnetic circuit stationary partsCooling/ventillation arrangementElectric machineCoolant flow

An improved fluid cooling arrangement for an electric machine, such as an electric motor, a generator, or a motor / generator assembly, is provided. In its most general sense, the fluid-cooled electric machine includes a rotor disposed on a motor shaft, a stator surrounding the rotor, and a motor housing surrounding the stator, with the stator formed of a laminated stack of stator plates that is plated at its outer surface.

Owner:KOLLMORGEN CORP

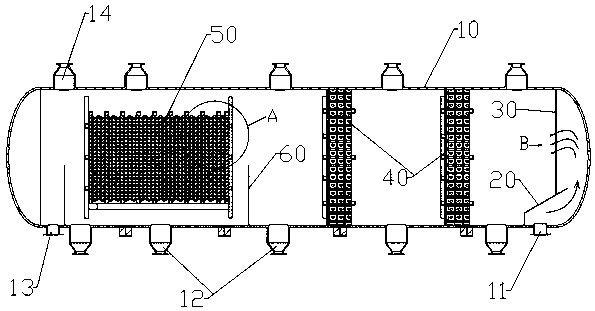

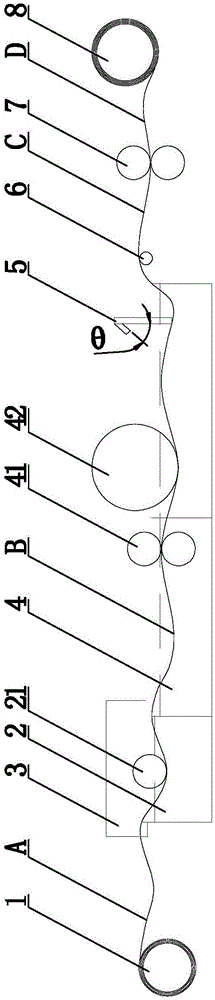

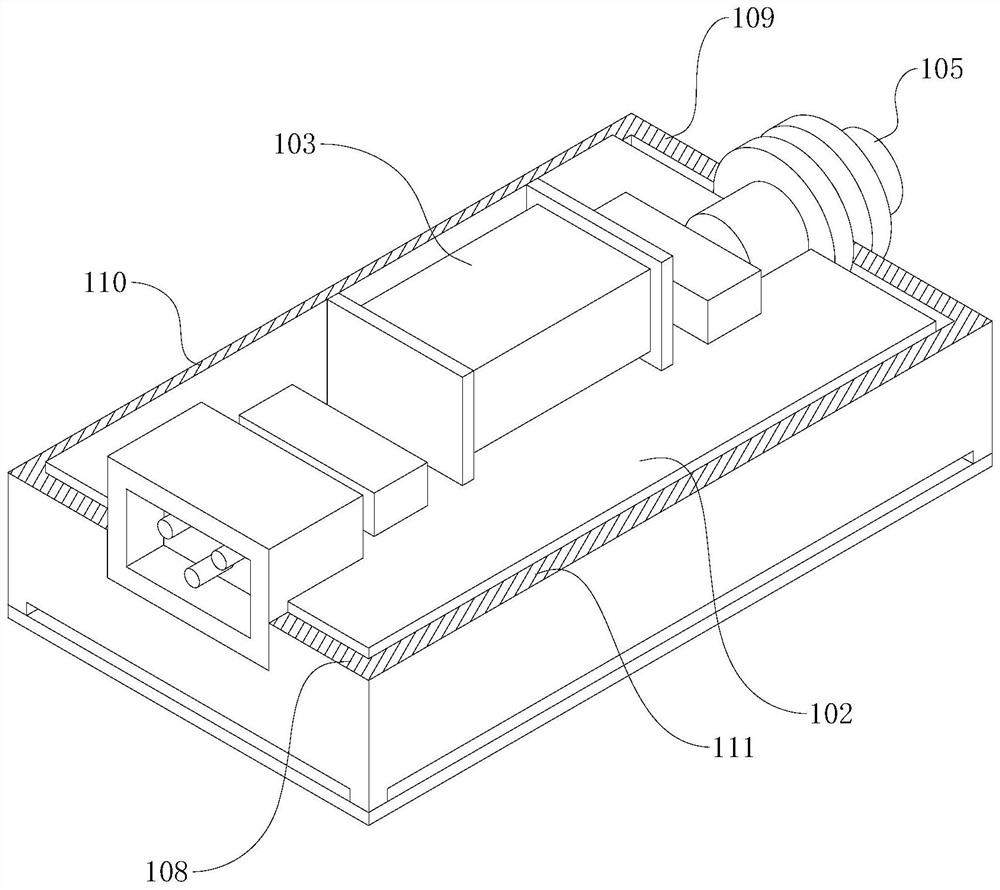

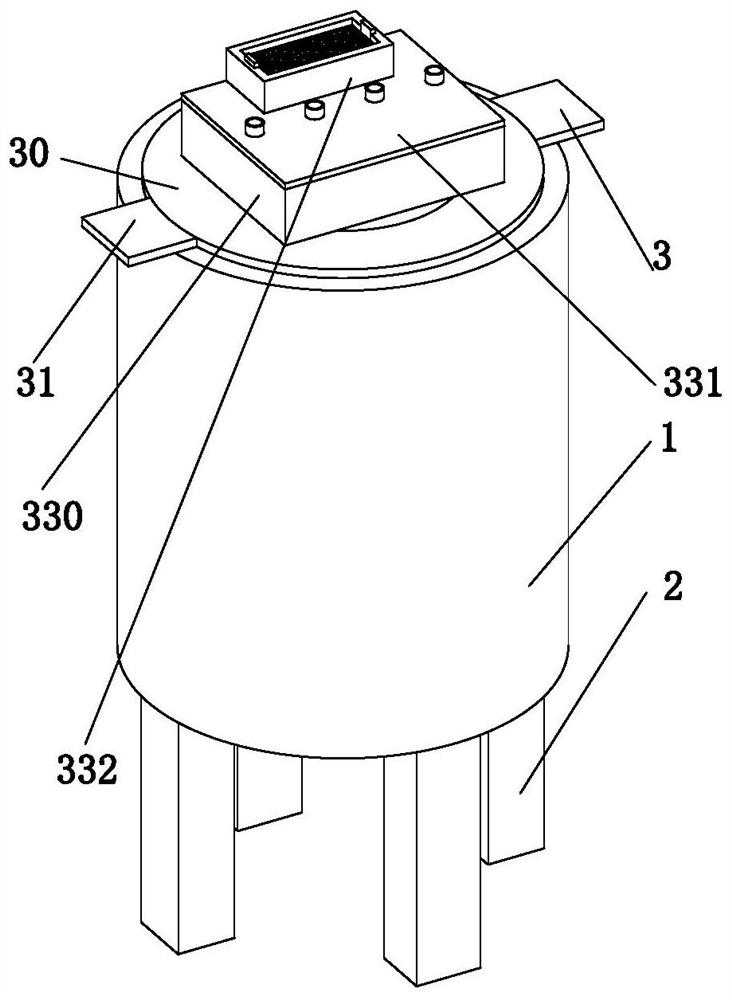

Coalescence degreaser for oilfield sewage treatment

ActiveCN111348769AThe number of deployments increasedSolve the problem of stable loweringWaste water treatment from quariesFatty/oily/floating substances removal devicesFiberYarn

The invention provides a coalescence degreaser for oilfield sewage treatment. The coalescence degreaser comprises a tank body, a flow stabilizing device, a rectifying device, a primary filtering device and an oil gathering device; the tank body sequentially comprises a lining layer formed by jet yarns in a jet molding mode, a structural layer formed by resin and fiber material composite materialsin an enveloping and winding mode and an outer surface layer formed by gel coat resin in a spraying mode from inside to outside in the thickness direction of the tank wall. The oil gathering device comprises a coalescence separation corrugated plate and a supporting piece. The thickness of corrugated plates in the prior art is reduced to increase the cross sectional area of a water flow channel between the adjacent corrugated plates, so that the sewage treatment capacity is greatly improved; and on the premise that the sewage treatment efficiency is not reduced, namely, the cross section of the water flow channel is kept unchanged, the arrangement number of the corrugated plates is greatly increased, so that the contact area of the corrugated plates and sewage is increased, and the oil gathering efficiency and effect are improved.

Owner:SHENGLI OIL FIELD XINDA PIPE IND TECH DEV CO LTD

Filter cartridge for a water tank of a coffee machine

ActiveUS7294266B2Improve efficiencySmall sizeTreatment involving filtrationWater/sewage treatment by ion-exchangeIon-exchange resinWaste management

Owner:KONINK PHILIPS ELECTRONICS NV

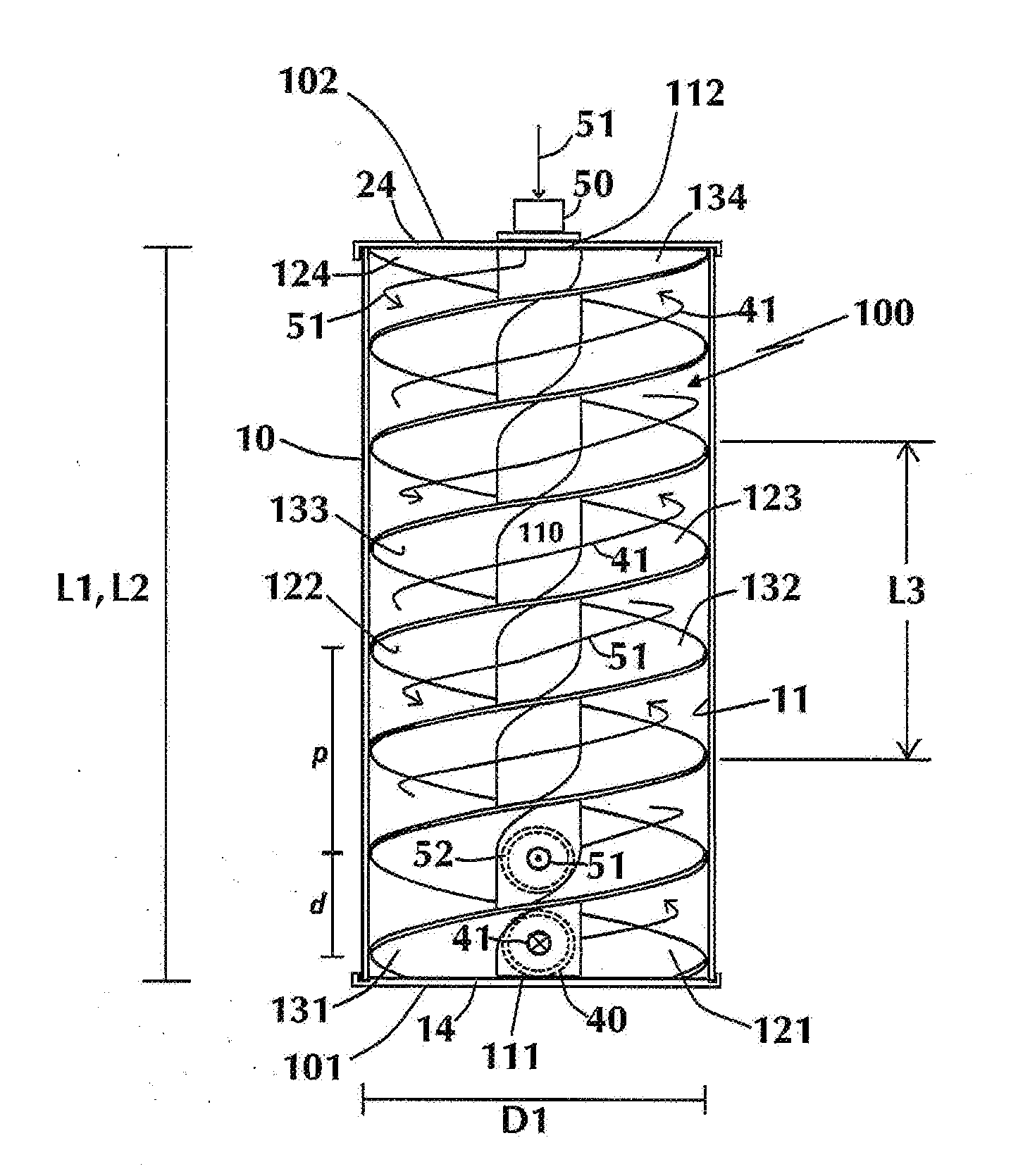

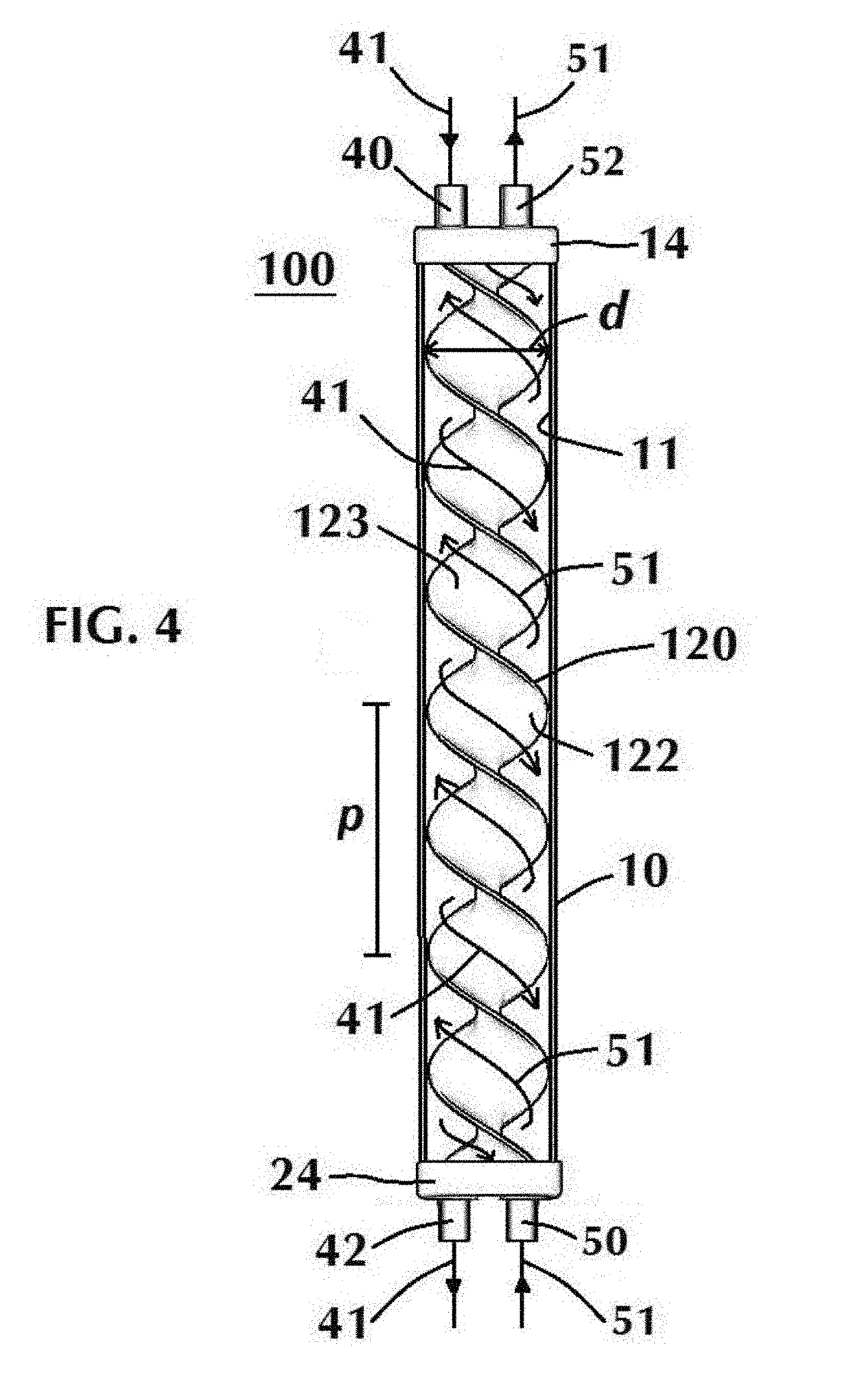

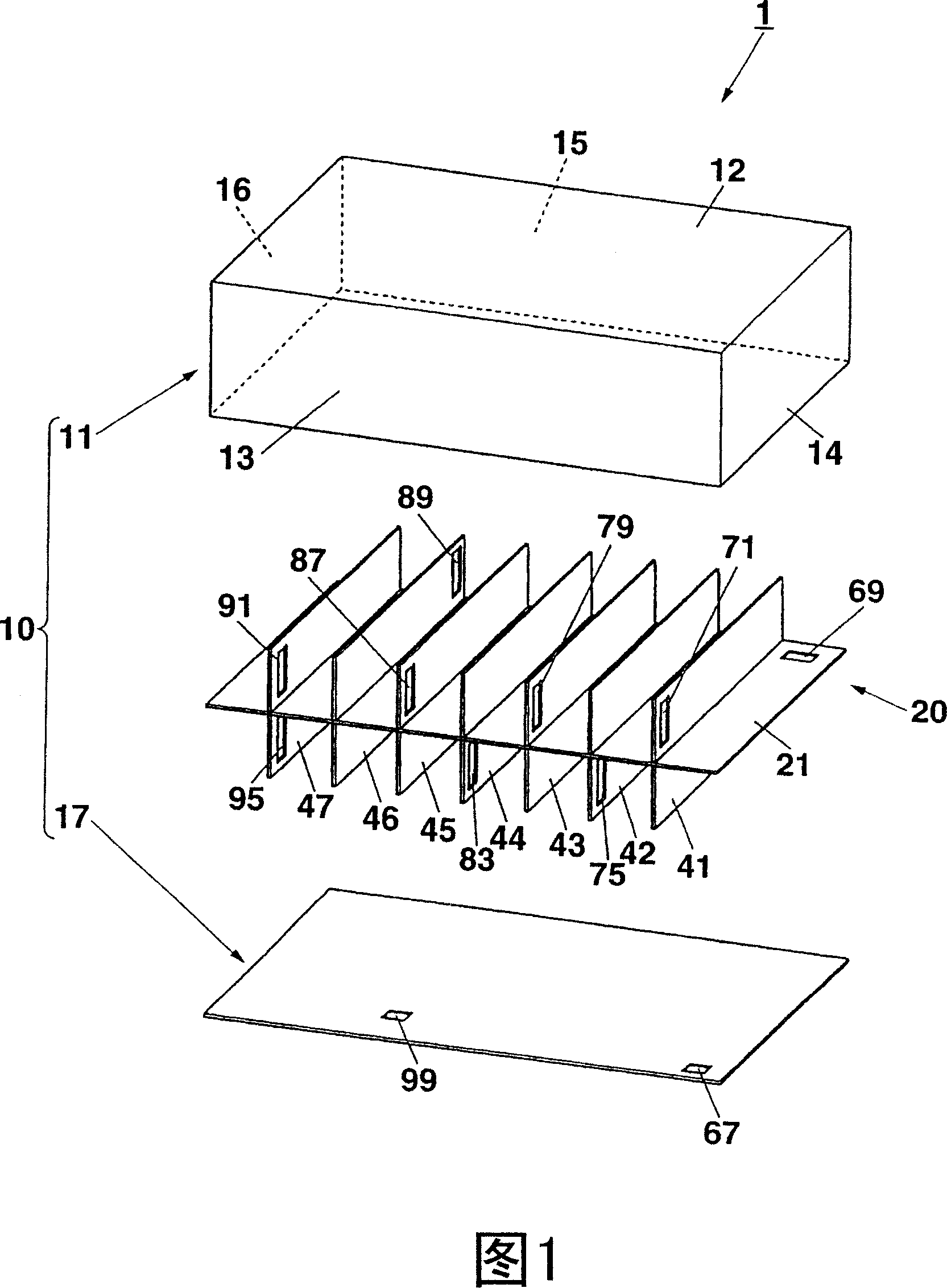

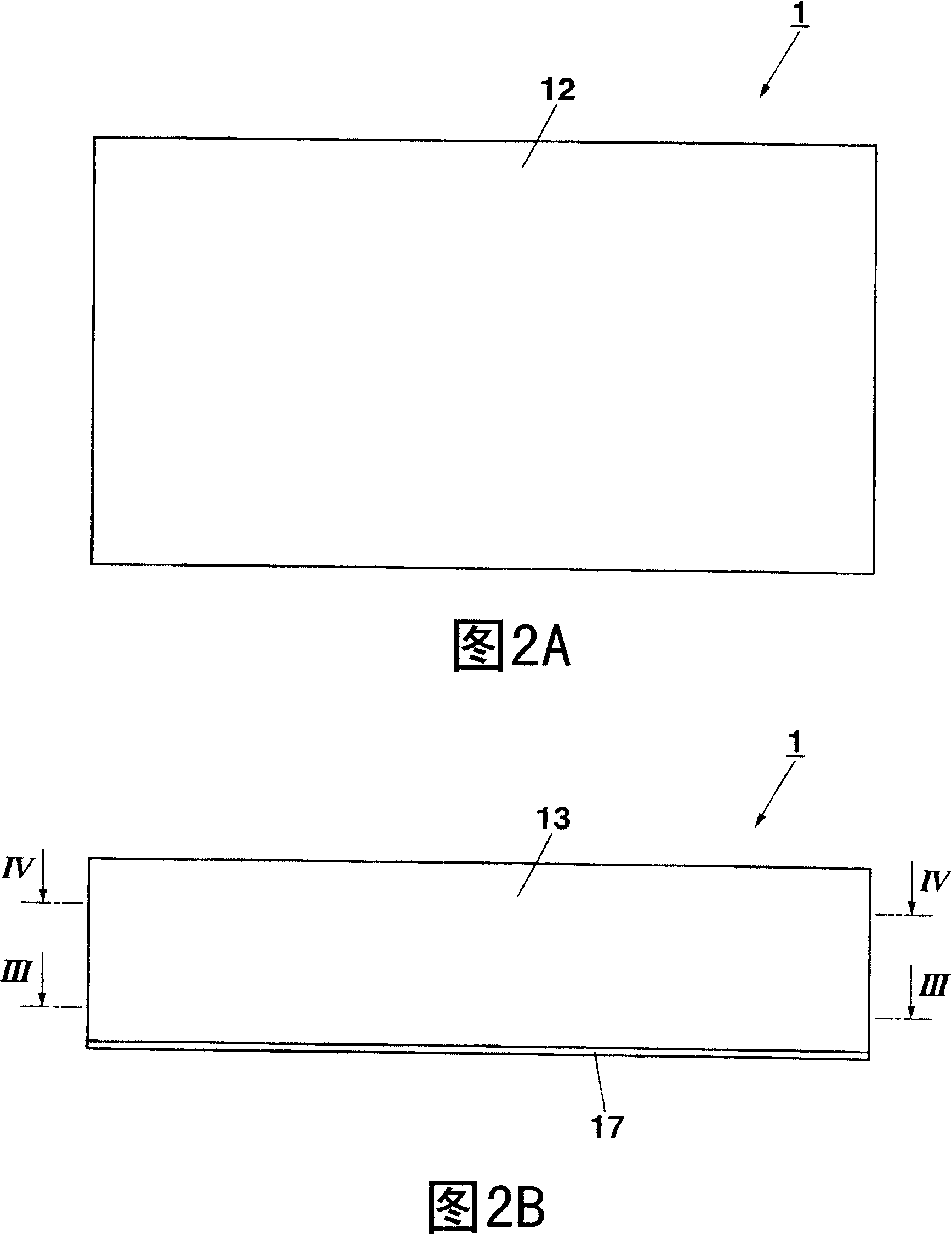

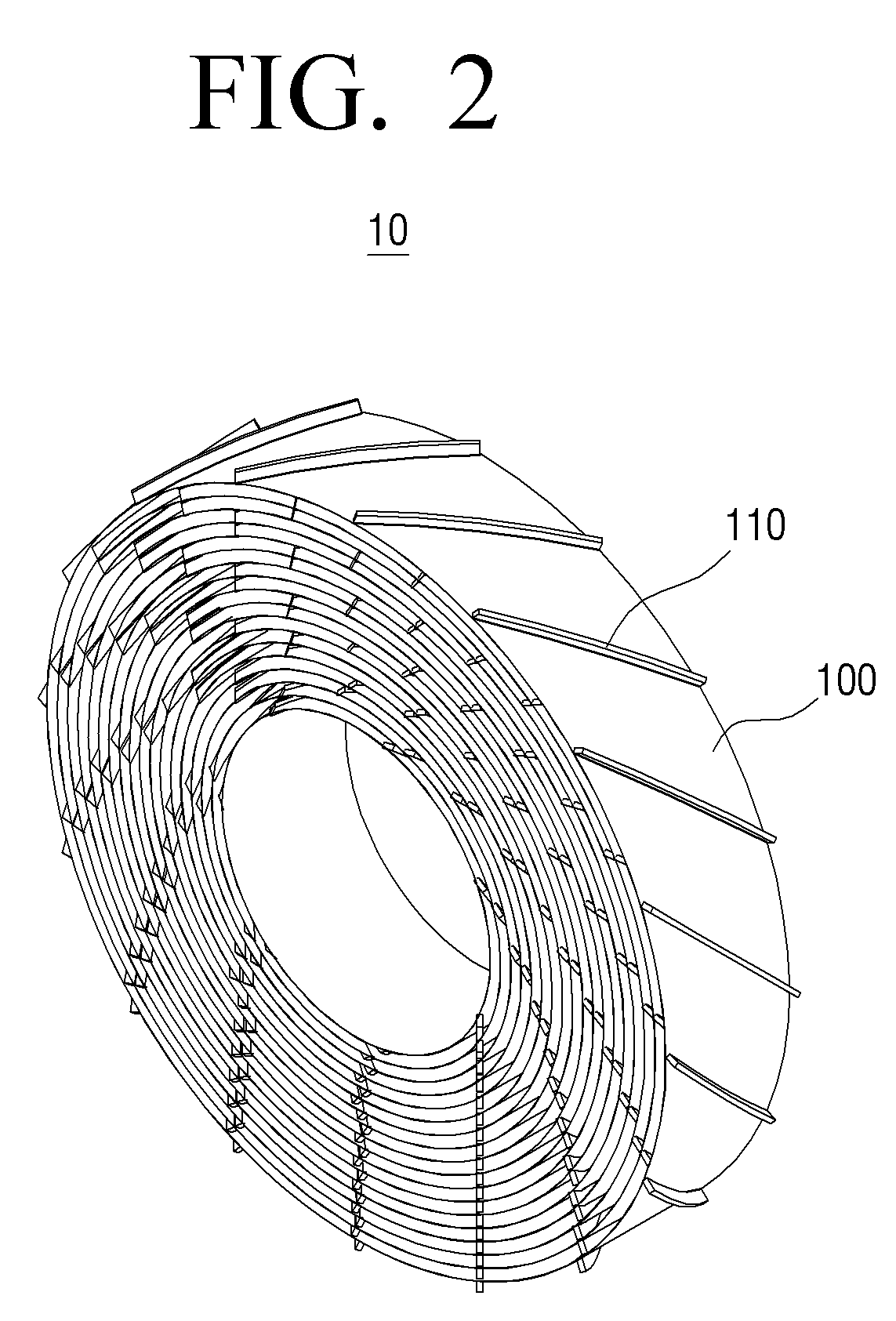

Counterflow helical heat exchanger

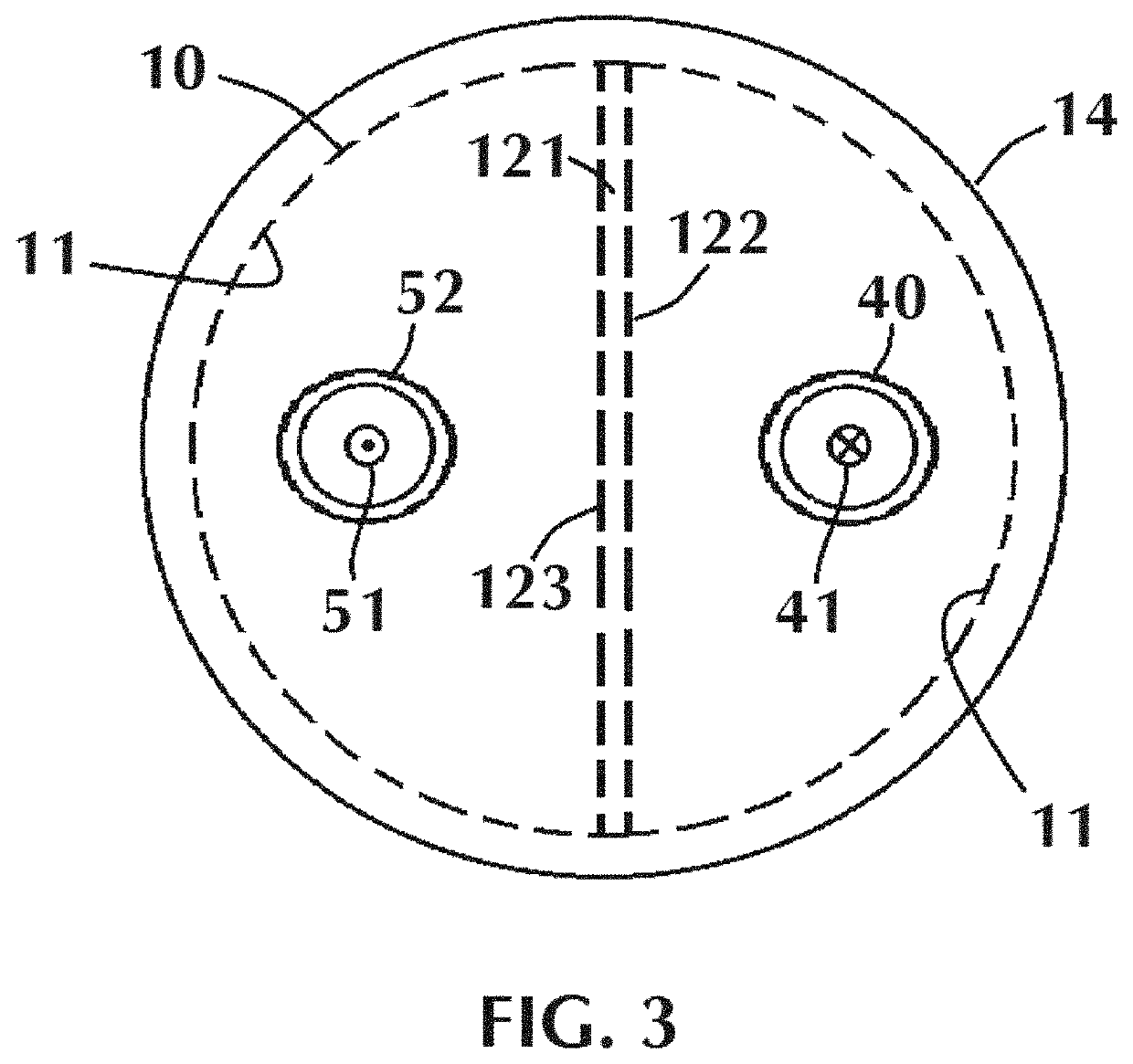

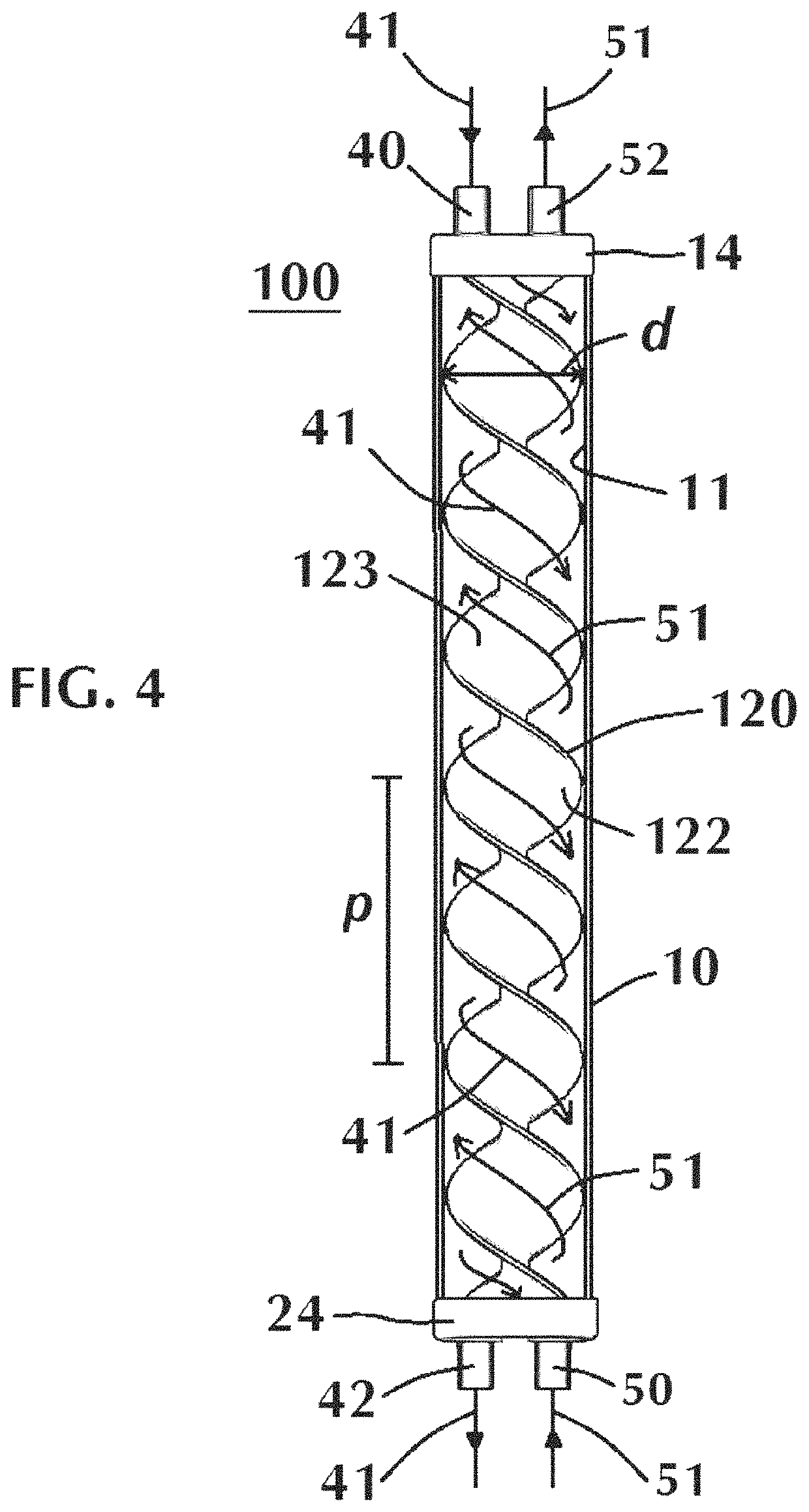

ActiveUS20190011190A1Improve heat transfer performanceExtend the length of the flow pathHeat exhanger sealing arrangementHeat exchanger casingsPlate heat exchangerEngineering

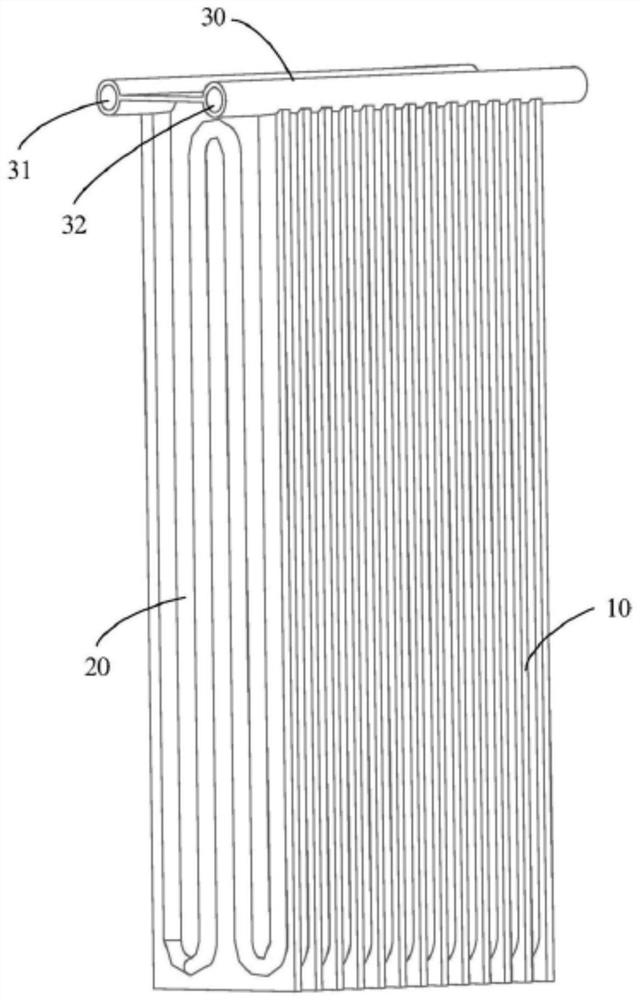

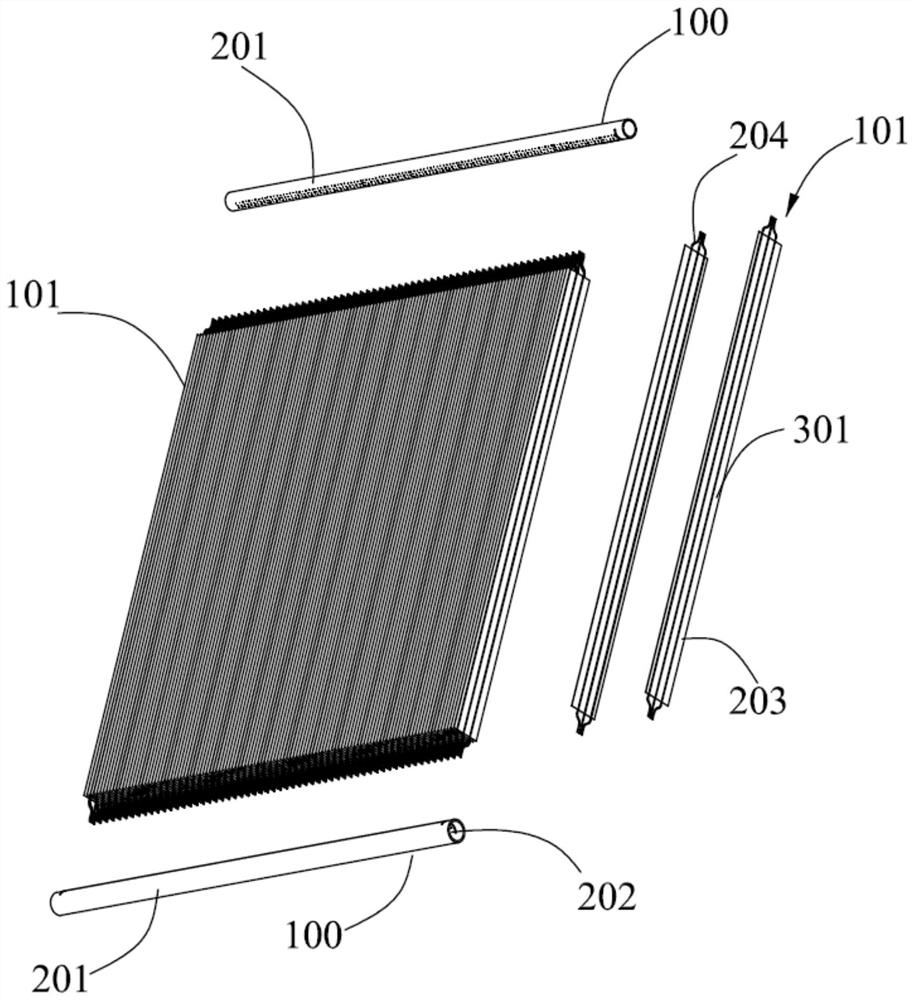

A helical heat exchanger assembly comprises a plurality of helical heat exchangers, each helical heat exchanger comprising a tube having first and second ends, a length, an inner diameter and a cross-section incorporating the inner diameter, a thermally conductive tube insert having a length and an outer diameter substantially equal to the inner diameter of the tube, the tube insert having first and second ends and comprising a single helix extending along the length of the tube insert and twisted around a central axis. The tube insert is sealed within the tube by sealing an outer edge of the helix to an inner surface of the tube to form fluid-tight first and second fluid flow paths defined between opposing sides of the helix and the inner surface of the tube, respectively. A plurality of inlet and outlet fluid ports are positioned for passage of a first and second fluid into and out of each tube. A first manifold connects each of the first ends of the heat exchanger tubes and a second manifold connects each of the second ends of the heat exchanger tubes, wherein at least one of the first or second manifolds includes baffles to direct fluid flow within the manifold such that at least some of the helical heat exchangers may be arranged in series, or in parallel, within the heat exchanger assembly via the baffles. Each helix has a predetermined pitch which may be less than or greater than the tube inner diameter and defines a length of the first and second fluid flow paths within each heat exchanger tube, wherein the pitch of the helix may be constant or variable along the length of the tube insert.

Owner:ENTEREX AMERICA

Humidification chamber and apparatus and systems including or configured to include said chamber

PendingUS20210008325A1Increase the amount of gasExtended stayRespiratorsMedical devicesThermodynamicsEngineering

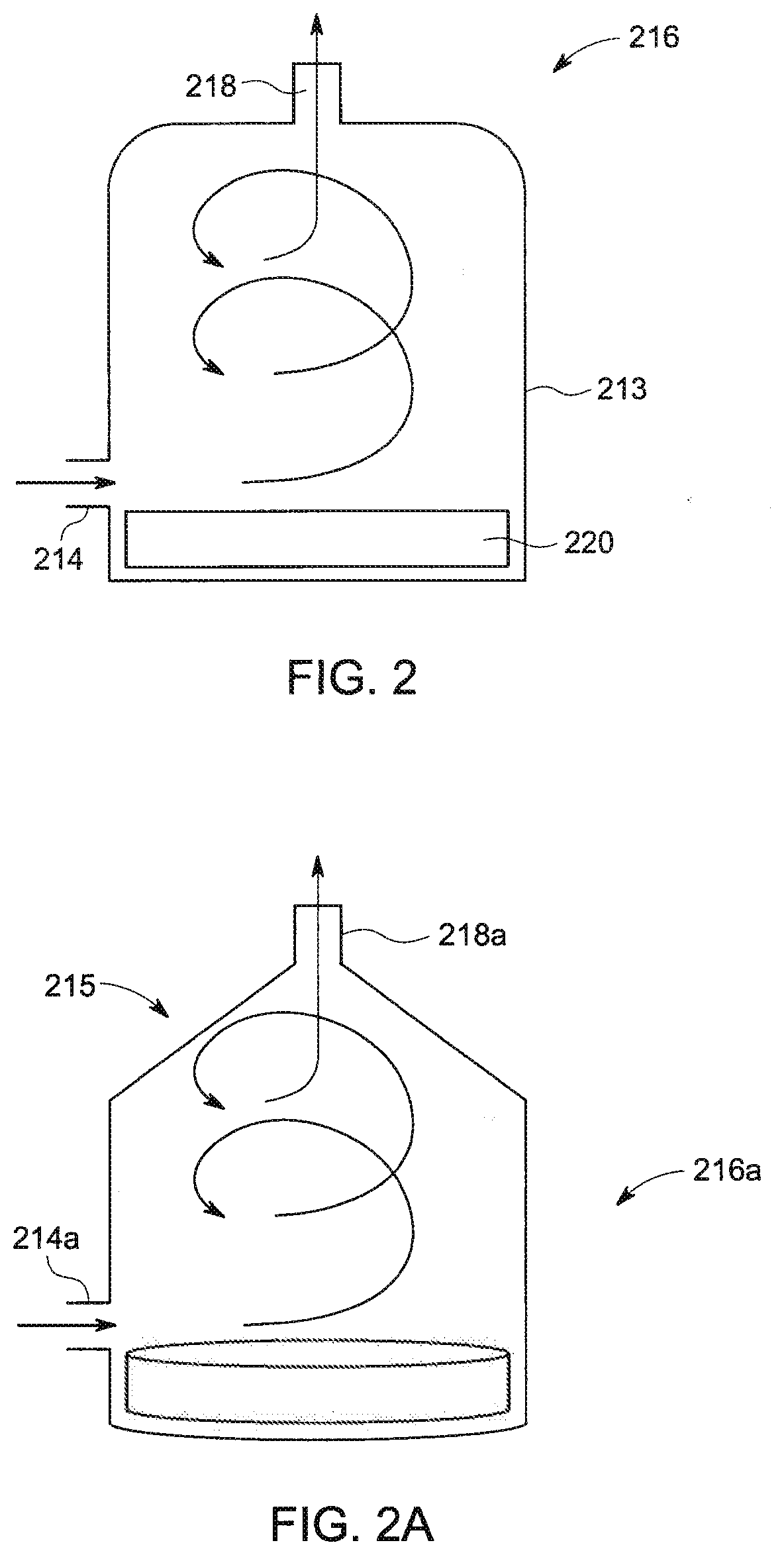

In one embodiment, there is provided a humidification chamber for use in a medical humidification system. The humidification chamber may comprise: a base and a top linked by a side wall to define the chamber, the chamber being configured to contain a volume of water; a gases inlet configured to receive a gases flow from a gases source; and a gases outlet, wherein the gases inlet is orientated relative to the side wall to introduce the gases flow to the humidification chamber at a direction substantially tangential to the side wall of the humidification chamber.

Owner:FISHER & PAYKEL HEALTHCARE LTD

A method of heat dissipation and cooling for high heat density cabinets in data centers

ActiveCN106385784BShorten the conveying distanceTake away quicklyCooling/ventilation/heating modificationsControl systemData center

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

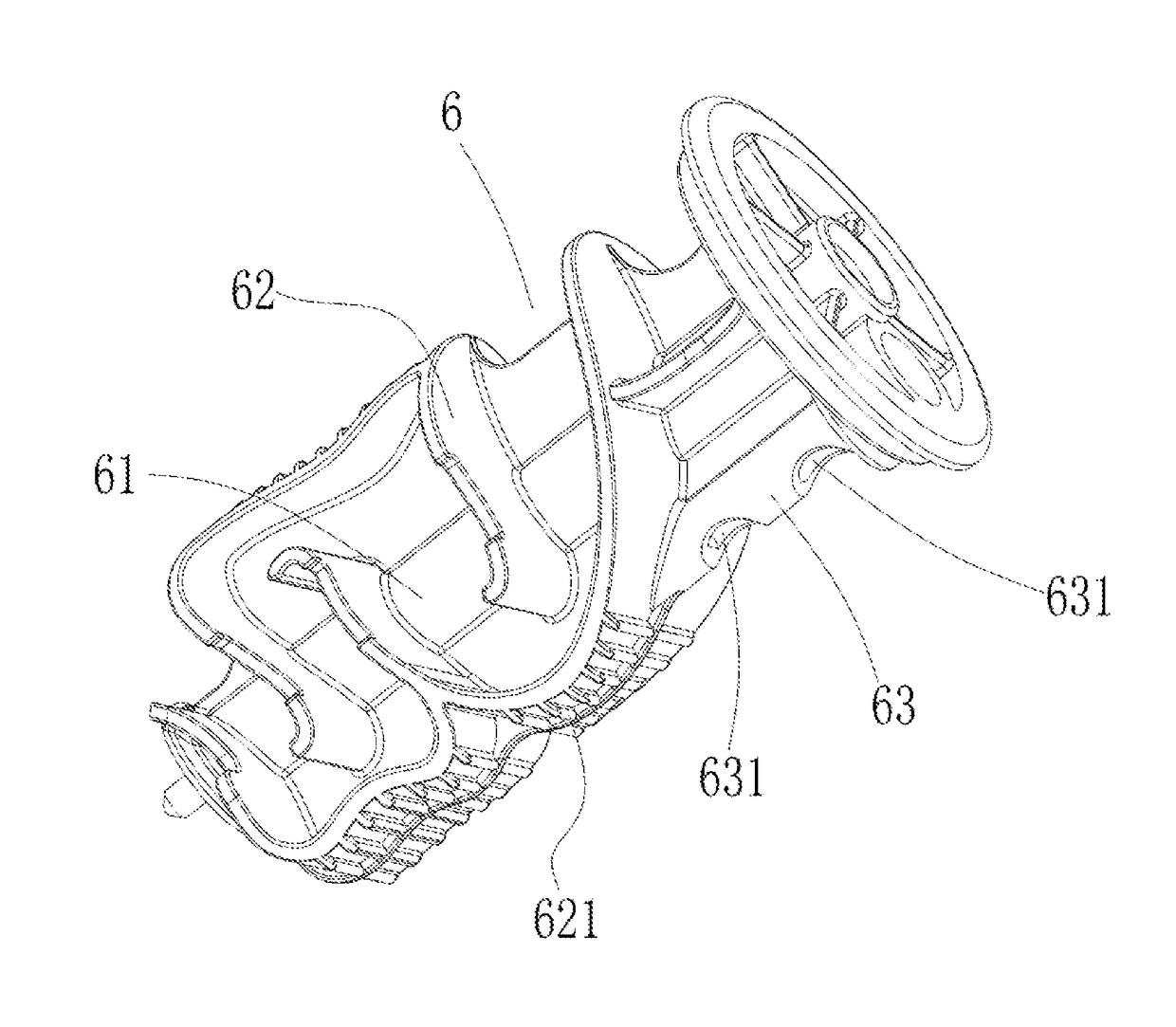

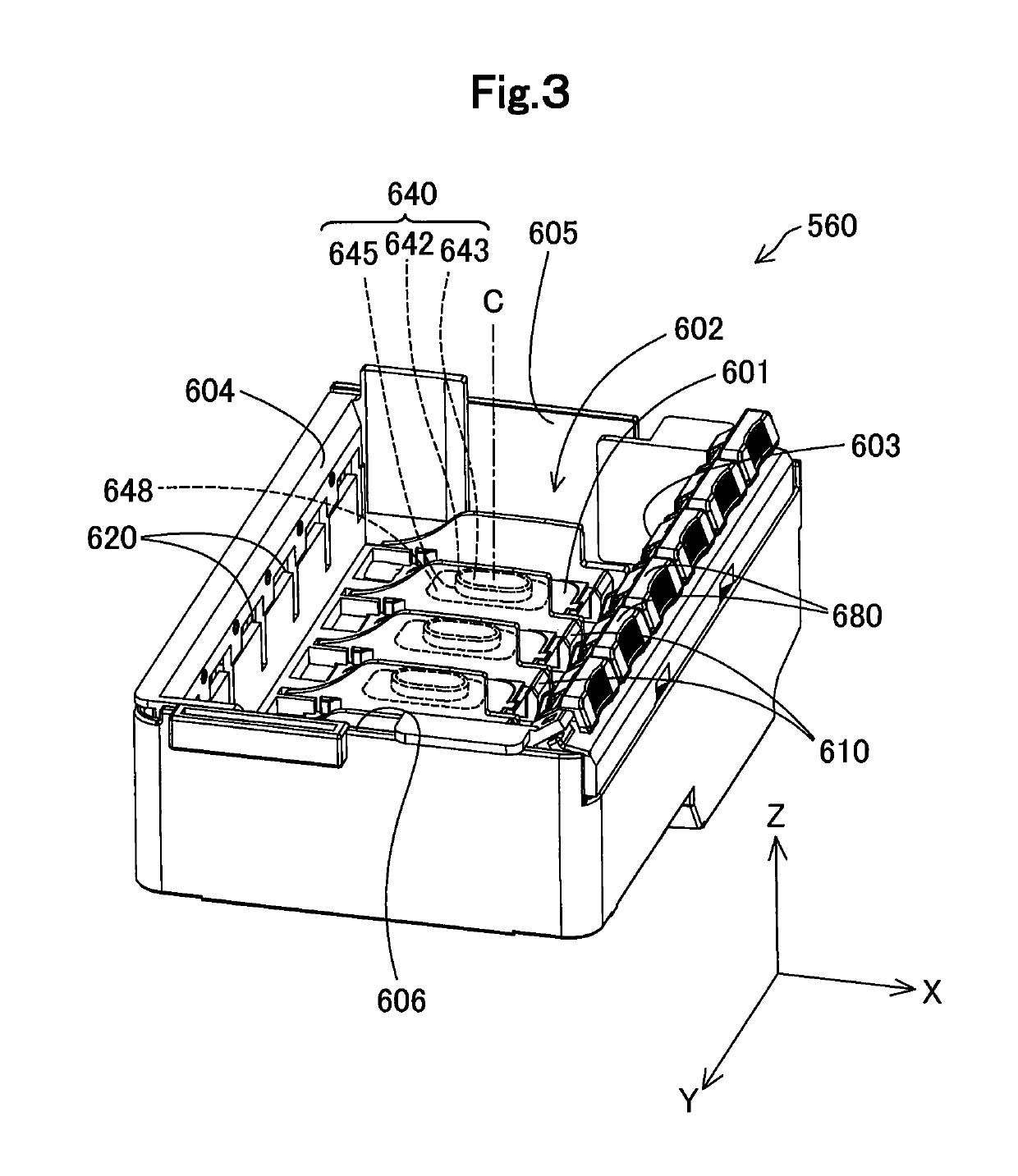

Reactor

InactiveCN1971997AEasy to assembleImprove rigidityHydrogenFuel cellsEngineeringMechanical engineering

Owner:CASIO COMPUTER CO LTD

Heat exchanger

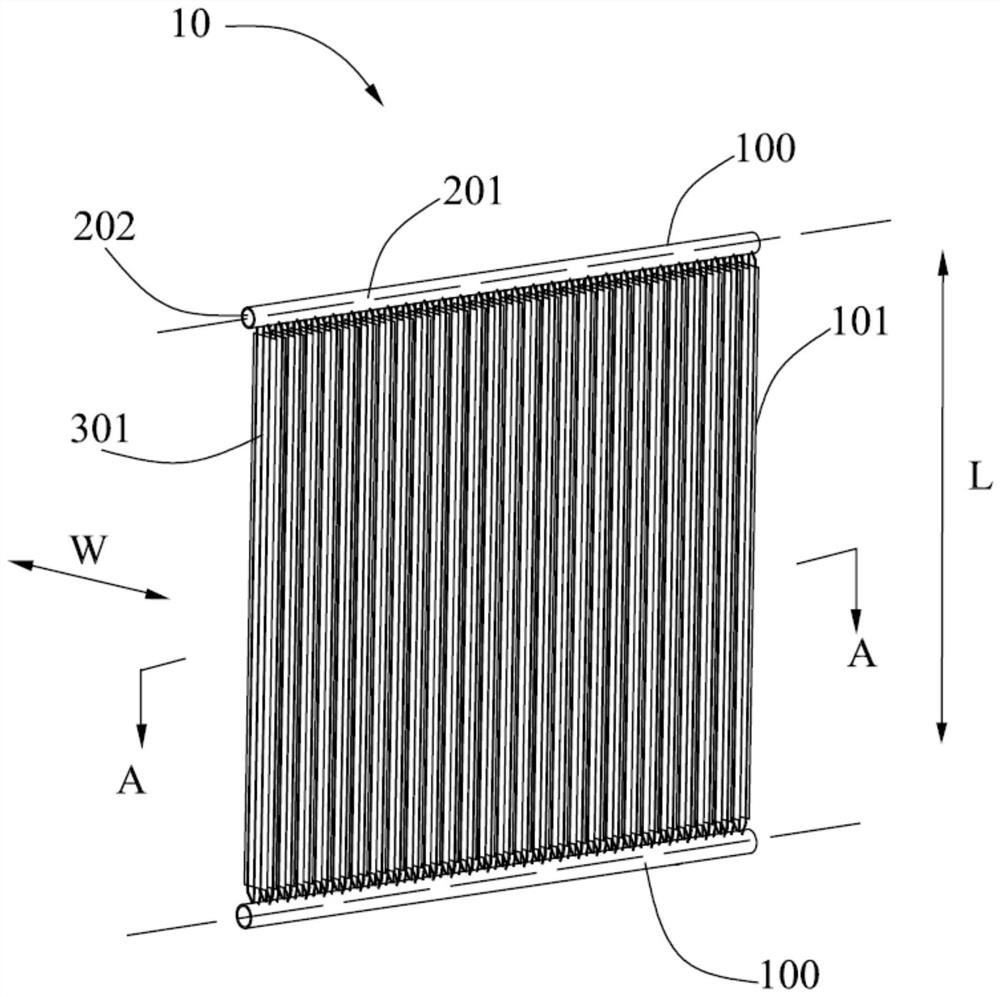

InactiveCN111829364AImprove heat transfer effectExtend the length of the flow pathStationary conduit assembliesTubular elementsEngineeringRefrigerant

The invention discloses a heat exchanger. The heat exchanger comprises a plurality of collecting pipes and a plurality of heat exchange assemblies; in the axial direction of the collecting pipes, theheat exchange assemblies are arranged at intervals; each heat exchange assembly comprises a fin plate and a plurality of heat exchange pipes; the heat exchange pipes of the heat exchange assemblies are divided into at least two groups in the width direction of the heat exchange assemblies, the number of each group of heat exchange pipes is at least one, and each group of heat exchange pipes is connected between the two collecting pipes; for the heat exchange pipes of the two adjacent groups, the inner cavities of the heat exchange pipes of the two groups respectively communicate with the innercavities of the two different collecting pipes on one side; and the inner cavities of the heat exchange pipes of the two groups communicate with the inner cavity of the same collecting pipe on the other side, or the inner cavities of the heat exchange pipes of the two groups respectively communicate with the inner cavities of the two different collecting pipes on the other side, and the inner cavities of the two collecting pipes on the other side communicate with each other, so that the flowing directions of a refrigerant in the inner cavities of the heat exchange pipes of the two groups areopposite. The heat exchange performance of the heat exchanger is improved.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

Bright pipe body processing craft

InactiveCN105728466AShort processing flowImprove finished product efficiencyFurnace typesWork cleaning devicesSteel beltBrightness perception

The invention relates to a bright pipe body processing technology, which belongs to the technical field of metal rolling. It includes feeding rolls, pickling tanks, cleaning tanks and rolling mills installed in sequence; there is a hot box above the pickling tank, and the hot box forms a closed structure above the pickling tank, and the wool supplied by the feeding rolls is in the pickling tank The acidified material is obtained, and the acidified material is sent to the cleaning tank to remove the surface acid to form a crude product; the crude product is sent to the joint rolling mill. Applying the invention to the processing of steel strips and pipe fittings has the advantages of short processing flow and high brightness of finished products.

Owner:SHAOXING HUANXIN PIPE IND

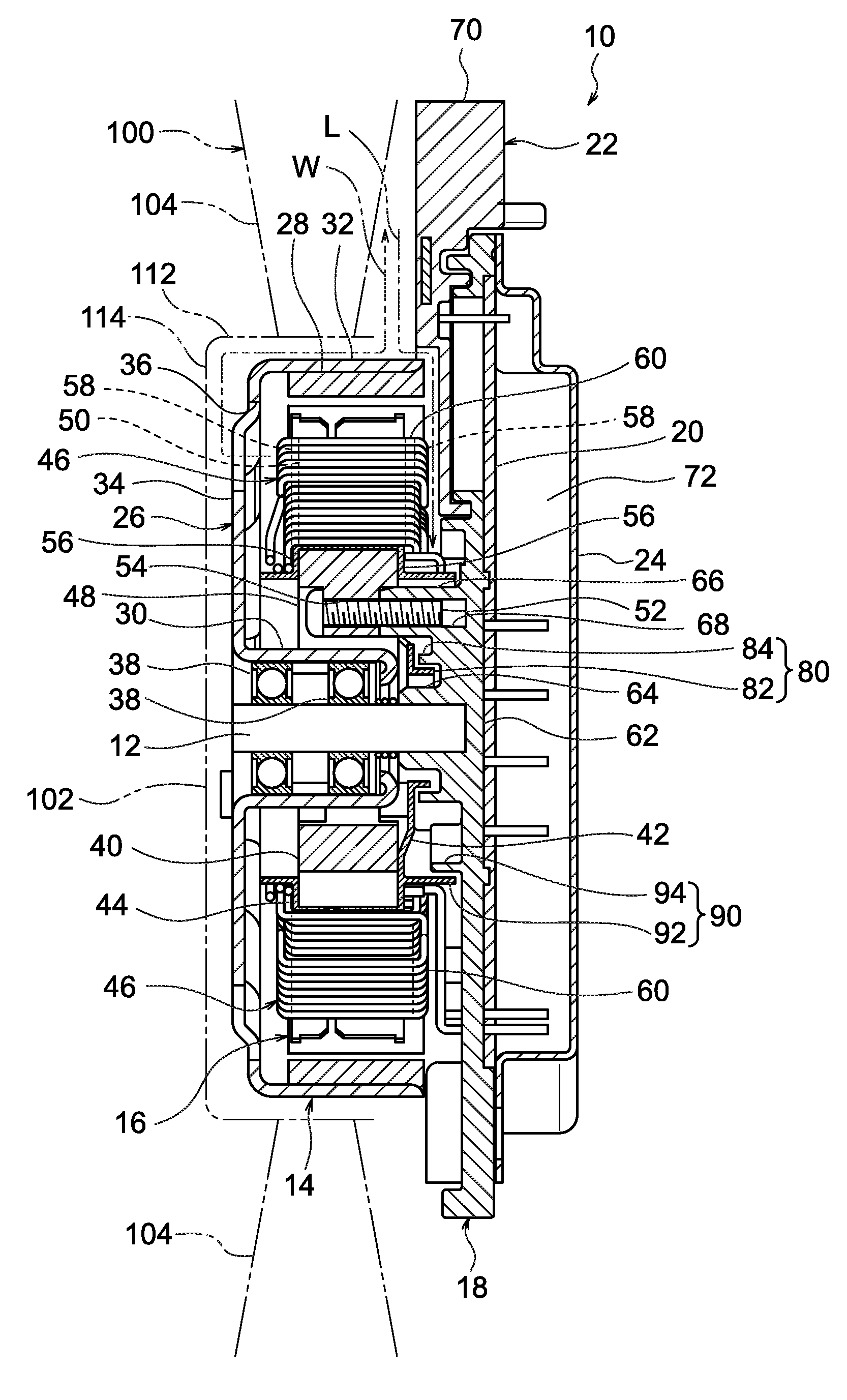

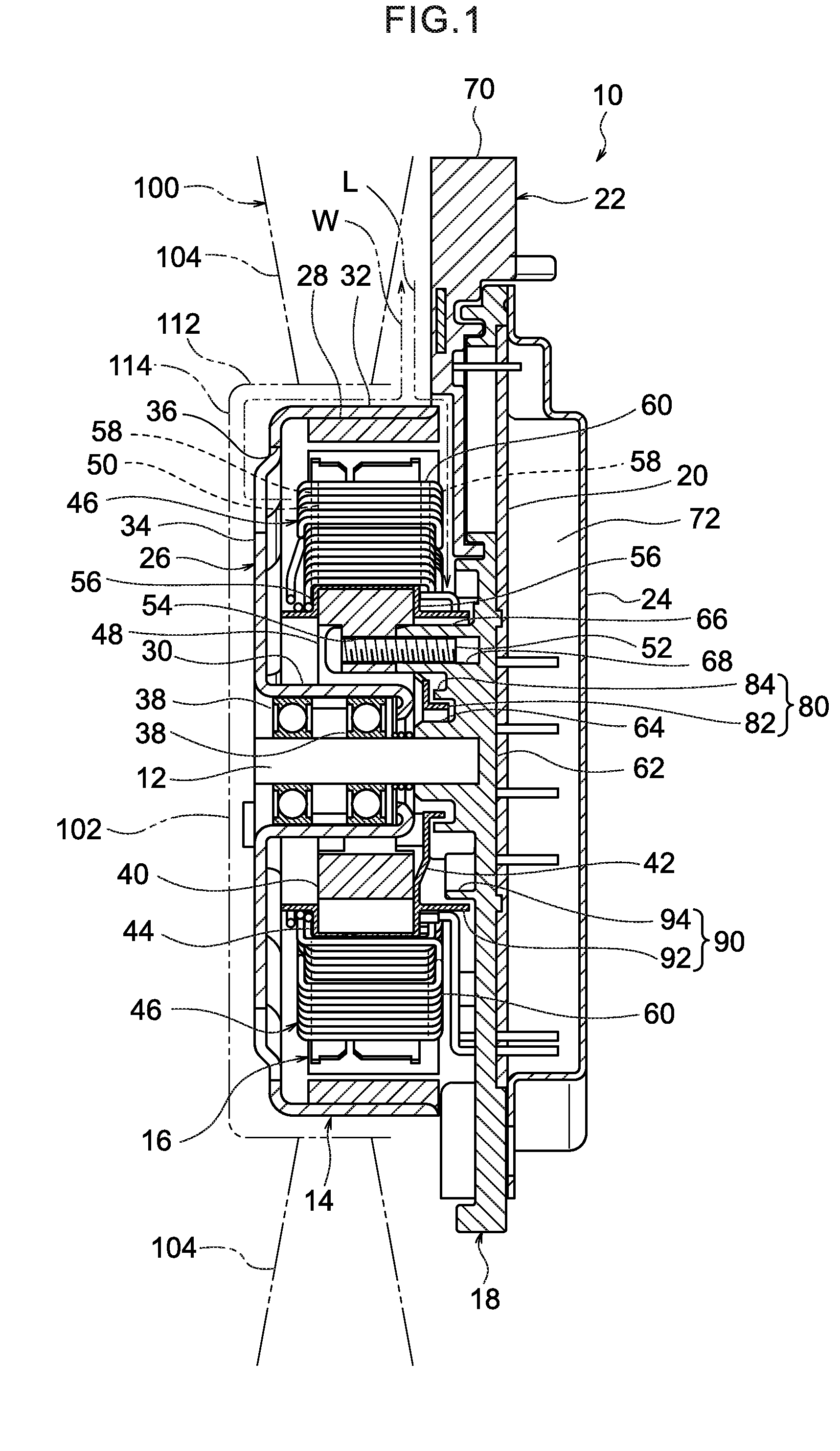

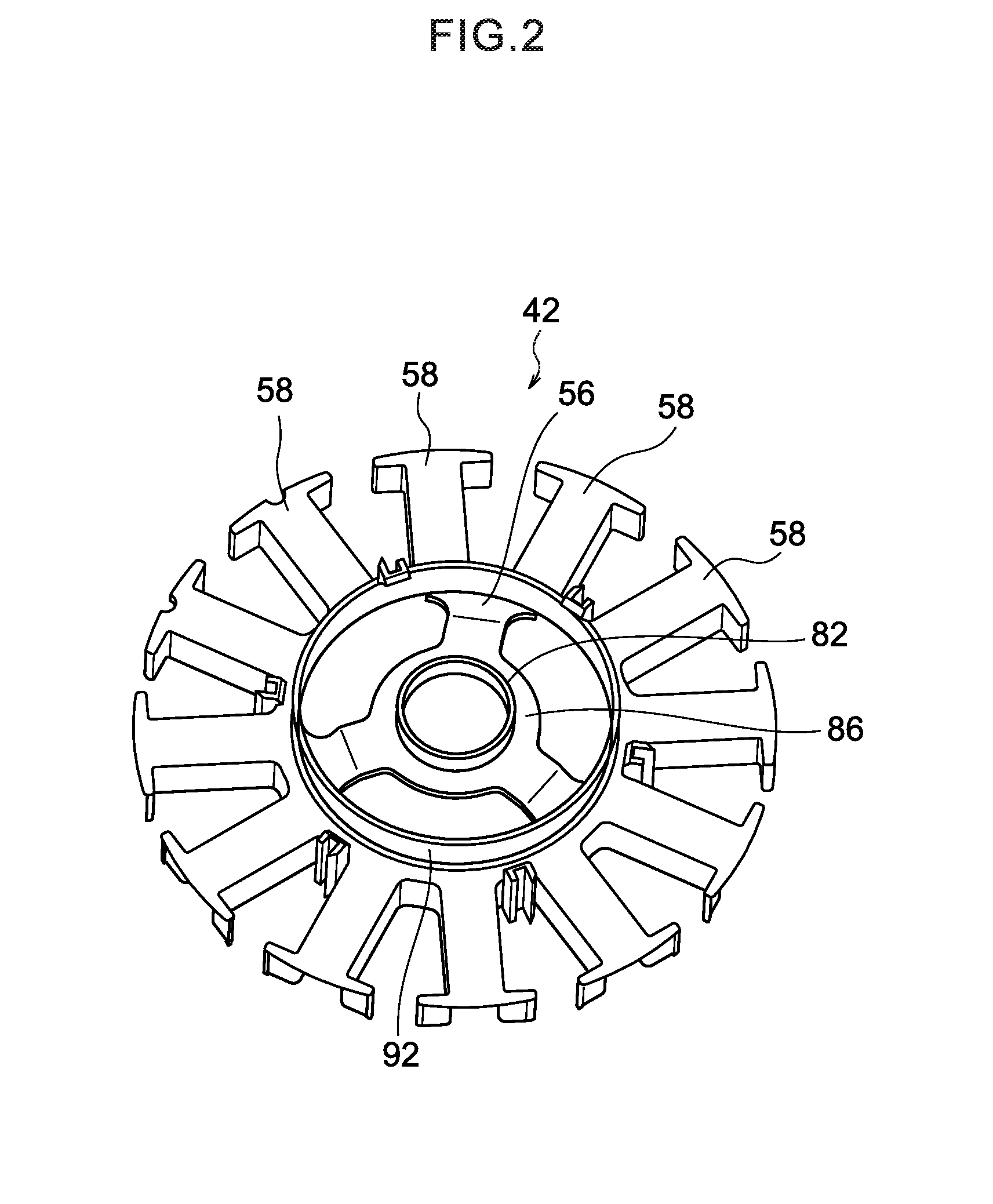

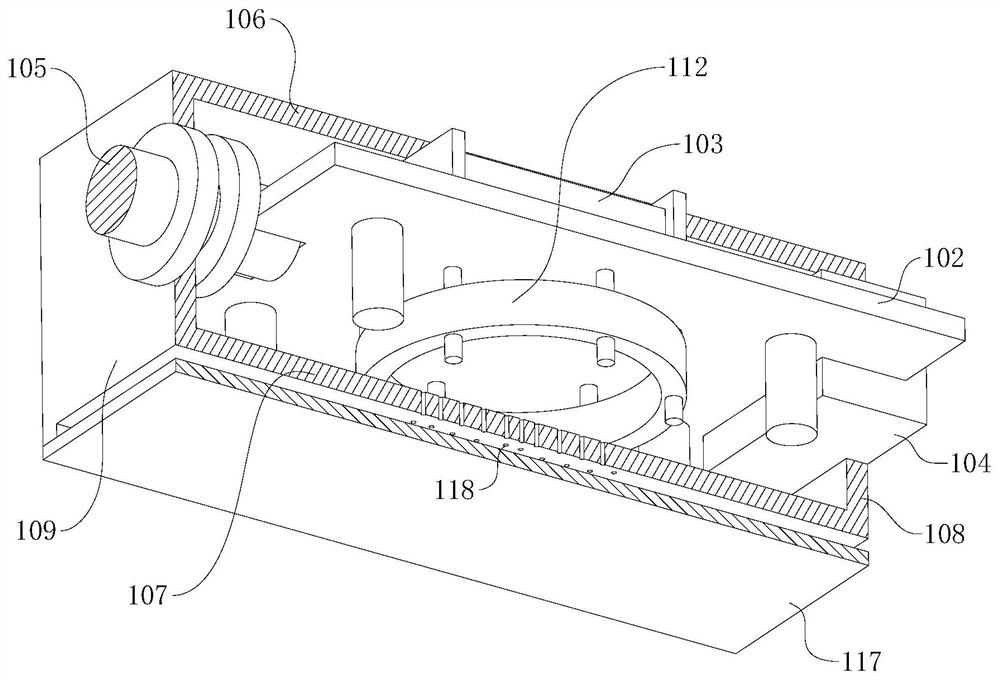

Brushless motor

ActiveUS20160268863A1Water stopping capability can be improvedExtend the length of the flow pathSupports/enclosures/casingsBrushless motorsEngineering

There is provided a brushless motor including (1) a motor shaft, (2) an insulator that includes a ring-shaped insulating portion covering the ring-shaped unit, (3) a centerpiece that includes a main body section that supports the motor shaft, (4) a first water stopping wall that is formed in a ring shape along the circumferential direction of the motor shaft, and that extends along the axial direction of the motor shaft from the ring-shaped insulating portion toward the main body section, and (5) a second water stopping wall that is formed in a ring shape along the circumferential direction of the motor shaft, that extends out along the axial direction of the motor shaft from the main body section toward the ring-shaped insulating portion, and that, together with the first water stopping wall, configures a labyrinth structure.

Owner:DENSO CORP

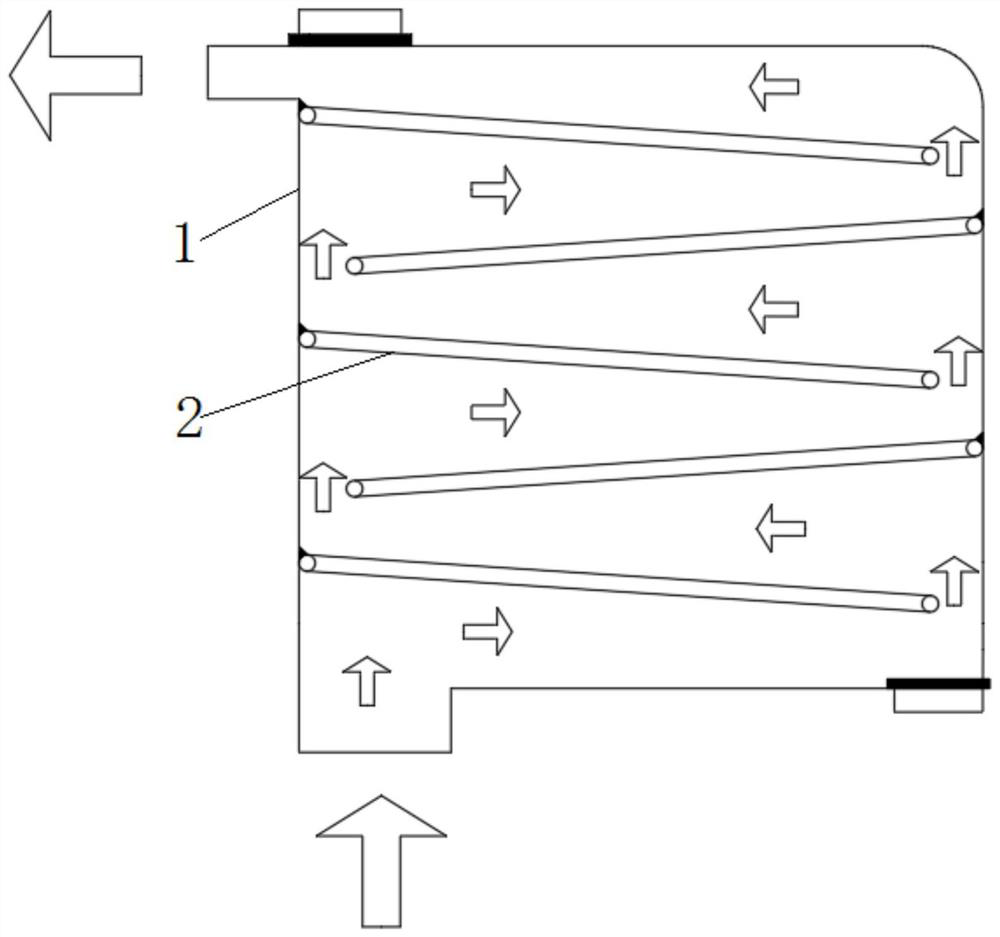

Staggered declination type sludge drying device

InactiveCN112358153AIncrease sludge volumeExtended staySludge treatment by de-watering/drying/thickeningSludgeHot blast

The invention discloses a staggered declination type sludge drying device, and belongs to the technical field of sludge treatment. A plurality of stages of conveying mesh belts inclining downwards ina staggered mode are arranged in the drying box body, an air outlet and a sludge feeding port are formed in the upper portion of the drying box body, and a sludge discharging port and an air inlet areformed in the bottom of the drying box body. The air outlet is formed in one side of the starting end of the uppermost-stage conveying mesh belt, and the sludge feeding opening is formed above the starting end of the uppermost-stage conveying mesh belt; the air inlet is formed below the starting end of the lowermost-stage conveying mesh belt and connected with the hot air system, and the sludge outlet is formed below the tail end of the lowermost-stage conveying mesh belt; the sludge discharge port is provided with a discharge port valve, and the sludge feed port is provided with a feed portvalve; and a sealing strip is arranged in a gap between the starting end of each stage of conveying mesh belt and the side wall of the drying box body. The drying device is reasonable in structure andair path design, small in occupied space, high in drying efficiency and low in energy consumption.

Owner:XI AN JIAOTONG UNIV

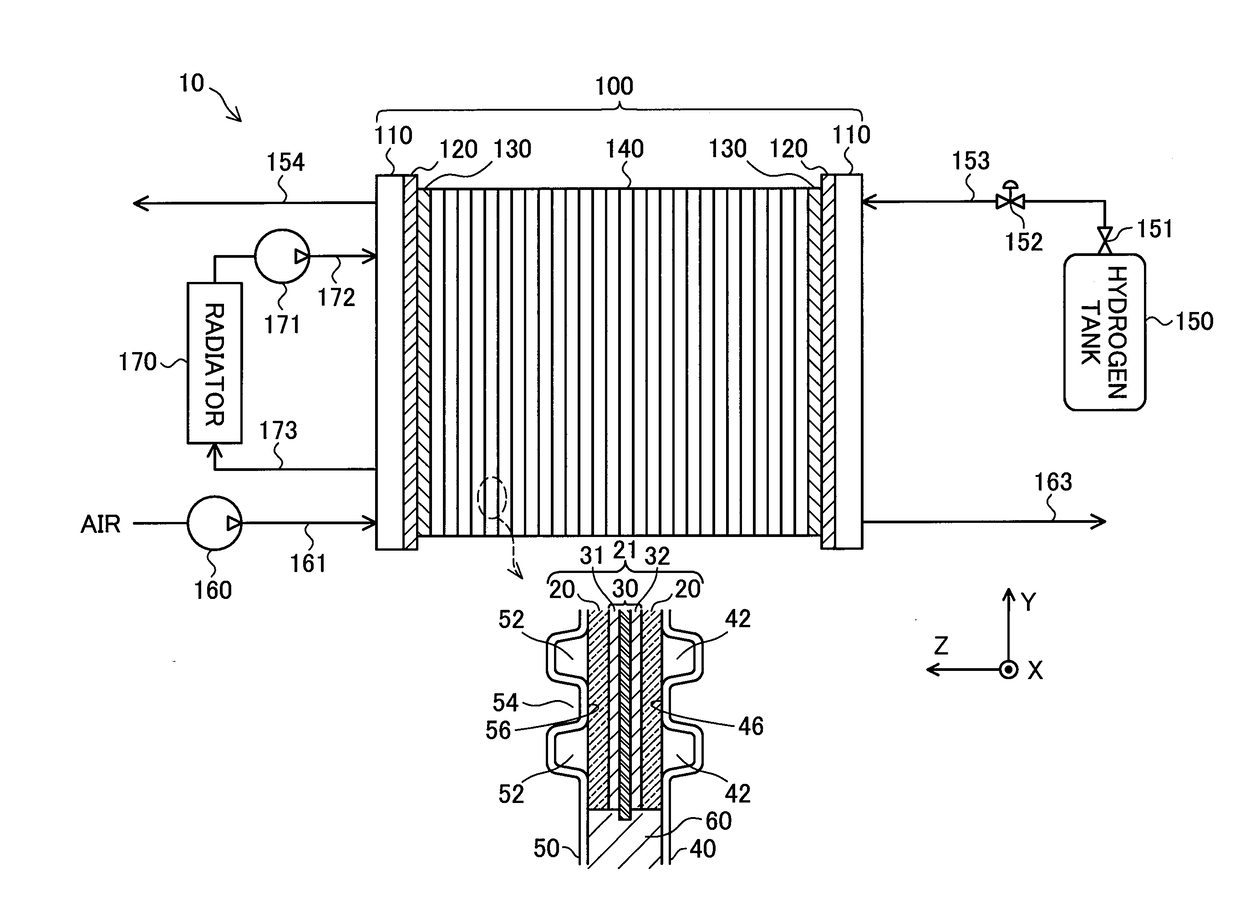

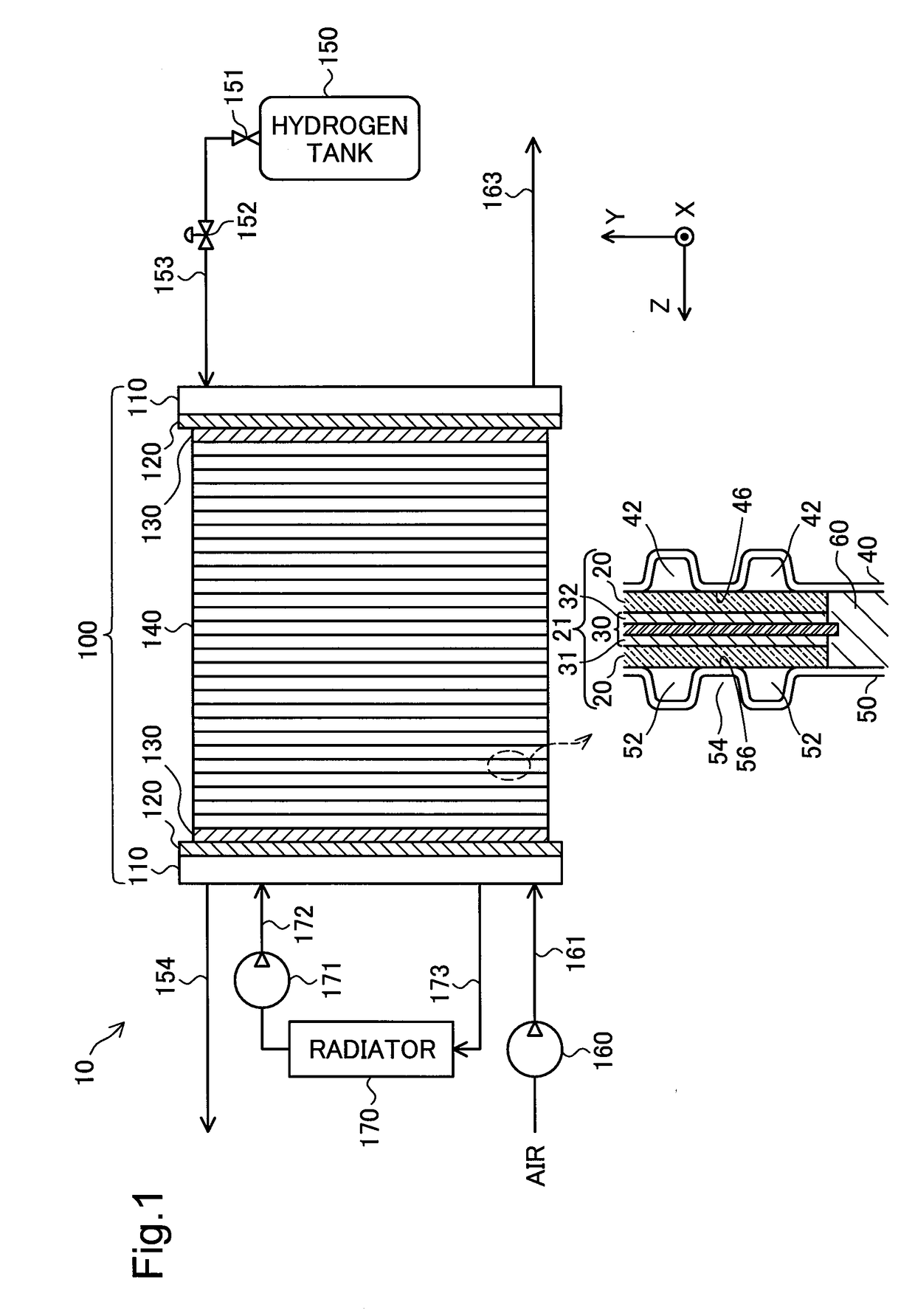

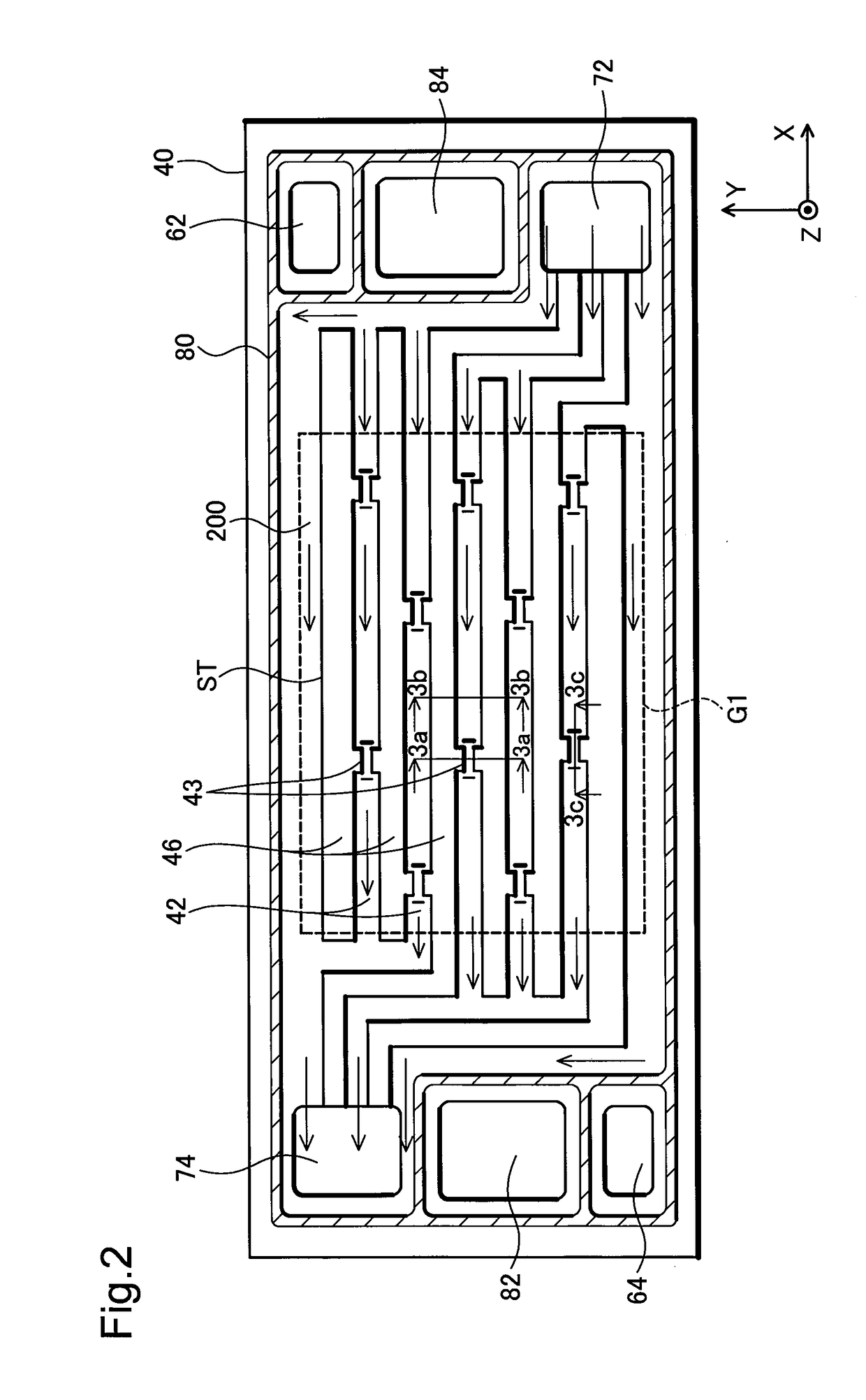

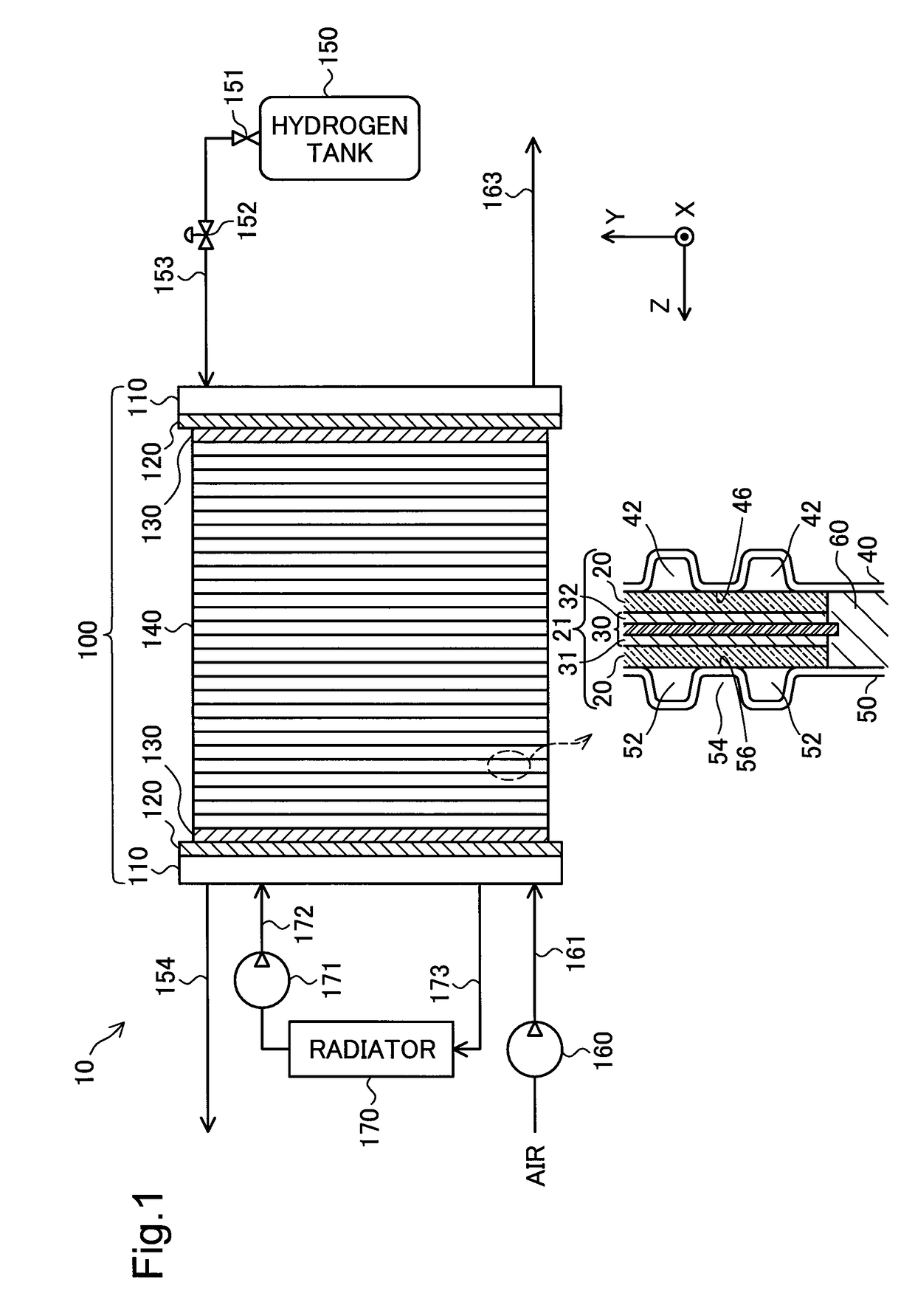

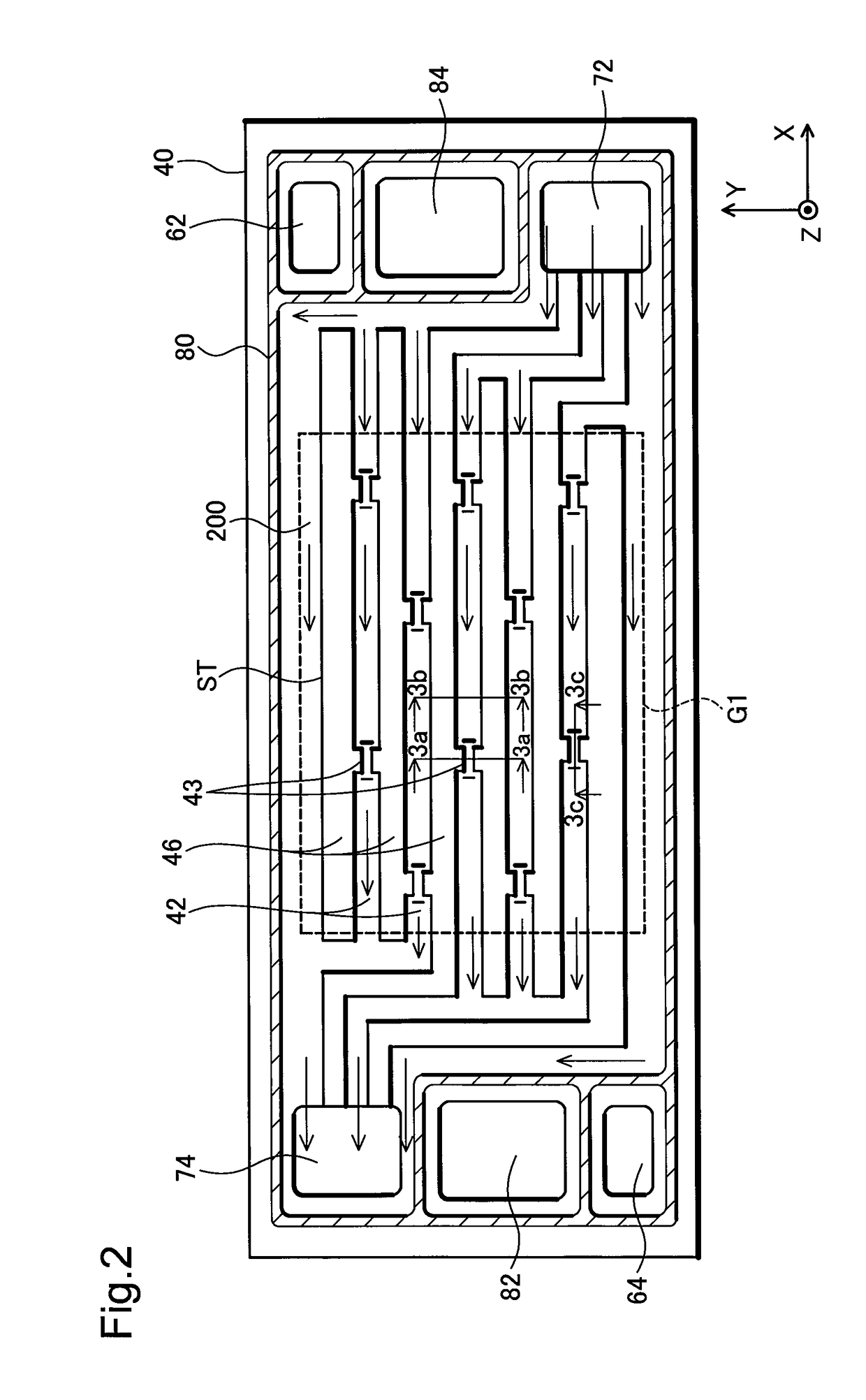

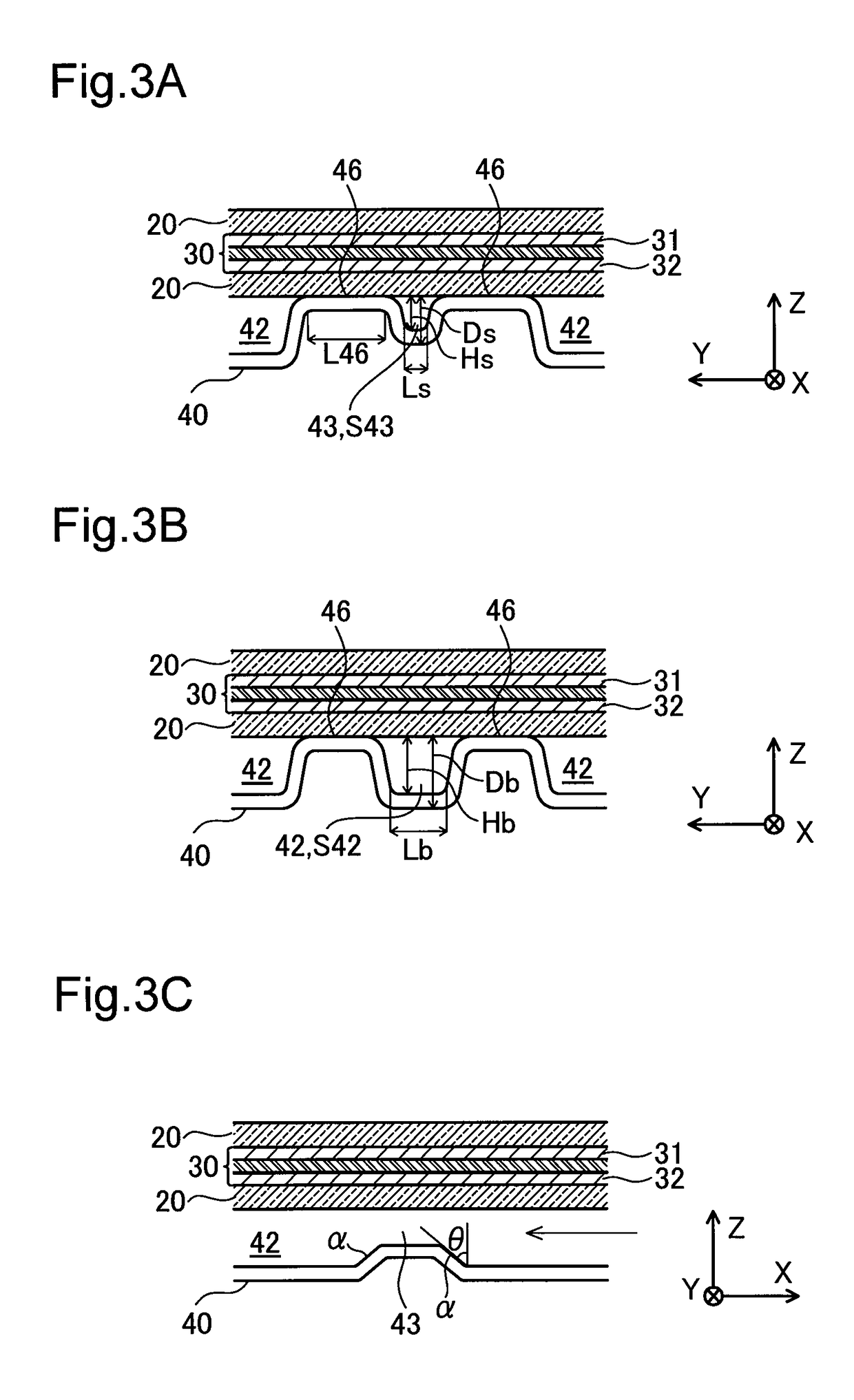

Fuel-cell unit cell

ActiveUS20170373336A1Preventing excessive concentration of compressive forceImprove utilization efficiencyCollectors/separatorsFuel cellsEngineering

A fuel-cell unit cell comprises: a membrane electrode and gas diffusion layer assembly; a cathode-side separator made of a press-molded plate, the cathode-side separator forming a plurality of cathode gas flow paths and non-flow-path portions therebetween on a cathode-side surface of the membrane electrode and gas diffusion layer assembly; and an anode-side separator made of a press-molded plate, the anode-side separator forming a plurality of anode gas flow paths and non-flow-path portions therebetween on an anode-side surface of the membrane electrode and gas diffusion layer assembly. At least one gas flow path among the plural cathode gas flow paths and the plural anode gas flow paths includes a constricting portion that is configured to reduce a flow-path height in a stacking direction of the fuel-cell unit cells as well as to reduce a flow path cross-sectional area of the gas flow path. When projected and observed along the stacking direction, the plural cathode gas flow paths and the plural anode gas flow paths are configured to have mutually different two-dimensional shapes, there exist intersect positions at which the cathode gas flow paths and the anode gas flow path intersect each other, and the constricting portion is provided at a position other than the intersect positions.

Owner:TOYOTA JIDOSHA KK

Counterflow helical heat exchanger

ActiveUS10782072B2Improve heat transfer performanceExtend the length of the flow pathHeat exhanger sealing arrangementHeat exchanger casingsCounter flowMechanical engineering

A helical heat exchanger assembly comprises a plurality of helical heat exchangers, each helical heat exchanger comprising a tube having first and second ends, a length, an inner diameter and a cross-section incorporating the inner diameter, a thermally conductive tube insert having a length and an outer diameter substantially equal to the inner diameter of the tube, the tube insert having first and second ends and comprising a single helix extending along the length of the tube insert and twisted around a central axis. The tube insert is sealed within the tube by sealing an outer edge of the helix to an inner surface of the tube to form fluid-tight first and second fluid flow paths defined between opposing sides of the helix and the inner surface of the tube, respectively. A plurality of inlet and outlet fluid ports are positioned for passage of a first and second fluid into and out of each tube. A first manifold connects each of the first ends of the heat exchanger tubes and a second manifold connects each of the second ends of the heat exchanger tubes, wherein at least one of the first or second manifolds includes baffles to direct fluid flow within the manifold such that at least some of the helical heat exchangers may be arranged in series, or in parallel, within the heat exchanger assembly via the baffles. Each helix has a predetermined pitch which may be less than or greater than the tube inner diameter and defines a length of the first and second fluid flow paths within each heat exchanger tube, wherein the pitch of the helix may be constant or variable along the length of the tube insert.

Owner:ENTEREX AMERICA

Reactor

InactiveCN100499237CEasy to assembleImprove rigidityHydrogenFuel cellsEngineeringMechanical engineering

Owner:CASIO COMPUTER CO LTD

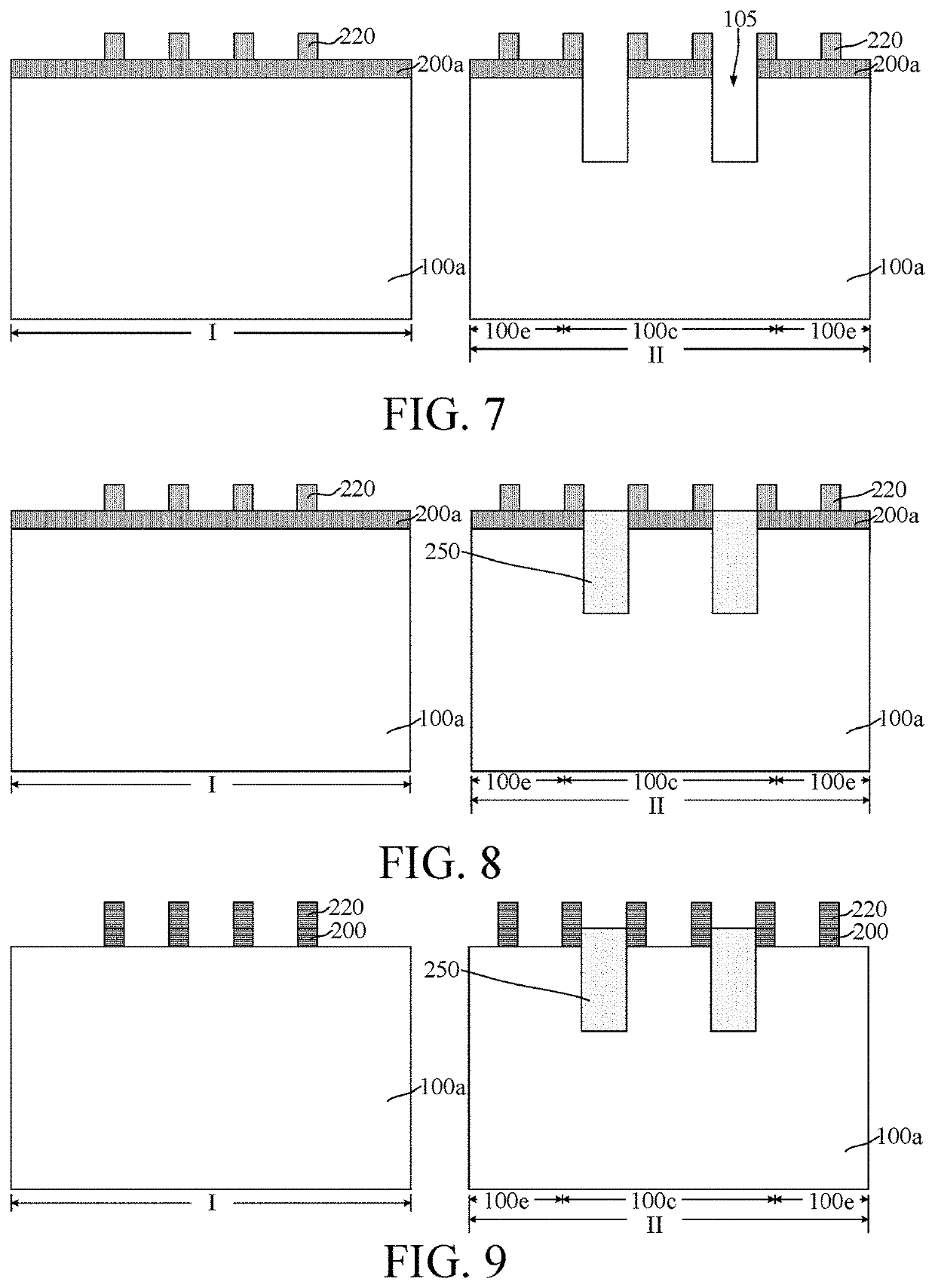

Semiconductor structure and method of forming a semiconductor structure

ActiveUS11145756B2Reduce voltage dropImprove breakdown voltageSolid-state devicesSemiconductor/solid-state device manufacturingLDMOSSemiconductor structure

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP +1

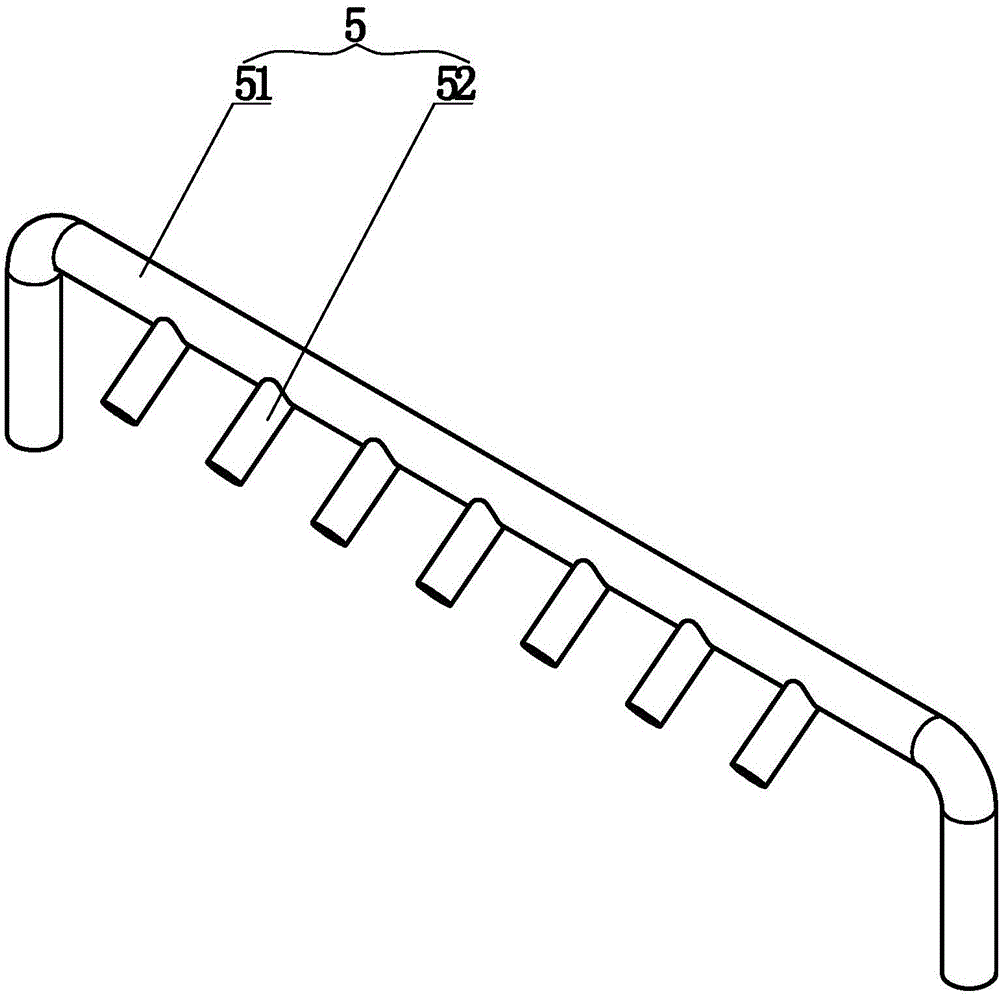

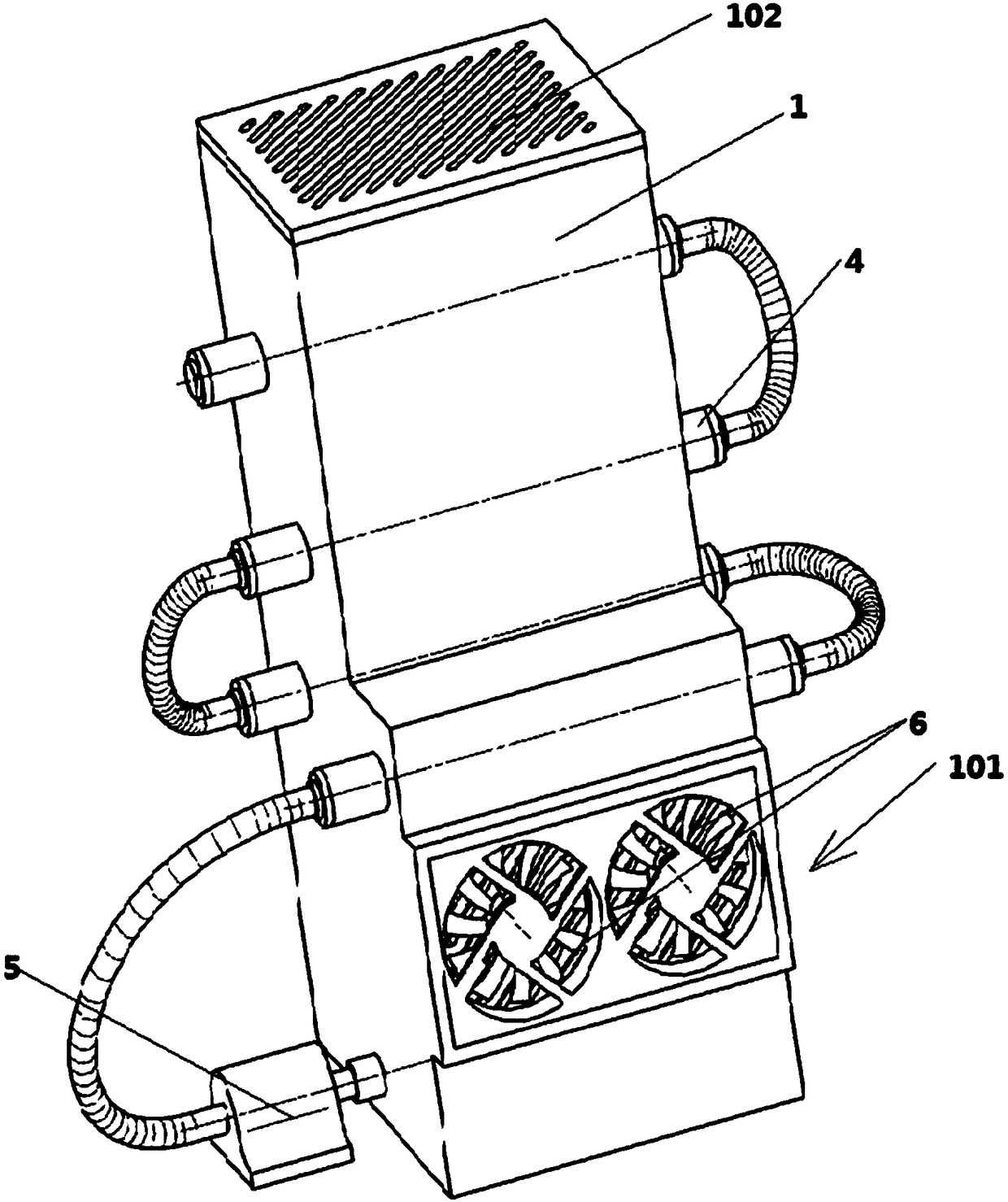

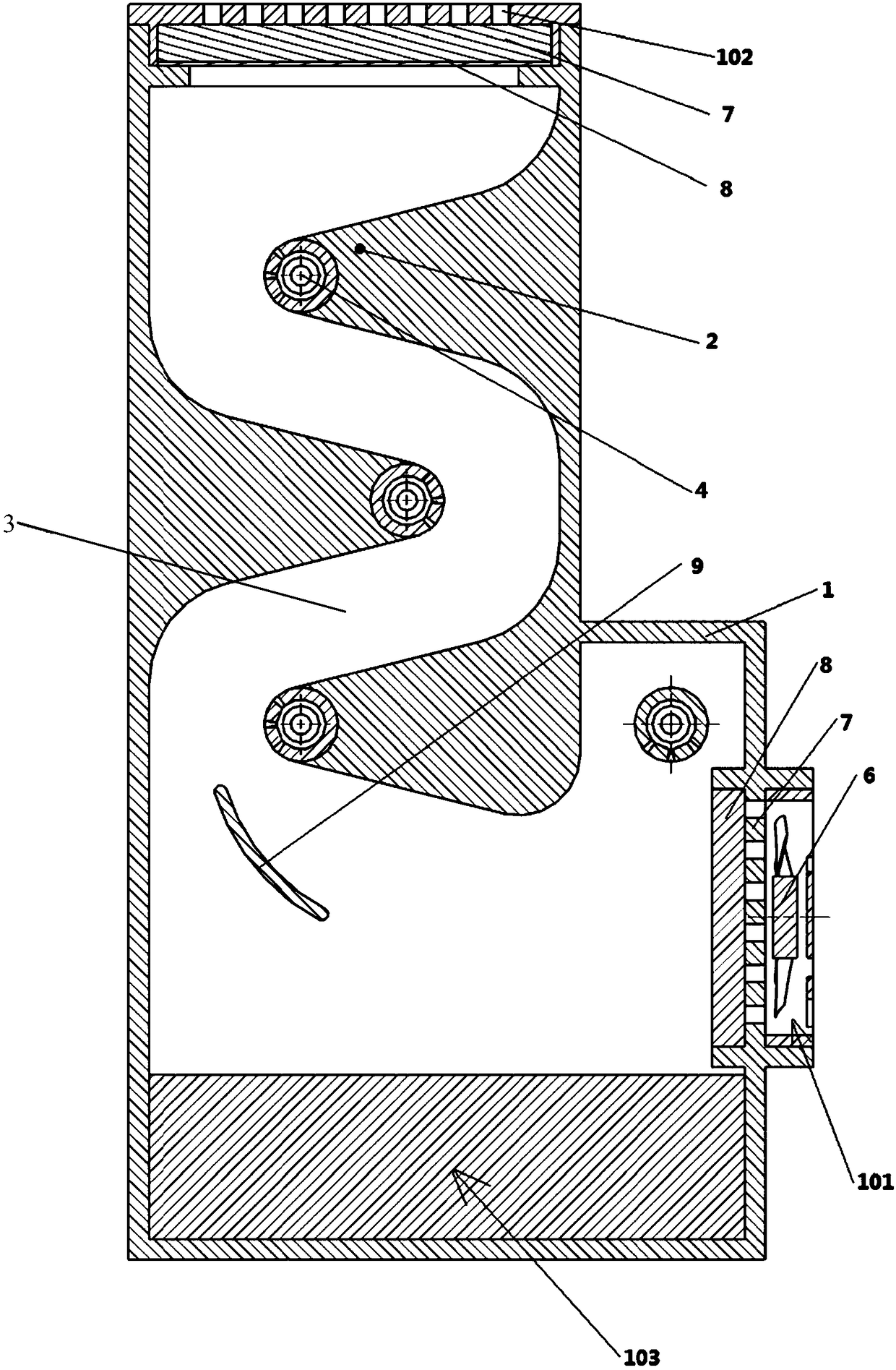

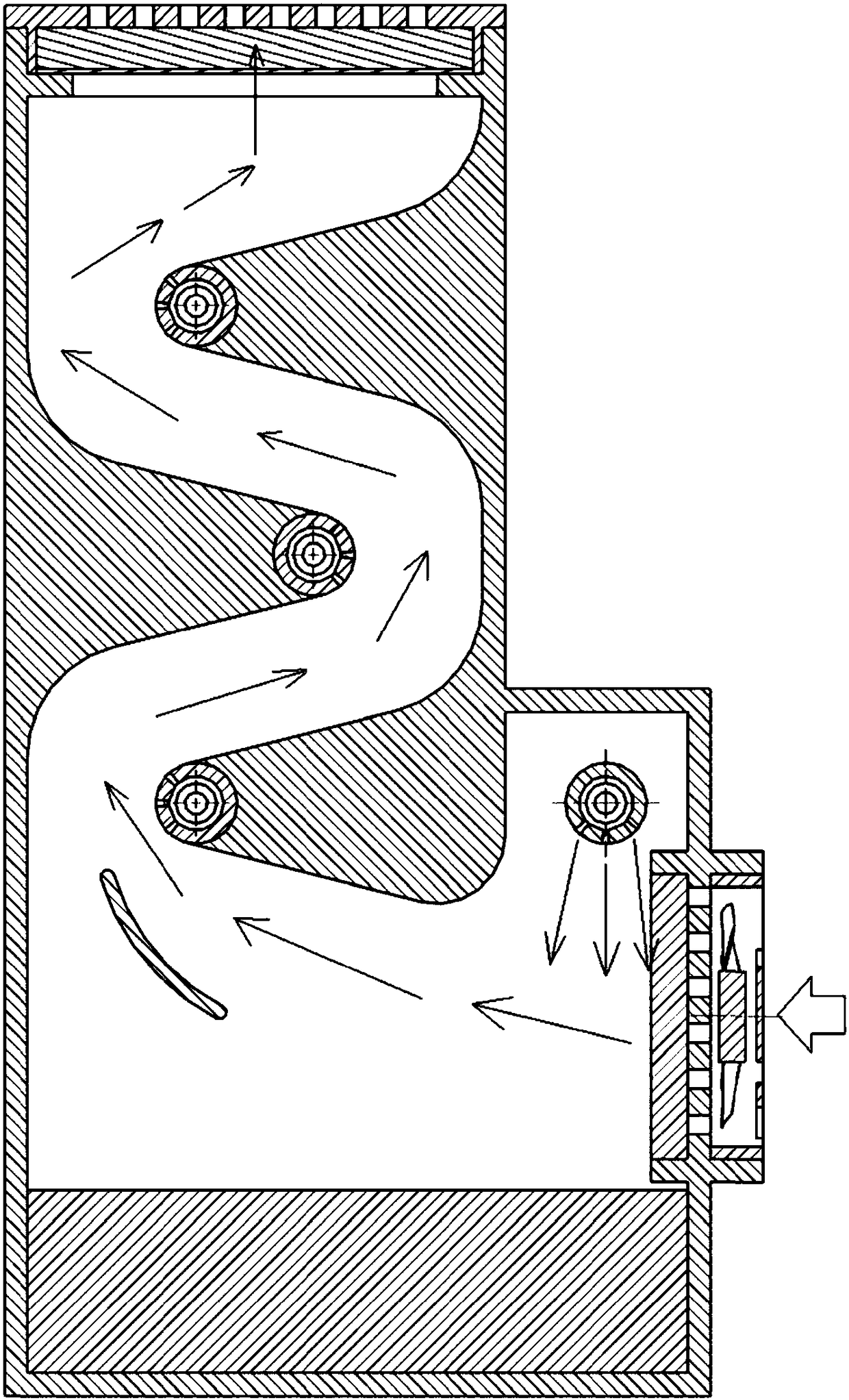

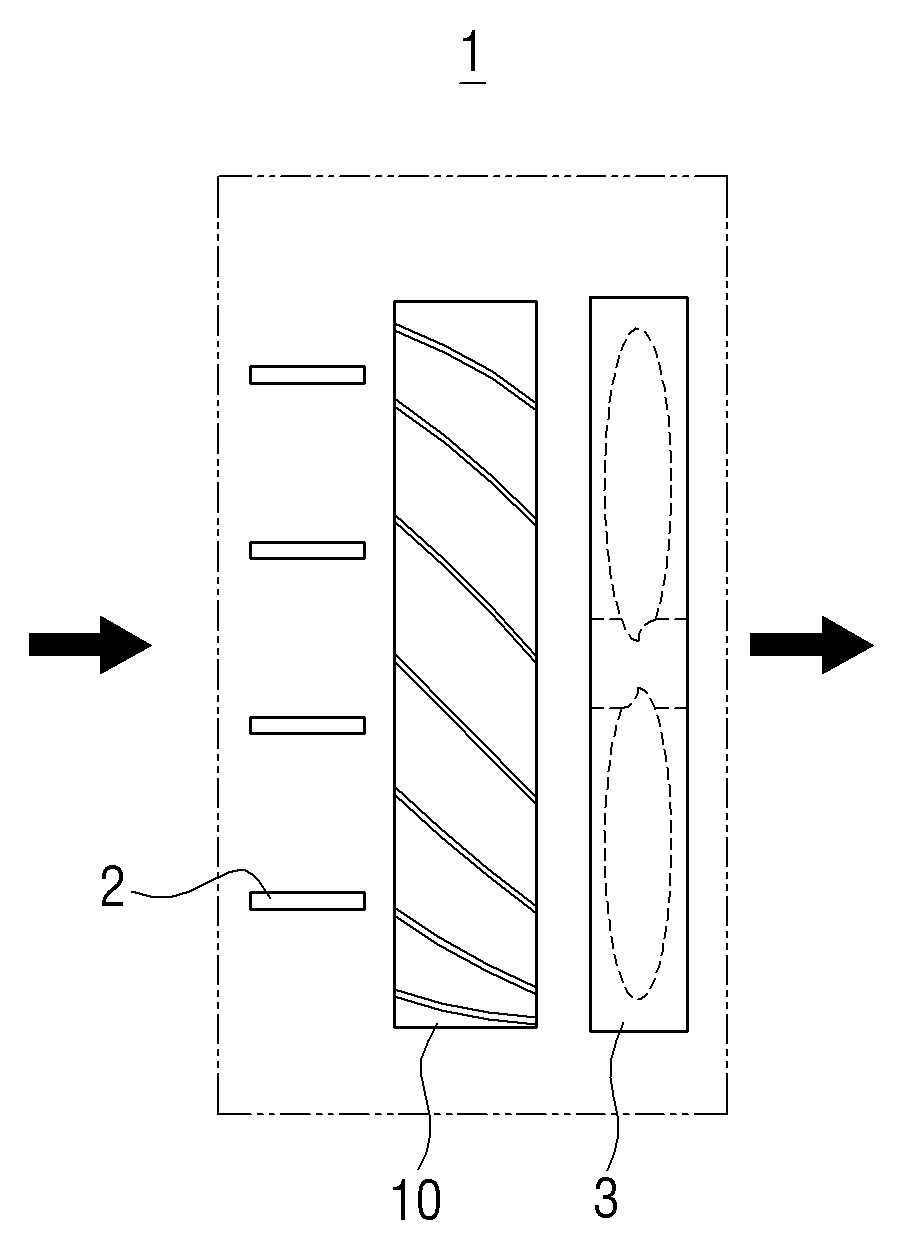

Air purifier

InactiveCN109078418AExtend the length of the flow pathExtend the overcurrent timeCombination devicesUsing liquid separation agentAir purifiersContact time

The invention relates to the technical field of air filtering and purifying, and discloses an air purifier. An air inlet and an air outlet are formed in an outer shell body of the air purifier, a plurality of baffle walls which transversely extend to one another are formed on the inner walls of two opposite sides in the cavity of the outer shell body; the baffle walls are arranged at intervals from bottom to top at intervals, the baffle walls on the two sides are intersected to one another to form a bent flow channel from bottom to top, each baffle wall is provided with a strip-shaped sprayingtube for spraying water to form a water curtain, air which enters from the air inlet is discharged from the air outlet through the bent flow channel, and when passing through the flow channel, the air is washed via the water curtain. An existing simple impact type washing mode is changed, and water-air contact time is prolonged to improve the air filtering and purifying efficiency.

Owner:MIDEA GRP CO LTD

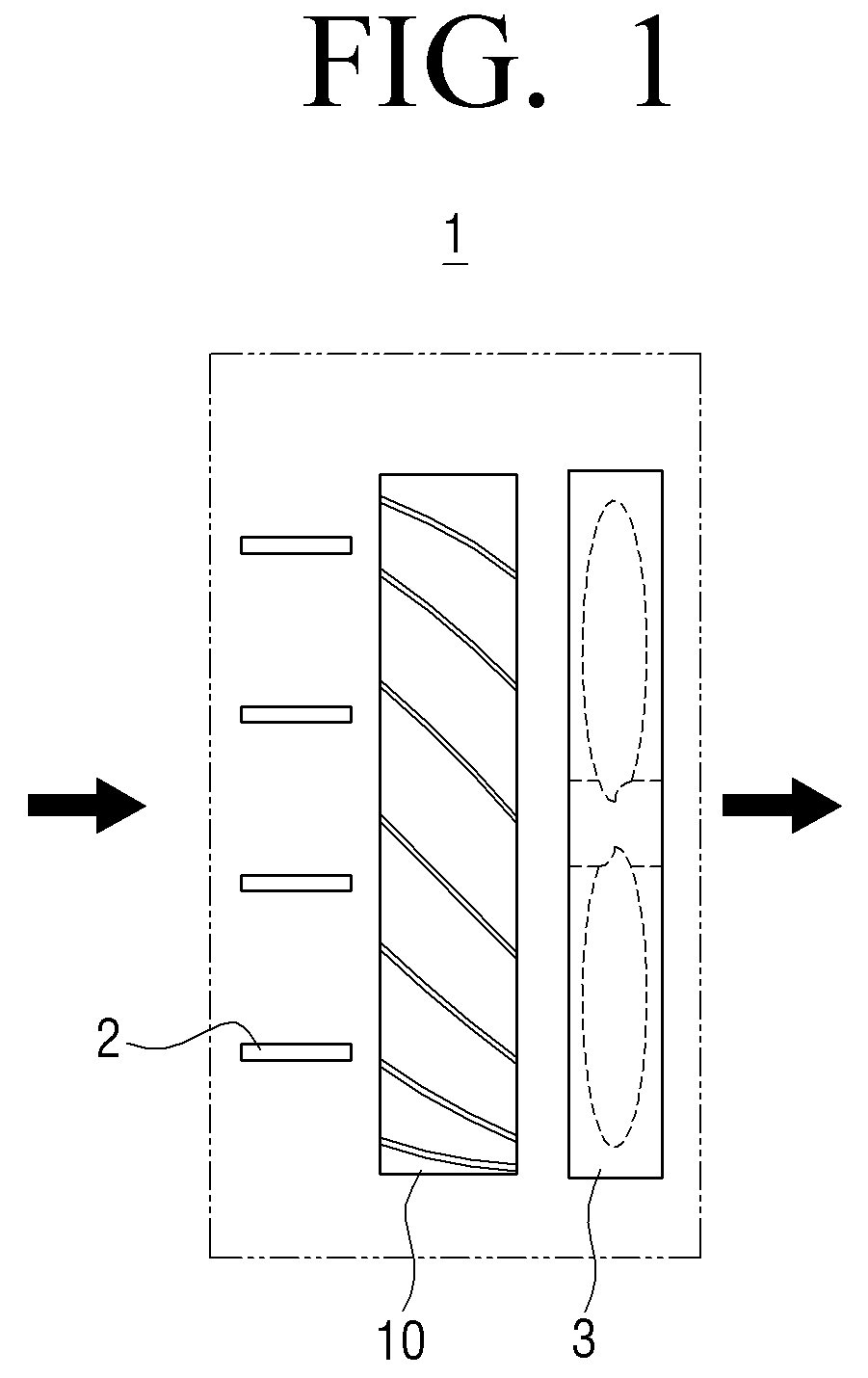

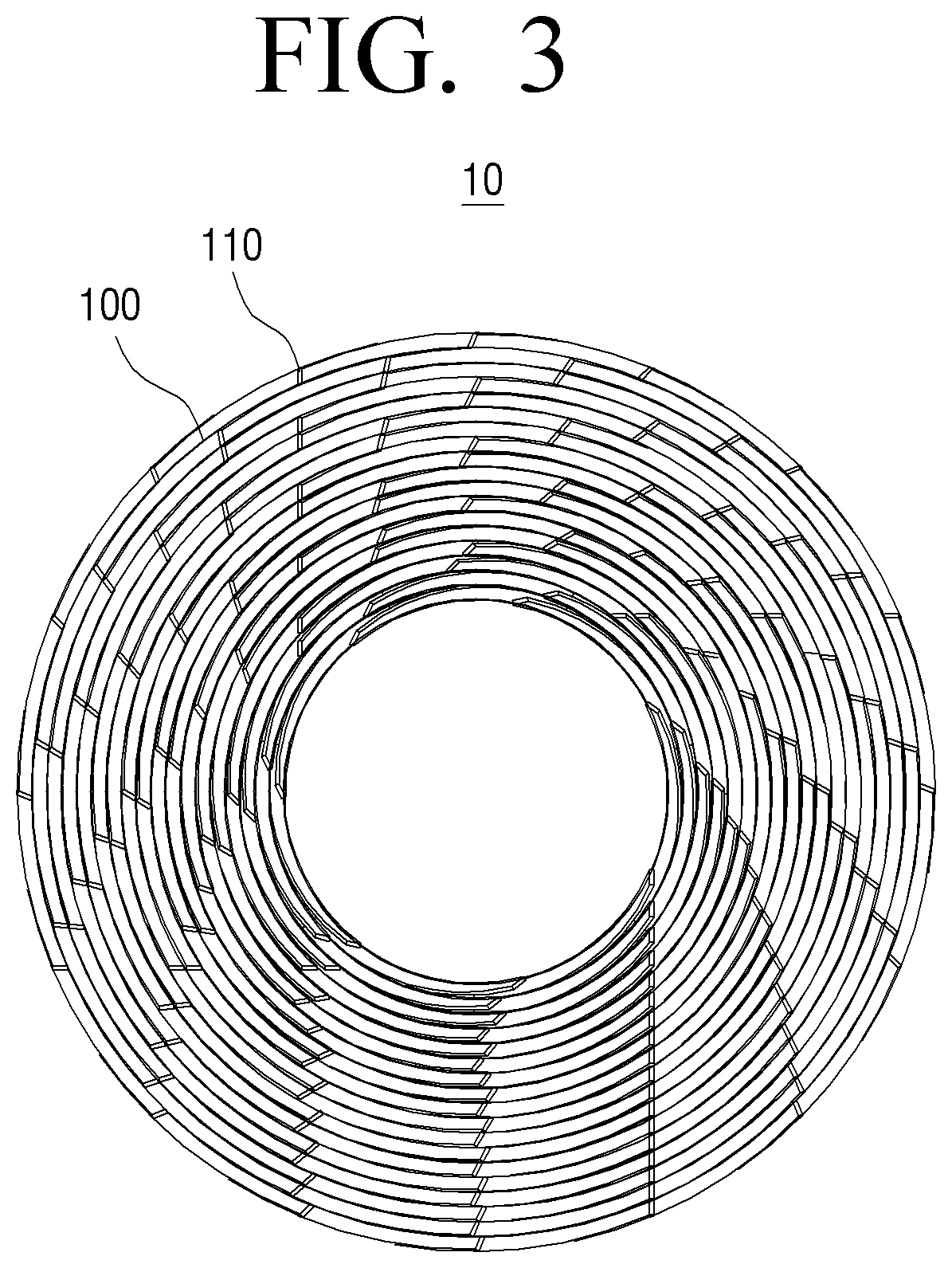

Scroll type electrostatic precipitator and air conditioning apparatus having the same

ActiveUS20180015483A1Improve collection efficiencyExtend the length of the flow pathElectrode carrying meansMechanical apparatusElectrostatic precipitatorEngineering

An electrostatic precipitator is provided. The electrostatic precipitator includes an electrode part including a high voltage electrode with voltage applied thereto and a ground electrode coiled in a circumferential direction along with the high voltage electrode while being spaced apart from the high voltage electrode, and a plurality of turning flow paths inclined with respect to an axial direction of the electrode part between the high voltage electrode and the ground electrode.

Owner:SAMSUNG ELECTRONICS CO LTD

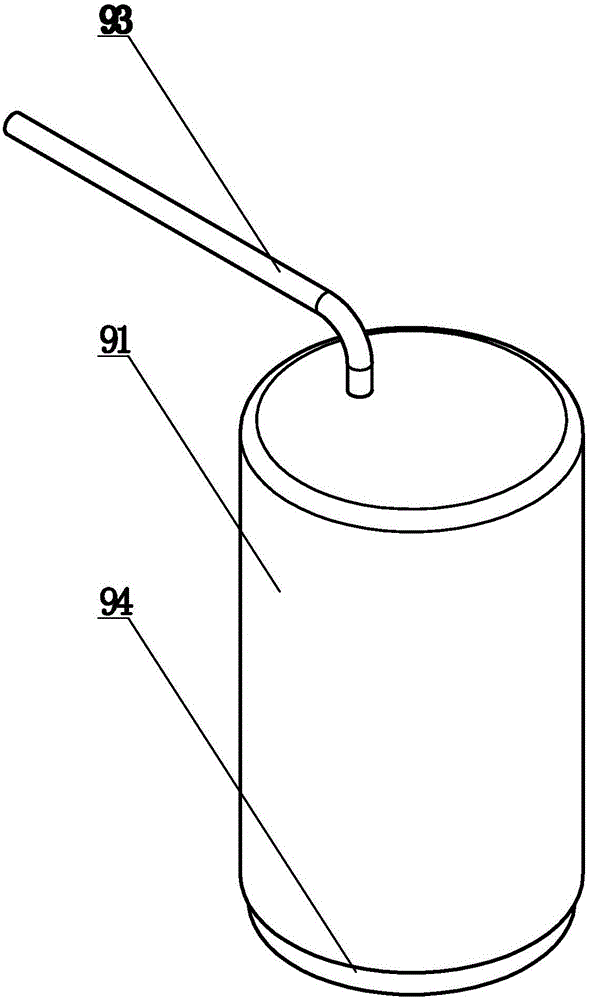

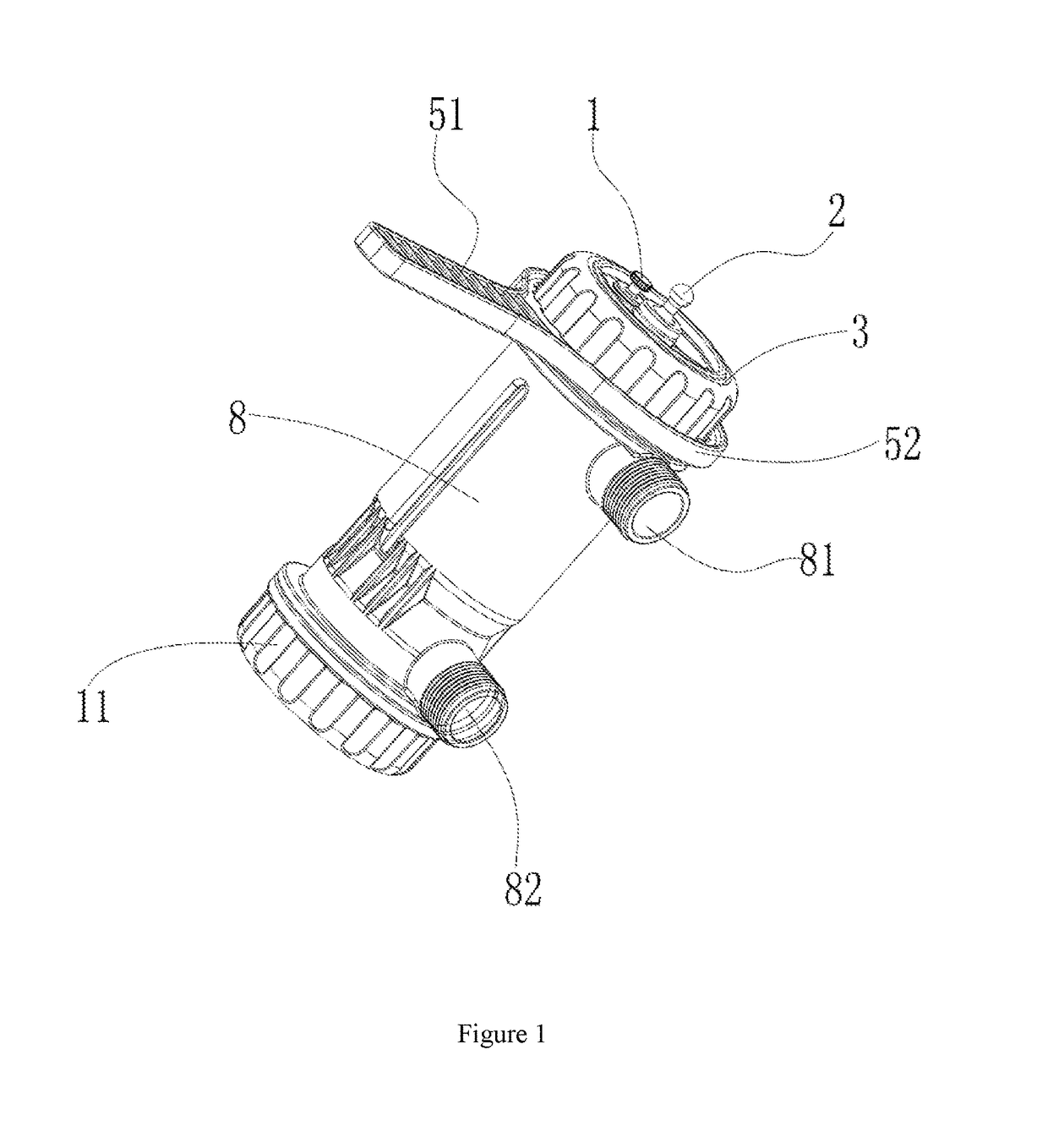

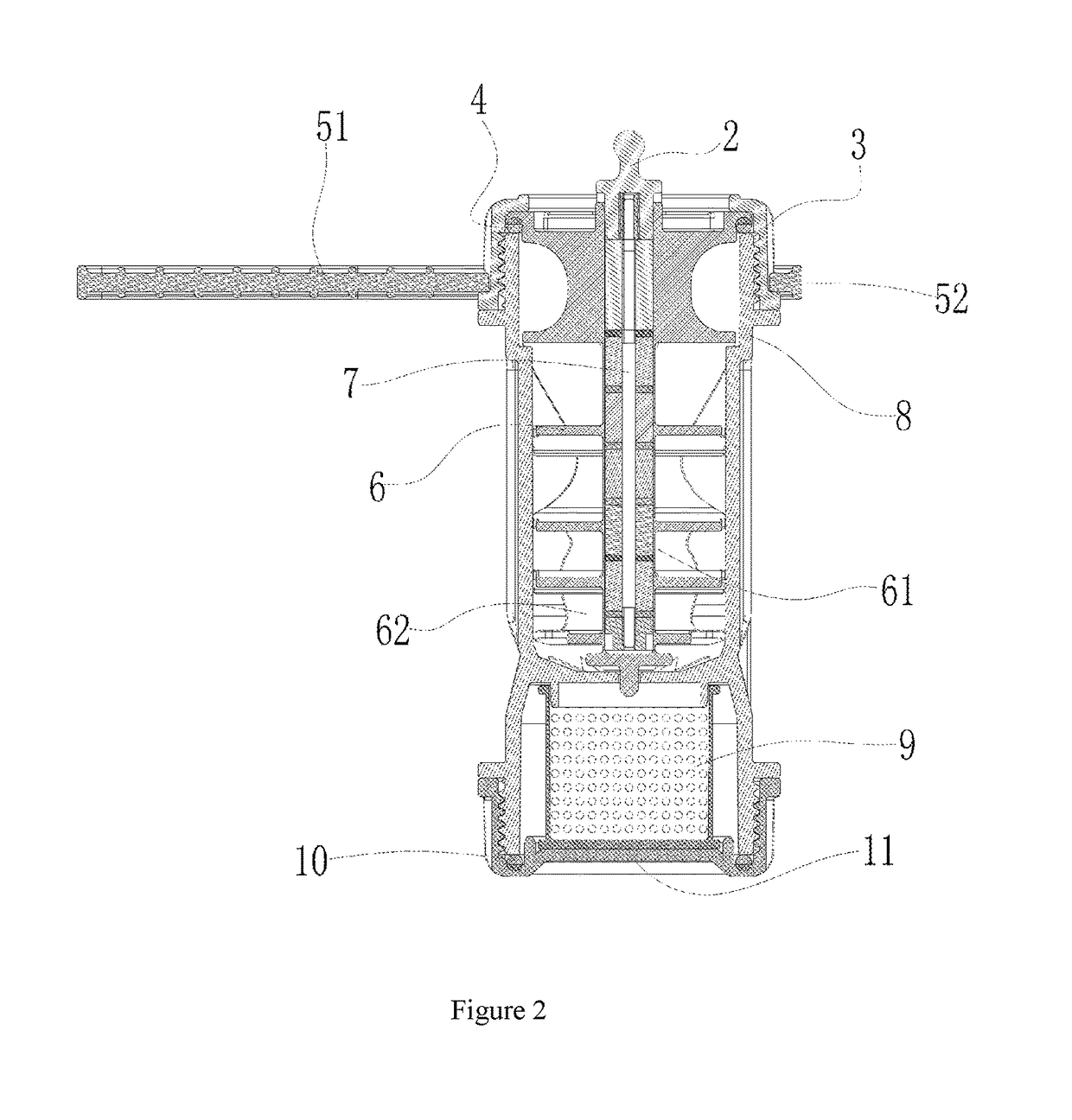

Filter with magnet and protective bushing

InactiveUS9884778B2High maintenance costExtend the length of the flow pathElectrostatic separationSpecific water treatment objectivesExhaust valveMetal impurities

The present disclosure relates to a filter, which comprises a housing, a protective bushing, a magnetic bar and a filter screen. The protective bushing, the magnetic bar and the filter screen are disposed in the housing. The protective bushing comprises a cavity and a channel. The channel is disposed along the axial direction of the cavity. The magnetic bar inside the filter adsorbs metal impurities in water in the channel. The shape of the channel increases the length of the flow path of the water so that the metal impurities in the water can be guaranteed to be sufficiently adsorbed by the magnetic bar. The filter screen filters out non-metal impurities in the water. An exhaust valve provided at the top of the protective bushing balances air pressure inside the filter and outside the filter, such that the water can flow out and in smoothly.

Owner:SHAO MEIJU

Mixing valve

InactiveCN108180302AAvoid easy cloggingSmall sizeValve members for absorbing fluid energyEqualizing valvesRefluxWater discharge

The invention relates to a mixing valve. The mixing valve comprises a valve body housing, wherein transverse two sides of the valve body housing are separately equipped with a left side connecting cover and a right side connecting cover; a water inlet connecting tube is arranged on the left side connecting tube; a ring-shaped water return tube is arranged on the outer wall of the water inlet connecting tube; one axial end of the water return tube is equipped with a sealed structure and the other end of the water return tube is provided with an opening structure; the end part of the water inletconnecting tube is further equipped with a water reflux tube; the outer wall of the water reflux tube is in sleeve connection to the inner part of the water return tube through the inner wall of thewater return tube; a tapered movable sleeve is arranged on a sealed position of the water reflux tube; one axial end of the movable sleeve is arranged on a tapered guide surface; the ring-shaped sidewall surface of the movable sleeve is in sliding connection with the sealed end of the water reflux tube; a water exhaust tube is further arranged on the right side connecting cover of the valve bodyhousing; a water discharge cover which is of a gradual reducing structure is connected on the water exhaust tube; a reducing end of the water discharge cover is connected with the water exhaust tube;the water exhaust tube is fixed with the movable sleeve; and a supporting spring is arranged between the water discharge cover and the water reflux tube.

Owner:NANJING CHUQING ELECTRONICS TECH CO LTD

a restrictor valve

ActiveCN108374918BAvoid easy cloggingReduce flow rateValve members for absorbing fluid energyEqualizing valvesMechanical engineeringMechanics

The invention relates to a flow-limiting valve which comprises a valve body shell. A water inlet connecting pipe is arranged on the left side of the valve body shell, an annular return water pipe is arranged on the outer wall of the water inlet connecting pipe, a reflux water pipe is further arranged at the end of the water inlet connecting pipe, the outer wall of the reflux water pipe is in sleeve connection with the inside of the return water pipe through the inner wall of the return water pipe, a conical reflux plate is arranged inside the reflux water pipe and connected in the middle of the reflux water pipe through an annular elastic supporting ring, a drain pipe is arranged on a right connecting cover of the valve body shell, a drain cover with a convergent structure is connected onto the drain pipe, a necking end of the drain cover is connected with the drain pipe, the drain pipe is connected onto the annular inner wall of a movable sleeve through a plurality of connecting rods,the conical back of the reflux plate is connected onto the drain pipe through a plurality of elastic connecting rods, a plurality of supporting spring pieces are annularly arrayed on the outer wall of the reflux water pipe, and a plurality of supporting rods are annularly arrayed on the drain cover and contact with the supporting spring pieces.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Fuel-cell unit cell

ActiveUS10164281B2Preventing excessive concentration of compressive forceImprove discharge efficiencyCollectors/separatorsFuel cellsEngineering

A fuel-cell unit cell comprises: a membrane electrode and gas diffusion layer assembly; a cathode-side separator made of a press-molded plate, the cathode-side separator forming a plurality of cathode gas flow paths and non-flow-path portions therebetween on a cathode-side surface of the membrane electrode and gas diffusion layer assembly; and an anode-side separator made of a press-molded plate, the anode-side separator forming a plurality of anode gas flow paths and non-flow-path portions therebetween on an anode-side surface of the membrane electrode and gas diffusion layer assembly. At least one gas flow path among the plural cathode gas flow paths and the plural anode gas flow paths includes a constricting portion that is configured to reduce a flow-path height in a stacking direction of the fuel-cell unit cells as well as to reduce a flow path cross-sectional area of the gas flow path. When projected and observed along the stacking direction, the plural cathode gas flow paths and the plural anode gas flow paths are configured to have mutually different two-dimensional shapes, there exist intersect positions at which the cathode gas flow paths and the anode gas flow path intersect each other, and the constricting portion is provided at a position other than the intersect positions.

Owner:TOYOTA JIDOSHA KK

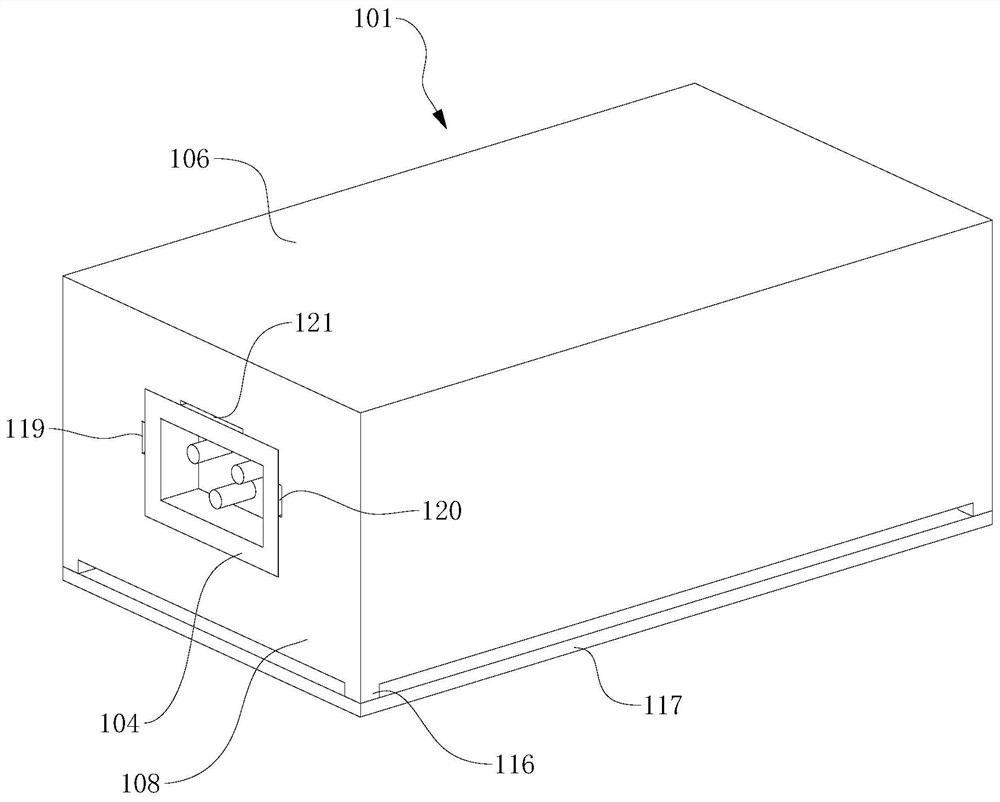

Charger with heat dissipation mechanism

PendingCN114069787AImprove cooling efficiencyExtended service lifeBatteries circuit arrangementsModifications for power electronicsThermodynamicsEngineering

The invention provides a charger with a heat dissipation mechanism. The charger comprises a shell, a PCB, an electronic component, a charging interface and a power line. The charger with the heat dissipation mechanism further comprises the heat dissipation mechanism, the heat dissipation mechanism comprises an electric fan, an air inlet and an air outlet, the electric fan is located in the shell and electrically connected with a circuit on the PCB, the PCB is horizontally arranged, the electric fan is located between the PCB and the bottom plate, and a shell of the electric fan is fixedly connected with the upper surface of the bottom plate. The air inlet is formed in the front end plate, penetrates through the front end plate and is located between the PCB and the top plate; the exhaust port is formed in the bottom plate and penetrates through the bottom plate, an air outlet of the electric fan faces the exhaust port, and an air inlet of the electric fan is communicated with the space between the PCB and the bottom plate; and a gap is formed between the edge of the PCB and the inner wall of the shell. Compared with a charger in the prior art, the charger with the heat dissipation mechanism is higher in heat dissipation efficiency.

Owner:天长市天越电子有限公司

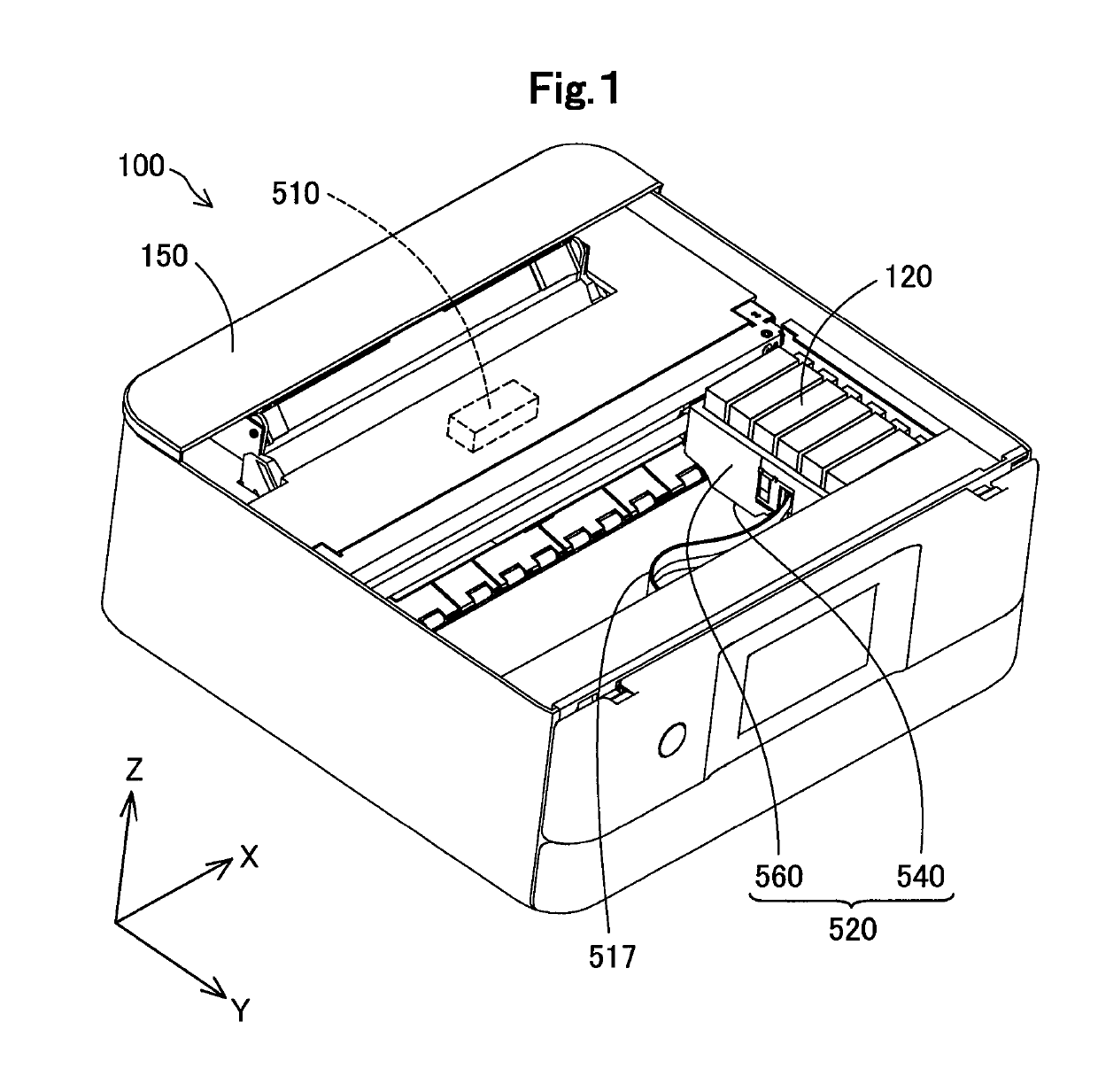

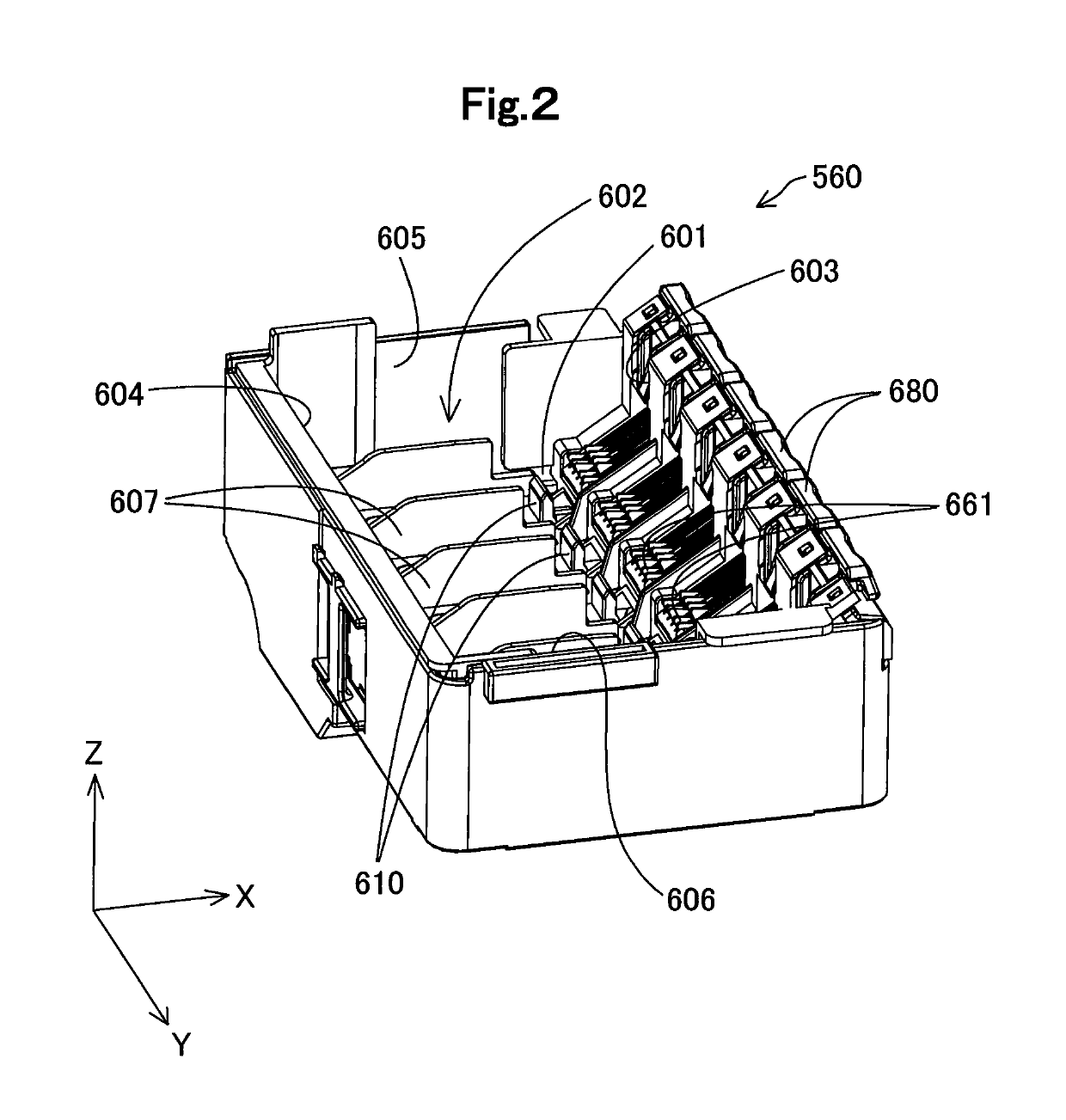

Liquid container

Owner:SEIKO EPSON CORP

Scroll type electrostatic precipitator and air conditioning apparatus having the same

ActiveUS10556241B2Improve collection efficiencyExtend the length of the flow pathElectrode carrying meansMechanical apparatusAir conditioningMaterials science

An electrostatic precipitator is provided. The electrostatic precipitator includes an electrode part including a high voltage electrode with voltage applied thereto and a ground electrode coiled in a circumferential direction along with the high voltage electrode while being spaced apart from the high voltage electrode, and a plurality of turning flow paths inclined with respect to an axial direction of the electrode part between the high voltage electrode and the ground electrode.

Owner:SAMSUNG ELECTRONICS CO LTD

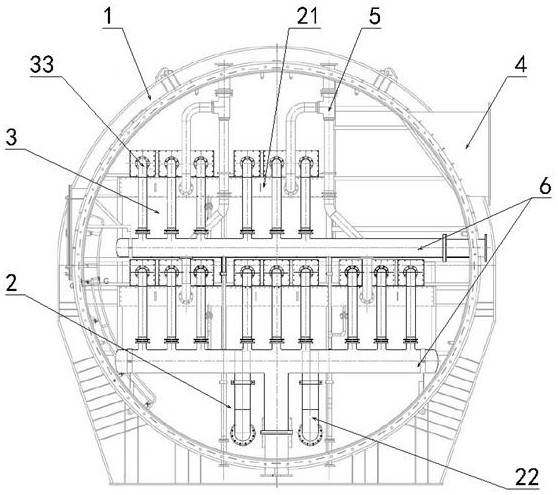

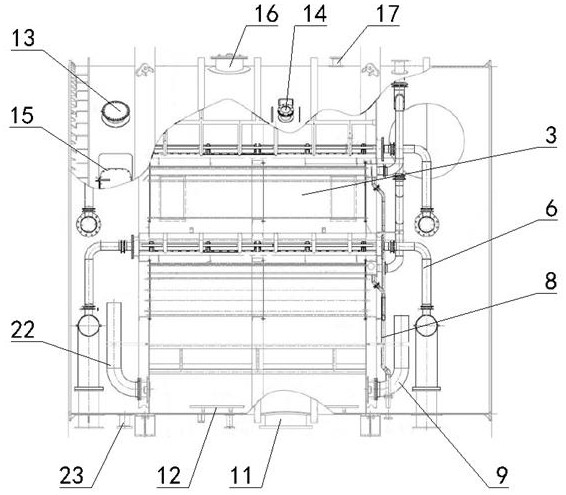

Falling film condenser of low-temperature multi-effect distillation seawater desalination system

ActiveCN114804266AExtend the length of the flow pathIncrease the heat exchange areaGeneral water supply conservationSeawater treatmentThermodynamicsEngineering

The invention relates to the technical field of seawater desalination, and provides a falling film condenser of a low-temperature multi-effect distillation seawater desalination system, a heat exchange tube support frame is arranged in a condenser shell, five groups of water chambers are arranged on the heat exchange tube support frame, and the water chambers are divided into two layers, two groups of upper layers and three groups of lower layers; the water chamber comprises a first channel heat exchange tube bundle set, a second channel heat exchange tube bundle set and a spraying tube bundle, the first channel heat exchange tube bundle set and the second channel heat exchange tube bundle set comprise a plurality of heat exchange tube bundles, the first channel heat exchange tube bundle set is arranged on the lower side of the second channel heat exchange tube bundle set, and the spraying tube bundle is arranged on the upper side of the second channel heat exchange tube bundle set. According to the heat exchange tube bundle assembly, the problems that in a conventional design, a heat exchange tube bundle is small in heat exchange area, low in waste heat recovery rate, tedious in leakage inspection and replacement, extremely prone to scouring and electrochemical corrosion and the like are solved.

Owner:TIANJIN SDIC JINNENG ELECTRIC POWER

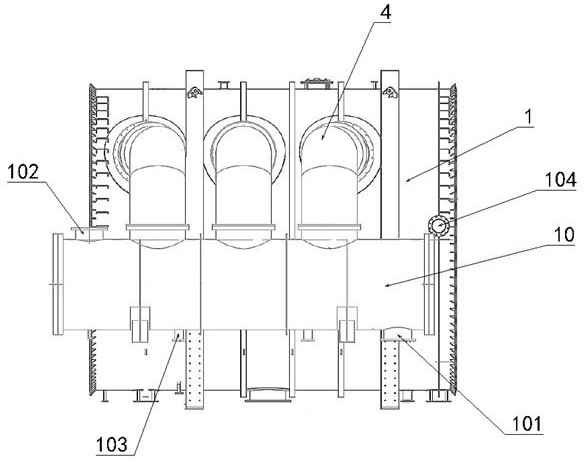

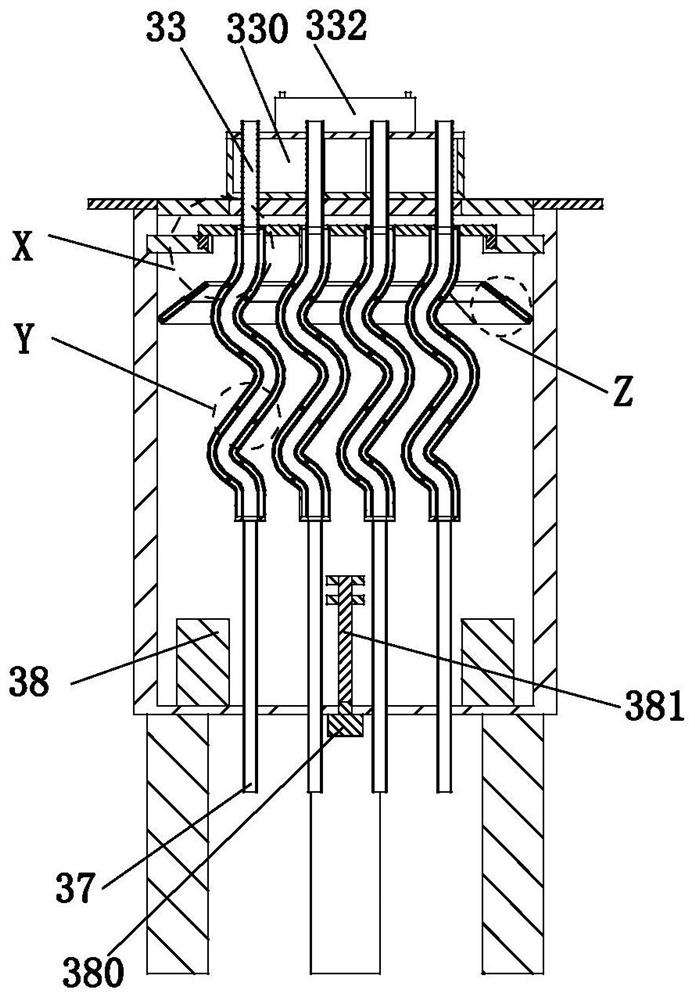

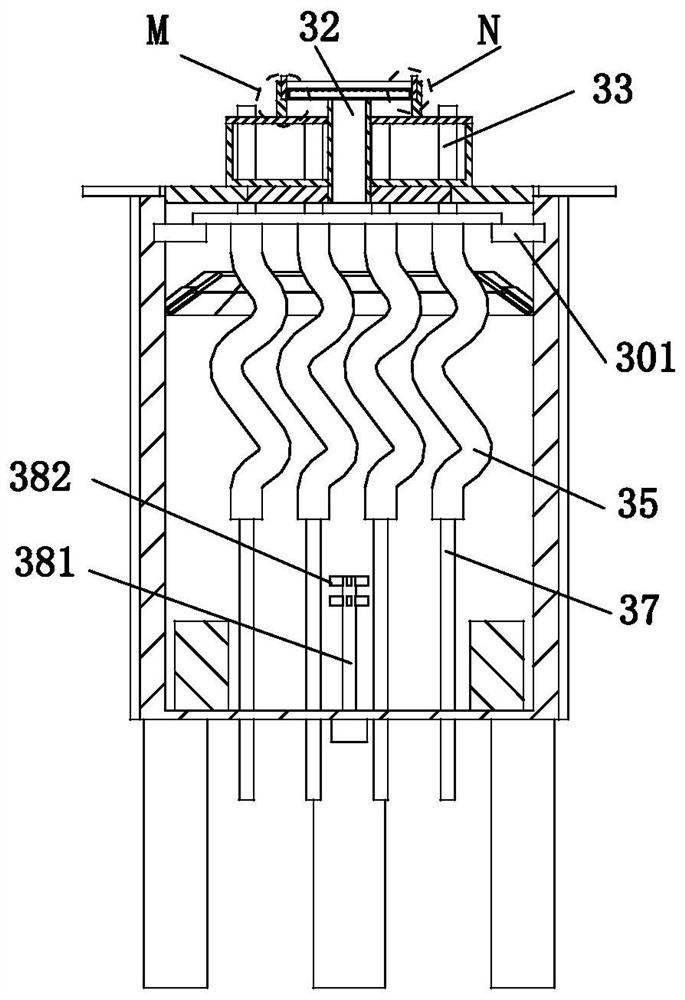

An industrial hydrogen production conversion furnace device

ActiveCN113398864BExtend the length of the flow pathIncrease profitProcess control/regulationHydrogenPtru catalystProcess engineering

The invention relates to an industrial hydrogen production conversion furnace device, comprising a furnace body, a base and a reaction mechanism, the lower end of the furnace body is equipped with a base, the bases are evenly arranged along the circumference of the furnace body, and the lower end of the base is connected to the existing ground , The upper end of the furnace body is provided with a reaction mechanism. The present invention adopts a combined design concept for industrial hydrogen production. The whole device adopts a flexible connection structure to facilitate disassembly and cleaning work quickly, which in turn facilitates regular maintenance and cleaning of the device. At the same time, the structure of the reaction between the raw material gas and the catalyst adopts an S-shaped structure, which can increase the length of the flow path of the raw material gas, so that the contact and reaction between the raw material gas and the catalyst are more sufficient, thereby increasing the production of hydrogen. output and improve the utilization rate of raw gas.

Owner:西安旭旌再生资源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com