A method of heat dissipation and cooling for high heat density cabinets in data centers

A technology for heat dissipation and cooling, data center, applied in cooling/ventilation/heating renovation, electrical components, electrical equipment structural parts, etc. problems, to achieve the best effect of shifting peaks and filling valleys, increasing the temperature difference of cold storage, and reducing the energy consumption of airflow transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

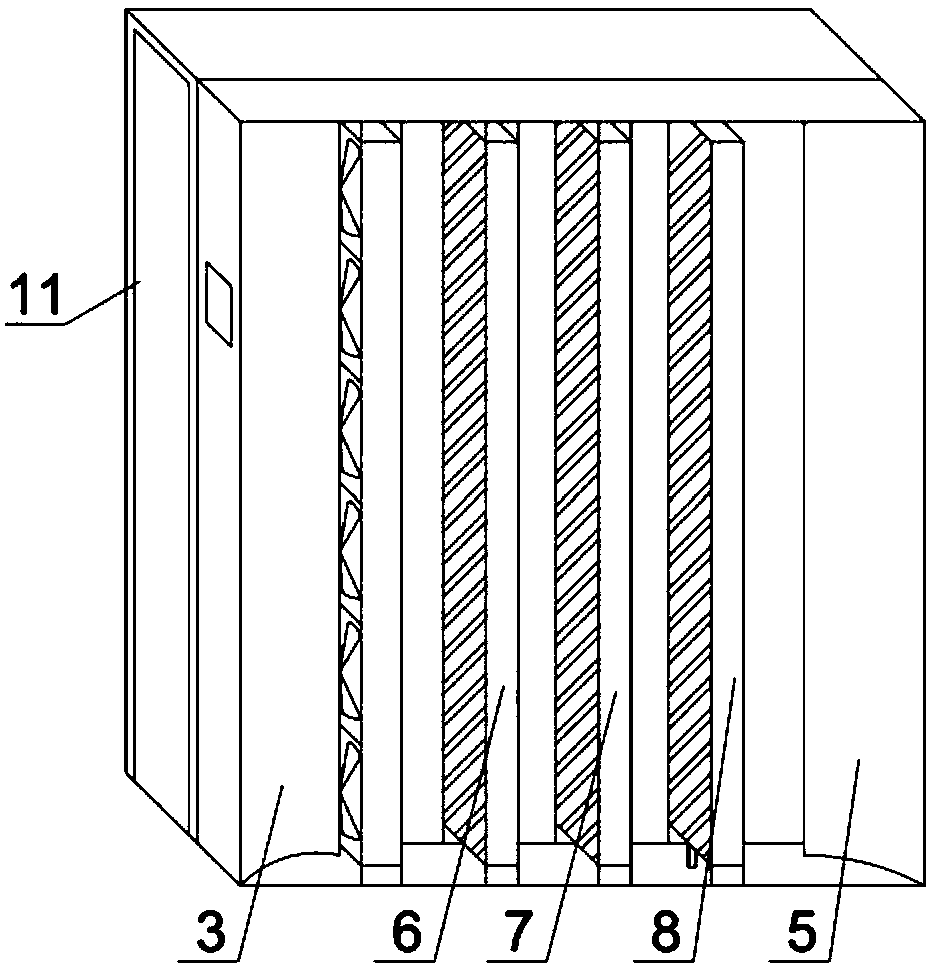

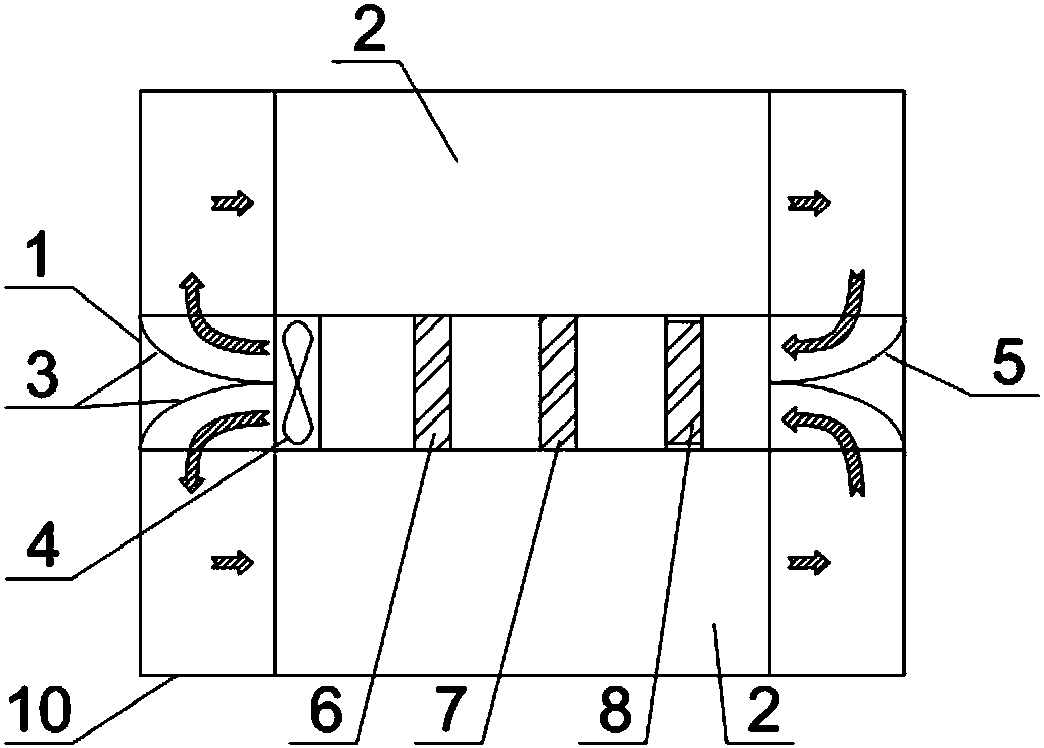

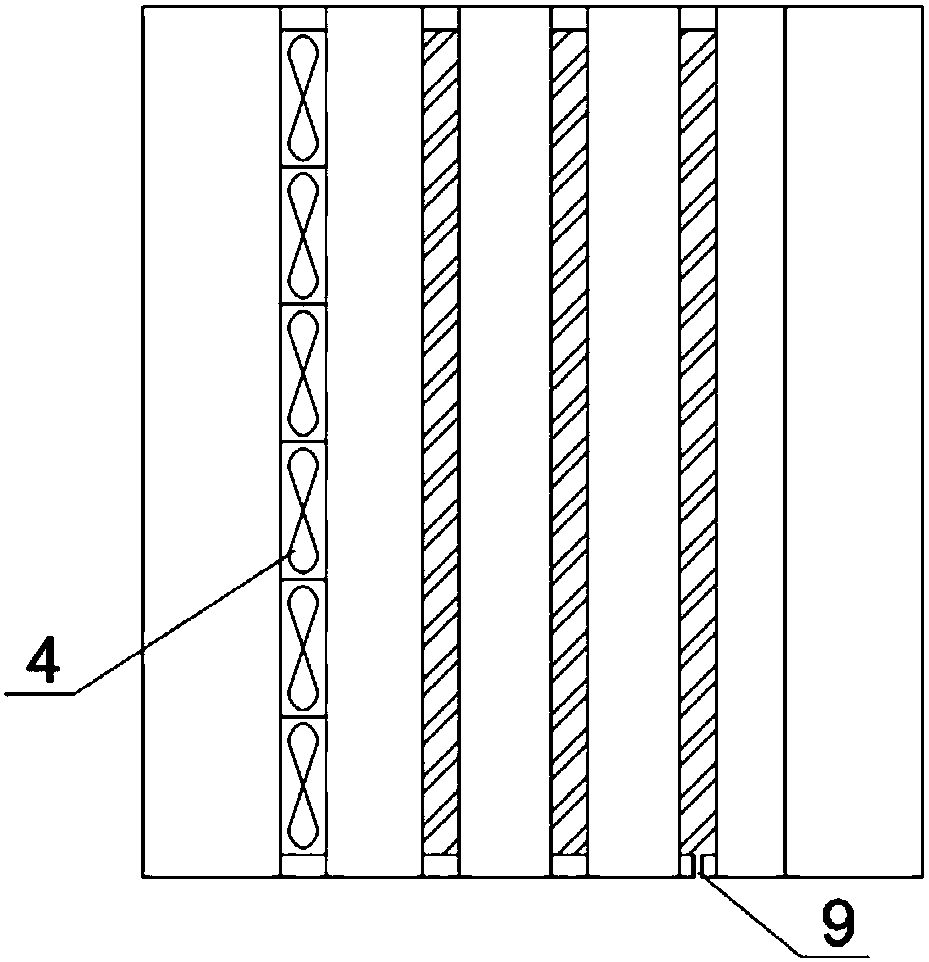

[0041] refer to Figure 1 to Figure 8 , figure 2 and Figure 5 The arrows show the path of the supply air flow, Figure 7 and Figure 8 Arrows show the direction of water flow. A large temperature difference air conditioner terminal device and heat dissipation cooling method for high heat density cabinets in a data center. The large temperature difference air conditioner terminal device used for cooling the cabinet and the cooled cabinet 2 are packaged in a structure 10 that is isolated from the environment of the machine room. To prevent heat transfer between the internal space of the building 10 and the external computer room environment, the large temperature difference air-conditioning terminal device used for cooling the cabinet is installed on one side of the cooled cabinet 2, or the large temperature difference air-conditioning terminal device used for cabinet cooling is installed on both sides of the cooled cabinet. between cooling cabinets;

[0042] The large te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com