Construction method for backfilling of underground foundation pit excavation soil

A technology of backfilling and construction method, applied in filling, soil protection, infrastructure engineering and other directions, can solve the problems of high excavation and filling cost, long cycle, large excavation and filling transportation volume, etc., achieving good social and economic benefits and shortening excavation and filling. Filling time and cost, ensuring the effect of dense quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

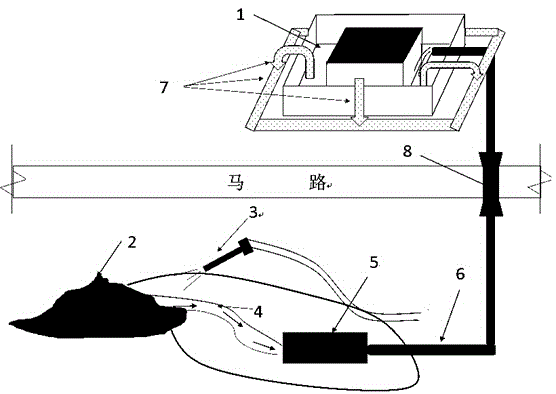

[0025] A construction method for backfilling excavated earth in an underground foundation pit. The method is to sort and accumulate temporary excavated earth on the ground near the deep foundation pit 1 on the site where the original deep foundation pit 1 was excavated, and then use the filling process to remove the excavated earth The soil is returned to the original deep foundation pit 1 in the form of mud. During the backfilling process, the backfilled soil is compacted by drainage, and the same layer of soil is balanced and regulated, so that it is backfilled layer by layer until the floor elevation controlled by the design So far; the specific steps of the backfill construction method are as follows:

[0026] The first step is to select the excavated soil storage site: select several temporary excavated soil storage sites 2 near the deep foundation pit 1;

[0027] The second step, excavation and excavation soil stacking: excavation of deep foundation pit earthwork, excava...

Embodiment 2

[0033] In this embodiment, on the basis of Example 1, when the excavation soil storage site 2 is selected in the first step, the excavation soil storage site is arranged at the diagonal of the deep foundation pit 1, thereby shortening the conveying distance of the mud and improving the filling efficiency; In addition, in order to ensure that the excavated soil is not easy to collapse, the excavated soil can be piled up to a height of 3-4m.

Embodiment 3

[0035] In this embodiment, on the basis of Embodiment 1, when the backfill system is preset in the third part, the mud conveying pipeline 6 adopts a rubber mud pipe with a diameter of Φ120, and the part of the mud conveying pipeline 6 located on the cement road should be equipped with The plate frame 8 protected by planks strengthens the protection of the mud delivery pipeline 6 and prolongs the service life of the mud delivery pipeline 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com