Falling film condenser of low-temperature multi-effect distillation seawater desalination system

A multi-effect distillation and condenser technology, applied in seawater treatment, heating water/sewage treatment, etc., can solve the problems of reducing the heat exchange area, heat exchange efficiency, and heat exchange area of falling film condensers, and achieve an improvement Overall space utilization, increasing the effective heat exchange area, and the effect of increasing the heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

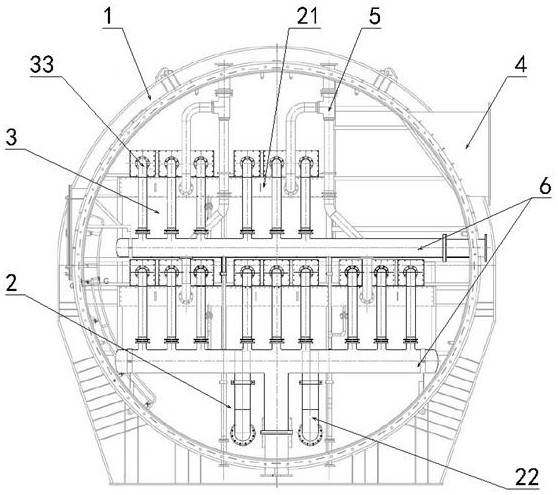

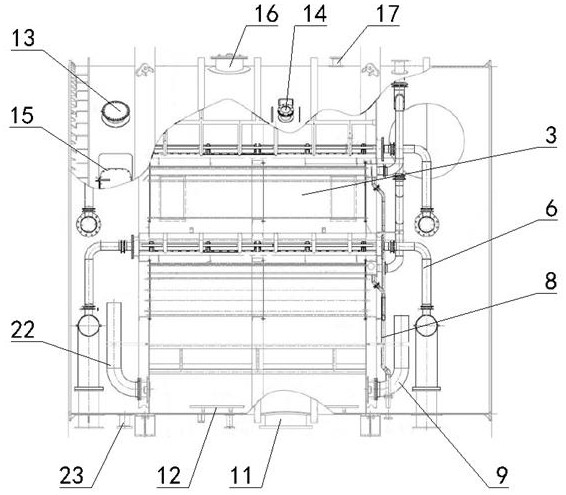

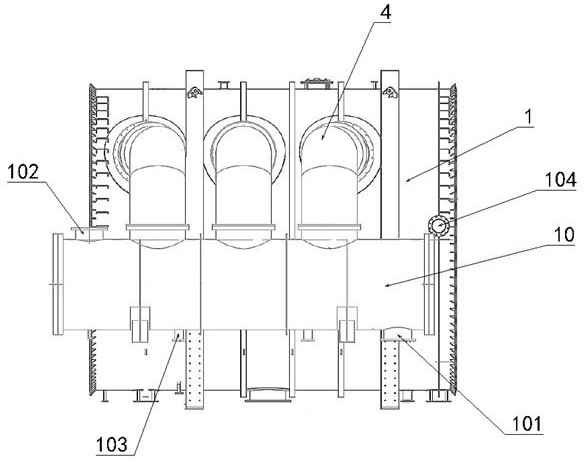

[0035] combine figure 1 and figure 2 Description, a falling film condenser of a low-temperature multi-effect distillation seawater desalination system, comprising: a condenser shell 1, a heat exchange tube support frame 2, a water chamber 3, a shell-side vacuum suction pipeline 4, and a tube-side vacuum suction pipeline 5 and the seawater inlet pipe 6, the heat exchange tube support frame 2 is arranged in the condenser shell 1,

[0036] The water chamber 3 is arranged on the heat exchange tube support frame 2, and the water chamber 3 is provided with five groups, which are divided into two layers, two groups on the upper layer, and three groups on the lower layer. The steam condensation efficiency of the stage-effect evaporator promotes the forward flow of steam in the low-temperature multi-effect seawater desalination system.

[0037] The water chamber 3 includes: a first channel heat exchange tube bundle 31, a second channel heat exchange tube bundle 32 and a spray tube bun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com