Patents

Literature

62results about How to "Improve finished product efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gauze cutting machine enabling good cutting effect

InactiveCN108998950AImprove cleanlinessConvenient for subsequent cutting and storageSevering textilesTextile shapingYarnSprayer

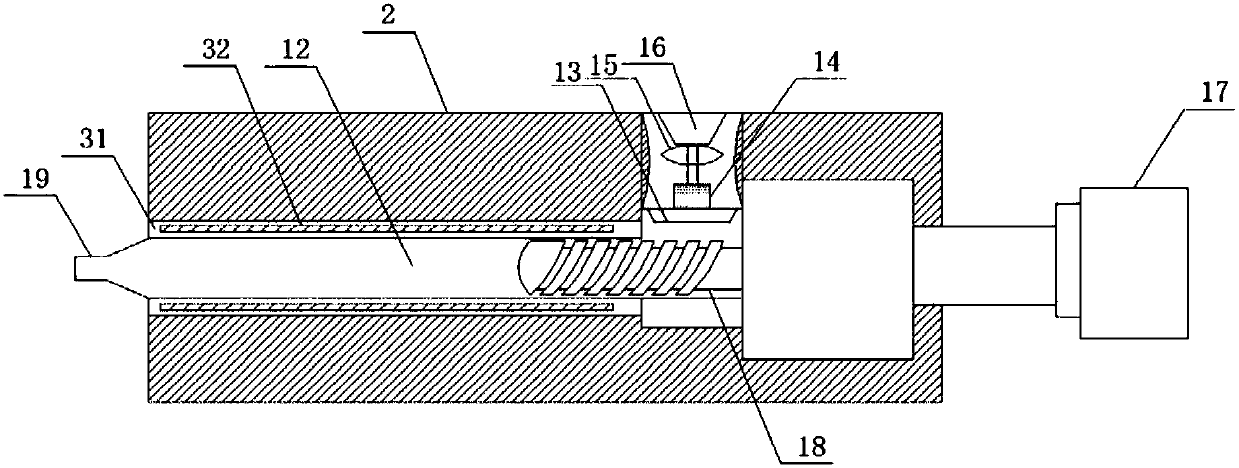

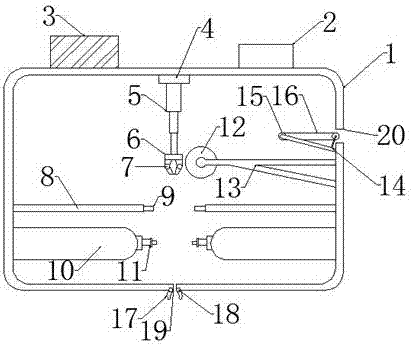

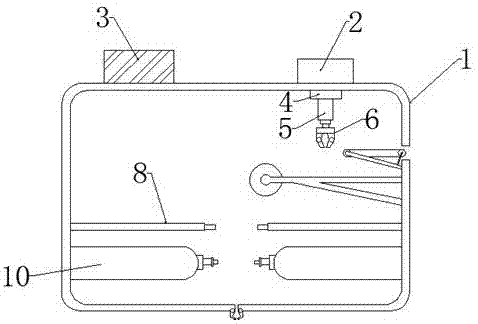

The invention provides a gauze cutting machine enabling a good cutting effect, and belongs to the gauze cutting machine technical field. The gauze cutting machine enabling a good cutting effect comprises a housing; a first cloth roller is fixedly mounted on the left side of the interior of the housing; a water pump is fixedly mounted at the upper part of the interior of the housing; a water tank is fixedly mounted to the right side of the water pump; and a sprayer is fixedly mounted below the water pump. With the gauze cutting machine enabling a good cutting effect adopted, gauze can be quickly dried and flattened; wrinkled gauze can be ironed to be flat, so that subsequent cutting and storage work can be facilitated; the gauze can be disinfected; and the cleanness of the gauze can be improved; the cutting device can perform automatic cutting, so that manpower can be saved; the service life of a blade can be prolonged; the replacement of the blade can facilitated; cutting quality can be improved; a situation that a large number of yarn ends are left and need to be manually removed can be avoided; and the efficiency of the finished product production of gauze can be improved.

Owner:江西美宝利实业有限公司

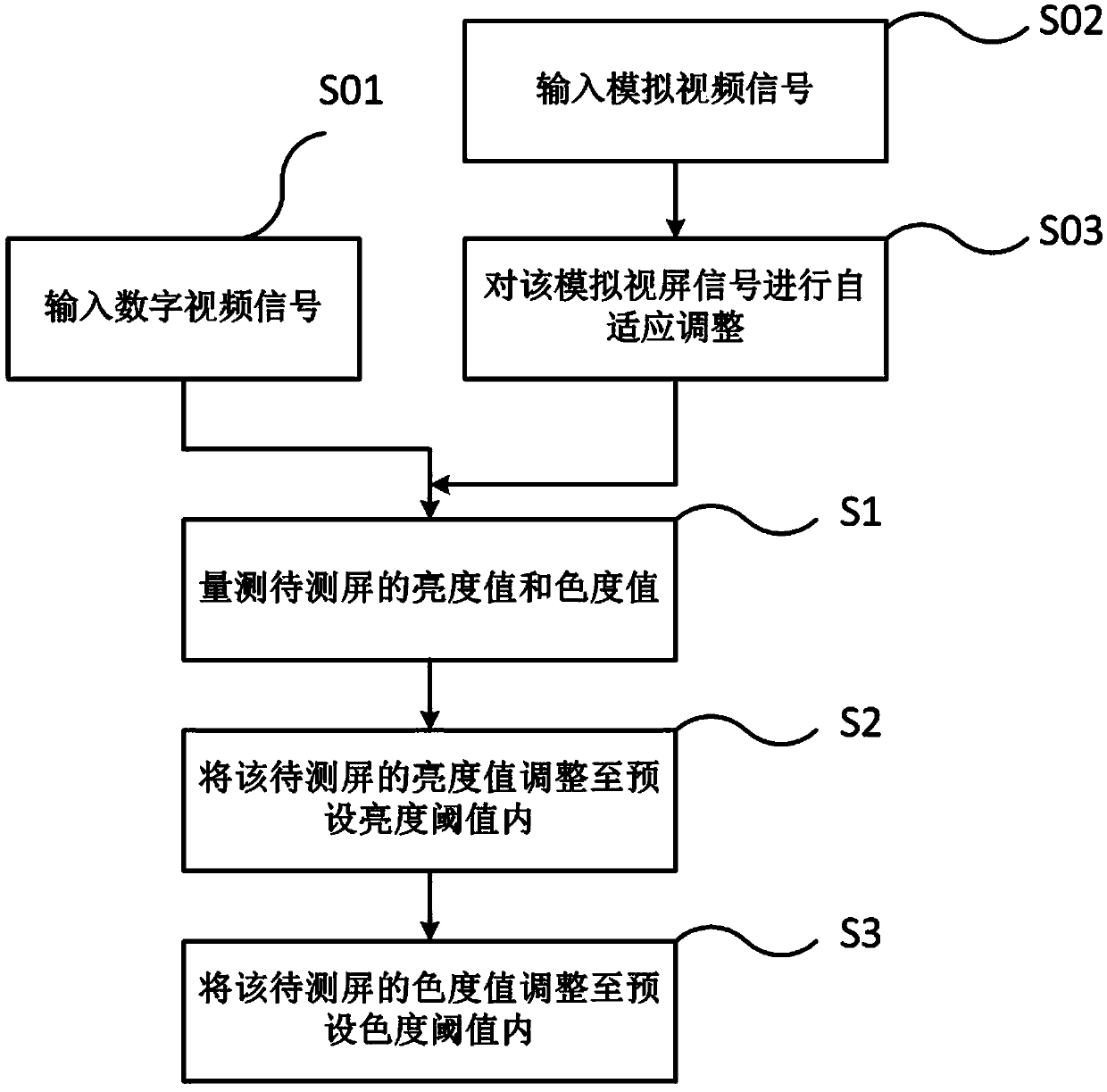

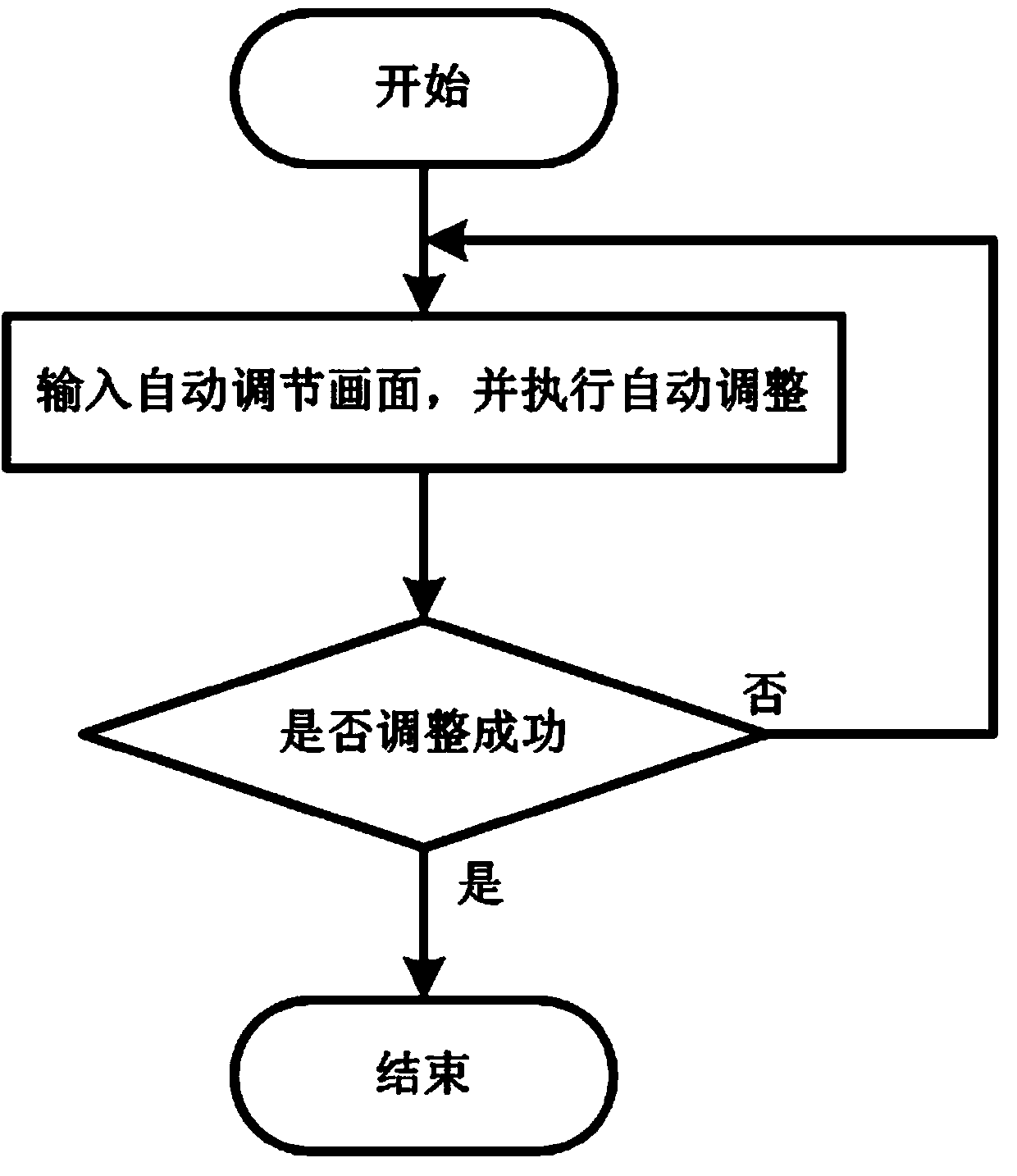

Fast adaptive white balance correction method

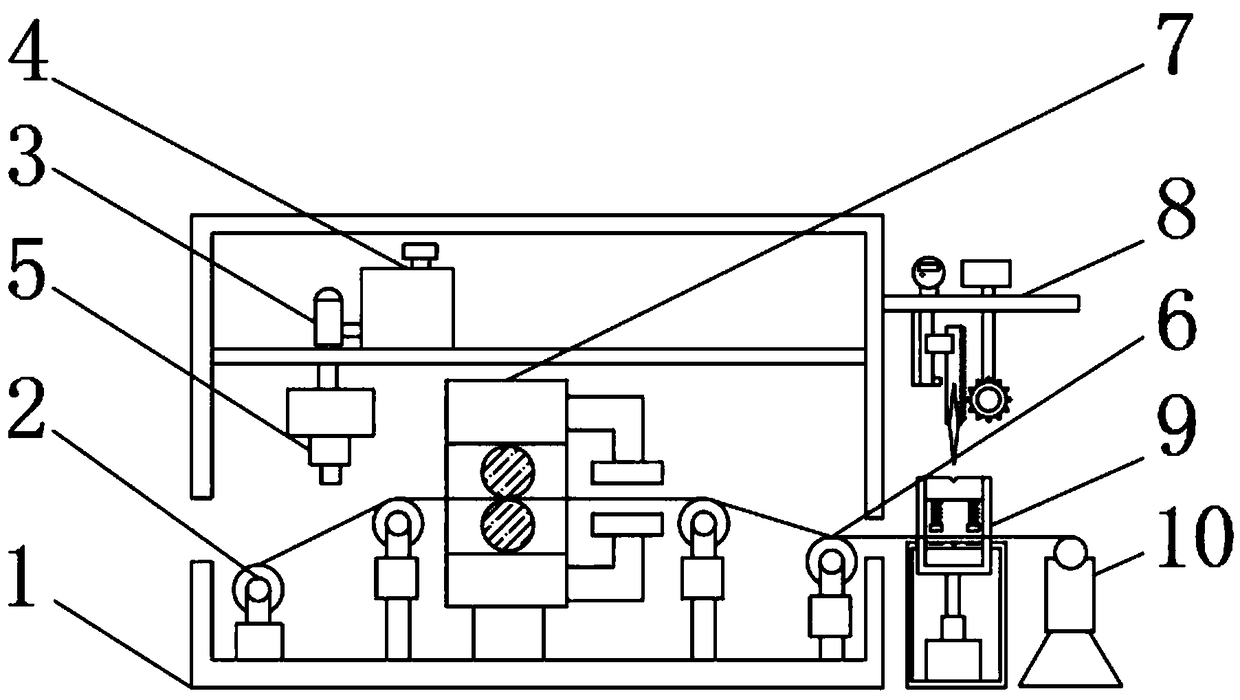

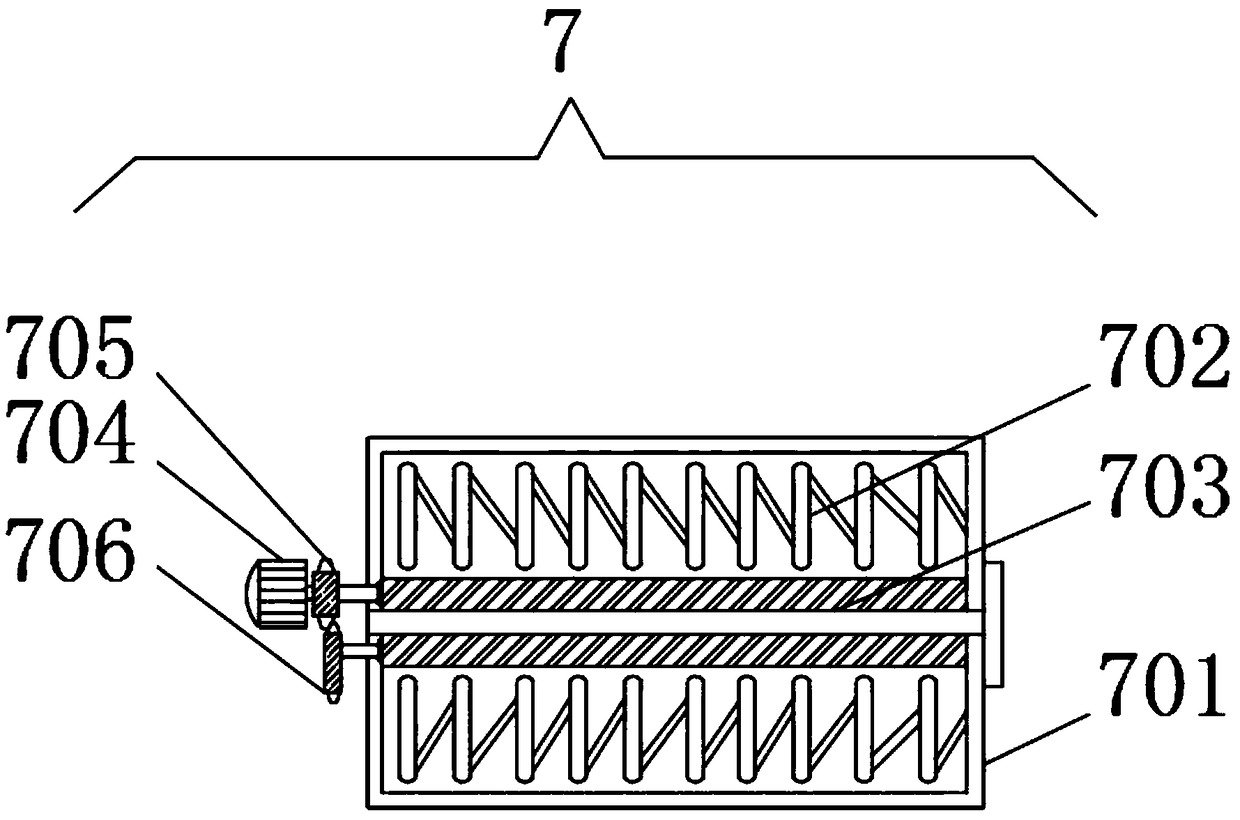

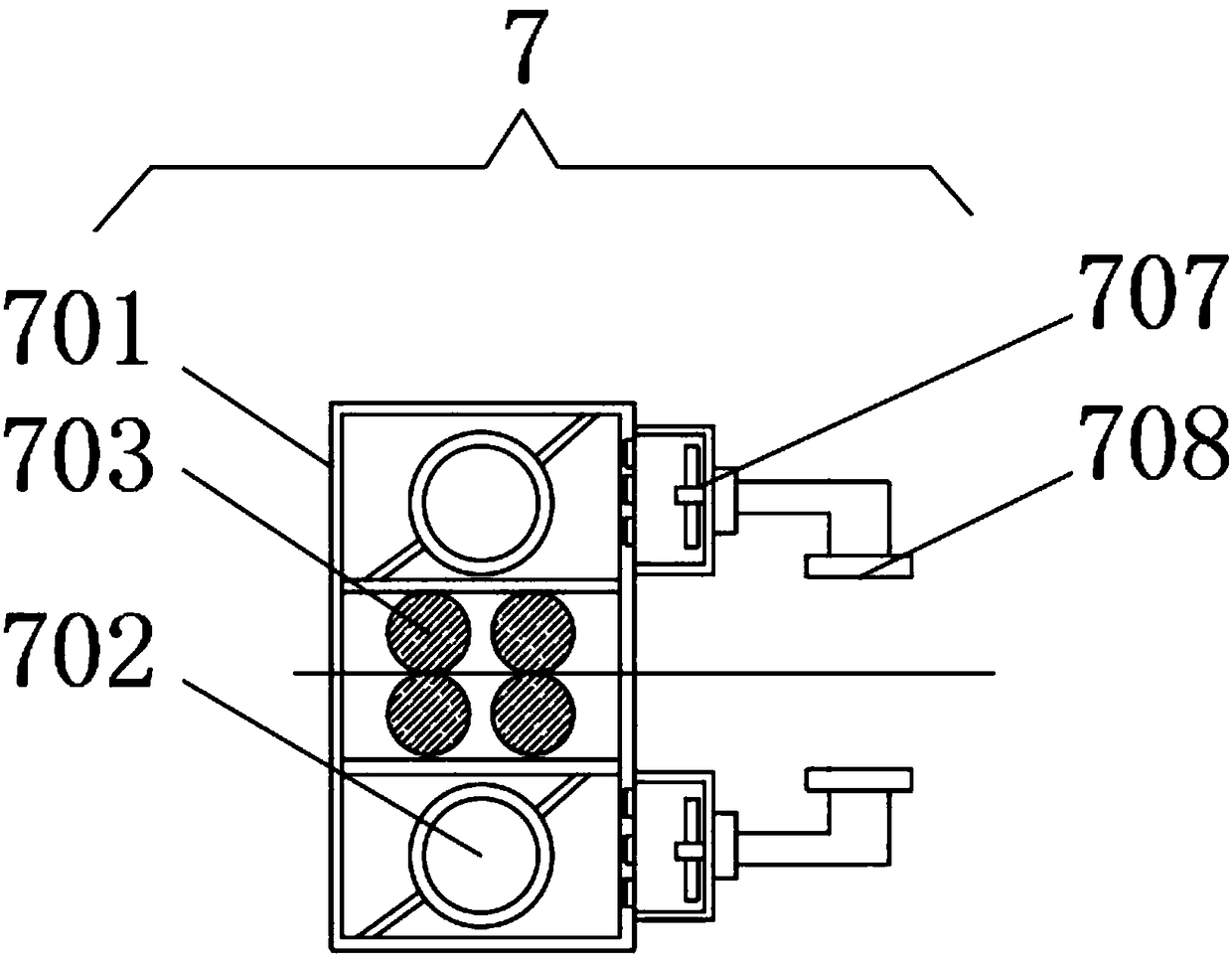

InactiveCN104200791AFast adjustmentImprove finished product efficiencyColor signal processing circuitsCathode-ray tube indicatorsSelf adaptiveComputer science

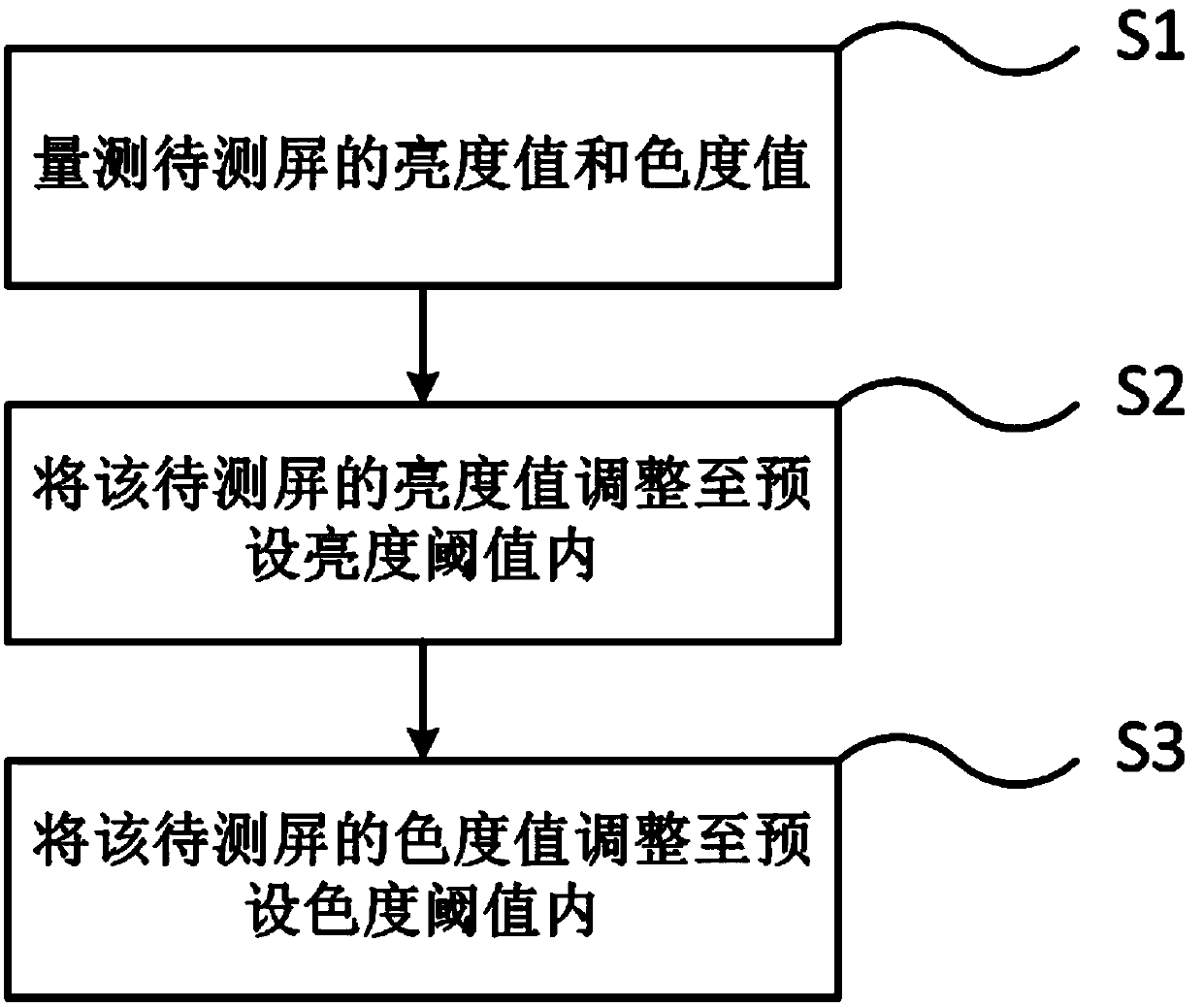

The invention relates to the field of display correction, in particular to a fast adaptive white balance correction method used for correcting the white balance of a display. The method includes measuring a display to be measured, namely measuring a brightness value and chroma value of the display to be measured; correcting the brightness, namely adjusting the brightness of the display to be measured into the range of a preset brightness value; correcting the chroma, namely adjusting the chroma of the display to be measured into the range of a preset chroma value. The adaptive method is adopted, according to the differences of the display, the brightness of the display is adjusted according to the optimal brightness, and the brightness adjusting speed is increased; one to three of a R value, a G value and a B value are adjusted synchronously according to the adjustment requirements, the speed of adjusting the chroma value to the range of the preset chroma value is increased greatly, the adjusting effect adaptive to the display most is achieved in an adaptive manner, the white balance adjusting speed can be increased, the adjusting accuracy and effect are improved, the finishing efficiency of liquid crystal screens is improved, and the producing efficiency is improved.

Owner:SHENZHEN MTC

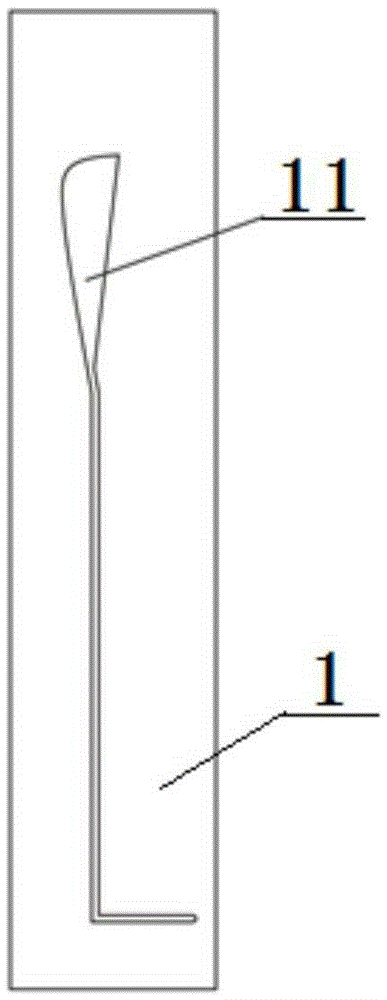

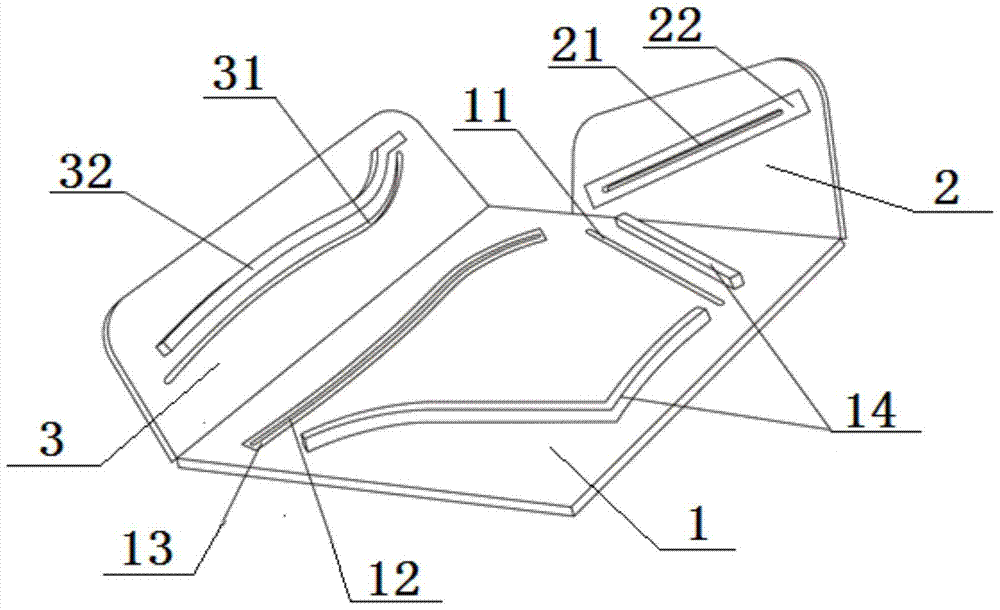

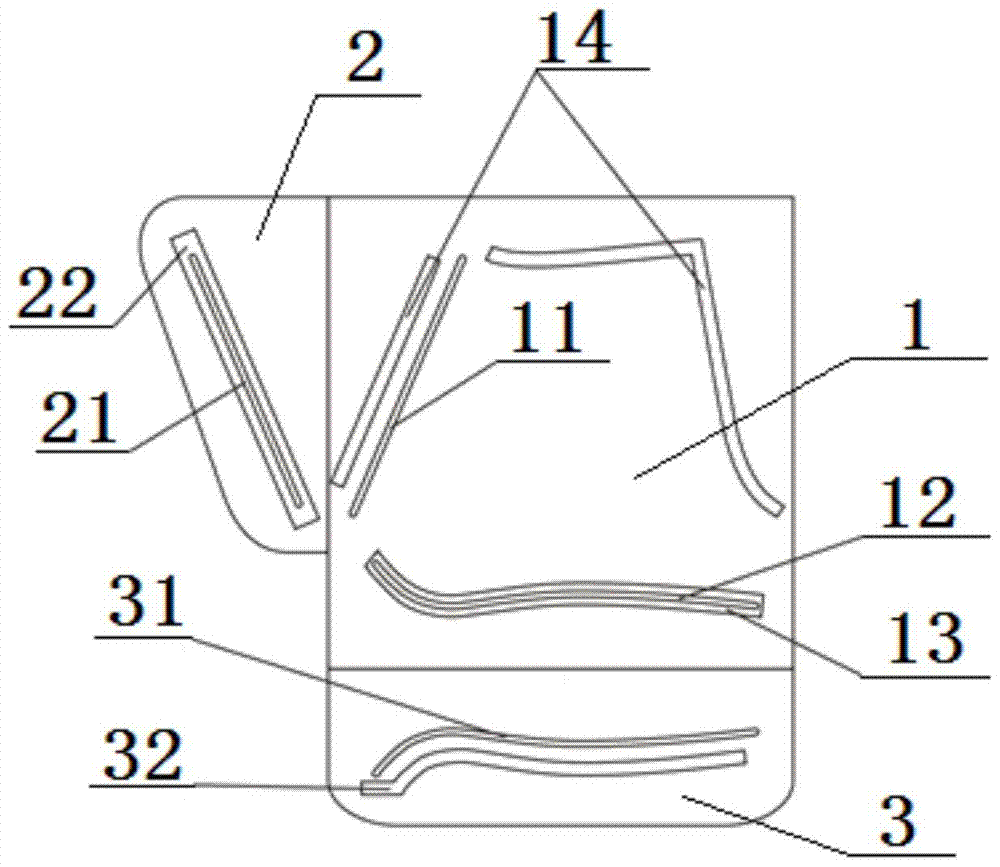

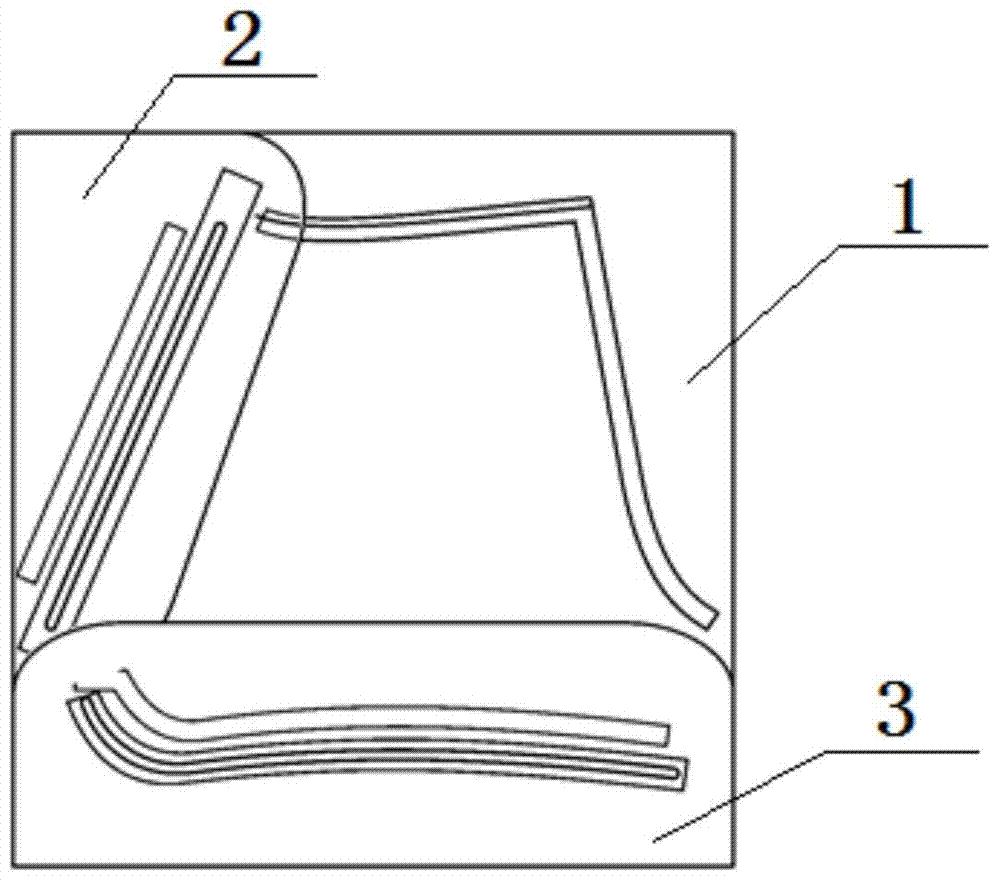

Sewing fixture for sewing suit front part with flap pocket adding with welt to front facing

InactiveCN105350189AShort working hoursEasy to operateWork-feeding meansClothes making applicancesWaste productEngineering

Owner:盛楠

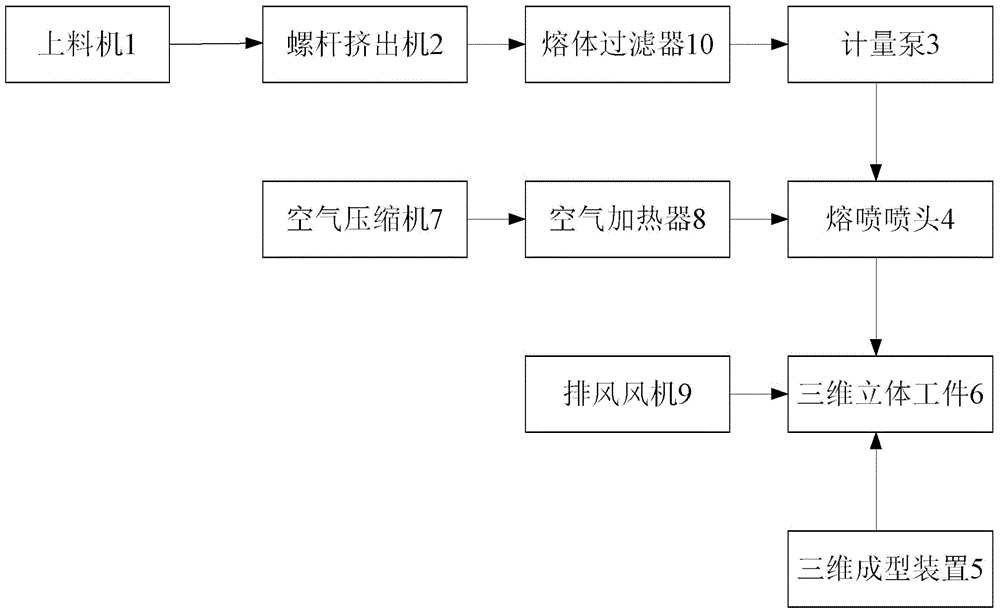

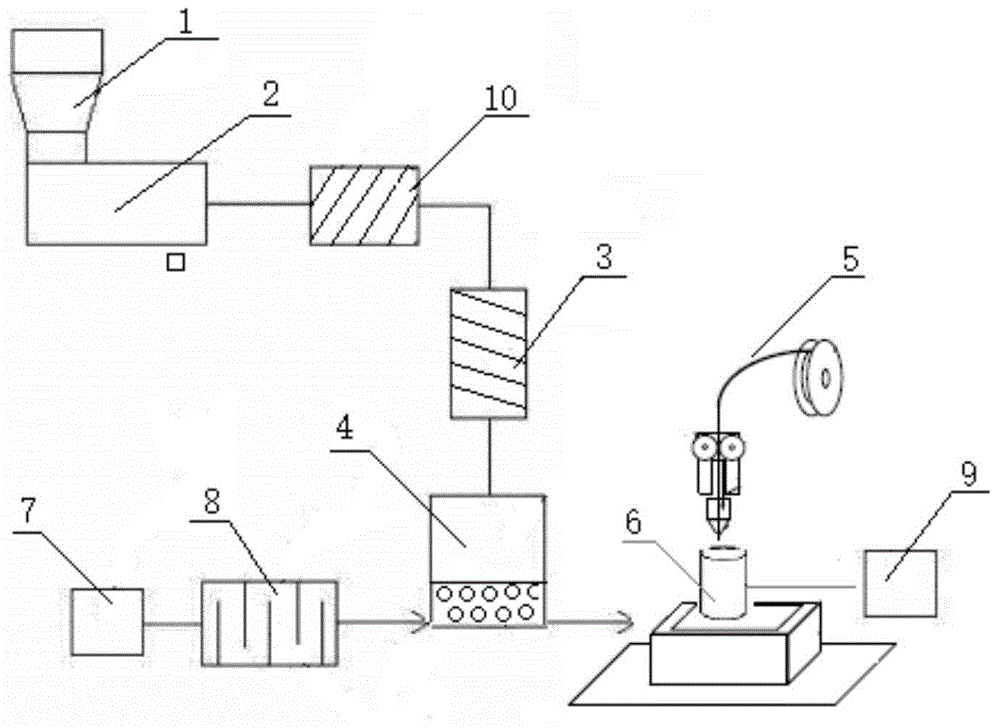

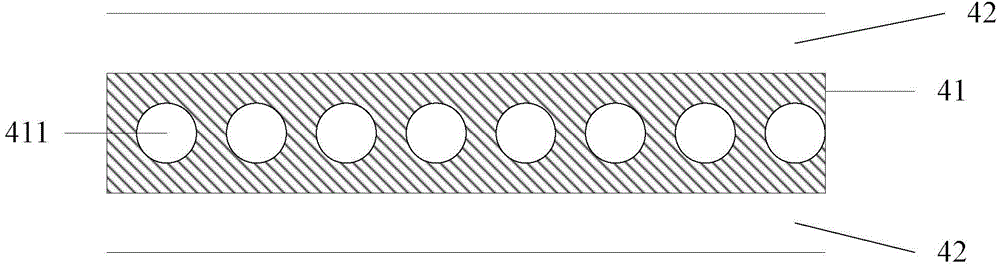

Three-dimensional flexible material molding system and method

ActiveCN104149338AEasy to printRealize production and processingAdditive manufacturing apparatusAdditive manufacturing with liquidsAir compressorMelt blowing

The invention provides a three-dimensional flexible material molding system and a three-dimensional flexible material molding method. The system comprises a feeder, a screw extruder, a metering pump, an air compressor, an air heater, a three-dimensional molding device, a melt-blowing nozzle and a solidification molding device, wherein the feeder is used for feeding molten polymers; the screw extruder is used for extruding the molten polymers; the metering pump is used for controlling the number of the molten polymers flowing into the melt-blowing nozzle; the air compressor is used for compressing air; the air heater is used for heating the compressed air; the three-dimensional molding device is used for processing and molding a three-dimensional workpiece for supporting a flexible material; the melt-blowing nozzle comprises a spinneret plate communicated with the metering pump and an air flow hole communicated with the air heater; a melt hole is formed in the spinneret plate; thin molten polymer flows are blown to the three-dimensional workpiece and are drawn into melt-blowing fibers through the air flow hole to be agglomerated on the three-dimensional workpiece; the solidification molding device is communicated with the three-dimensional workpiece and is used for solidifying the melt-blowing fibers agglomerated on the three-dimensional workpiece to generate the flexible material. According to the system and the method, the flexible material can be conveniently and quickly printed.

Owner:INVENTECSHANGHAI TECH +2

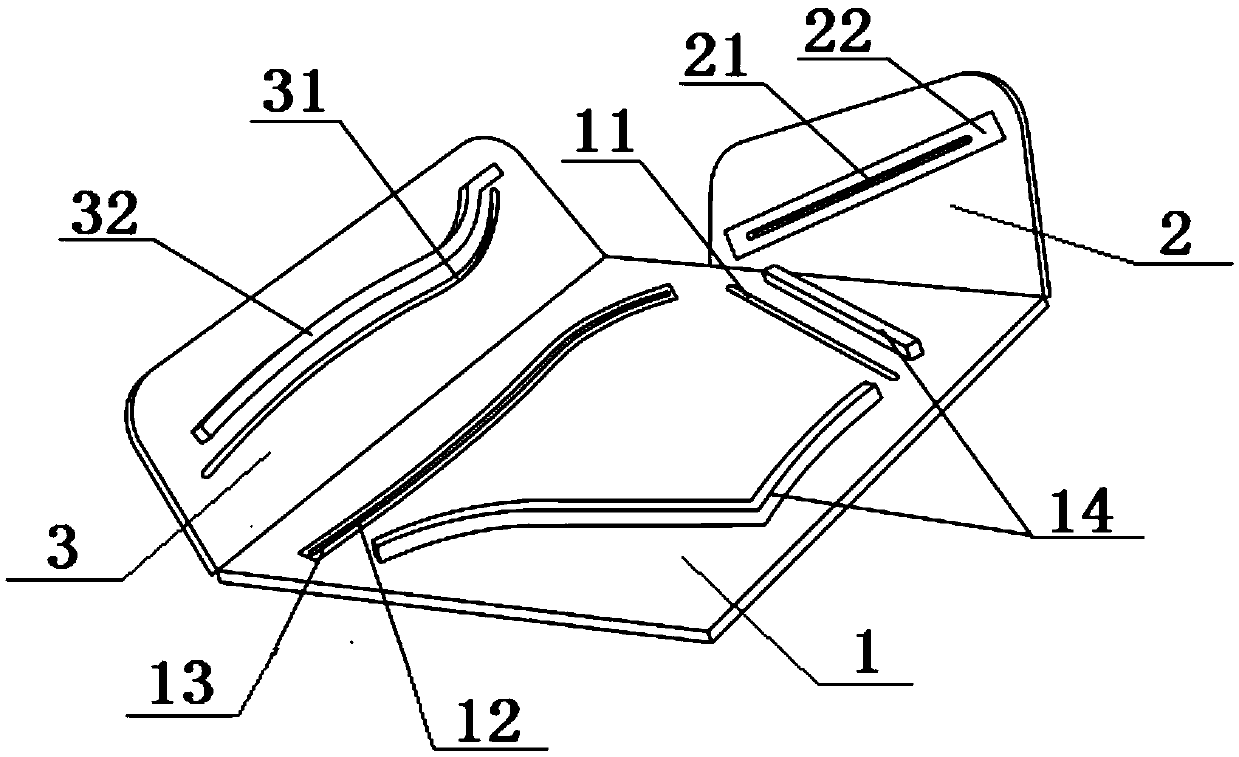

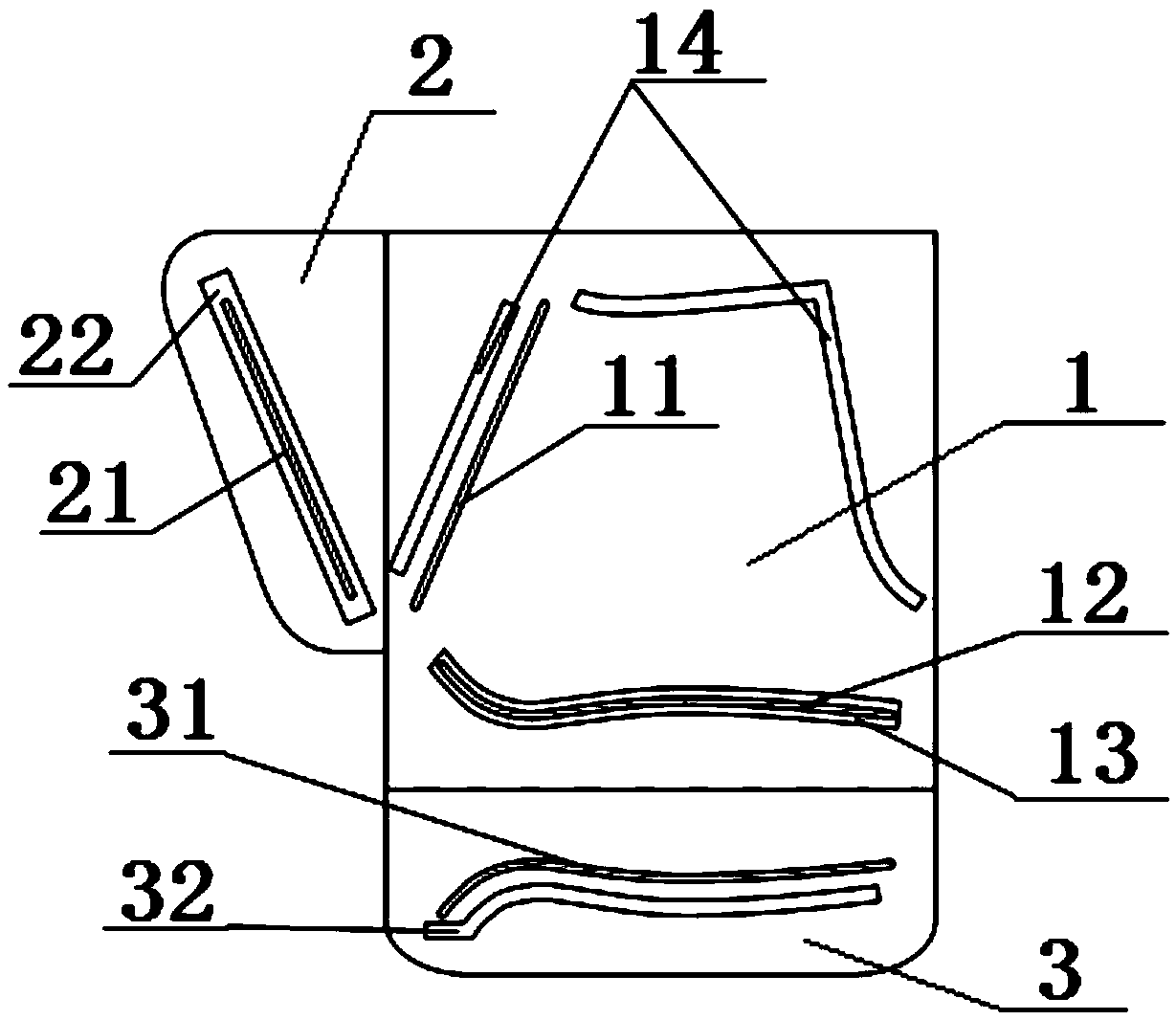

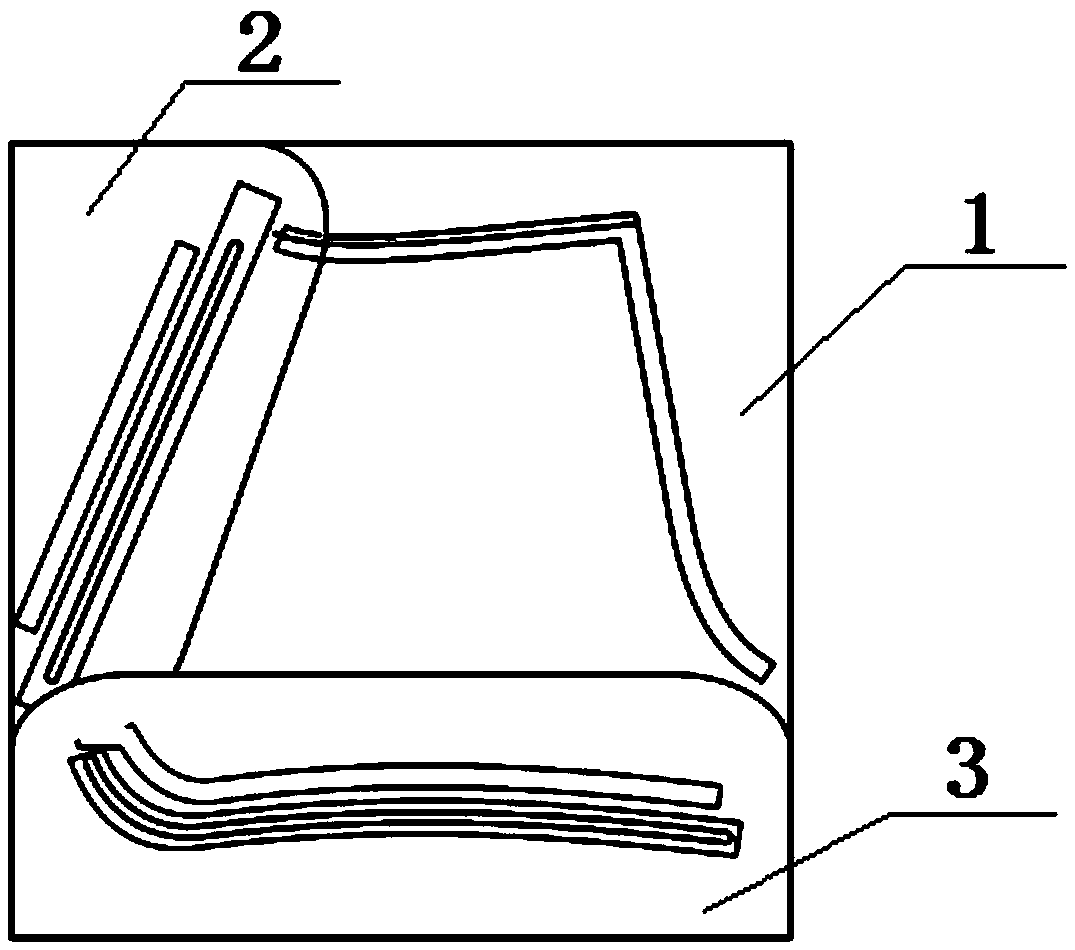

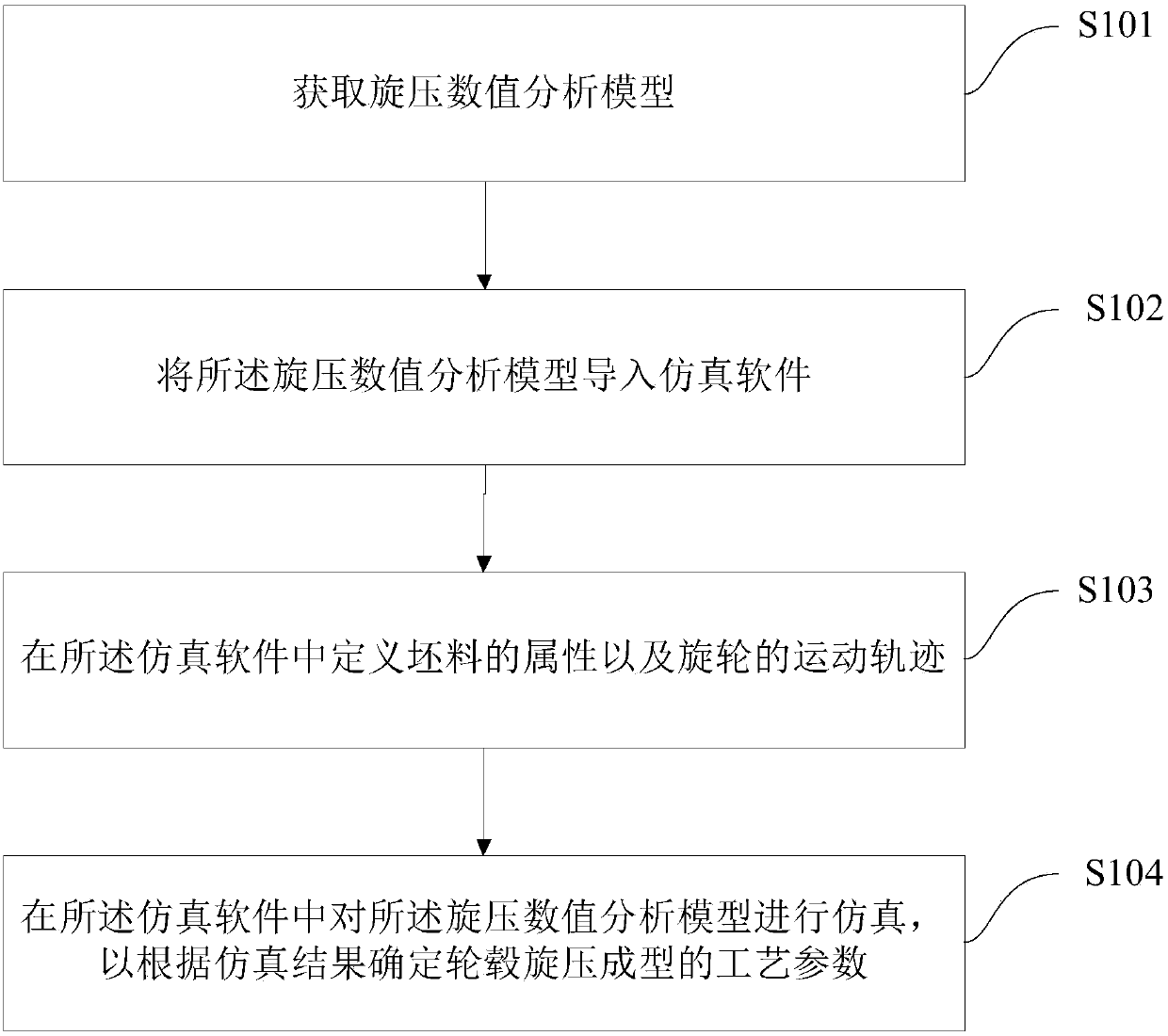

Spinning forming numerical analysis method and system

InactiveCN107895057ASolve technical problemsPrecise spinning process parametersDesign optimisation/simulationSpecial data processing applicationsEngineeringProduct defect

The invention discloses a spinning forming numerical analysis method and system. The method includes the following steps of acquiring a spinning numerical analysis model; importing the spinning numerical analysis model into a simulation software; defining the attribution of blank and motion curve of spinning wheels; simulating the spinning numerical analysis model in the simulation software to determine a technological parameter of the wheel hub spinning forming according to the simulation results. The method can provide accurate and reliable the wheel hub spinning forming technological parameter for the wheel hub spinning forming, and accordingly improves the matters that in the process of the wheel hub spinning forming, high reject rate, double heating, product defect and the like causedby high-strength materials characters are improved, and the rate of finished products of the wheel hubs and the efficiency of the finished products are improved.

Owner:BORGWARD AUTOMOTIVE CHINA CO LTD

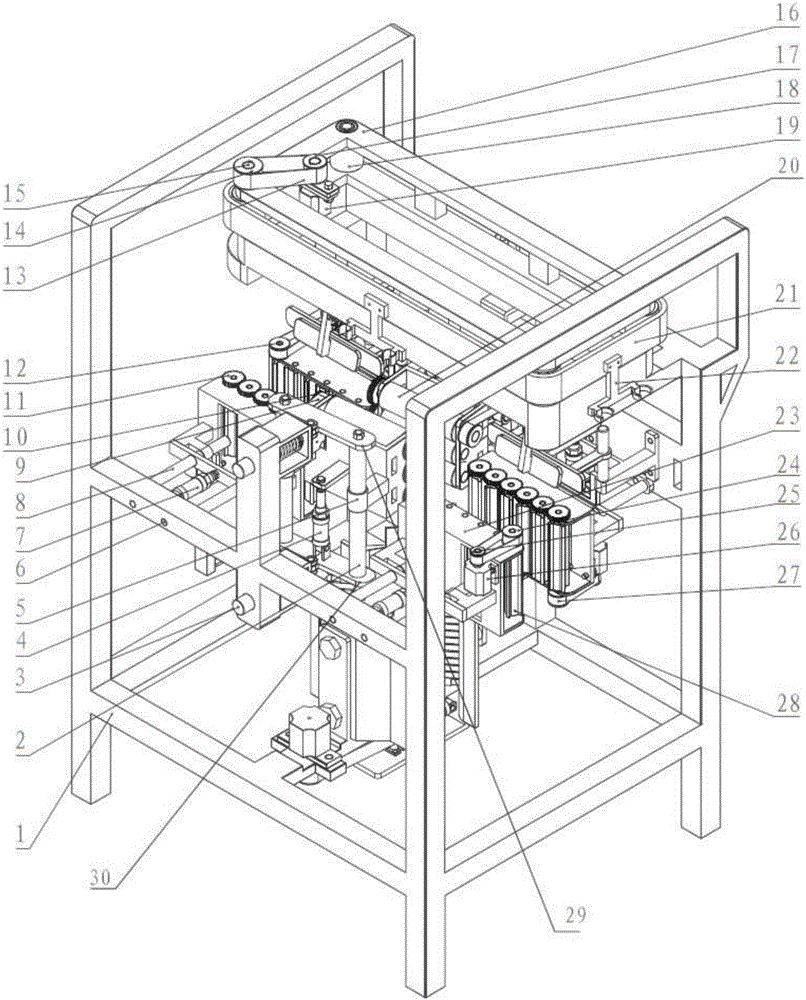

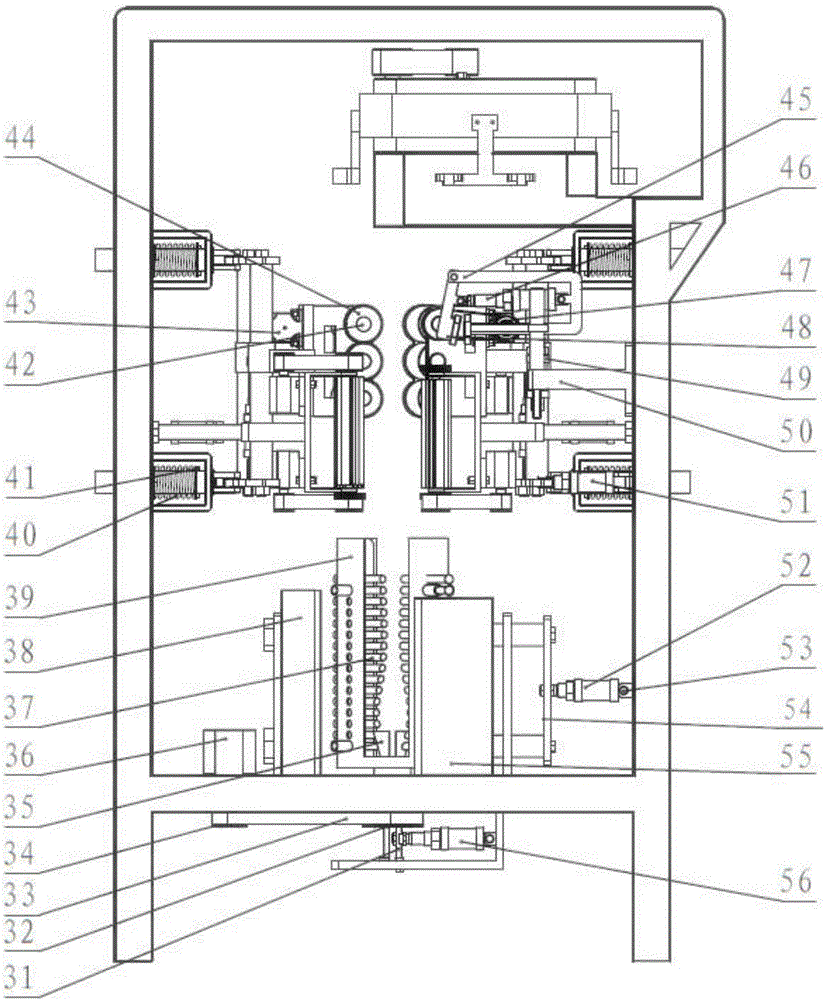

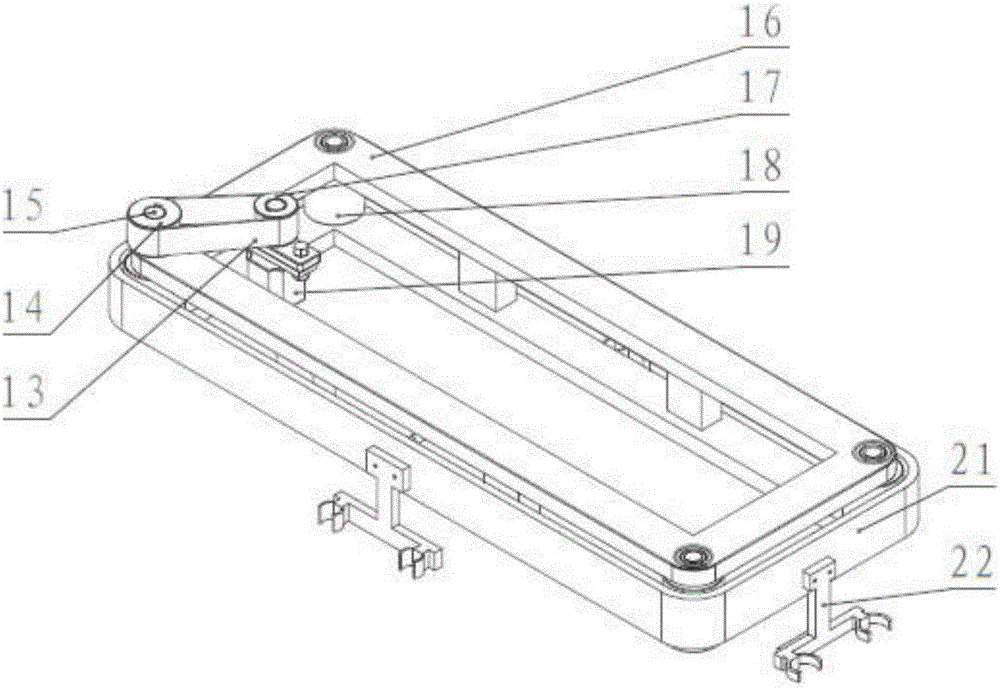

Packaging box edge folding and package forming machine

PendingCN112776414AImprove molding efficiencySave spacePaper-makingBox making operationsFolded formStructural engineering

The invention is suitable for the technical field of packaging box forming, and discloses a packaging box edge folding and package forming machine. The packaging box edge folding and package forming machine is used for folding packaging paper composed of surface paper and lining paper attached to the surface paper into a packaging box, and comprises a first side folding lug edge folding device used for bending and attaching a first side folding lug of the surface paper to the lining paper to obtain an edge-folded intermediate product, and an edge-folded intermediate product edge folding forming device used for packaging the edge-folded intermediate product to form the packaging box, wherein the edge-folded intermediate product edge folding forming device comprises a first conveying mechanism, a package forming mechanism, a first transferring mechanism, a first gear mechanism and a second gear mechanism; and the first gear mechanism comprises a first blocking piece and a first driving member used for driving the first blocking piece to perform lifting movement or horizontal movement, so that the first blocking piece can limit the folded-edge intermediate product and can release limit of the folded-edge intermediate product. According to the packaging box edge folding and package forming machine, multi-station packaging box forming is achieved, the forming efficiency is greatly improved, and the occupied area is small.

Owner:东莞市韦安自动化科技有限公司

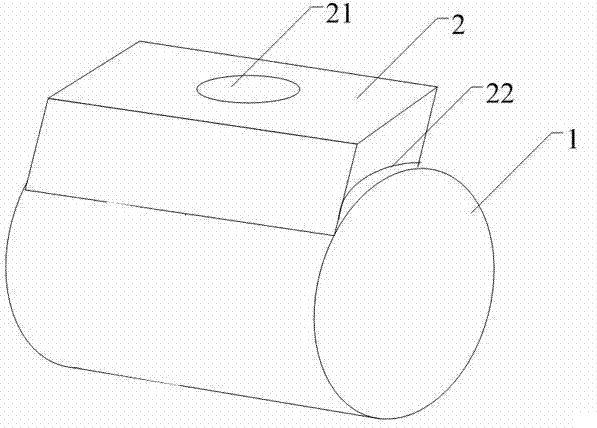

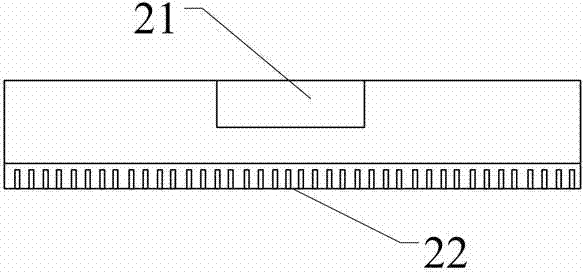

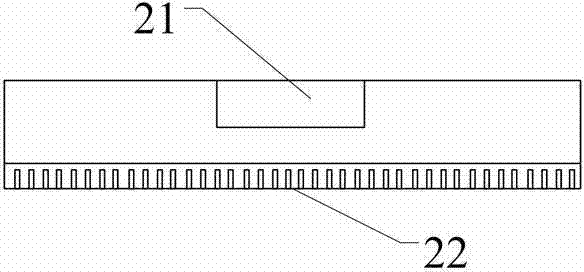

Novel paint vertical roller painting system

ActiveCN110624753AAvoid uniformityAvoid problems such as rough surface of the paint filmLiquid surface applicatorsCoatingsDiaphragm pumpAdditional values

The invention provides a novel paint vertical roller painting system which comprises a diaphragm pump, a paint feeding pipe, a motor, a worm gear reducer, a coating roller, a quantitative roller, a paint recovering tank, a paint recovering pipe and an X-Y slide table. The motor and the worm gear reducer are used for driving the coating roller to rotate. The rotating direction of the coating rolleris the same as the movement direction of a to-be-painted workpiece. The quantitative roller and the coating roller are the same in rotating speed and opposite in direction. The diaphragm pump sprayspaint between the coating roller and the quantitative roller through the paint feeding pipe, the paint is evenly distributed on the coating roller after being squeezed, and the coating roller is usedfor coating the surface of the to-be-painted workpiece with the paint. By means of the technical scheme, the problems of paint sagging of the edges of the workpiece, the uneven thickness of a paint film and the coarse surface of the paint film can be easily avoided, the quality of the paint film of the paint on the edges of the workpiece is improved, the paint surface is high in cleanliness, the paint texture is attractive, the paint production efficiency is improved, the paint consumption is reduced, and the additional value of the product is improved.

Owner:NANJING FORESTRY UNIV

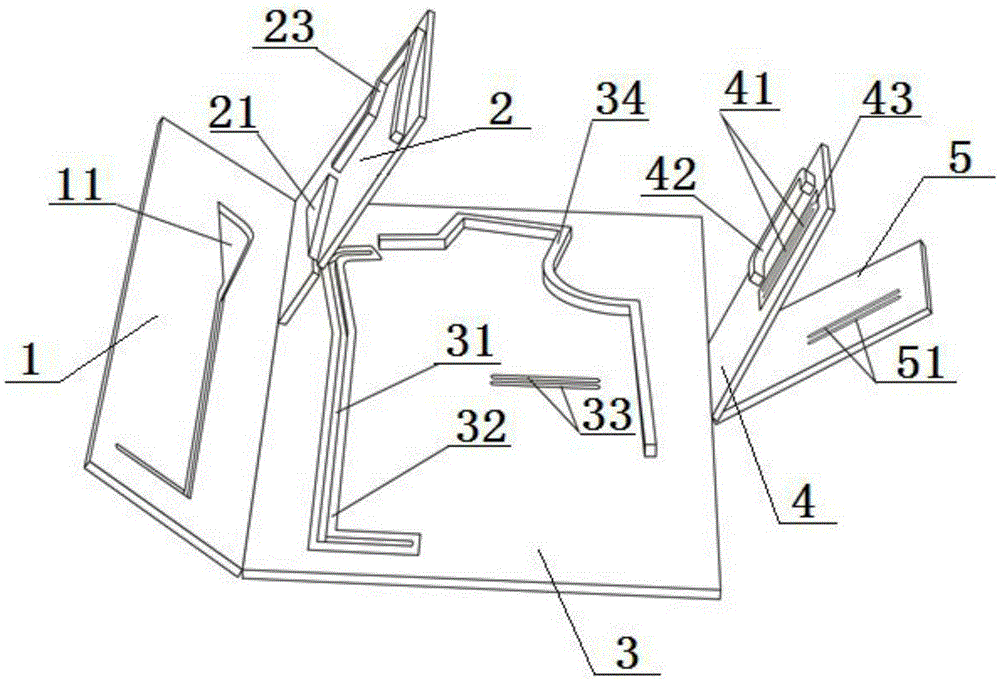

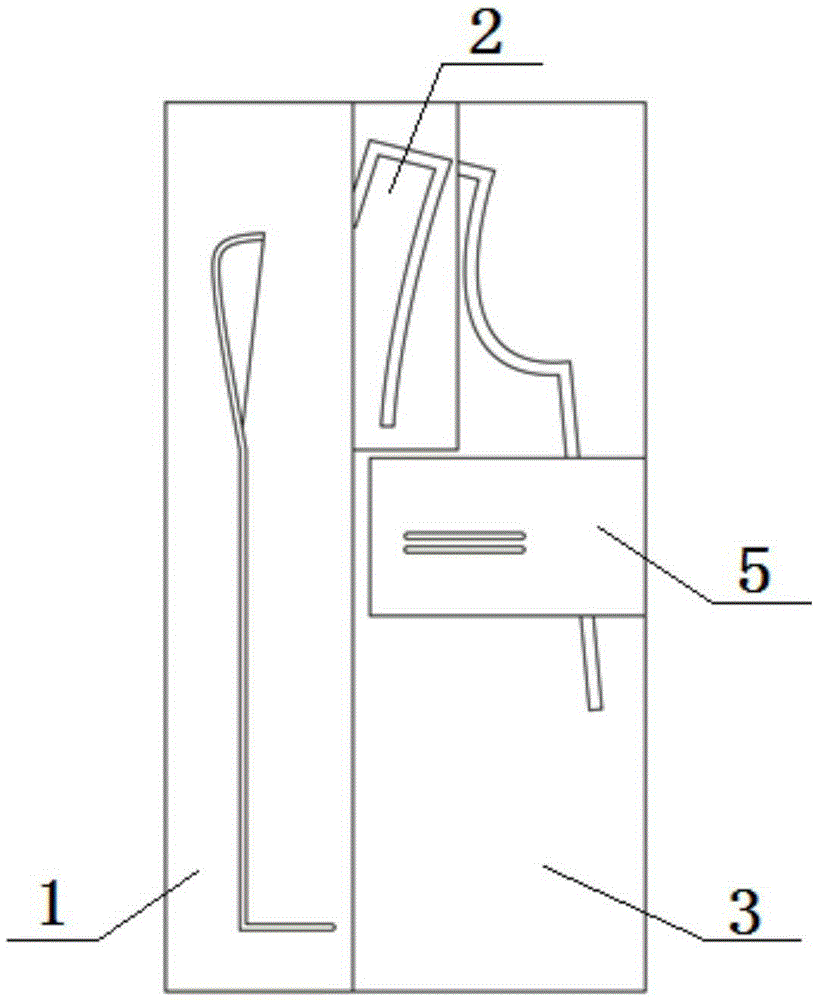

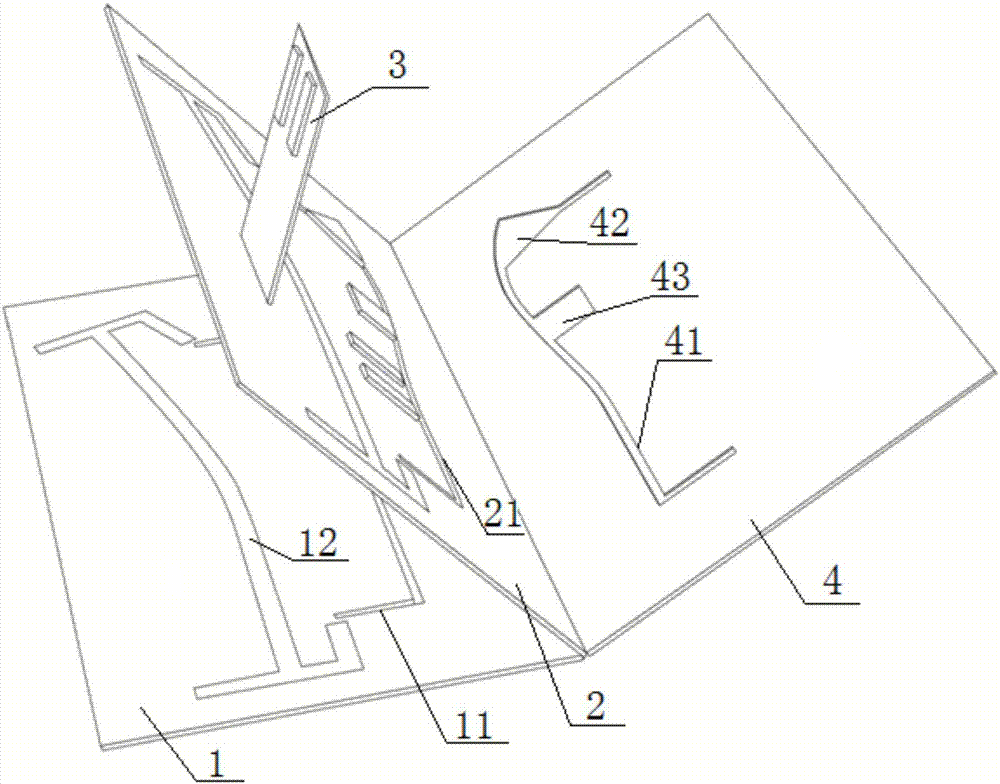

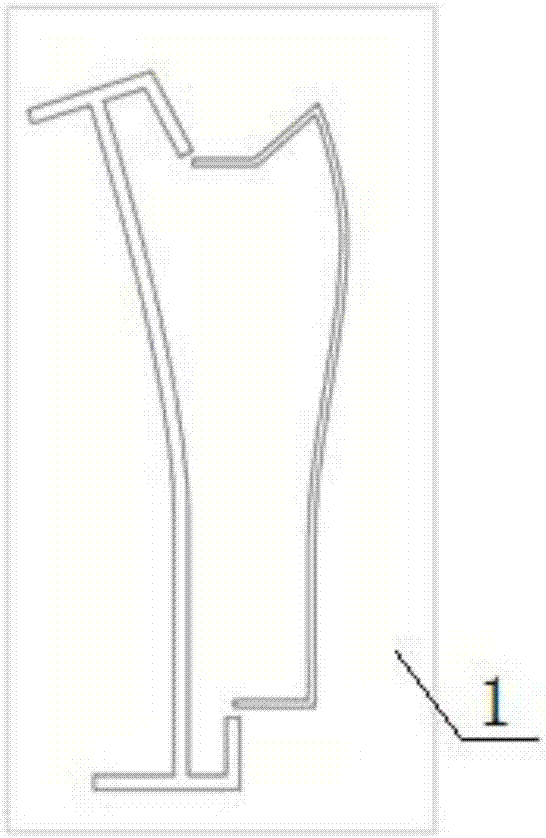

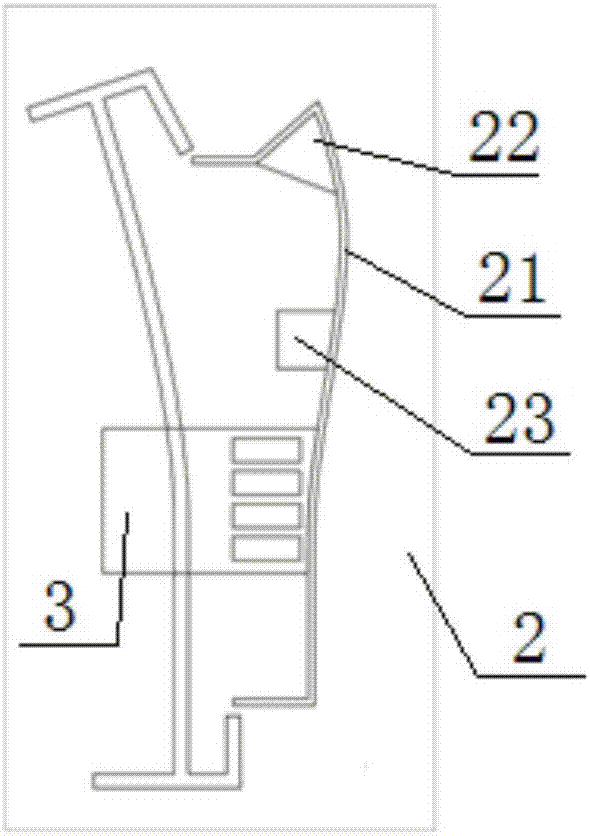

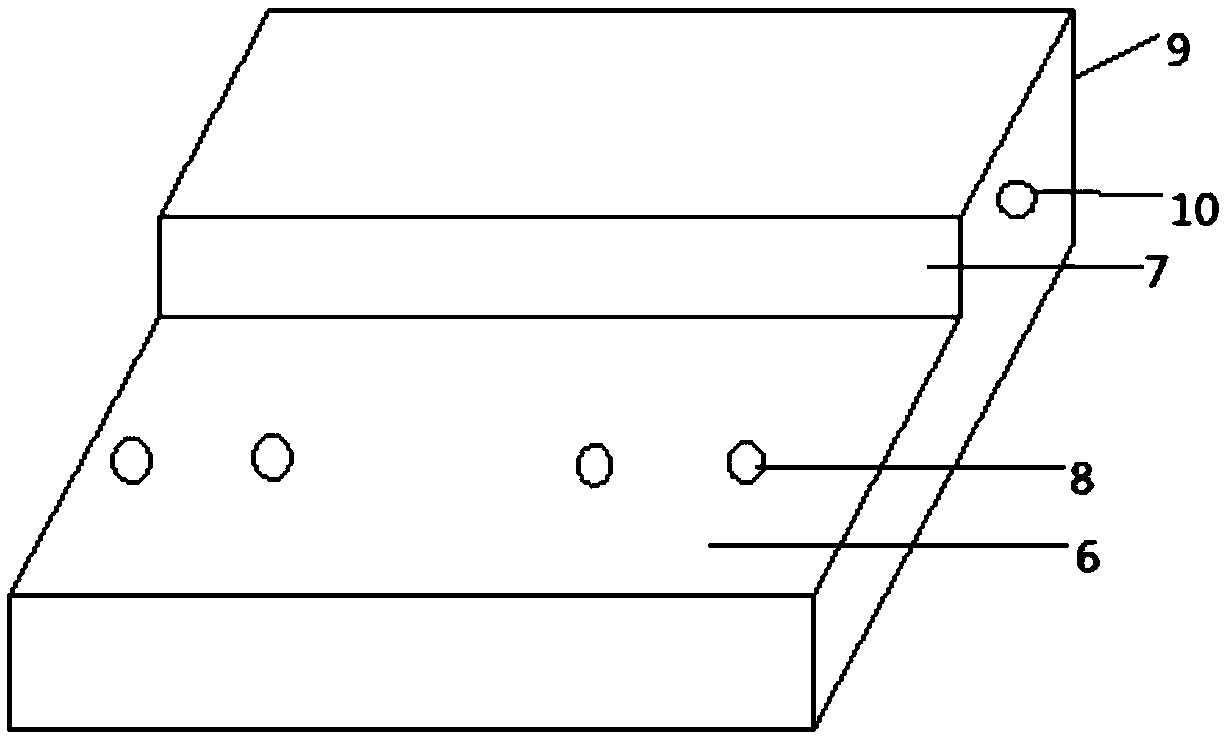

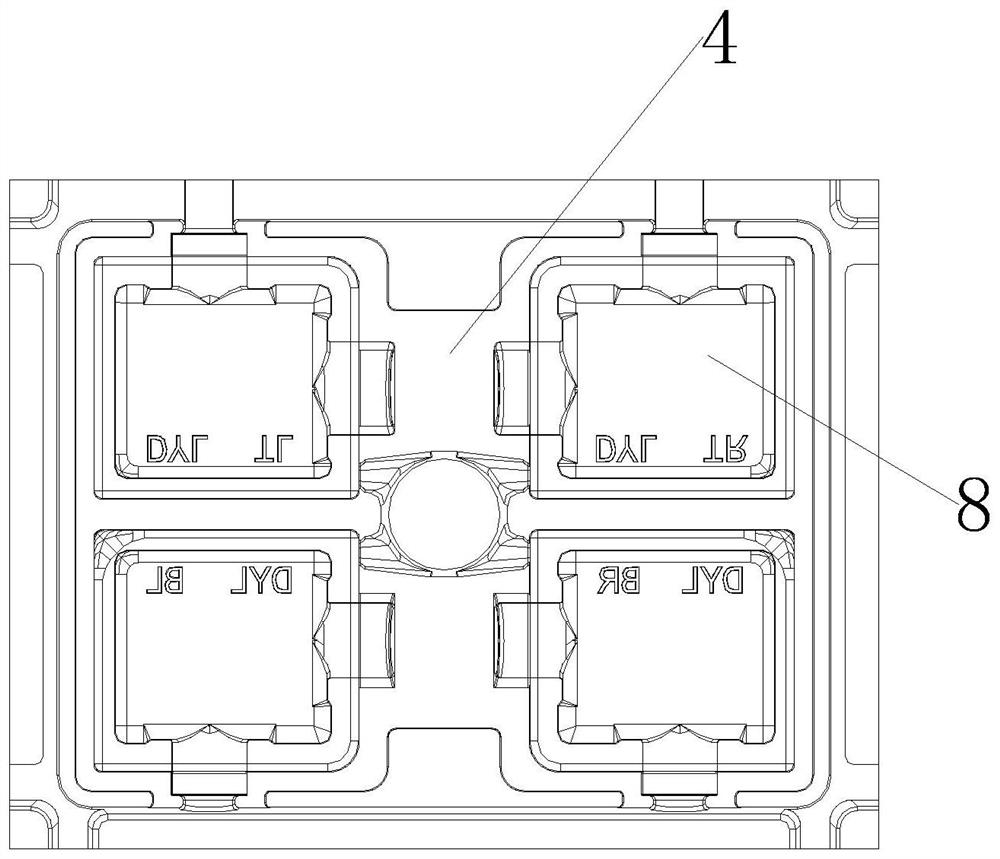

Combined sewing template clamp of medium thick suit hanging surface natural nest potential

The invention discloses a combined sewing template clamp of medium thick suit hanging surface natural nest potential. The combined sewing template clamp comprises four templates. The first template is a basic template, the second template and the fourth template are installed on the first template in a folded mode, and the templates are used for sewing lapel fold lines of a medium thick suit. The third template is installed on the second template in a folded mode, by means of a lapel cushion plate, a lapel collar cushion plate, a lapel containing groove and a lapel collar containing groove, a lapel part and a lapel collar part are positioned, and the lapel part and the lapel collar part achieve the attractive and smooth effect. It is guaranteed that the lapel part and the lapel collar part are attractive and smooth while sewing of the lapel fold lines of the medium thick suit is achieved through the four templates, and the combined sewing template clamp of the medium thick suit hanging surface natural nest potential has the advantages of being simple in sewing, short in needed man hour and high in finished product efficiency.

Owner:HUAIBEI NORMAL UNIVERSITY

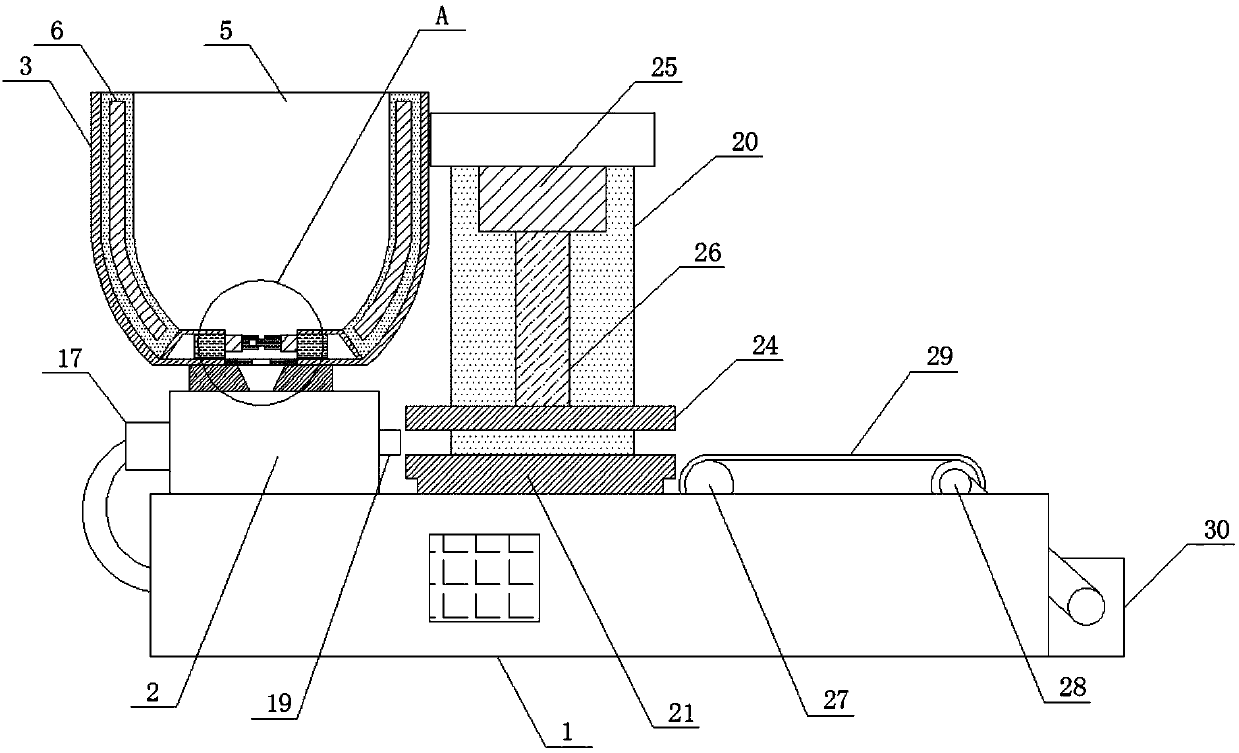

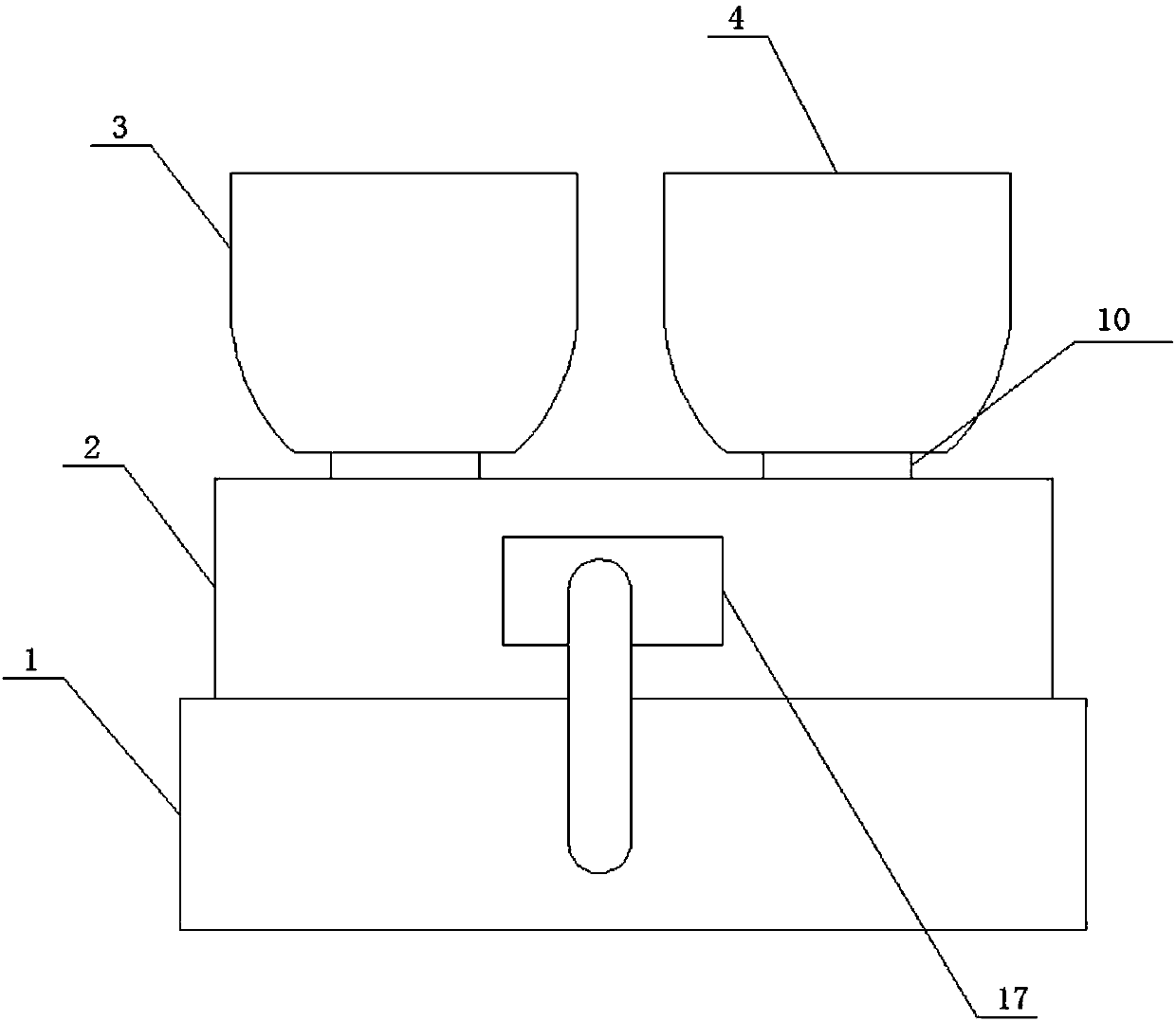

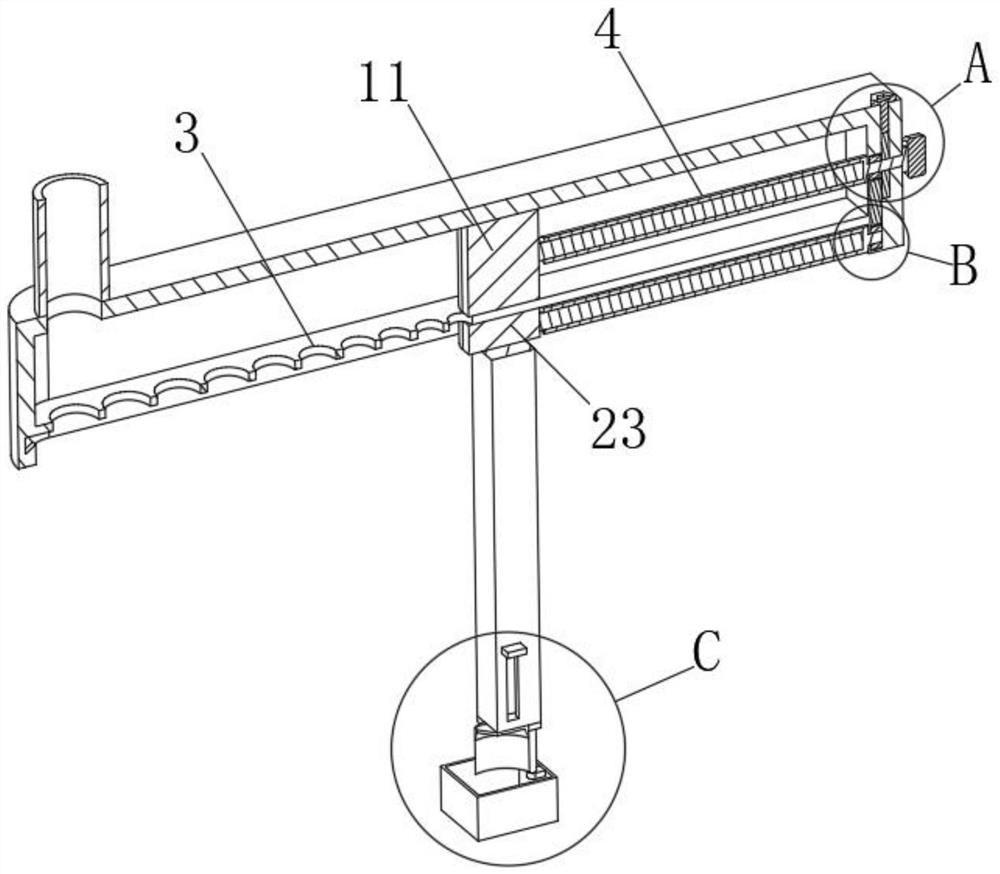

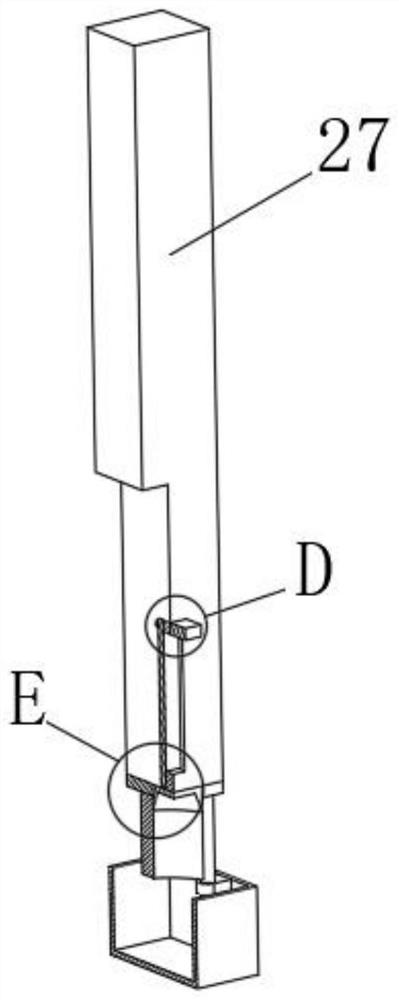

Equipment for producing large-size wood-plastic composite board

ActiveCN108044910AImprove finished product efficiencyImprove work efficiencyFlat articlesFiberTurbine blade

The invention discloses equipment for producing a large-size wood-plastic composite board. The equipment comprises a working table. An extruder is arranged on one side of the top end of the working table, a plastic melting feeder and an organic fiber feeder are arranged at the top end of the extruder, and the organic fiber feeder is arranged on one side of the plastic melting feeder. Containing grooves are formed in the plastic melting feeder and the organic fiber feeder, and a first heating wire is arranged on one side of each containing groove. Plastic and organic fibers are uniformly mixedby rotating turbine blades through a flowmeter according to a certain proportion, then a mixture is preliminarily extruded into the shape of a board by utilizing the extruder, and then the board is subjected to smoothing and line processing by using a lower pressing plate and an upper pressing plate, so that the wood-plastic composite board is manufactured. The producing steps adopt full automaticprocessing, and the working efficiency is improved; and the wood-plastic composite board is simple in structure and safe to use, and the produced wood-plastic composite board is high in rate of finished products.

Owner:马鞍山金晟木塑板材有限公司

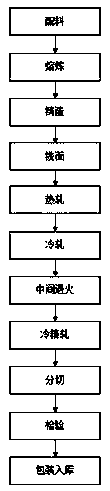

Aluminum-base material used for power battery cover body and method used for manufacturing power battery cover body

The invention relates to an aluminum-base material used for a power battery cover body. The material is characterized by comprising, by mass percent, 0.18 to 0.19% of Si, 0.54 to 0.60% of Fe, 0.080% to 0.095% of Cu, 1.00 to 1.10% of Mn, 0.002 to 0.005% of Mg, 0.0006 to 0.0009% of Cr, 0.006 to 0.007% of Ni, 0.01 to 0.02% of Zn, 0.03 to 0.04% of Ti, not larger than 0.15% of the total amount of otherimpurities, not larger than 0.05% of the content of single impurities and the balance Al. The process is simple, the cost is reduced, the mass is small, the density is small, heat and corrosion are resisted, the automaton degree is good, control is facilitated and the yield is high.

Owner:镇江龙源铝业有限公司

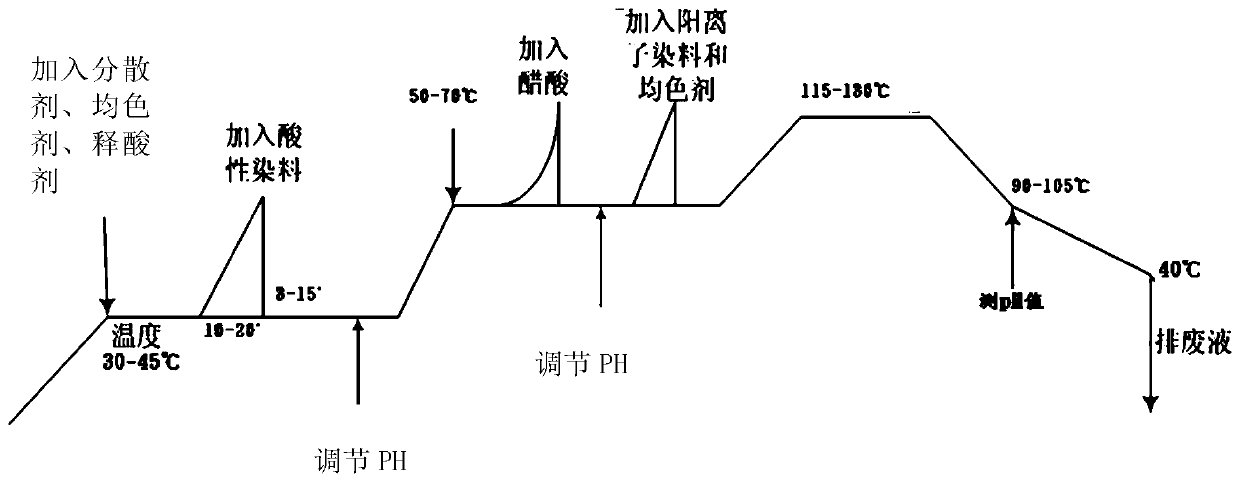

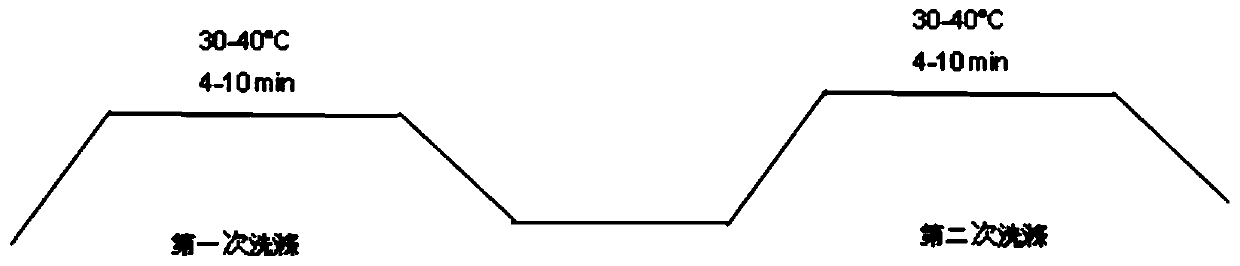

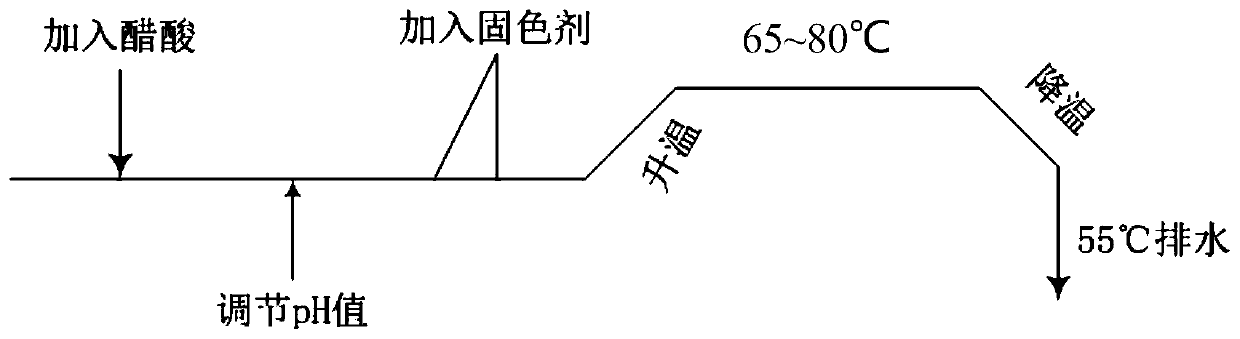

Dyeing method of elastic patterned gray blended knitted fabric

The invention relates to a dyeing method of an elastic patterned gray blended knitted fabric. The method comprises the following steps of (1) pretreatment, wherein oil removal and gray cloth setting are carried out on an elastic gray cloth of the elastic patterned gray blended knitted fabric; (2) dyeing, wherein the elastic gray cloth is put into a dyeing vat, and water, a dispersant, a part of acolor homogenizing agent and an acid releasing agent are added for dyeing; (3) post-treatment, wherein a color fixing agent is added for color fixing after the gray cloth is washed with water. According to the method, a two-step approach based on one bath is adopted, the pretreatment of oil removal and gray cloth setting is carried out, and then the dispersant, the color homogenizing agent and theacid releasing agent are adopted, so that oligomer agglomeration is prevented, it is ensured that a stable acidic environment is formed in the dyeing process, and a great coloring effect is realized;finally, the color stability of the dyed gray cloth is ensured through the post-treatment of washing and color fixing; the color fastness is high, a dyeing and finishing process is optimized, the dyeing process is simplified, the working time is shortened, the energy consumption is reduced, the color difference of fabrics after dyeing and finishing processing is avoided, and the finished productefficiency is obviously improved.

Owner:PACIFIC (PANYU) TEXTILES LTD

Processing method of fermented bean milk

InactiveCN108812918AGive full play to nutrientsRaise interest ratesMilk substitutesFood scienceFermentationNutrient

The invention discloses a processing method of fermented bean milk, and relates to the technical field of processing of bean milk. The processing method is characterized by comprising the following steps of screening raw materials, soaking soybeans, peeling soybeans, performing breaking, soaking soybean flour, performing colloidization, performing refining and grinding, performing seasoning, performing sterilizing, performing homogenizing treatment, and performing filling and packing. Through the adoption of the processing method, fermentation of the bean milk is realized, finished products ofthe fermented bean milk are fine, smooth and good in mouth feel, the fermentation efficiency is high, and the nutrient value is high.

Owner:FUYANG XINRONG FOOD CO LTD

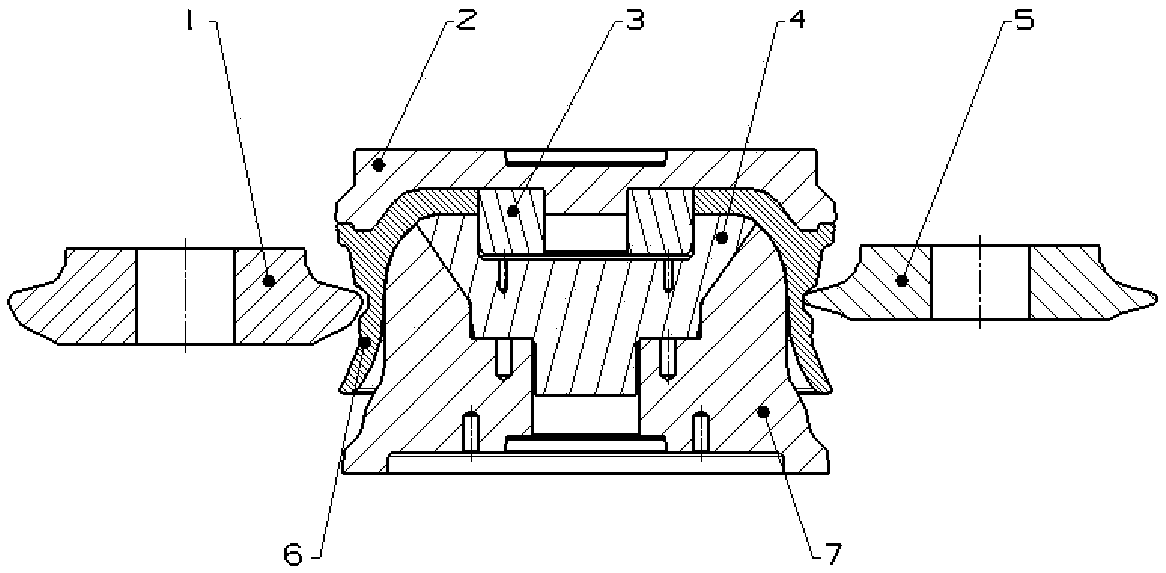

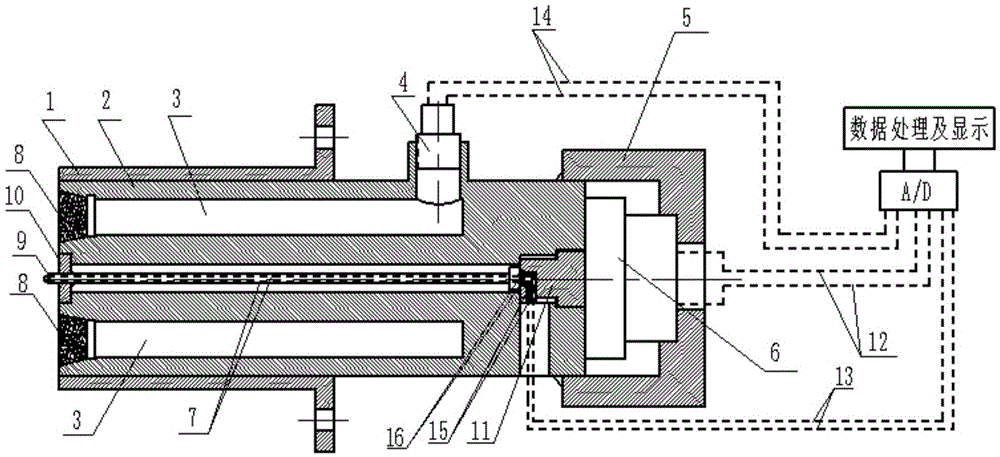

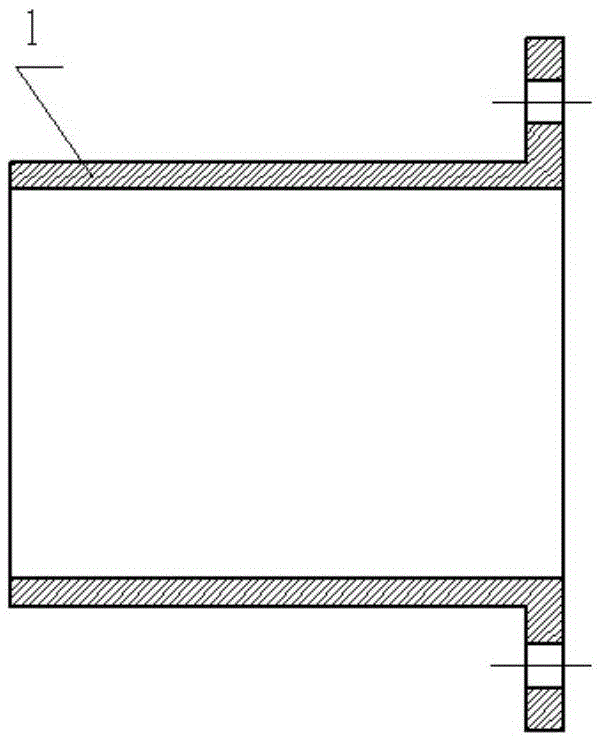

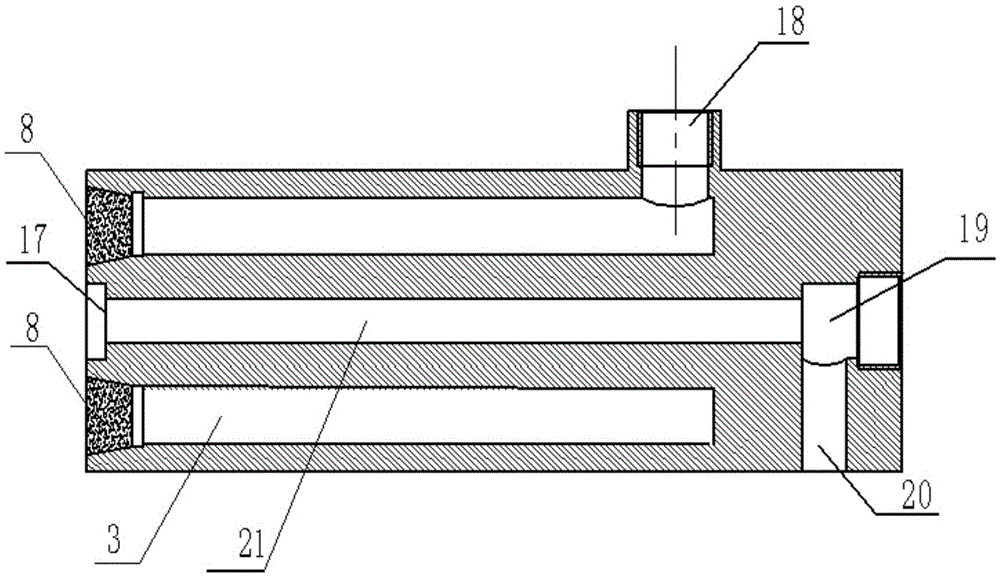

Pressure casting real-time monitoring device in mould cavity

The invention discloses a pressure casting real-time monitoring device in a mould cavity. The pressure casting real-time monitoring device comprises a valve element and a valve sleeve for fixing the valve element in the mould cavity. The front end face of the valve element serves as a molded face, and a valve seat is further arranged on the rear end face of the valve element. The valve element is provided with gas exhaust and overflow holes, a trumpet-shaped opening is formed in the front end of each gas exhaust and overflow hole, and the openings are filled with filter materials. A first pressure sensor fixing hole is formed in the tail end of one gas exhaust and overflow hole in the direction perpendicular to the axial direction, and a first pressure sensor is arranged in the first pressure sensor fixing hole. A second pressure sensor is arranged at the tail end of the valve element, and when the valve element slides front and back relative to the valve seat, the second pressure sensor is triggered. A thermocouple tube is further arranged at the axis of the valve element in the axial direction, and the rear end of the thermocouple tube is fixed through a thermocouple fixing seat arranged in the valve element. According to the monitoring device, various important technological parameters in the mould cavity can be precisely measured and monitored in real time.

Owner:广东鸿图武汉压铸有限公司 +2

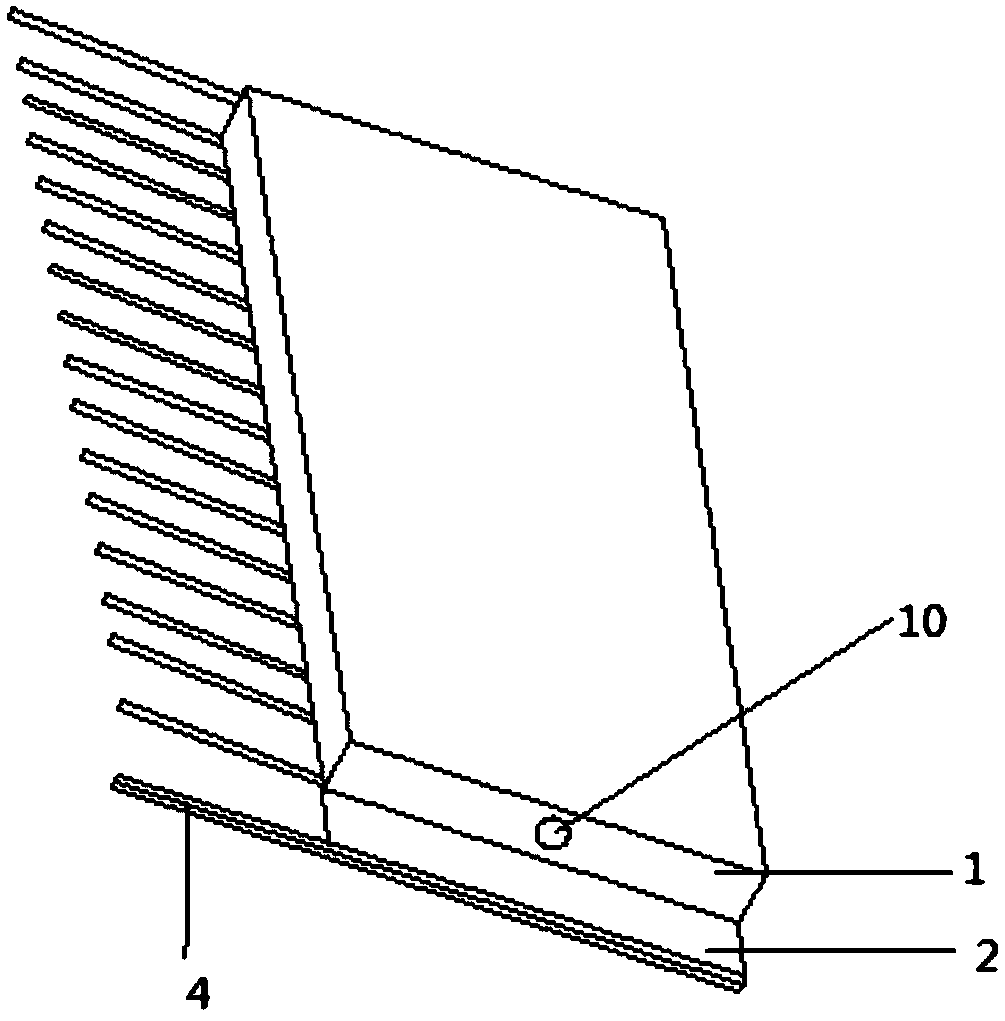

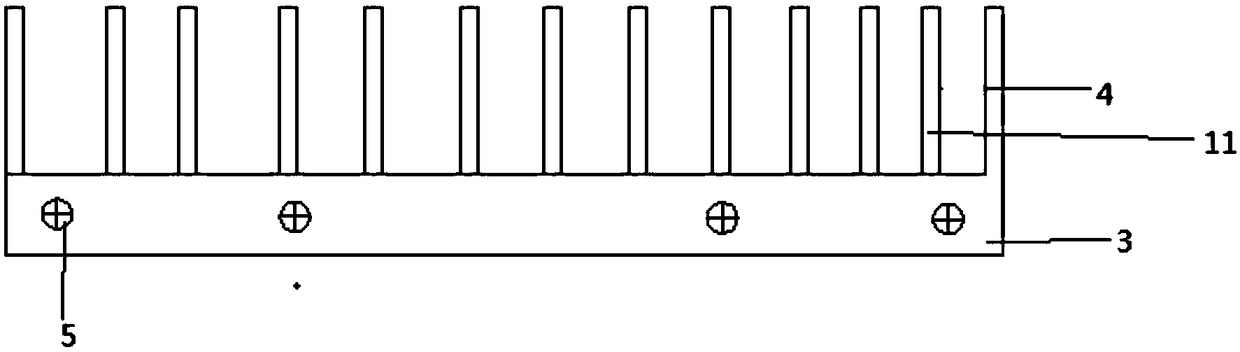

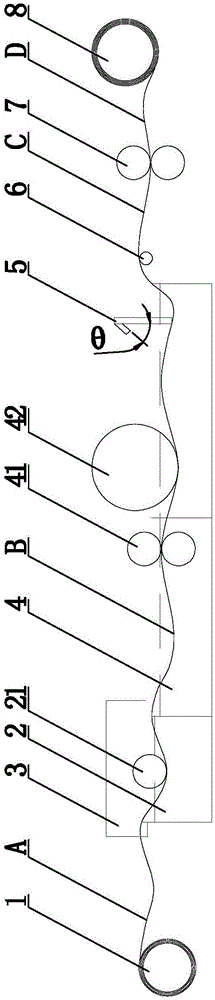

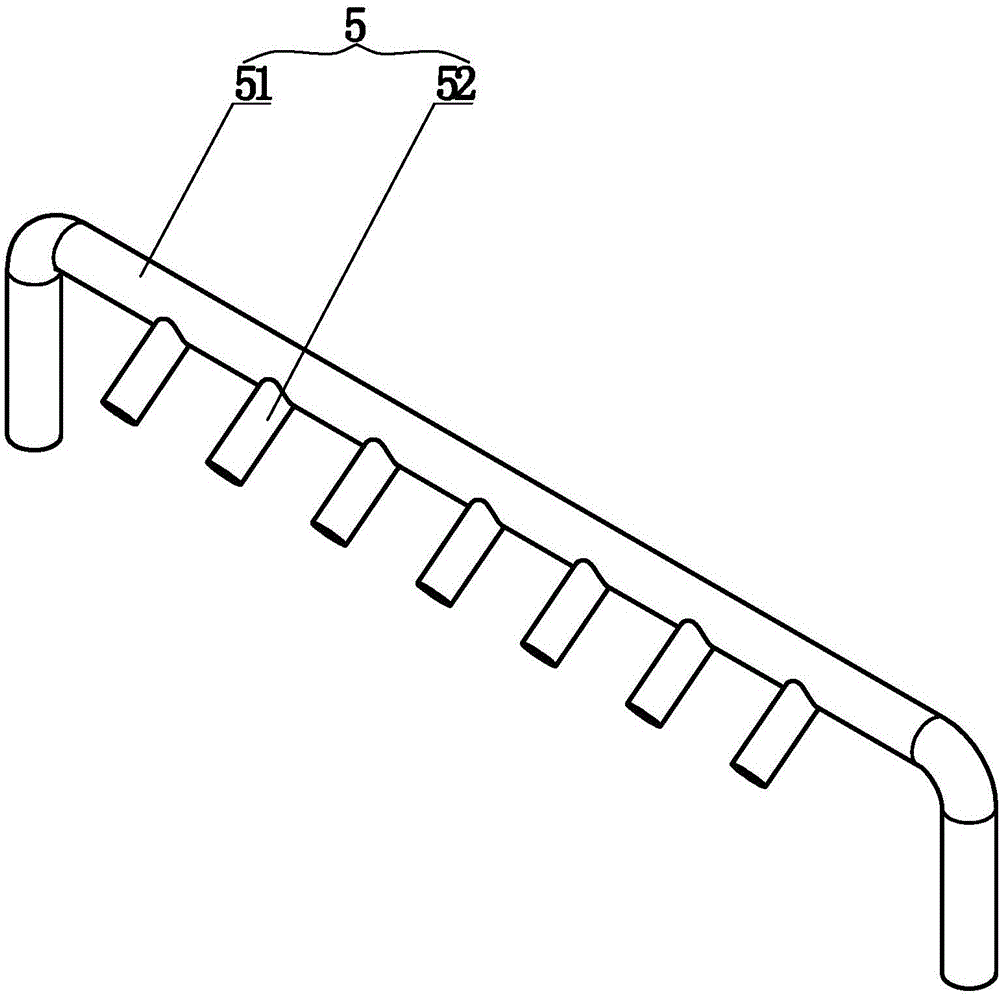

Oil distribution device for rolling mill

InactiveCN102294360AImprove the uniformity of oil coatingImprove finished product efficiencyRollsMetal rolling arrangementsOil distributionDistributor

The invention discloses an oil distribution device for a rolling mill. The rolling mill has an upper pressing roll and a lower pressing roll for laminating two metal plates. It is characterized in that the upper pressing roll is integrated with an oil distribution device. Oil injection holes are provided on the first side of the device on the back of the upper pressure roller, and uniformly dense oil outlet holes are arranged on the second side close to the upper pressure roller, and the oil outlet holes communicate with the oil injection holes. The application and implementation of the oil distributing device of the present invention improves the uniformity of the oil coating on the surface of the upper pressing roller through the distributed guidance from one oil injection hole to a plurality of uniformly densely distributed oil outlet holes. Effectively improves the finished product efficiency of bimetallic cladding.

Owner:张家港市宏翔金属制品有限公司

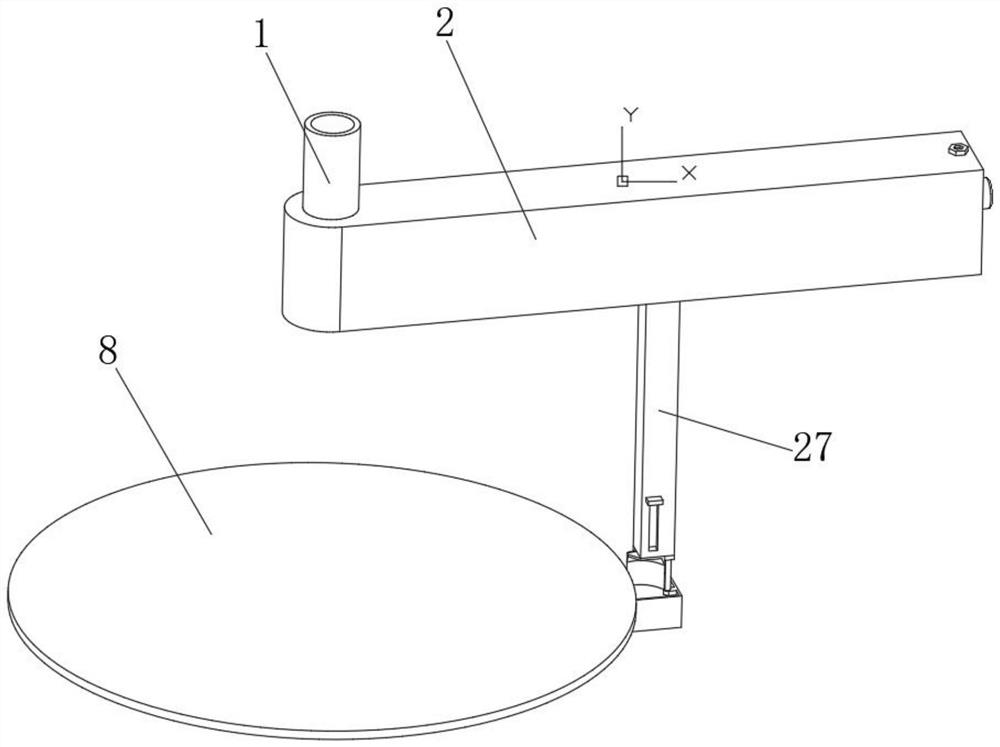

Glue spraying equipment for semiconductor photoetching processing

InactiveCN113376966AImprove glue spraying efficiencyAvoid edge exposurePhotomechanical coating apparatusWaferEngineering

The invention discloses glue spraying equipment for semiconductor photoetching processing. The equipment comprises a glue inlet and a nozzle pipe fixedly mounted at the bottom of the glue inlet; the bottom of the nozzle pipe is provided with a plurality of glue spraying openings; and the nozzle pipe is internally provided with an anti-blocking sealing element for adjusting the number of the glue spraying openings; a limiting piece is arranged above the end part of the anti-blocking sealing element;and the lower part of the anti-blocking sealing element is connected with an auxiliary device through a connecting piece; the side surface of the auxiliary device is provided with a discharging device to deal with excess sprayed glue outside a wafer; and a material collection device is arranged below the discharging device. According to the glue spraying equipment for the semiconductor photoetching processing, the number of the glue spraying openings in the nozzle pipe can be adjusted through the anti-blocking sealing element and the auxiliary device according to the outer diameter of the wafer; a positioning scraper on the auxiliary device can remove redundant sprayed glue on the outer side of the wafer while performing positioning, so that the glue spraying efficiency of the surface of the wafer is improved, edge exposure of the wafer in the subsequent process can be avoided, and the finished product efficiency of the wafer is effectively improved.

Owner:深圳恩必德电子科技有限公司

Horizontal hand feeling wood grain metal heat transfer printing process

InactiveCN108636744AImprove bindingNot easy to decolorizeDuplicating/marking methodsPretreated surfacesChromium freeEngineering

The invention relates to a horizontal hand feeling wood grain metal heat transfer printing process, and mainly solves the problems of high production cost of hand feeling wood grains, low efficiency of finished products, chromatic aberration and the like. The process comprises the following steps: (S1) pretreatment of metal original profiles: the metal original profiles are dedusted by purified water for oil removal, medicine removal and chromium-free passivation; (S2) baking: the cleaned metal original profiles are put in a baking room for drying; (S3) spraying: the air blowing and dust removing treatment is performed on the metal original profiles by an air blowing machine; then, the hanging is performed; and the metal original profiles enter a spraying room for powder electrostatic primer spraying; (S4) curing: primer-sprayed products are directly fed in the baking room for high-temperature curing; (S5) the step (S3) is carried out for primer spraying; (S6) the hand feeling wood grains are manufactured; (S7) paper through bags are used for packing; and (S8) the heat transfer printing is performed. The process is suitable for the technical field of heat transfer printing of metalhand feeling wood grains.

Owner:四川鼎际恒荣金属材料有限公司

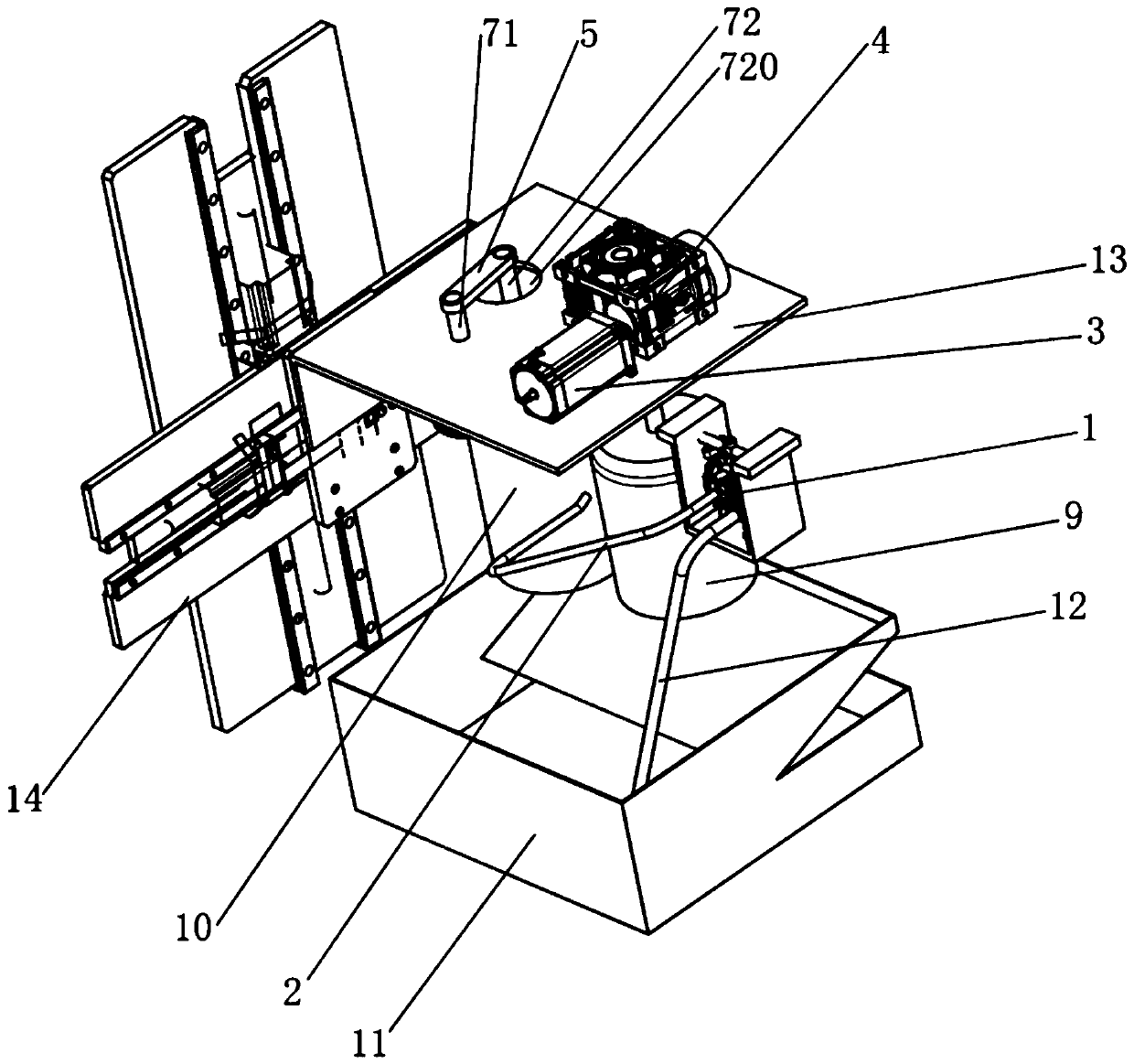

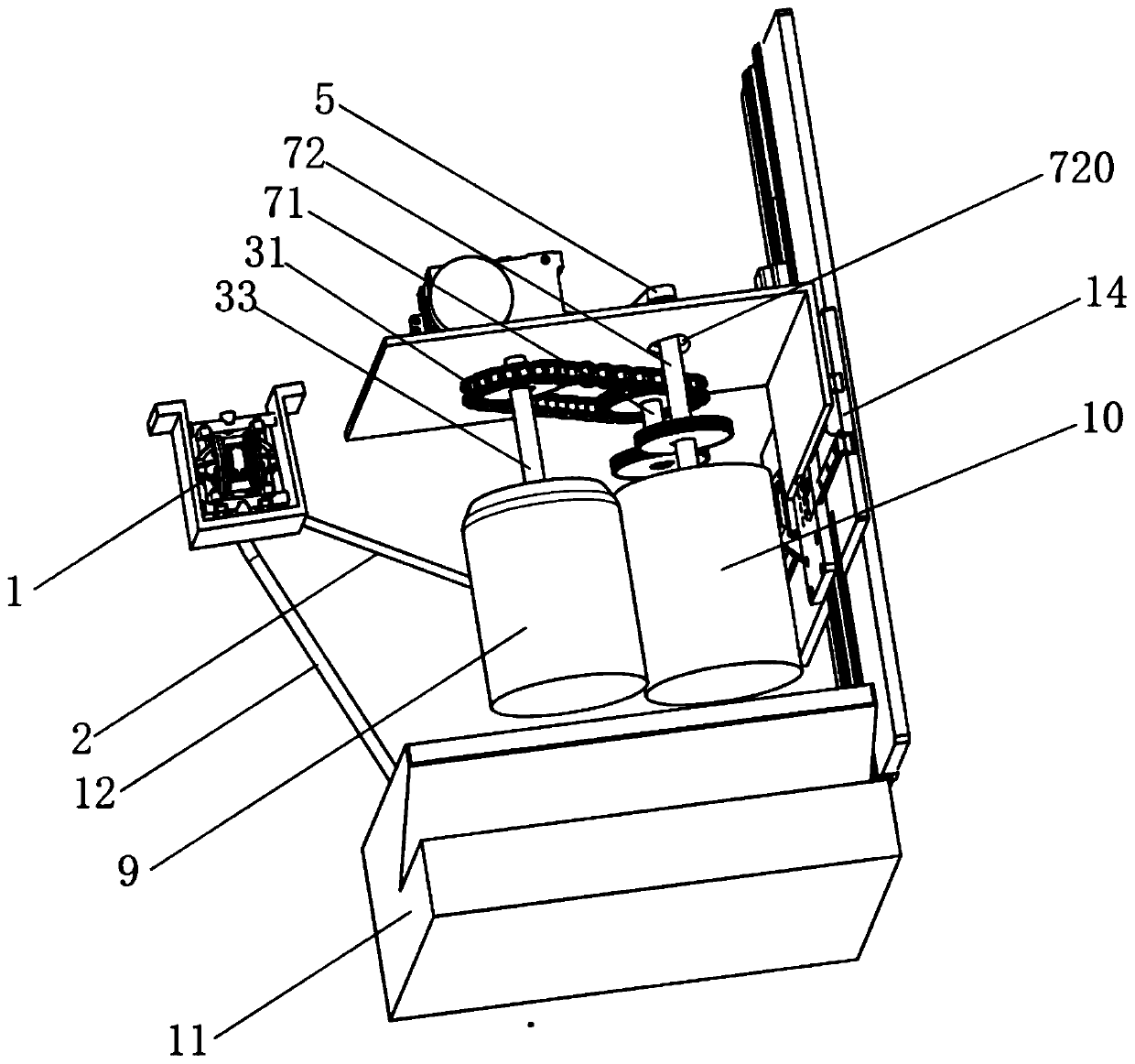

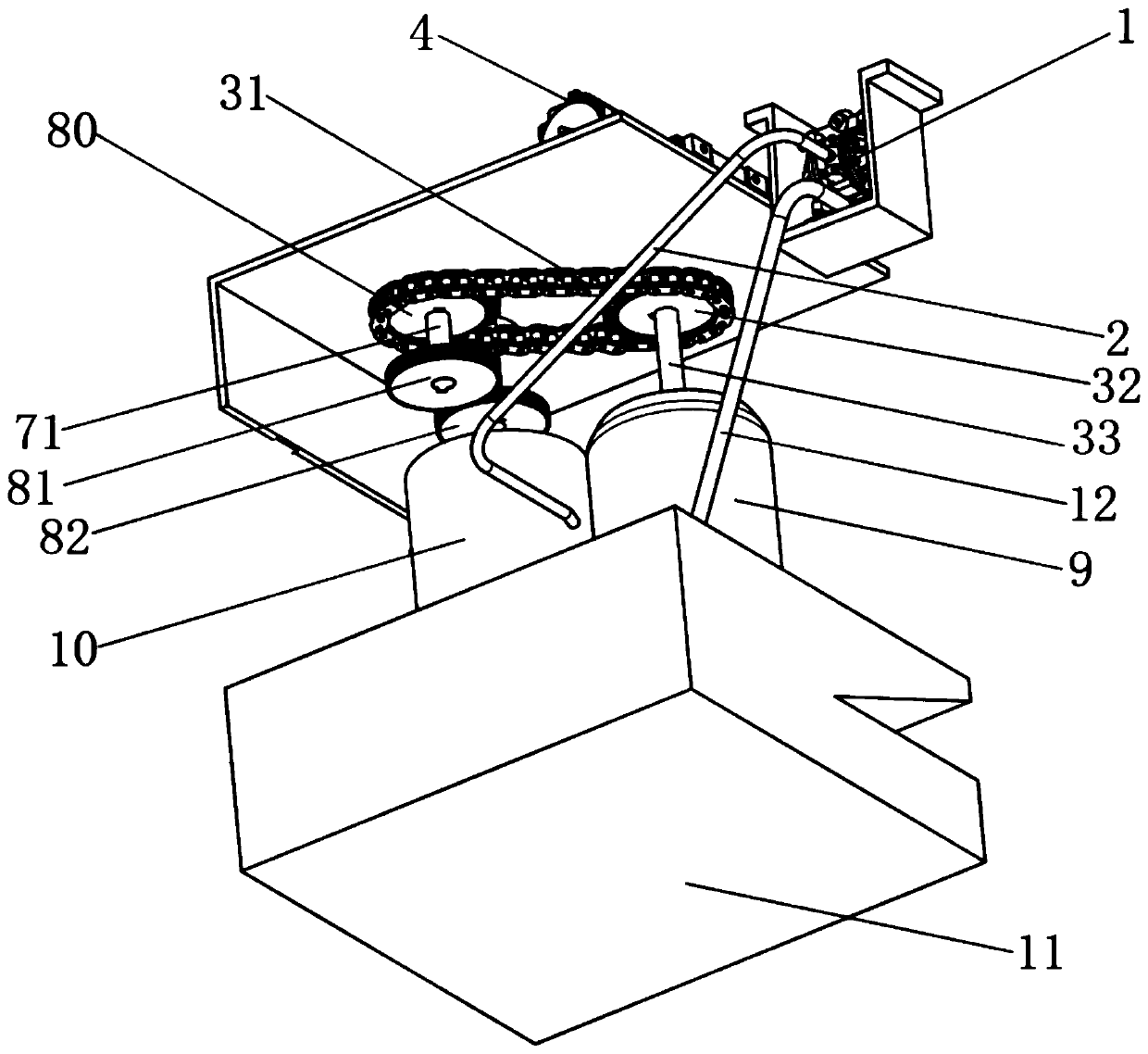

Suspension type goose feather eliminating device

ActiveCN106490115AQuick clearAccurate and powerful contactSlaughtering accessoriesEngineeringGoose feathers

The invention provides a suspension type goose feather eliminating device, and relates to the field of animal husbandry processing equipment. The suspension type goose feather eliminating device is used for automatically eliminating feathers on the surface of a goose body with no damage to the liver of the goose body and solving the problem of low output efficiency of the goose body. According to the technical scheme adopted for solving the technical problem, the suspension type goose feather eliminating device is characterized by comprising a device support and components such as back removal guide rails, a back removal support, a wing removal fixing pin hole, a wing removal air cylinder, a back removal motor wheel, a fastening clamp, a black removal air cylinder, a rotating air cylinder, a fixed pin, a rotating supporting plate, a moving baffle plate and a clamping air cylinder which are arranged on the device support. The suspension type goose feather eliminating device has the beneficial effects that the whole device is capable of automatically cleaning up feathers on the surface of the goose body with no damage to the liver of the goose body through coordination and cooperation of the components, and reduces the input cost while increasing the efficiency of finished products.

Owner:台州科金中高技术转移有限公司

Bright pipe body processing craft

InactiveCN105728466AShort processing flowImprove finished product efficiencyFurnace typesWork cleaning devicesSteel beltBrightness perception

The invention relates to a bright pipe body processing technology, which belongs to the technical field of metal rolling. It includes feeding rolls, pickling tanks, cleaning tanks and rolling mills installed in sequence; there is a hot box above the pickling tank, and the hot box forms a closed structure above the pickling tank, and the wool supplied by the feeding rolls is in the pickling tank The acidified material is obtained, and the acidified material is sent to the cleaning tank to remove the surface acid to form a crude product; the crude product is sent to the joint rolling mill. Applying the invention to the processing of steel strips and pipe fittings has the advantages of short processing flow and high brightness of finished products.

Owner:SHAOXING HUANXIN PIPE IND

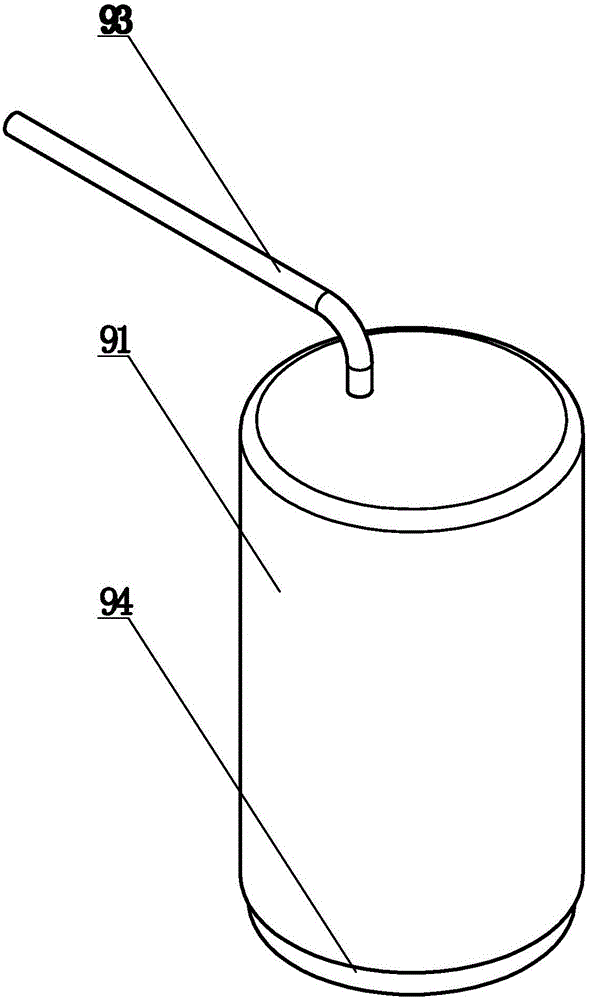

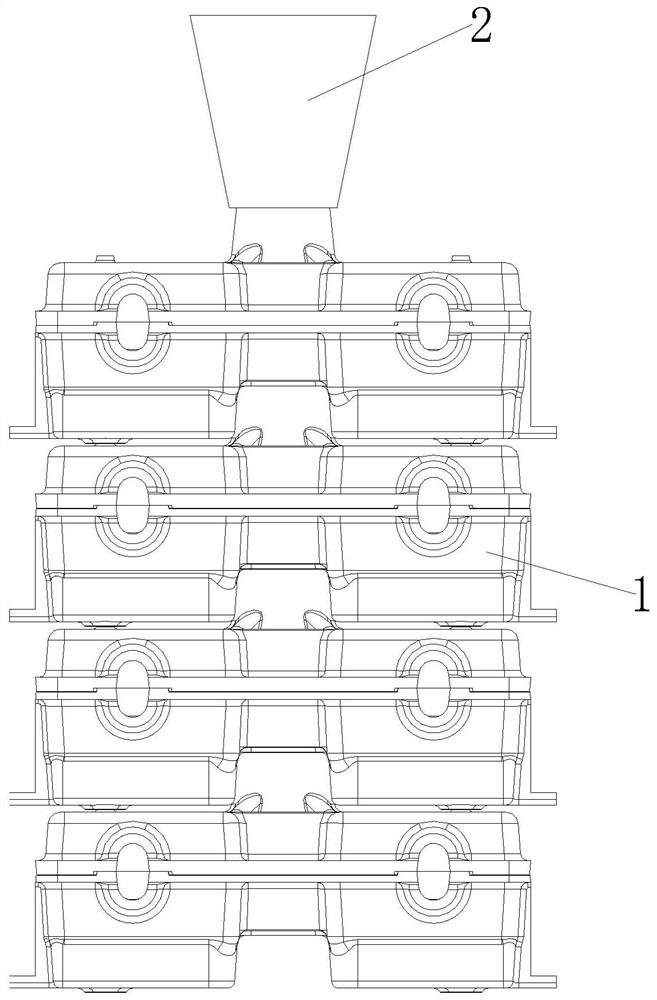

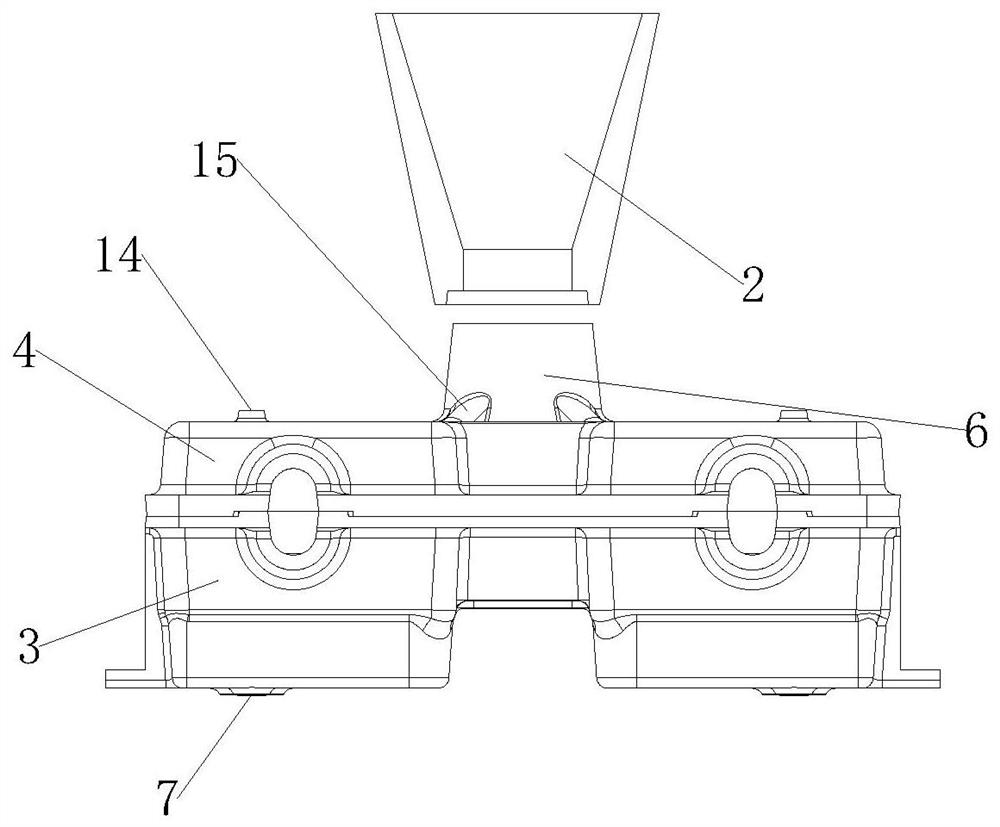

Multi-layer combined type container corner fitting precoated sand shell mold and pouring process

PendingCN112642996AIncrease profitImprove finished product efficiencyFoundry mouldsFoundry coresWhole bodyMolten steel

The invention discloses a multi-layer combined type container corner fitting precoated sand shell mold and a pouring process, and particularly relates to the technical field of container corner fitting precoated sand shells and pouring processes. The multi-layer combined type container corner fitting precoated sand shell mold comprises a corner fitting precoated sand shell whole body and a movable pouring cup, and the number of the layers of the precoated sand shell whole body is one to four. According to the combined type container corner fitting precoated sand shell and the pouring process, two layers, three layers, four layers and at most four layers can be arranged as a group to pour 16 corner fitting castings, the finished product efficiency of the corner fitting castings can be improved through sand shell pouring, the overall finished product efficiency of the corner fitting precoated sand shell is improved, the molten steel pouring frequency and weight are reduced, a chilling block is arranged in the sand shell in the shell manufacturing process, the distance between the sand shell and the chilling block is 3-4 mm, the chilling block is not in direct contact with molten steel in the casting process, shrinkage cavities of corner piece castings cannot be generated due to the fact that the molten steel is cooled too fast, and the problems that according to an existing container corner piece precoated sand shell and pouring process, the molten steel utilization rate is low, the finished product percent of pass is low and cost is high are solved.

Owner:JIANGSU YAWEI POUNDRY MATERIAL TECH CO LTD

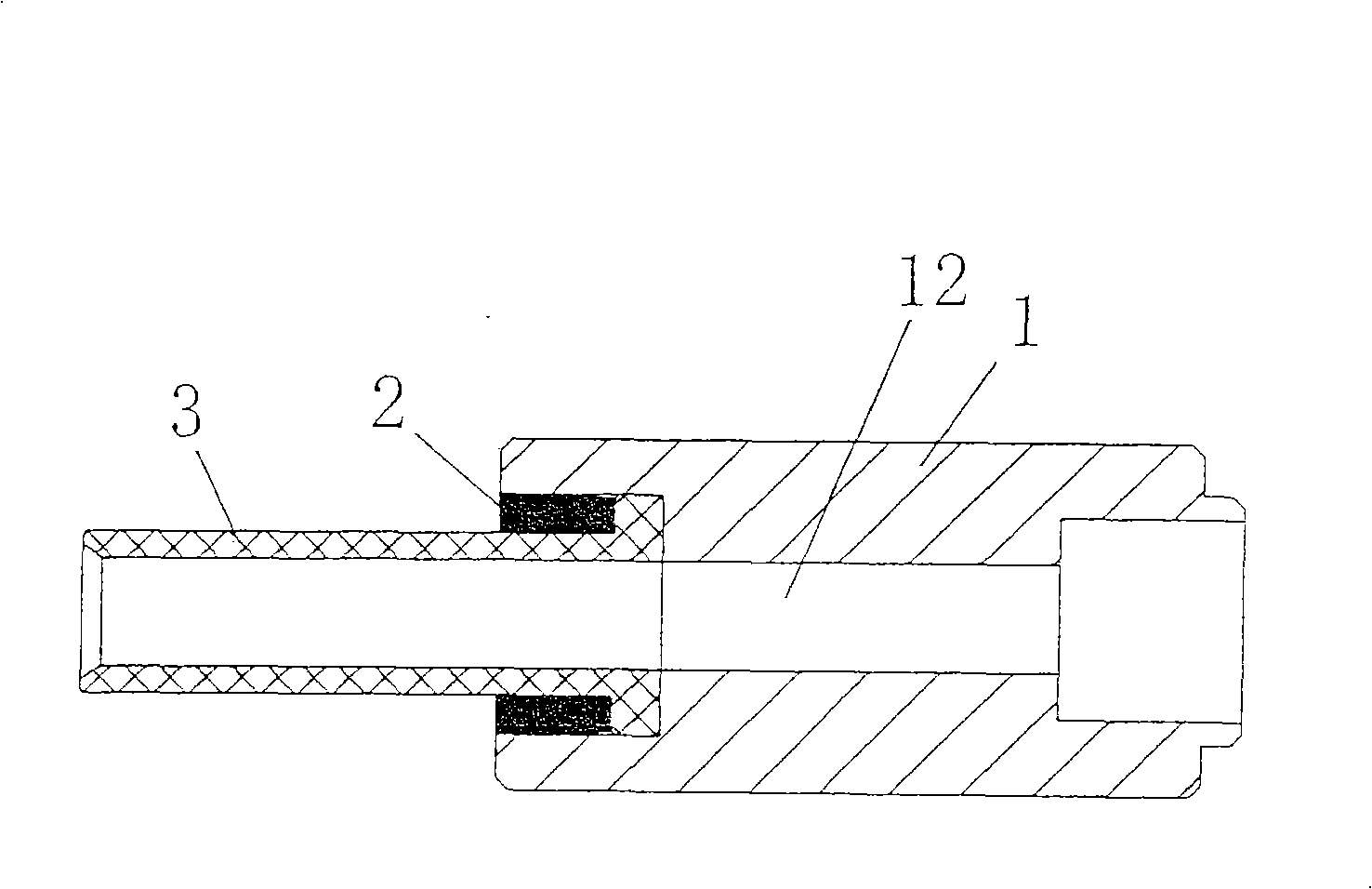

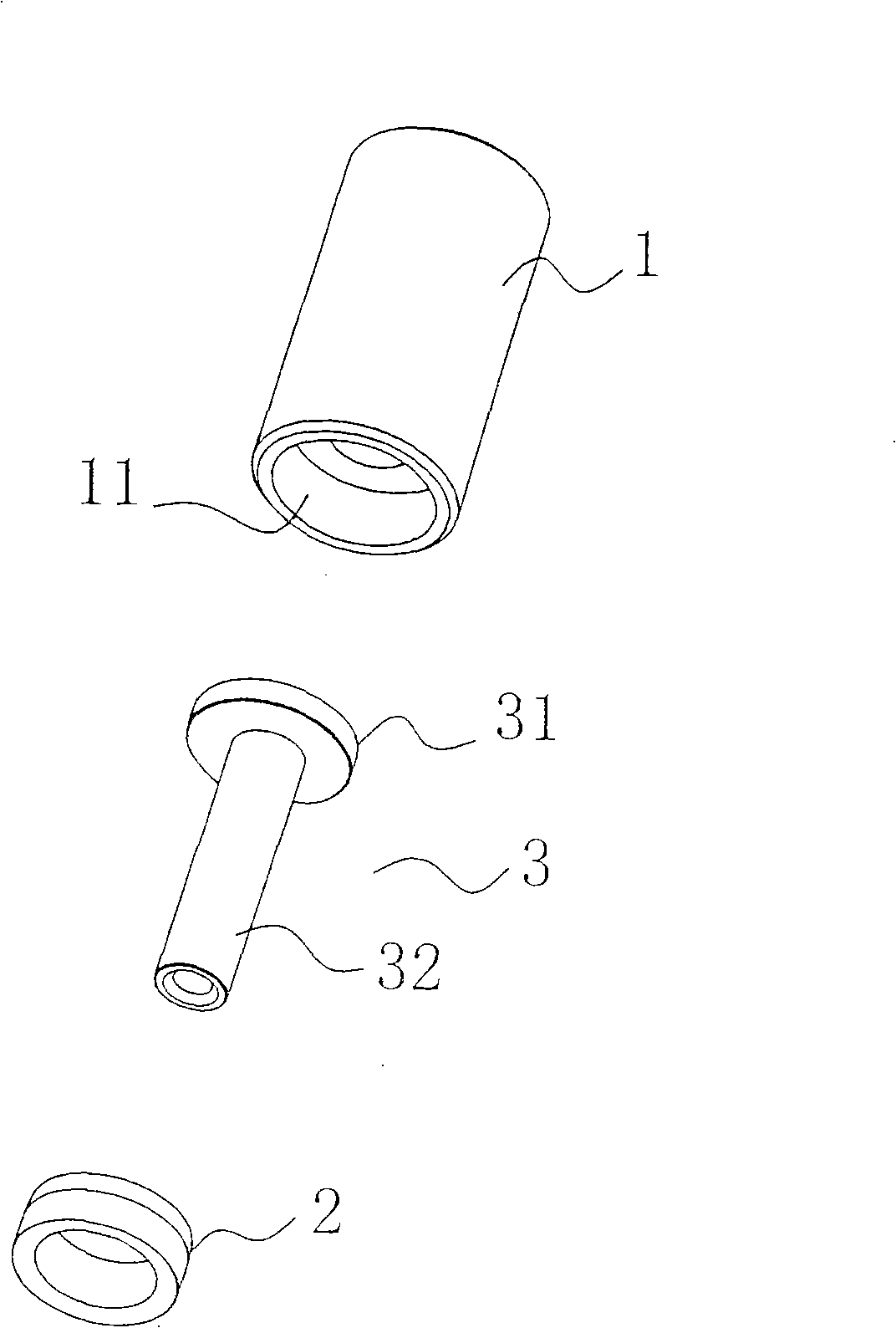

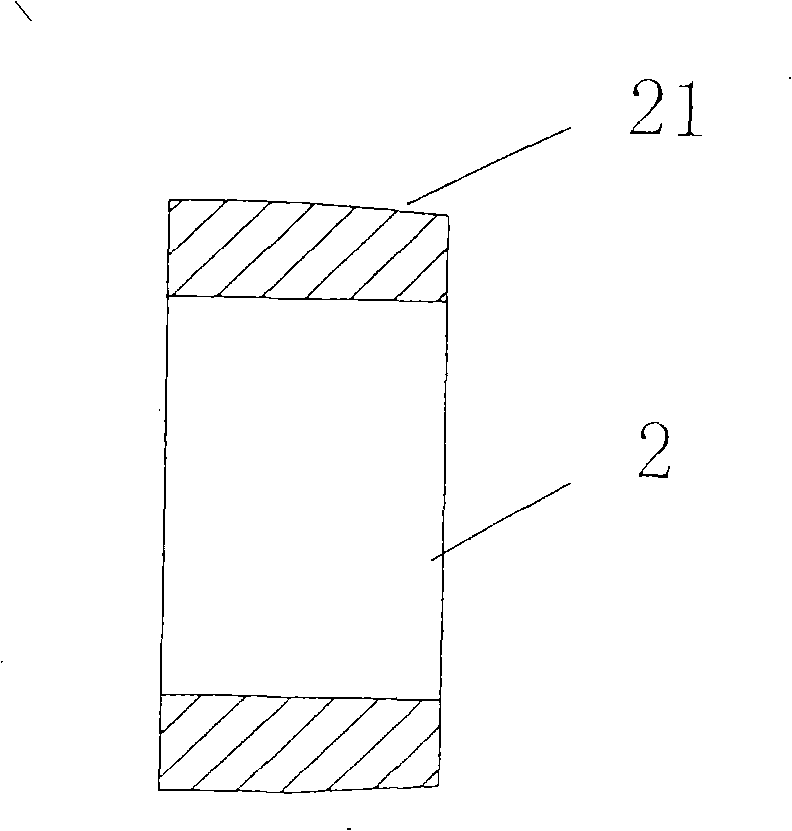

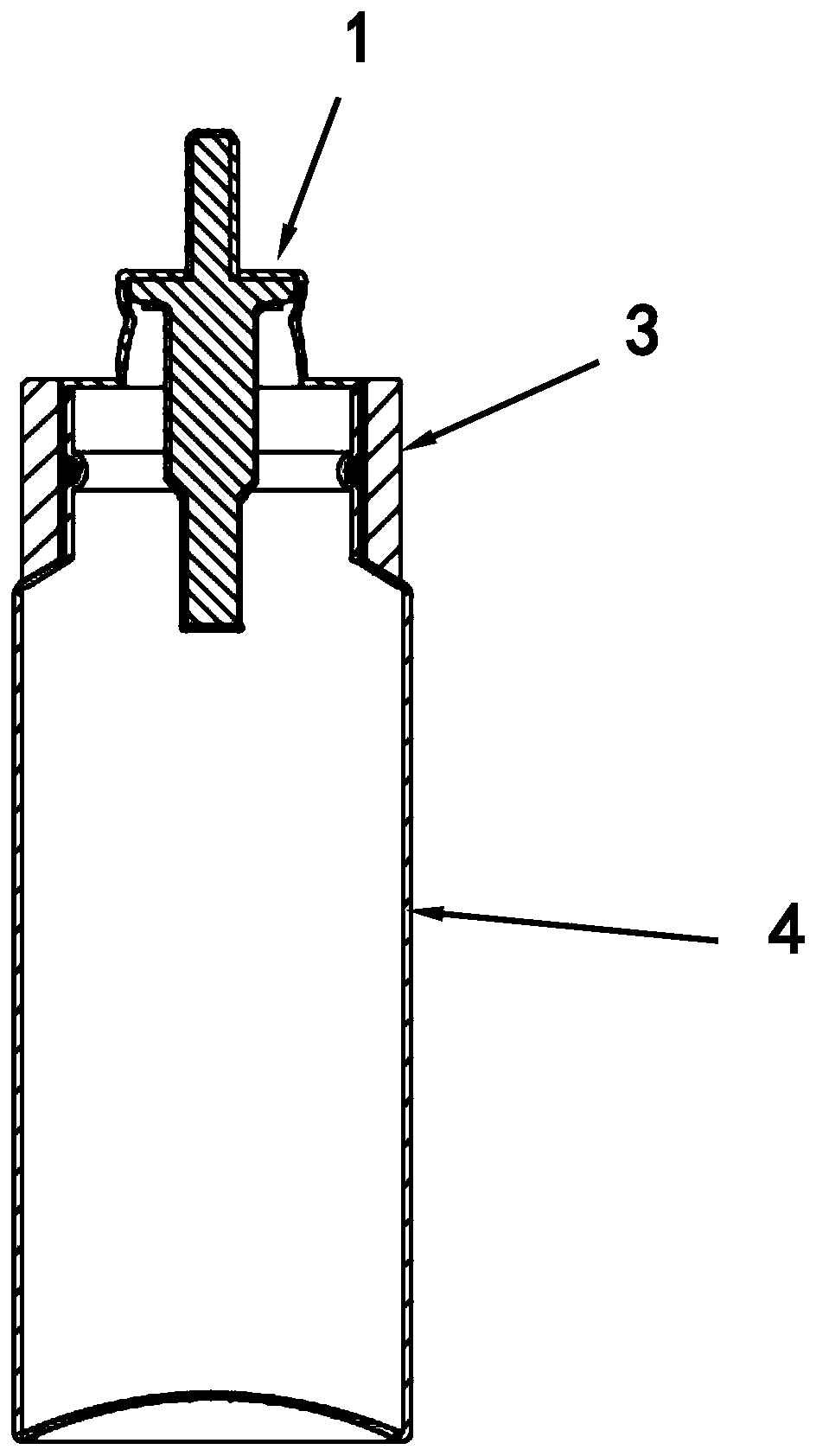

Novel piston used in plunger type water pump

InactiveCN101344083ALow costOvercoming problems requiring multiple machining passesPositive displacement pump componentsLiquid fuel engine componentsPistonMetallic materials

The invention relates to a novel piston which is applied to a plunger-typed water pump and consisits of a metal core, a fixing ring and a piston head, wherein, the metal core which is made of magnetic conductive metallic material is a hollow columnar structure, the connecting end of the metal core is opened with a groove which is communicated and coaxial with the hollow through hole of the metal core, the piston head is a T-shaped hollow structure, the inner bore of the fixing ring leads the fixing ring to be just sheathed on the shaft of the piston head, the shape and size of the outer section of the fixing ring corresponds to those of the groove section of the metal core in an interference fit way, the depth of the groove of the metal core is larger than the thickness of the T-shaped piston head connecting face, and when being assembled, the connecting end of the piston head is inserted in the groove of the metal core, and the fixing ring which is sheathed on the shaft of the piston head is tightly pressed on the interstitial position after the matching of the groove of the metal core and the connecting end of the piston head by a special holding-down device. The invention is characterized by novel structure, adopts a combined structure, and has low cost and easy assembly.

Owner:SHENZHEN CNHT LTD

Oxidation resisting sunshade net and processing technology thereof

InactiveCN112385461AImprove antioxidant capacityStrong insect repellentConjugated cellulose/protein artificial filamentsBiochemical treatment with enzymes/microorganismsCelluloseMasterbatch

The invention relates to the technical field of sunshade nets, and particularly discloses an oxidation resisting sunshade net. The oxidation resisting sunshade net comprises the following materials of, in parts by weight, 45 parts-60 parts of polyethylene fibers, 10 parts-30 parts of plant fibers, 8 parts-12 parts of hydroxymethyl cellulose, 100 parts-120 parts of high-density polyethylene masterbatch, 8 parts-10 parts of carbon nanotubes, 4 parts-8 parts of an antioxidant and 3 parts-5 parts of a light stabilizer. The invention further discloses a processing technology of the oxidation resisting sunshade net. Through the formula provided by the oxidation resisting sunshade net and the processing technology, the energy-saving and environment-friendly sunshade net has the advantages of being high in oxidation resistance and insect prevention, meanwhile, the toughness is high, the service life of the sunshade net can be prolonged, the processing technology is simple, the finished product efficiency is high, pollutants harmful to the environment are not generated in the production process, the atmospheric environment is favorably operated, energy is saved, and the environment is protected.

Owner:无棣益展塑业有限公司

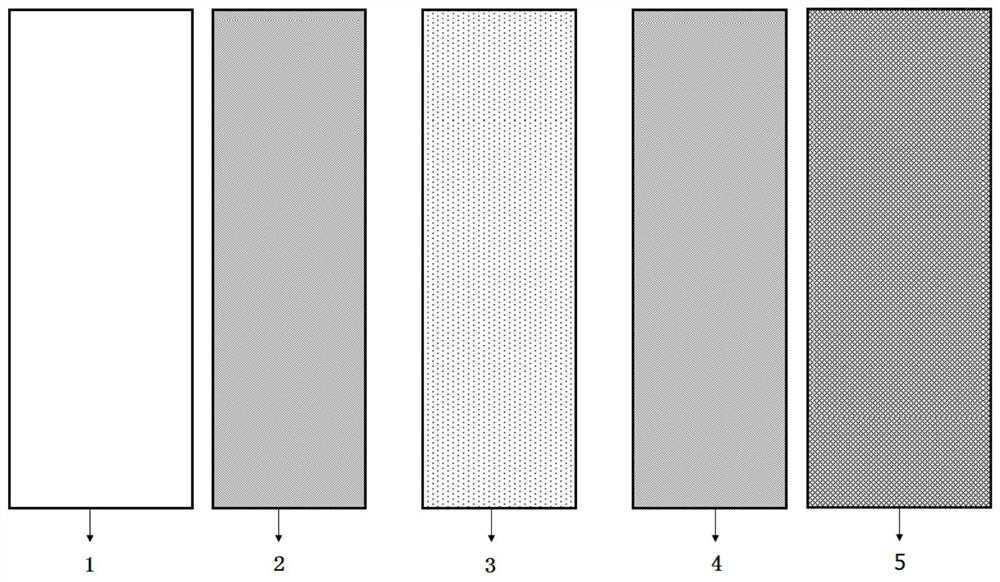

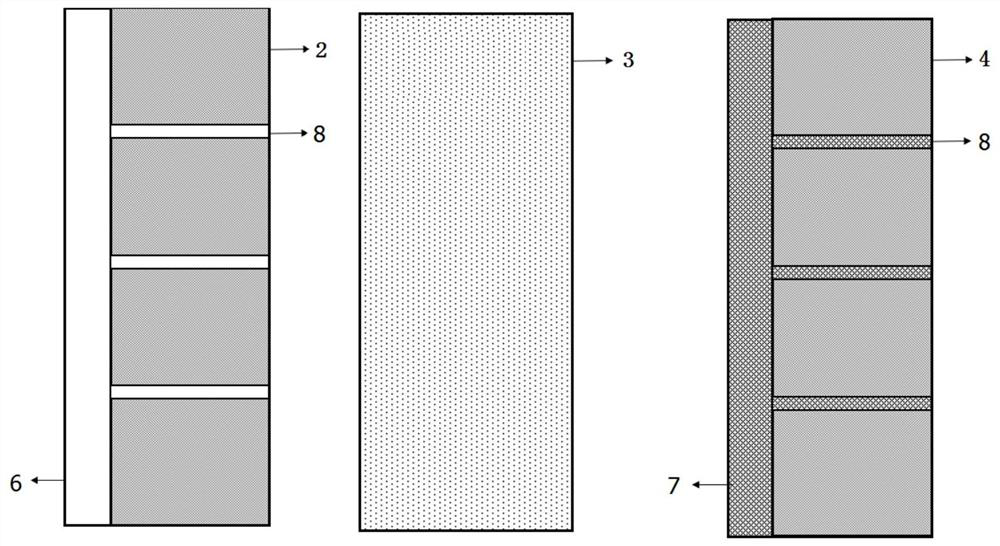

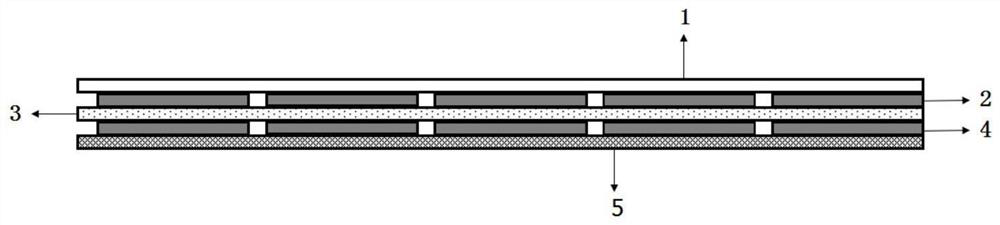

TPU acoustic film and preparation method thereof

ActiveCN110774717ASimple processEasy to operateSynthetic resin layered productsLaminationEpoxyPolymer science

The invention discloses a TPU acoustic film, which sequentially comprises a first outer layer, a first adhesion layer, a core layer, a second adhesion layer and a second outer layer from top to bottom, wherein the core layer is formed by a modified 1-chloromethyl-2,4-diisocyanobenzene / dimethyl dioxime polycondensate film, the first outer layer and the second outer layer are independently a modified TPU film, and the first adhesion layer and the second adhesion layer are independently formed by carrying out melt extrusion, cooling curing and roller calendering on at least one selected from an ethylene-vinyl acetate copolymer adhesive, an epoxy resin adhesive and a polyurethane adhesive at 220-250 DEG C. According to the invention, the TPU acoustic film retains the excellent characteristicsof high strength, tear resistance, wear resistance and the like of the TPU material, and further has characteristics of excellent heat resistance, excellent flame retardance, excellent environmental protection performance, high sensitivity, high consistency, good performance stability and long service life.

Owner:苏州市伽俐电子有限公司

Novel textile jet-dyeing machine

InactiveCN107164894AImprove finished product efficiencyImprove adaptabilityHeating/cooling textile fabricsTextile treatment by spraying/projectingElectric machineryIndustrial engineering

The invention discloses a novel textile jet-dyeing machine. The machine comprises a jet-dyeing machine frame, a clamping block, a clamping block shaft and a feed inlet, the left side of the upper end of the jet-dyeing machine frame is provided with a motor, the right side of the upper end of the jet-dyeing machine frame is provided with a control table, the upper end of the inner wall of the jet-dyeing machine frame is provided with a slide rail, the slide rail is slidably connected with a slide block, the bottom end of the slide block is fixedly connected with an extension rod, one side of a pulley support is in coupling with a pulley, the upper middle part of the right side of the inner wall of the jet-dyeing machine frame is fixedly connected with a delivery table support, the delivery table support is in coupling with a delivery shaft, the delivery shaft is in coupling with a delivery belt, the upper middle part of the right side of the inner wall of the jet-dyeing machine frame is provided with a discharging opening. By adding heaters, cloth dyeing and heating are integrated into one, and thus the textile product finishing efficiency is improved; through the adoption of the design of independent work of the heaters and dyestuff sprinkling nozzles, the adaptability of the jet-dyeing machine is higher.

Owner:SUZHOU DANFANG TEXTILE R & D

Hyodeoxycholic acid refining method

The invention relates to a hyodeoxycholic acid refining method. The hyodeoxycholic acid refining method comprises the following steps of carrying out reflux extraction of a hyodeoxycholic acid crude product having a melting point above 170 DEG C 9 to 45 times by an ester organic solvent, rejecting the extract obtained by the 1 to 5th reflux extraction processes, collecting the extract obtained by the 6 to 45th reflux extraction processes, carrying out concentration heating until crystals are precipitated, cooling, carrying out filtration, and drying and crushing the filter residues to obtain hyodeoxycholic acid having high purity greater than 98%, a melting point greater than or equal to 196.5 DEG C, a melting range less than 2 DEG C and no fishy smell. The hyodeoxycholic acid refining method has the advantages of high product quality, high yield, high production efficiency, low production cost, simple processes and good repeatability, is suitable for pharmacy industrial application and has a good application prospect.

Owner:SHINEWAY PHARMA GRP LTD

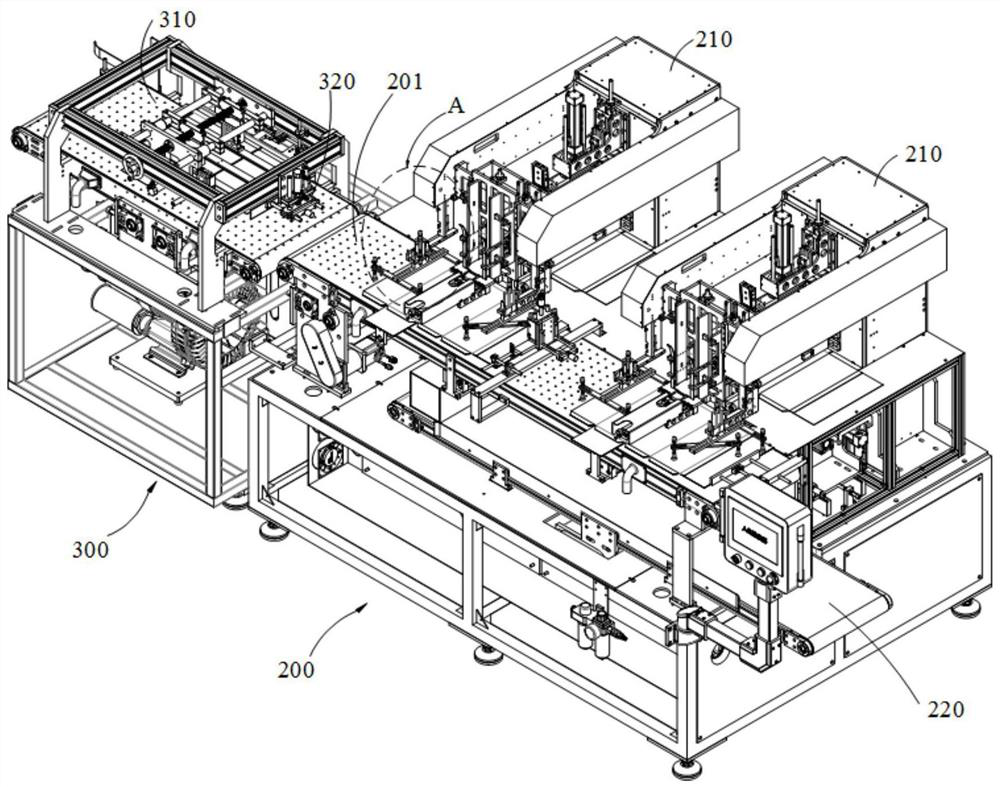

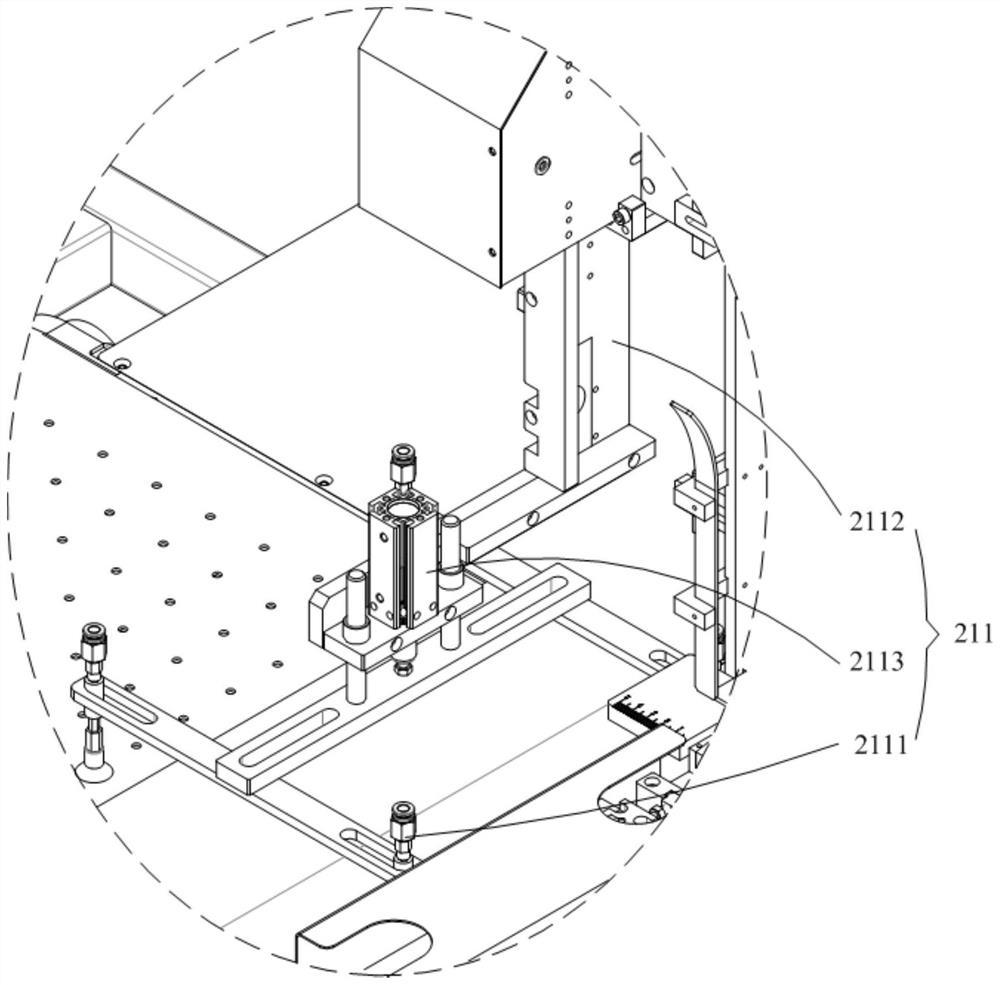

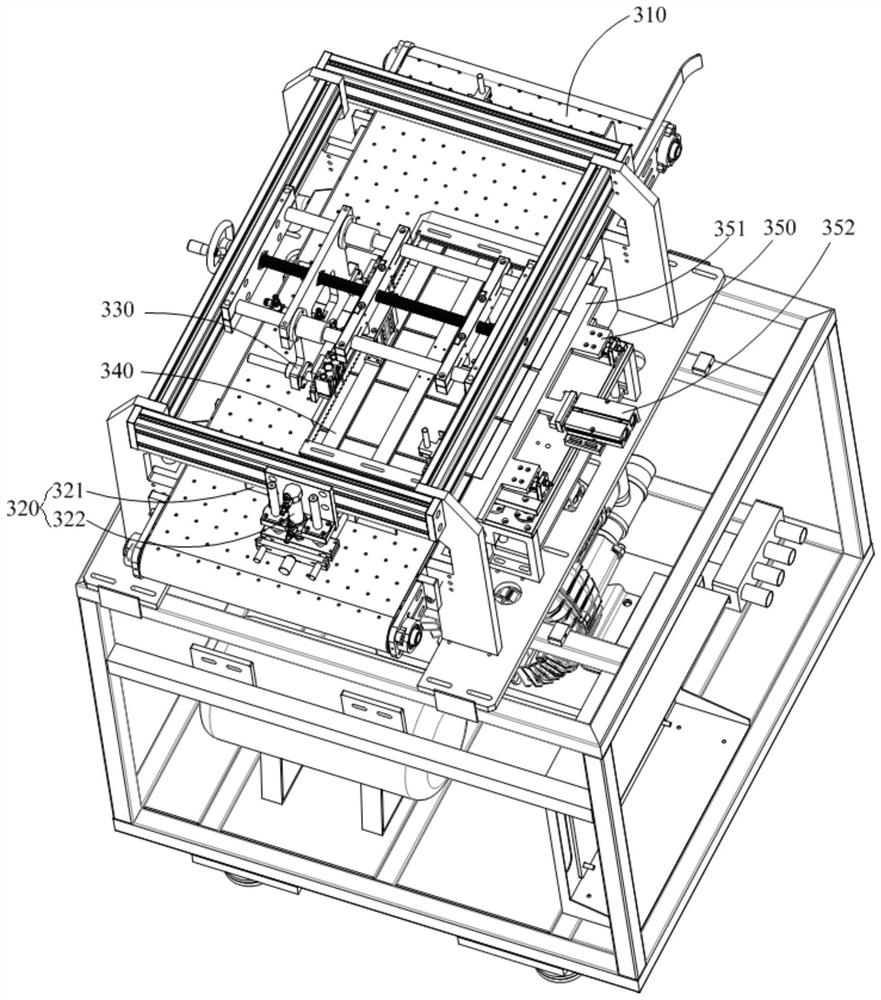

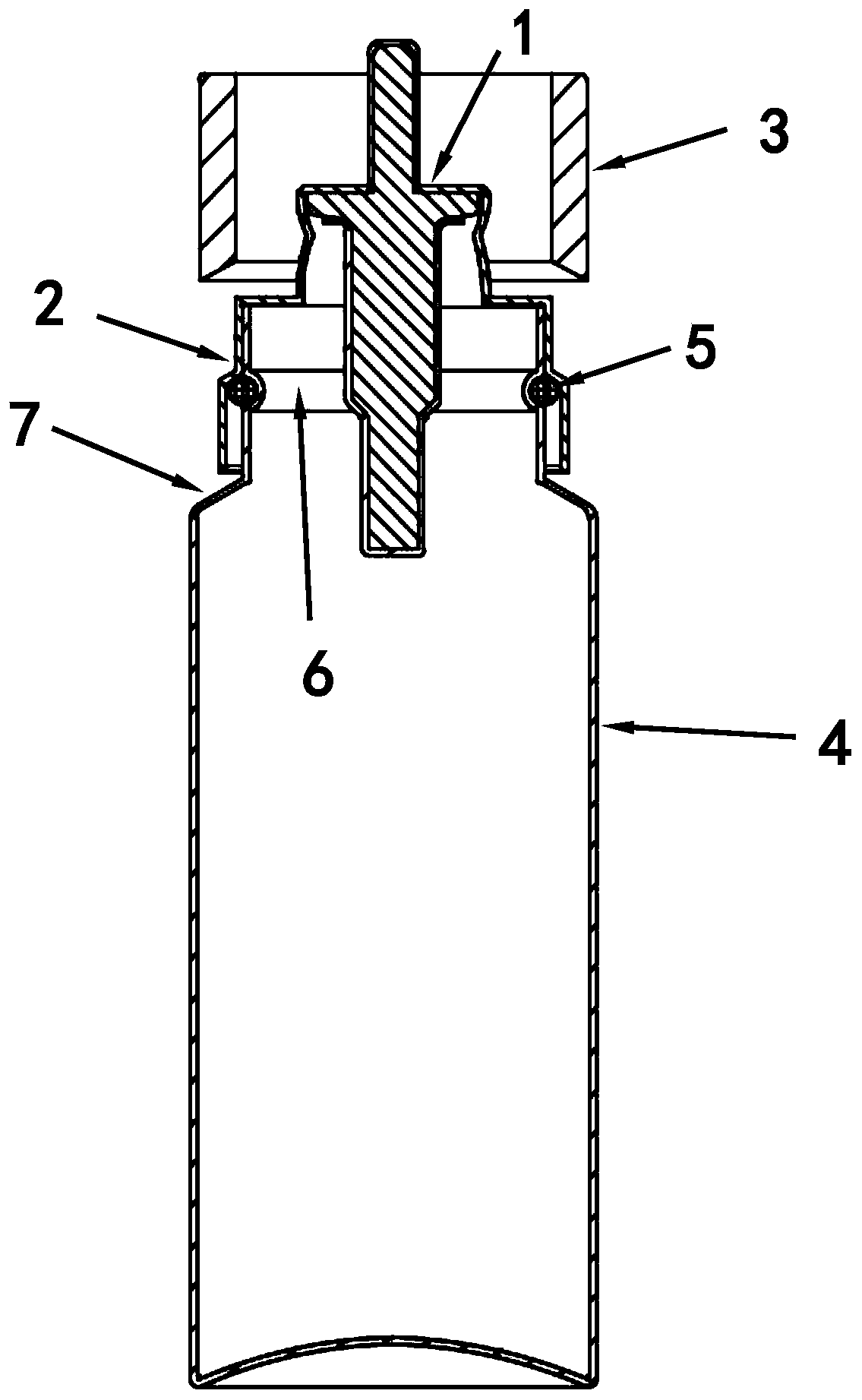

Rapid packaging method of aerosol packaging system

PendingCN110789764AReduce areaShorten the timePackaging under special atmospheric conditionsAerosol sprayEngineering

The invention discloses a rapid packaging method of an aerosol packaging system, in particular to a rapid packaging method of an aerosol packaging system based on a sealing ring, a sealing seal ring and a sealing seal ring assembling position. The rapid packaging method aims to solve the problems that in the case of a traditional packaging mode, debugging is difficult, calculation and measurementof the position of a grabbing port are tedious, and the cost and quality control problems are caused by special sealing equipment. The rapid packaging method comprises the following steps that 1, thesealing seal ring is mounted, wherein the sealing seal ring is assembled in a seal groove below a bottle opening of an aerosol bottle, one half of the sealing seal ring is embedded into the seal groove, and the other half of the sealing seal ring is exposed out of the seal groove; 2, an aerosol quantitative valve is mounted, and specifically the aerosol quantitative valve is coaxially arranged onthe aerosol bottle in a sleeving mode; and 3, the aerosol sealing ring is mounted, wherein the sealing ring is coaxially arranged a valve deck of the quantitative valve in a sleeving mode, the sealingring presses downwards, so that the inner diameter of the valve deck is contracted, the sealing seal ring is squeezed to form sealing, the sealing ring presses downwards to a certain degree to abut against the stopping surface, and packaging is completed. After the method is adopted, packaging can be carried out without debugging, the position of the grabbing port of the valve deck and the compression amount of the seal ring do not need to be measured, calculated and calibrated, special sealing equipment is also not needed, meanwhile, the contact area between the seal ring and the liquid chemical can be greatly reduced, the contact time between the seal ring and the liquid chemical can be greatly shortened, and leaching impurities in the liquid chemical are reduced.

Owner:泛卡医药科技(上海)有限公司

A cell manufacturing process based on dry film formation

ActiveCN111952679BImprove finished product efficiencyImprove securityFinal product manufactureSecondary cellsPhysical chemistryEngineering

The invention provides a battery cell preparation process based on dry film formation. In the process, firstly, the self-supporting positive and negative electrode dry film obtained by the dry process is combined with the positive and negative electrode collectors to obtain the positive and negative electrode sheets; Then scrape off part of the dry-process film to leave a blank area; finally, combine the positive and negative plates with the separator and perform Z-folding as a whole to obtain the finished battery cell. At the same time, the invention also discloses a battery comprising the above electric core. Based on the cell preparation process provided by the present invention, it is different from traditional winding cells and laminated cells, and can effectively avoid the generation of burrs and kinks on the die-cutting edges during production, and improve the production of cells. Efficiency and safety performance, simple process leads to equipment structure and cost reduction. The battery cell prepared based on the invention can increase the electrochemical stability and safety of the cycle process.

Owner:郜明文

Hyodeoxycholic acid refining method

The invention relates to a hyodeoxycholic acid refining method. The hyodeoxycholic acid refining method comprises the following steps of carrying out reflux extraction of a hyodeoxycholic acid crude product having a melting point above 170 DEG C 9 to 45 times by an ester organic solvent, rejecting the extract obtained by the 1 to 5th reflux extraction processes, collecting the extract obtained by the 6 to 45th reflux extraction processes, carrying out concentration heating until crystals are precipitated, cooling, carrying out filtration, and drying and crushing the filter residues to obtain hyodeoxycholic acid having high purity greater than 98%, a melting point greater than or equal to 196.5 DEG C, a melting range less than 2 DEG C and no fishy smell. The hyodeoxycholic acid refining method has the advantages of high product quality, high yield, high production efficiency, low production cost, simple processes and good repeatability, is suitable for pharmacy industrial application and has a good application prospect.

Owner:SHINEWAY PHARMA GRP LTD

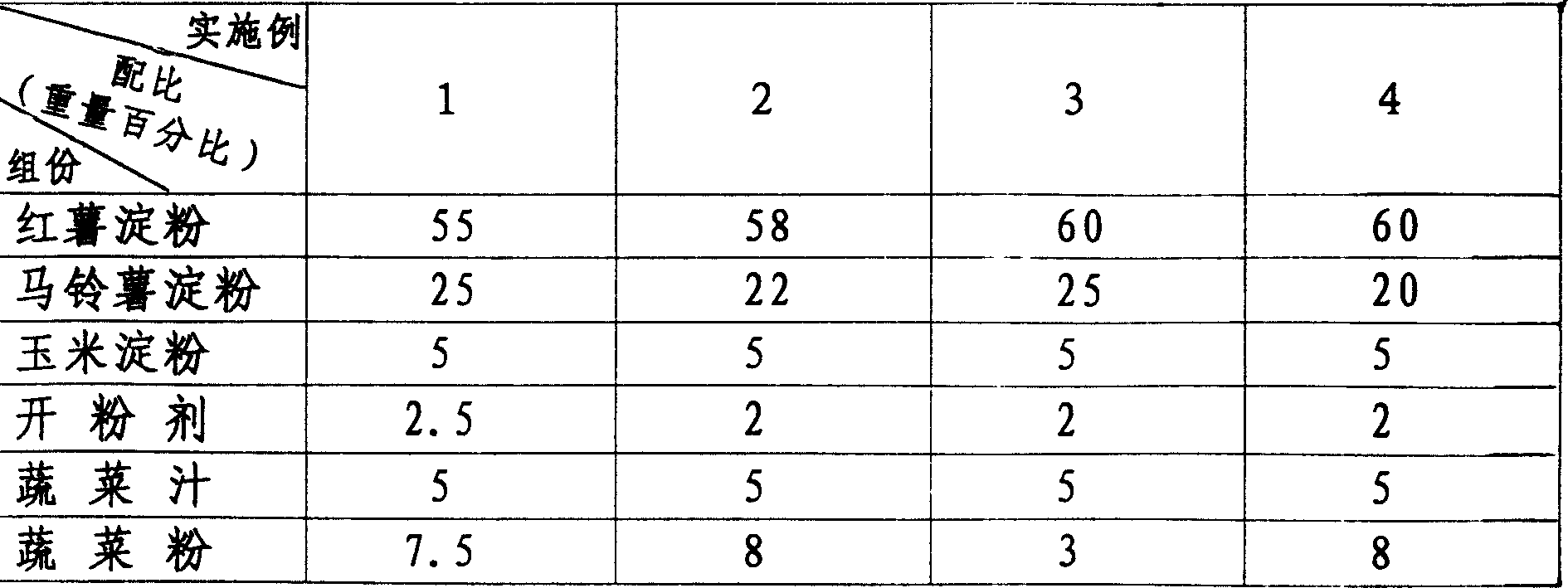

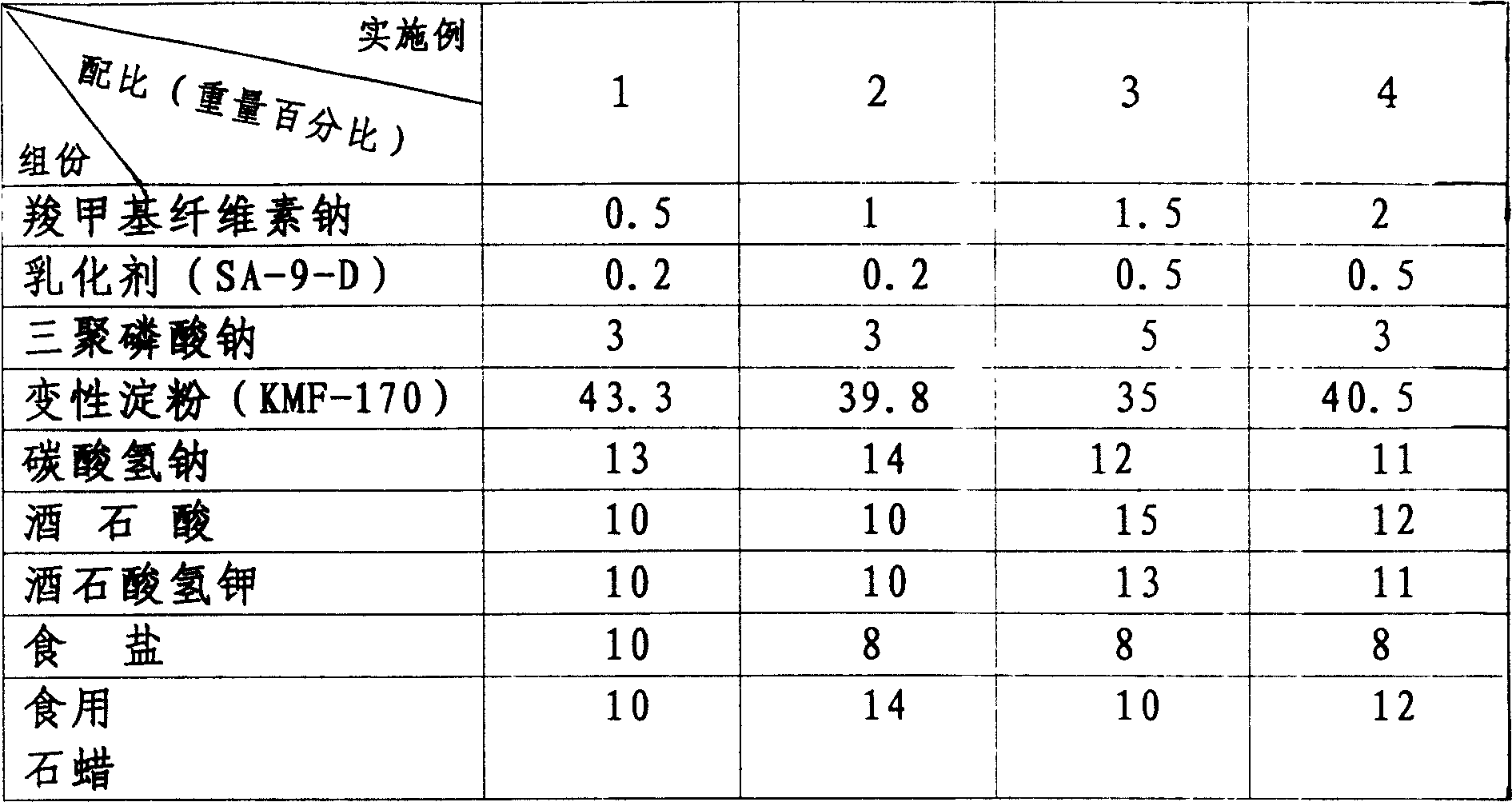

Vegetable powder cake and its production process

InactiveCN1237898CGood rehydrationGreat tasteFood preservationFood preparationBiotechnologySodium bicarbonate

The vegetable powder cake is produced with sweet potato powder, potato powder, corn starch, powder dispersing agent, vegetable juice and vegetable powder, and its powder dispersing agent consists of carboxymethylcellulose sodium emulsifier, sodium tripolyphosphate, modified starch, sodium bicarbonate, tartaric acid, sodium bitartrate, salt and edible paraffin. The present invention also provides the production process of the vegetable powder cake. The vegetable powder cake may be well mixed with water for restoring and is delicious and tough.

Owner:SICHUAN BAI JIA FOOD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com