Three-dimensional flexible material molding system and method

A flexible material and three-dimensional forming technology, which is applied in the direction of liquid material additive processing, additive processing, processing and manufacturing, etc., can solve the problems of inability to form finished products with materials, achieve convenient and fast printing, improve the efficiency of finished products, and realize the effect of production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

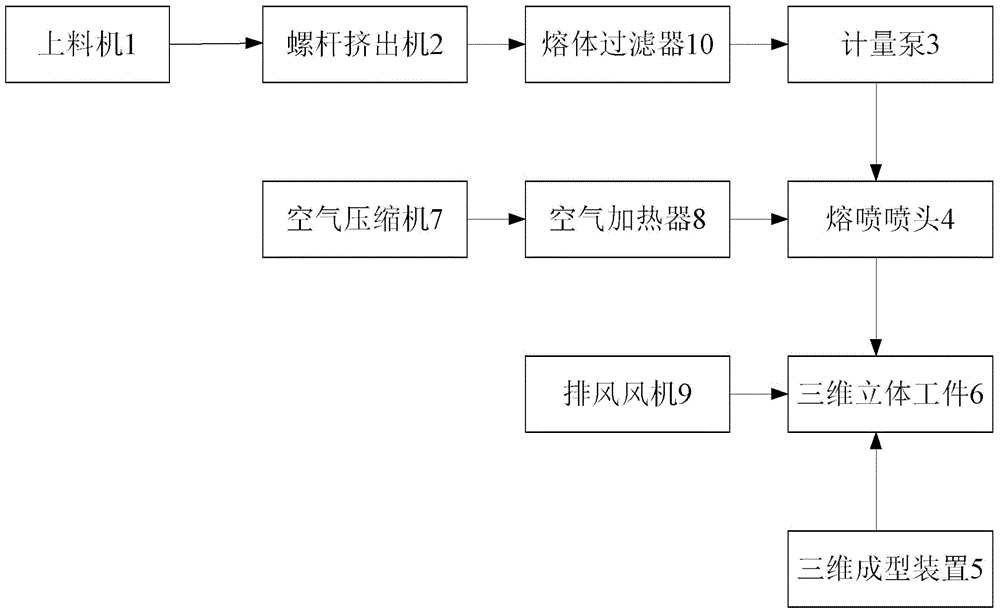

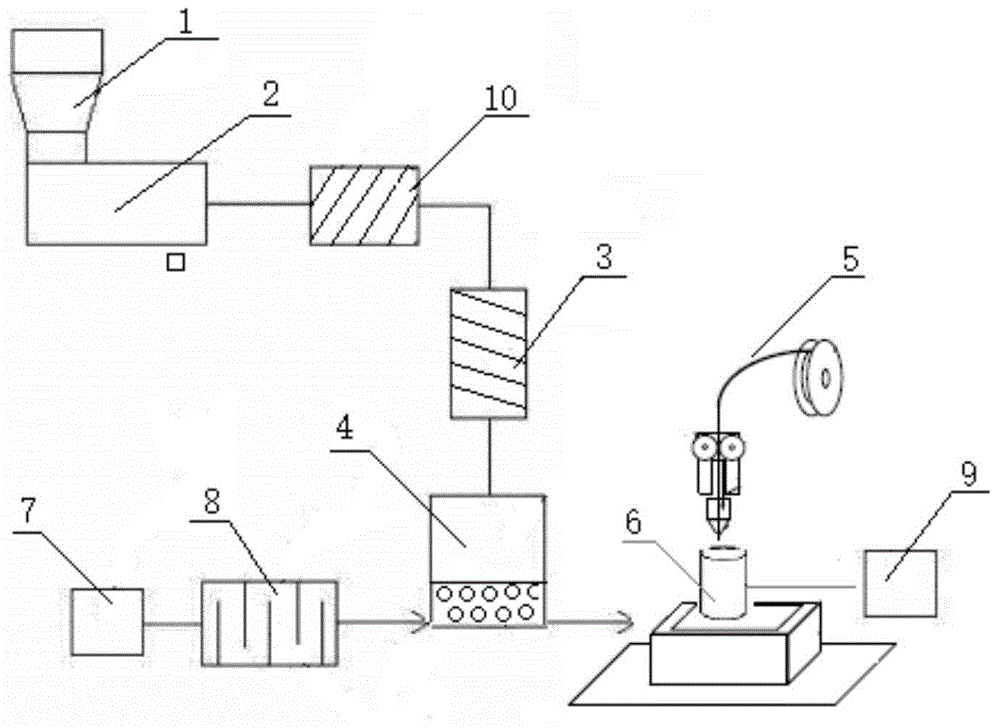

[0041] Such as Figure 1~3 As shown, the present invention provides a flexible material three-dimensional molding system, comprising:

[0042] feeder 1, used to provide polymer melt;

[0043] A screw extruder 2 communicated with the feeder 1 for extruding the polymer melt;

[0044] The metering pump 3 that is communicated with described screw extruder 2, is used for controlling the quantity of the polymer melt that flows into melt blowing nozzle 4;

[0045] Air compressor 7, used to compress air;

[0046] An air heater 8 communicated with the air compressor 7 for heating the compressed air;

[0047] The three-dimensional forming device 5 is used to process and shape the three-dimensional workpiece 6 supporting the flexible material; specifically, the three-dimensional workpiece 6 is used as a receiving layer for supporting the flexible material; the material used to form the three-dimensional workpiece can be a soluble material, such as polyvinyl alcohol PVA;

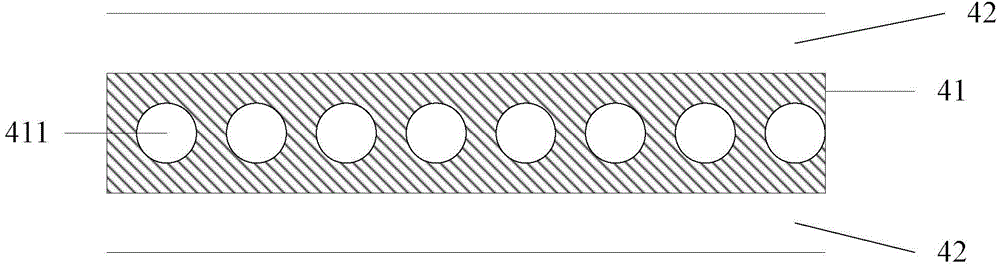

[0048] Mel...

Embodiment 2

[0059] Such as Figure 4 As shown, the present invention also provides another three-dimensional molding method for flexible materials, using the three-dimensional molding system for flexible materials in Embodiment 1, the method includes:

[0060] Step S1, the feeder provides the polymer melt to the screw extruder;

[0061] Step S2, the screw extruder extrudes the polymer melt to a metering pump;

[0062] Step S3, the metering pump controls the quantity of the polymer melt flowing into the melt blowing nozzle;

[0063] Step S4, the three-dimensional forming device processes the three-dimensional workpiece supporting the flexible material;

[0064] Step S5, the air compressor delivers the compressed air to the air heater, and the air heater heats the compressed air and delivers it to the airflow hole;

[0065] Step S6, the melt hole on the spinneret of the melt-blown nozzle ejects a fine flow of polymer melt to the three-dimensional workpiece, and the airflow hole of the me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com