Patents

Literature

221 results about "Polymer flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

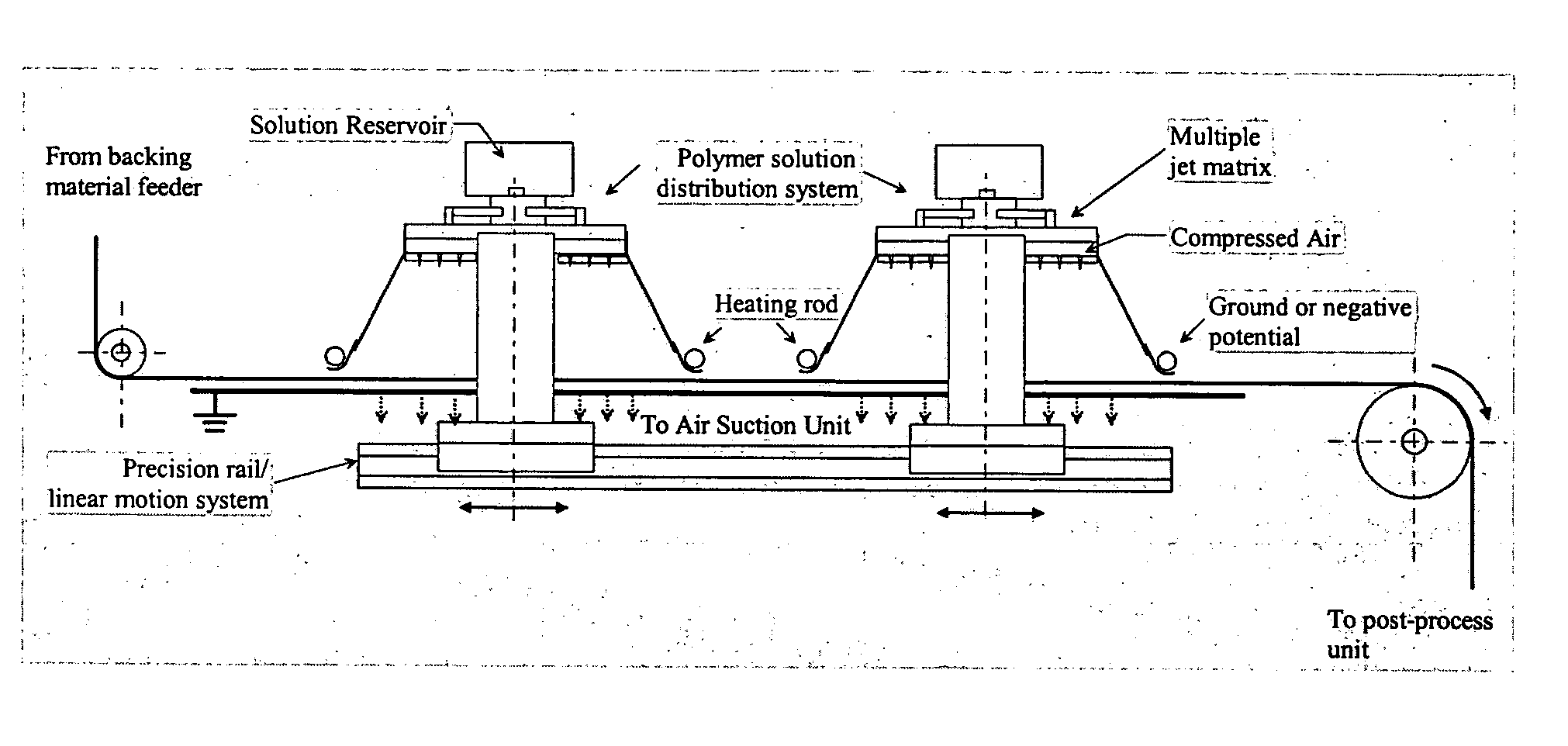

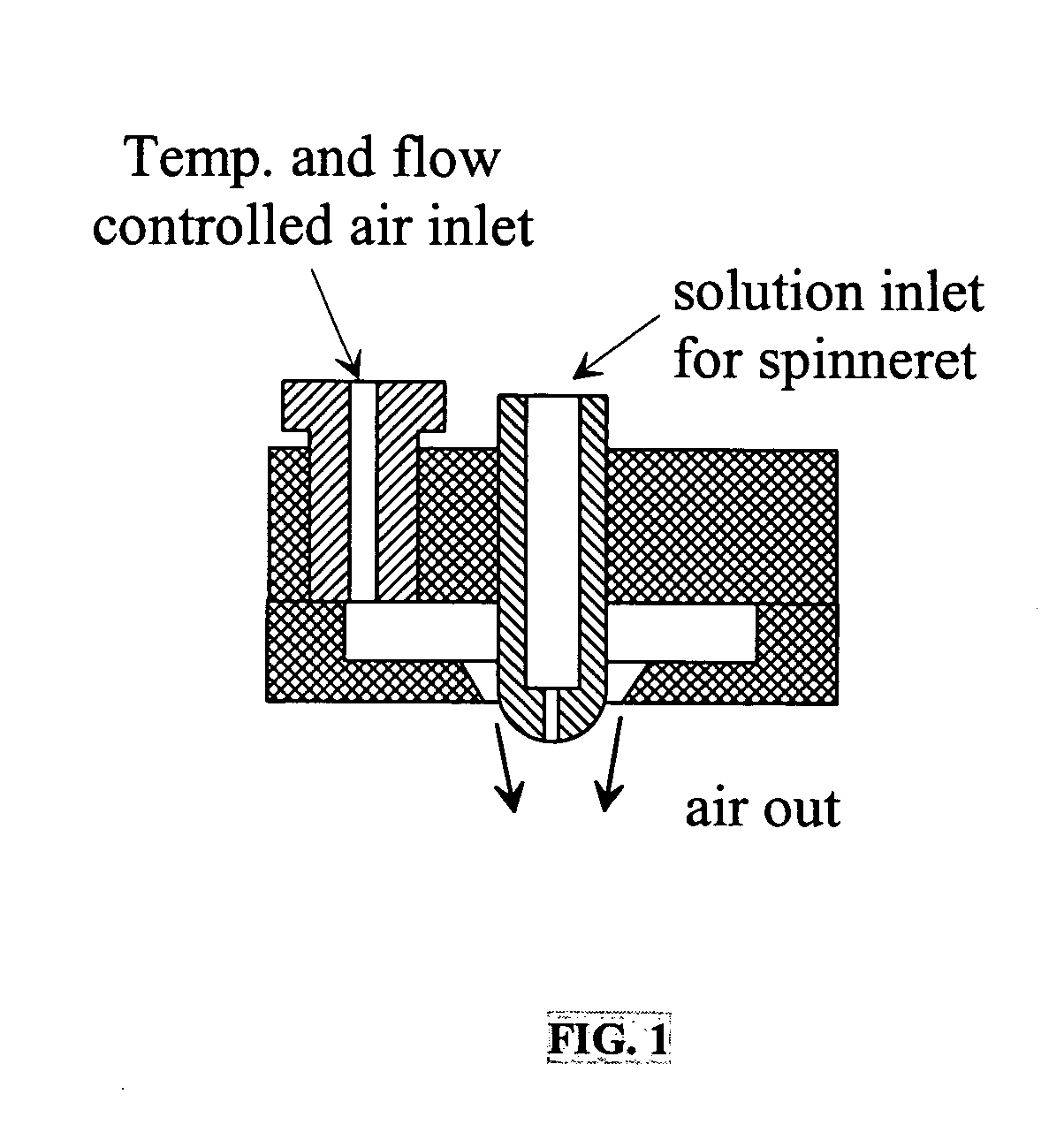

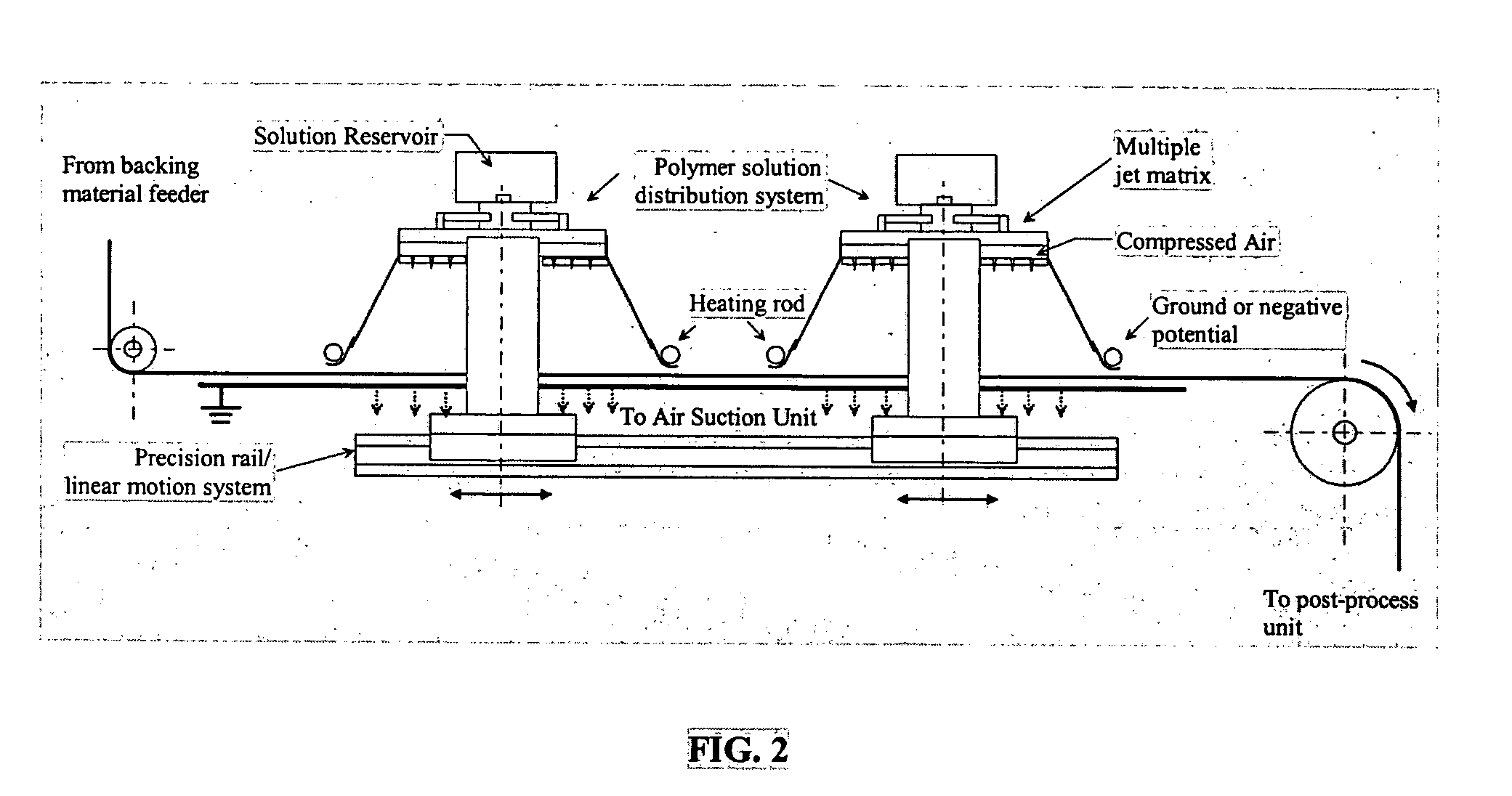

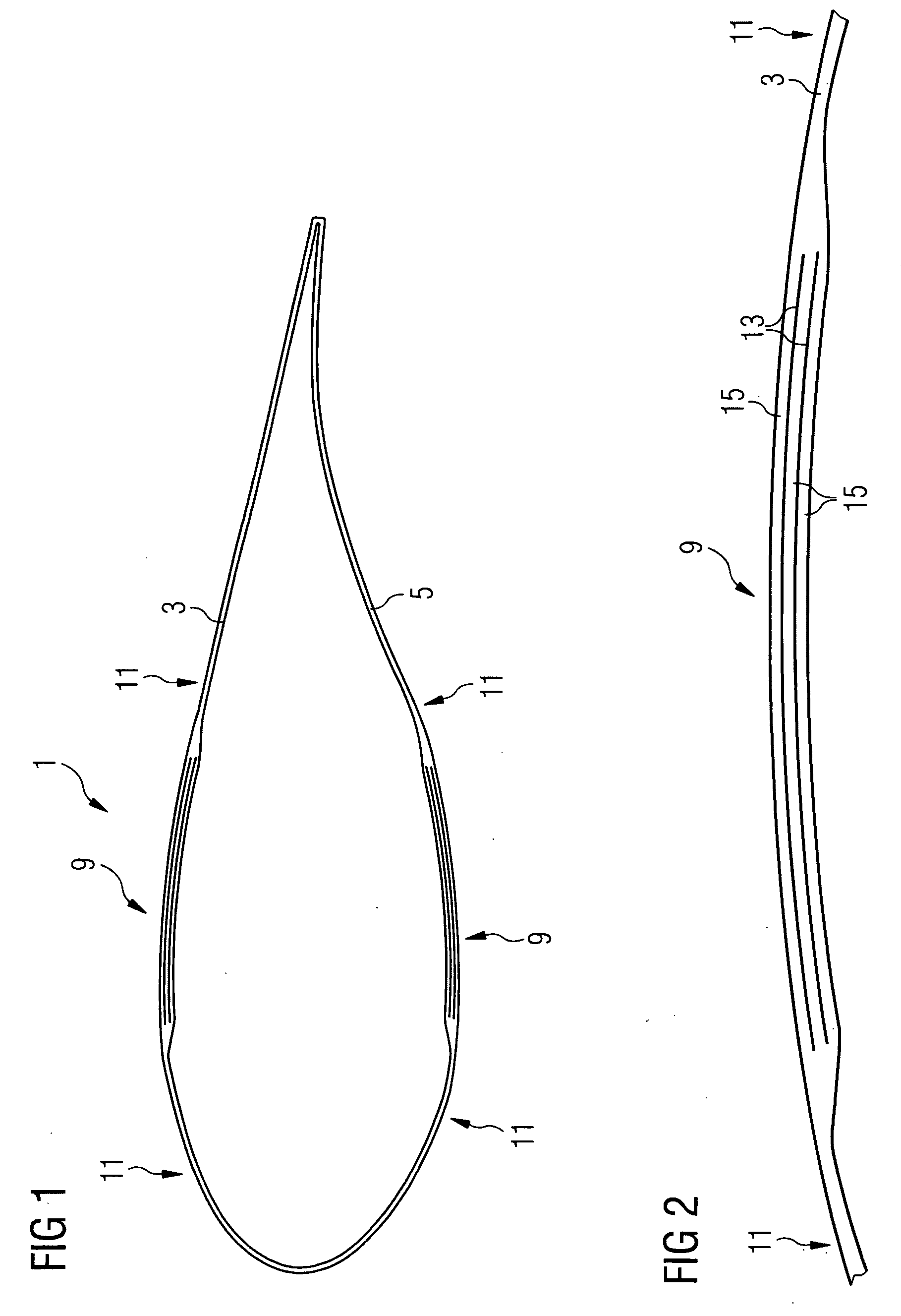

Electro-blowing technology for fabrication of fibrous articles and its applications of hyaluronan

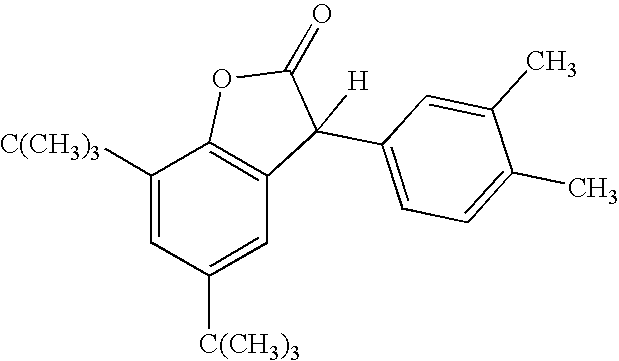

InactiveUS20050073075A1Improve the situationHigh productElectric discharge heatingFibre chemical featuresFiberNanofiber

A method for electroblowing fibers is provided which involves the steps of: forcing a polymer fluid through a spinneret in a first direction towards a collector located a first distance from the spinneret, while simultaneously blowing a gas through an orifice that is substantially concentrically arranged around the spinneret, wherein the gas is blown substantially in the first direction; wherein an electrostatic differential is generated between the spinneret and the collector; and collecting the fibers, and its use in preparing submicron scale fibers of various types, particularly hyaluronan fibers, and the hyaluronan nanofibers thus formed.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

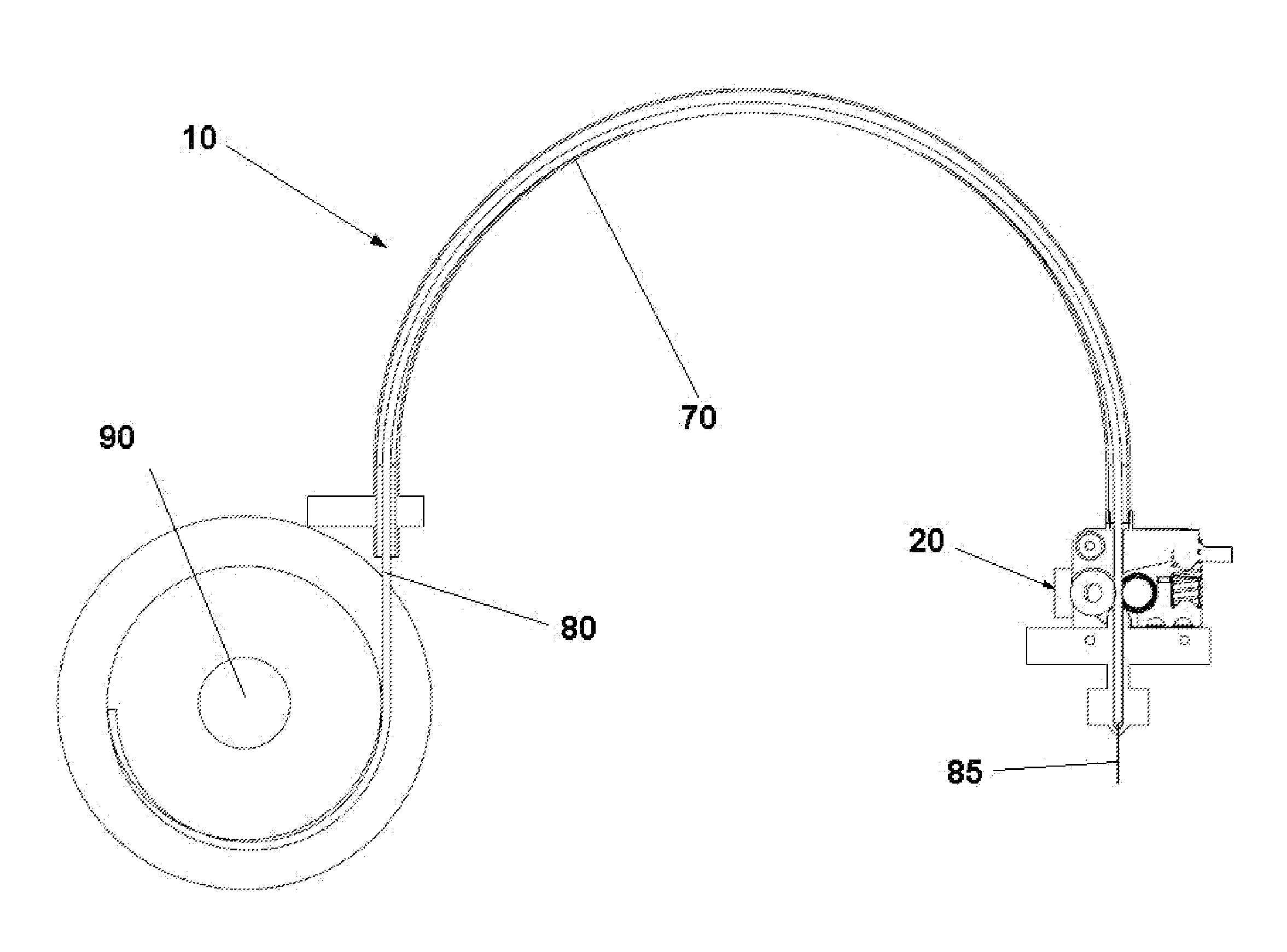

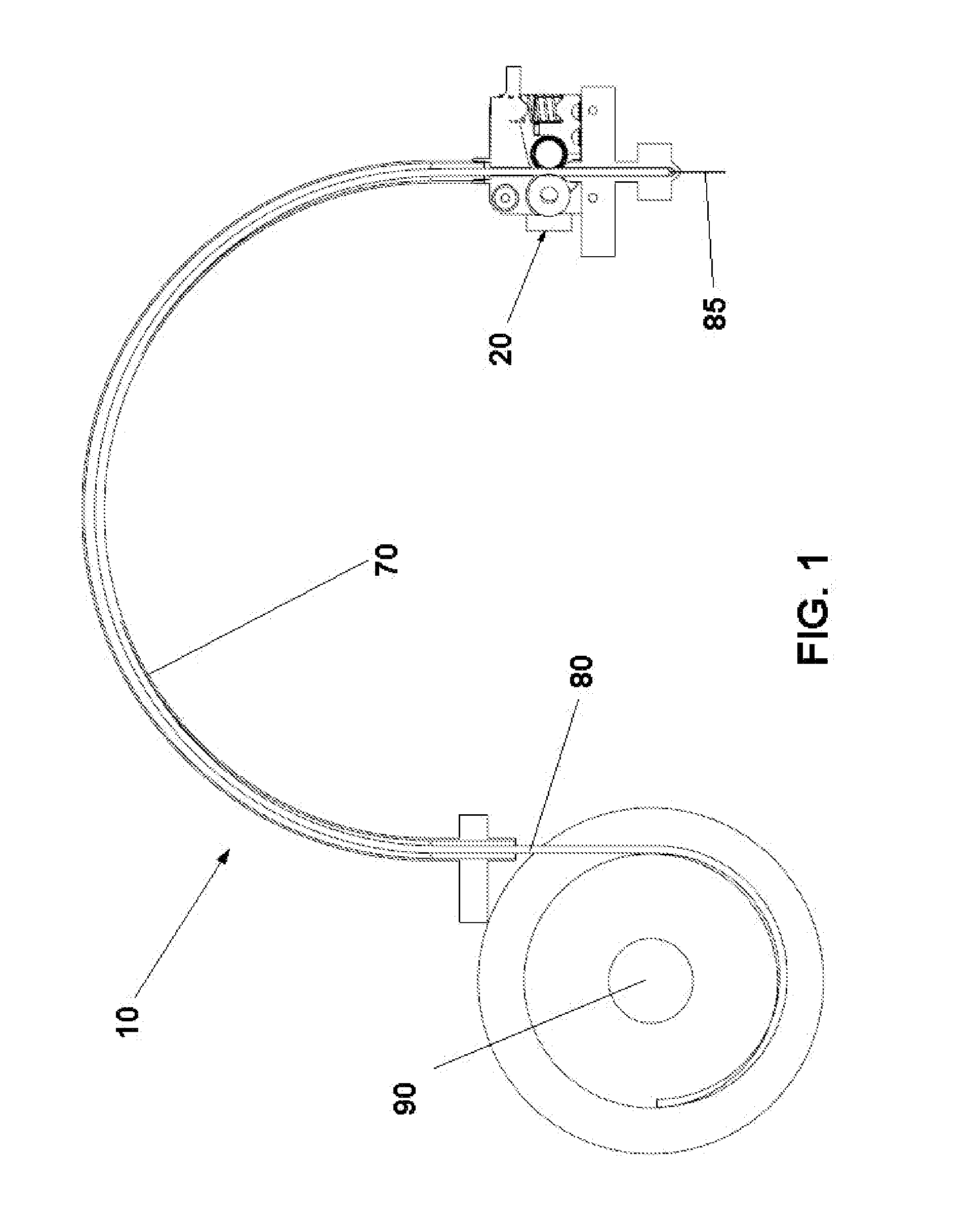

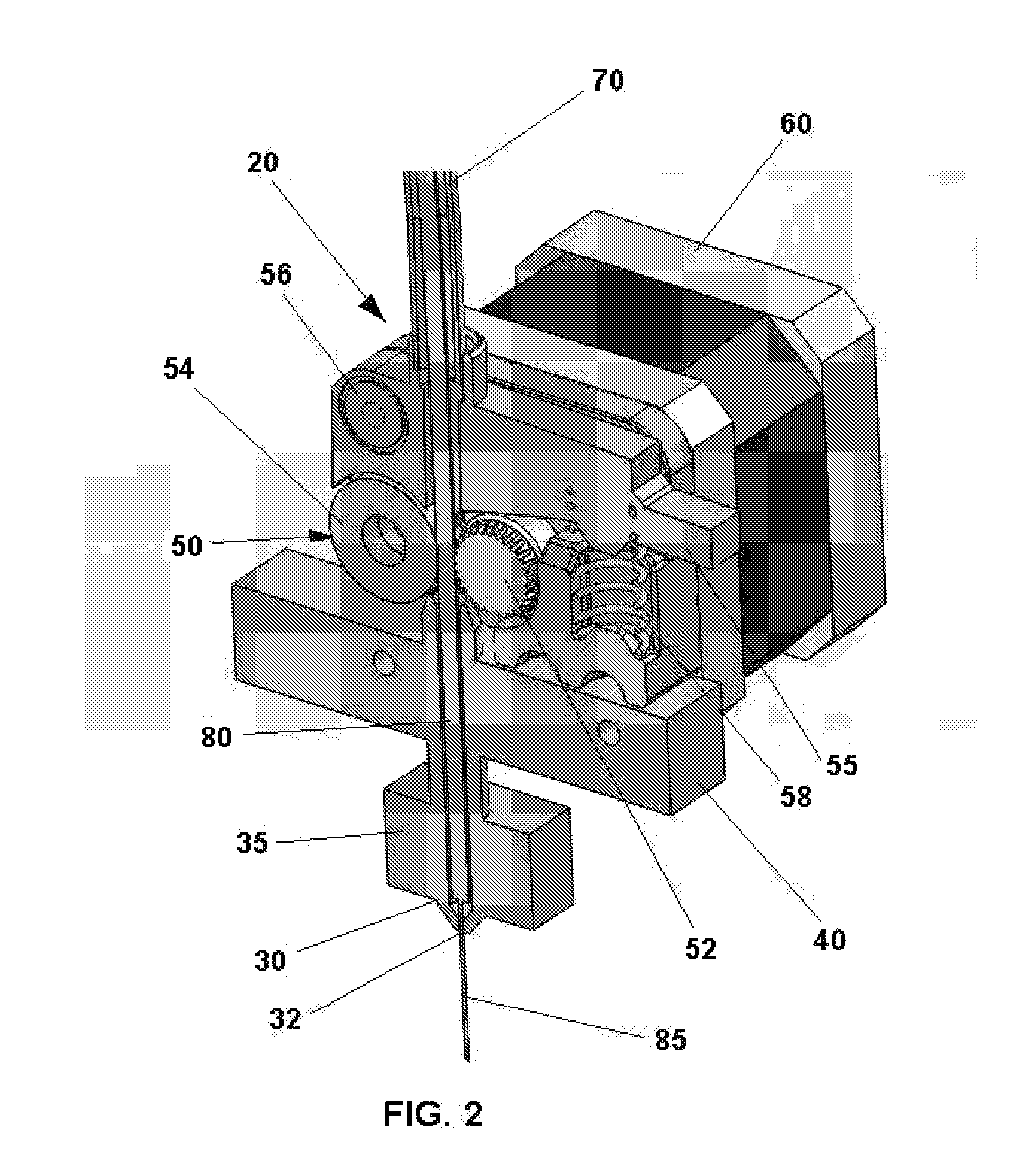

Filament for fused deposit modeling

InactiveUS20150084222A1Reduce viscosityImprove abilitiesAdditive manufacturing apparatusAuxillary shaping apparatusInstabilityEngineering

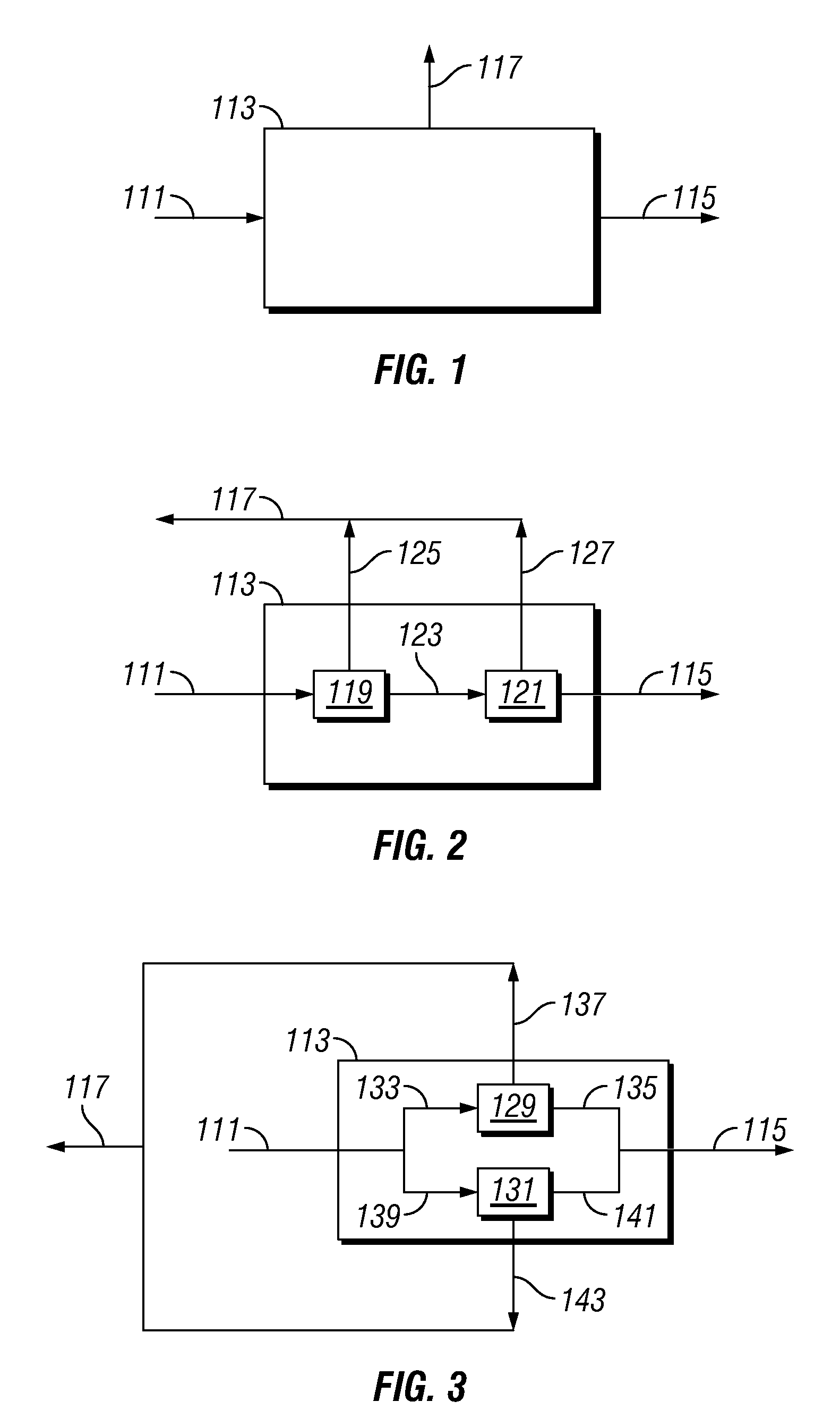

An apparatus for forming an object by an additive process, commonly referred to as 3-D printing, is provided. The apparatus includes a filament comprising a series of irregularities along the length of the filament, a nozzle depositing a layer of melted material onto a surface and a feeder feeding the filament to the nozzle. A heating element melts the filament and a controller controls the position of the nozzle in a plane to control the configuration of the layer of melted material deposited by the nozzle. Additionally, a method for forming polymer filament used in 3-D printing devices is also provided. The method includes the steps of melting a polymer, selecting an extrusion characteristic calculated to induce a polymer flow instability and extruding the melted polymer using the selected extrusion characteristic to produce an extrusion having distortions created by the polymer flow instability.

Owner:FENNER PLC

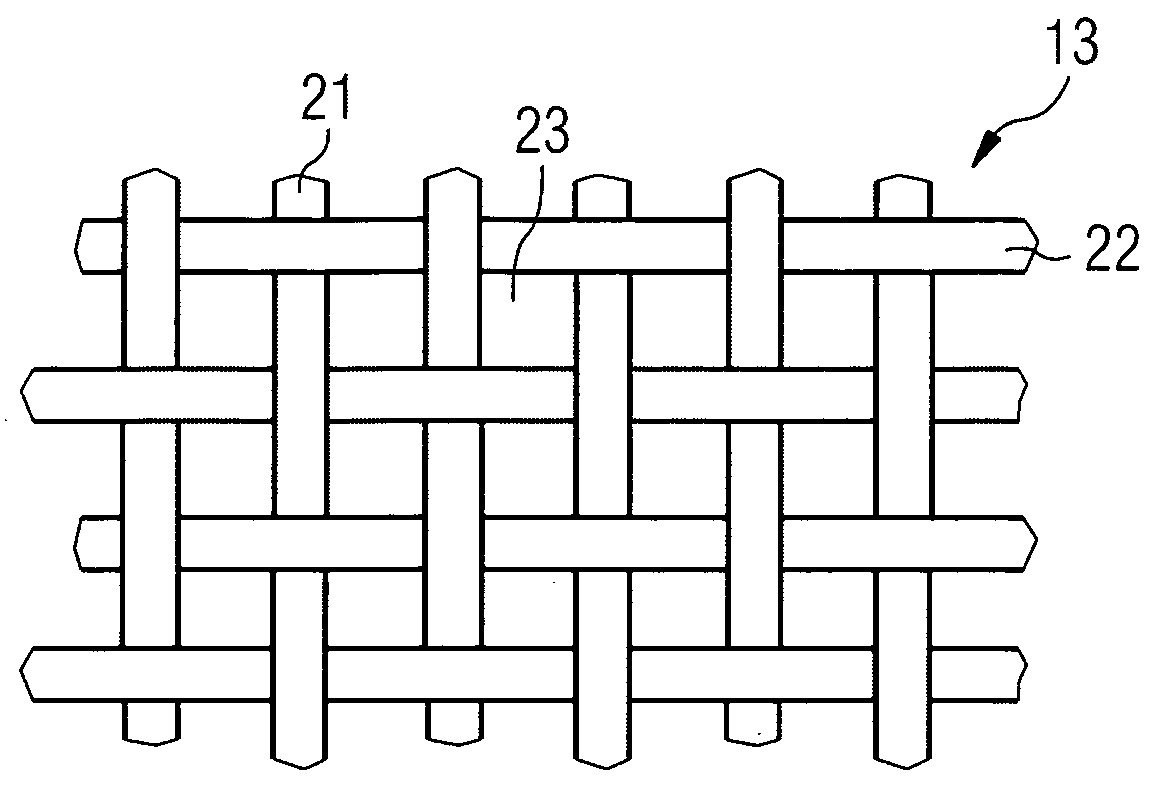

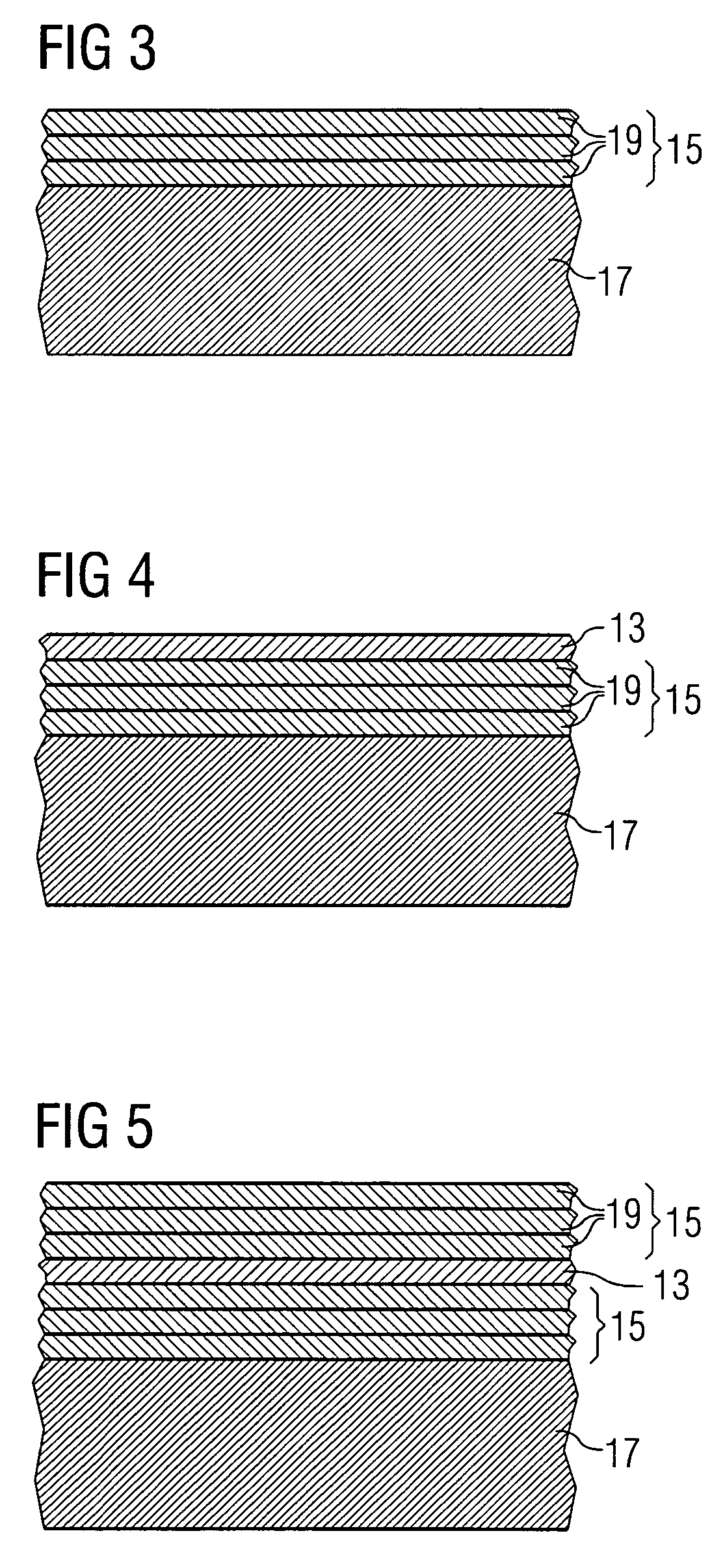

Method for producing fibre reinforced laminated structures

InactiveUS20080277053A1Fully moistenedReduce riskFinal product manufactureDomestic articlesLiquid statePolymer chemistry

There is described a method of producing fibre reinforced laminated structures by layering a number of dry fibre reinforcement layers by placing them on top of each other in a mould, infusing a curable viscous or liquid polymer into the mould after the fibre reinforcement layers have been layered in the mould and curing the polymer, wherein a flow enhancing layer for enhancing the polymer flow during infusion of the polymer is placed between two fibre reinforcement layers when layering the number of dry fibre reinforcement layers and wherein a pre-cured solid layer is used as the flow enhancing layer.

Owner:SIEMENS AG

Black pigment ink for ink-jet printer and method for preparing the same

The invention provides a black ink for ink-jet printers, which comprises 10-30% of carbon black, 0.1-1.25% of amphiprotic polymerized substance, 0.1-1.5% of levelling agent, 10-30% of wetting agent, 0.05%-0.5% of defoaming agent and deionized water, 20-33% of carbon black dispersion liquid, 0.05-2% of surface active agent, 5-50% of humectant, 0.1-2% of pH regulator, 0.5-2% of drier, 0.1-0.5% of preservative agent, 0.1-0.5% of mold preventive, 0.01-0.5% of chelating agent, 0.1-2% of resin and deionized water.

Owner:大连思创信息材料有限公司

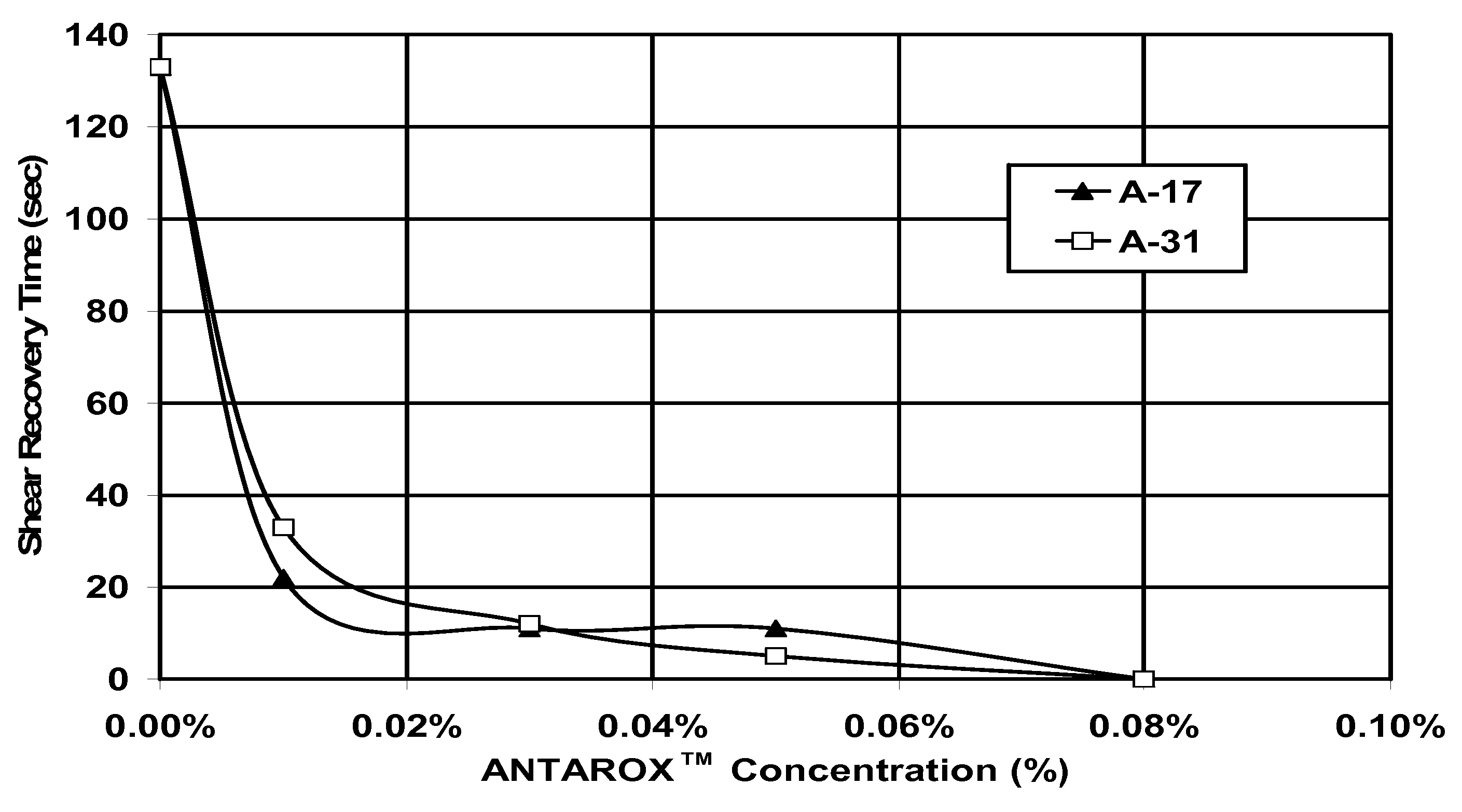

Rheology Modifiers

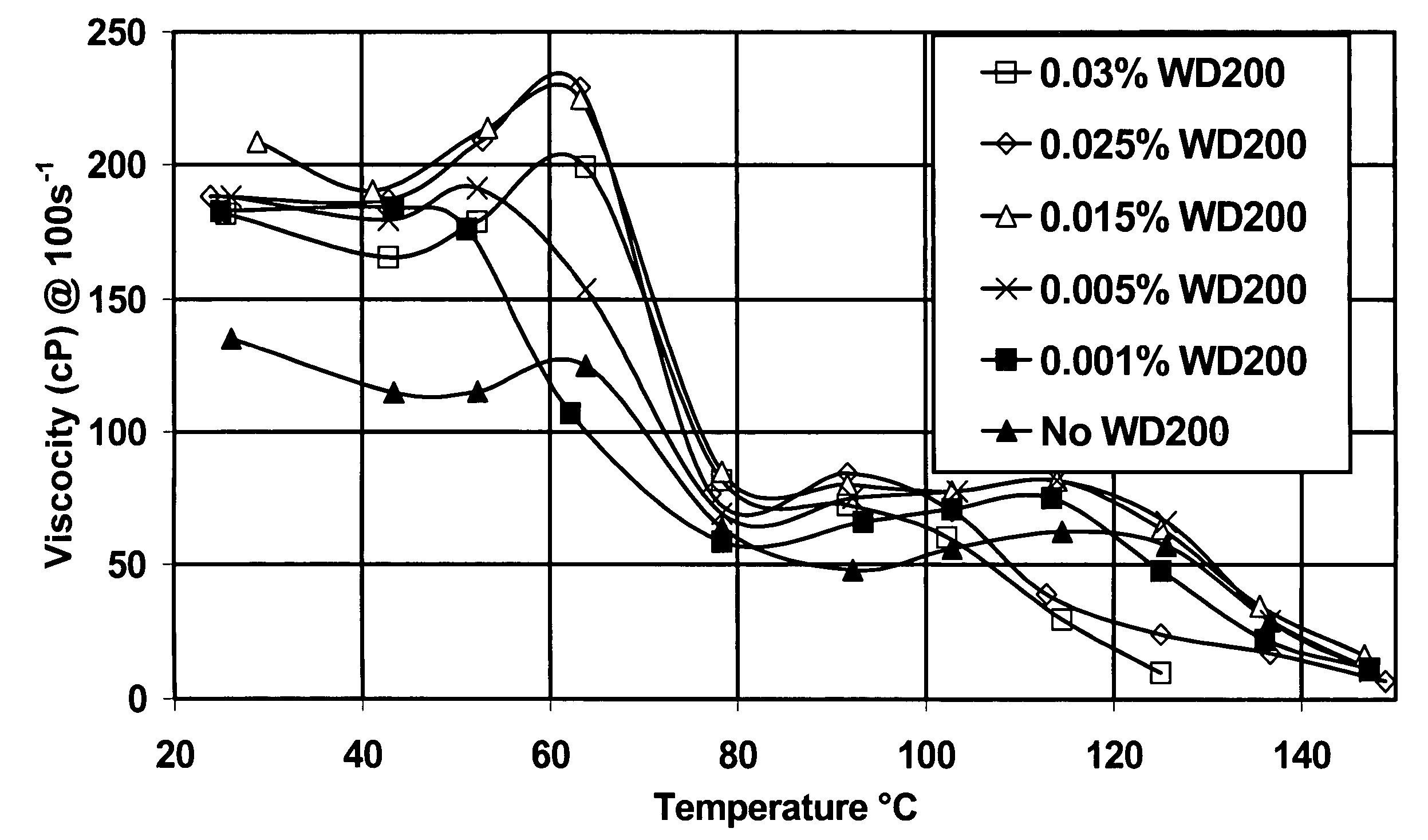

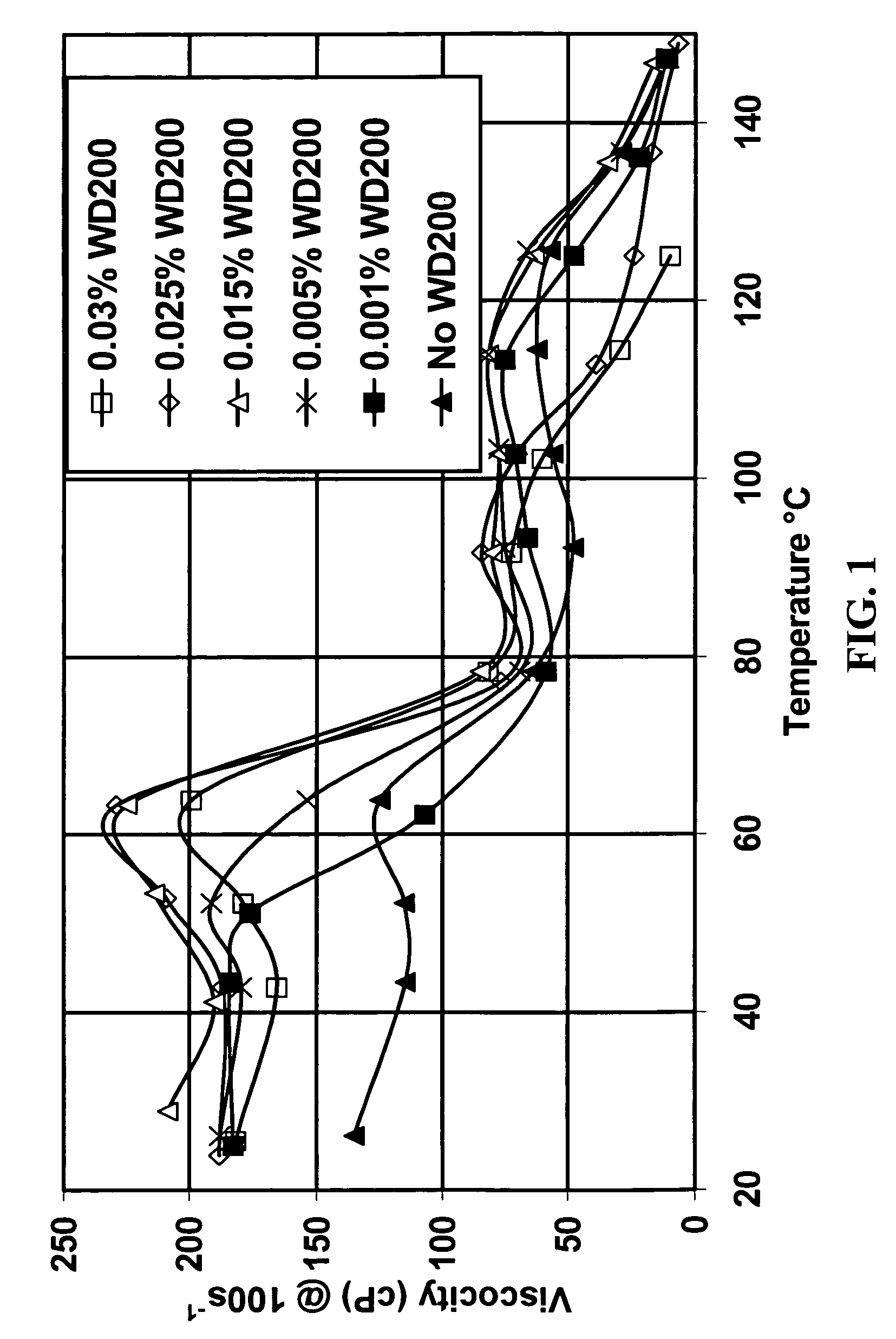

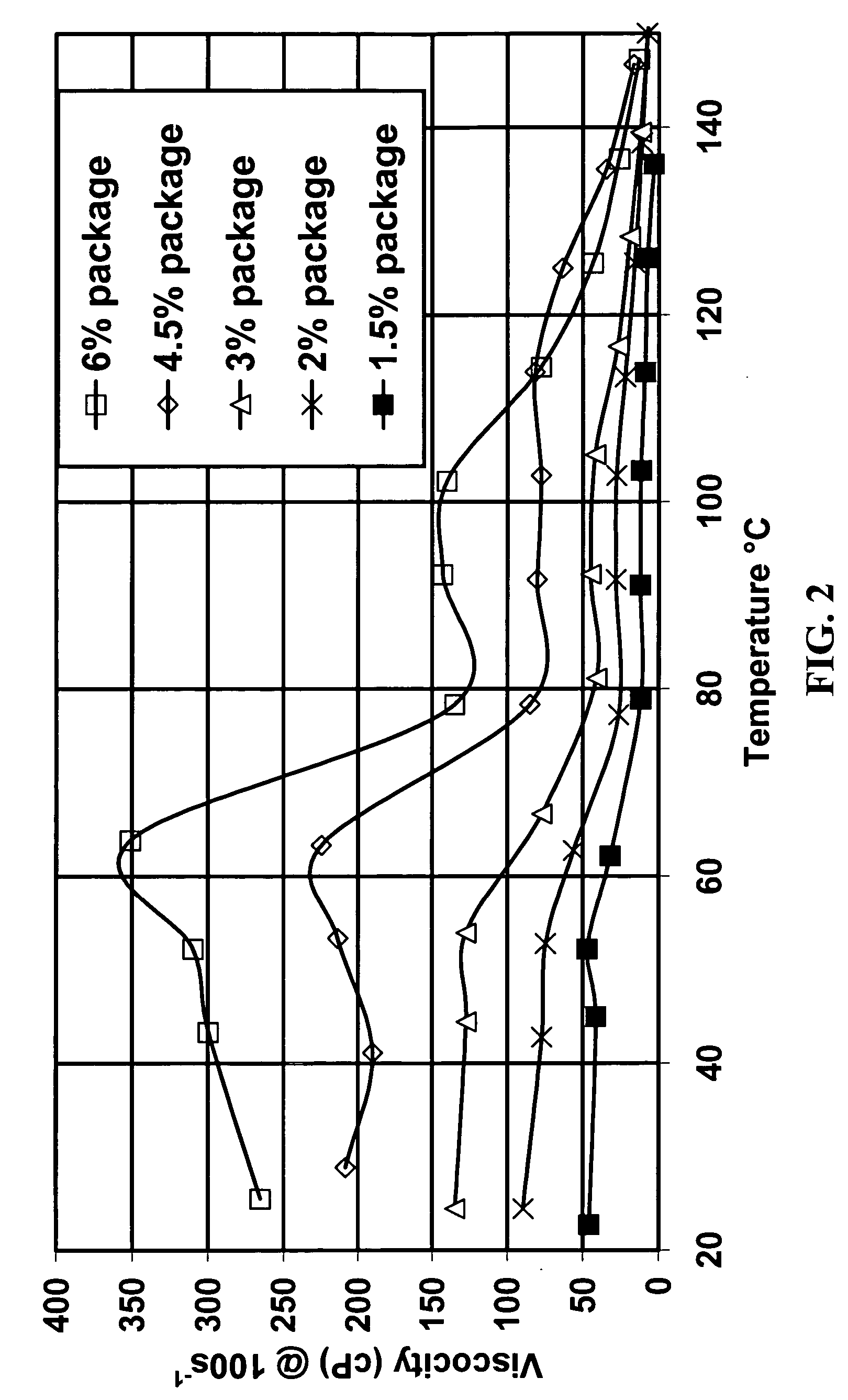

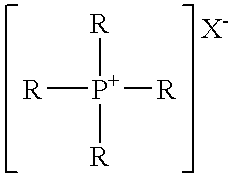

InactiveUS20060185842A1Increase ratingsIncrease shear rateCleaning apparatusFluid removalPolymer scienceBetaine

A method for increasing the rate of shear rehealing of fluids made with cationic, zwitterionic, and amphoteric viscoelastic surfactant fluid systems by adding an effective amount of a polymeric rheology enhancer selected from polypropylene glycols and block copolymers of polypropylene glycol and polyethylene glycol. For applications in which rapid shear rehealing is required, the rheology enhancer allows fluids to be made and used at lower viscoelastic surfactant concentrations. Preferred surfactants are betaines and quaternary amines. The fluids are useful in oilfield treatments, for example fracturing and gravel packing.

Owner:SCHLUMBERGER TECH CORP

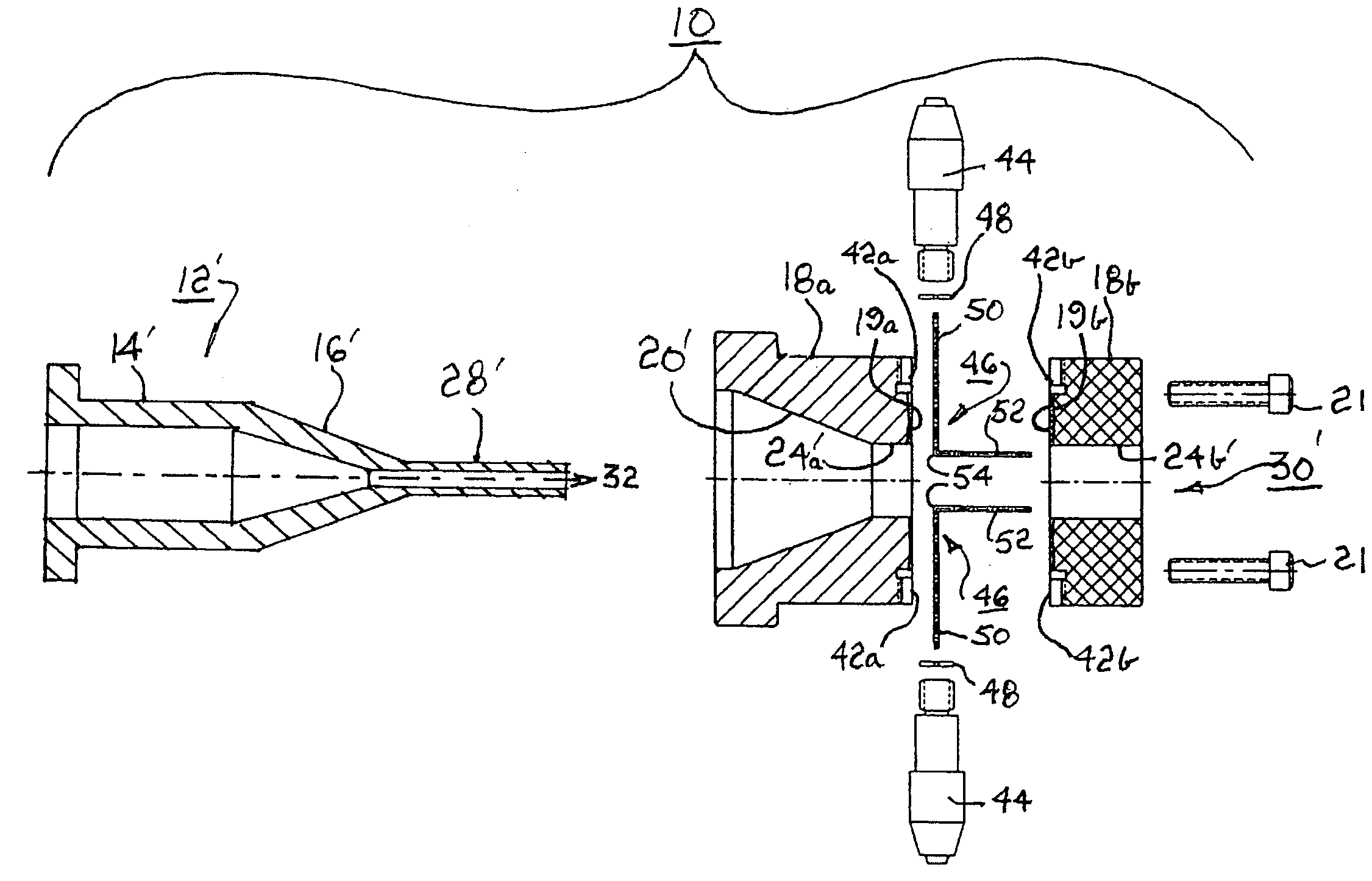

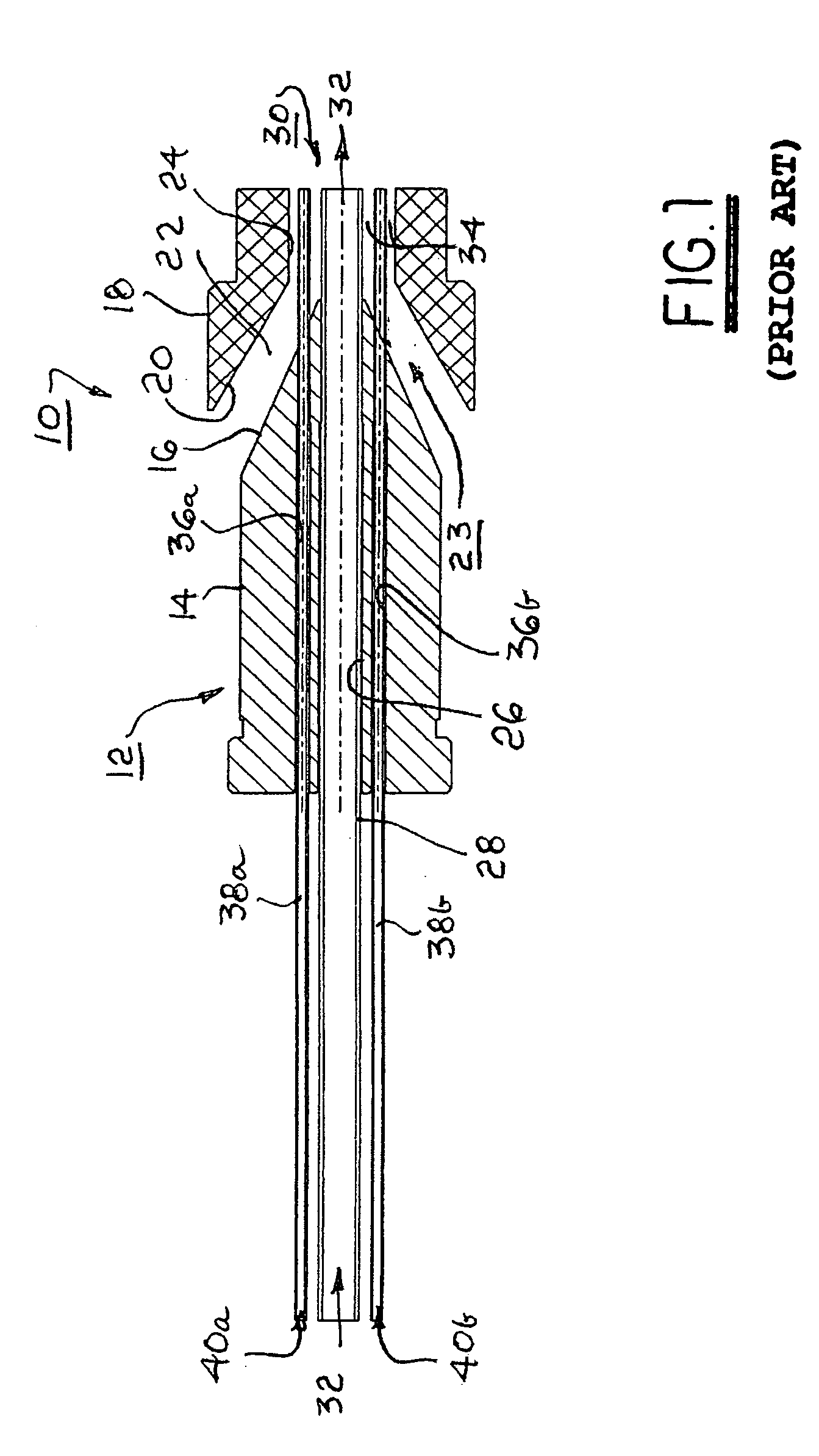

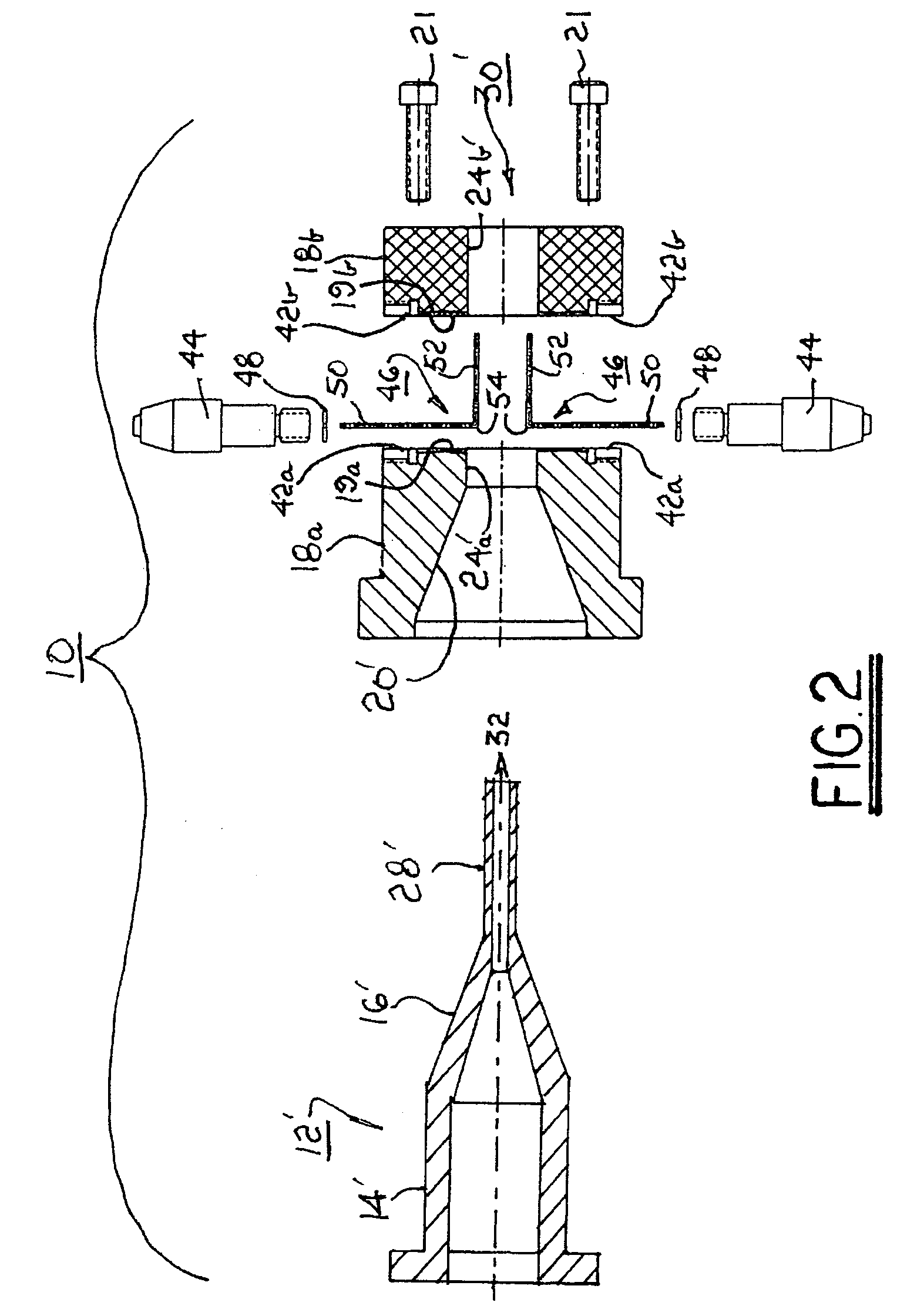

Extrusion process for fabricating plastic optical fiber

An improved process for extruding plastic optical fiber without the need to prepare a preform is provided. Specifically, it was discovered that conventional extrusion techniques, e.g., screw extruders, tended to introduce an undesirable amount of particulate contaminants which increased the loss of the drawn fiber. To overcome this problem, the invention substantially reduces the number of mechanical interactions that contribute to such contamination. The process of the invention does so by using fluid pressure, instead of, e.g., screw extruders, to induce polymer flow. The process also controls the flow characteristics of the polymer, or halts the flow altogether, without mechanical controls. Specifically, the temperature of the sections through which the polymer flows is controllably adjusted, such that it is possible to bring the polymer to a desired flow rate or even to a solid state to provide a plug.

Owner:FITEL USA CORP

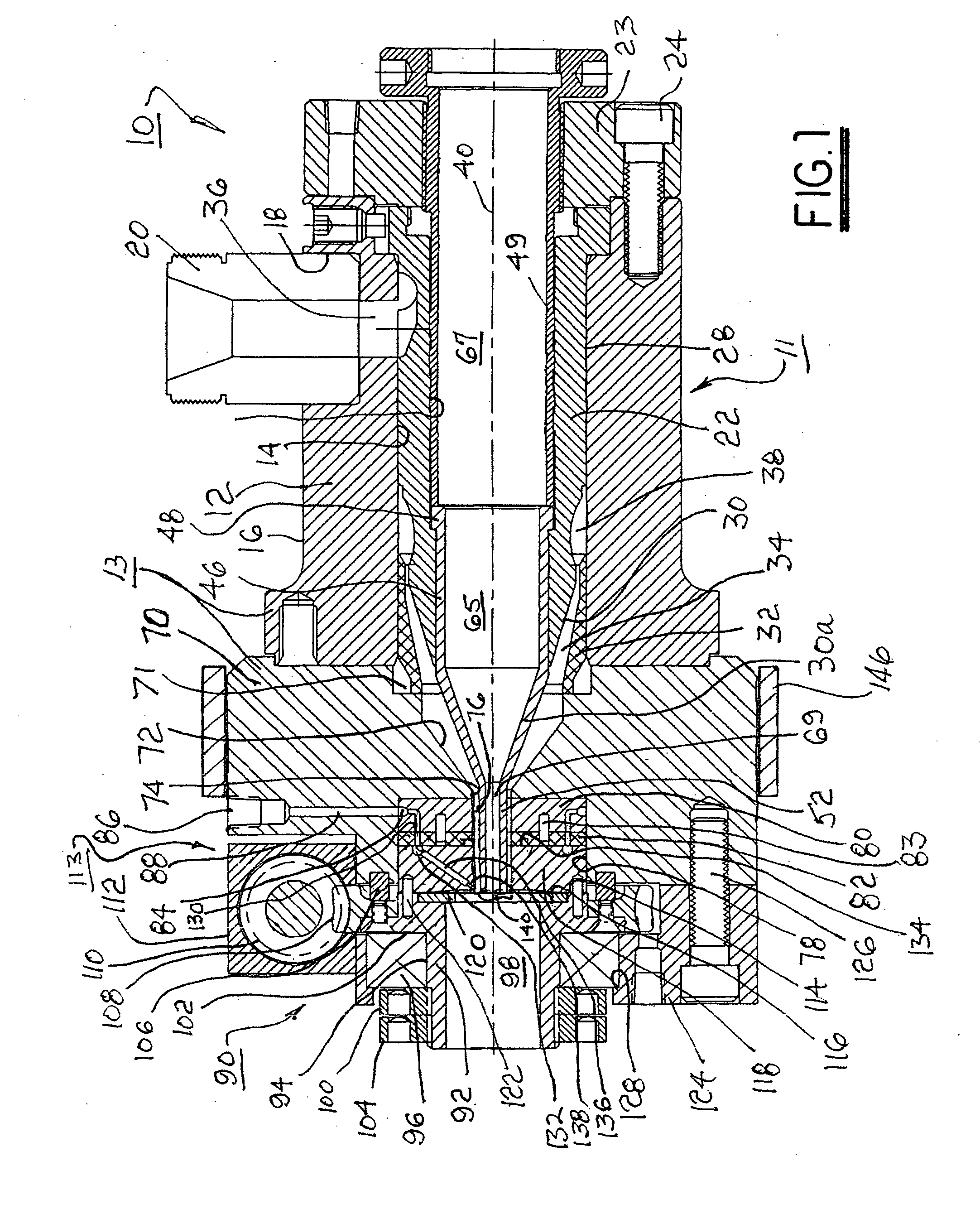

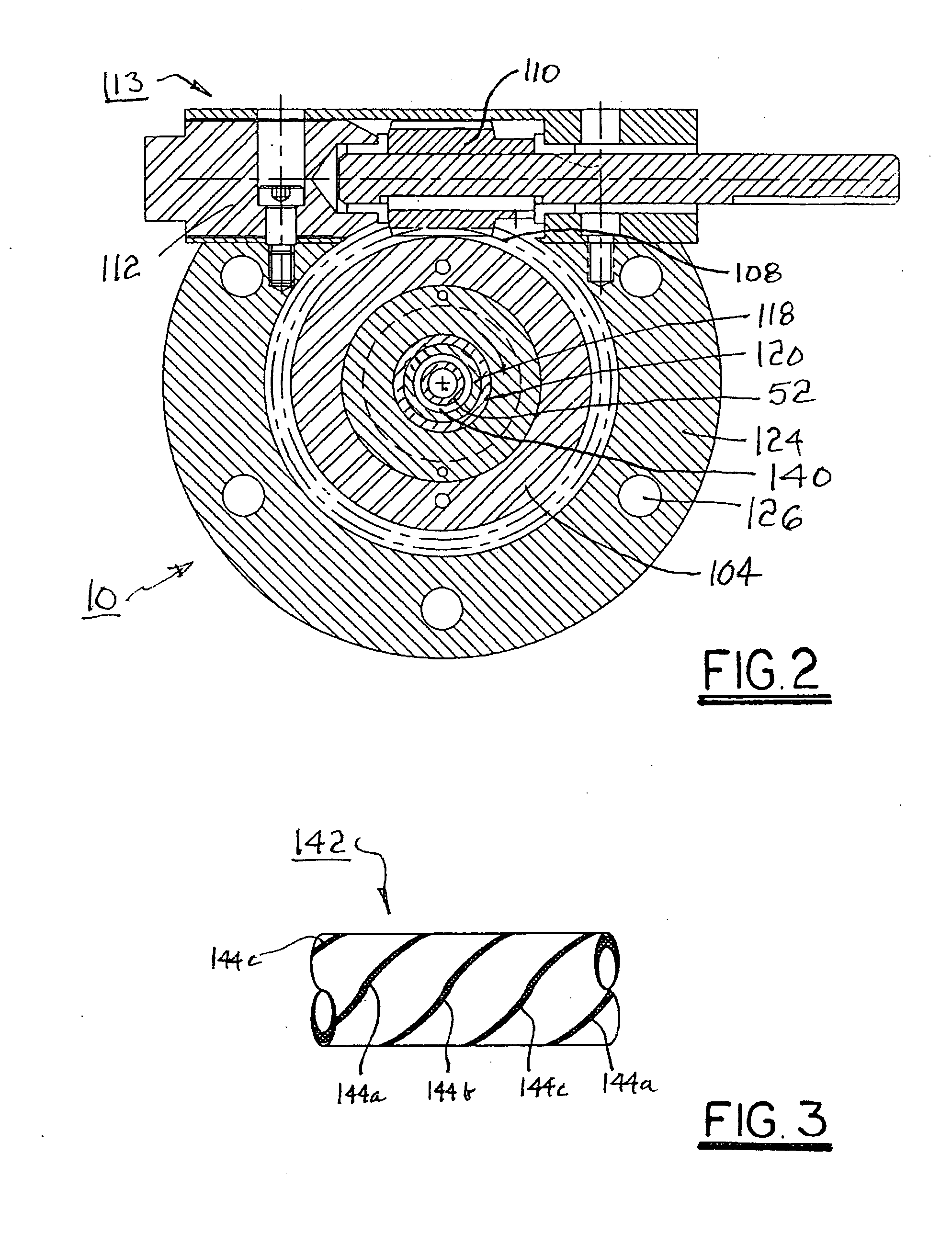

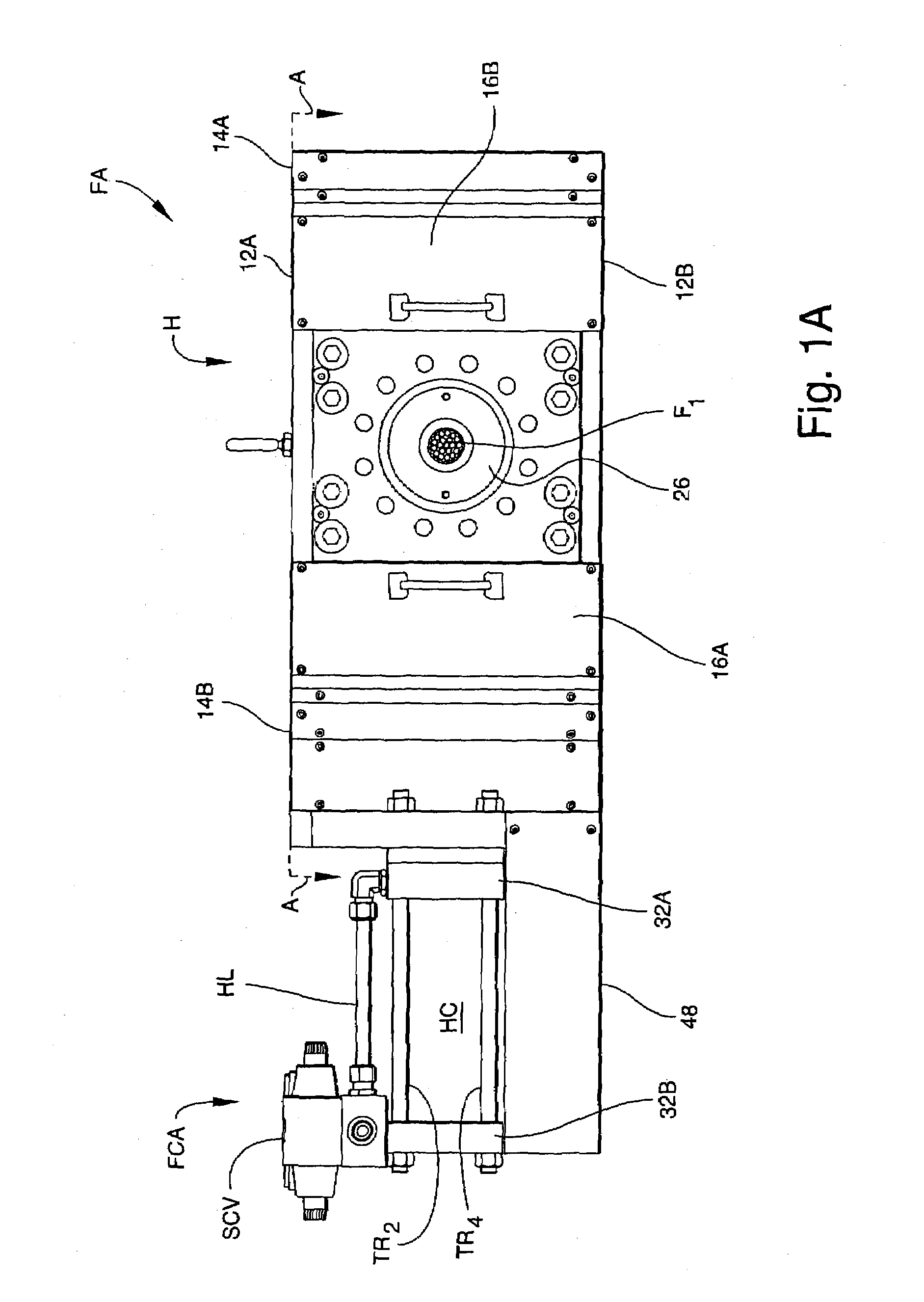

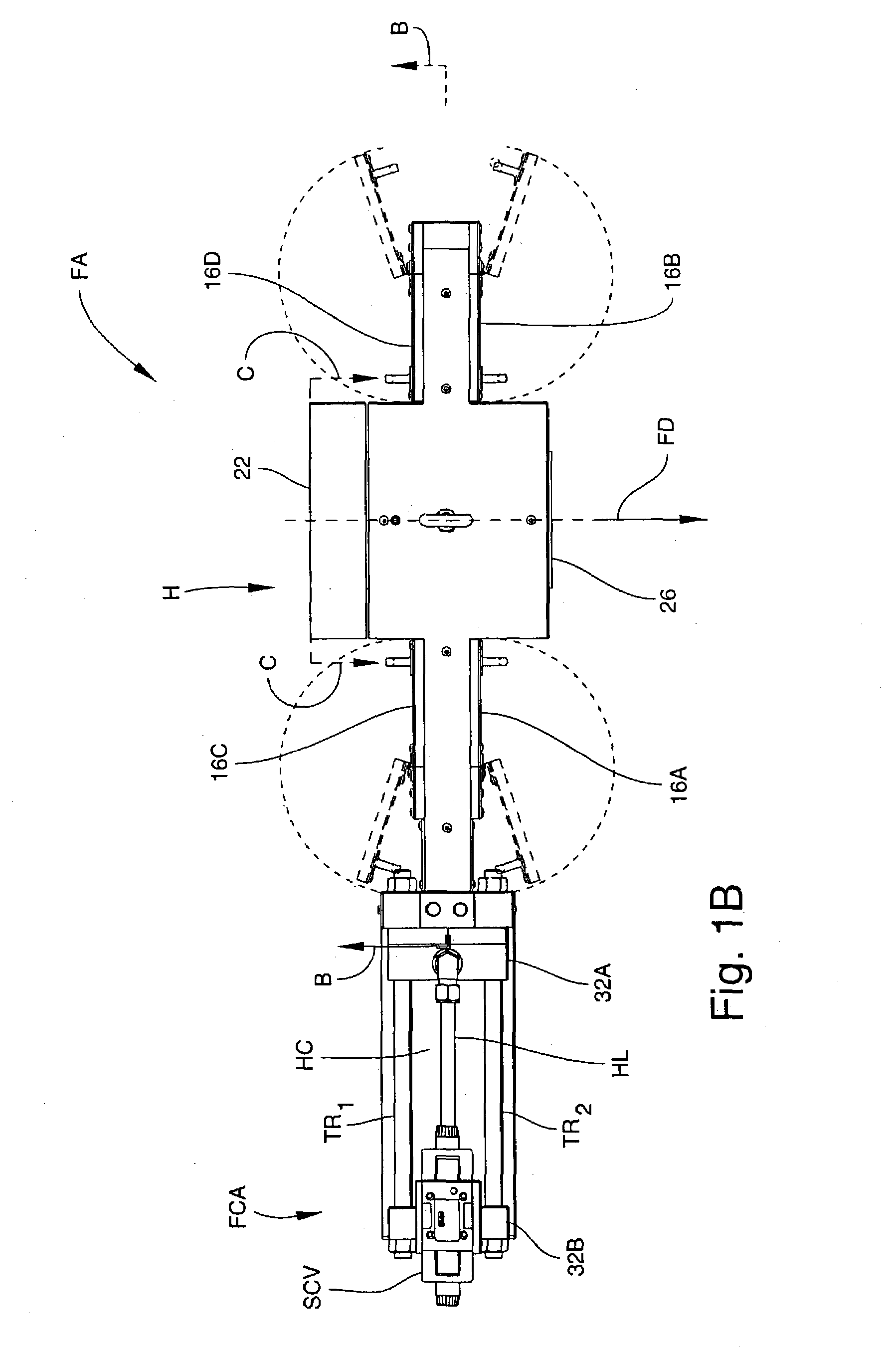

Rotatable head for forming spiral extrusions

InactiveUS20050260408A1Increase sealing forceAvoid pollutionConfectioneryFilament/thread formingEngineeringCounterbore

A polymer extrusion crosshead assembly for forming a spirally-striped extrusion. The assembly includes conventional components for admitting, turning, and accelerating primary molten polymer toward a novel rotating die sub-assembly. A body element includes an axial counterbore for receiving a manifold supply block in communication with a source of secondary striping polymer. A wear plate is attached to the manifold block. The die sub-assembly includes a striping die having an annular passage for conveying the primary polymer to form an extruded tube or a core material coating. The die is loaded against the wear plate by a Belleville washer. The die includes one or more striping nozzles in communication with the manifold block for injecting secondary striping polymer into the annular stream of primary polymer flowing through the die, creating a longitudinal stripe of striping polymer. Rotating the die while extruding both polymers yields a helically striped (spiral) extrusion.

Owner:CANGEN HLDG

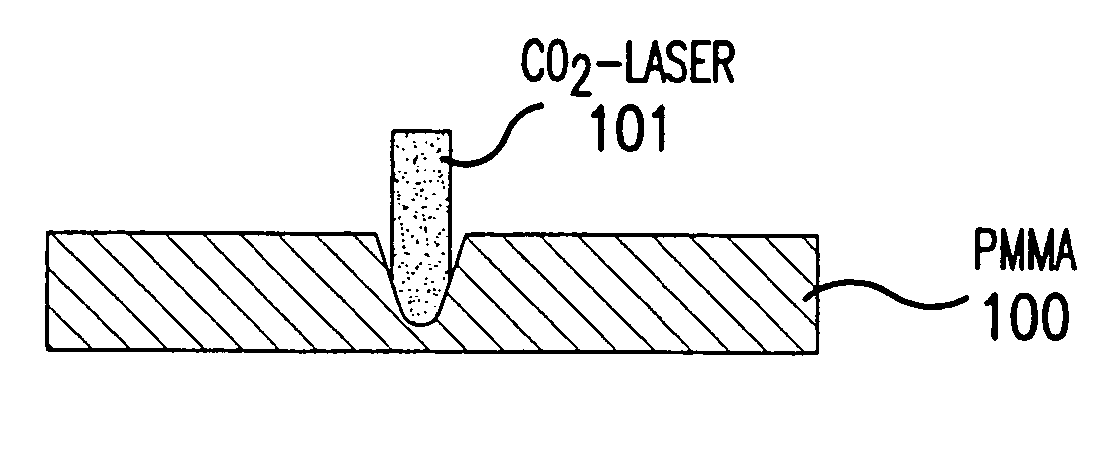

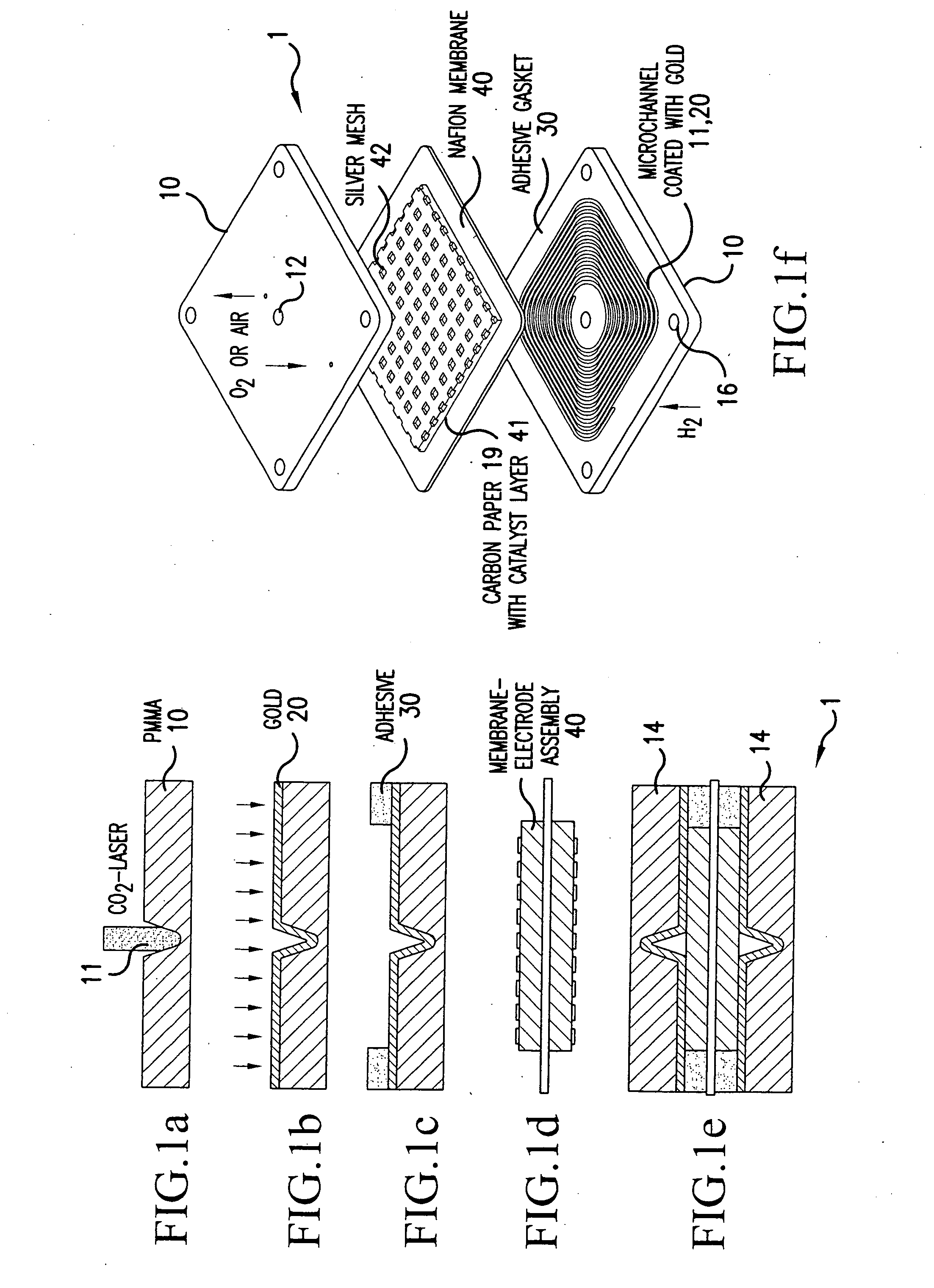

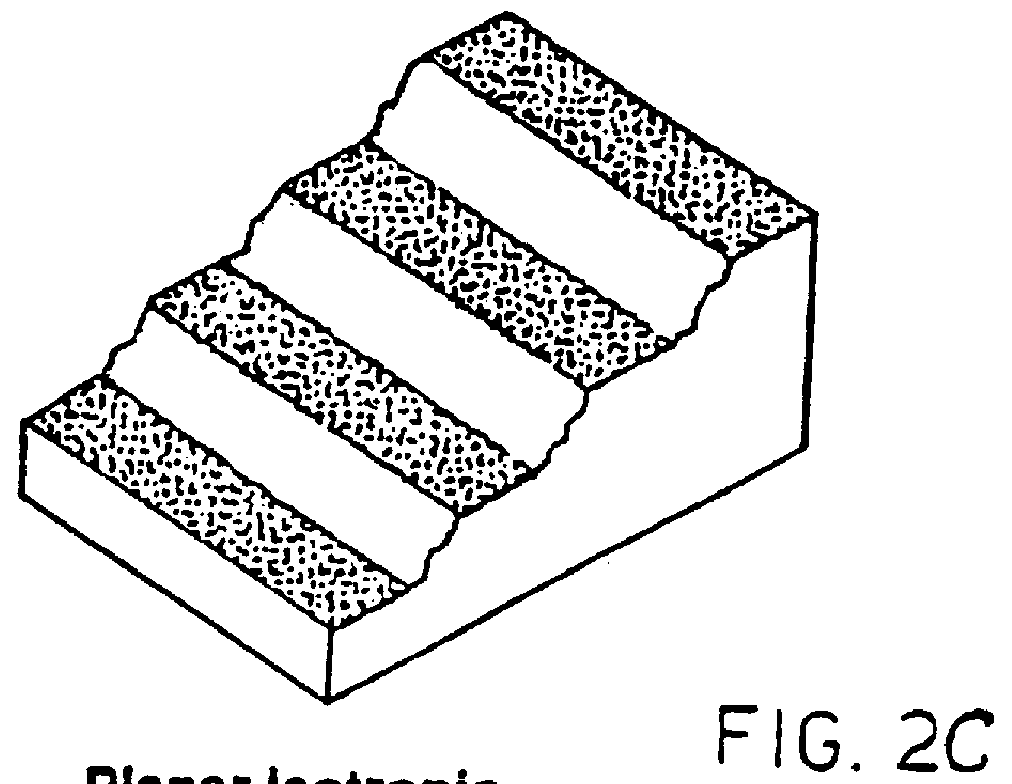

Pattern molding of polymeric flow channels for micro fuel cells

The invention relates to a method for large scale manufacturing of polymeric micro fuel cells using a metallic mold. The method includes creating a Gaussian-shaped channel on a first substrate using a laser; sputtering a metallic seed layer over the first substrate using a first metal; electroplating a second metal over the seed layer to create a negative mold; releasing the negative mold from the first substrate; fabricating a plurality of second substrates, each having a Gaussian-shaped channel, and using the negative mold to fabricate multiple fuel cells. The method provides lower cost and greater flexibility as compared with conventional ablation and etching processes of manufacturing of polymeric micro fuel cells.

Owner:NANYANG TECH UNIV

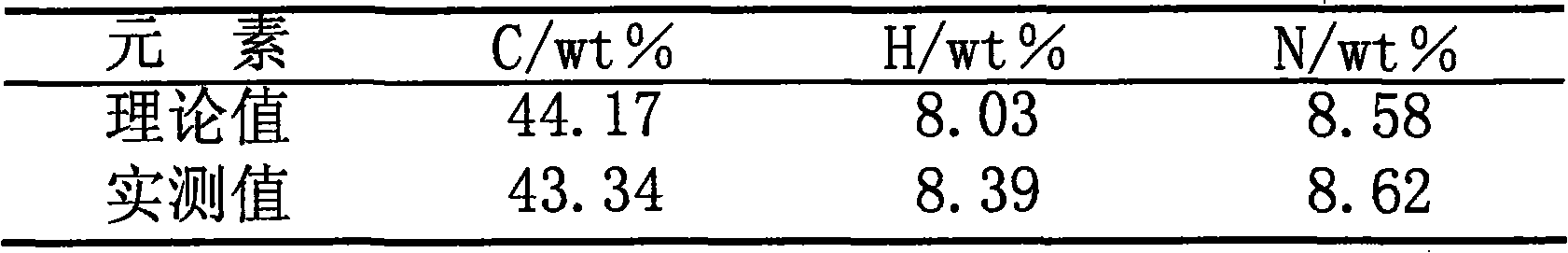

Epoxy end group hyperbranched poly (amide-ester) and preparation method

The invention provides an epoxy end group hyperbranched poly (amide-ester) and a preparation method. The preparation method comprises the following steps: taking dihydroxy amide ester as a chain propagation monomer, adding multifunctionalmolecule polylol as a core, reacting in the presence of a catalyst and inert gases to obtain hydroxyl end group amido hyperbranched poly (amide-ester); and then enabling a hydroxyl end group to react with epoxy chloropropane to generate the epoxy end group hyperbranched poly (amide-ester). The epoxy end group hyperbranched poly (amide-ester) is in an approximately sphere symmetrical three-dimensional structure with high functionality, has the relatively molecular weight as high as 10,000-20,000 and the molecular weight distribution coefficient as much as 1.02-1.35, can be used as a rheologicalproperty regulator or polymer rheological processing modifier, can improve the compatibility when being blended with a polymer containing an epoxy group, improvethe tensile strength by 40 percent compared with a pure polymer, improve the breaking strength by 60 percent compared with the pure polymer and achieve the functions of toughening and strengthening.

Owner:CHANGCHUN UNIV OF TECH

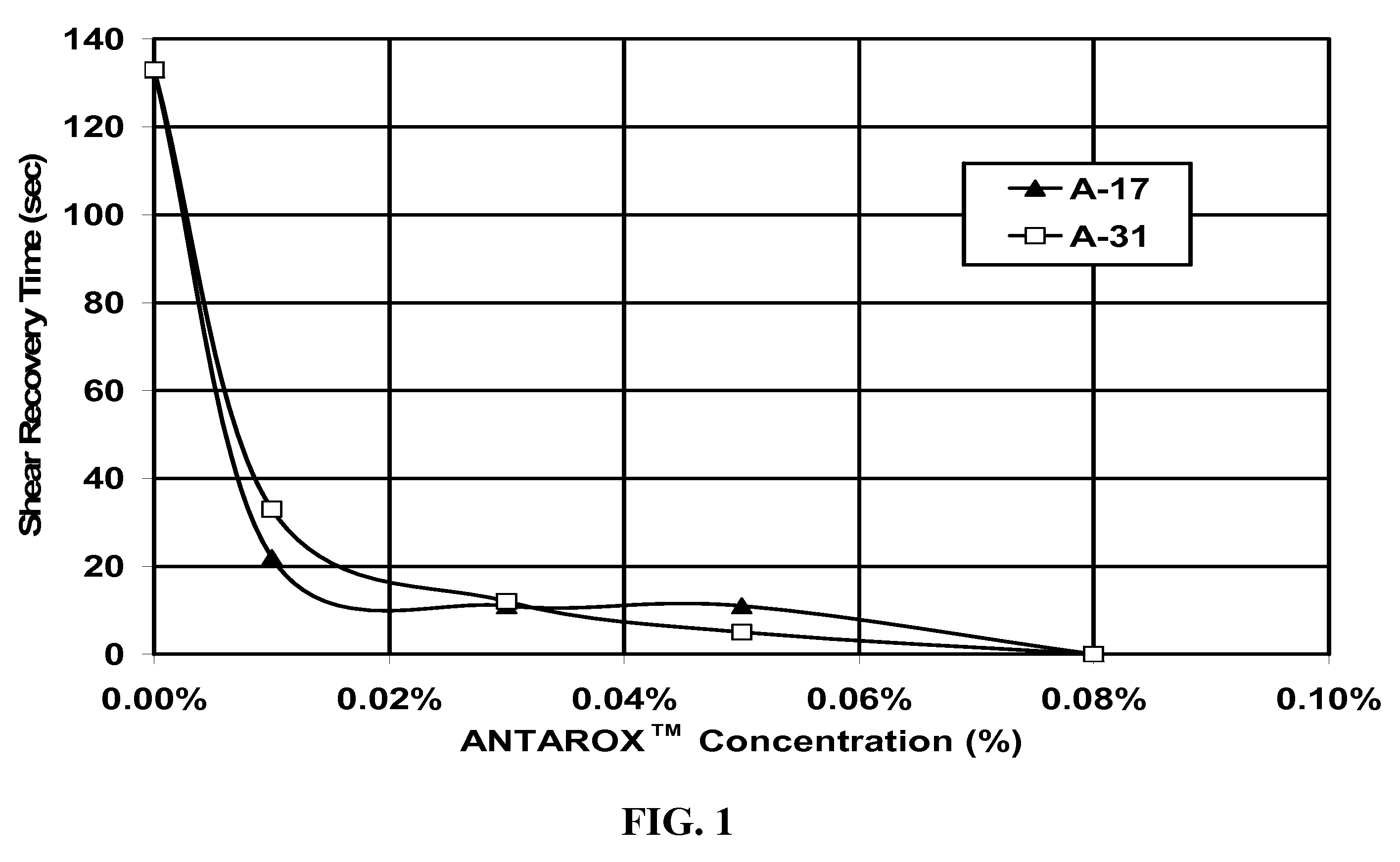

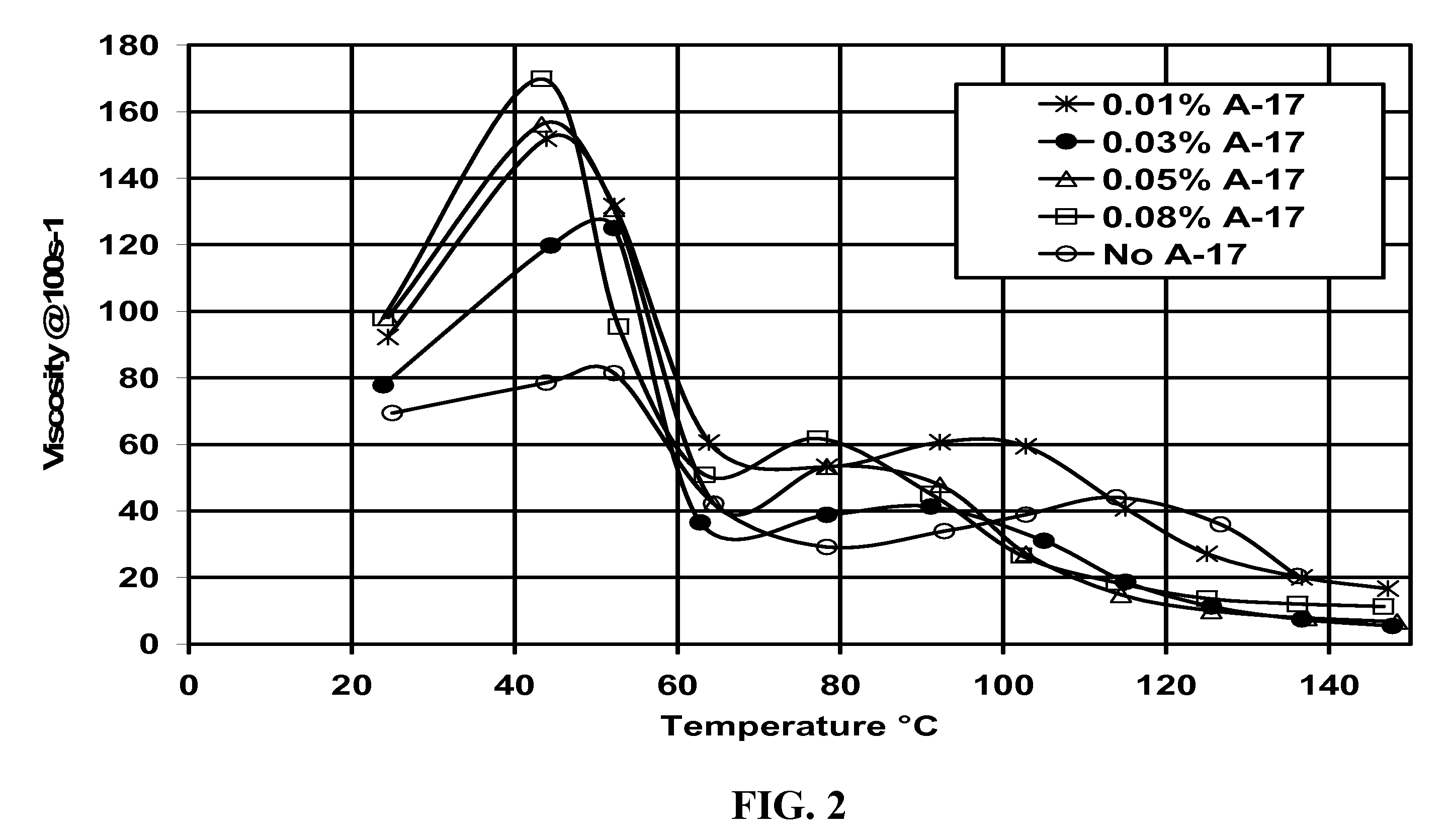

Viscoelastic surfactant rheology modification

ActiveUS20060128598A1Shortening shear recovery timeHigh viscositySurface-active detergent compositionsFluid removalQuaternary amineFluid system

A method for shortening the shear recovery time of cationic, zwitterionic, and amphoteric viscoelastic surfactant fluid systems by adding an effective amount of an amphiphilic polymeric rheology enhancer containing at least one portion that is a partially hydrolyzed polyvinyl ester or partially hydrolyzed polyacrylate. The rheology enhancer also increases fluid viscosity and very low rheology enhancer concentration is needed. Preferred surfactants are betaines and quaternary amines. The fluids are useful in oilfield treatments, for example fracturing and gravel packing.

Owner:SCHLUMBERGER TECH CORP

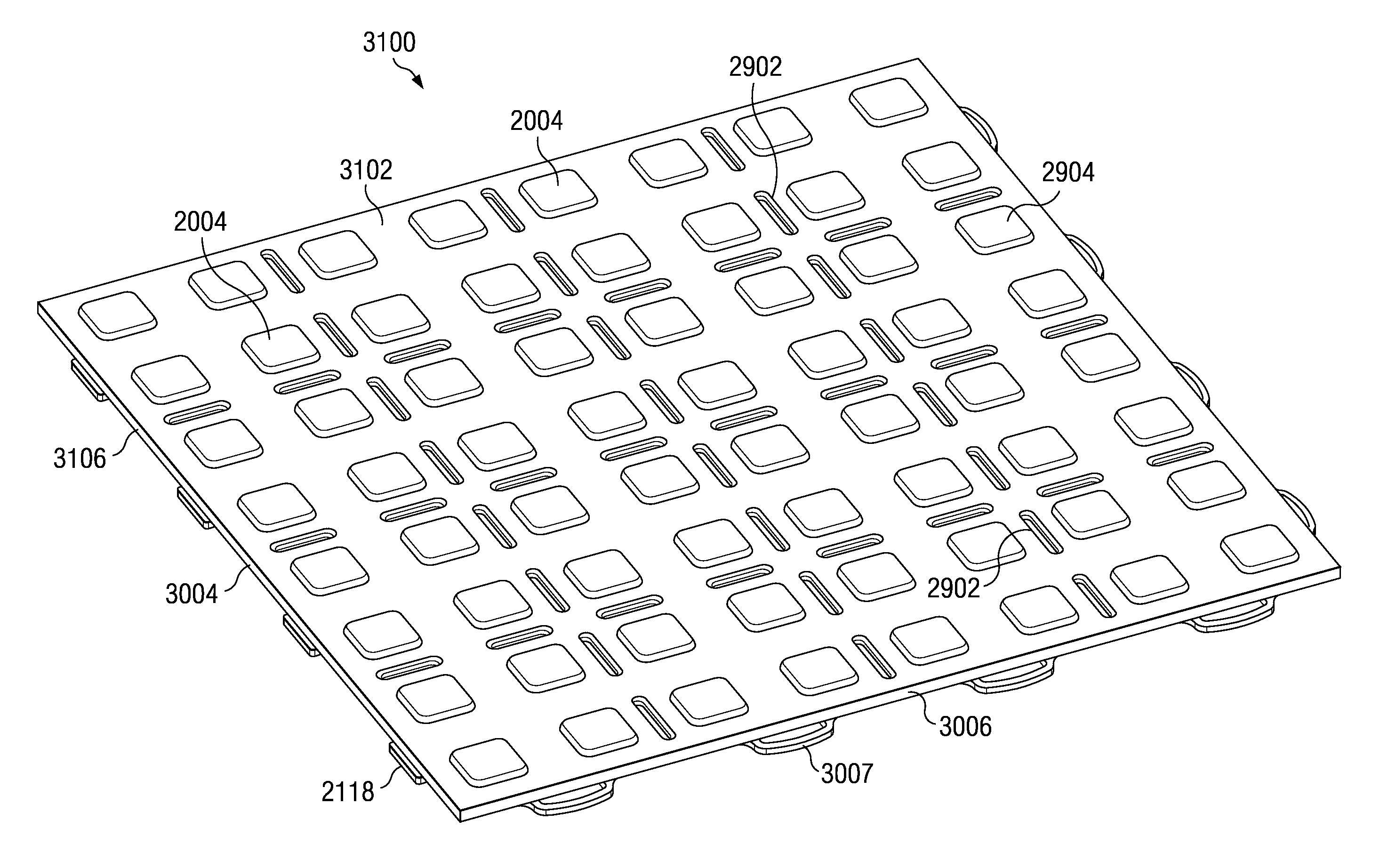

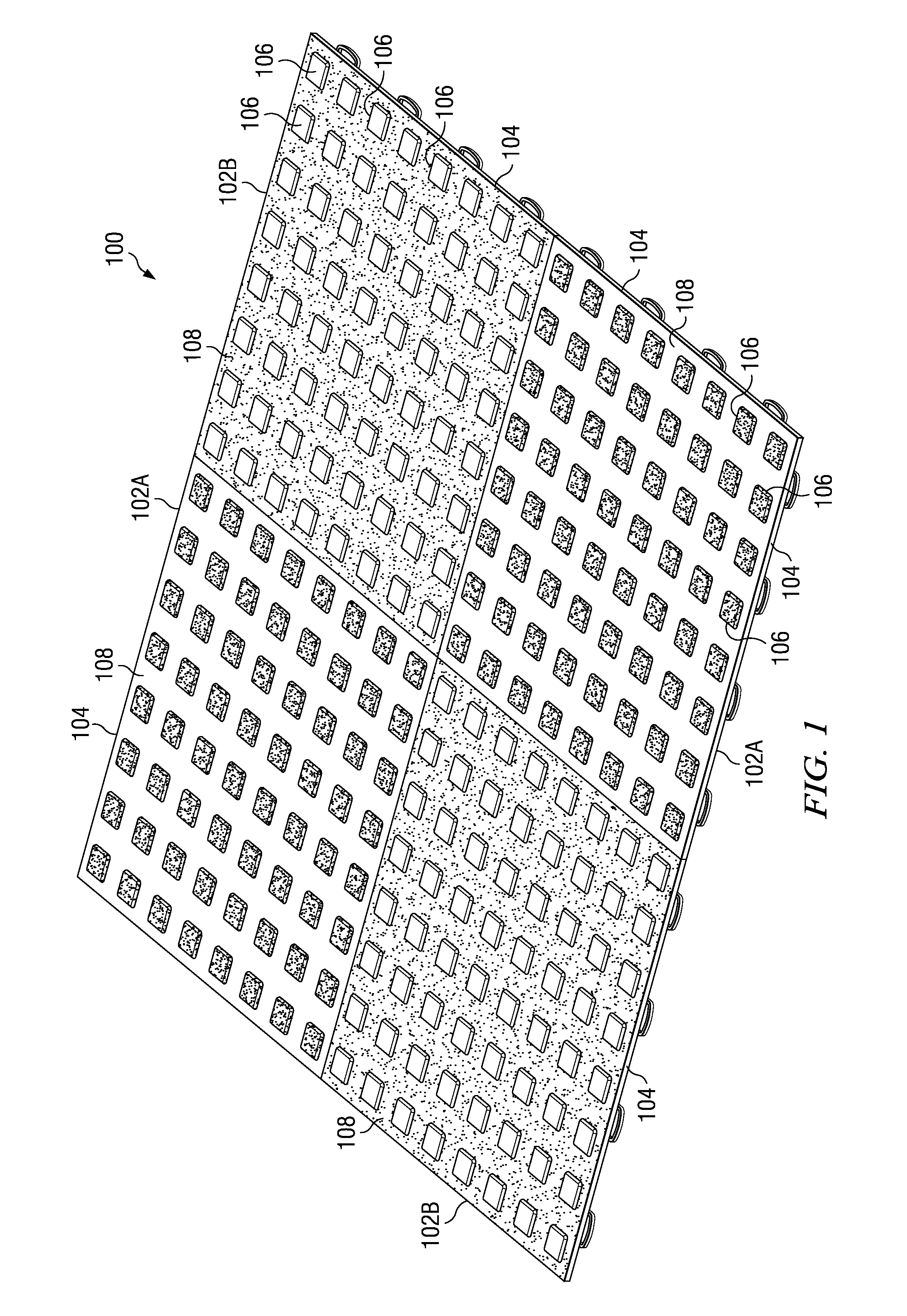

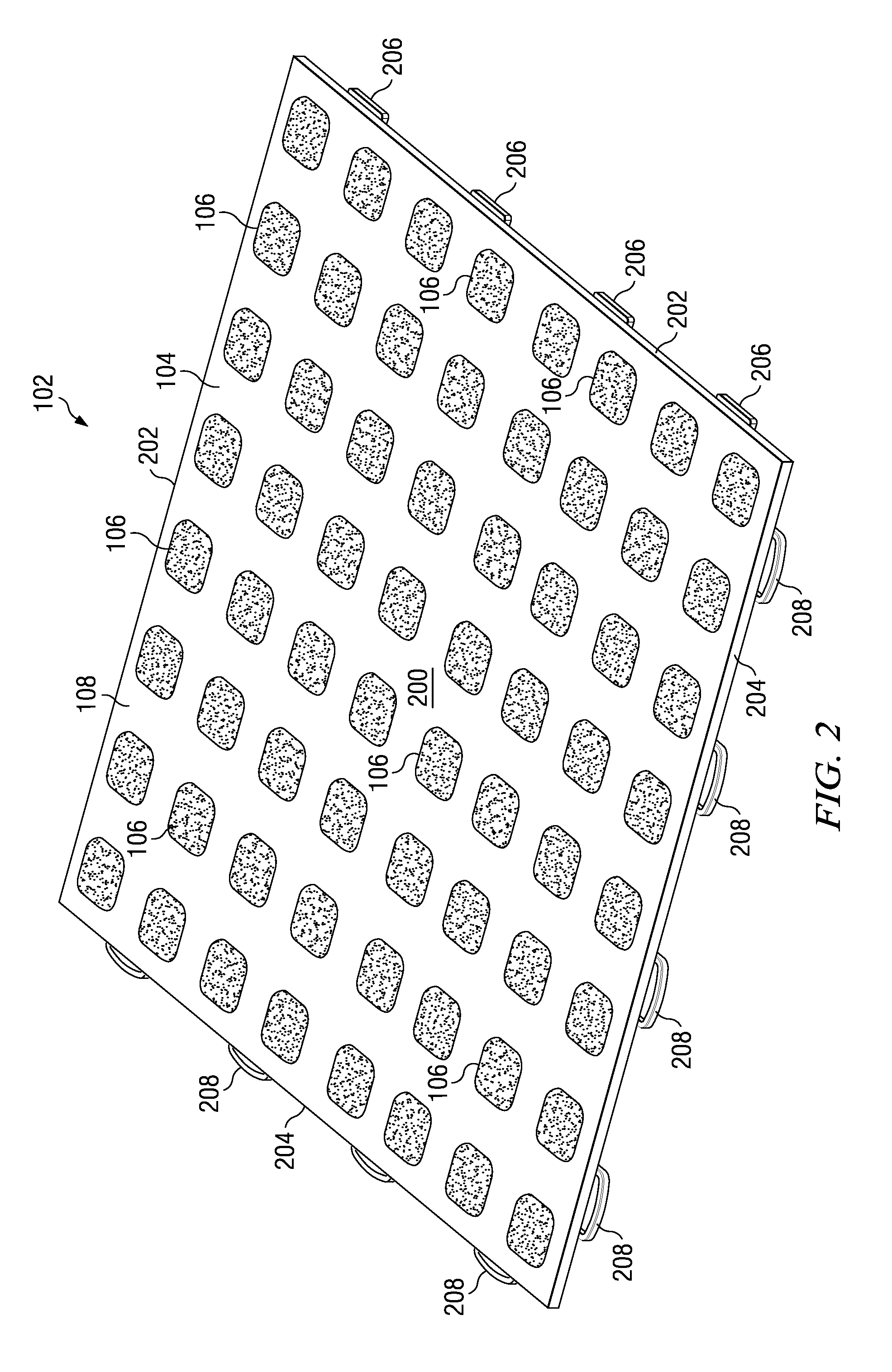

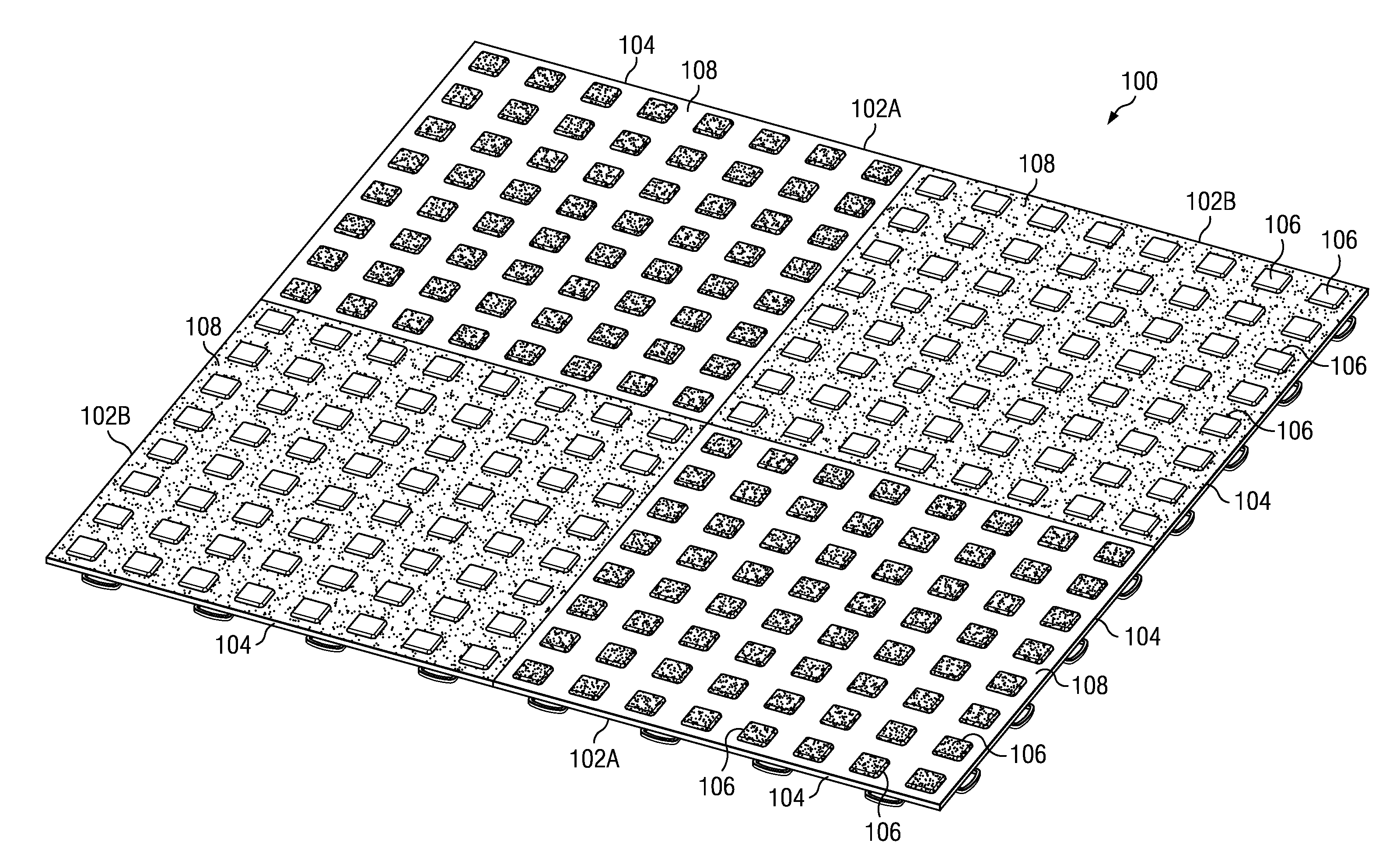

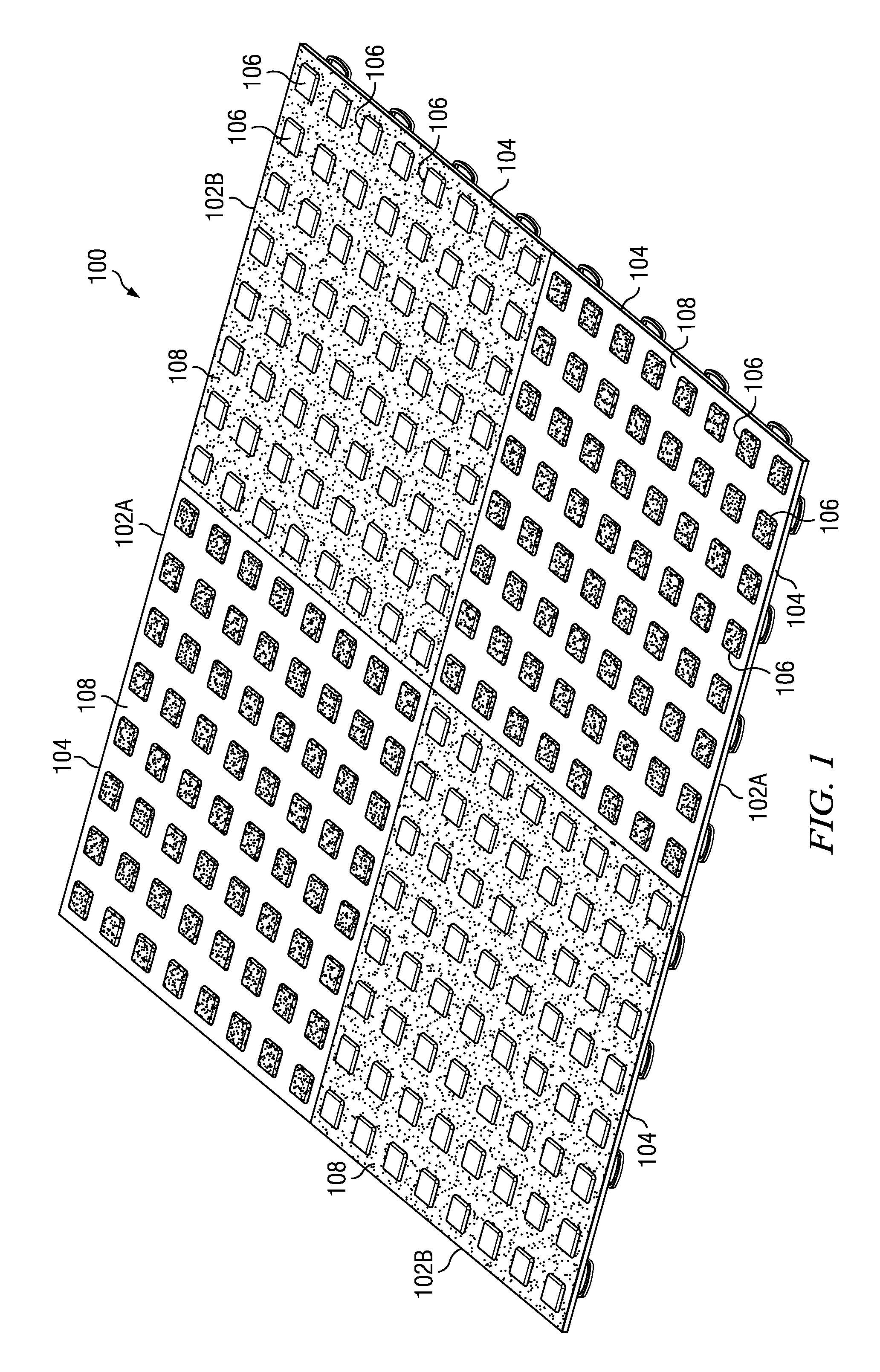

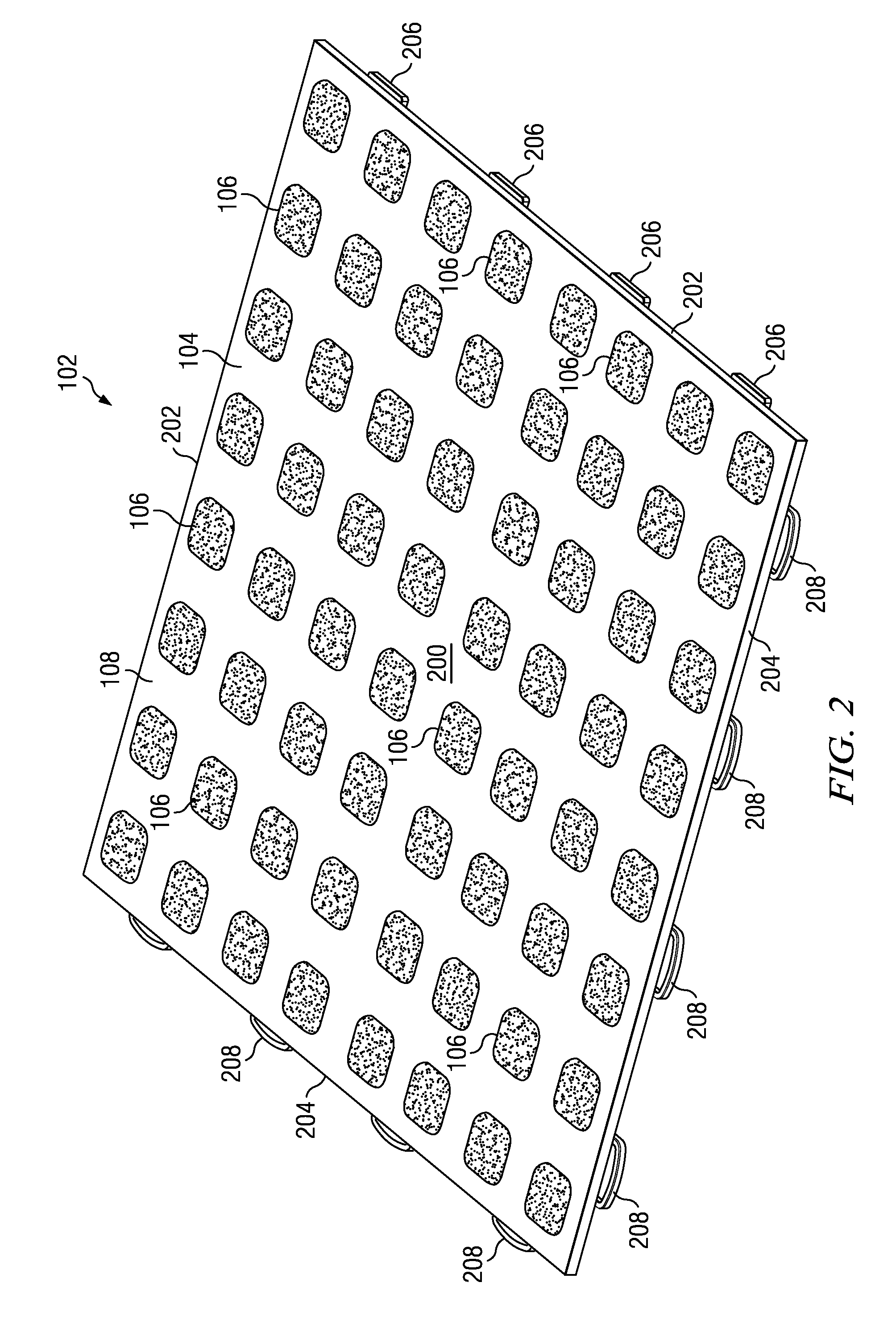

Injection molded floor tiles with drainage vents

InactiveUS20130111836A1Difference in rigidityAvoid flashSingle unit pavingsFloorsEngineeringMechanical engineering

Modular plastic floor tiles have elongate drainage vents formed to extend from the general upper surfaces of the tiles to general lower surfaces thereof. In a two-shot injection molded embodiment, the vents are laterally spaced from locations of overmolded features, and may be disposed within channels defined by downwardly depending support ribs. In one embodiment, groups of elongate vents are disposed around respective fill points in radiant fashion, so as to minimize the impedance to polymer flow within the injection mold. The vents may be radiussed at the tile's upper surface to enhance their fluid collecting capability.

Owner:MACNEIL IP

Two-shot injection molded floor tile with vent hole

ActiveUS20130047528A1Difference in coefficient of frictionDifference in rigidityTreadsConstruction materialEngineeringMechanical engineering

A modular plastic floor tile has a body of a first polymer compound and at least one upper feature overmolded onto an upper surface of the body from a second polymer compound which is injected from a gate adjacent the lower surface of the body. At least one through-hole communicates the gate to the upper feature. At least one vent hole, spaced from the through-hole, communicates the upper feature to the lower surface of the body. The vent hole allows any gas in the polymer flow path to be displaced from the upper feature, thereby preventing or minimizing defects that can affect adhesion and appearance.

Owner:MACNEIL IP

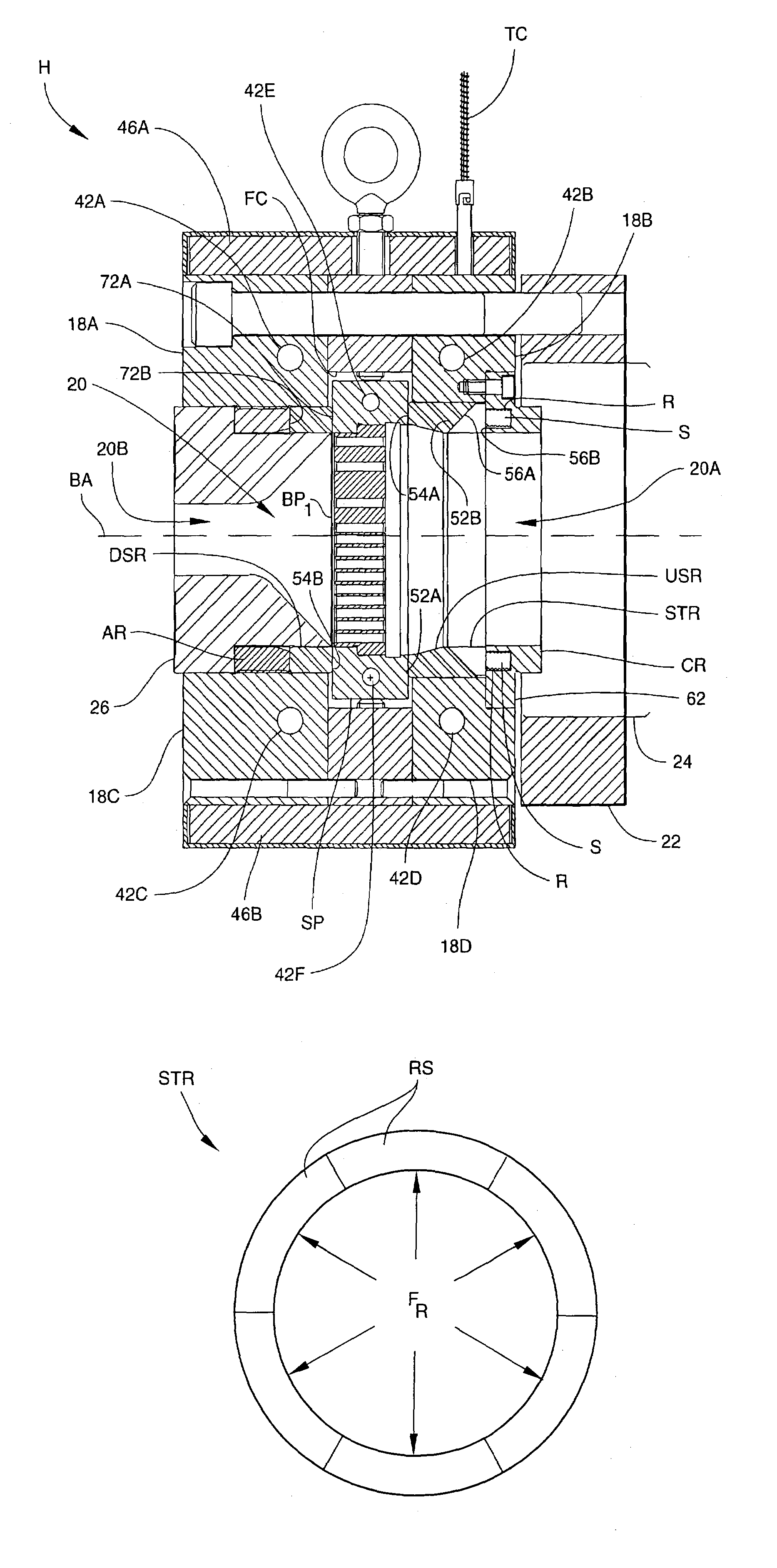

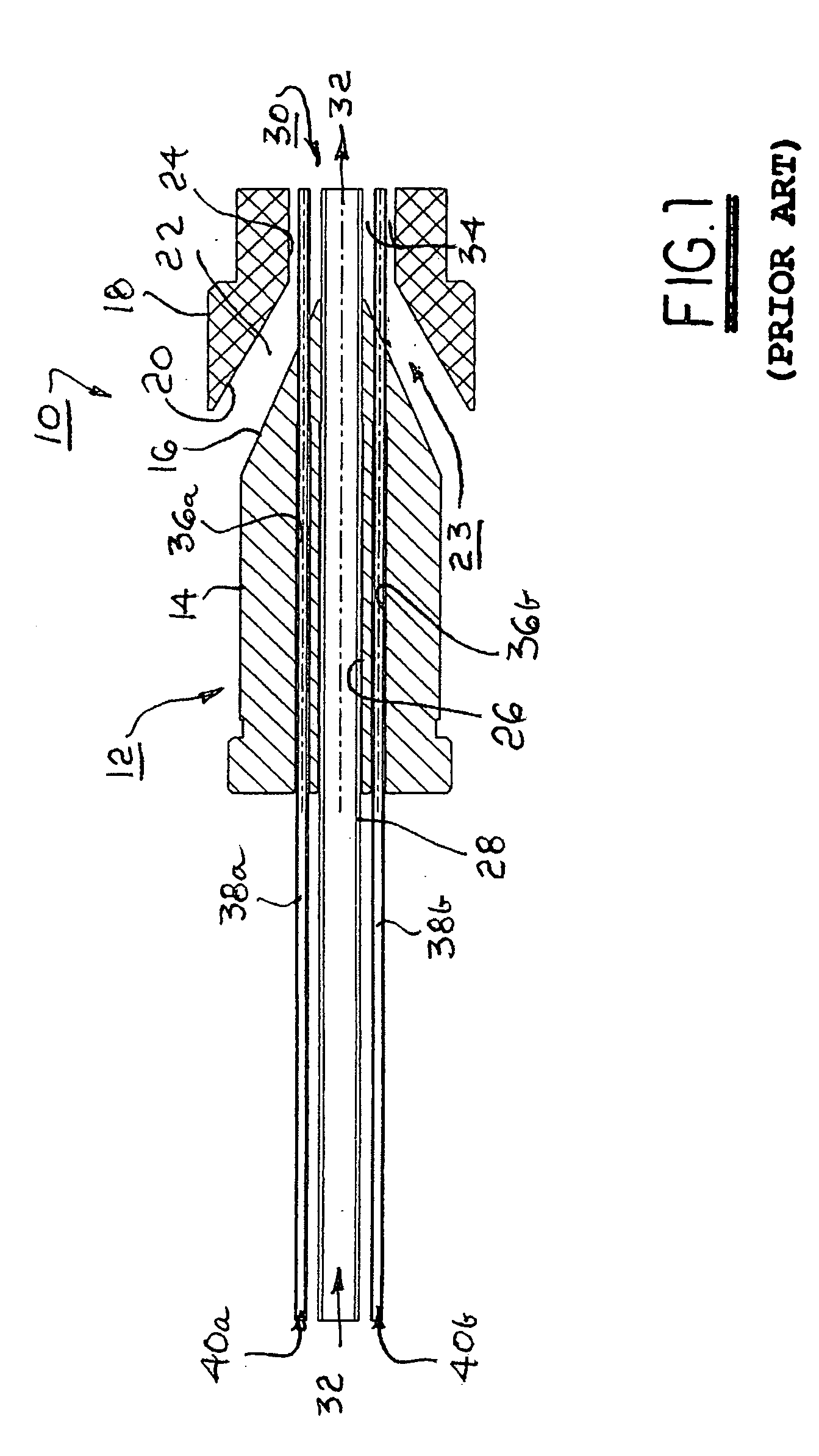

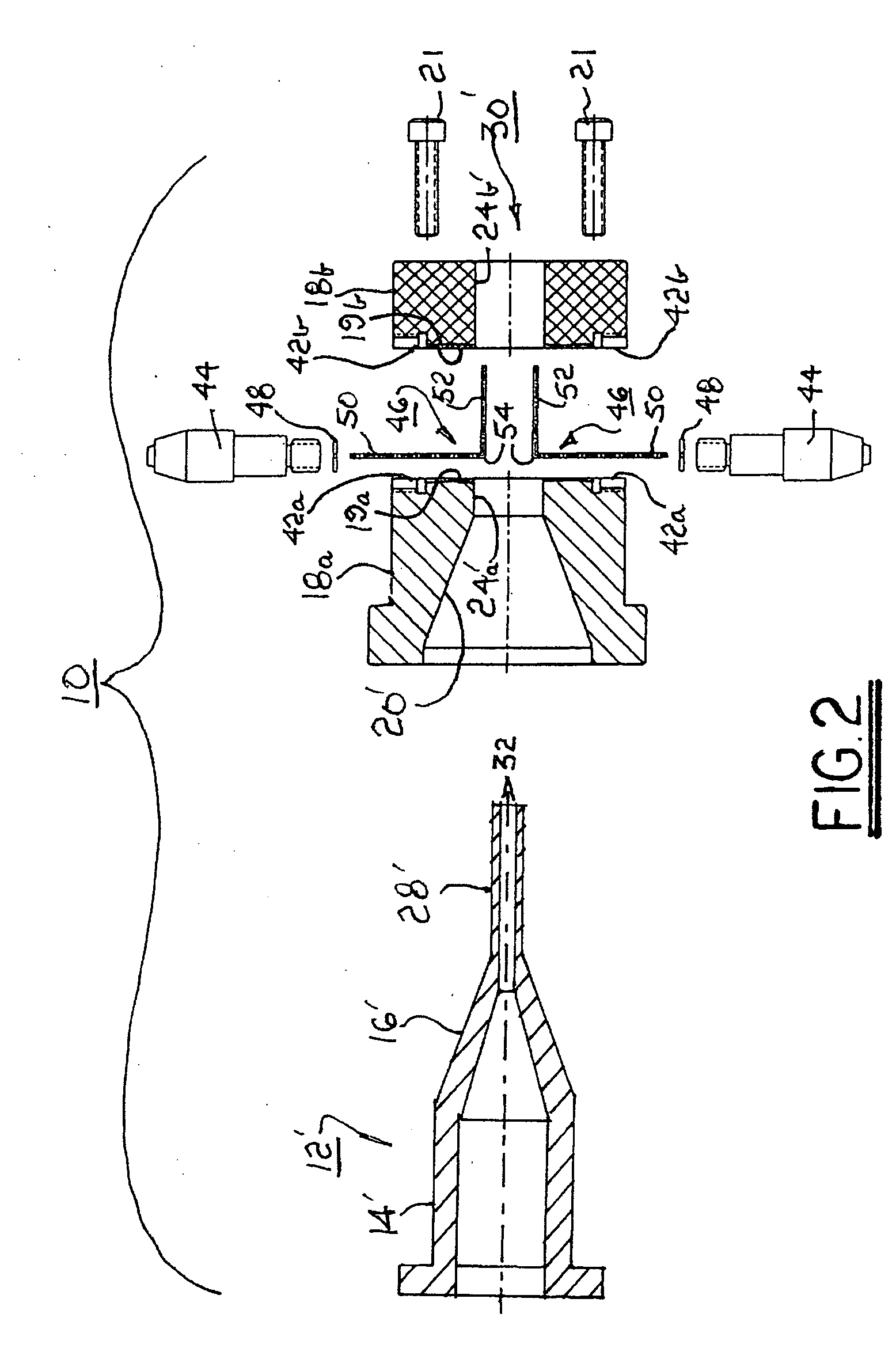

Sliding plate filter with segmented sealing ring

A filtration apparatus for use in polymer processing includes a housing having an internal bore for directing polymer flow and a channel oriented transversely to the bore. A slide plate for supporting filters is movable through the channel and across the bore. An annular upstream seal ring sealably contacts the slide plate. A surface of the upstream seal ring facing the upstream direction is angled with respect to the bore. A plurality of ring segments are arranged to form an annular segmented ring. The segmented ring presents a tapered ring surface that is generally complimentarily angled relative to the angled surface of the upstream seal ring. Pressurized polymer flowing through the bore imparts radially forces on the ring segments, causing the ring segments to impart axial forces on the upstream seal ring to enhance the seal interface between the upstream seal ring and the slide plate.

Owner:PSI POLYMER SYST

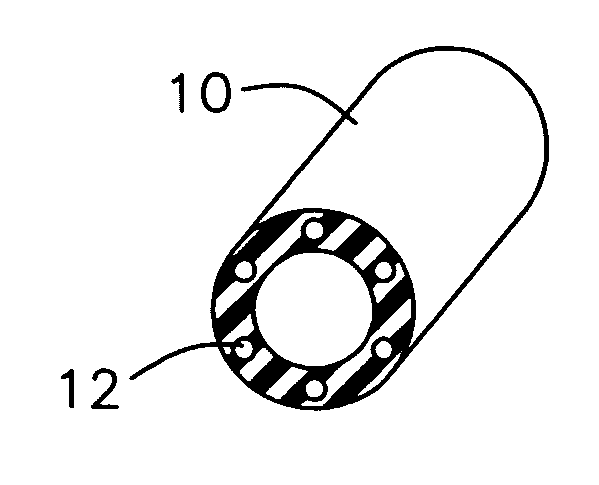

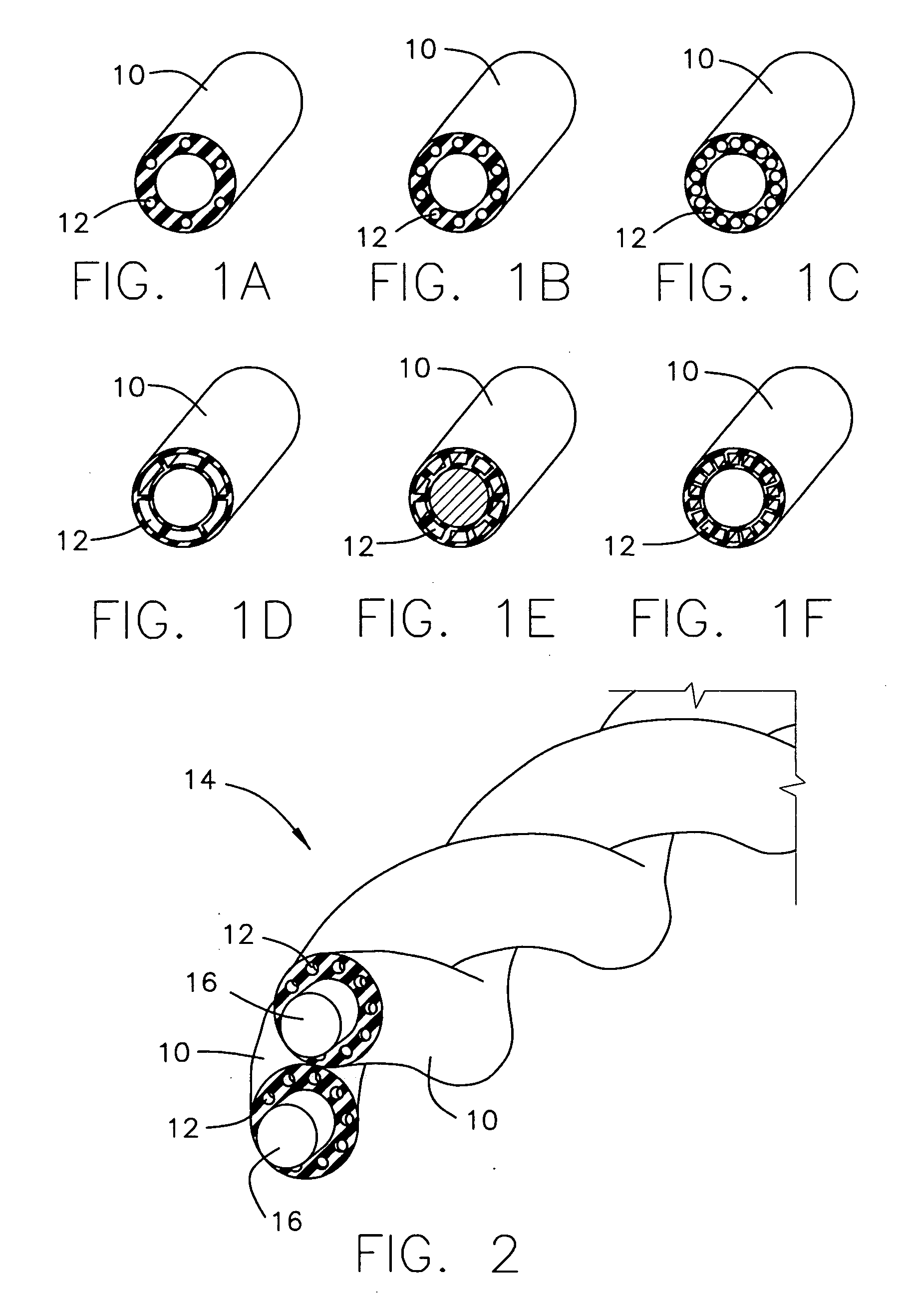

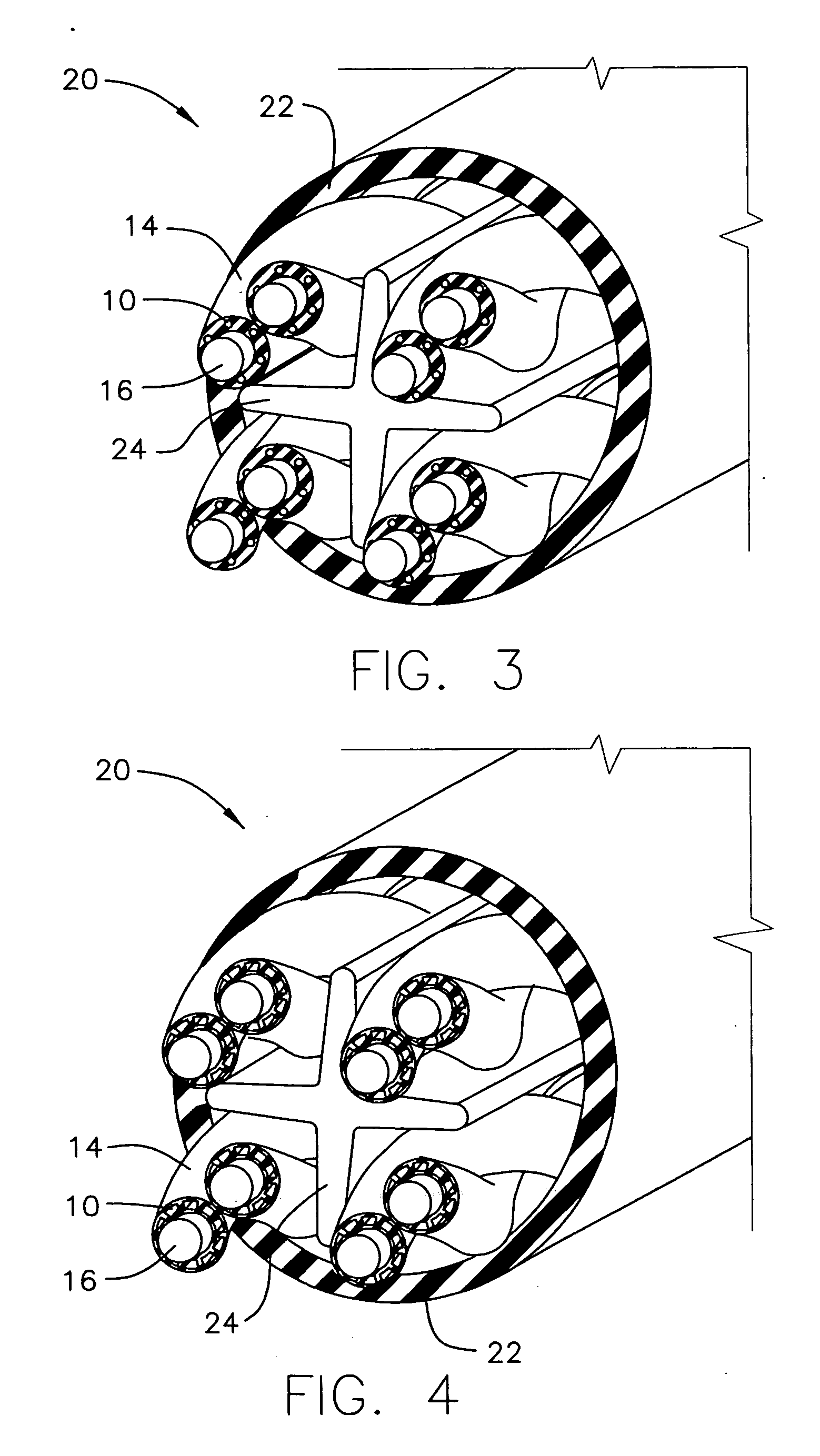

Profiled insulation LAN cables

A device for making a profiled insulation having an extrusion die with an extrusion tip and a polymer chamber surrounding the extrusion tip. The polymer chamber has at least one air chamber therein. The air chamber is held in place and coupled to the outside of the extrusion die by a vertical fin extending outwards from the extrusion tip. When molten polymer flows through the polymer chamber around the air chamber, an opening is introduced into the polymer such that the profiled insulation is formed as the polymer exits the extrusion die, having a longitudinal cavity therein corresponding to the location of the opening formed by the at least one air chamber.

Owner:BERK TEK

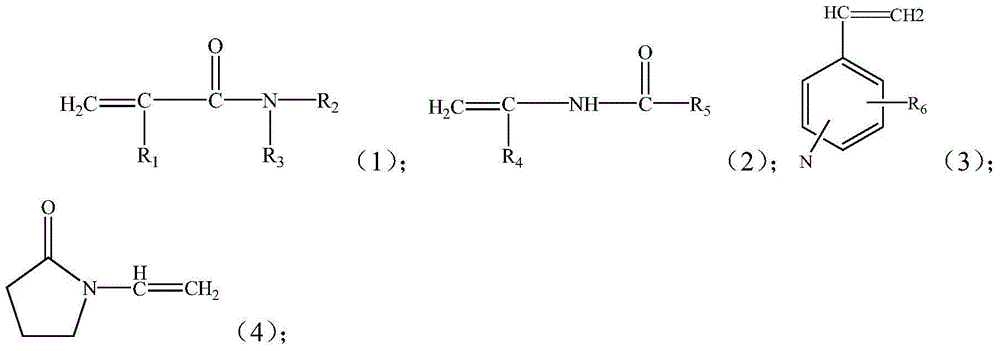

Polymer mobility control agent suitable for high-temperature and high-salinity harsh reservoir and preparation method of polymer mobility control agent

ActiveCN104448128AGood temperature and salt resistanceGood thermal stabilityDrilling compositionSalt resistancePolymer science

The invention relates to a polymer mobility control agent suitable for a high-temperature and high-salinity harsh reservoir and a preparation method of the polymer mobility control agent, and the polymer mobility control agent is mainly used for solving the problems that the polymer in the prior art is poor in heat and salt resistance and long-term stability, and cannot meet the requirements of tertiary oil recovery. In order to better solve the problems, the technical scheme adopted by the invention is as follows: an amphoteric hydrophobic association polymer is prepared from the following raw materials in parts by weight: 5-99.9 parts of a non-ionic water-soluble monomer, 0-50 parts of an anionic monomer or / and cationic monomer, 0.1-10 parts of a hydrophobic monomer with surface activity, 0-20 parts of a viscosity stabilizer and 0-20 parts of a surfactant. The preparation method can be applied to industrial production and application of the polymer mobility control agent for the high-temperature and high-salinity harsh reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

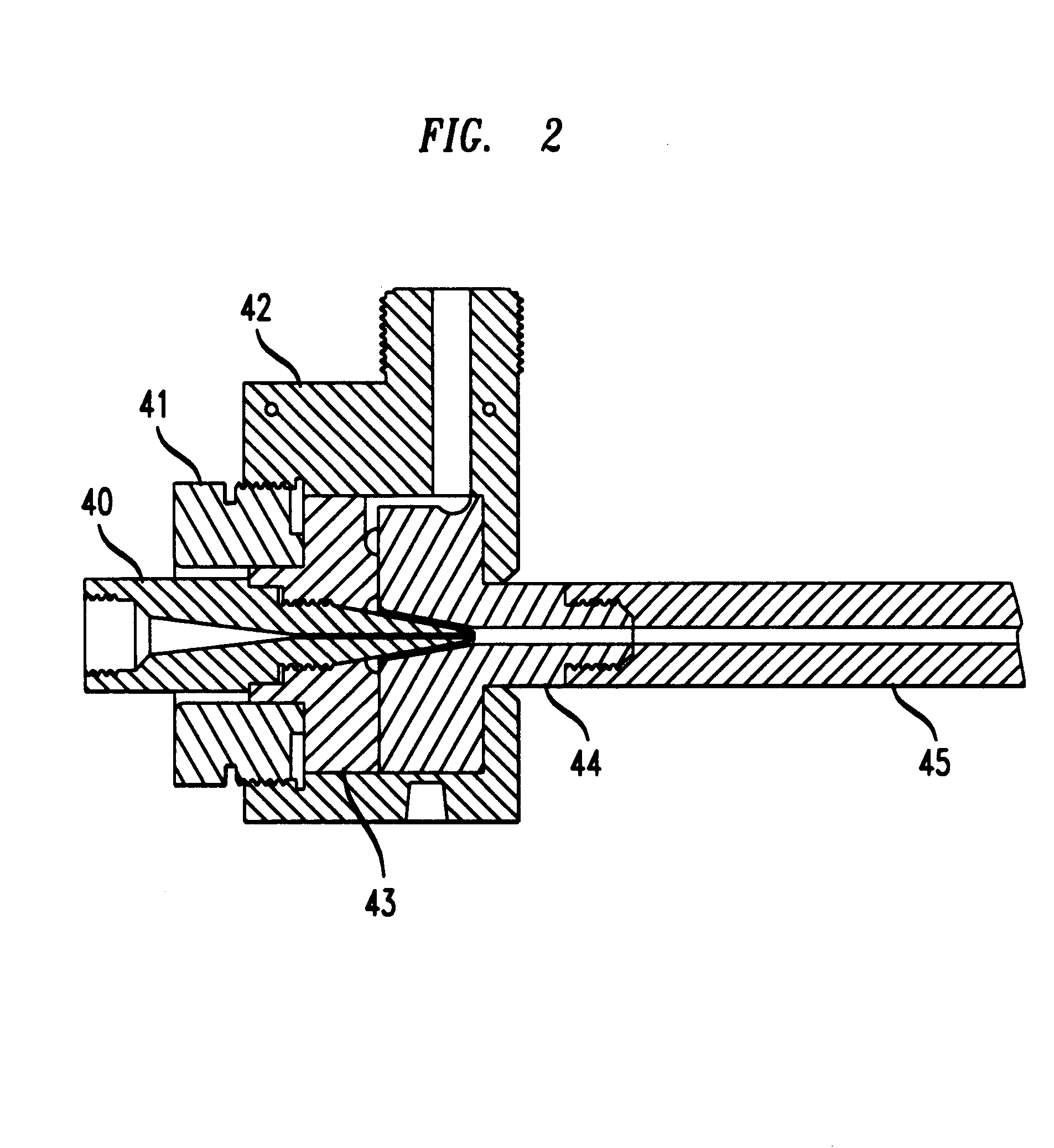

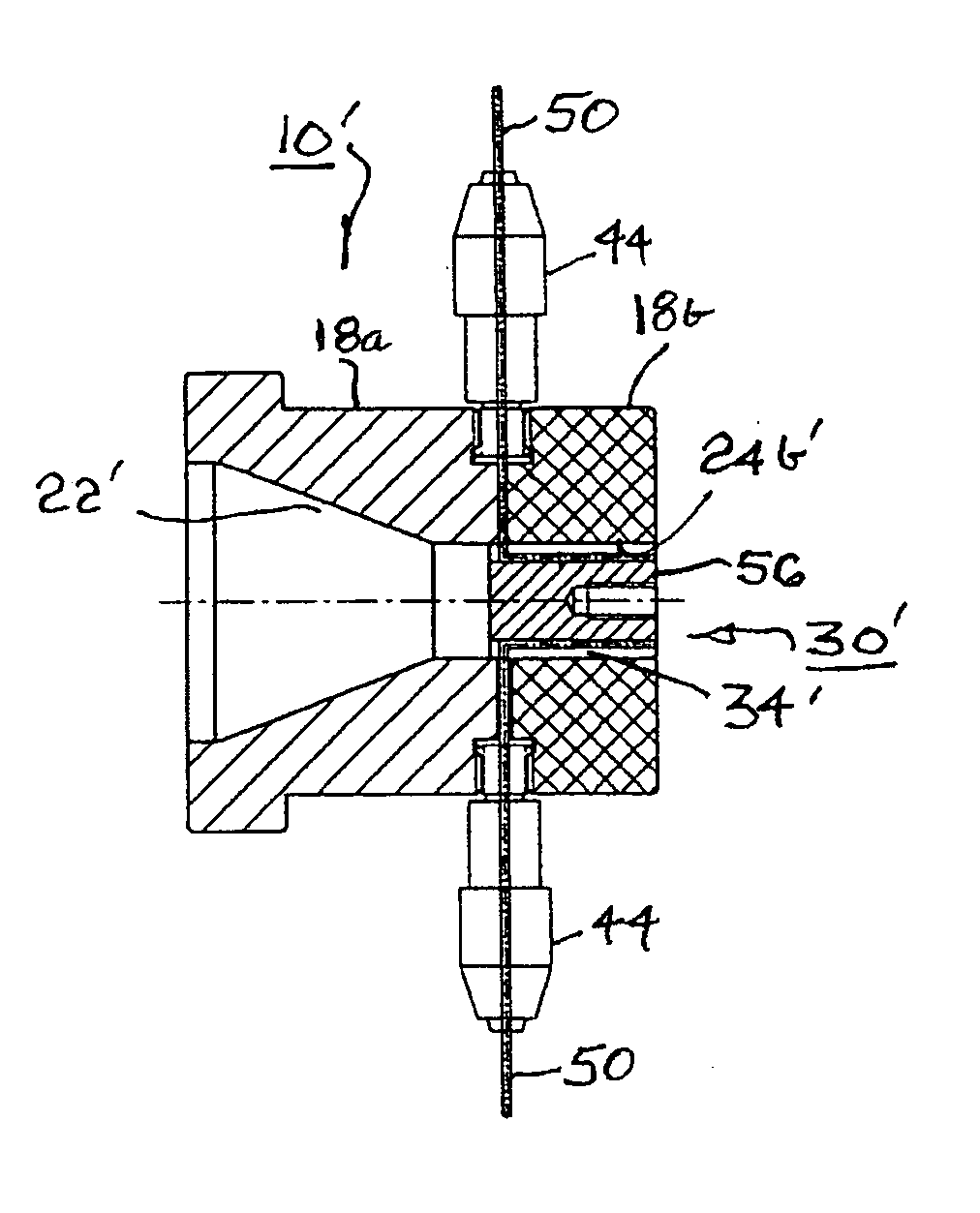

Method and apparatus for incorporating lumens into the wall of a tubular extrusion

A polymer extrusion head for forming continuous shapes having one or more lumens therein. The head includes an extrusion mandrel and die. At least one lumen pipe is disposed radially through a port in the die to intersect the polymer flow in the annular region between the tip and the die. The lumen pipe is a welded assembly having a 90° turn formed as a mitered joint with zero bend radius. The lumen pipe is held in a pin vise engaged in the die such that position of the lumen pipe may be readily adjusted. Axial and radial positions are established during assembly by means of a gauge block. A plurality of lumen pipes may be accommodated for a plurality of lumens by a manifold distribution system including individual lumen pipe assemblies.

Owner:CANGEN HLDG

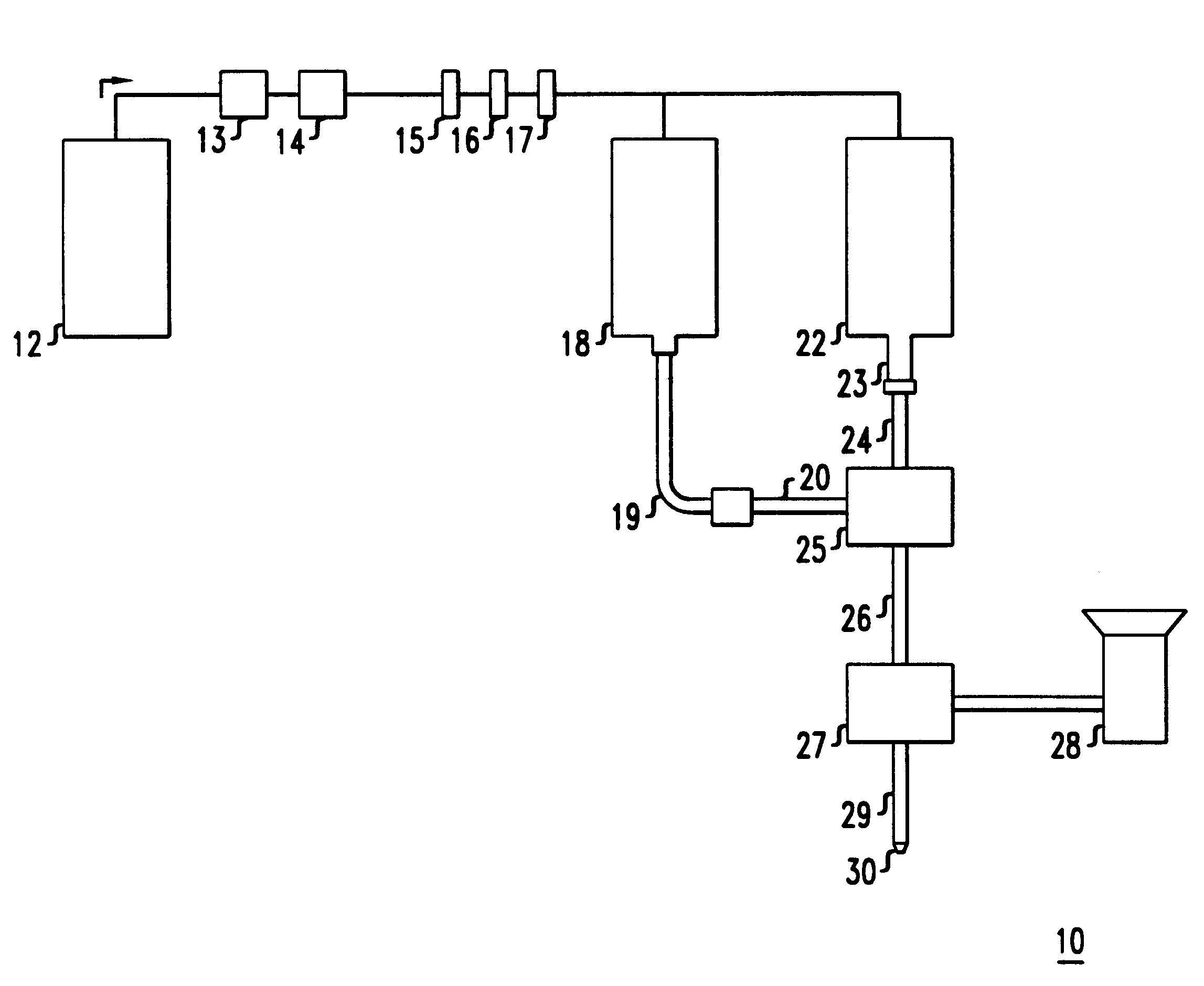

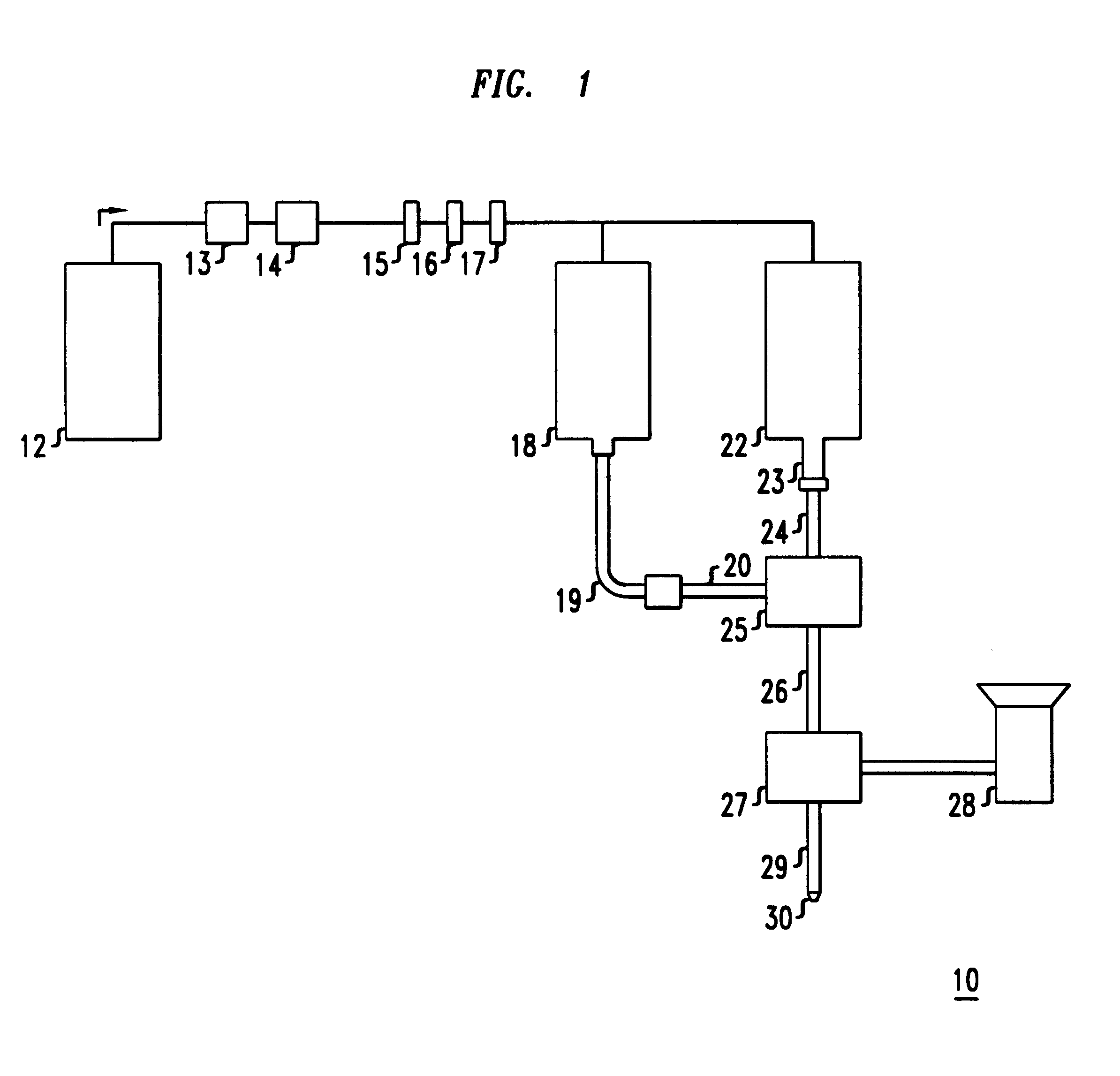

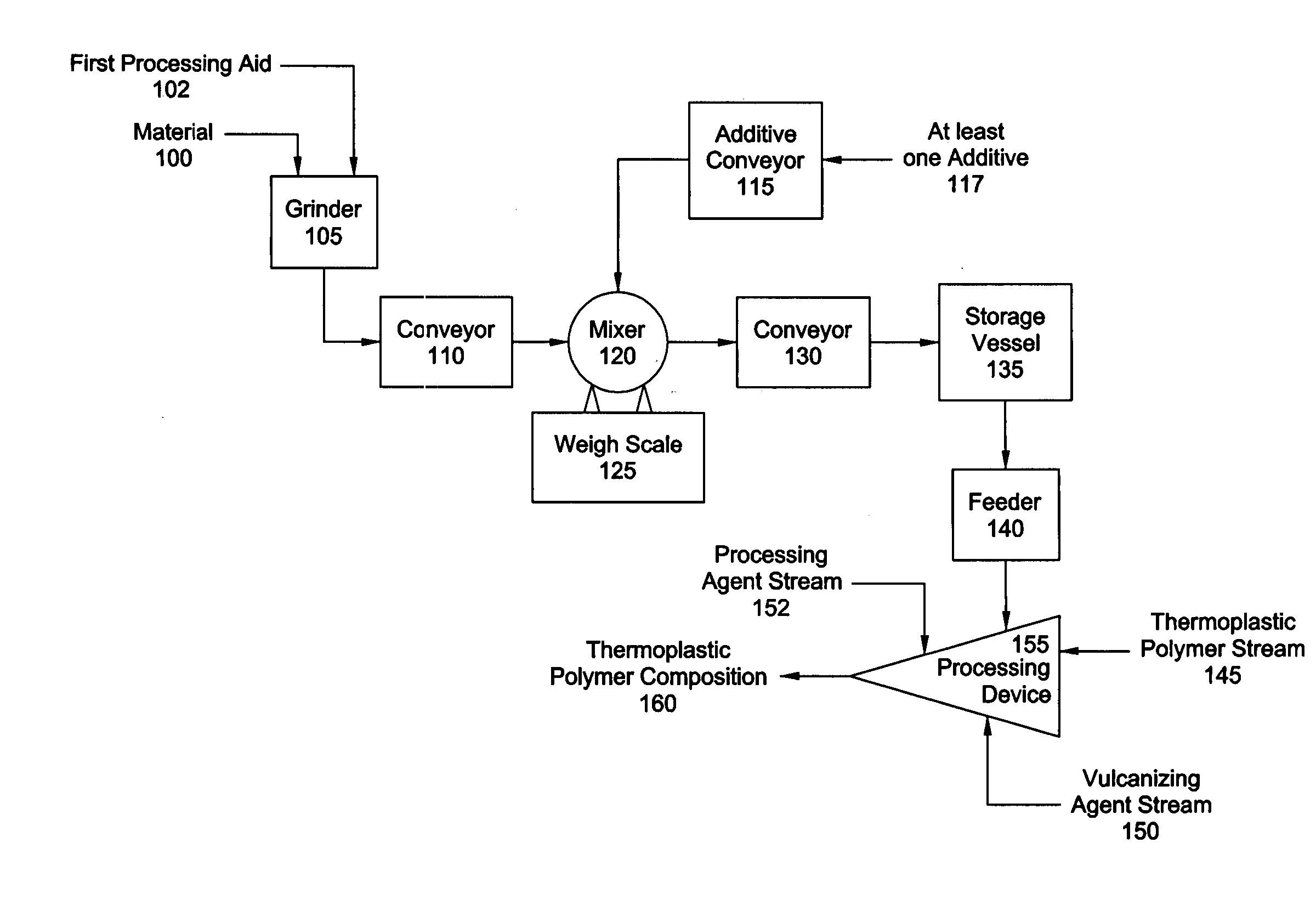

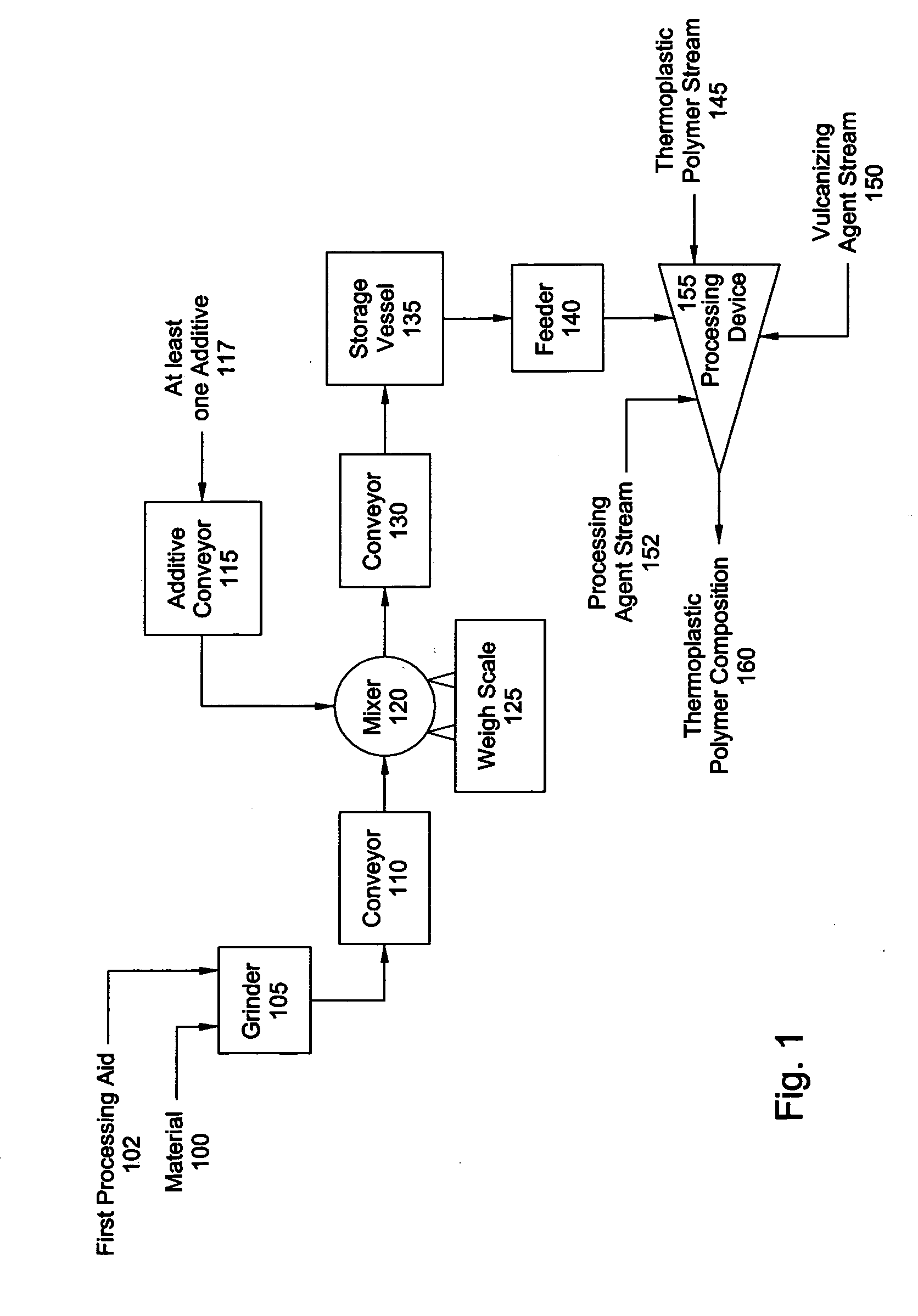

Process and apparatus for preparation of thermoplastic polymer blends

InactiveUS20070244264A1Efficient mixingTransportation and packagingMixer accessoriesMaterial transferThermoplastic polymer

Provided for preparing thermoplastic polymer blends is (1) an apparatus comprising a grinder, a mixer, at least one material transfer device, a weigh scale, means for addition of additives to the mixer, a storage vessel, a processing device and means for feeding polymer to the processing device; and (2) a process comprising mixing a known amount of a first material with a desired amount of at least one additive based on a predetermined weight ratio of additive to first material to form individual batches of pre-mix, storing the pre-mix batches in a storage vessel, continuously feeding the pre-mix from the storage vessel to a processing device, adding a polymer stream to the processing device at a rate based on the first material feed rate to the processing device, optionally adding at least one vulcanizing agent stream to the processing device at a rate based on the polymer stream feed rate to the processing device and melt mixing all materials in the processing device to form a thermoplastic polymer blend.

Owner:ADVANCED ELASTOMER SYST LP

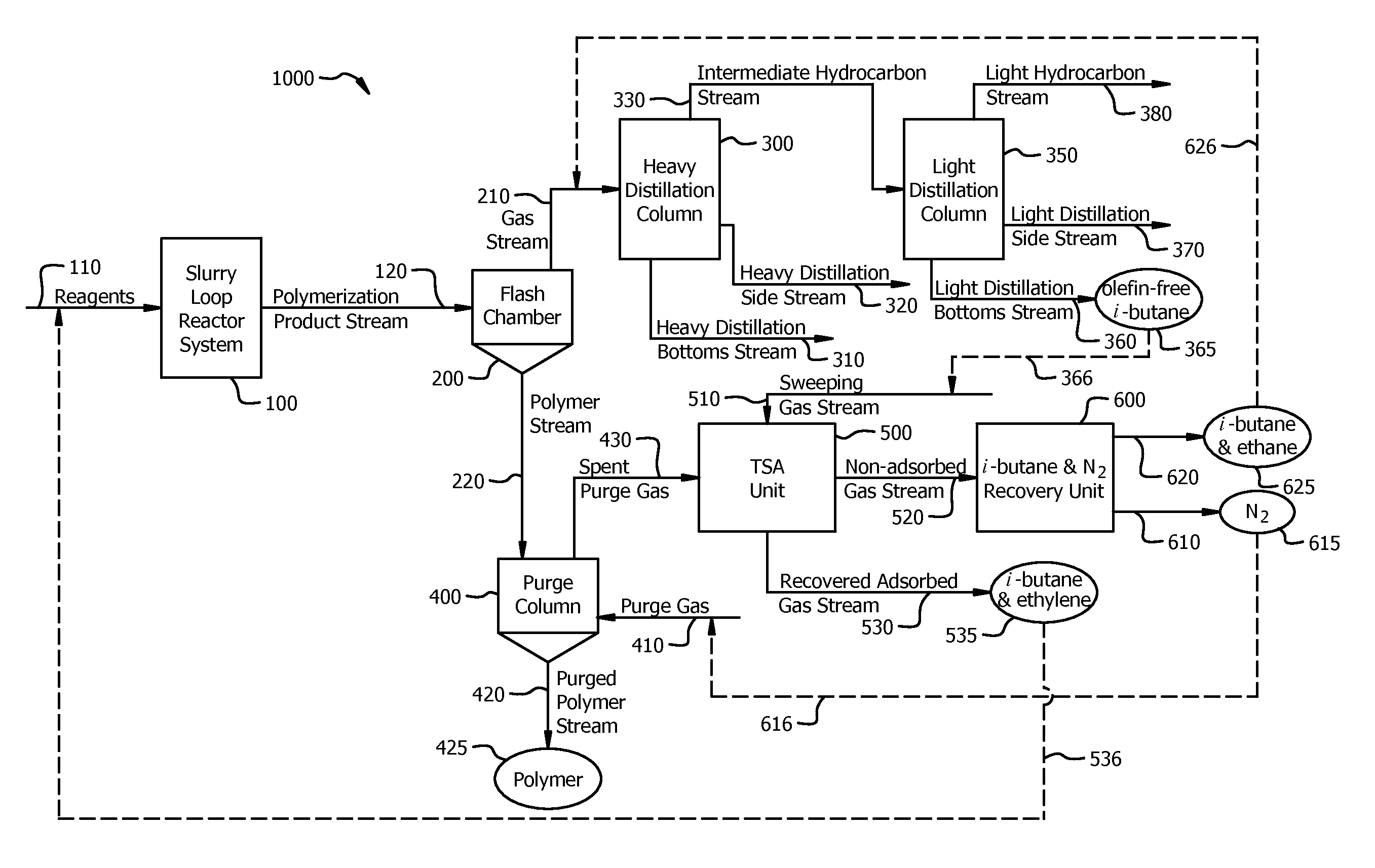

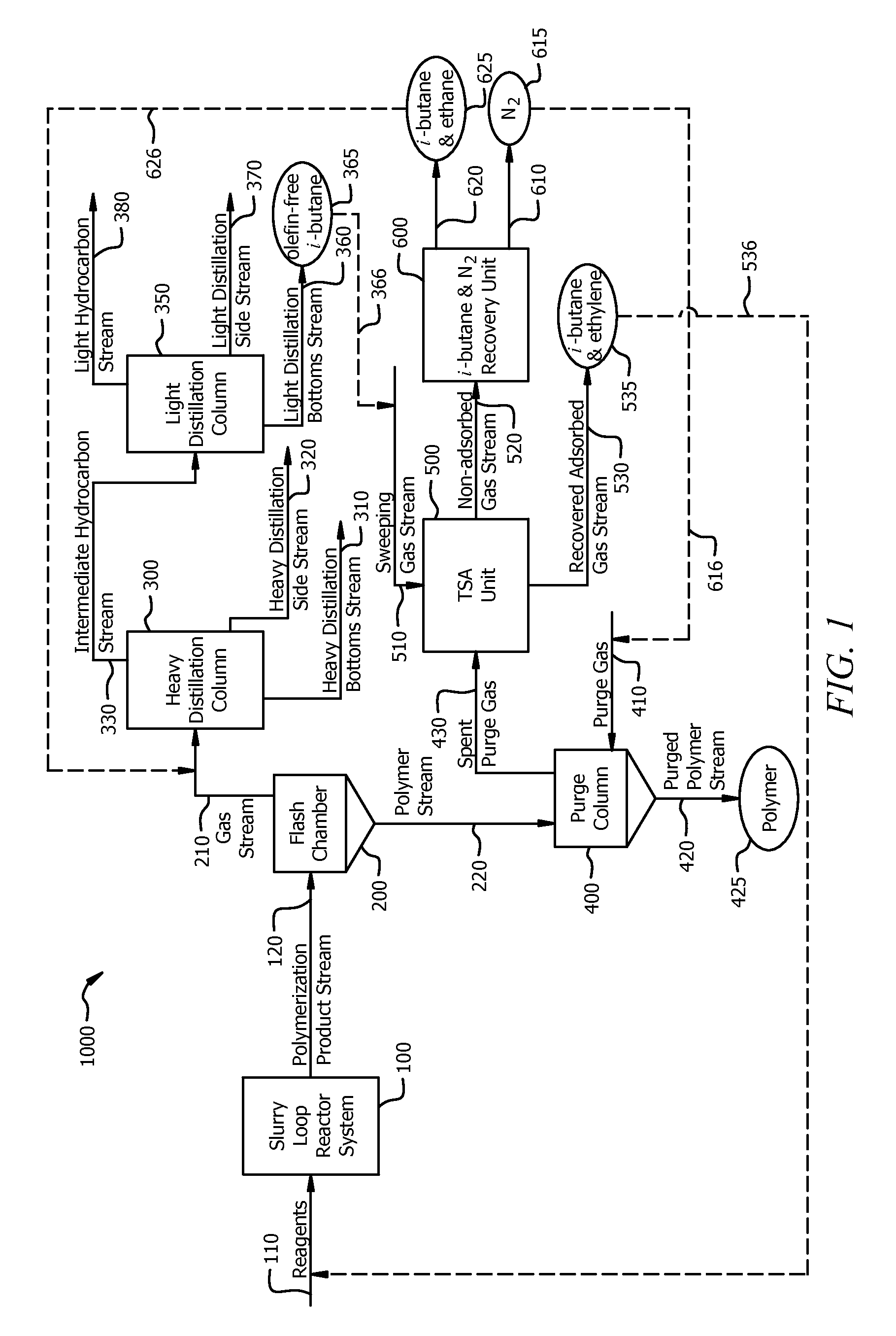

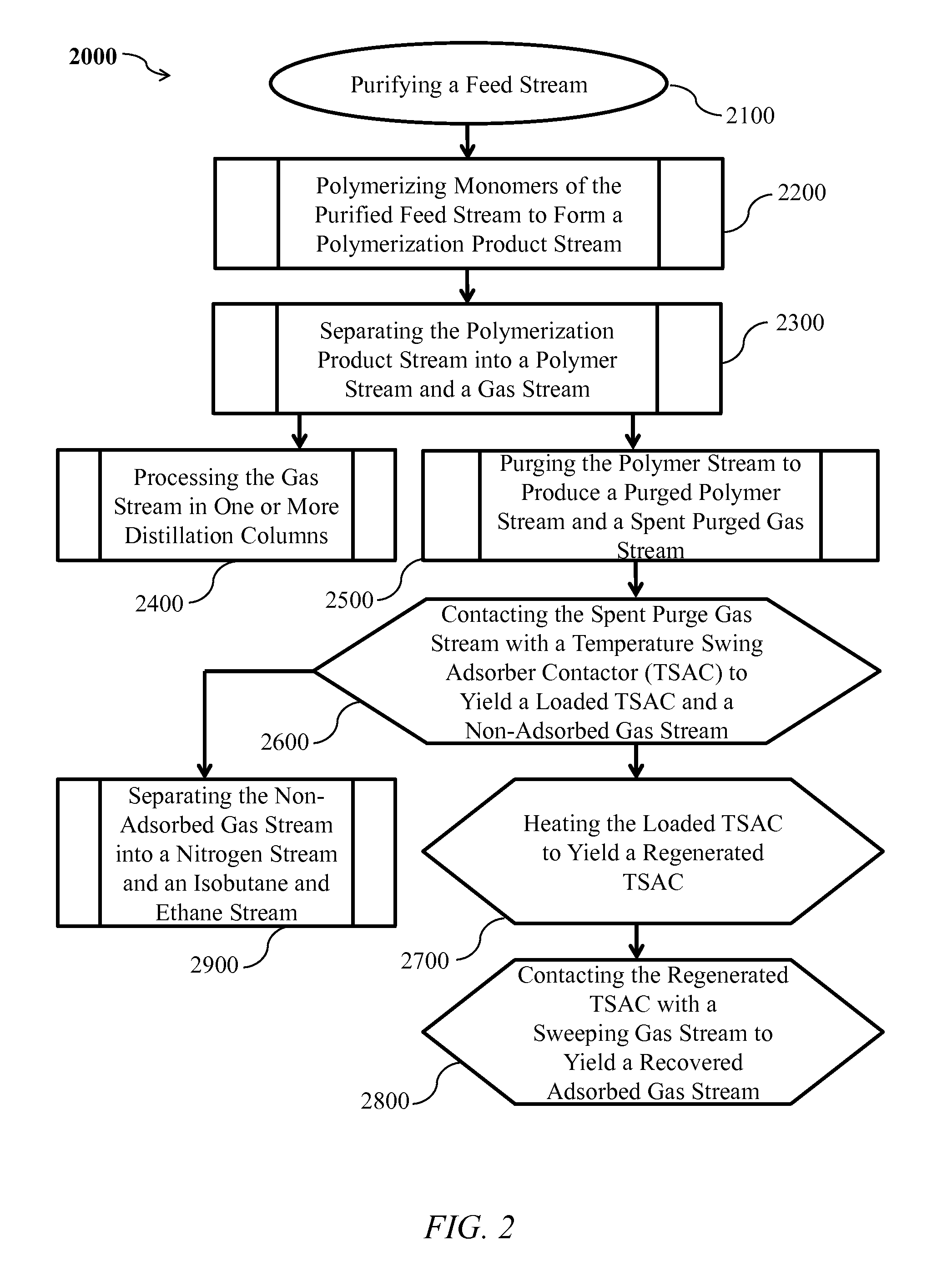

Ethylene separation with temperature swing adsorption

A process for component separation in a polymer production system, comprising (a) separating a polymerization product stream into a gas stream and a polymer stream, (b) contacting the polymer stream with a purge gas to yield a purged polymer and a spent purge gas comprising purge gas, ethylene, and ethane, (c) contacting the spent purge gas with a temperature swing adsorber contactor (TSAC) to yield a loaded TSAC, wherein at least a portion of the ethylene is adsorbed by the TSAC at a first temperature to yield TSAC-adsorbed ethylene, wherein a portion of the ethane is adsorbed by the TSAC at the first temperature to yield TSAC-adsorbed ethane, (d) heating the loaded TSAC to a second temperature to yield a regenerated TSAC, and (e) contacting the regenerated TSAC with a sweeping gas stream to yield a recovered adsorbed gas stream comprising sweeping gas, recovered ethylene and recovered ethane.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

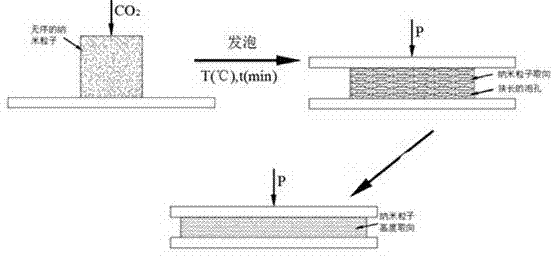

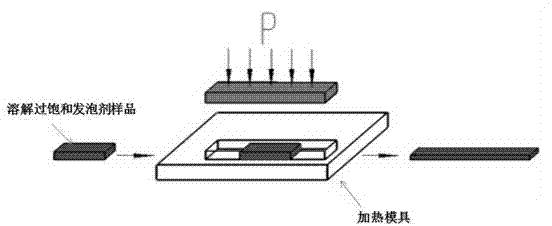

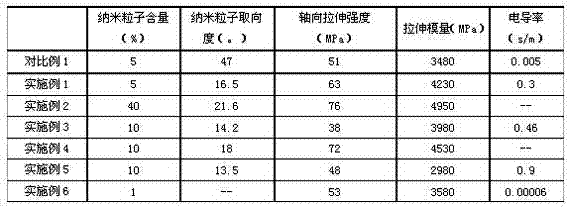

Preparation method for polymer base nanometer composite material with highly oriented nanoparticles in polymer matrix

The invention relates to a preparation method for a polymer base nanometer composite material with highly oriented nanoparticles in the polymer matrix, and belongs to the technical field of polymer materials. The preparation method comprises that during a foaming process of a polymer nanometer composite material formed by carrying out melt co-mixing on a polymer and nanoparticles, external force is applied to make the foam hole in the material grow along the uniaxial direction in an oriented growth manner, and the polymer flows under the double induction of the external force and the foam hole growth to achieve the high orientation of the nanoparticles so as to obtain the polymer base nanometer composite material with the highly oriented nanoparticles in the polymer matrix. The method has advantages of simple operation, mild condition, high orientation degree of the nanoparticles in the prepared polymer nanometer composite material, and the like.

Owner:ZHEJIANG UNIV OF TECH

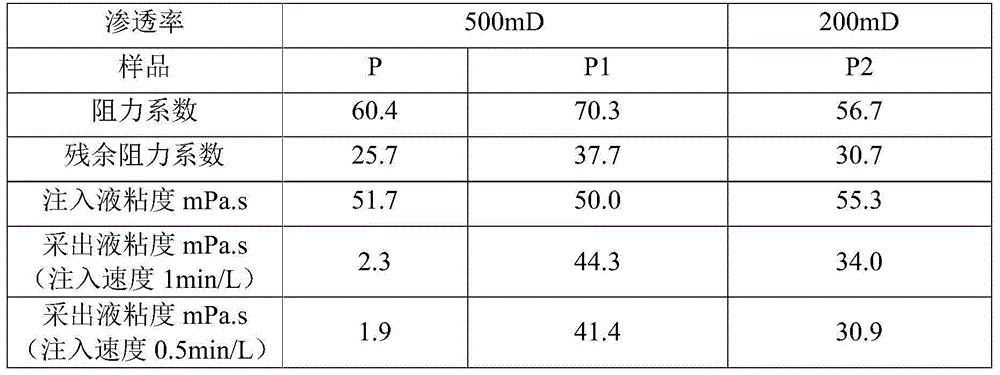

Oil-displacement composition with improved injectivity, and preparation method and application thereof

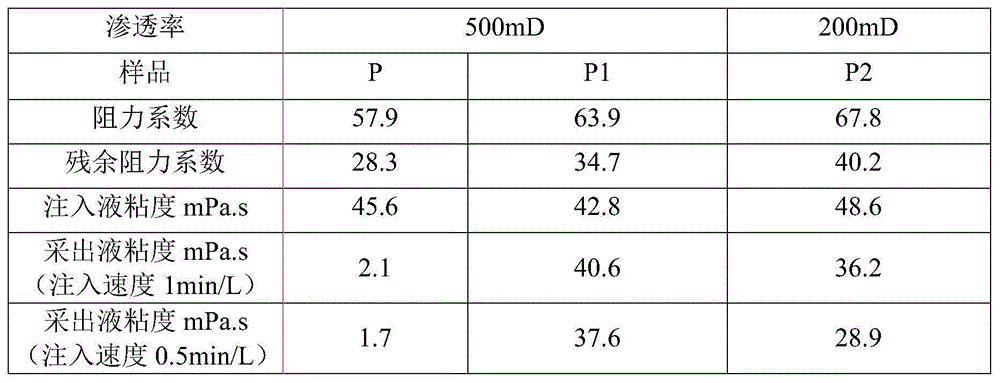

ActiveCN105567208AEasy injectionGood temperature and salt resistanceDrilling compositionThroatPolymer science

The invention relates to an oil-displacement composition with improved injectivity, and a preparation method and application thereof. The main objective of the invention is to overcome the problems of poor injectivity at zones near a well on site due to proneness to obstruction at pore throats of strata caused by strong adsorption effect of hydrophobic associated polymers on the surface of sandstone. The oil-displacement composition with improved injectivity comprises, by weight, 0.01 to 1 part of an anti-adsorption agent, 0.3 to 3 parts of a hydrophobic associated polymer and 96 to 99.69 parts of water, wherein the anti-adsorption agent is at least one or a mixture of two or more selected from a group consisting of nonionic surfactants and anionic surfactants. The oil-displacement composition provided by the invention perfectly overcome the above-mentioned problem and can be used for on-site injection of a polymer fluidity control agent into a high-temperature high-salt severe oil reservoir for oil displacement.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gel reduction device and gel reduction method

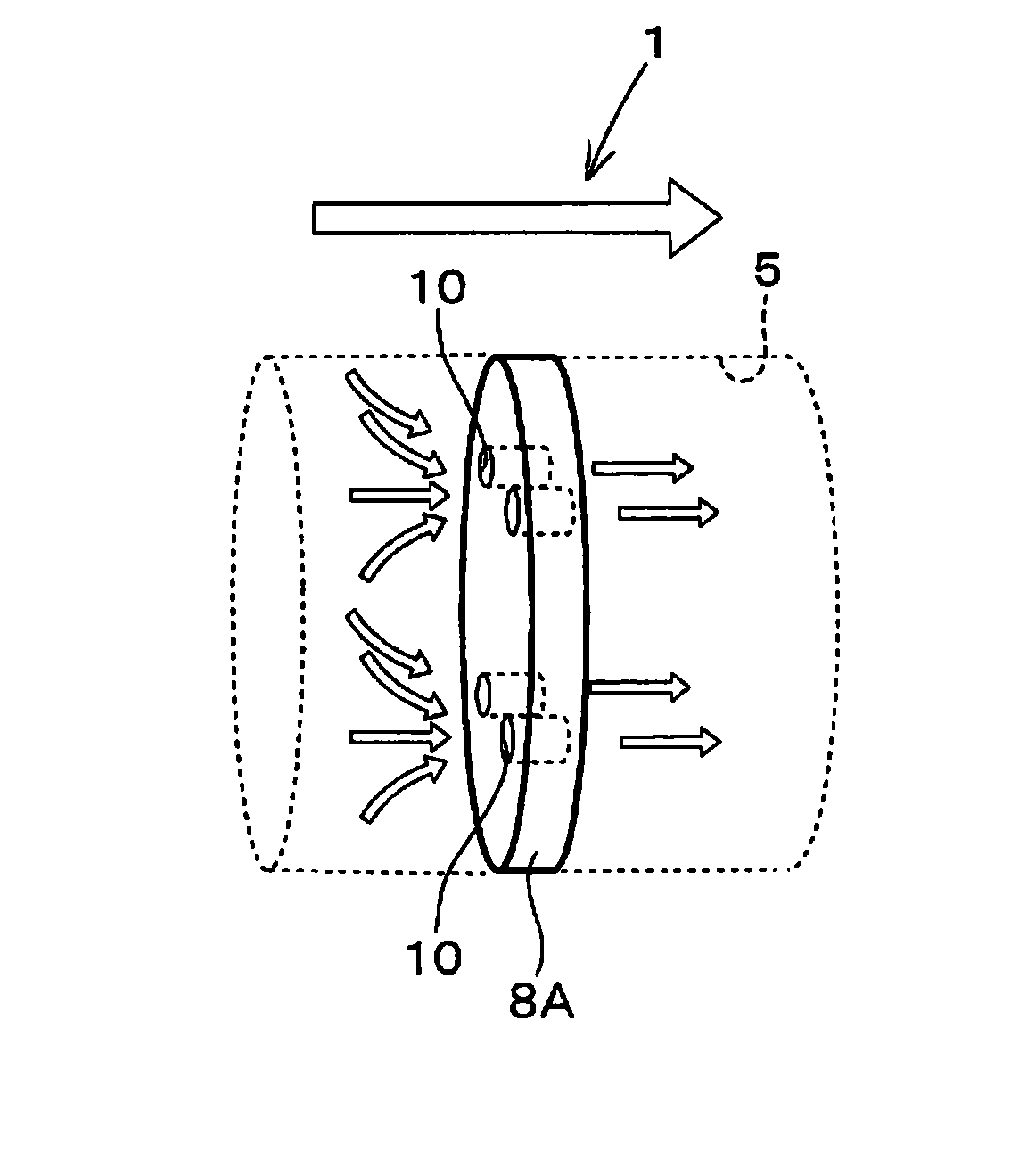

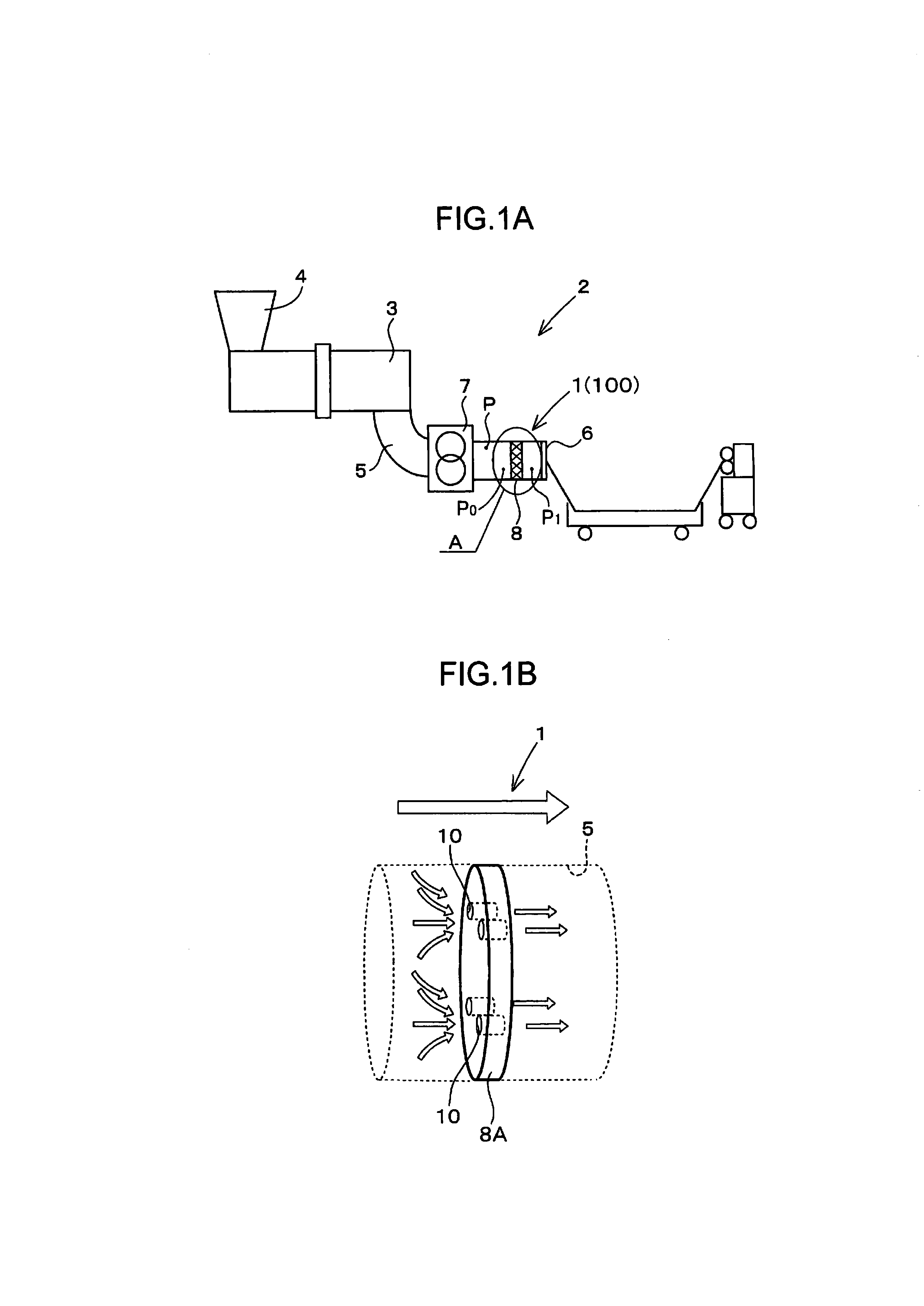

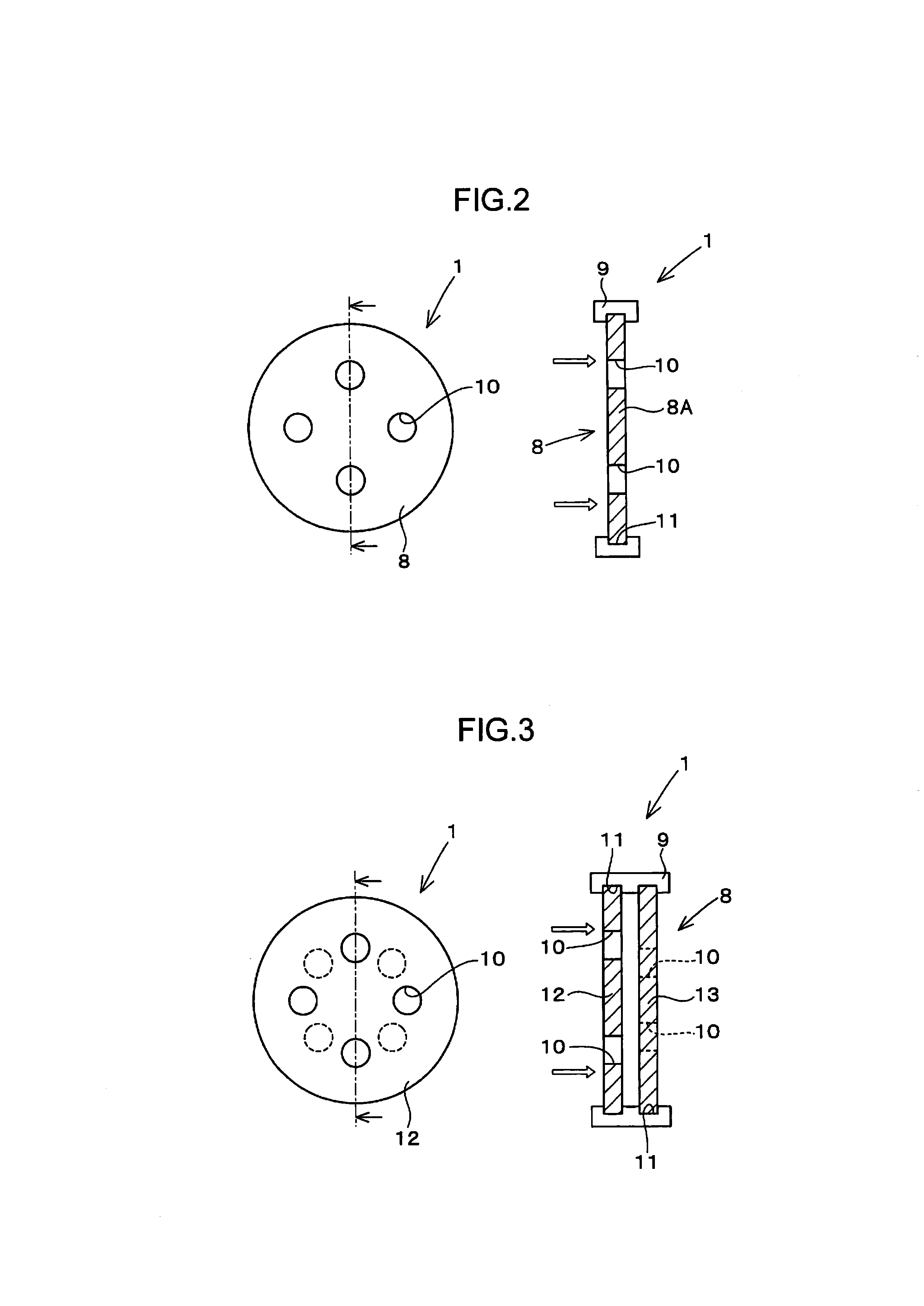

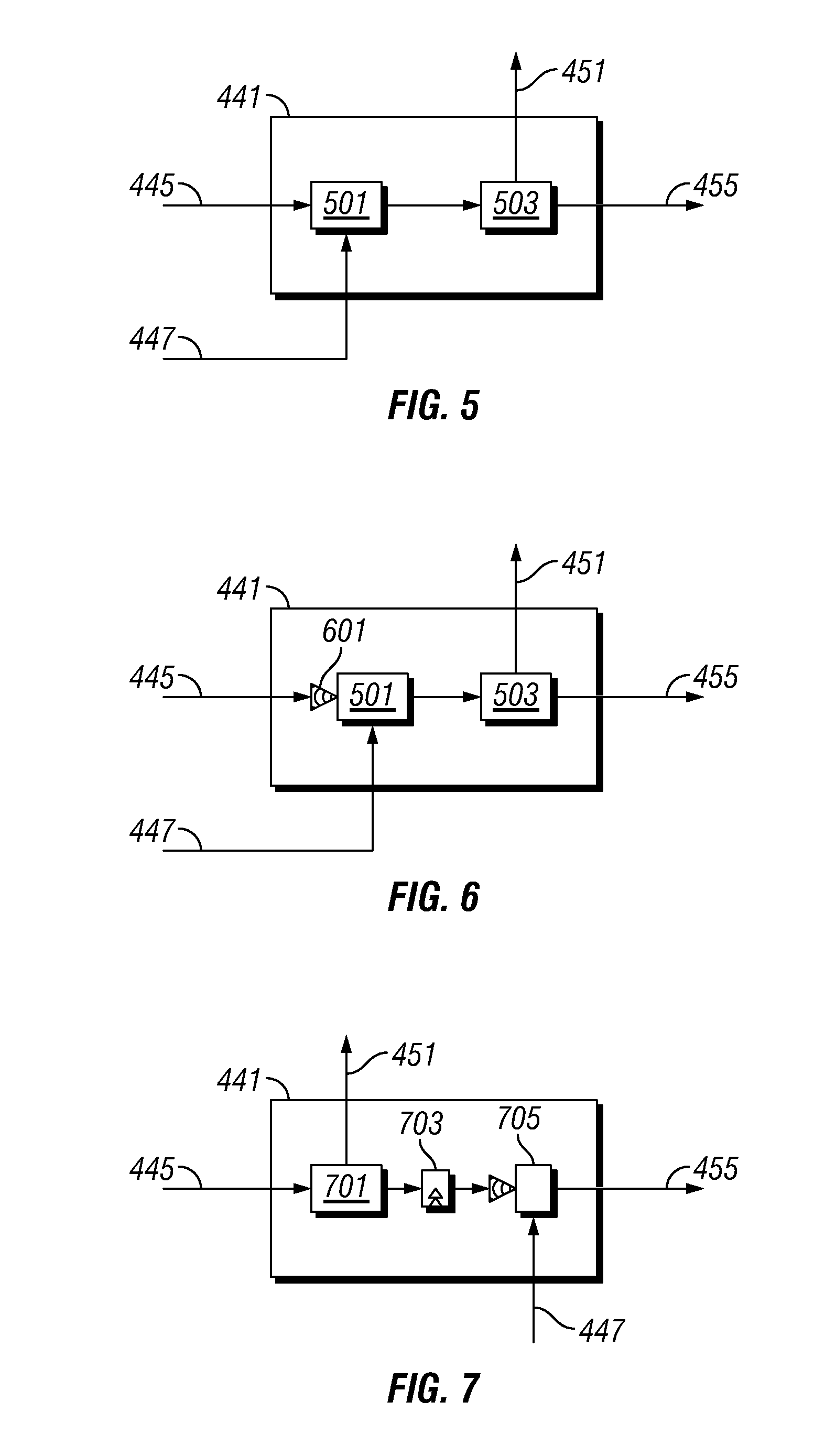

InactiveUS20130176810A1Reduce compoundingImprove productivityFlow mixersRotary stirring mixersEngineeringPolymer flow

A gel reduction device 1 of the present invention includes a gel reduction mechanism 8 provided in a polymer flow duct 5 in which a polymer kneaded compound flows and adapted to reduce gel present in the polymer kneaded compound. The gel reduction mechanism 8 includes at least one or more squeezing flow paths 10 having a flow path cross-sectional area smaller than the polymer flow duct 5, and a squeeze ratio S1 / S2 of the squeezing flow paths 10 is set to be 25 to 180 so as to be able to generate an extensional flow in the kneaded compound flowing in the squeezing flow paths 10.

Owner:KOBE STEEL LTD

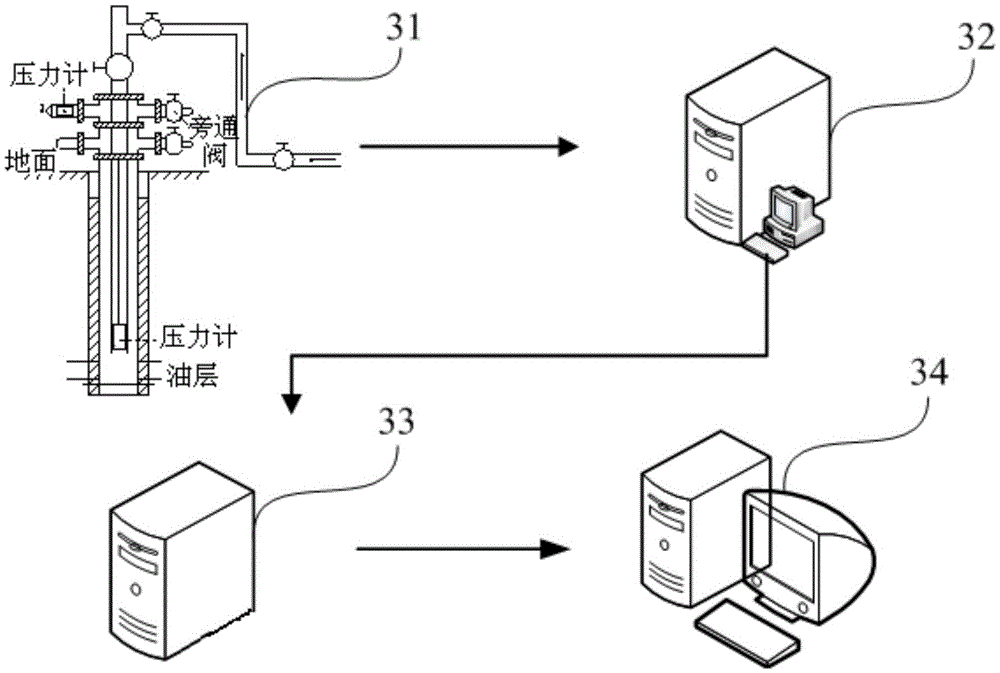

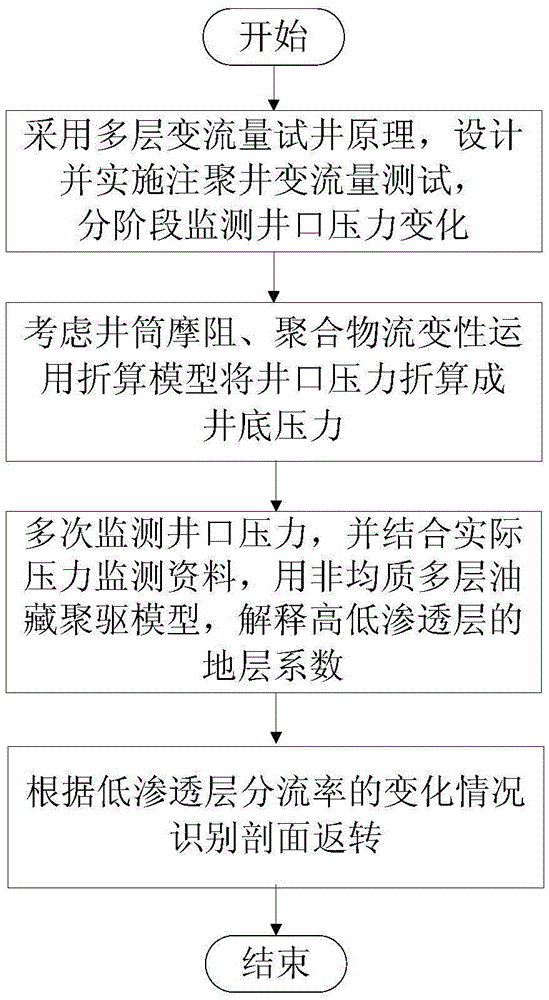

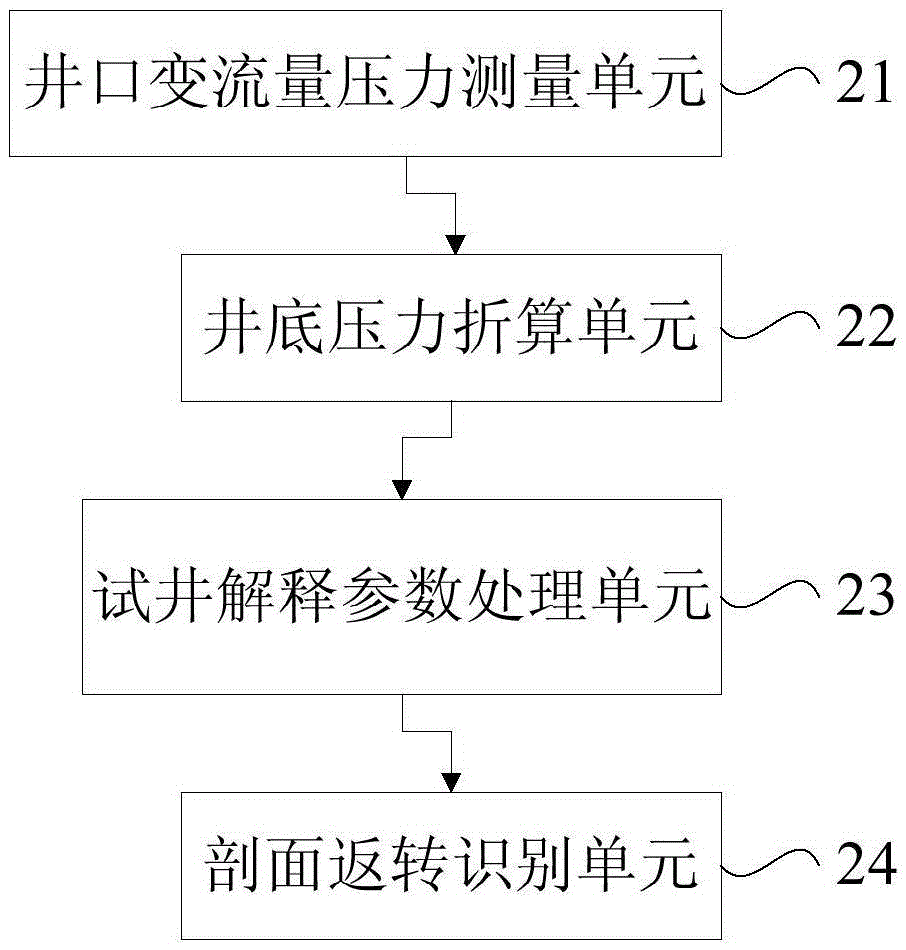

Wellhead pressure monitoring method and control system

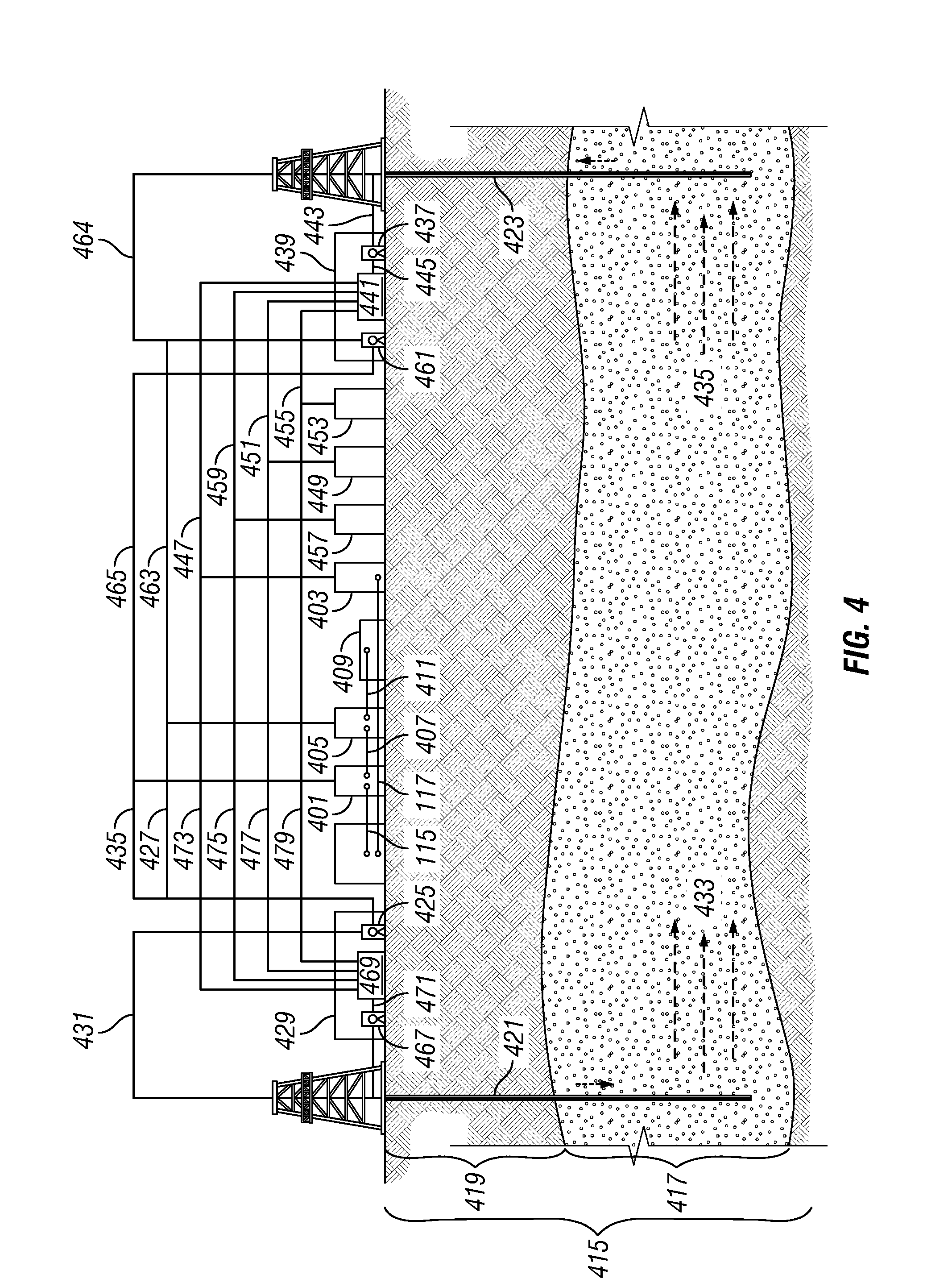

ActiveCN105464644AHigh feasibilityAlleviate flooding phenomenon of "suction profile reversal"SurveyControl systemWell test

The invention relates to a wellhead pressure monitoring method and a control system. The method is used for multilayer oil reservoir polymer flooding profile reversal recognition, and comprises the following steps that the polymer injection well variable flow test is designed and implemented by adopting a variable flow well test principle; the wellhead pressure change is monitored in stages; accurate pressure and flow data is obtained during the test period, and the variable flow well test can be performed under the well opening condition; the wellhead pressure is converted into the well bottom pressure by considering the well tube friction and the polymer rheological property and using a converting module; the wellhead pressure is monitored for many times, and the converted well bottom pressure data is subjected to well test explanation by combining the actual pressure monitoring data and using an anisotropic multilayer oil reservoir polymer flooding model to obtain the formation conductivity of high-permeability and low-permeability layers; and the data is converted into the conversion condition of the fractional flow rate of the low-permeability layer for recognizing the profile reversal according to the obtained formation conductivity of each formation. A wellhead pressure test monitoring method is used, so that the limitation that a pressure meter of a pipe column structure cannot enter the well is avoided; and meanwhile, the pressure test cost is reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Oxidizability and reducibility conducting polymer flow anode used for flow battery

InactiveCN102646835ALow costRich sourcesCell electrodesRegenerative fuel cellsConductive polymerPolymer chemistry

The invention discloses an oxidizability and reducibility conducting polymer flow anode with used for a flow battery. An oxidizability and reducibility conducting polymer or a conducting polymer and an inorganic substance composite material are dispersed in electrolyte solution to form electrolyte of the flow battery, the electrolyte and a three-dimensional mesh current-collection body commonly constitute an emulsus flow electroactive polymer anode, and anode flow passes an anode chamber in a flowing form in the charging and discharging processes and is used for forming a flow battery system. As the dimension of the conducting polymer and the dimension of the inorganic substance composite material of the conducting polymer are large, the battery can adopt a common porous diaphragm; in addition, the corrosion of a medium system of the electrolyte of the battery used for an electroactive material to a solid current collector is small, and therefore, the environmental pollution is small in the production and using processes; the conducting polymer is rich in source, so as to be prepared on a large scale by an organic synthesis method; and the cost of the flow battery can be greatly lowered.

Owner:CENT SOUTH UNIV

Process for the introduction of additives, into polymer melts

A process for making a thermoplastic molding composition comprising (i) forming a vertically falling stream of molten polymer, and (ii) bringing at least one additive in solid or liquid states, in solution, in the form of a dispersion or in suspension into contact with at least a part of the surface of said stream and to introduce the additive in said stream to produce combined stream, and (iii) introducing the combined stream into a pump to form a pre-mix and (iv) introducing the premix into a mixer to form a homogeneous polymer melt. The entraining stream is then introduced to a pump to form a pre-mix which is then introduced to a mixer to form a homogeneous polymer melt. The process results in a compositions having advantageous material properties.

Owner:BAYER MATERIALSCIENCE AG

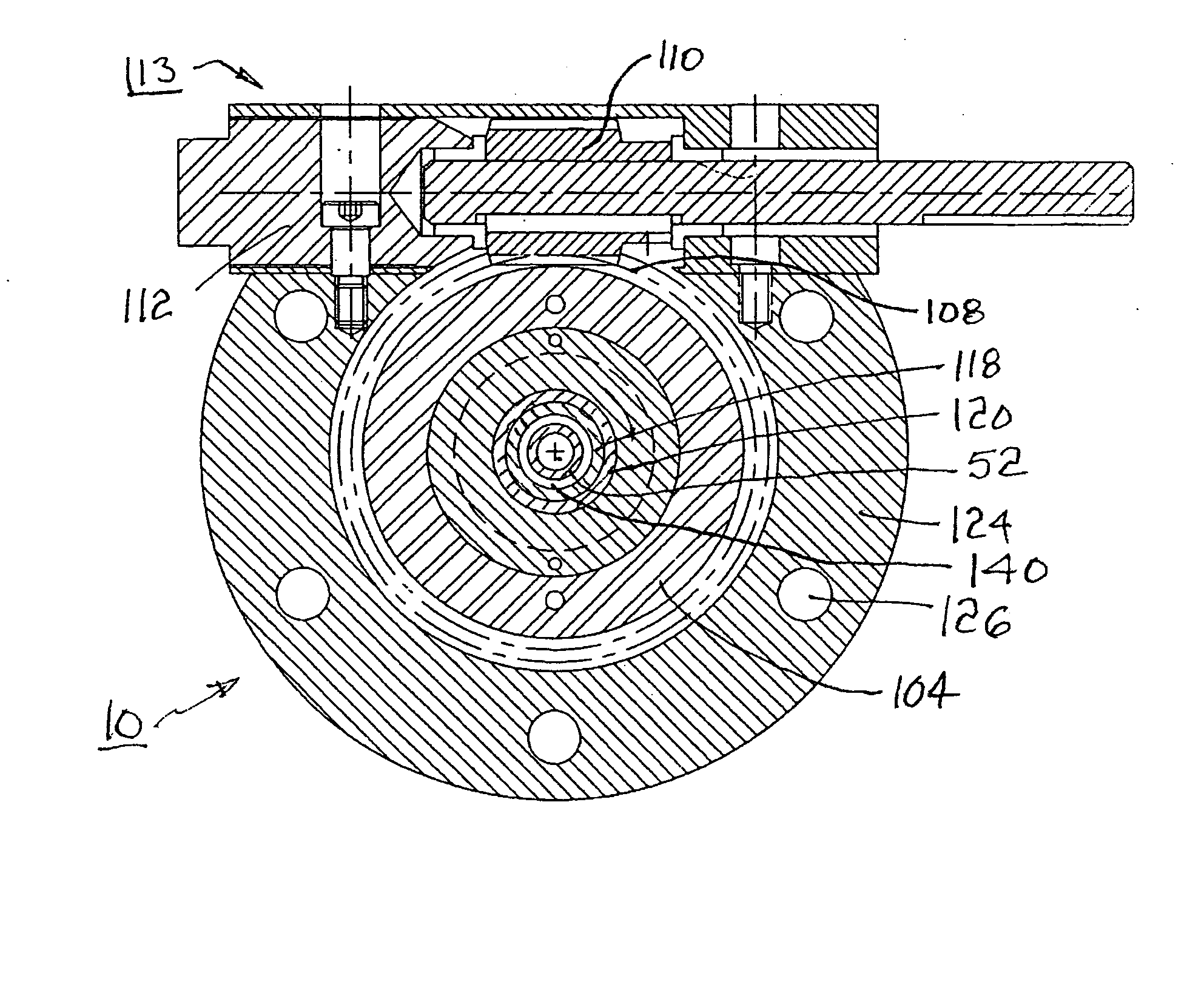

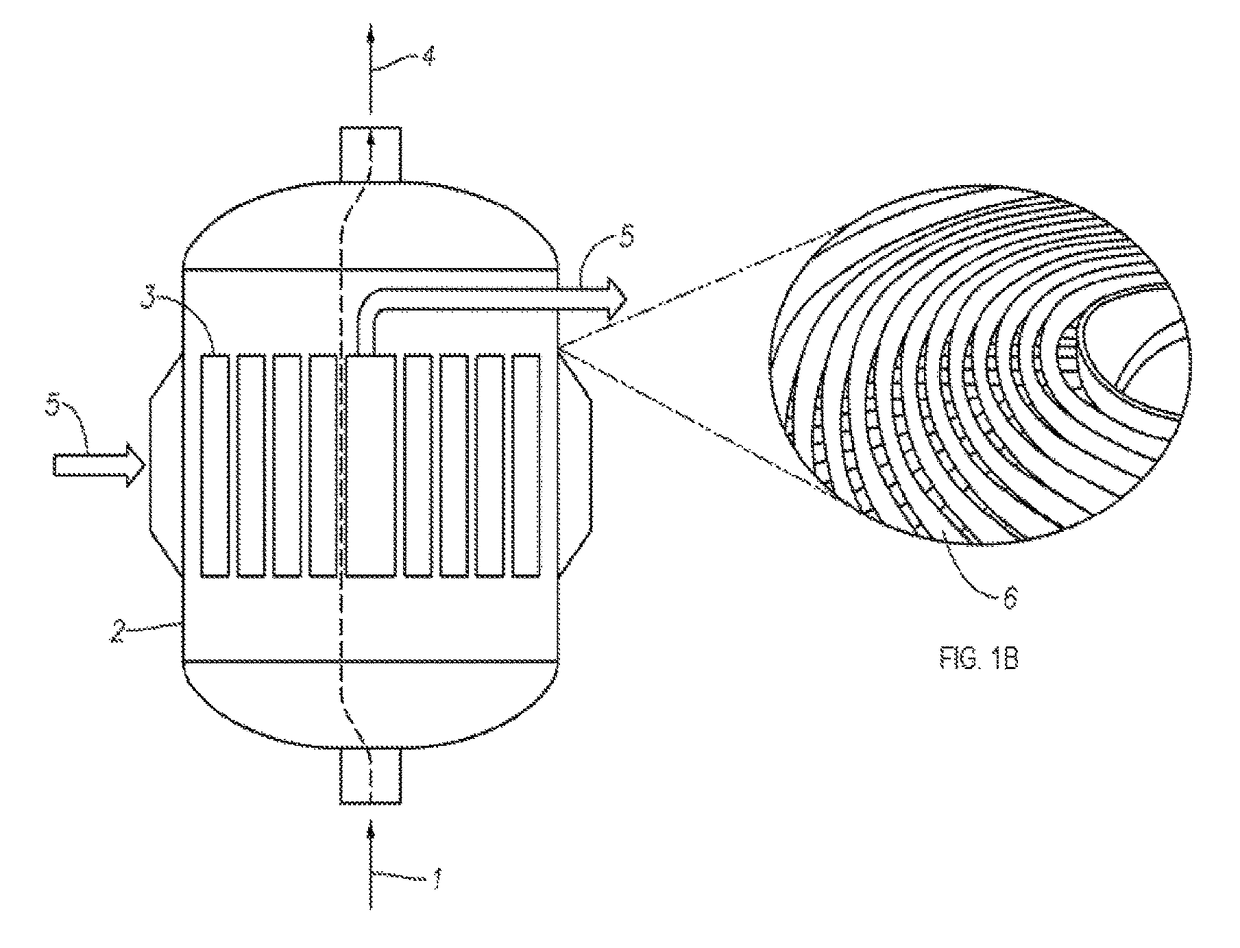

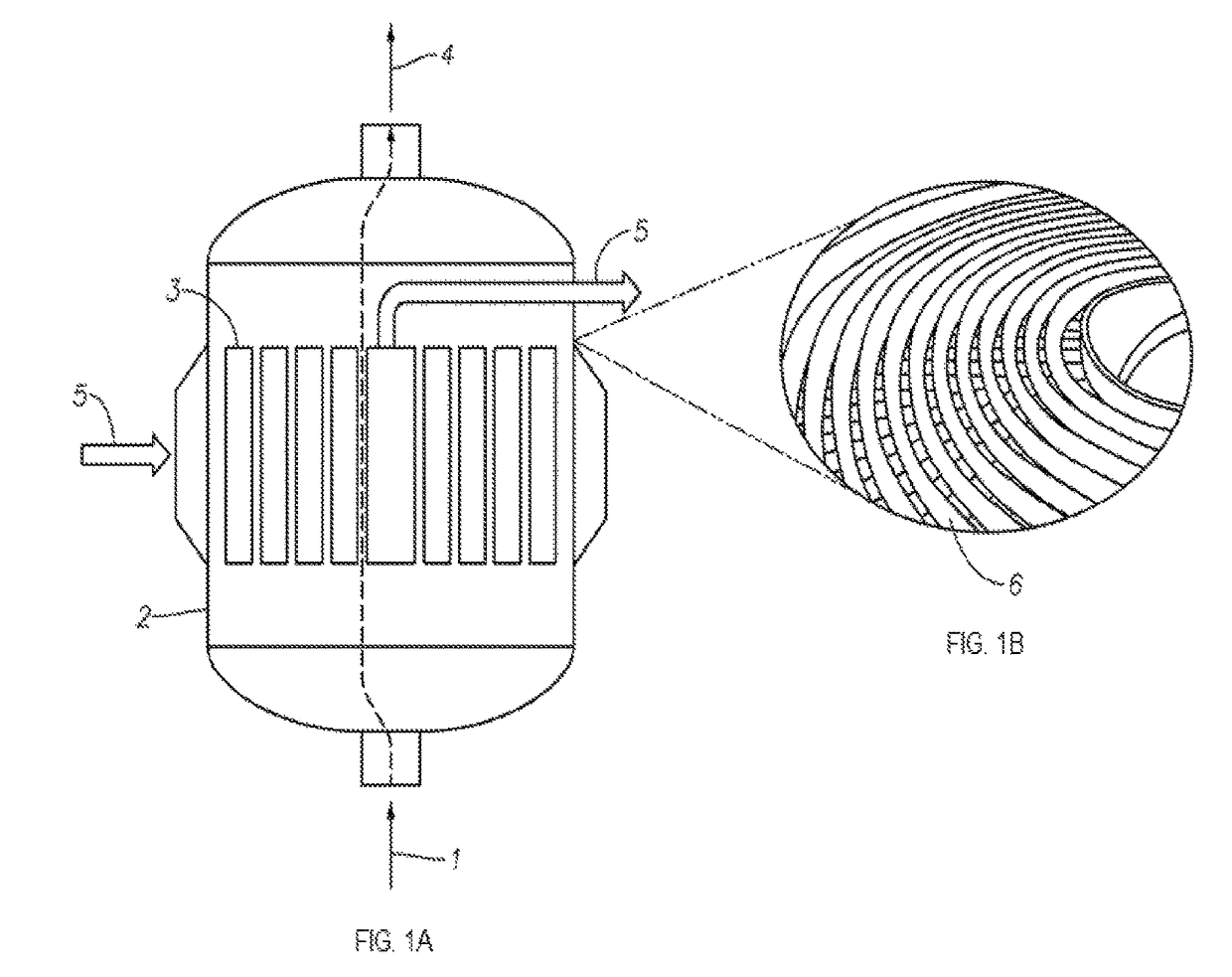

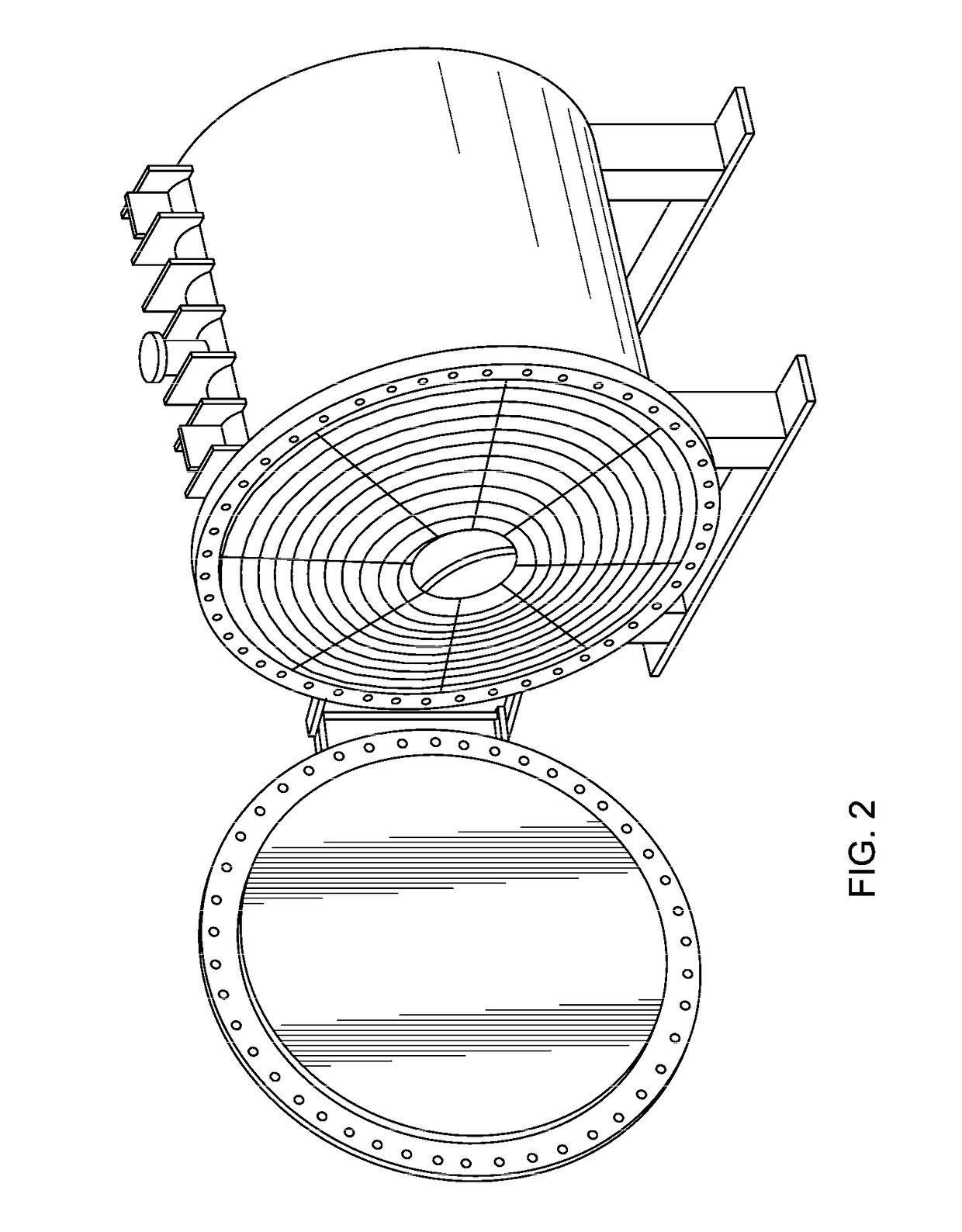

Polymerization using a spiral heat exchanger

ActiveUS9708428B2Compression machines with reversible cycleStationary tubular conduit assembliesPolymer scienceReaction zone

This invention relates to a polymerization process for forming polymer comprising: contacting (typically in a solution or slurry phase), a monomer and a catalyst system in a reaction zone comprising at least one spiral heat exchanger and recovering polymer, wherein the monomer, the catalyst system and the polymer flow through the at least one spiral heat exchanger in a cross-flow direction relative to spirals of the at least one spiral heat exchanger.

Owner:EXXONMOBIL CHEM PAT INC

On the fly catalyst transitions

A process for transitioning between Ziegler Natta (Z / N) polymerization catalysts and Second Polymerization catalysts in a polymerization system which includes at least two polymerization reactors. During the transition, the Z / N catalyst is used in the “downstream” reactor, thereby providing a flow of polymer to finishing operations. This eliminates the need for lengthy shutdowns of finishing equipment and thereby improves the efficiency of the plant operations.

Owner:NOVA CHEM (INT) SA

Process for reducing viscosity of polymer-containing fluid produced in the recovery of oil

The present invention is directed to a process for producing a fluid containing oil and water from an oil-bearing formation and separating an oil phase and an aqueous phase from the produced fluid. An aqueous polymer mixture is formed by mixing polymer in water having a total dissolved solids content of from 200 ppm to 15,000 ppm. The aqueous polymer mixture is injected into an oil-bearing formation, and, after injecting the aqueous polymer mixture into the formation, a fluid is produced from the oil-bearing formation containing an oil phase and an aqueous polymer-containing phase. Brine is mixed with the produced fluid to enhance separation of the oil phase from the aqueous polymer phase.

Owner:SHELL USA INC

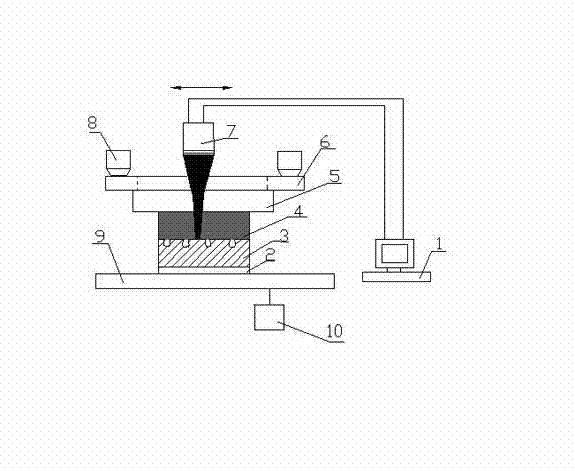

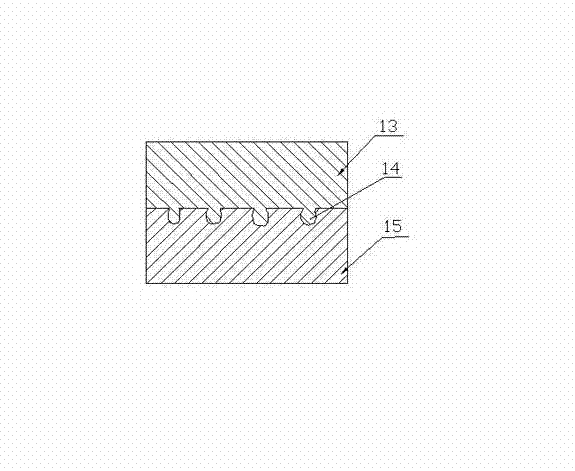

High-strength laser transmission connecting method

InactiveCN103071922AImprove connection strengthStrong local connectionLaser beam welding apparatusPolymeric surfaceMetallic materials

The invention discloses a high-strength laser transmission connecting method, belongs to the technical field of laser transmission welding, and especially relates to the laser transmission welding between polymers. The method comprises the following steps: treating a to-be-welded surface of a metal material by adopting a drilling machining method and forming pits on the surface; at a welding moment, taking the metal with the surface subjected to the drilling machining treatment as a lower-layer light-absorbing material and taking the polymer as an upper-layer light-transmitting material; adopting a lapped connecting mode and using a restraint layer for clamping and applying welding pressure; and using a semiconductor laser device for performing laser transmission welding, causing the surface temperature to quickly reach the melting point of the upper-layer polymer and melting the surface of the polymer. The pits are formed on the polymer surface through drilling mechanical treatment, so that under the action of a welding pressure, the melted polymer flows into the pits, an occlusion interface with a riveted structure is formed at a welding joint, and the high-strength laser transmission welding is realized. The high-strength laser transmission connecting method can be widely applied to the field of the laser transmission welding with higher demand on the connecting strength.

Owner:JIANGSU UNIV

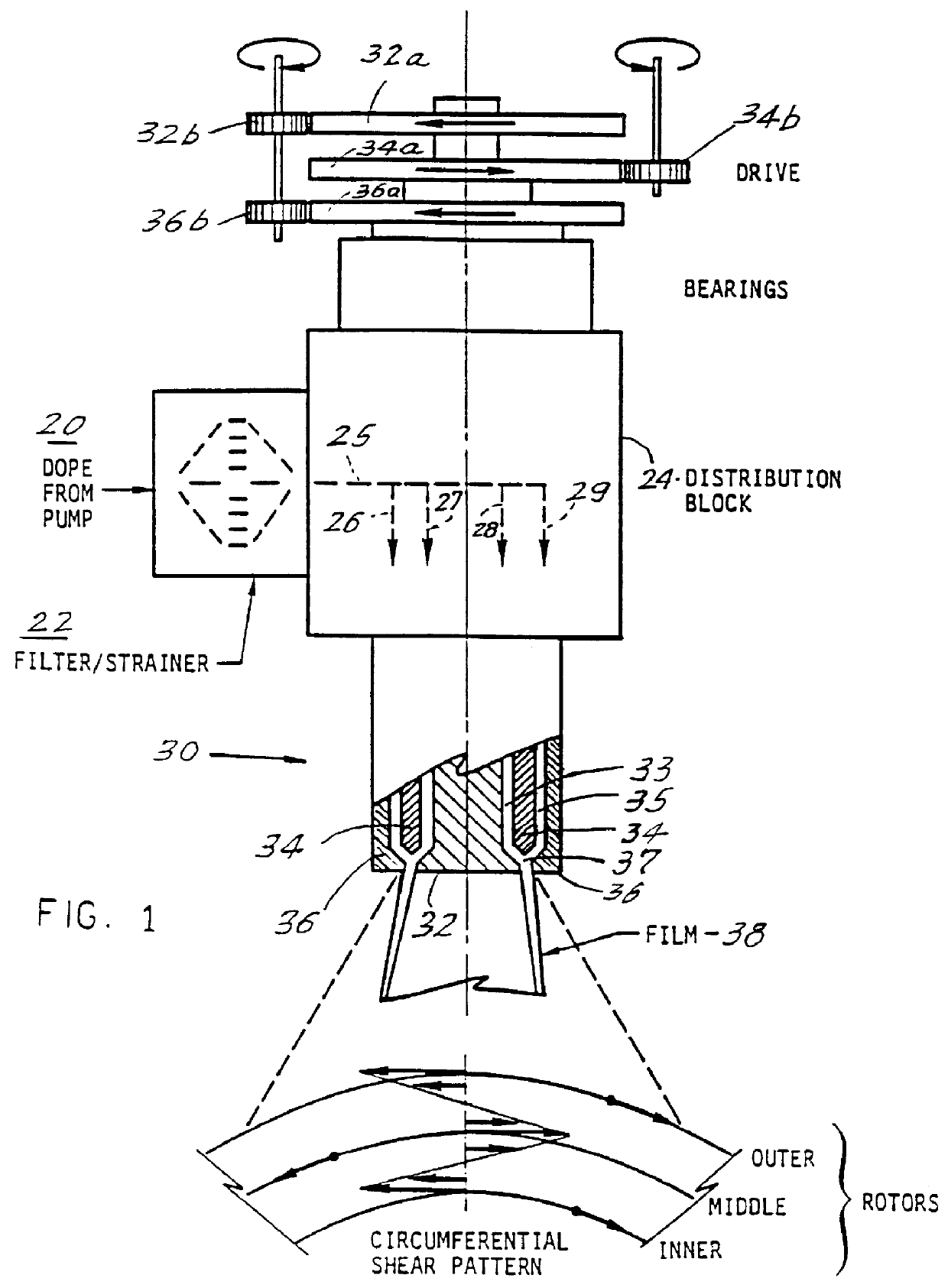

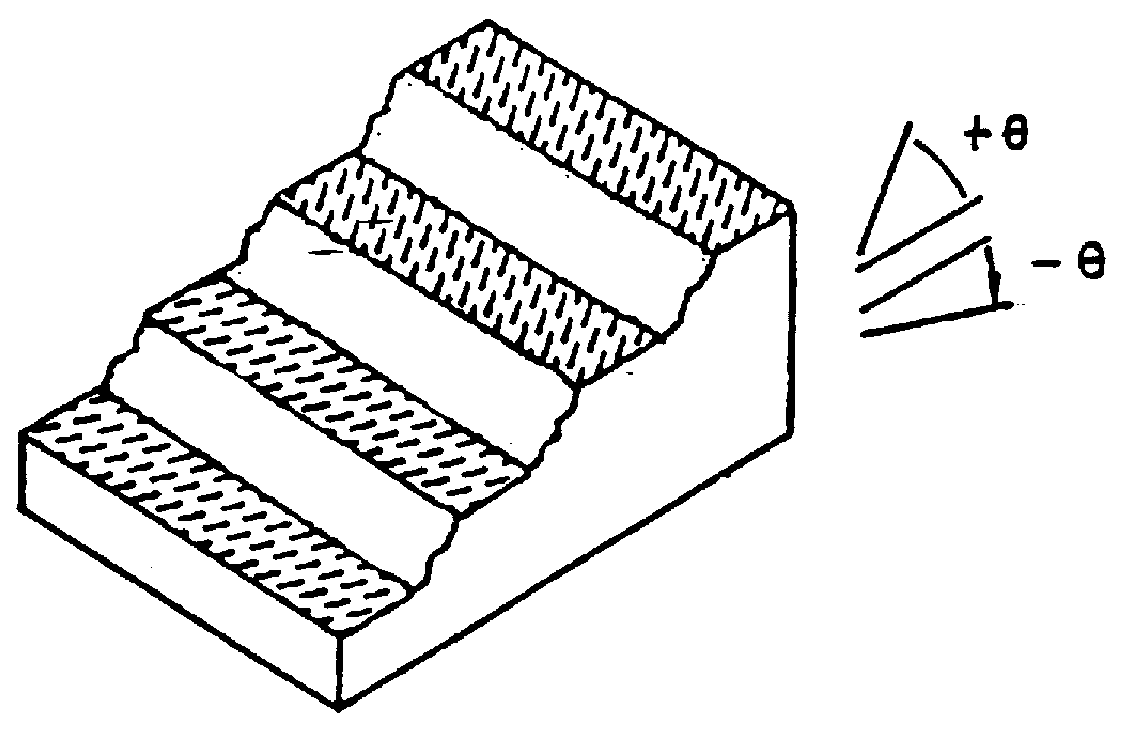

Coextrusion of liquid crystal polymers and thermoplastic polymers

InactiveUS6045737ALiquid crystal compositionsArtificial filament physical treatmentThermoplasticLiquid-crystal display

A flat and nearly mechanically isotropic polymer film or sheet, or a tube, can be formed by laminating two or more films, preferably by coextrusion of a liquid crystal polymer film and a thermoplastic polymer film. A liquid crystal polymer layer may be combined with one or more thermoplastic polymer layer in various arrangements. The liquid crystal, and possibly the thermoplastic as well, may have a controlled molecular orientation. The film may be formed by passing a polymer through a set of two or three tubular rotors which are concentric and have facing surfaces which define inner and outer annular polymer flow channels.

Owner:SUPEREX POLYMER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com