Gel reduction device and gel reduction method

a gel reduction device and gel reduction technology, applied in clay mixing equipment, rotary stirring mixers, transportation and packaging, etc., can solve the problems of high production rate and excessive pressure drop between upstream and downstream of the gel reduction device, and achieve the effect of reducing the gel in the compound and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0039]First, a mixing and extrusion equipment 2 in which a gel reduction device 1 is provided is briefly described prior to describing the gel reduction device 1 of the present invention.

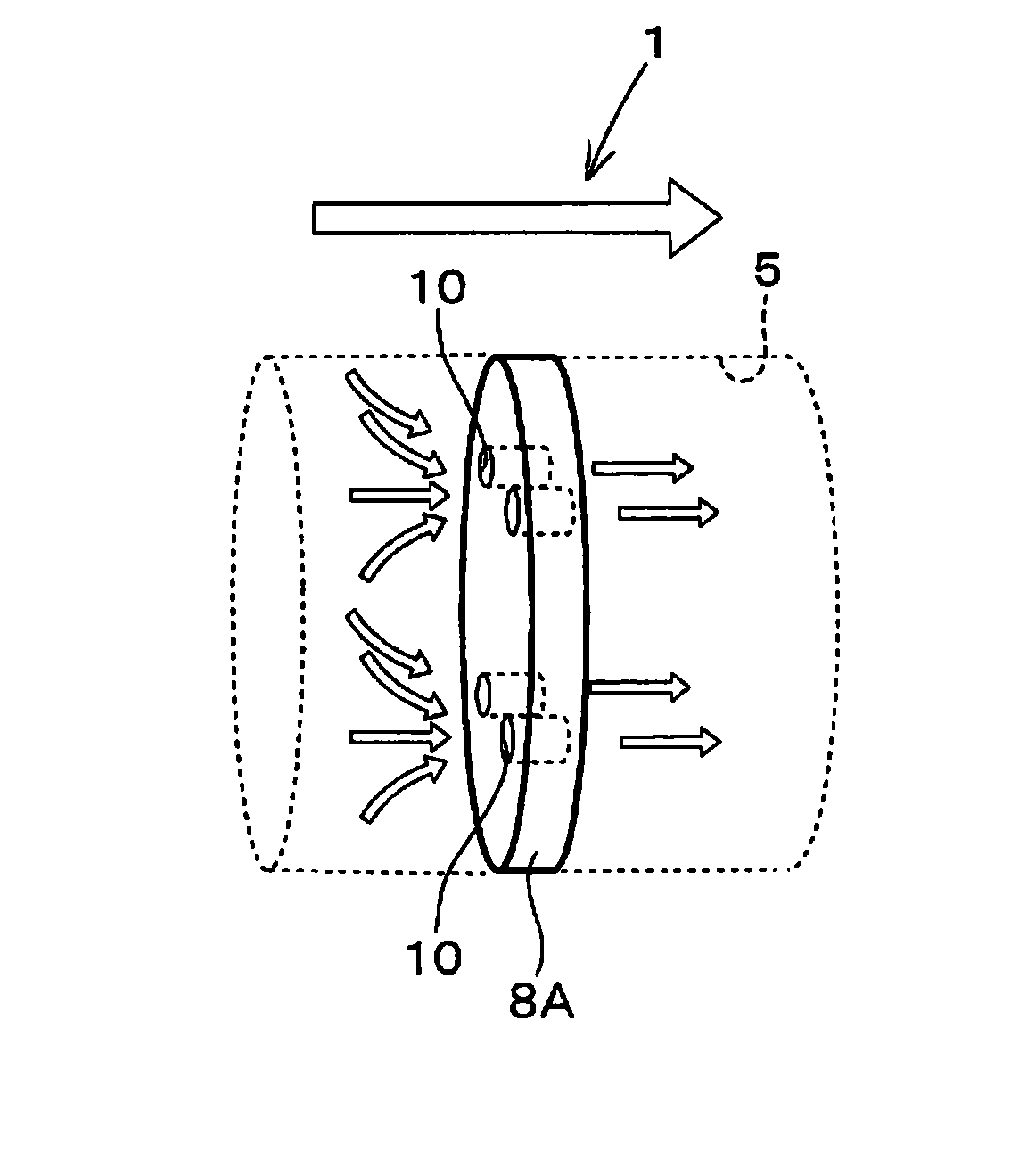

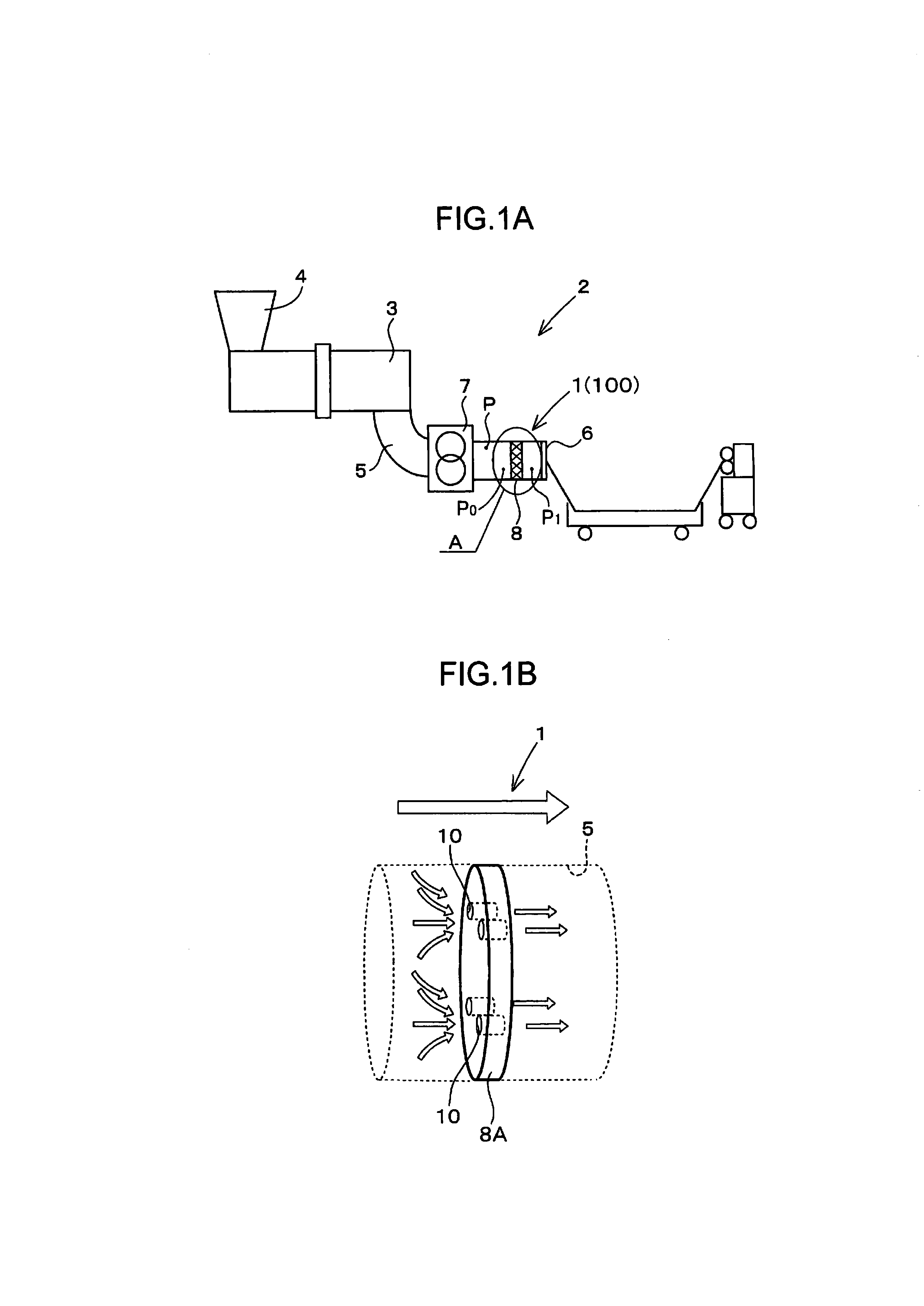

[0040]FIG. 1A shows an example of the mixing and extrusion equipment 2 (an example of a continuous mixer) in which the gel reduction device 1 of the present invention is provided.

[0041]The mixing and extrusion equipment 2 of the shown example is a kneader for kneading a resin material by twin mixing rotors (not shown) inserted through a barrel 3. A hopper 4 capable of feeding materials into the barrel 3 is provided at one end (left end in FIG. 1A) of this barrel 3, and a polymer flow duct 5 for discharging the kneaded resin material to the outside of the kneader is provided at the other end.

[0042]A strand die 6 for extruding the polymer kneaded compound is provided at the leading end of this polymer flow duct 5, and a gear pump 7 for pressurizing the polymer kneaded compound to the strand die 6 is a...

second embodiment

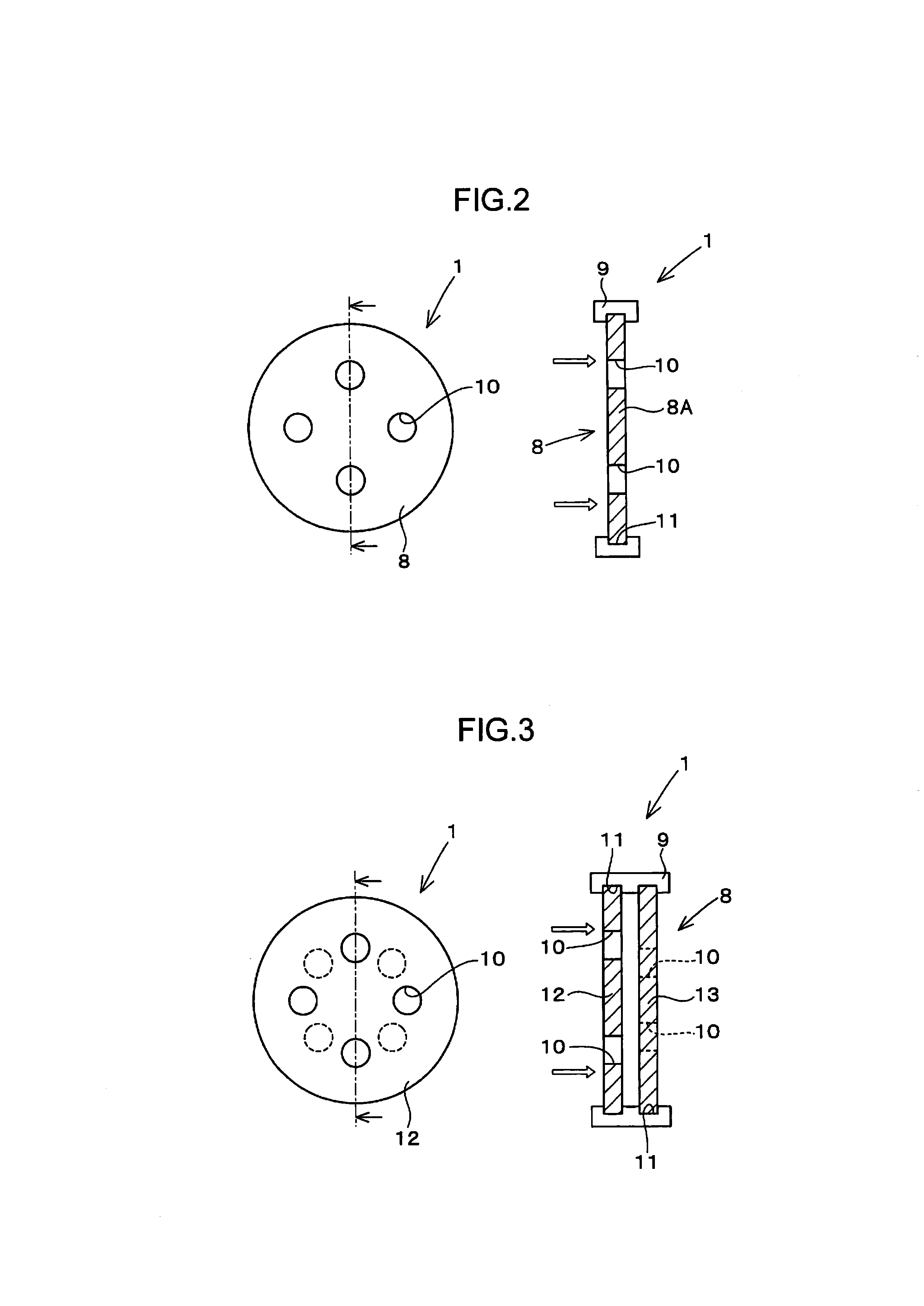

[0062]Next, a gel reduction device 1 of a second embodiment is described.

[0063]As shown in FIG. 3, a gel reduction mechanism 8 of the gel reduction device 1 of the second embodiment is so formed that a plurality of gel reduction members 8A of the first embodiment are arranged while being spaced apart in the laying direction of the polymer flow duct 5 (extending direction of the polymer flow duct 5 or axial center direction of the polymer flow duct 5). Specifically, this gel reduction device 1 includes a first gel reduction member 12 arranged at an upstream side and a second gel reduction member 13 arranged at a downstream side.

[0064]The first gel reduction member 12 is a disk-like member having the same thickness as the gel reduction member 8A of the first embodiment and includes four squeezing flow paths 10 penetrating from the upstream side toward the downstream side. The perforated positions and flow path cross-sectional areas of these squeezing flow paths 10 are also exactly the...

third embodiment

[0070]As shown in FIG. 4A, a gel reduction device 1 of a third embodiment includes a filter-like member 14, which is a circular metal plate formed with a multitude of passage pores, as a gel reduction mechanism 8.

[0071]This filter-like member 14 is a metal mesh formed by interweaving metal strands such that a mesh size of the passage pores is 180 μm or smaller and allows passage of foreign matters other than those having large sizes such as gel in a polymer kneaded compound. The thickness of this filter-like member 14 is very small as compared with the gel reduction mechanisms 8 of the first and second embodiments. Also in a shown example, the thickness of the gel reduction mechanism 8 of the third embodiment is about 1 / 10 of those of the gel reduction mechanisms 8 of the first and second embodiments.

[0072]The porous gel reduction mechanism 8 described above is formed with four squeezing flow paths 10 similar to the first and second embodiments. These squeezing flow paths 10 are for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| mesh size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com