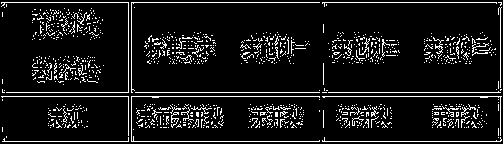

Patents

Literature

34results about How to "Reduce flow viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

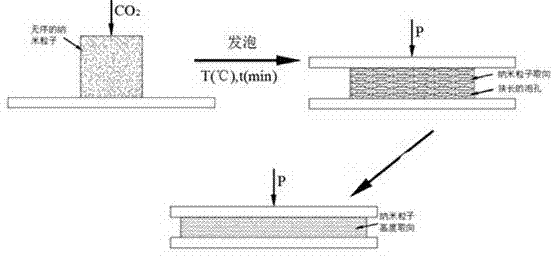

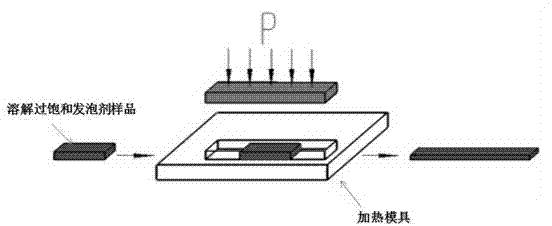

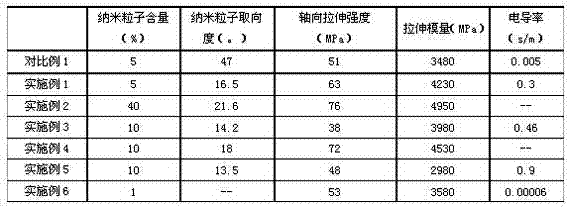

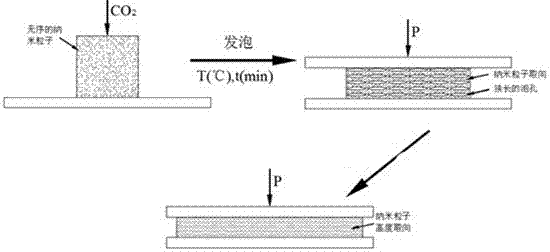

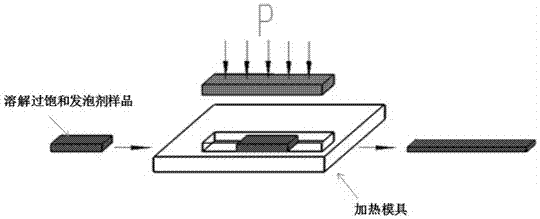

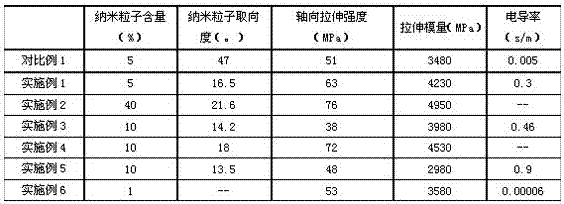

Preparation method for polymer base nanometer composite material with highly oriented nanoparticles in polymer matrix

The invention relates to a preparation method for a polymer base nanometer composite material with highly oriented nanoparticles in the polymer matrix, and belongs to the technical field of polymer materials. The preparation method comprises that during a foaming process of a polymer nanometer composite material formed by carrying out melt co-mixing on a polymer and nanoparticles, external force is applied to make the foam hole in the material grow along the uniaxial direction in an oriented growth manner, and the polymer flows under the double induction of the external force and the foam hole growth to achieve the high orientation of the nanoparticles so as to obtain the polymer base nanometer composite material with the highly oriented nanoparticles in the polymer matrix. The method has advantages of simple operation, mild condition, high orientation degree of the nanoparticles in the prepared polymer nanometer composite material, and the like.

Owner:ZHEJIANG UNIV OF TECH

Storage battery colloidal electrolyte and preparation method thereof

InactiveCN102044709AImprove electrochemical performanceSimple preparation processFinal product manufactureLead-acid accumulators constructionColloidViscosity

The invention relates to a storage battery colloidal electrolyte containing natural acicular nanocrystalline or microfiber, mainly comprising the following components in weight ratio: 3.0-12 percent of gelatinizing agent (silicon-contained gel), 0.01-0.1 percent of flow improver, 5.0-13.8 percent of complex additive and the balance of electrolyte (a sulfuric acid dilute solution), wherein the flow improver is the natural acicular nanocrystalline or microfiber. The colloidal electrolyte has good thixotropic flowability and gel stability and low colloidal kinetic viscosity; the glue pouring efficiency of the colloidal electrolyte and the immersional wetting effect of the colloidal electrolyte on a partition board and a polar plate are improved, and the resistance of the colloidal electrolyte is reduced; and therefore, the colloidal electrolyte can be used for assembling storage batteries with different applications and different modes.

Owner:SOUTH CHINA NORMAL UNIVERSITY

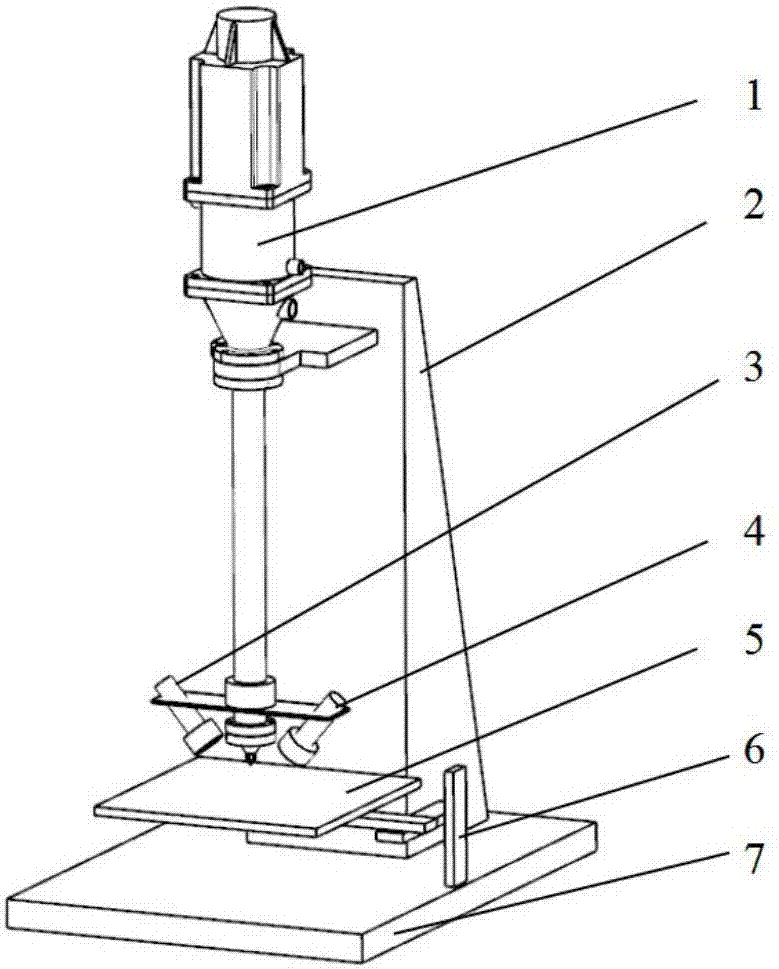

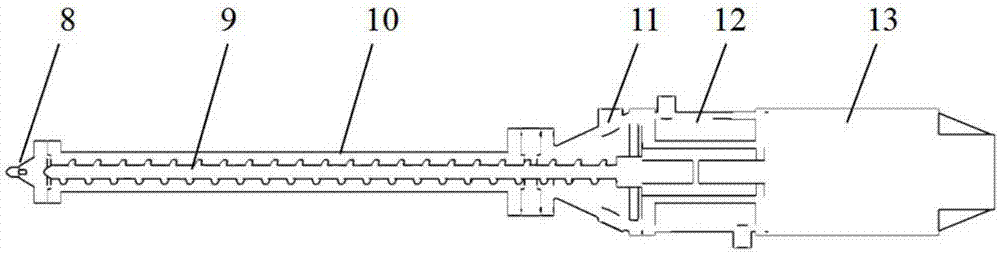

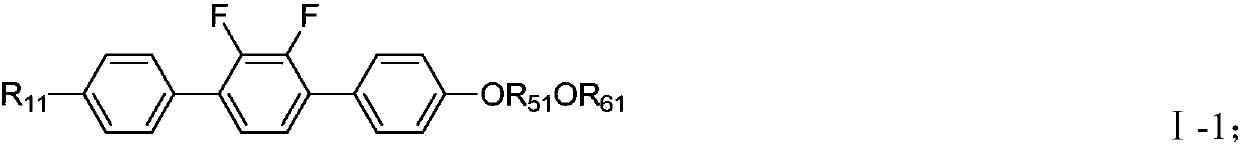

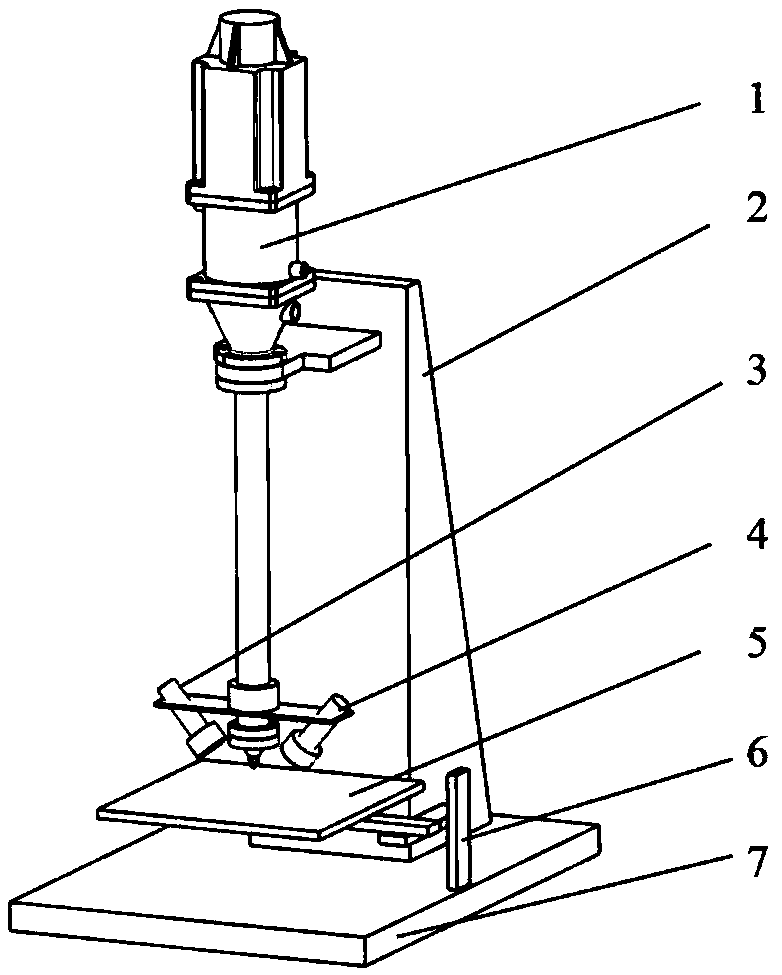

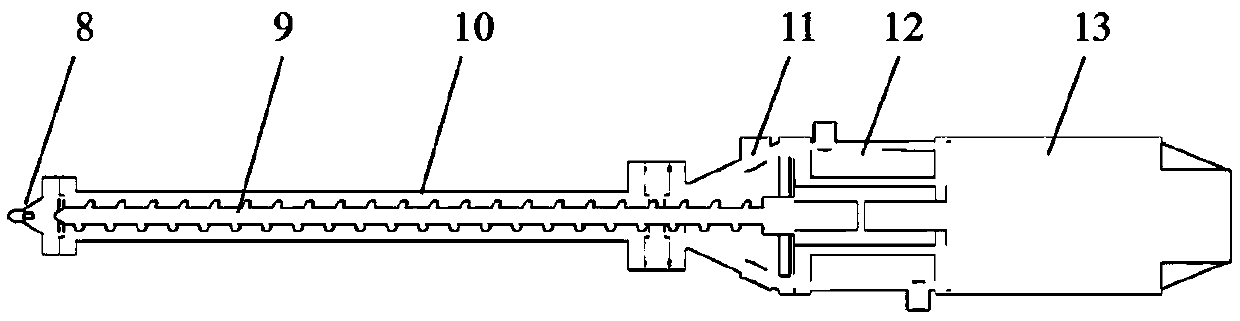

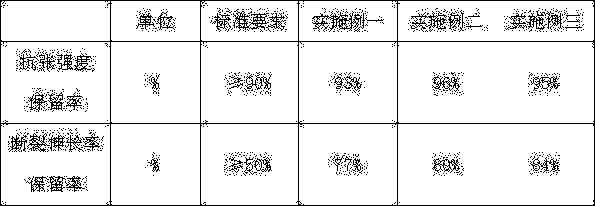

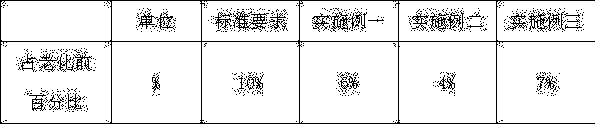

3D printing device and method for high-molecular-weight silicone rubber

ActiveCN107283819AExtended service lifeQuality improvementAdditive manufacturing with liquidsApplying layer meansEngineeringUltimate tensile strength

The invention discloses a 3D printing device and method for high-molecular-weight silicone rubber. A hundred-micron-level micropore nozzle with the high shearing rate and high extruding strength and for screw extruding force is adopted in a 3D printing head system, the flowing viscosity of the high-molecular-weight silicone rubber is greatly reduced, and 3D printing forming of a high-molecular-weight, high-compression-modulus and long-service life silicone rubber material is achieved. The extrusion and expansion stability of the material on the hundred-micron-level micropore nozzle is improved, the dimensional precision of a 3D printing fluid line is accurately controlled, and high quality, high precision and high efficiency in the 3D printing process are achieved. A photo-thermal two-order curing material 3D printing manner is adopted, the curing rate and dimensional precision of the 3D printing material are greatly increased, the high quality and stability of the 3D printing high-molecular-weight silicone rubber material are improved, and the macro-performance and structure adjustability of the 3D printing material are achieved.

Owner:XIAN LIANCHUANG ADVANCED MFG A SPECIALIZED INCUBATOR CO LTD

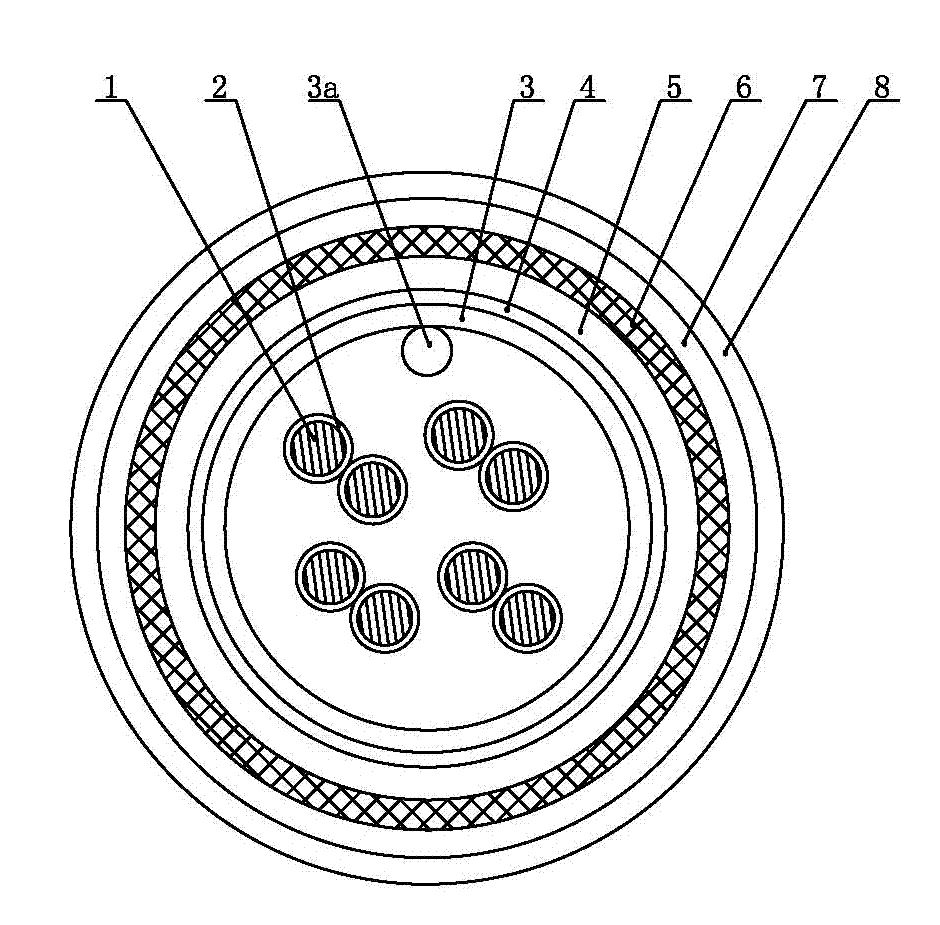

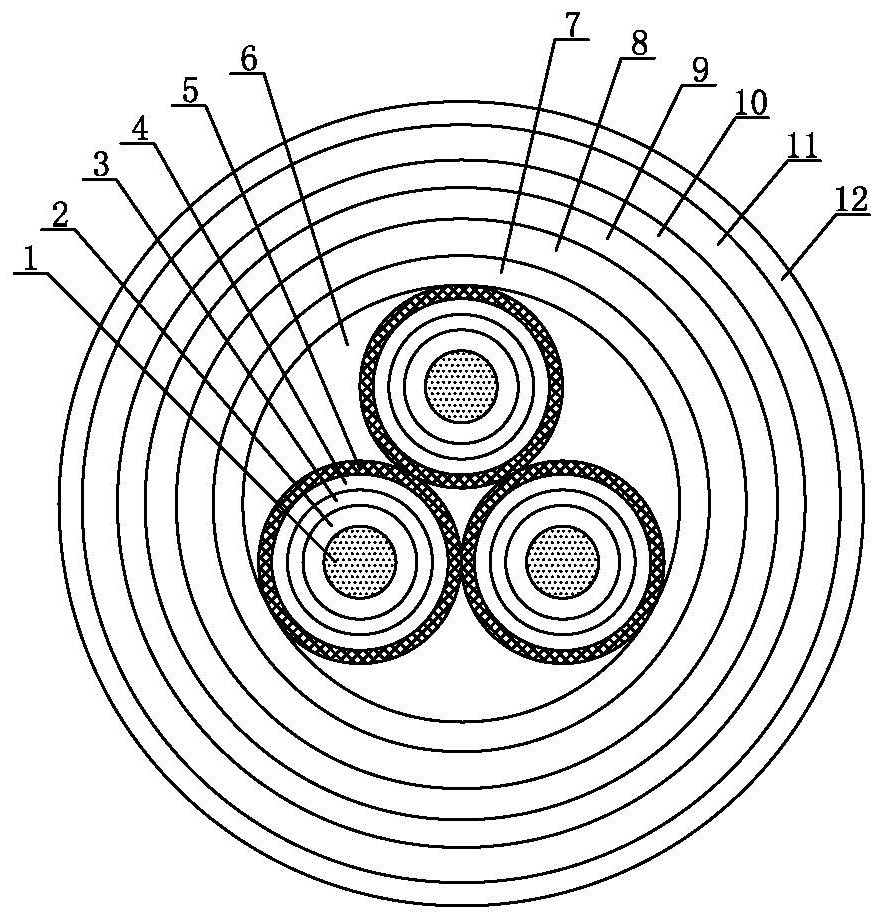

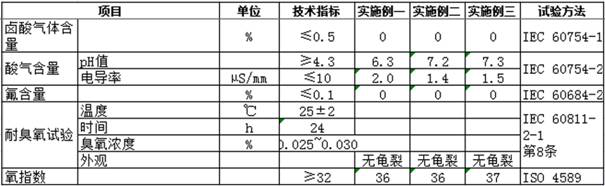

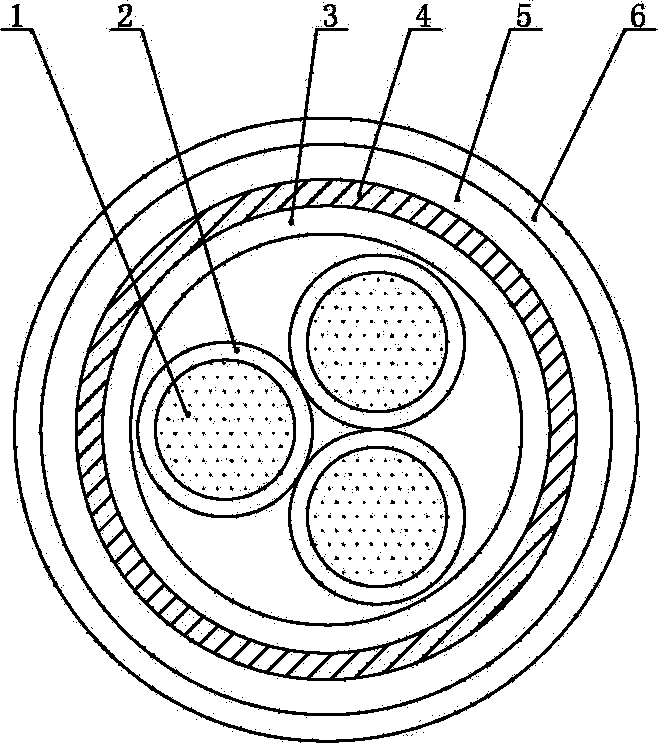

High-temperature-resistant soft bulk-shielding instrument cable for maritime oil and gas engineering and manufacturing method thereof

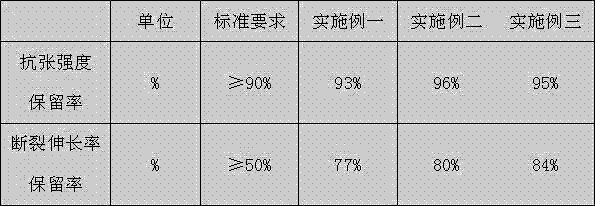

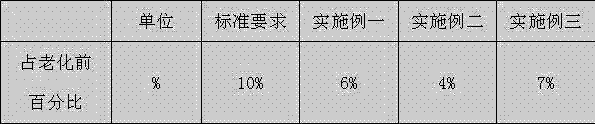

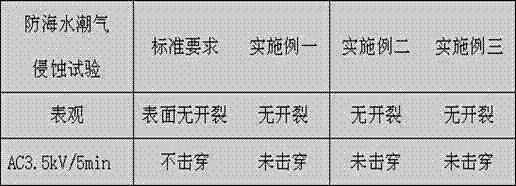

InactiveCN102969058AImprove high temperature resistanceImprove aging resistanceFlexible cablesFlexible conductorsCopper conductorCross-link

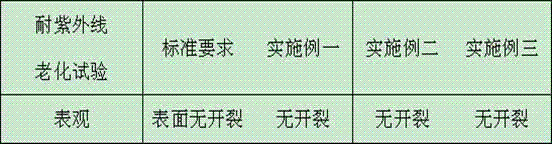

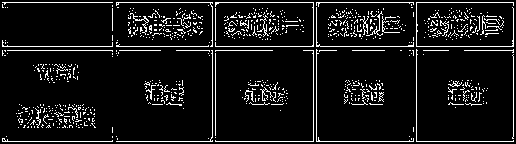

The invention relates to a high-temperature-resistant soft bulk-shielding instrument cable for maritime oil and gas engineering and a manufacturing method thereof. The cable is characterized in that a chemical cross-linked polyolefin insulation layer is extruded at the periphery of a tin-plated annealed stranded copper conductor to form a power cable insulation wire core; every two insulation wire cores are twisted to form twisted wire pairs, and the twisted wire pairs are stranded to form a cable core; the periphery of the cable core is successively wrapped with a copper foil polyester composite tape shielding layer and a polyester tape; and the periphery of the polyester tape is successively provided with an extruded inner sheath, a clad copper alloy wire weaving armor layer, a wrapped water-proof wrapping tape, and an extruded outer sheath. The insulation layer is prepared from the following raw material components: 12 parts of ethylene / vinyl acetate copolymer, 6 parts of high density polyethylene, 2 parts of ethylene-methacrylic acid copolymer, 0.5-1 part of cross-linking agent DCP (Dicumyl Peroxide), 0.4-0.9 part of antioxidant 1076, 0.2-0.4 parts of antioxidant DNP, 0.2-1 part of lubricant stearic acid, 25-30 parts of aluminum hydroxide, 0.6-1 part of red phosphorus, and 0.05-0.1 parts of ultraviolet ray absorber UV-326. The insulation layer of the cable is excellent in high-temperature resistance and ageing resistance, and long in service life.

Owner:JIANGSU YUANYANG DONGZE CABLE

Pressure-resistant impact-resistant PE pipe material and preparation method thereof

The invention provides a pressure-resistant impact-resistant PE pipe material and a preparation method thereof, and belongs to the technical field of PE pipe materials. The pressure-resistant impact-resistant PE pipe is composed of the following components in parts by weight: 60-80 parts of polyethylene, 5-30 parts of coupled inorganic silica, 2-10 parts of heat stabilizer, 0.5-2 parts of dispersing agent, 0.5-3 parts of toughening agent, and 0.5-5 parts of paraffin. The invention also provides a preparation method of the pressure-resistant impact-resistant PE pipe material. The PE pipe material of the invention has good pressure and impact resistance.

Owner:芜湖万隆新材料有限公司

Layered silicate-containing colloidal electrolyte for storage batteries and preparation method thereof

InactiveCN102044710AImprove electrochemical performanceSimple preparation processLead-acid accumulatorsColloidViscosity

The invention relates to a layered silicate-containing colloidal electrolyte for storage batteries, which mainly comprises a silicon-containing gel, a thixotropic agent, a complex additive and electrolyte, wherein the thixotropic agent is layered silicate with the width / thickness ratio of 100-2,000. The colloidal electrolyte comprises the following components in percentage by weight: 2.0 to 10.0 percent of gelatinizing agent, 0.05 to 0.5 percent of thixotropic agent, 5.0 to 13.0 percent of complex additive and the balance of dilute solution of sulfuric acid. The colloidal electrolyte has goodthixotropic liquidity and gel stability and low colloid kinetic viscosity; and the filling efficiency of the colloidal electrolyte and the infiltration of the colloidal electrolyte on the baffle plate and polar plates are greatly improved. The electrolyte can be used for assembling storage batteries with different purposes, such as starting batteries, stationary batteries, traction batteries and the like.

Owner:SOUTH CHINA NORMAL UNIVERSITY

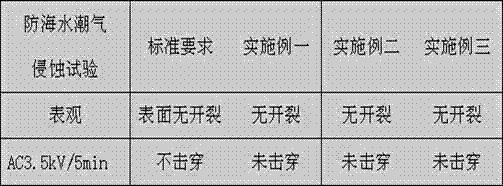

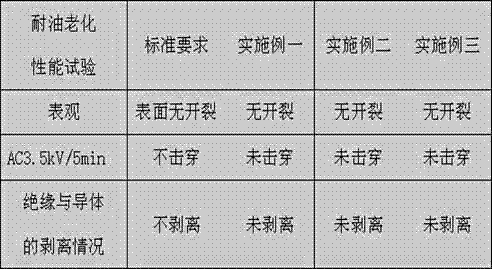

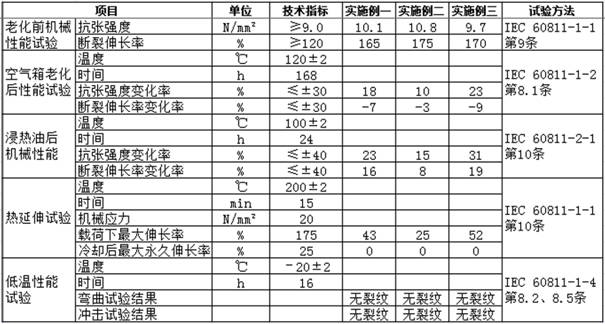

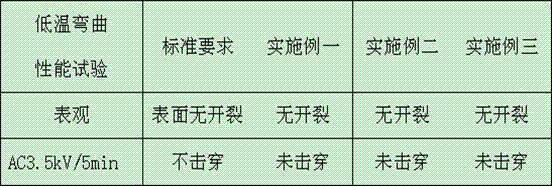

Chemical crosslinking polyolefin insulating rubber for offshore oil gas engineering cable and manufacturing method

InactiveCN102964668AReduce drippingAvoid drippingPlastic/resin/waxes insulatorsAntioxidantCarvacryl acetate

The invention discloses chemical crosslinking polyolefin insulating rubber for an offshore oil gas engineering cable in the field of cables and a manufacturing method. The raw materials include 12 parts of ethylene / vinyl acetate copolymer, 6 parts of HDPE (high-density polyethylene), 2 parts of ethylene / methacrylic acid copolymer, 0.5-1 part of crosslinking agent DCP (dicumyl peroxide), 0.4-0.9 part of antioxidant 1076, 0.2-0.4 part of antioxidant DNP (N,N'-di-2-naphthyl-p-phenylenediamine), 0.2-1 part of stearic acid, 25-30 parts of aluminum hydroxide, 0.6-1 part of red phosphorus and 0.05-0.1 part of ultraviolet absorbent UV-326. The method comprises the following steps of: firstly adding the ethylene / vinyl acetate copolymer, the HDPE and the ethylene / methacrylic acid copolymer, and uniformly plastifying and mixing; adding the antioxidant, the ultraviolet adsorbent and flame retardant, and mixing uniformly before blanking; adding a lubricant and the crosslinking agent and mixing uniformly; and performing triangle packaging on the mixed glue, thinning for 4-6 times, and cutting and cooling for use. The insulating rubber has high heat resistance level and excellent ultraviolet resistance, seawater moisture erosion resistance and oil aging resistance.

Owner:JIANGSU YUANYANG DONGZE CABLE

High-temperature-resistant soft power cable for maritime oil and gas engineering and manufacturing method thereof

InactiveCN102969063AGood aging resistanceExtended service lifePower cables with screens/conductive layersCable/conductor manufactureDicumyl peroxideStearic acid

The invention relates to a high-temperature-resistant soft power cable for maritime oil and gas engineering and a manufacturing method thereof. The power cable is characterized in that a chemical cross-linked polyolefin insulation layer is extruded at the periphery of a tin-plated annealed stranded copper conductor to form a power cable insulation wire core; a plurality of insulation wire cores are stranded to form a cable core; an inner sheath is extruded at the periphery of the cable core; the periphery of the inner sheath inner sheath inner sheath is coated with a copper alloy wire weaving armor layer; the periphery of the copper alloy wire weaving armor layer is wrapped with a water-proof wrapping tape; and an outer sheath is extruded at the periphery of the water-proof wrapping tape. The insulation layer is prepared from the following raw material components: 12 parts of ethylene / vinyl acetate copolymer, 6 parts of high density polyethylene, 2 parts of ethylene-methacrylic acid copolymer, 0.5-1 part of cross-linking agent DCP (Dicumyl Peroxide), 0.4-0.9 part of antioxidant 1076, 0.2-0.4 part of antioxidant DNP, 0.2-1 part of lubricant stearic acid, 25-30 parts of flame retardant aluminum hydroxide, 0.6-1 part of flame retardant red phosphorus, and 0.05-0.1 parts of ultraviolet ray absorber UV-326. The insulation layer of the cable is excellent in high-temperature resistance and ageing resistance, and long in service life.

Owner:JIANGSU YUANYANG DONGZE CABLE

High-temperature-resistant soft non-shield instrument cable for maritime oil and gas engineering and manufacturing method thereof

InactiveCN102969049AImprove high temperature resistanceImprove aging resistanceFlexible cablesCable/conductor manufactureCopper conductorCross-link

The invention relates to a high-temperature-resistant soft non-shield instrument cable for maritime oil and gas engineering and a manufacturing method thereof. The cable is characterized in that a chemical cross-linked polyolefin insulation layer is extruded at the periphery of a 0.35-2.5mm2 tin-plated annealed stranded copper conductor to form an insulation wire core; every two insulation wire cores are twisted to form twisted wire groups, and all the twisted wire groups are stranded to form a cable core; an inner sheath is extruded at the periphery of the cable core; the periphery of the inner sheath is coated with a copper alloy wire weaving armor layer; the periphery of the copper alloy wire weaving armor layer is wrapped with a water-proof wrapping tape; and an outer sheath is extruded at the periphery of the water-proof wrapping tape. The insulation layer is prepared from the following raw material components: 12 parts of ethylene / vinyl acetate copolymer, 6 parts of high density polyethylene, 2 parts of ethylene-methacrylic acid copolymer, 0.5-1 part of cross-linking agent DCP (Dicumyl Peroxide), 0.4-0.9 part of antioxidant 1076, 0.2-0.4 part of antioxidant DNP, 0.2-1 part of lubricant stearic acid, 25-30 parts of aluminum hydroxide, 0.6-1 part of red phosphorus, and 0.05-0.1 part of ultraviolet ray absorber UV-326. The insulation layer of the cable is excellent in high-temperature resistance and ageing resistance, and long in service life.

Owner:JIANGSU YUANYANG DONGZE CABLE

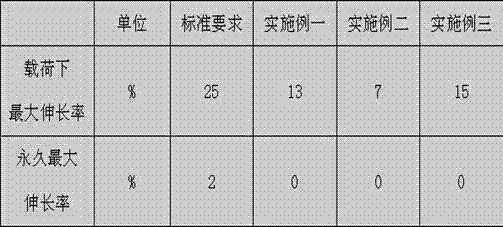

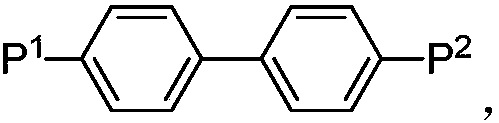

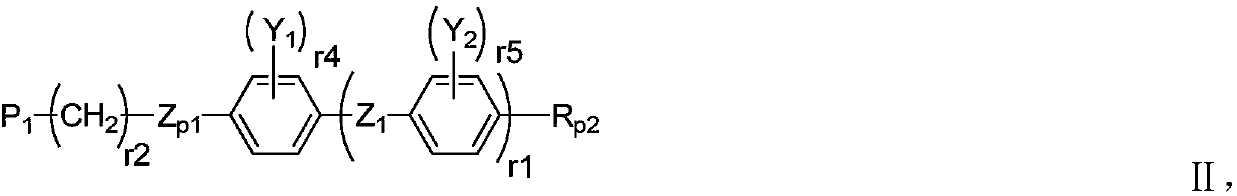

Liquid crystal composition and liquid crystal display device

ActiveCN109575954AAppropriate optical anisotropySuitable for dielectric anisotropyLiquid crystal compositionsDielectric anisotropyDisplay device

The invention discloses a liquid crystal composition. The liquid crystal composition contains at least one compound of a formula I, and at least one polymerizable compound of a formula II. The liquidcrystal composition provided by the invention has suitable optical anisotropy, suitable dielectric anisotropy, low flow viscosity, appropriate rotary viscosity, and also has good pretilt angle stability while maintaining a relatively high clearing point, wherein the pretilt angle does not basically shift under long-time voltage driving. The invention also discloses a liquid crystal display devicecontaining the liquid crystal composition. When the liquid crystal composition is applied to a PSA type liquid crystal display, the display effect is excellent. The invention also provides the liquidcrystal display device containing the liquid crystal composition.

Owner:JIANGSU HECHENG DISPLAY TECHCO

Water-based copper wire drawing liquid with excellent lubricity and preparation method of water-based copper wire drawing liquid

InactiveCN104611106AReasonable formulaReduce flow viscosityAdditivesTritolyl PhosphatesBenzotriazole

The invention discloses a water-based copper wire drawing liquid with excellent lubricity. The water-based copper wire drawing liquid is characterized by comprising raw materials by weight: 1 to 2 parts of dichloro-tetrafluoromethane, 3 to 4 parts of propylene glycol, 0.8 to 1.5 parts of hydrofluoric acid, 1 to 2 parts of tea saponin, 2 to 3 parts of tritolyl phosphate, 2.5 to 4 parts of ricinolic acid polyester, 7 to 9 parts of SN 150 base oil, 3 to 4 parts of peregal O, 1 to 2 parts of methyl benzotriazole, 5 to 7 parts of nano aluminum oxide, 1 to 2 parts of melamine cyanurate, 5 to 7 parts of additives, and 900 to 950 parts of deionized water. The water-based copper wire drawing liquid is reasonable in formula, is low in flow viscosity and high in flowability and cooling performance by adopting a water-based formula, is favorable in lubricity by additionally adopting melamine cyanurate, is favorable in wear resistance, dispersity, lubricity and film-forming property by adopting the additives, and can form a protecting film on the surface of metal when being used with a surfactant. A copper wire drawn with the water-based copper wire drawing liquid is uniform in line font, bright in surface, and low in rust possibility.

Owner:ANHUI WANGDA COPPER DEV

Calixarene solution for printed circuit board and preparation method thereof

The invention discloses a calixarene solution for a printed circuit board. The calixarene solution for the printed circuit board is characterized by comprising calixarene, terephthalaldehyde, plasticizer, coupling reagent and aromatic solvent. The components in parts by weight are as follows: 100 parts of calixarene, 50-70 parts of terephthalaldehyde, 10-20 parts of plasticizer, 5-10 parts of coupling reagent and 200-400 parts of aromatic solvent. The calixarene solution for the printed circuit board disclosed by the invention has high liquidity and is practically suitable for printing production of circuit board.

Owner:GUANGDONG CHENGDE ELECTRONICS TECH CO LTD +1

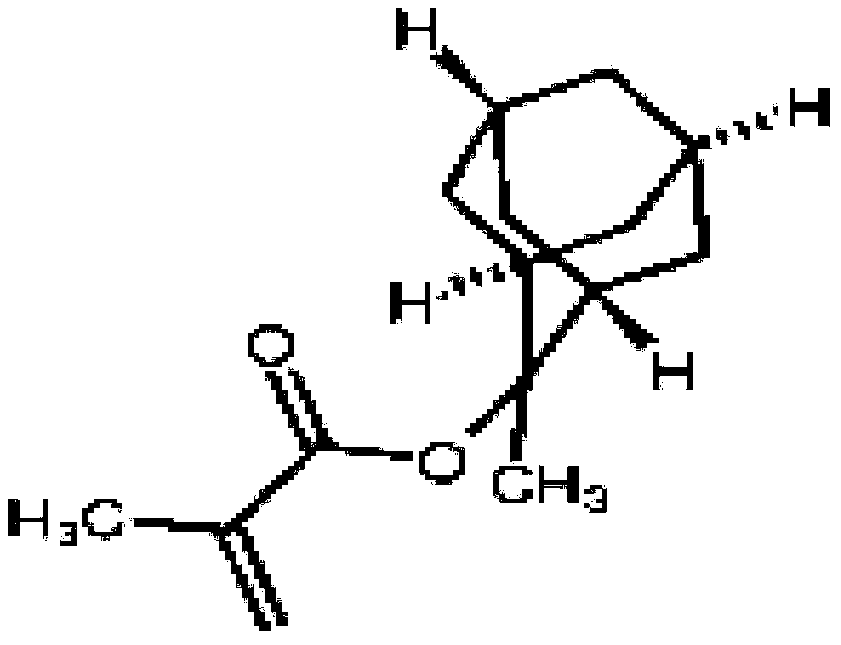

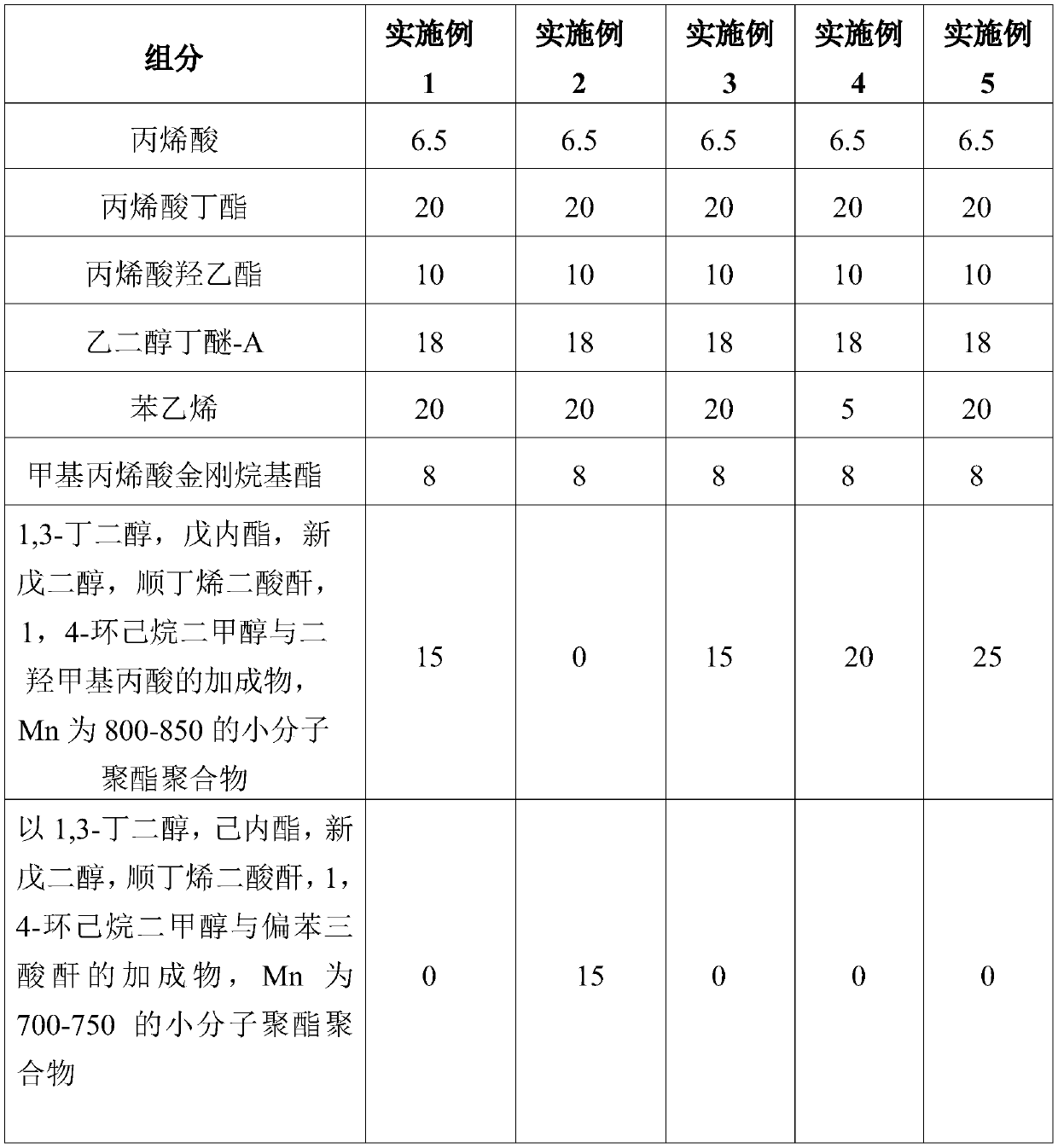

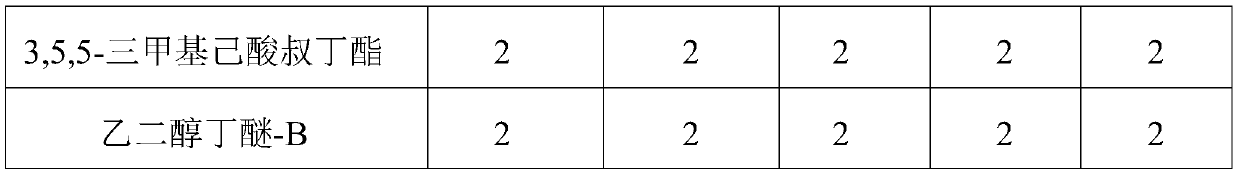

Preparation method of high-solid low-viscosity polyester modified water-soluble acrylic resin

The invention discloses a preparation method of high-solid low-viscosity polyester modified water-soluble acrylic resin. The preparation method comprises the following steps of: adding a cosolvent ethylene glycol butyl ether and a micromolecular polyester intermediate into a reactor; introducing nitrogen, and keeping the final pressure in the reactor at 2-4 Kg; raising the temperature; uniformly mixing acrylic acid, hydroxyethyl acrylate, adamantyl methacrylate, styrene and butyl acrylate, and recording a mixture as a material A; uniformly mixing the ethylene glycol butyl ether with tert-butylperoxy-3, 5, 5-trimethylhexanoate, and recording a mixture as a material B; dropwise adding the material A and the material B into the reactor; and after the dropwise adding, keeping the temperatureuntil an acid value is qualified, performing cooling and discharging. The micromolecular polyester is adopted to improve the solid content of the system and reduce the viscosity, and meanwhile, the adamantyl methacrylate is adopted to improve the hardness of the material, so that the obtained water-soluble acrylic acid has the characteristics of high solid content and low viscosity, and also has relatively high hardness and flexibility.

Owner:YICHENG BARRIER ZHANGJIAGANG TECH CO LTD

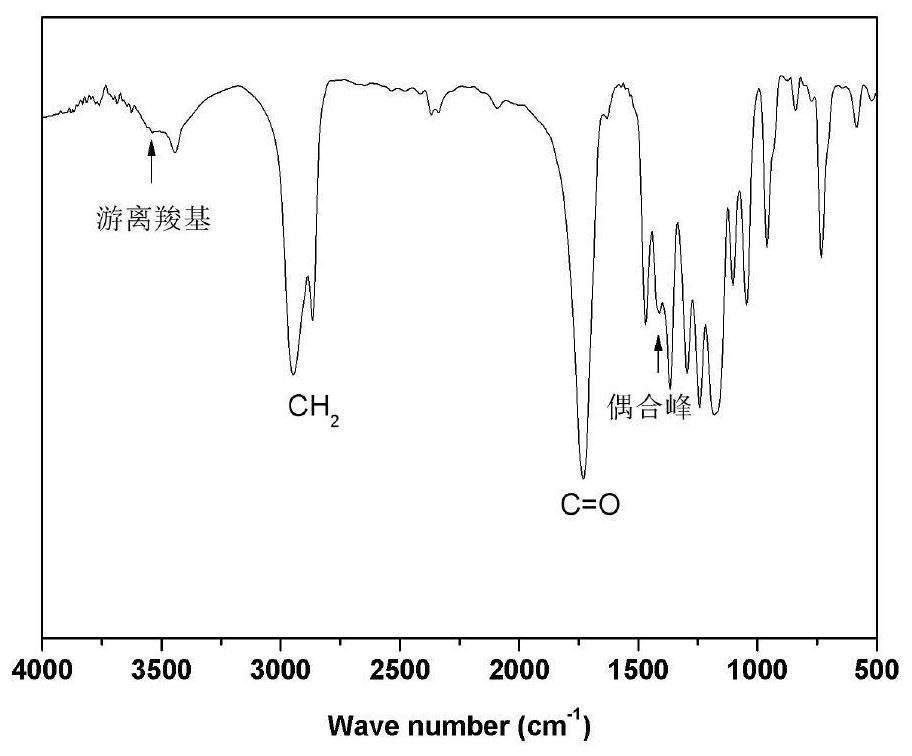

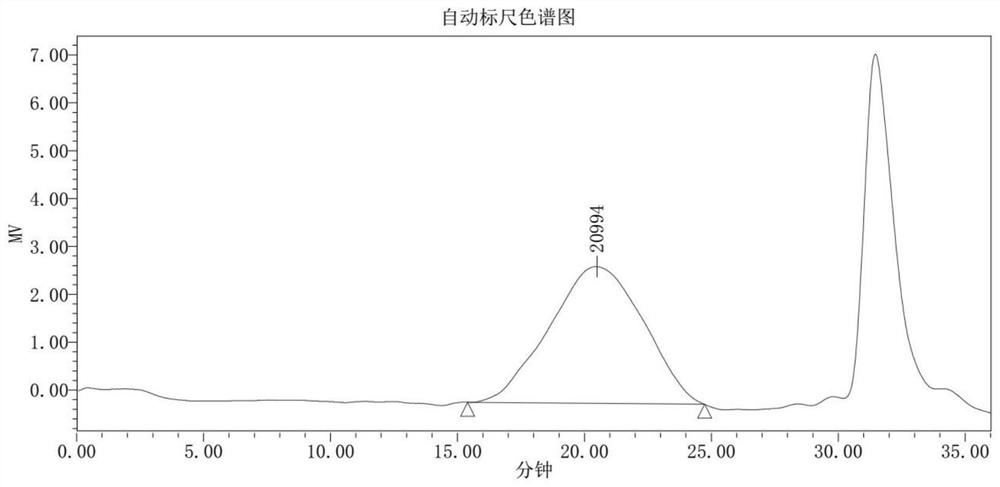

Biscarboxy polycaprolactone compound and preparation method and application as inorganic filler dispersant thereof

ActiveCN110643028ARelaxed water content requirementsFast wetting and dispersing speedPolymer sciencePropanoic acid

The invention discloses a biscarboxy polycaprolactone compound and a preparation method and application as an inorganic filler dispersant thereof. In the method, high-purity nitrogen or high-purity argon-protected epsilon-caprolactone and a monohydric alcohol are placed in a reactor, a catalyst stannous octoate is added, and a reaction is carried out at 100-130 DEG C for 4-48 h to obtain a monohydroxy-terminated polycaprolactone; at 4-dimethylaminopyridine and 10-40 DEG C, the hydroxyl-containing polycaprolactone and maleic anhydride are subjected to an esterification reaction in a solution; and under the action of an initiator, the obtained product of the esterification reaction is then reacted with 3-mercaptopropionic acid to obtain the polycaprolactone containing biscarboxyl groups at the terminal end of the molecular chain. The biscarboxy polycaprolactone compound prepared by the method as the dispersant can be quickly and firmly adsorbed on the surface of an inorganic filler, dispersion needs of different inorganic filler particles are met, the kinematic viscosity of an inorganic particle filling system is significantly reduced, and the processing or construction performance of the system is significantly improved.

Owner:YANTAI UNIV

Storage battery colloidal electrolyte and preparation method thereof

InactiveCN102044709BReduce internal frictional resistanceReduce flow viscosityFinal product manufactureLead-acid accumulators constructionColloidViscosity

The invention relates to a storage battery colloidal electrolyte containing natural acicular nanocrystalline or microfiber, mainly comprising the following components in weight ratio: 3.0-12 percent of gelatinizing agent (silicon-contained gel), 0.01-0.1 percent of flow improver, 5.0-13.8 percent of complex additive and the balance of electrolyte (a sulfuric acid dilute solution), wherein the flow improver is the natural acicular nanocrystalline or microfiber. The colloidal electrolyte has good thixotropic flowability and gel stability and low colloidal kinetic viscosity; the glue pouring efficiency of the colloidal electrolyte and the immersional wetting effect of the colloidal electrolyte on a partition board and a polar plate are improved, and the resistance of the colloidal electrolyte is reduced; and therefore, the colloidal electrolyte can be used for assembling storage batteries with different applications and different modes.

Owner:SOUTH CHINA NORMAL UNIVERSITY

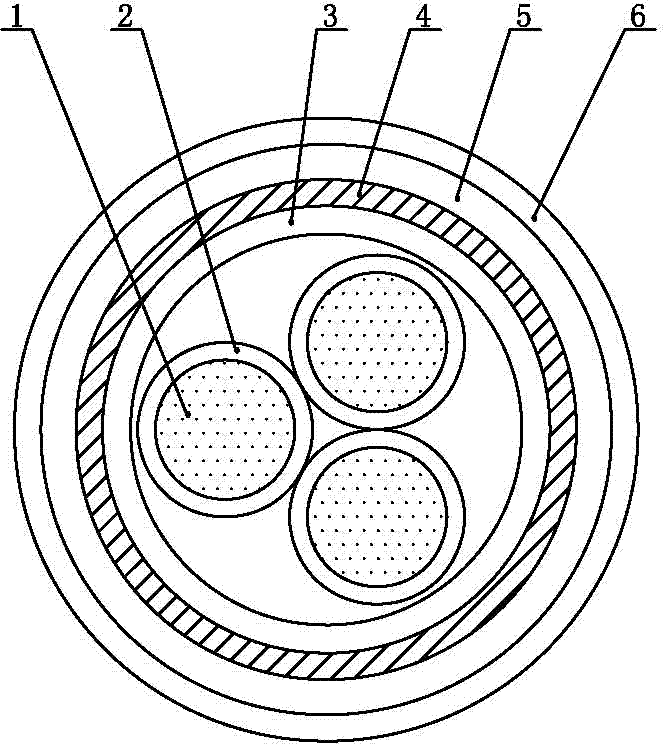

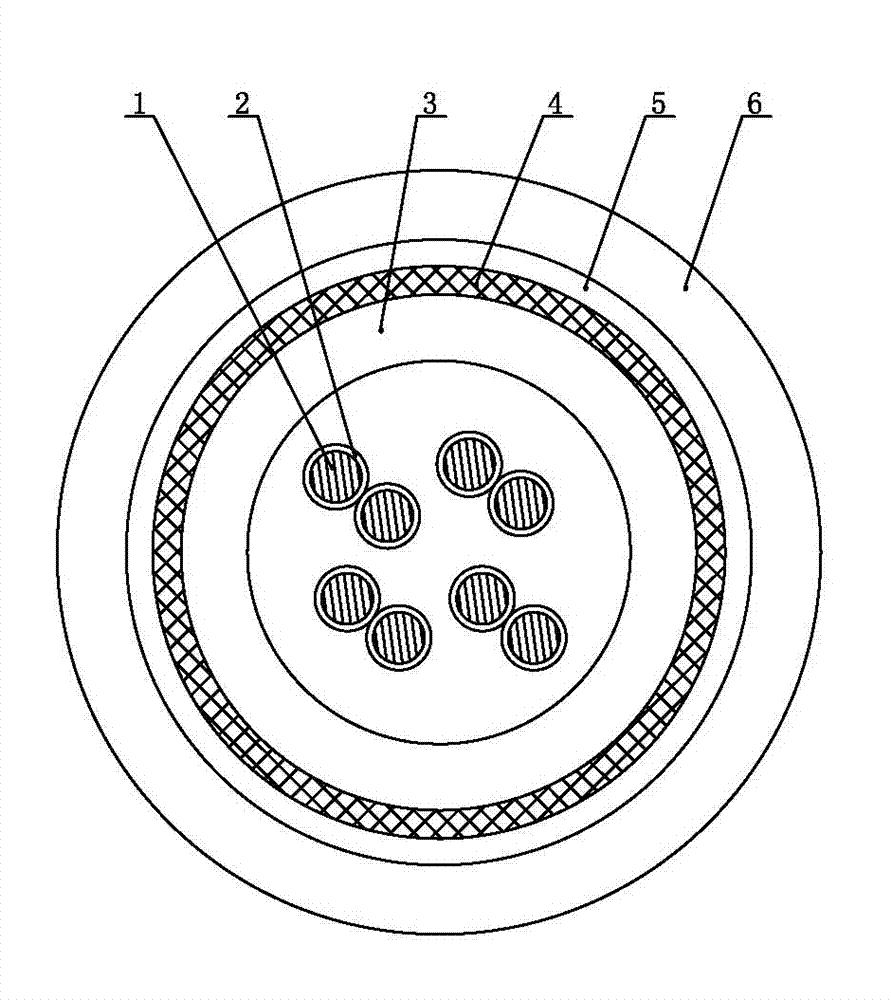

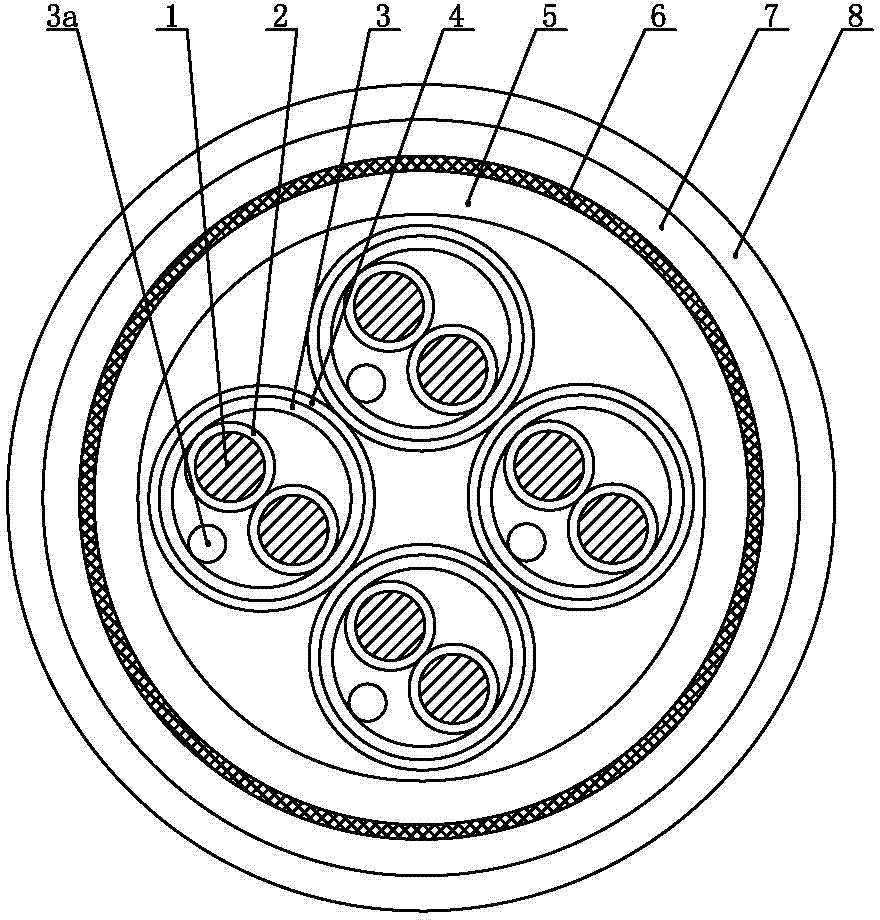

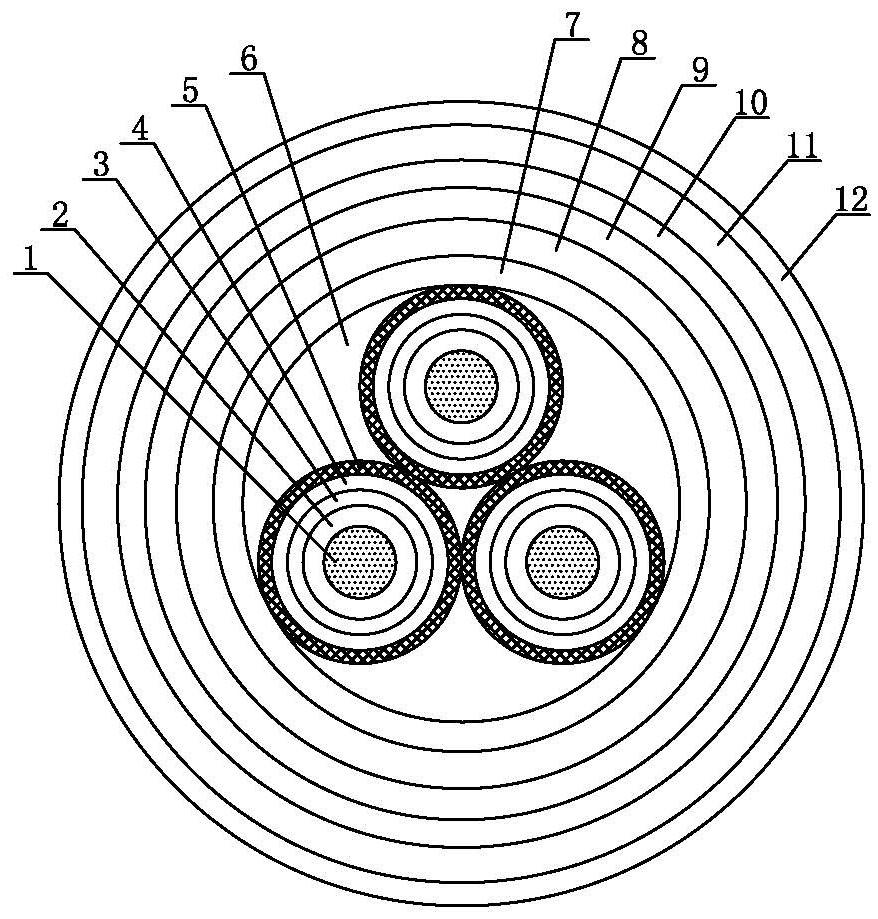

Jet flame and hydrocarbon flame resistant medium-voltage cable for offshore oil platform and manufacturing method thereof

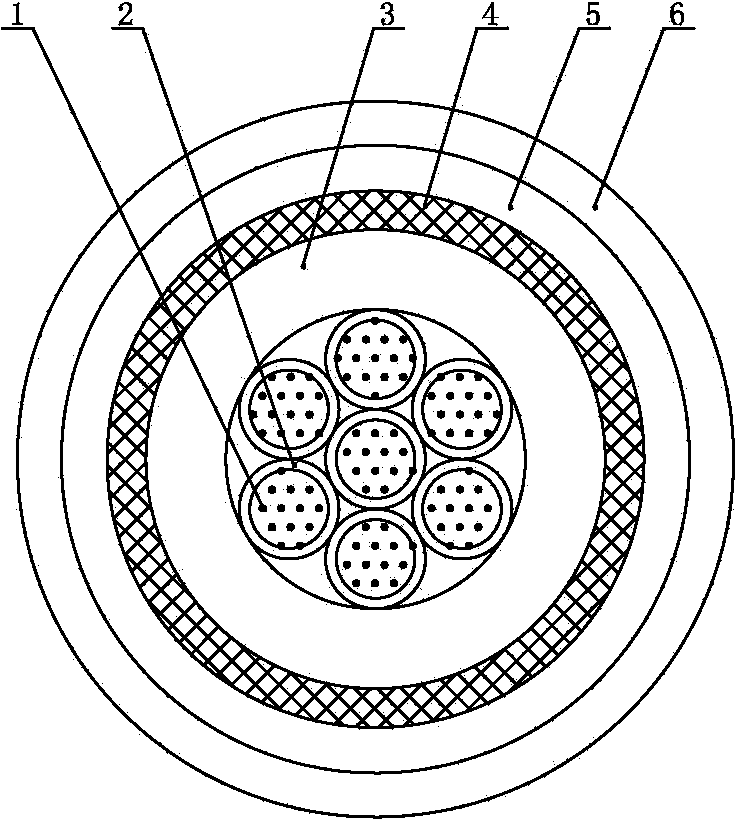

ActiveCN112466536AEasy to slideSmall outer diameterClimate change adaptationInsulated cablesCopper conductorPolyolefin

The invention relates to a jet flame and hydrocarbon flame resistant medium-voltage cable for an offshore oil platform and a manufacturing method thereof. A semi-conductive conductor shielding layer,an insulating layer and a semi-conductive insulating shielding layer wrap the periphery of a stranded tin-plated annealed copper conductor from inside to outside in a three-layer co-extrusion mode; atinned copper wire shielding layer is woven on the periphery of a semi-conductive insulation shielding layer to form a shielding wire core, a plurality of shielding wire cores are twisted to form a cable core, an inner silicone oil layer is extruded on the periphery of the cable core, an inner lining layer is extruded on the periphery of the inner silicone oil layer, a fireproof wrapping tape is wrapped on the periphery of the inner lining layer, and an armor layer is wrapped on the periphery of the fireproof wrapping tape; the periphery of the armor layer is extruded with an outer silicone oil layer, the periphery of the outer silicone oil layer is extruded with a jet flame and hydrocarbon flame resistant inner sheath, and the periphery of the jet flame and hydrocarbon flame resistant inner sheath is extruded with a slurry resistant cross-linked polyolefin outer sheath. The cable adopts a double-layer composite sheath, can bear high-temperature flame of 1300 DEG C for 120 minutes under rated voltage, and does not have a grounding fault or a short circuit.

Owner:WUXI MINGZHU CABLE

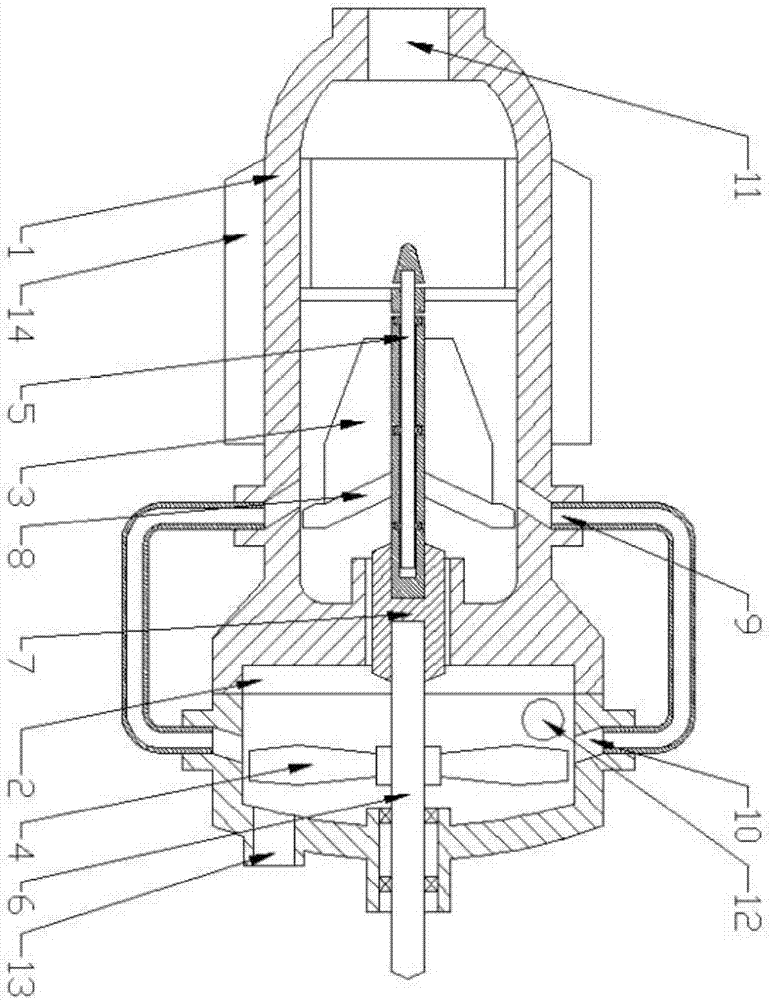

Petroleum mixing and conveying pump

InactiveCN106968960AReduce flow viscosityHigh speed driveSpecific fluid pumpsPump componentsImpellerEngineering

The invention relates to a petroleum mixing and conveying pump. The pump casing body is divided into an inflow cavity and a driving cavity; the constricted end of the inflow cavity is provided with a feeding port; A pressure impeller with a conical table structure is rotatably connected to the tail, and the pressure impeller includes a support block. A number of driving blades coplanar with the axis of the support block are arranged in an array on the support block. A plurality of discharge nozzles are arranged in an annular array on the inner wall of the inflow cavity corresponding to the distribution plate. A centrifugal impeller is rotatably connected in the driving cavity. The centrifugal impeller includes a rotating block. The annular array is provided with a number of centrifugal blades on the rotating block. The centrifugal impeller The support block and the rotating block of the pressure impeller are coaxially rotated and fixed, and a number of inflow nozzles are arranged in an annular array on the inner wall of the driving cavity. The inner wall is provided with a liquid inlet, and a liquid discharge port is provided at the end of the axis of the drive cavity.

Owner:YANCHENG JINRUI PETROLEUM MACHINERY CO LTD

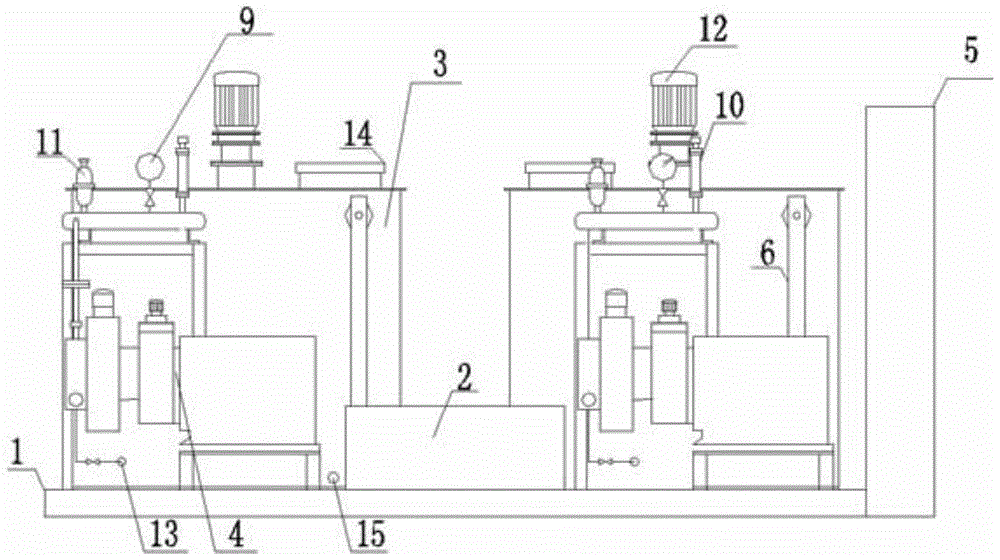

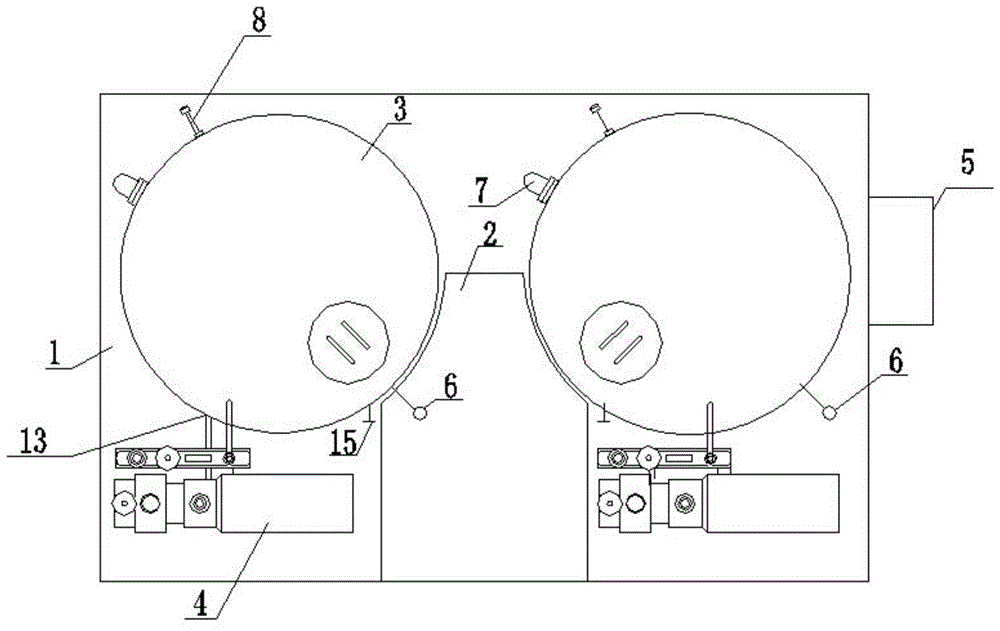

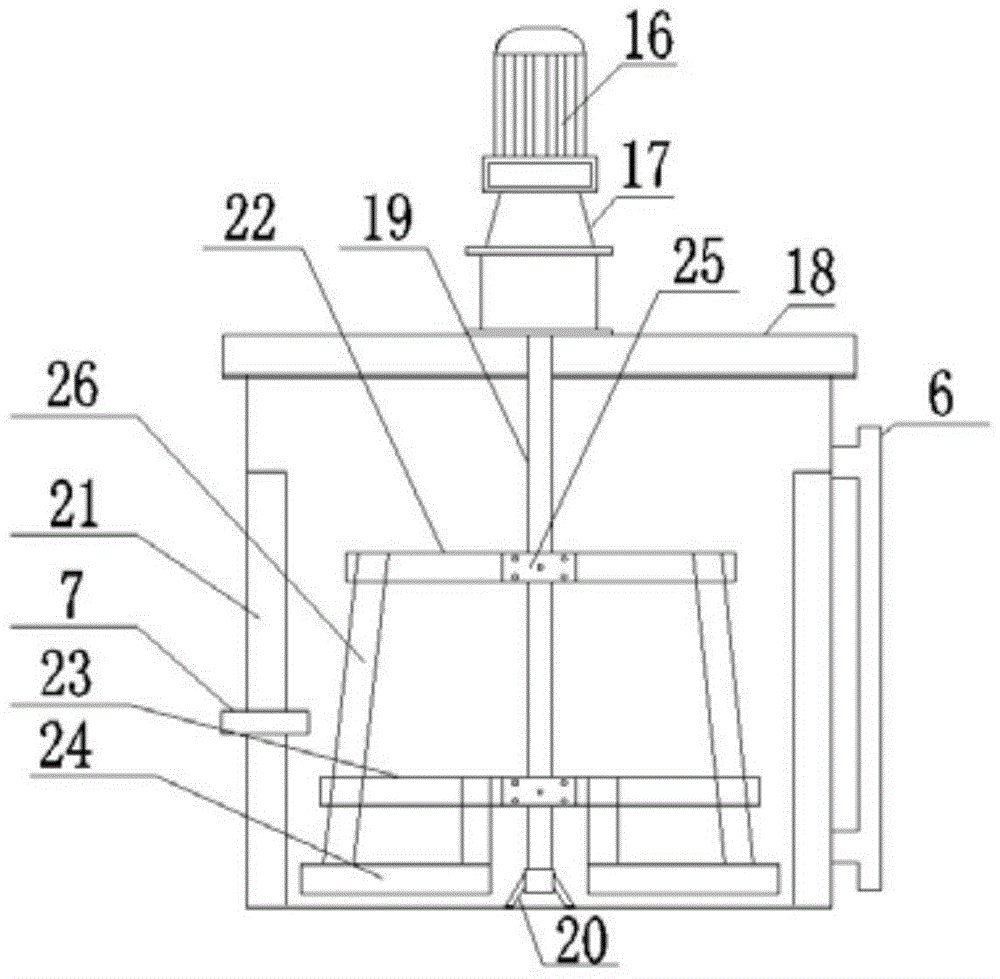

Skid-mounted high-pressure dosing device and method

InactiveCN104147959AAchieve simplicityFully automatedRotary stirring mixersMixer accessoriesTemperature controlHigh pressure

The invention provides a skid-mounted high-pressure dosing device and method. The device comprises a base, a platform, a medicament tank, a dosing pump, a control cabinet, a liquid level meter and a stirring device, wherein the stirring device consists of a paddle blade and a baffle plate, and is used for realizing uniform stirring of medicaments without damaging the monomer forms of the medicaments; a heater and a temperature control device are arranged inside the medicament tank; and by controlling the temperature inside the medicament tank, the flowing viscosities of the medicaments are lowered while the medicament properties are not lowered. By adopting the device and the method, the functions of stirring, heating, metering, high-pressure injection and the like are integrated, so that the technical problem of difficulty in injecting high-viscosity liquid medicaments is solved, and a dosing process is simplified, automatized and integrated.

Owner:SINOPEC ENERGY & ENVIRONMENTAL ENG CO LTD

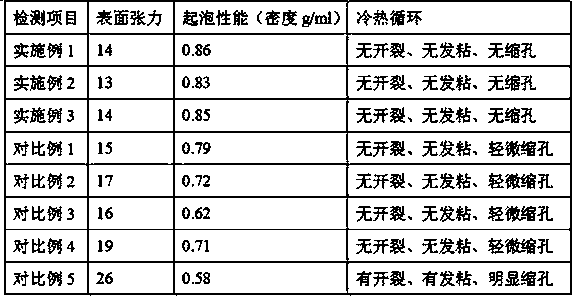

Levelling agent for coating and preparation method of levelling agent

InactiveCN110698906AImprove the lubrication effectImprove high temperature resistanceCoatingsEndcappingPolymer science

The invention discloses a levelling agent for a coating and a preparation method of the levelling agent, and belongs to the technical field of coatings. A prepared silicone oil substrate makes the levelling agent have better lubricating properties, and active hydrogen in hydrogen-terminated polydimethylsiloxane can be reacted with an allyl polyether to introduce the active siloxane into the molecular chain of a levelling agent to form the self-lubricating levelling agent; a prepared modification active agent forms a more water-resistant surface layer, so that the high temperature resistance ofthe silicone oil levelling active agent is improved, and the levelling agent can still maintain better emulsification stability under high-temperature conditions without phase separation; a preparedviscosity-reducing active agent makes the levelling agent have increased horizontal fluidity and higher gloss, and form a smooth surface; and a prepared defoaming active agent improves defoaming in the self-levelling process, reduces levelling resistance brought by foam and improves the levelling effect. The levelling agent provided by the invention solves the problems that a current levelling agent has poor thermal stability and is easy to foam.

Owner:廖华平

High-temperature-resistant soft independent shield instrument cable for maritime oil and gas engineering and manufacturing method thereof

InactiveCN102969050BImprove high temperature resistanceImprove aging resistanceFlexible cablesCable/conductor manufactureCopper conductorCross-link

The invention relates to a high-temperature-resistant soft independent shield instrument cable for maritime oil and gas engineering and a manufacturing method thereof. The cable is characterized in that a chemical cross-linked polyolefin insulation layer is extruded at the periphery of a tin-plated annealed stranded copper conductor to form a power cable insulation wire core; every two insulation wire cores are twisted to form twisted wire pairs, and each twisted wire pair is successively wrapped with a copper foil polyester composite tape shielding layer and a polyester tape at the periphery, and then the twisted wire pairs are stranded to form a cable core; and the cable core is successively provided with an extruded inner sheath, a clad copper alloy wire weaving armor layer, a wrapped water-proof wrapping tape, and an extruded outer sheath at periphery. The insulation layer is prepared from the following raw material components: 12 parts of ethylene / vinyl acetate copolymer, 6 parts of high density polyethylene, 2 parts of ethylene-methacrylic acid copolymer, 0.5-1 part of cross-linking agent DCP (Dicumyl Peroxide), 0.4-0.9 part of antioxidant 1076; 0.2-0.4 part of antioxidant DNP, 0.2-1 part of lubricant stearic acid, 25-30 parts of aluminum hydroxide, 0.6-1 part of red phosphorus, and 0.05-0.1 part of ultraviolet ray absorber UV-326. The insulation layer of the cable is excellent in high-temperature resistance and ageing resistance, and long in service life.

Owner:JIANGSU YUANYANG DONGZE CABLE

A kind of preparation method of aralkyl epoxy resin material for sealing semiconductor equipment

InactiveCN104098870BSimple internal structureIncrease flow lengthSemiconductor/solid-state device detailsSolid-state devicesTetrabromobisphenol AMixed materials

The invention discloses a preparation method of a semiconductor equipment sealing aralkyl epoxy resin material, and the method is as follows: putting 60 to 70 parts of by mass of silica powder, 5 to 10 parts of by mass of phenolic resin, 2 to 6 parts of by mass of polyester resin, 2 to 8 parts of by mass of tetrabromobisphenol A epoxy resin, 0.5 to 1 part of by mass of carnauba wax, 5 to 10 parts of by mass of antimonous oxide, 0.5 to 1 part of by mass of triphenylphosphine, , 0.5 to 1 part of by mass of zinc naphthenate and 3 to 8 parts of by mass of tetraglycidyl diamino-diphenyl methane into a mixer to mix uniformly; putting the mixed material in a kneader for kneading at 90-100 DEG C for 10-20 minutes, and discharging after the kneading is completed; finally crushing the kneaded material to obtain the finished product. The semiconductor equipment sealing aralkyl epoxy resin material prepared by the method has the advantages of low viscosity, good heat resistance and humidity resistance and good curing properties, and can be effectively used in semiconductor equipment sealing.

Owner:ANHUI JIALAN NEW MATERIAL CO LTD

High-temperature-resistant soft control cable for maritime oil and gas engineering and manufacturing method thereof

InactiveCN102969047BImprove high temperature resistanceImprove aging resistancePlastic/resin/waxes insulatorsFlexible cablesCross-linkCopper conductor

The invention relates to a high-temperature-resistant soft control cable for maritime oil and gas engineering and a manufacturing method thereof. The cable is characterized in that a chemical cross-linked polyolefin insulation layer is extruded at the periphery of a 0.35-2.5mm<2> tin-plated annealed stranded copper conductor to form an insulation wire core; a plurality of insulation wire cores are twisted to the right at 20-24 times of standing lay ratio to form a cable core; an inner sheath is extruded at the periphery of the cable core; the inner sheath inner sheath inner sheath is coated with a copper alloy wire weaving armor layer at the periphery; the periphery of the copper alloy wire weaving armor layer is wrapped with a water-proof wrapping tape; and an outer sheath is extruded at the periphery of the water-proof wrapping tape. The insulation layer is prepared from the following raw material components: 12 parts of ethylene / vinyl acetate copolymer, 6 parts of high density polyethylene, 2 parts of ethylene-methacrylic acid copolymer, 0.5-1 part of cross-linking agent DCP (Dicumyl Peroxide), 0.4-0.9 part of antioxidant 1076; 0.2-0.4 part of antioxidant DNP, 0.2-1 part of lubricant stearic acid, 25-30 parts of aluminum hydroxide, 0.6-1 part of red phosphorus, and 0.05-0.1 part of ultraviolet ray absorber UV-326. The insulation layer of the cable is excellent in high-temperature resistance and ageing resistance, and long in service life.

Owner:JIANGSU YUANYANG DONGZE CABLE

A kind of 3D printing equipment and printing method for high molecular weight silicone rubber

ActiveCN107283819BExtended service lifeQuality improvementAdditive manufacturing with liquidsApplying layer meansEngineeringUltimate tensile strength

The invention discloses a 3D printing device and method for high-molecular-weight silicone rubber. A hundred-micron-level micropore nozzle with the high shearing rate and high extruding strength and for screw extruding force is adopted in a 3D printing head system, the flowing viscosity of the high-molecular-weight silicone rubber is greatly reduced, and 3D printing forming of a high-molecular-weight, high-compression-modulus and long-service life silicone rubber material is achieved. The extrusion and expansion stability of the material on the hundred-micron-level micropore nozzle is improved, the dimensional precision of a 3D printing fluid line is accurately controlled, and high quality, high precision and high efficiency in the 3D printing process are achieved. A photo-thermal two-order curing material 3D printing manner is adopted, the curing rate and dimensional precision of the 3D printing material are greatly increased, the high quality and stability of the 3D printing high-molecular-weight silicone rubber material are improved, and the macro-performance and structure adjustability of the 3D printing material are achieved.

Owner:XIAN LIANCHUANG ADVANCED MFG A SPECIALIZED INCUBATOR CO LTD

Jet flame and hydrocarbon flame resistant medium voltage cable for offshore oil platform and its manufacturing method

ActiveCN112466536BImprove high temperature resistanceAvoid heat agingClimate change adaptationInsulated cablesCopper conductorTinning

Owner:WUXI MINGZHU CABLE

Dicarboxypolycaprolactone compound and its preparation method and application of inorganic filler dispersant

The invention discloses a dicarboxy polycaprolactone compound, a preparation method thereof and an application of an inorganic filler dispersant. In the method, high-purity nitrogen or high-purity argon-protected ε-caprolactone and monohydric alcohol are placed in a reactor, a catalyst stannous octoate is added, and the reaction is carried out at 100-130° C. for 4-48 hours to obtain monohydroxyl-terminated Polycaprolactone; at 4-dimethylaminopyridine and 10-40°C, hydroxyl-containing polycaprolactone and maleic anhydride are esterified in solution; under the action of an initiator, the obtained product is regenerated React with 3-mercaptopropionic acid to obtain polycaprolactone with dicarboxyl groups at the end of the molecular chain. As a dispersant, the dicarboxypolycaprolactone compound prepared by the present invention can be quickly and firmly adsorbed on the surface of inorganic fillers, which not only meets the dispersion requirements of different inorganic filler particles, but also can significantly reduce the kinematic viscosity of the inorganic particle filling system, significantly improving The processing or construction performance of the system is improved.

Owner:YANTAI UNIV

Anticorrosive wire drawing liquid used for metal and preparation method thereof

The invention discloses an anticorrosive wire drawing liquid used for metal, and is characterized by comprising the following raw materials by weight: 3-5 parts of sodium alcohol ether sulphate, 1-2 parts of citric acid, 2.5-3 parts of zinc butyl octyl dithiophosphate, 1.5-2.5 parts of diisobutyl phthalate, 3-4 parts of pentaerythritol, 2-3 parts of tributyl phosphate, 8-12 parts of rapeseed oil, 8-10 parts of nanometer titanium dioxide, 1-2 parts of dispersant NNO, 5-7 parts of auxiliary agent and 900-950 parts of deionized water. A formula of the wire drawing liquid is reasonable, the added zinc butyl octyl dithiophosphate has good antioxidant and anti-corrosive property, odor of the wire drawing liquid can be avoided, and service life is prolonged; and the added auxiliary agent has good antiwear, dispersion, lubrication and film forming ability. The aqueous formula is employed, and the wire drawing liquid has the advantages of low flow viscosity and good fluidity, has good heat radiation effect and excellent lubrication performance, the wire type of brass wires and aluminum wires drawn by the product of the invention is uniform, surface is bright, and corrosion is difficult.

Owner:ANHUI TATSU PRECISION ALLOY

Preparation of polymer-based nanocomposites with highly oriented nanoparticles in a polymer matrix

The invention relates to a preparation method for a polymer base nanometer composite material with highly oriented nanoparticles in the polymer matrix, and belongs to the technical field of polymer materials. The preparation method comprises that during a foaming process of a polymer nanometer composite material formed by carrying out melt co-mixing on a polymer and nanoparticles, external force is applied to make the foam hole in the material grow along the uniaxial direction in an oriented growth manner, and the polymer flows under the double induction of the external force and the foam hole growth to achieve the high orientation of the nanoparticles so as to obtain the polymer base nanometer composite material with the highly oriented nanoparticles in the polymer matrix. The method has advantages of simple operation, mild condition, high orientation degree of the nanoparticles in the prepared polymer nanometer composite material, and the like.

Owner:ZHEJIANG UNIV OF TECH

High-temperature-resistant soft power cable for maritime oil and gas engineering and manufacturing method thereof

InactiveCN102969063BImprove high temperature resistanceImprove aging resistancePower cables with screens/conductive layersCable/conductor manufactureCopper conductorCross-link

The invention relates to a high-temperature-resistant soft power cable for maritime oil and gas engineering and a manufacturing method thereof. The power cable is characterized in that a chemical cross-linked polyolefin insulation layer is extruded at the periphery of a tin-plated annealed stranded copper conductor to form a power cable insulation wire core; a plurality of insulation wire cores are stranded to form a cable core; an inner sheath is extruded at the periphery of the cable core; the periphery of the inner sheath inner sheath inner sheath is coated with a copper alloy wire weaving armor layer; the periphery of the copper alloy wire weaving armor layer is wrapped with a water-proof wrapping tape; and an outer sheath is extruded at the periphery of the water-proof wrapping tape. The insulation layer is prepared from the following raw material components: 12 parts of ethylene / vinyl acetate copolymer, 6 parts of high density polyethylene, 2 parts of ethylene-methacrylic acid copolymer, 0.5-1 part of cross-linking agent DCP (Dicumyl Peroxide), 0.4-0.9 part of antioxidant 1076, 0.2-0.4 part of antioxidant DNP, 0.2-1 part of lubricant stearic acid, 25-30 parts of flame retardant aluminum hydroxide, 0.6-1 part of flame retardant red phosphorus, and 0.05-0.1 parts of ultraviolet ray absorber UV-326. The insulation layer of the cable is excellent in high-temperature resistance and ageing resistance, and long in service life.

Owner:JIANGSU YUANYANG DONGZE CABLE

Layered silicate-containing colloidal electrolyte for storage batteries and preparation method thereof

InactiveCN102044710BReduce internal frictional resistanceReduce flow viscosityLead-acid accumulatorsColloidViscosity

The invention relates to a layered silicate-containing colloidal electrolyte for storage batteries, which mainly comprises a silicon-containing gel, a thixotropic agent, a complex additive and electrolyte, wherein the thixotropic agent is layered silicate with the width / thickness ratio of 100-2,000. The colloidal electrolyte comprises the following components in percentage by weight: 2.0 to 10.0 percent of gelatinizing agent, 0.05 to 0.5 percent of thixotropic agent, 5.0 to 13.0 percent of complex additive and the balance of dilute solution of sulfuric acid. The colloidal electrolyte has goodthixotropic liquidity and gel stability and low colloid kinetic viscosity; and the filling efficiency of the colloidal electrolyte and the infiltration of the colloidal electrolyte on the baffle plate and polar plates are greatly improved. The electrolyte can be used for assembling storage batteries with different purposes, such as starting batteries, stationary batteries, traction batteries and the like.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com