Biscarboxy polycaprolactone compound and preparation method and application as inorganic filler dispersant thereof

A technology of polycaprolactone and dicarboxyl group is applied in the application field of dicarboxyl polycaprolactone compound and its preparation, inorganic filler dispersant and inorganic filler dispersant, which can solve the problem of high water content and insufficient adsorption. , poor dispersion stability and other problems, to achieve the effect of shortening the dispersion time, simple and efficient synthesis method, and low kinematic viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A kind of synthetic method of dicarboxy polycaprolactone dispersant, comprises the following steps:

[0046] S1: Under a high-purity nitrogen atmosphere, put 3.426g (30mmol) ε-caprolactone and 0.324g (3mmol) benzyl alcohol into the reactor, add 12.2mg (0.03mmol) stannous octoate, and react at 130°C Obtain the polycaprolactone of monohydroxyl termination in 48 hours;

[0047] S2: Add 34.3g tetrahydrofuran to the product of step S1, stir to dissolve it into a homogeneous solution, add 0.353g (3.6mmol) maleic anhydride, add 0.183g (1.5mmol) of 4-dimethylaminopyridine and 40 ° C Next, react for 3 hours;

[0048] S3: Add 0.318 g (3 mmol) of 3-mercaptopropionic acid and 16.0 mg of azobisisobutyronitrile to the product obtained in step 2, and react at 60° C. for 48 hours. After the reaction finished, the reaction product was removed most of the solvent with a rotary evaporator, and then precipitated in a precipitant (methanol and ethanol mixture, the mass ratio of the two was ...

Embodiment 1

[0050] The product of embodiment 1 is mixed with tetrahydrofuran and the solution that mass concentration is 30% is dispersing aid, and dispersing aid is respectively mixed with epoxy resin (brand is E-51), unsaturated resin (commercial brand is 191), phenolic resin (the trade mark is 176), polyurethane resin, amino resin (trade name is 747) mix, and add-on is 0.5% of resin weight.

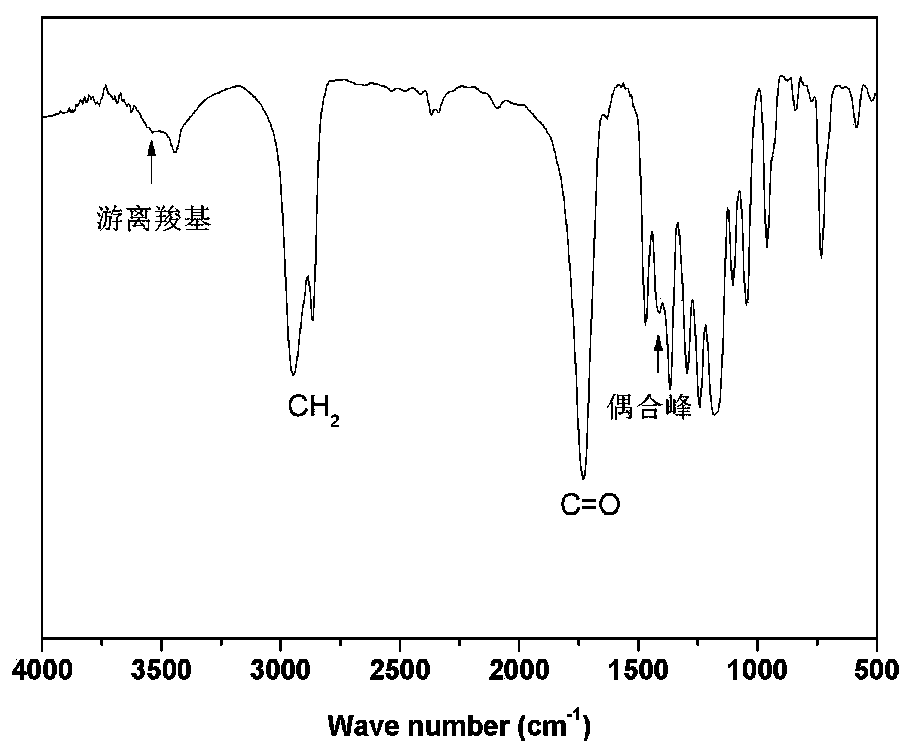

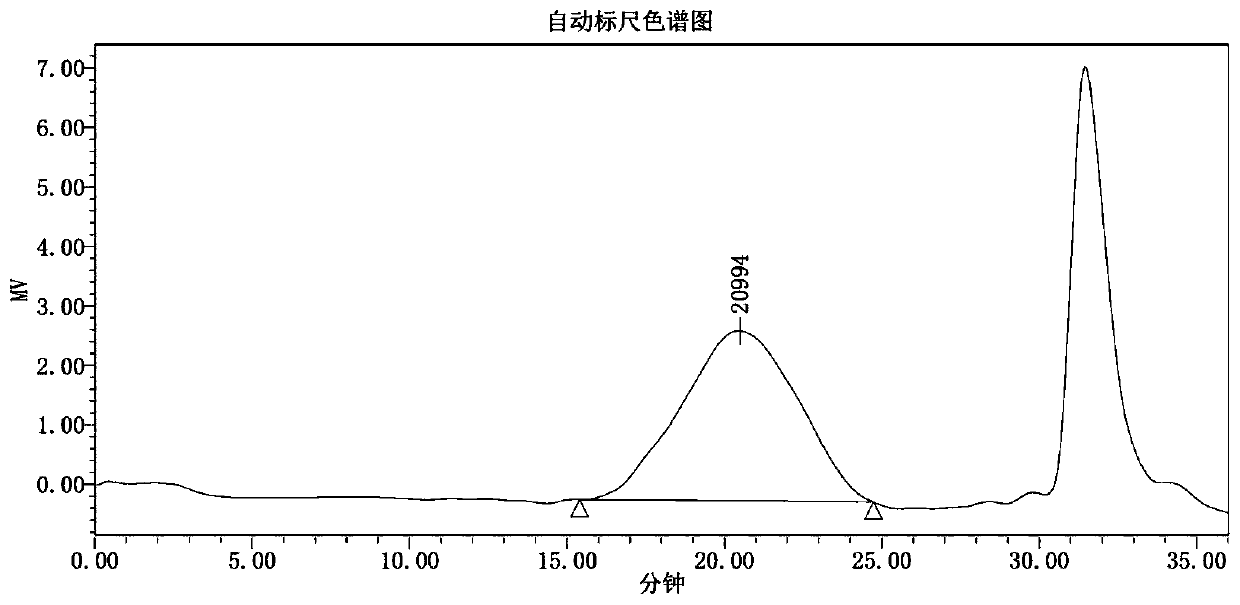

[0051] figure 2 It is the gel permeation chromatogram of Example 1. The number average molecular weight of the product is 15700g / mol (the peak molecular weight is 20994g / mol), and the molecular weight distribution is 1.66, indicating that the product is a high molecular weight polymer. When used as a dispersant, the adsorption of polycaprolactone molecules on the surface of inorganic particles can form a certain thickness of the adsorption layer (produce a large enough steric hindrance), which is conducive to maintaining the stability of dispersed inorganic particles.

[0052] Mixing photos of ...

Embodiment 2

[0056] A kind of synthetic method of dicarboxy polycaprolactone dispersant, comprises the following steps:

[0057] S1: Under a high-purity argon atmosphere, 9.131g (80mmol) ε-caprolactone and 0.163g (1.6mmol) n-hexanol were placed in the reactor, and 648mg (1.6mmol) of stannous octoate was added, at 100°C React for 4 hours to obtain monohydroxyl-terminated polycaprolactone;

[0058] S2: Add 9.3g 1,4-dioxane to the product of step S1, stir to make it dissolve into a homogeneous solution, add 0.157g (1.6mmol) maleic anhydride, in 19.5mg (0.16mmol) of 4- Dimethylaminopyridine and 10°C, reacted for 72 hours;

[0059] S3: Add 0.848 g (8 mmol) of 3-mercaptopropionic acid and 0.254 g (1.0 mmol) of azobisisoheptanonitrile to the product obtained in step 2, and react at 90° C. for 2 hours. After the reaction was finished, the reaction product was removed with a rotary evaporator to remove most of the solvent, and then precipitated in a precipitant (petroleum ether and ether mixture,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com