Preparation method for polymer base nanometer composite material with highly oriented nanoparticles in polymer matrix

A nano-composite material and nano-particle technology is applied in the field of preparation of polymer-based nano-composite materials. Viscosity, the effect of expanding the range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

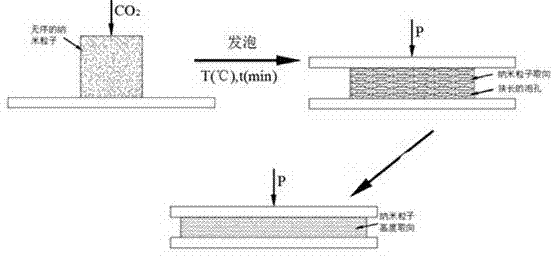

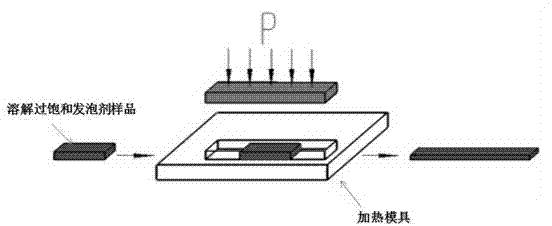

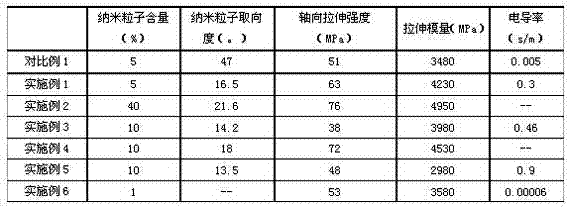

Embodiment 1

[0030] Polystyrene (PS) and graphene (mass ratio 95:5) were melt-blended and extruded at 200°C with an extruder, and then pressed to obtain a nanocomposite sample, which was sealed in an autoclave; a small amount of CO 2 After purging the autoclave for 2 min, inject supercritical CO 2 , control the pressure at 15MPa, seal and soak at room temperature for 12 hours; quickly release the pressure and take the sample out of the autoclave and put the sample into a mold cavity with a temperature of 150°C consisting of an upper mold and a lower mold (the mold cavity structure is as follows figure 2shown), pressurize the mold to 20MPa for 30s, hold the pressure for 5min, then cool to room temperature and open the mold to obtain a polymer-based nanocomposite material with highly oriented nanoparticles in the polymer matrix. The schematic diagram of the preparation of the above-mentioned nanoparticle highly oriented polymer-based microporous nanocomposite is as follows: figure 1 shown...

Embodiment 2

[0032] Polymethyl methacrylate (PMMA) and organically modified montmorillonite (mass ratio 60:40) were melt-blended in an internal mixer at 220°C, and then pressed into tablets to obtain nanocomposite samples, which were loaded into high-pressure Seal the inside of the autoclave; use a small amount of freon to purge the autoclave for 2 minutes and then inject freon, control the pressure to 5MPa, seal and soak at room temperature for 18 hours; quickly release the pressure and take the sample out of the autoclave and put the sample into a tool with a temperature of 180 In the mold cavity at ℃, pressurize the mold to 30MPa for 15s, hold the pressure for 3min, then cool to room temperature and open the mold to obtain a polymer-based nanocomposite material with highly oriented nanoparticles in the polymer matrix.

Embodiment 3

[0034] Polypropylene (PP) and carbon nanotubes (mass ratio 90:10) were melt-blended and extruded at 200°C with an extruder, and then pressed into tablets to obtain nanocomposite samples, which were put into an autoclave and sealed; with a small amount of Purge the autoclave with butane for 2 minutes, then inject butane, control the pressure at 8MPa, seal and soak at room temperature for 18 hours; quickly release the pressure and take the sample out of the autoclave and put the sample into a mold cavity with a temperature of 180°C , pressurize the mold to 3MPa for 30s, hold the pressure for 3min, then cool to room temperature and open the mold to obtain a polymer-based nanocomposite material with highly oriented nanoparticles in the polymer matrix.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com