3D printing device and method for high-molecular-weight silicone rubber

A 3D printing, high molecular weight technology, applied in coating devices, manufacturing, liquid material additive processing, etc., can solve the problem of low curing efficiency and degree, low compressive modulus, and difficulty in accurately controlling 3D printing droplets and fluids Dimensional accuracy and other issues, to achieve the effect of improving curing rate and dimensional accuracy, improving extrusion and expansion stability, and improving high quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

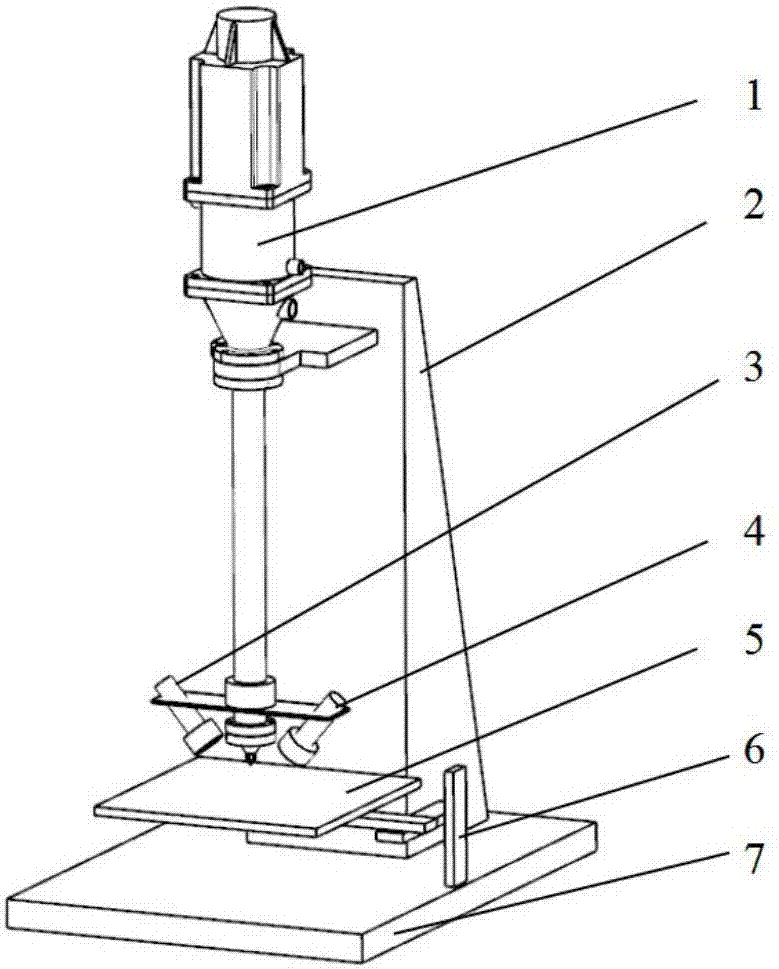

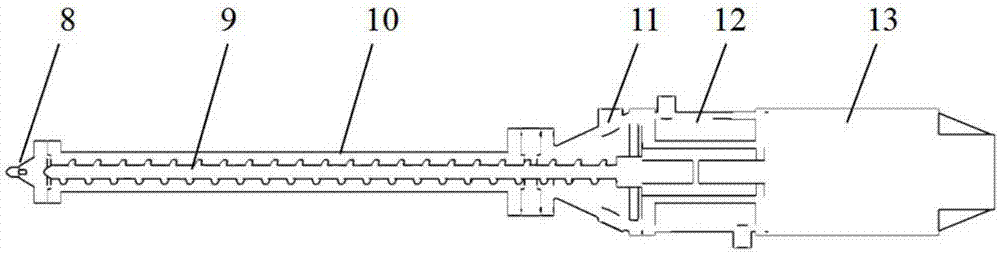

[0029] refer to figure 1 , a 3D printing device for high molecular weight silicone rubber, comprising a 3D mobile platform system 6 connected to a 3D printer frame 7, a 3D printer substrate 5 is installed on the 3D mobile platform system 6, and a 3D The print head system 1, the photocuring controller 3 and the thermal curing controller 4, the 3D printing head system 1, the photocuring controller 3, the thermal curing controller 4 and the 3D mobile platform system 6 are connected to the 3D printer control box 2.

[0030] The 3D printing head system 1 has a nozzle microporous structure of hundreds of microns (100 μm-150 μm), which realizes the extrusion function of high-molecular-weight and high-viscosity polymer silicone rubber.

[0031] The 3D printer control box 2 adopts PID control technology to realize precise micro-extrusion process contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com