Chemical crosslinking polyolefin insulating rubber for offshore oil gas engineering cable and manufacturing method

An insulating rubber and chemical cross-linking technology, applied in the field of cable insulating rubber, can solve the problems of inability to meet the high temperature operating environment requirements of offshore oil and gas engineering cables, inability to meet high temperature resistance, large current carrying capacity, high moisture erosion, unsuitable insulation materials, etc. Excellent anti-aging and non-discoloration, low smoke carbon monoxide generation, excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

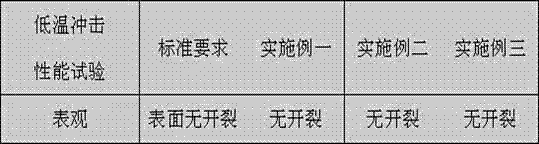

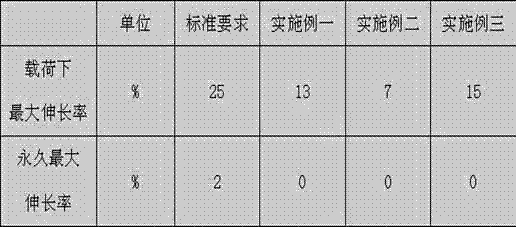

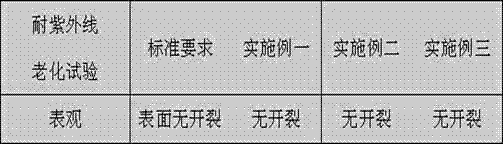

Examples

Embodiment 1

[0021] The preparation steps of chemically cross-linked polyolefin insulating rubber for offshore oil and gas engineering cables are as follows: (1) Prepare raw materials according to the following components and weight content, ethylene / vinyl acetate copolymer: 12 parts; high-density polyethylene: 6 parts; ethylene - Methacrylic acid copolymer: 2 parts; Crosslinking agent dicumyl peroxide: 0.5 part; Antioxidant β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate: 0.4 parts; antioxidant N,N'-di-β-naphthyl-p-phenylenediamine: 0.2 parts; lubricant stearic acid: 0.2 parts; flame retardant aluminum hydroxide: 25 parts; flame retardant red phosphorus: 0.6 parts; UV absorber 2-(2'-hydroxy-3'-tert-butyl-5'-methylphenyl)-5-chlorobenzotriazole: 0.05 parts; The temperature rises to 130°C, add the above-mentioned ethylene / vinyl acetate copolymer, high-density polyethylene and ethylene-methacrylic acid copolymer in sequence, and plasticize and knead evenly, then add the antioxidant...

Embodiment 2

[0024] The preparation steps of chemically cross-linked polyolefin insulating rubber for offshore oil and gas engineering cables are as follows: (1) Prepare raw materials according to the following components and weight content, ethylene / vinyl acetate copolymer: 12 parts; high-density polyethylene: 6 parts; ethylene -Methacrylic acid copolymer: 2 parts; crosslinking agent dicumyl peroxide: 0.8 part; antioxidant beta-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate: 0.7 parts; antioxidant N,N'-di-β-naphthyl-p-phenylenediamine: 0.3 parts; lubricant stearic acid: 0.6 parts; flame retardant aluminum hydroxide: 28 parts; flame retardant red phosphorus: 0.8 parts; UV absorber 2-(2'-hydroxy-3'-tert-butyl-5'-methylphenyl)-5-chlorobenzotriazole: 0.08 parts; The temperature rises to 140°C, add the above-mentioned ethylene / vinyl acetate copolymer, high-density polyethylene and ethylene-methacrylic acid copolymer in sequence, and plasticize and knead evenly, then add the antioxida...

Embodiment 3

[0027] The preparation steps of chemically cross-linked polyolefin insulating rubber for offshore oil and gas engineering cables are as follows: (1) Prepare raw materials according to the following components and weight content, ethylene / vinyl acetate copolymer: 12 parts; high-density polyethylene: 6 parts; ethylene -Methacrylic acid copolymer: 2 parts; crosslinking agent dicumyl peroxide: 1 part; antioxidant β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate: 0.9 parts; antioxidant N,N'-di-β-naphthyl-p-phenylenediamine: 0.4 parts; lubricant stearic acid: 1 part; flame retardant aluminum hydroxide: 30 parts; flame retardant red phosphorus: 1 part; UV absorber 2-(2'-hydroxy-3'-tert-butyl-5'-methylphenyl)-5-chlorobenzotriazole: 0.1 part; The temperature rises to 150°C, add the above-mentioned ethylene / vinyl acetate copolymer, high-density polyethylene and ethylene-methacrylic acid copolymer in sequence, and plasticize and knead evenly, then add the antioxidant β-(3,5-di ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com