High-temperature-resistant soft bulk-shielding instrument cable for maritime oil and gas engineering and manufacturing method thereof

A technology of overall shielding and instrumentation cables, applied in the manufacture of cables/conductors, insulation of conductors/cables, insulated cables, etc., can solve the problems that cannot meet the high temperature operating environment requirements of offshore oil and gas engineering cables, high temperature resistance, and large current carrying capacity. Moisture erosion, unsuitable insulation materials, etc., to achieve excellent seawater corrosion resistance, avoid melting and dripping, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

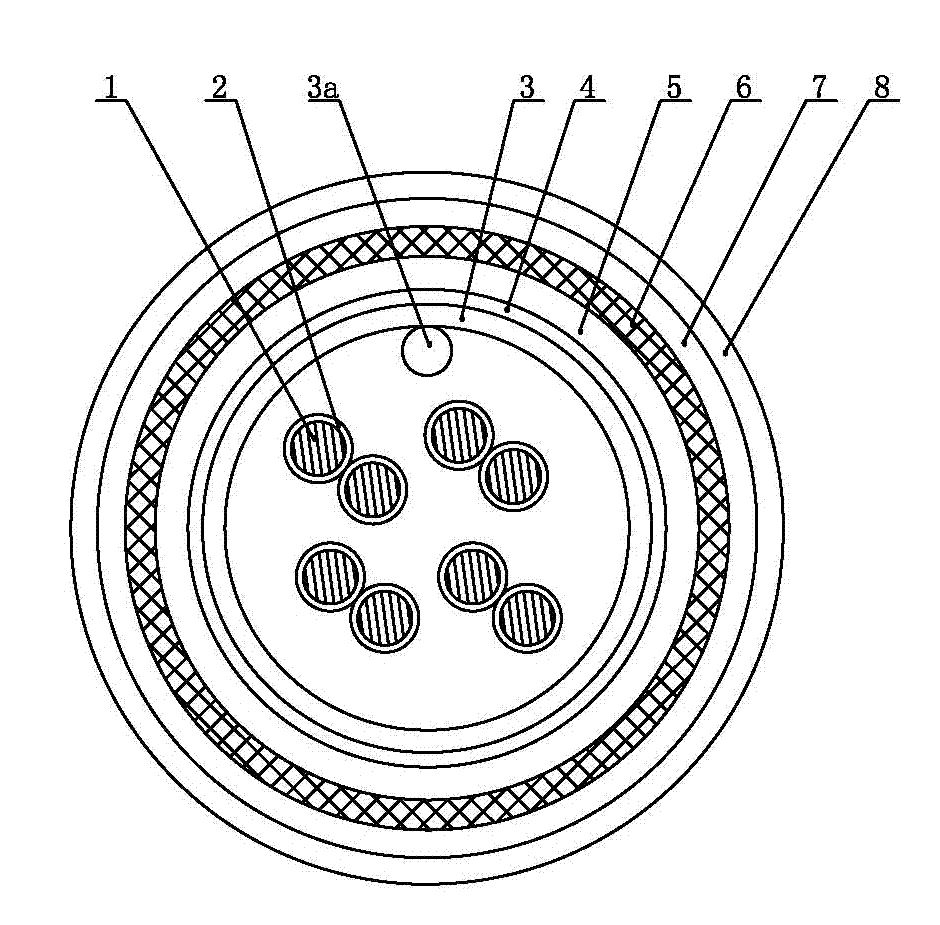

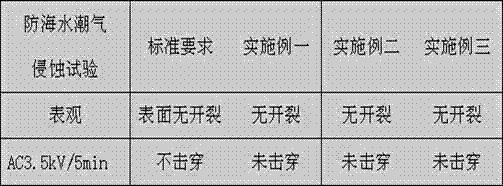

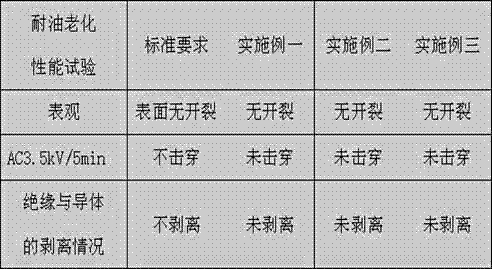

[0023] like figure 1 As shown, the high-temperature-resistant soft overall shielding instrument cable for offshore oil and gas engineering of the present invention is manufactured according to the following steps: extruding a chemically cross-linked polyolefin insulating layer 2 on the periphery of a 0.35mm tinned annealed stranded copper conductor 1 to form an insulating core , the insulated wire cores are twisted in pairs to form a pair of twisted wires, the twisted pitch of each pair of twisted wires is not greater than 120mm and all pairs of twisted wires use different twisted pitches; all pairs of twisted wires are 16 times the ratio of twisting pitch diameter to right-hand twisting to form the cable core, and the copper foil polyester composite tape shielding layer 3 is wrapped around the outer periphery of the cable core with the copper foil facing inward, and the inner side of the copper foil polyester composite tape shielding layer 3 is set There are tinned stranded c...

Embodiment 2

[0029]The high-temperature-resistant soft overall shielded instrument cable for offshore oil and gas engineering of the present invention is manufactured according to the following steps: extrude a chemically cross-linked polyolefin insulating layer 2 on the outer periphery of a tinned annealed stranded copper conductor 1 of 1.25mm2 to form an insulating core, and an insulating wire The cores are twisted in pairs to form a pair of twisted wires. The twisted pitch of each pair of twisted wires is not greater than 120mm and all pairs of twisted wires use different twisted pitches; all pairs of twisted wires are 20 times The ratio of stranded pitch diameter to right-handed stranding constitutes the cable core, and the copper foil polyester composite tape shielding layer 3 is wrapped around the outer circumference of the cable core with the copper foil facing inward, and the inner side of the copper foil polyester composite tape shielding layer 3 is provided with tin plating. Twist...

Embodiment 3

[0035] The high-temperature-resistant soft overall shielded instrument cable for offshore oil and gas engineering of the present invention is manufactured according to the following steps: extruding a chemically cross-linked polyolefin insulating layer 2 on the outer periphery of a tinned annealed stranded copper conductor 1 of 2.5mm2 to form an insulated wire core, and an insulated wire The cores are twisted in pairs to form a pair of twisted wires. The twisted pitch of each pair of twisted wires is not greater than 120mm and all pairs of twisted wires use different twisted pitches; all pairs of twisted wires are 24 times The ratio of stranded pitch diameter to right-handed stranding constitutes the cable core, and the copper foil polyester composite tape shielding layer 3 is wrapped around the outer circumference of the cable core with the copper foil facing inward, and the inner side of the copper foil polyester composite tape shielding layer 3 is provided with tin plating. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com