Graphene based conductive ink and preparation method thereof as well as flexible conductive thin film

A conductive ink and graphene-based technology, which is applied to inks, conductive layers on insulating carriers, household appliances, etc., can solve the problems of conductive inks such as easy agglomeration, high contact resistance, and poor dispersion, and achieve good conductive effect and easy printing , the effect of not easy to reunite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The invention discloses a preparation method of graphene-based conductive ink, comprising the following steps:

[0045] (A) Dispersing the pH regulator in the solvent to obtain a uniform first mixed solution; the pH regulator is one of triethanolamine, dimethylformamide and ammonia water with a mass concentration of 25% to 27% or various;

[0046] (B) mixing the first mixed liquid with a binder to obtain a second mixed liquid;

[0047] (C) mixing the second mixed solution with conductive components and additives to obtain a graphene-based conductive ink; the conductive components include graphene sheets loaded with metal particles or metal sheets, and the metal particles are deposited or Dispersed in graphene sheets.

[0048] In the present invention, the graphene-based conductive ink is prepared from conductive components, solvents, binders and pH regulators.

[0049]The conductive component includes graphene sheets loaded with metal particles or metal sheets. The ...

Embodiment 1

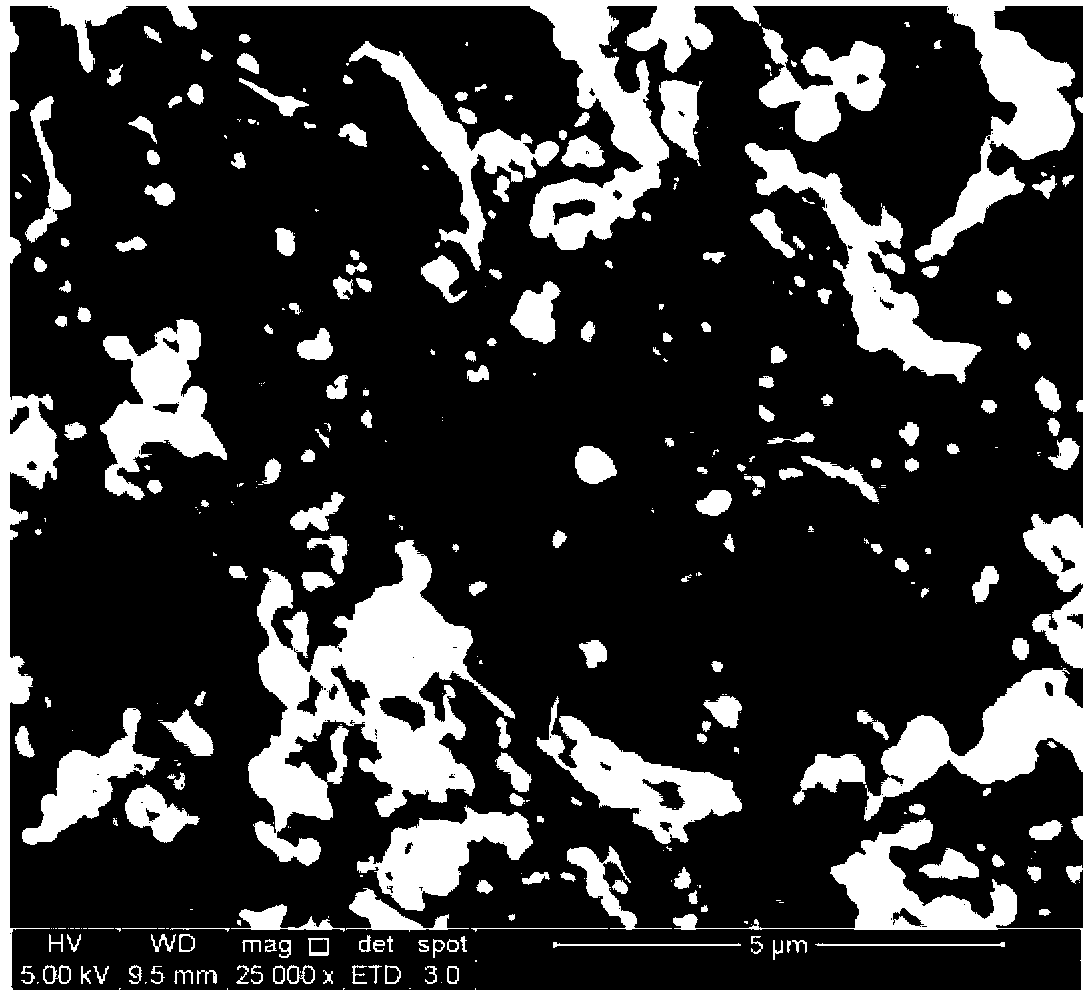

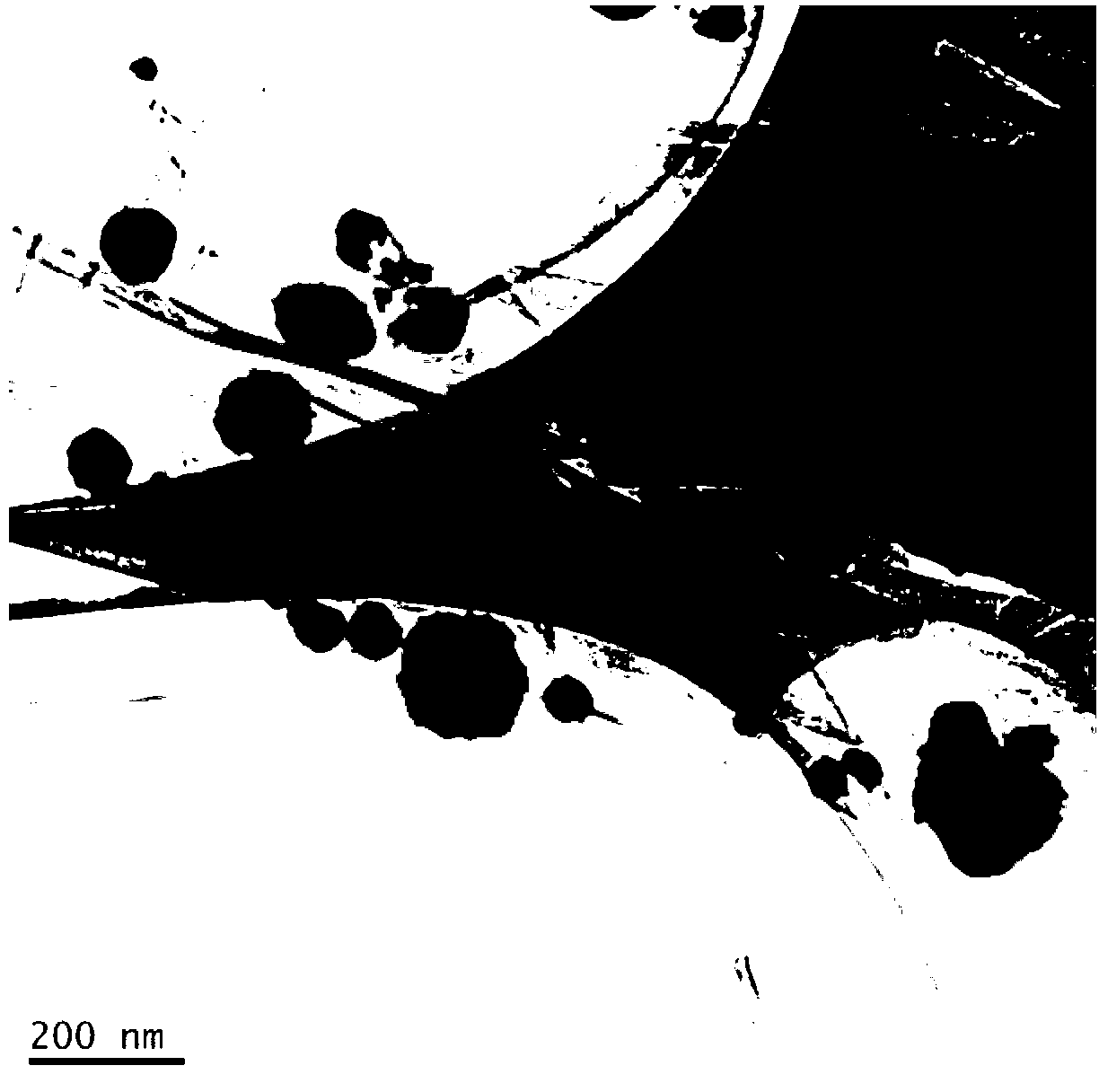

[0061] Weigh 0.001mol / L of AgNO 3 Solution 1000mL, add 20g graphene powder, stir evenly, add 1g polyvinylpyrrolidone, add 10ml concentration of 0.1mol / L ammonia water to carry out silver mirror reaction until the precipitation is completely formed, then add 5g glucose, and react at 55°C. Then carry out centrifugal drying to obtain graphene sheets loaded with metallic silver powder. figure 1 The scanning electron micrograph of the graphene sheet that is loaded with metallic silver powder for the preparation of embodiment 1; figure 2 The transmission electron micrograph of the graphene sheet that is loaded with metallic silver powder for the preparation of embodiment 1, by figure 1 and figure 2 It can be seen that the present invention has prepared graphene sheets loaded with metallic silver powder.

[0062] Weigh 9.50g of isopropanol, 20.00g of diethylene glycol, 10.00g of terpineol, 10.5g of glycerol, and 1.00g of triethanolamine, mix them thoroughly, put them into an ult...

Embodiment 2

[0068] Weigh 0.001mol / L of AgNO 3 Solution 1000mL, add 20g graphene powder, stir evenly, add 1g polyvinylpyrrolidone, add 10ml concentration of 0.1mol / L ammonia water to carry out silver mirror reaction until the precipitation is completely formed, then add 5g glucose, and react at 55°C. Then carry out centrifugal drying to obtain graphene sheets loaded with metallic silver powder.

[0069] Weigh 5.00g of isopropanol, 10.00g of diethylene glycol, 15.00g of terpineol, 20.00g of diethylene glycol dibenzoate, and 0.5g of dimethylformamide, mix them thoroughly, and put them into an ultrasonic cleaner , carry out ultrasonic dispersion, the dispersion time is 15min, and obtain the first mixed liquid.

[0070] Weigh 20.00 g of the first mixed solution, add 10.00 g of rosin modified resin and 3.00 g of hydroxyethyl cellulose therein. After stirring evenly, place it in a water bath at 80° C. for heating and dissolving to obtain a second mixed solution.

[0071] After the binder is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com