Patents

Literature

156results about How to "Not easy to decolorize" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous flexible plate printing ink and preparation thereof

InactiveCN101328329AReduce pollutionFine inkInksOther printing apparatusSolubilityAtmospheric contamination

A water-basedsoft printing ink comprises the following compositions: 30 to 35 percent of pigment, 25 to 32 percent of acrylic resin, 0.2 to 0.5 percent of antifoaming agent, 2 to 5 percent of ethylene glycol monomethyl ether, 1.0 to 2.5 percent of wax slurry, 0.9 to 1.5 percent of leveling agent, and 23 to 30 percent of water. A preparation method comprises the three working procedures of colored slurry grinding, aquosity treatment and printing ink preparation in turn. The water-basedsoft printing ink has novel compositions, scientific blending, simple preparation, lower cost, fine ink quality, mellow brightness, high color saturation, brilliant color, high drying speed, grid point superimposition and overprinting, good water solubility, easy cleaning, corrosiveness free on printing rollers, low viscosity, high color content, good penetrability and printing adaptability, suitability for multicolor machine high-speed printing, high abrasion resistance, difficult decolorization, wide color range, closeness to a normal color sample, and consistency to the requirements on top-grade printing; and the printing ink also meets EU ROHS standards, and facilitates safe production and environmental protection with low air pollution and without any noxious solvent residual.

Owner:广东佳景科技股份有限公司

Color pearl growing method

InactiveCN1416694ABreeding method is simpleNot easy to decolorizeClimate change adaptationPisciculture and aquariaSecretionSecreted substance

The present invention relates to the growing method of pearl, especially color pearl. Before nucleus transplanting operation of pearl shell, pearl nucleus and transplanted cell piece are treated biologically with rose and other colored animal or plant nutriment; and after further cell piece transplantation and pearl transplanting, the pearl shell is cultivated in sea water to produce color pearl through cell fluid secretion and transmission. It has the beneficial effects of producing color pearl with bright and fast color via the simple biological process.

Owner:石子聪

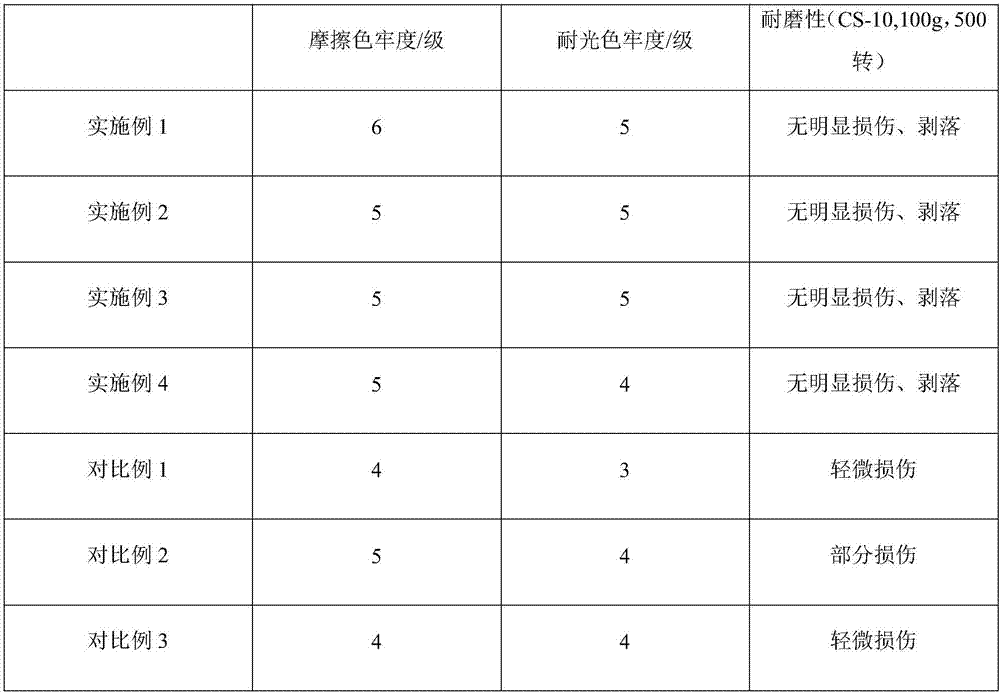

Multi-color TPO vehicle interior decoration material and preparation method thereof

ActiveCN107351495AMeet individual requirementsSolve the disadvantage of single colorSynthetic resin layered productsTurning toolsMasterbatchPolyolefin

The invention discloses a multi-color TPO vehicle interior decoration material, which sequentially comprises a polyolefin sponge layer, a multi-color TPO surface leather layer and an aqueous polyurethane coating from bottom to top, wherein the multi-color TPO surface leather layer is formed by compounding and splicing at least two mono-color TPO surface leathers, and each mono-color TPO surface leather comprises, by weight, 20-40 parts of high-density polyethylene, 20-40 parts of polypropylene, 5-10 parts of an ethylene-acrylic acid copolymer, 30-50 parts of ethylene propylene diene monomer, 15-20 parts of a tackifying resin, 0-8 parts of an inorganic filler, 2-10 parts of color masterbatch, and 1-5 parts of an auxiliary agent. The invention further discloses a preparation method of the multi-color TPO vehicle interior decoration material. According to the present invention, the multi-color TPO vehicle interior decoration material has a variety of colors, the multiple colors can be freely combined and matched, the disadvantage of the single color of the traditional TPO material is solved, and the personalized requirements of vehicle manufacturers on interior decoration materials can be met.

Owner:BENECKE CHANGSHUN AUTO TRIMZHANGJIAGANG

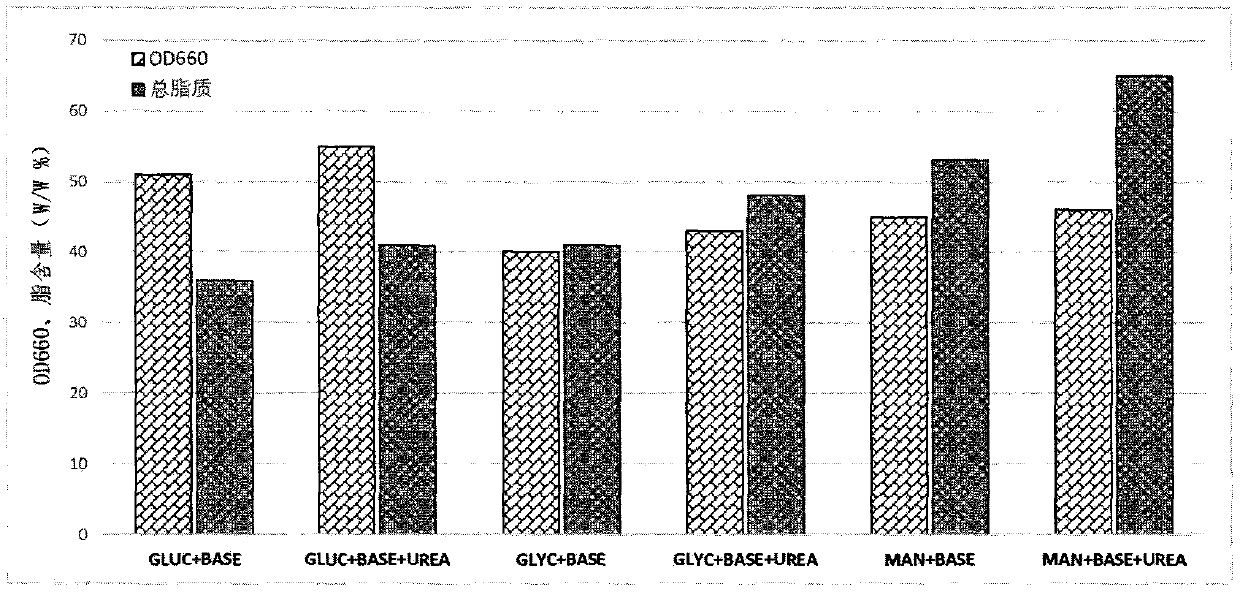

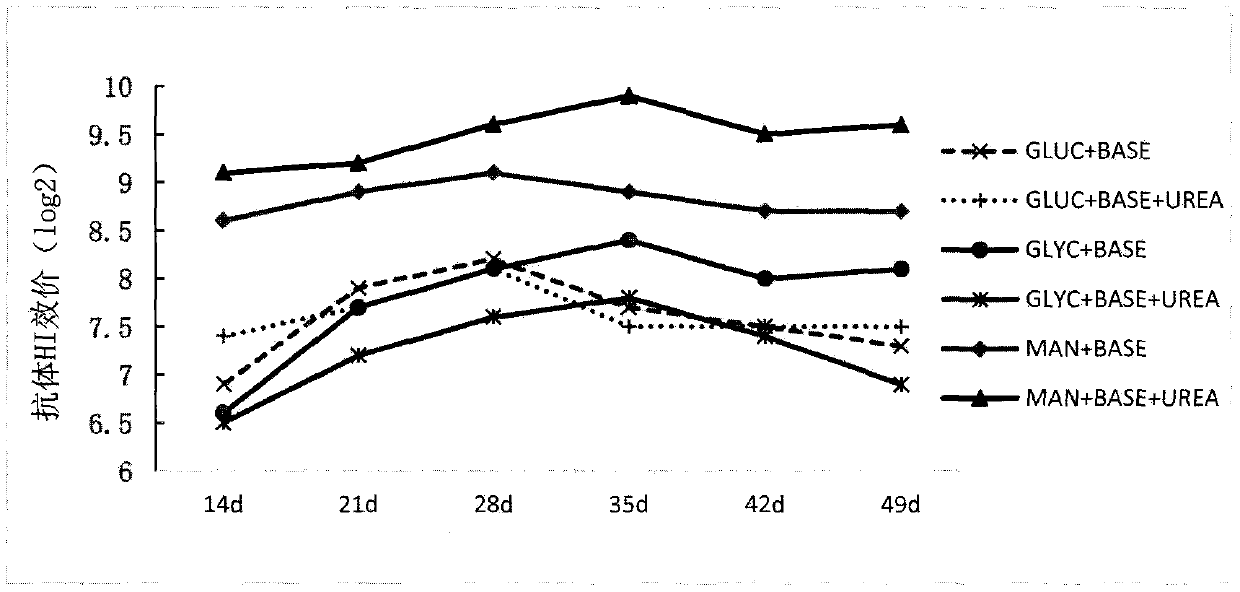

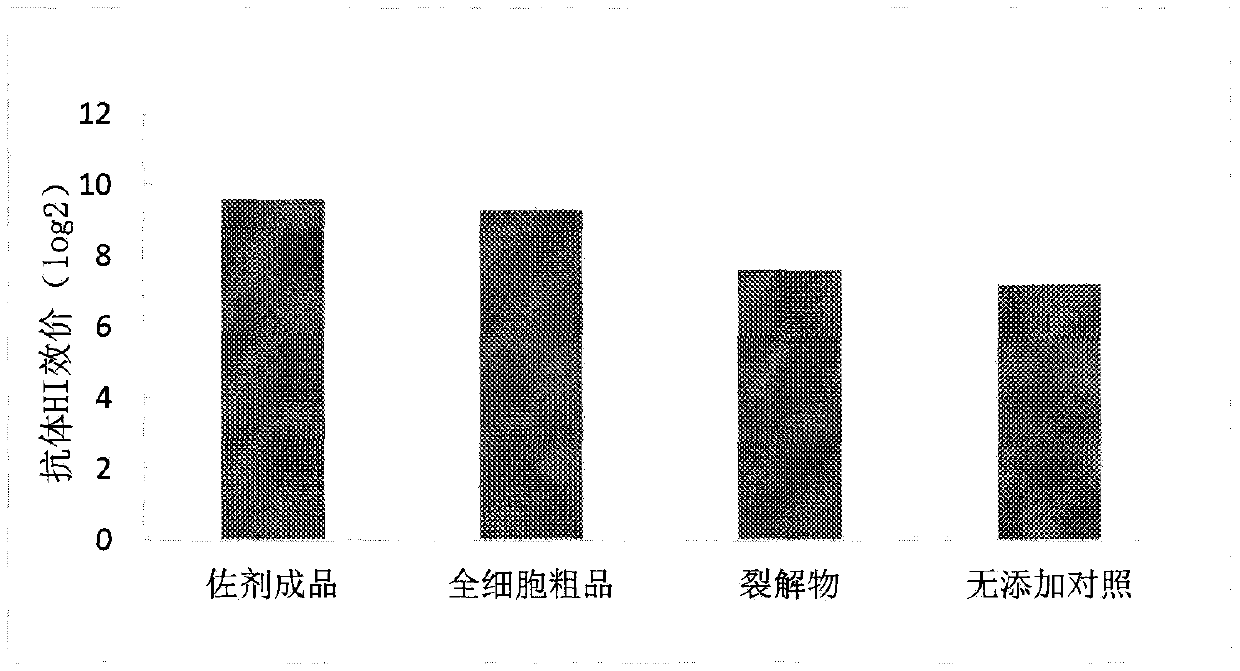

Rhodococcus ruber fermentation method and application thereof as adjuvant in animal vaccines

ActiveCN109666609AUnusual humoral immunomodulatory effectsImprove securityBacteriaMicroorganism based processesAdjuvantAnimals vaccines

The invention relates to a special rhodococcus ruber (CGMCC NO. 17012) fermentation method, a preparation process of adjuvants with different dosage forms and an application as an adjuvant in animalvaccines. Rhodococcus ruber strains are separated from a farm and obtained through single colony cloning purification and identification, the invention provides a special fermentation process where the strain inactivation product is used as an animal vaccine adjuvant, and provides a preparation process of different dosage forms of adjuvants containing the strain and the product. Animal experimentsprove that when the adjuvant product is used for univalent or multivalent animal vaccines, particularly Newcastle disease inactivated vaccine, avian influenza inactivated vaccine and swine fever livevaccine, definite non-specific immune enhancement effect can be provided, specifically, the antibody peak value level induced by the animal vaccine is obviously improved, the time for producing the protective antibody level is advanced, the antibody maintenance period is prolonged, and the immune effect of the animal vaccines is enhanced.

Owner:刘春郁

Method for producing paperboards and paper tubes

InactiveCN102248562AImprove adhesionHigh compressive and flexural strengthWood compressionGrain treatmentsFiberAnimal fiber

The invention relates to a method for producing paperboards and paper tubes, comprising the following steps of: (1) carrying out steam blasting and fluid energy milling on plant waste materials to obtain a raw material A; (2) carrying out the steam blasting on waste and old textiles and animal fibers to obtain a raw material B; (3) preparing a sodium silicate solution with the mass concentration of 12-15% to obtain a raw material C; (4) uniformly mixing the raw material A with the mass percent of 84-86%, the raw material B with the mass percent of 6-9%, the raw material C with the mass percent of 6-8% and thermosetting resin with the mass percent of 0-4%, putting the mixture into a paper pressing machine to prepare the paperboards and the paper tubes; and (5) carrying out air drying and curing on the obtained paperboards and paper tubes or curing by adopting a drying machine or a blast blower. The invention has the advantages that: process is simple, raw materials are available; manpower and energy are saved, production efficiency is improved, production cost is reduced; and the obtained paperboards and the paper tubes have good and stable quality, thus the method is applicable topopularization and application and is environment-friendly for papermaking.

Owner:强光初

Five-colour handicraft decoration, spray-drawing and oil-painting cloth and making technology

InactiveCN101070039ABright colorSimple manufacturing processArtist's paintsPaperhangingCotton gauzePolymer science

The invention discloses the colorful decoration, jet drawing, canvas and their preparation technologies. The process canvas takes cotton gauze as substrate and coats setting colored slurry layer and setting mucilage layer on them in turn. The technology contains the following steps: (1) mix colorful slurry: mix white emulsion and talc in proportion, add lithopone, defoamer, multi-functional industry promoter and graining paste and stir then uniformly. Add some specific gravity of graining paste to get colorful slurry. (2) Mix mucilage: mix white emulsion and water, add some proportion of colorful plates and stir uniformly. (3) Coat the two mixed slurries onto the cotton gauze uniformly by a coater to prepare the process canvas. Complete high temperature setting by using the coater under 100-200 degree C. The two mixed slurries can accrete on the cotton gauze uniformly by the three sizing processes. The products are colorful technology canvas, which have bright and colorful exteriors. The products processed by the special technology are uneasy to decolor.

Owner:郑仕清

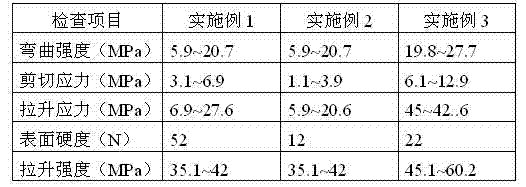

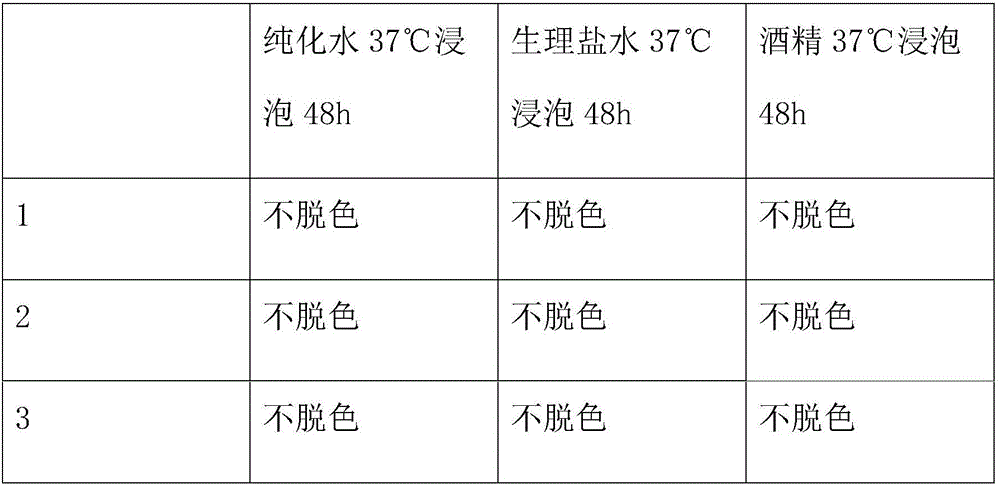

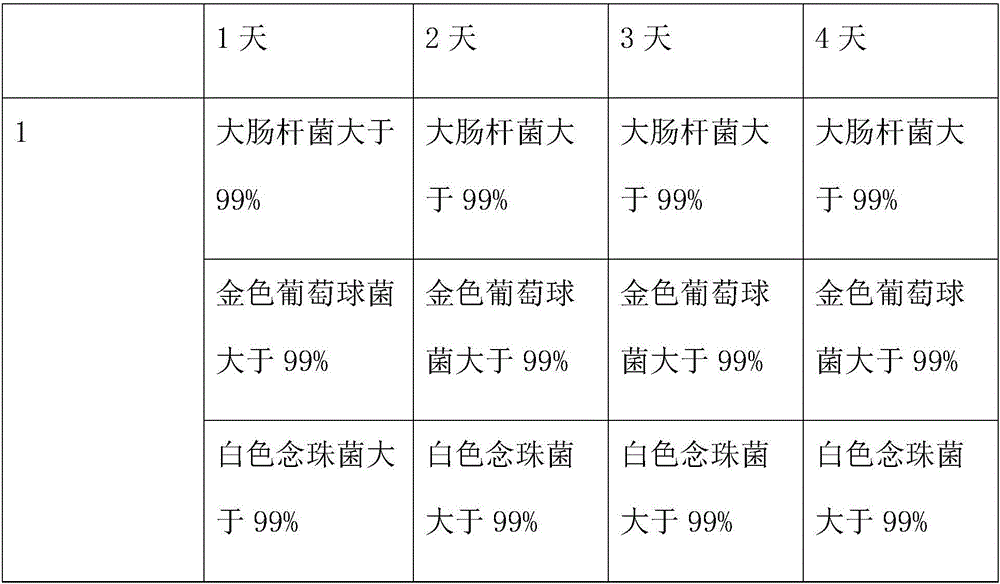

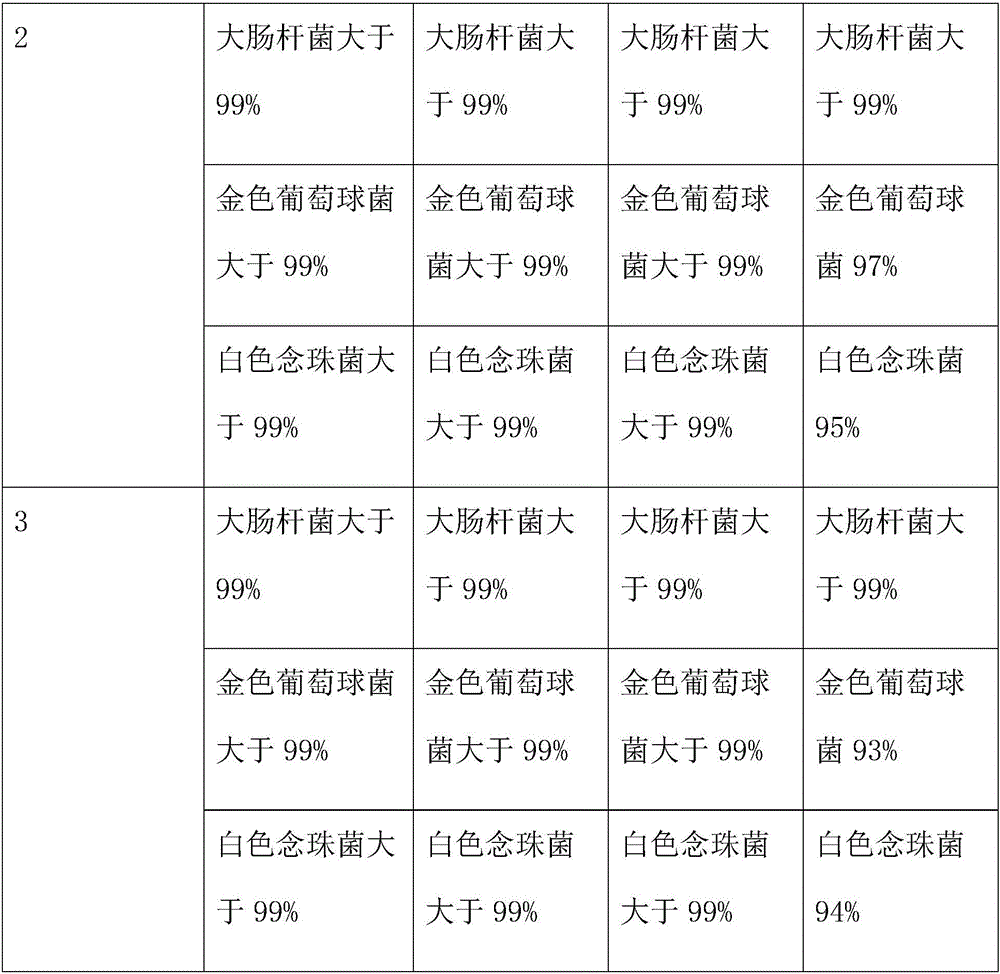

Functional medical dressing and preparation method thereof

InactiveCN106421873ANot easy to decolorizeGood antibacterial effectBiochemical fibre treatmentAbsorbent padsCobalt-60Polymer science

A functional medical dressing and a preparation method thereof are provided; a multi-amino monomer is cooled with ice-water bath, a vinyl monomer and a solvent are dropwise added into the multi-amino monomer under the protection of nitrogen by using a dropper, reacting is allowed for 4 hours after dropwise adding to generate a light yellow intermediate, and the intermediate is placed on a rotary evaporator to remove the solvent under reduced pressure and is heated and depressurized to obtain multi-amino hyperbranched polymer; a modifier is added to the multi-amino hyperbranched polymer, and heating and depressurizing are performed to obtain closed spatial network structural polyamide tree-like macromolecular polymer; silver ion compound solution is added to the closed spatial network structural polyamide tree-like macromolecular polymer solution to complex-reduce the polymer to obtain stable nano silver solution; rolled pure-cotton nonwoven or degreased gauze is passed through an immersion tank holding the above nano silver solution, and is then subjected to padding, hot blast drying, cutting, packaging and cobalt 60 irradiation sterilization to obtain the medical dressing.

Owner:长沙海润生物技术有限公司

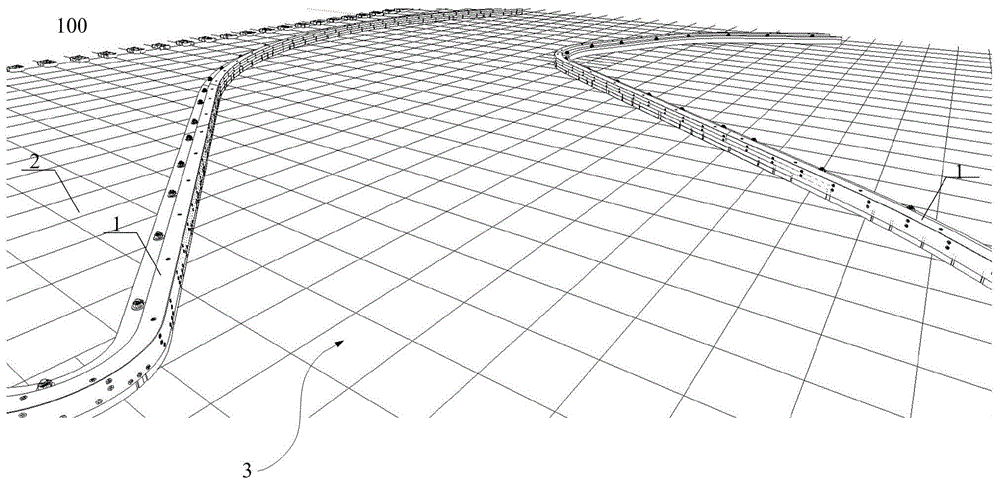

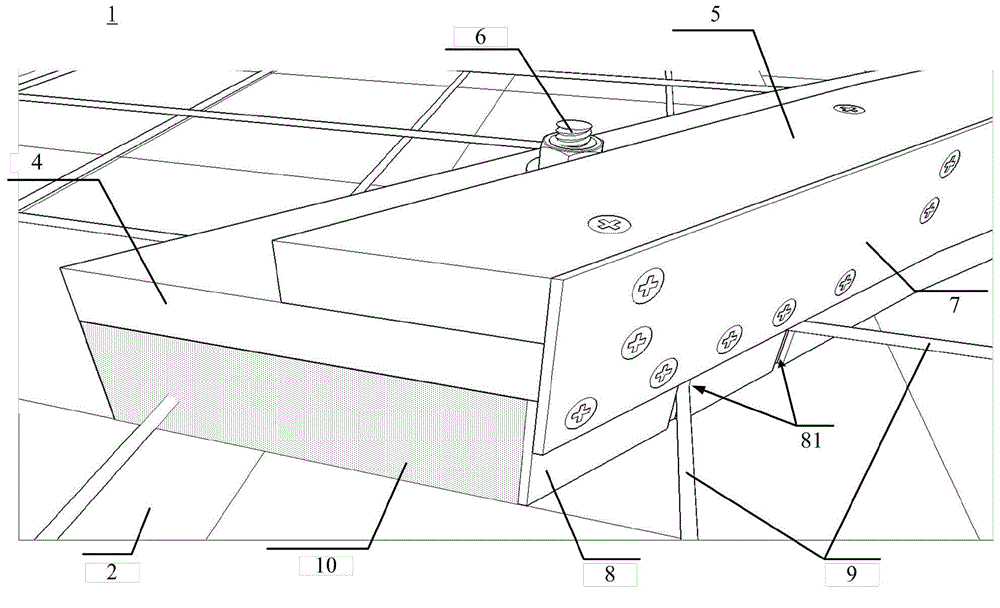

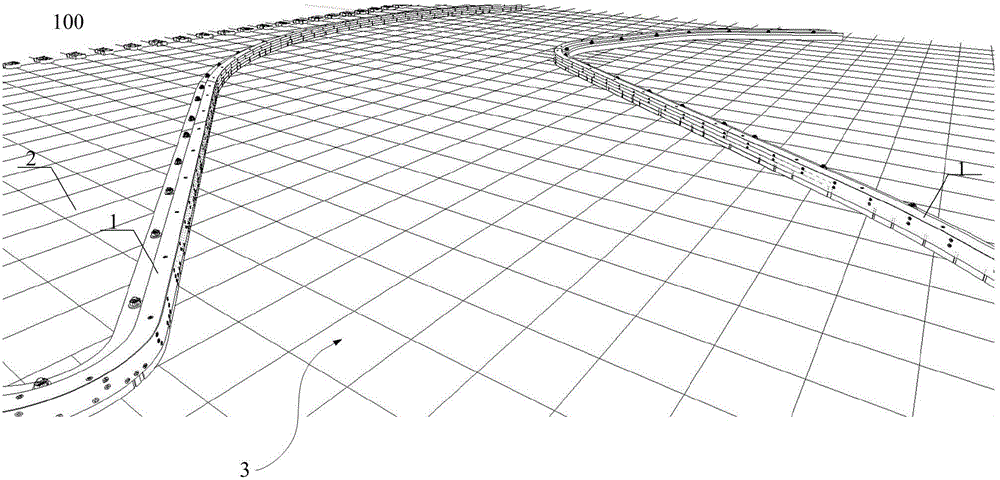

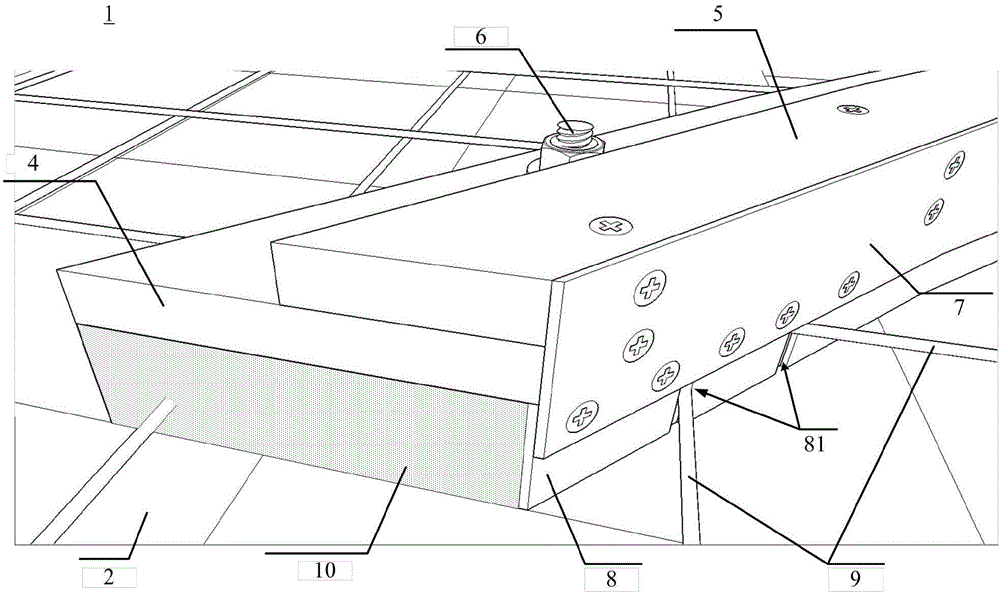

Concrete, pathway terrace and template system and construction method

ActiveCN104829198AImprove flatnessPrevent discolorationIn situ pavingsRoads maintainenceLow noiseSurface layer

The invention provides a concrete, pathway terrace and template system and a construction method, aiming at solving a series of problems in the prior art that a pathway terrace cannot meet ultra-flat, ultra-hard, anti-sliding, low-noise and de-coloring requirements and the like. A concrete formula used in the pathway terrace is improved so that the problem that the early strength of the concrete of the pathway terrace is low is solved, a bleeding phenomenon in an initial set process of the concrete of the pathway terrace is avoided, and the deformation degree of the concrete pathway terrace is controlled. Meanwhile, the whole strength of the concrete of the pathway terrace is greatly improved, and the ultra-hard and wear-resisting use function requirements of the pathway terrace are met. A concrete construction process is improved, a special ultra-flat pathway terrace system is developed, and the high flatness can be kept when the pouring of the pathway terrace is finished, so that the ultra-flat target is realized. Furthermore, the concrete formula is further improved and the decoration effect is improved; and colored concrete is used for pouring the pathway terrace, so that the de-coloring problem does not occur even if the terrace is abraded. Meanwhile, a surface layer is arranged on the surface of the concrete terrace, so that the ultra-hard and wear-resisting effects are enhanced, and the anti-sliding and low-noise effects are realized.

Owner:SHANGHAI BUILDING DECORATION ENG GRP

Concrete

The invention provides concrete for a track terrace, and the concrete is used for solving a series of problems that the track terrace can not meet the requirements for excessive flatness, excessive hardness, decoloring and the like in the prior art. The concrete comprises the following components in percentage by weight: 10%-25% of terrace cement, 30%-40% of sand, 35%-50% of gravels, 5%-10% of water, 0.15%-0.7% of high-efficiency water reducing agents and 0.005%-0.015% of fibers. The concrete provided by the invention can be used for solving the problem of low early strength of track terrace concrete by improving a concrete formula, preventing the track terrace from generating the phenomenon of water bleeding in the initial congealing process of the concrete and controlling the deformation degree of the concrete track terrace and meets the requirements for using functions of excessive hardness and abrasion resistance of the track terrace through the great enhancement of the integral strength of the concrete.

Owner:SHANGHAI BUILDING DECORATION ENG GRP

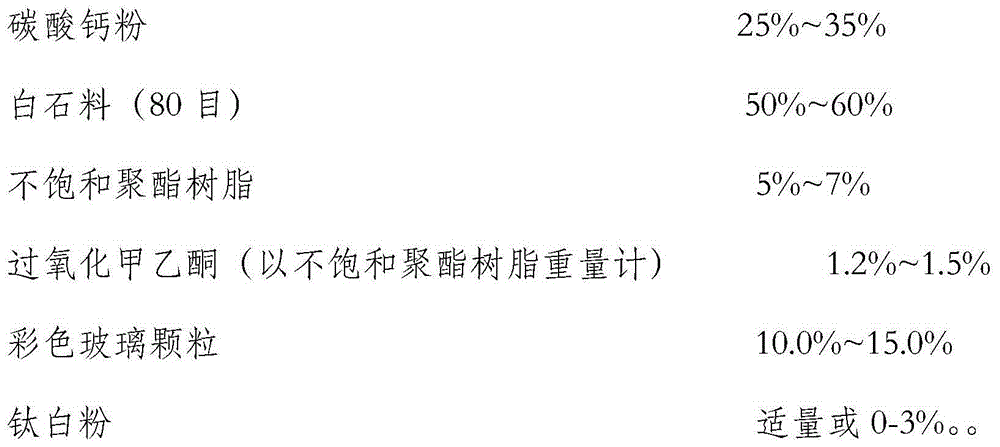

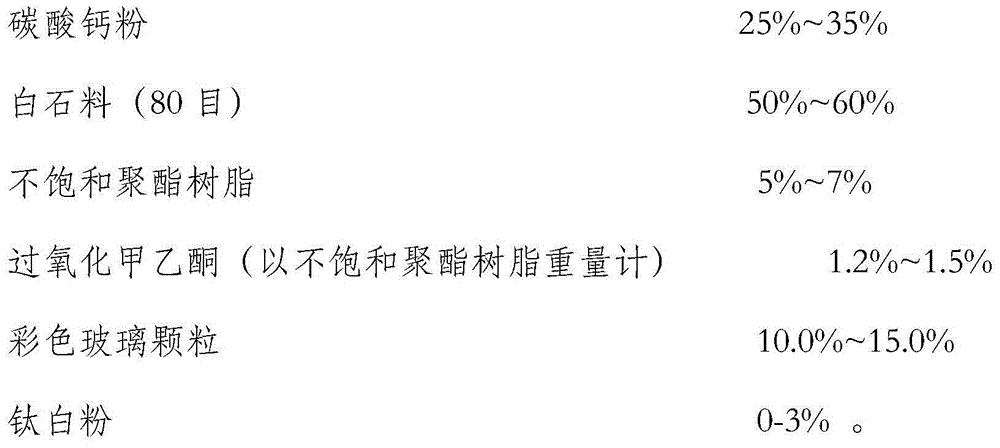

Preparation method of artificial stone from colored glass particles

The invention relates to a preparation method of artificial stone from colored glass particles. The preparation method comprises the steps: (1) uniformly stirring an adhesive, a curing agent, additives and glass particles together in a stirrer; (2) adding flashlight powder or luminescent phosphors into glass particles wetted in the step (1), enabling the flashlight powder or the luminescent phosphors to cover the glass particles, and curing the glass particles coated with the flashlight powder or the luminescent phosphor for 3 to 4 hours at the room temperature to obtain the colored glass particles; and (3) optimizing the colored glass particles obtained in the step (2) according to a material grade-preparation principle, and producing the artificial stone. Epoxy resin and unsaturated polyester resin are mixed to be used as an adhesive, so that the product is good in cohesive force and flexibility; the color is bright and glisters; the decorative effect is good; moreover, the method is low in cost, simple and easy, easy for massive preparation and wide in application prospect in the field of building materials.

Owner:GUANGXI LISHENG STONE CO LTD

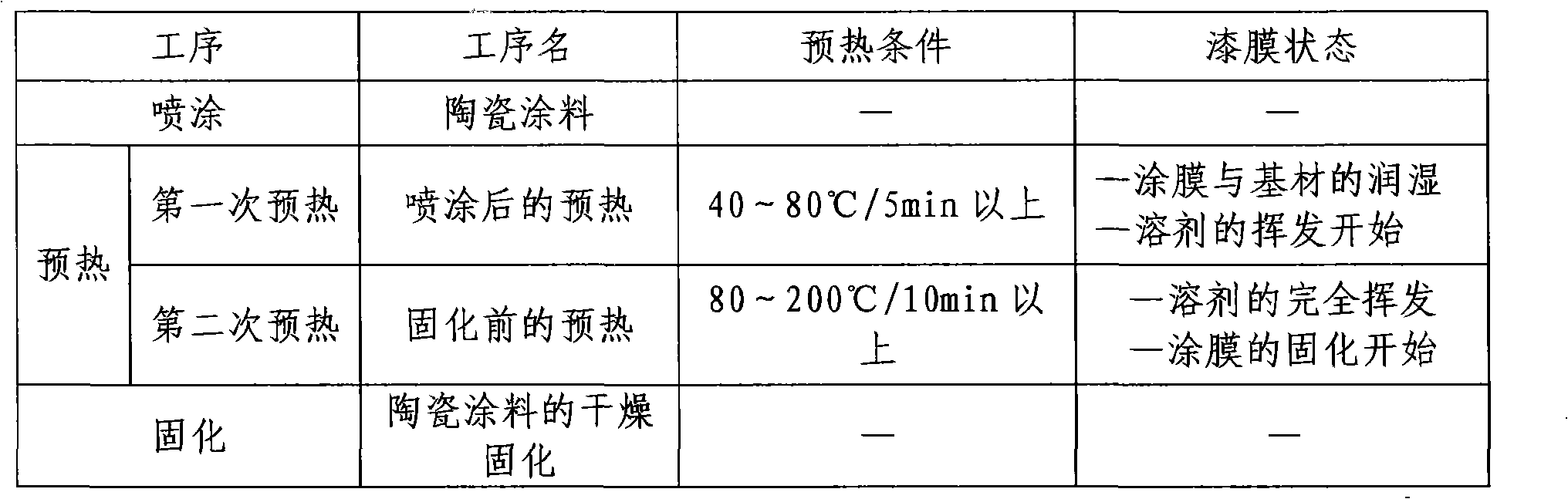

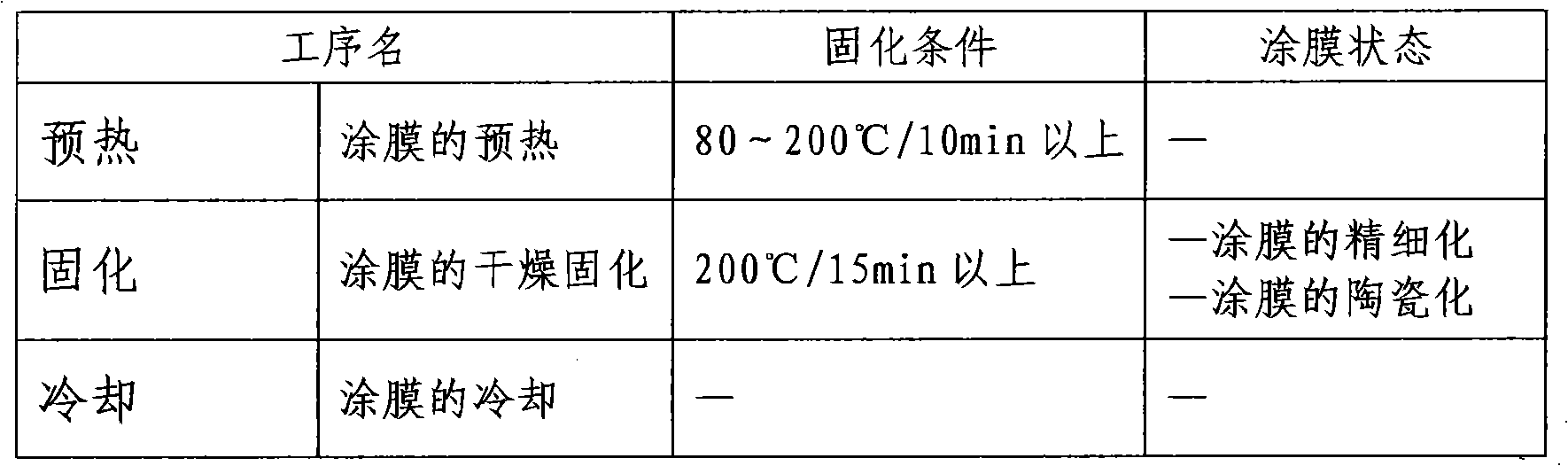

Surface treating method of electric iron metal base plate

InactiveCN101288867AIncrease profitNot easy to decolorizePretreated surfacesCoatingsMachining processImpurity

The invention provides a surface disposal method for an electric iron metal soleplate, comprising the steps as follows: 1) substrate disposal: the surface of the substrate of the soleplate is treated, so as to comply with the basic requirement of spraying; 2) coating aging: the coating is sufficiently and uniformly dispersed; meanwhile, the impurities in the coating are filtrated; 3) spraying procedure: the coating is uniformly sprayed and coated on the surface of the substrate; 4) drying and cooling: the sprayed product is dried and cooled. The method of the invention effectively reduces the times of surface spraying in the production process, reduces the consumption in the practical production process, greatly reduces the complexity of the process in the whole machining process, thus improving the utilization ratio of the whole resource and improving the production efficiency and the comprehensive performance of the products. The method has uniform surface spraying, high temperature resistance and wearability of the oxide film and difficult decoloration, and contains no heavy metals, thus having simple technical process, low fabrication expense and low loss in the machining process.

Owner:MIDEA GRP CO LTD

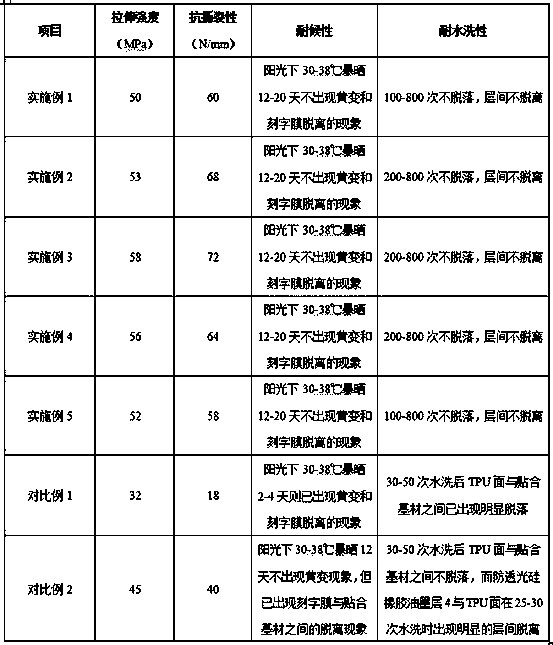

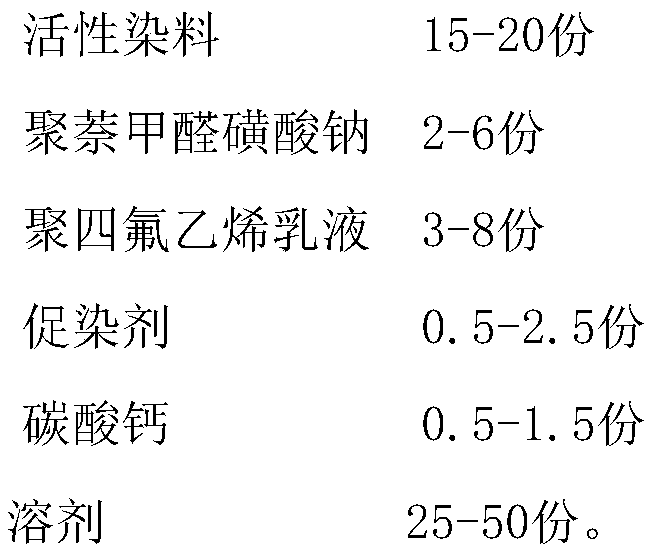

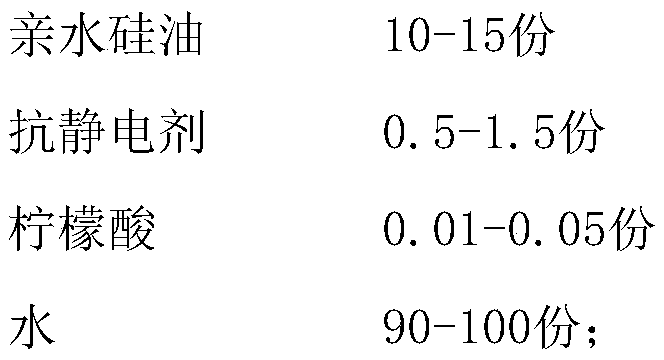

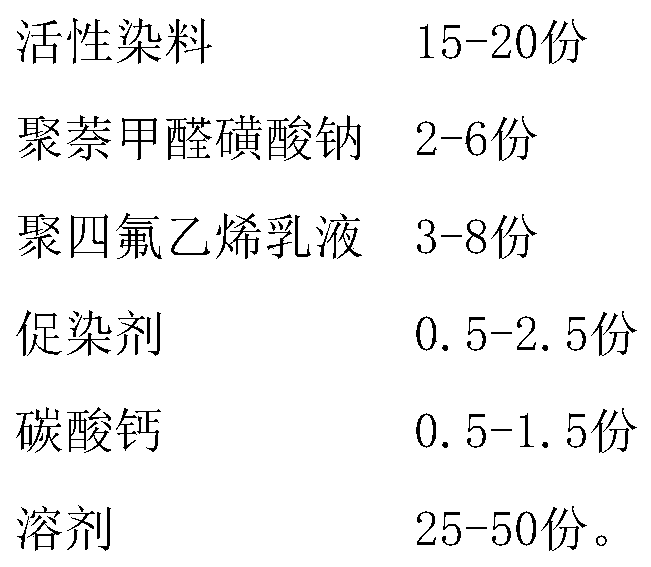

High-elasticity silicone rubber lettering film and preparation method and application method thereof

ActiveCN108610997AIncrease elasticityAvoid deformationPolyureas/polyurethane adhesivesInksRubber materialPolymer science

The invention relates to the technical field of thermal transfer printing lettering film, and in particular, relates to a high-elasticity silicone rubber lettering film and a preparation method and anapplication method thereof. The high-elasticity silicone rubber lettering film comprises a load-bearing substrate, a release layer, a surface layer silicone rubber ink layer, an anti-photopermeable silicone rubber ink layer, an adhesive interfacial agent layer and a TPU hot melt adhesive film which are connected from bottom to top successively; the adhesive interfacial agent layer is prepared from an adhesive interfacial agent, and the adhesive interfacial agent is an adhesive interfacial agent containing dual-resin components. The silicone rubber lettering film has the advantages of both thesilicone rubber material and the TPU material, has good elasticity, tearing strength, weatherability, yellowing resistance, water washing resistance and other comprehensive properties, has layers noteasy to separate, is not easy to discolor or fade by sunlight exposure, and has the water-washing fading rate not less than 0.5%, is not easy to dye when being mixed and washed with materials with other colors, and is high in stability, easy to bond with a variety of materials, high in bonding strength, not easy to peel off, good in stability, delicate in hand feeling, good in aesthetic degree, and long in service life.

Owner:卢汉军

Fabric with low washing shrinkage rate and preparation process thereof

ActiveCN110774683AImprove wearing comfortGood skin affinitySynthetic resin layered productsGrip property fibresYarnPolymer science

The invention relates to the technical field of clothing fabrics, in particular to a fabric with low washing shrinkage rate and a preparation process thereof. The fabric is formed by weaving of a composite yarn, the composite yarn is formed by laminating a surface yarn, an elastic fiber yarn and a bottom yarn, after lamination shaping, the surface yarn forms a surface layer, the elastic fiber yarnforms an elastic middle layer, and the bottom yarn forms a base layer; the surface yarn is unshrinkable wool fiber with a metric number of 1 / 80Nm-1 / 60Nm and a count of 90S; the elastic fiber yarn islow-temperature spandex with Denier of 30-60D; and the base yarn is polypropylene fiber with Denier of 45-75D and a hole count of 45-75F. By adopting the three yarn fibers for blending weaving, the prepared fabric includes three sequentially formed yarn layers, and the middle layer has elasticity, thus improving the wearing comfort and skin friendliness of the fabric, and the fabric has the functions of environmental protection, warmth retention, machine washability, no ironing and the like, does not generate stuffiness and skin-sticky feel, is comfortable to wear, and low in washing shrinkagerate.

Owner:DONGGUAN SENLIN TEXTILE LTD

Fore-edge transfer printing method

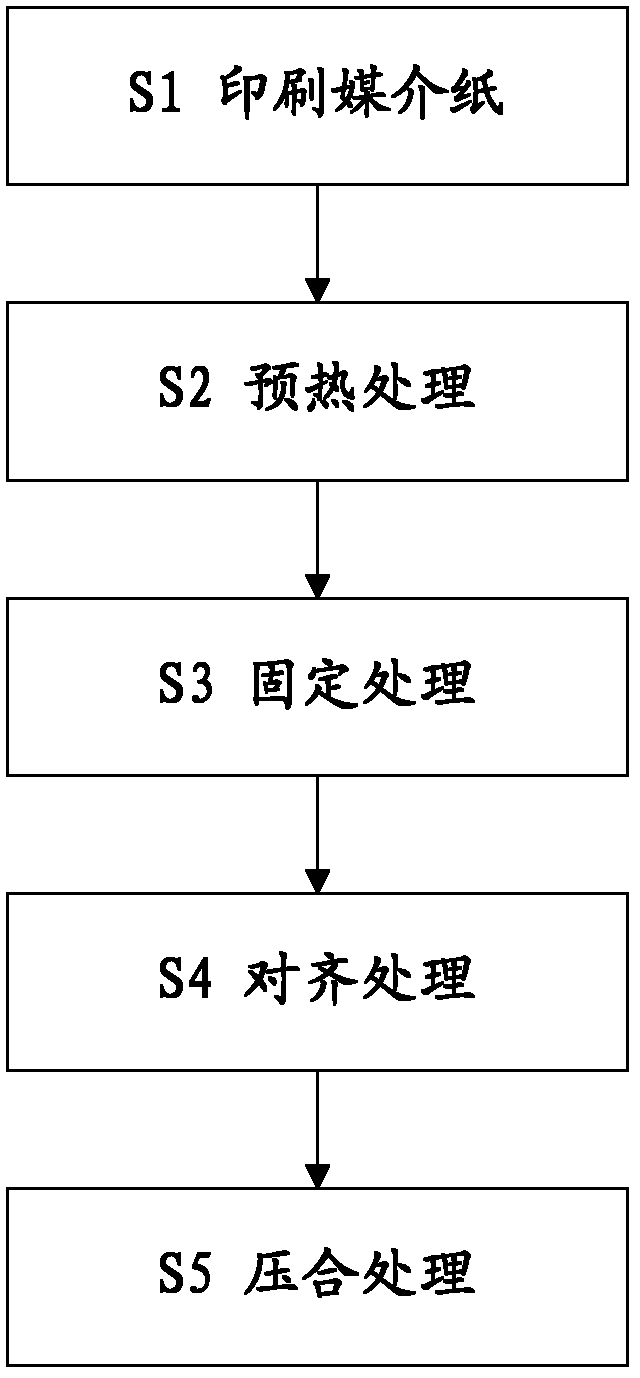

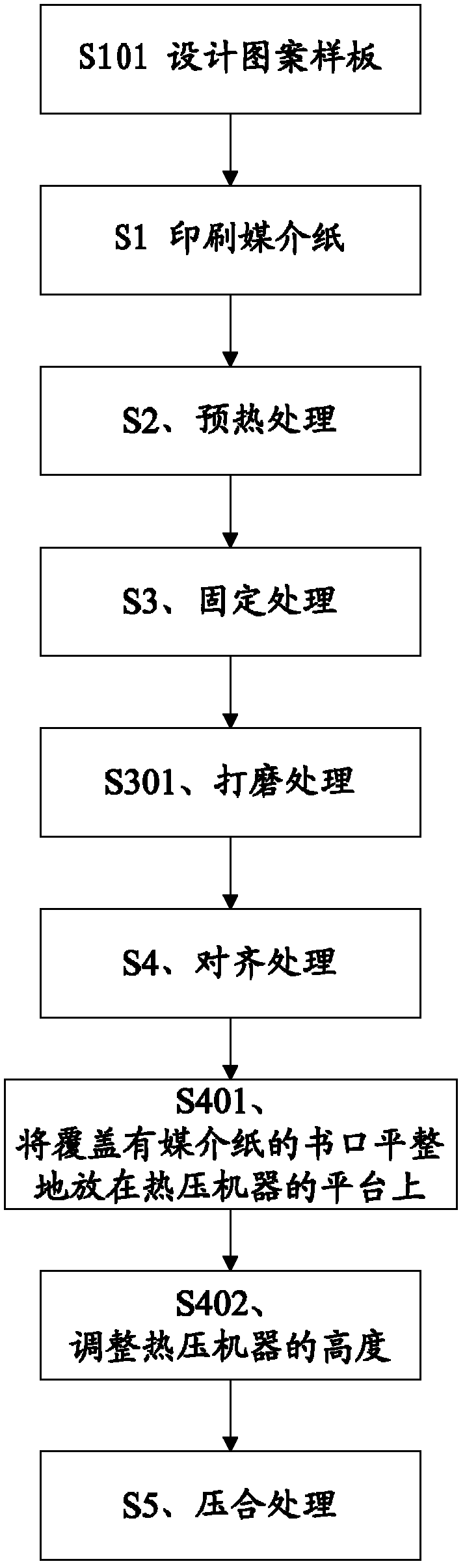

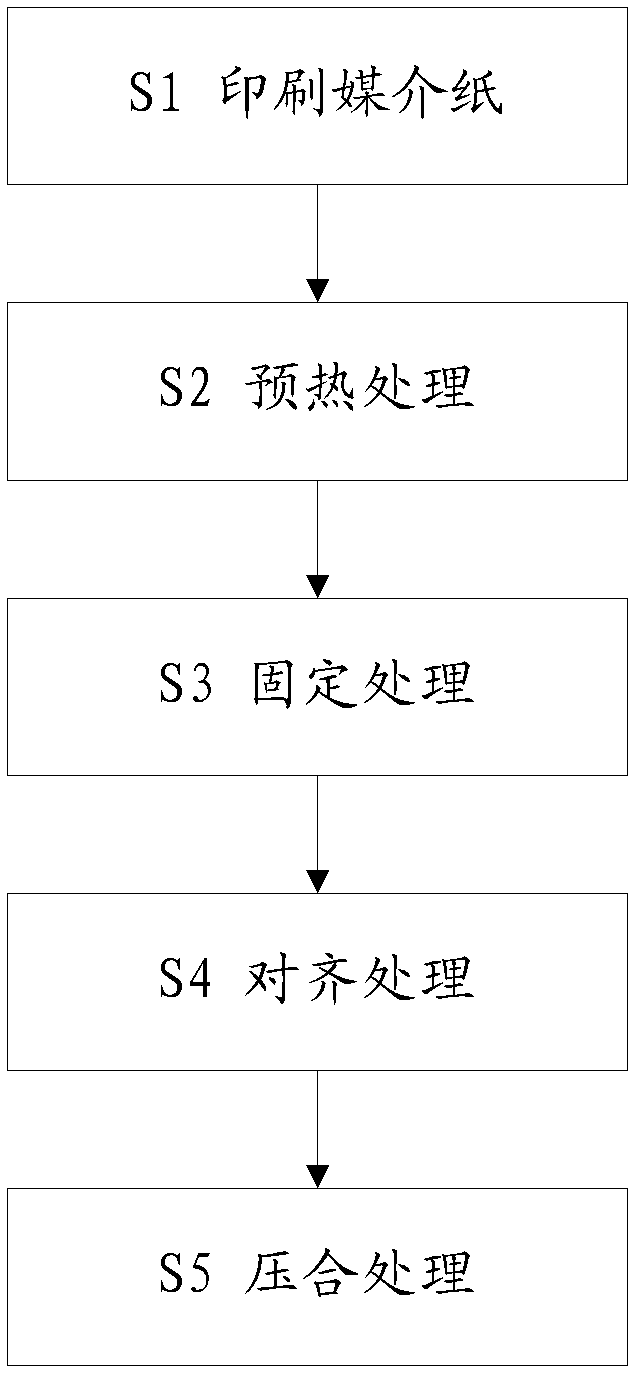

InactiveCN102501671AImprove printing qualityImprove printing effectDuplicating/marking methodsPattern printingPrinting inkEngineering

The invention discloses a fore-edge transfer printing method, which comprises the following steps: S1, printing media paper: printing ink patterns on the media paper; S2, preheating treatment: performing the preheating treatment on a pressing plate of a hot press; S3, fixing treatment: fixing a book by using a fixture; S4, aligning treatment: aligning the layout of the media paper in the step S1, on which the ink patterns are printed, with a fore-edge face, and covering on a fore-edge; and S5, laminating treatment: laminating the media paper and the fore-edge by the preheated pressing plate to enable the ink patterns printed on the media paper to be transferred to the fore-edge. The production efficiency of fore-edge printing is greatly improved, the printing cost is saved, and the printing quality is improved.

Owner:DONGGUAN DANGNA PRINTING CO LTD

Cosmetics pigment composition containing safflower natural pigment extract and preparation method thereof

ActiveCN103446020AImprove thermal stabilitySimple preparation processCosmetic preparationsMake-upLipstickPigment composition

The invention discloses a cosmetics pigment composition containing a safflower natural pigment extract and a preparation method thereof. The cosmetics pigment composition containing a safflower natural pigment extract comprises a water-phase component and an oil-phase component, wherein the water-phase component comprises distilled water, safflower natural pigment, coloring agent powder and a water-soluble liquid nonionic emulsifier with HLB value of greater than 7; the oil-phase component comprises an oil-soluble liquid nonionic emulsifier with HLB value of less than 7, liquid grease and a preservative. The preparation method comprises the following steps: preparing the safflower natural pigment before the water-phase component and oil-phase component; and adding the oil-phase component into the water-phase component and stirring uniformly to obtain the cosmetics pigment composition containing the safflower natural pigment extract, which is natural and safe with strong coloring and covering ability, low irritation, bright color and adjustable color as well as an antioxidant function; moreover, the preparation technology is simple and feasible, and the cosmetics pigment composition is suitable for the cosmetics pigment such as lipstick.

Owner:广州市魅卡化妆品有限公司

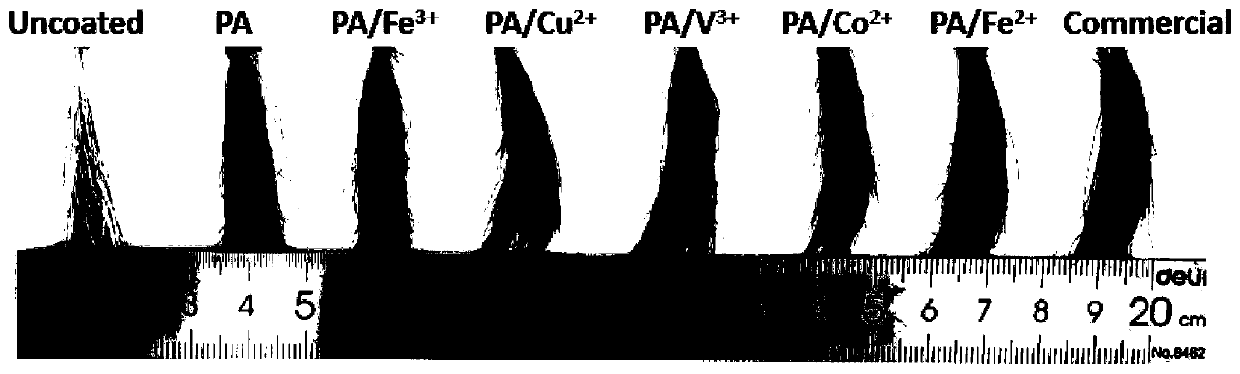

Circulating hair dyeing method based on metal-polyphenol network structure

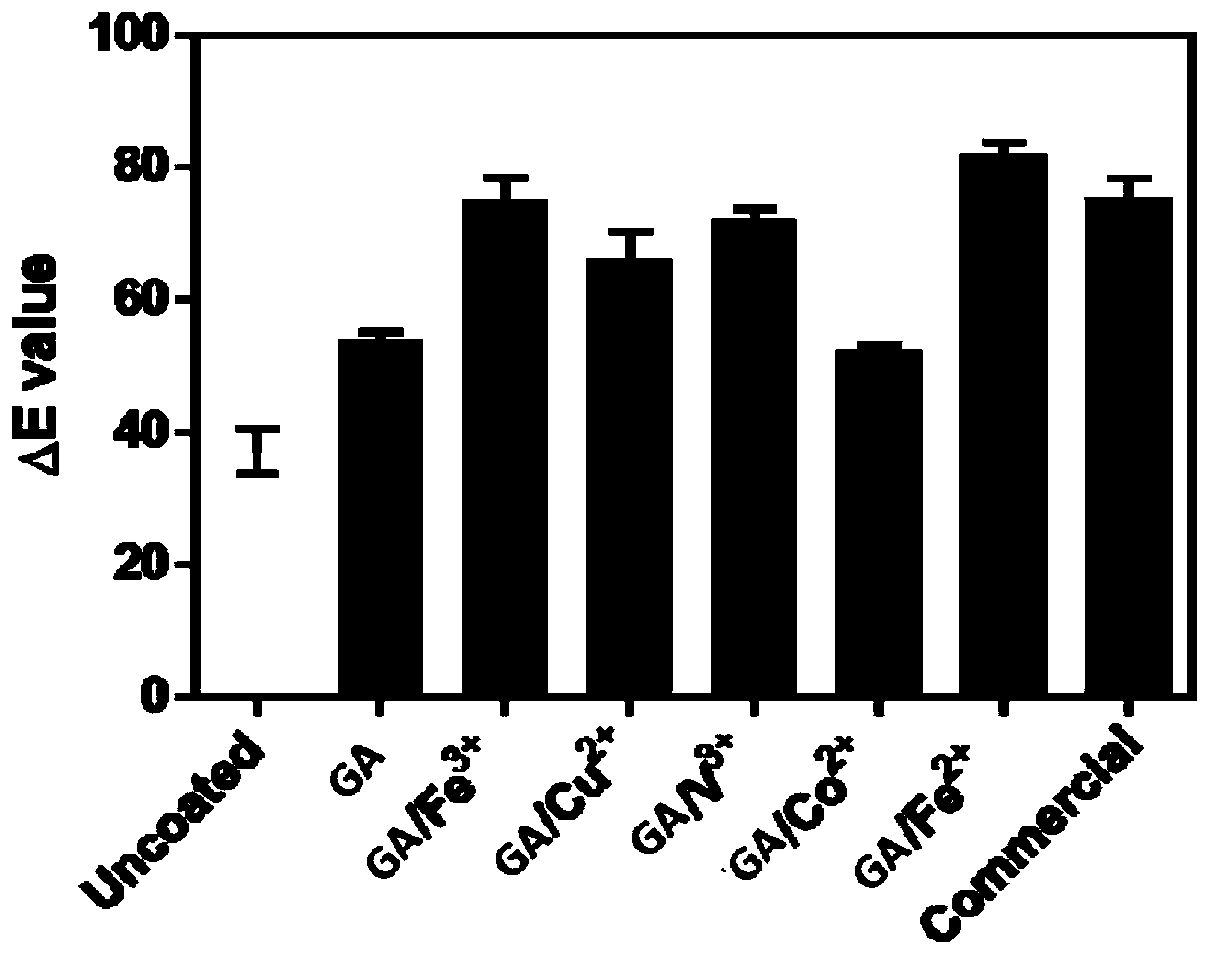

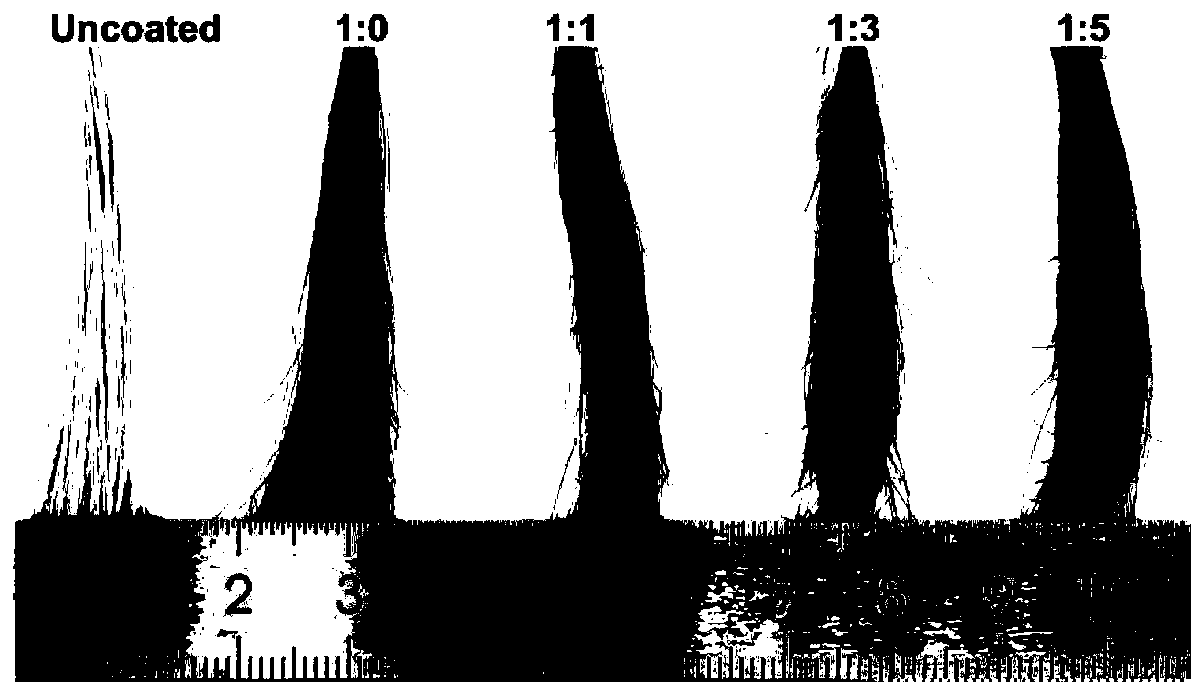

InactiveCN110840763ANot easy to decolorizeImprove use valueCosmetic preparationsHair cosmeticsMacromolecular SubstancesPolymer chemistry

The invention relates to a circulating hair dyeing method based on a metal-polyphenol network structure. Small-molecule plant polyphenol is adopted to form the metal-polyphenol network structure withmetal ions inside hair so as to develop color. According to the dyeing method disclosed by the invention, small molecules are used as raw materials, thus, under the condition that hair scales are notdamaged, the small molecules penetrate into a cortex layer and form a strong adhesive color development coating on the surface of hair, the hair is better protected, and the hair is prevented from being damaged again. The metal ions and polyphenols are polymerized in the hair, macromolecular substances are not easy to diffuse, the dyeing is firm, and the method has the advantages of washing resistance and difficulty in decolorization when the hair meets water at room temperature.

Owner:SHANDONG UNIV

Dyeing process of jeans fabric

InactiveCN102561073AImprove dye uptakeEvenly distributedDyeing processSodium bicarbonateColour fastness

The invention provides a dyeing process of a jeans fabric. The dyeing process comprises the following steps of fabric pretreatment, dyeing at a raised temperature, soaping, rinsing and drying and specifically comprises the steps of: subjecting a dyeing solution to ultrasonic pretreatment for 10-50min before the dyeing at the raised temperature; raising the temperature to 80-120 DEG C, and putting a fabric into the dyeing solution for dyeing, wherein the dyeing time is controlled within 50-80min; soaping the fabric to fix the color; repeating the dyeing step 2-5 times; drying the fabric; soaking the fabric in an active-carbon-doped sodium bicarbonate solution for 4-10h; and soaping, rinsing and drying the fabric to complete the dyeing. According to the invention, as the dyeing solution is subjected to ultrasonic pretreatment before the dyeing, dye-pickup of the fabric is increased, and the obtained color is good, and has a high fasteness; as the step of soaking the fabric in the sodium bicarbonate solution is added before the soaping, color of the fabric can be stabilized, and molecules which are not dyed firmly are adsorbed; and moreover the fabric prepared by the steps of soaping, rinsing and drying has high dyefastness, and is not easy to fade during the cleaning.

Owner:潘雪峰

Antistatic surface tensile-shear thick needle single faced flannelette and production method thereof

InactiveCN102965805ASoft and comfortableRich in colorWeft knittingHeating/cooling textile fabricsYarnPulp and paper industry

The invention discloses antistatic surface tensile-shear thick needle single faced flannelette and a production method thereof. The thick needle single faced flannelette comprises surface yarns and bottom yarns, wherein the surface yarns are knitted by 900D / 768F terylene, the 900D / 768F terylene is twisted by 30% of common terylene and 70% of cation modified terylene in the draw texturing process, the bottom yarns are knitted by 150D / 48F terylene, the surface yarns and the bottom yarns are inter-looped, grey fabric knitted by the surface yarns and the bottom yarns is subjected to dyeing and drying, and the surface of the fabric is subjected to tensile and shearing treatment and the antistatic treatment, so that the thick needle single faced flannelette with rough style and soft and comfortable handfeel is formed.

Owner:JIANGSU SHENGLI ENTERPRISE

Liquid eyelash grower

InactiveCN102860964APromote growthNon-irritatingCosmetic preparationsMake-upParaffin waxVegetable oil

The invention relates to a liquid eyelash grower. The liquid eyelash grower is prepared from the following components in parts by weight: 60-80 parts of vegetable oil, 3-5 parts of lanum, 5-10 parts of pigment, 0.5-1.5 parts of collagen, and 0.6-1.5 parts of vitamin E. The vegetable oil is castor oil or olive oil, and the pigment is carbon black or iron oxide brown. The liquid eyelash grower provided by the invention takes the natural vegetable oil as the main component, and is added with the components of the collagen, the vitamin E and the like to nourish eyelashes and promote the growth of the eyelashes. Moreover, the liquid eyelash grower takes the lanum to replace materials such as paraffin was, bee wax and the like, so that the liquid eyelash grower can both nourish eyelashes and make the eyelashes elastic and resist the ultraviolet irradiation. The components of the liquid eyelash grower is harmless and nonirritant, firm and uniform in coloring, hard to decolour, and convenient to use.

Owner:SUZHOU GULI BIOTECH

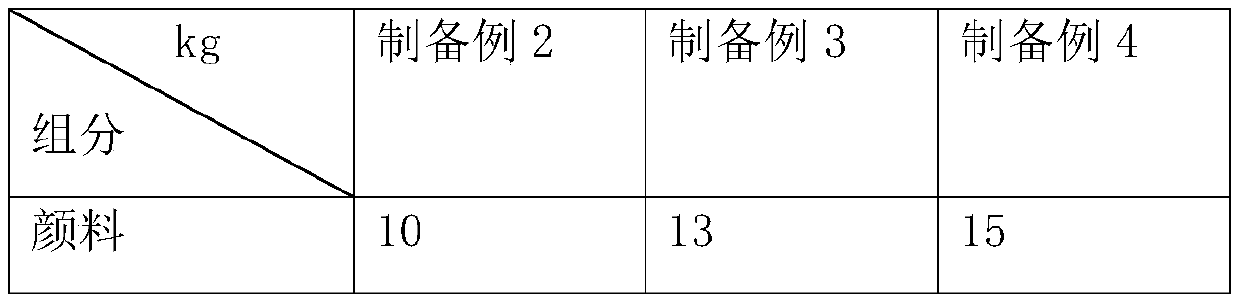

Environmental-friendly printing ink containing plant adhesive and preparation method thereof

The invention discloses environmental-friendly printing ink containing a plant adhesive, and relates to the technical field of printing. The environmental-friendly printing ink is prepared from the following raw materials: 250 to 260 parts of waterborne polyurethane emulsion, 3 to 5 parts of pigment, 2 to 4 parts of antifoaming agent, 5 to 7 parts of dispersing agent, 6 to 8 parts of polyethylene wax, 8 to 10 parts of mineral oil, 5 to 7 parts of drying agent, 40 to 50 parts of water, 2 to 4 parts of tung oil, 5 to 7 parts of linseed oil, 15 to 25 parts of starch glue, 15 to 25 parts of abietate, 20 to 30 parts of ethyl alcohol, 10 to 20 parts of Aloe vera gel, 6 to 8 parts of organic base modifier and 2 to 4 parts of water-resistant agent. The environmental-friendly printing ink has the beneficial effects that the printing ink adhesive prepared by the invention is reasonable in formula and simple in preparation process, and uses non-toxic and harmless raw materials; due to adding of the plant raw materials, the environmental-friendly printing ink is natural and healthy, not only ensures health, but also has effects of strong coloring and less possibility in decoloration, and has great advantages for environmental protection and healthy; the prepared ink can be applied in various fields, and is convenient for practical popularization and wide use.

Owner:ANHUI ZHIBO NEW MATERIAL TECH CO LTD

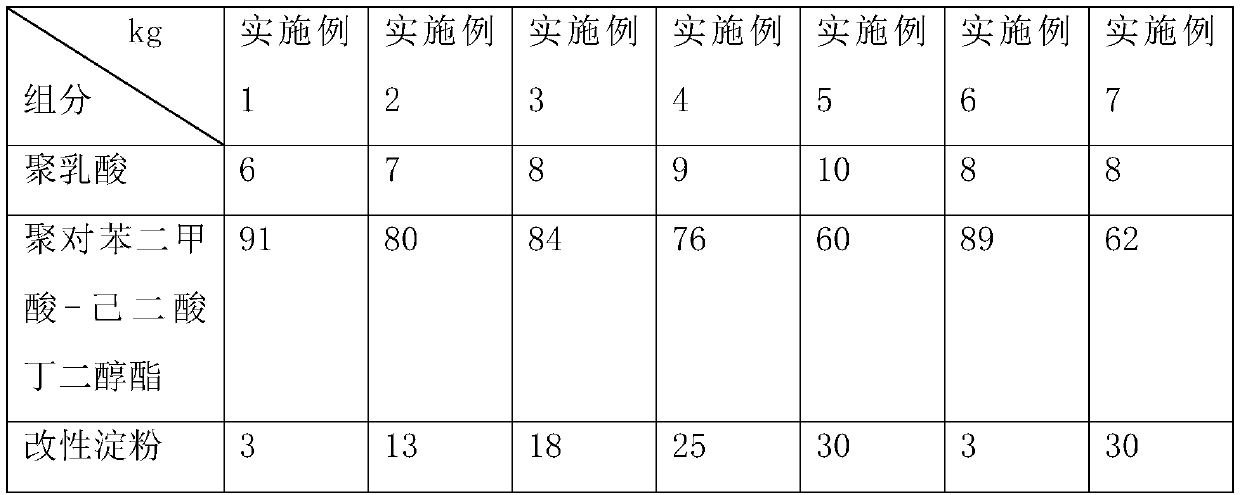

100% biodegradable garbage bag with traceable two-dimensional code identifier and production method

The invention discloses a 100% biodegradable garbage bag with a traceable two-dimensional code identifier and a production method. The 100% biodegradable garbage bag with the traceable two-dimensionalcode identifier comprises a bag body and the two-dimensional code identifier printed on the bag body, wherein the bag body comprises the following components in percentage by weight: 6-10% of polylactic acid, 60-91% of poly (butyleneadipate-co-terephthalate) and 3-30% of modified starch; and the two-dimensional code identifier is produced through soybean oil ink spraying and curing. The 100% biodegradable garbage bag with the two-dimensional code identifier has the advantages that pollution to the environment can be reduced, the 100% biodegradable garbage bag with the two-dimensional code identifier is safe and environmentally friendly, both the two-dimensional code identifier and the garbage bag body are 100% degradable, and a two-dimensional code is high in adhesion, not liable to fadeand high in traceability.

Owner:QINGDAO ZHOUSHI PLASTIC PACKAGE

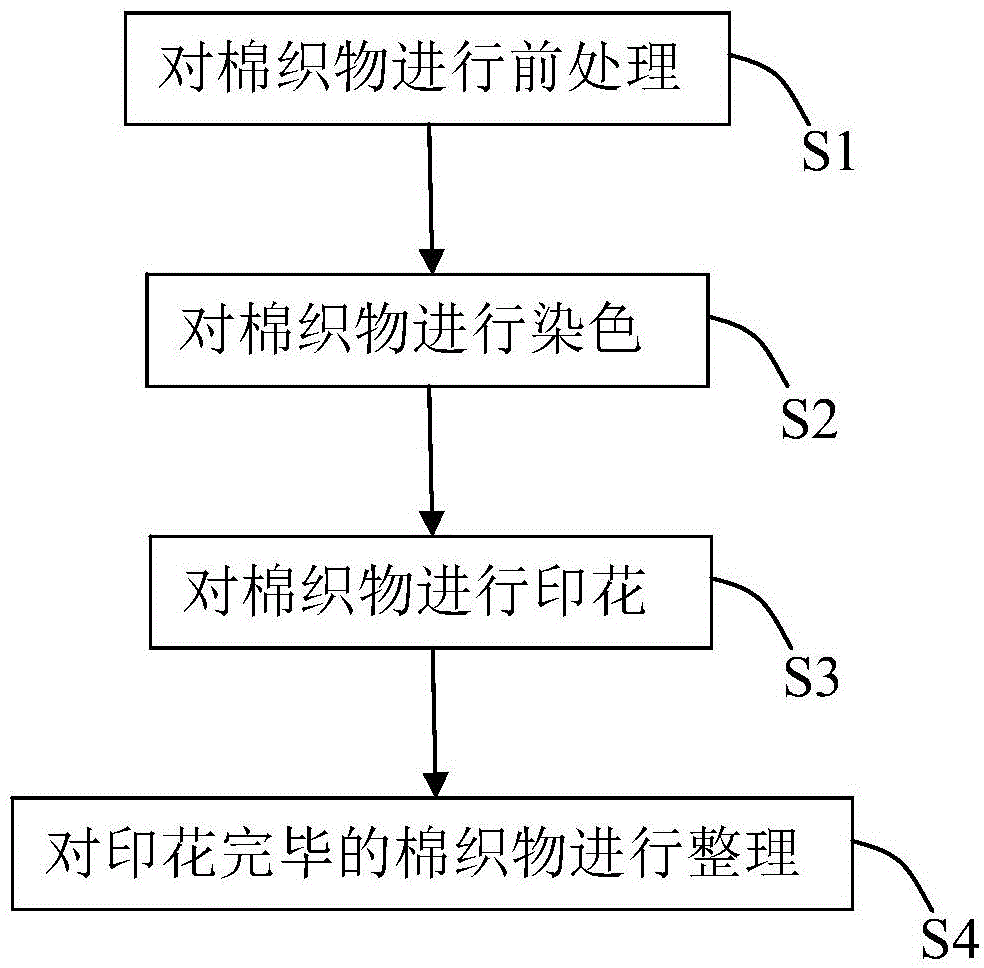

Cotton fabric printing and dyeing process

InactiveCN106320027ASimple printing and dyeing processEasy to operateBleaching apparatusDyeing processCooking & bakingEconomic benefits

The invention discloses a cotton fabric printing and dyeing process, which comprises the following steps: S1. providing a cotton fabric to be printed and dyed, and then pretreating the cotton fabric to be printed and dyed, and the pretreatment comprises singeing and neutralization of the cotton fabric to be printed and dyed, scouring and bleaching with a liquid mixture formed by sodium hydroxide and hydrogen peroxide, and tensioning of the cotton fabric to be printed and dyed for treatment with a concentrated alkali; S2. dyeing the pretreated cotton fabric to be printed and dyed, during the dyeing, dipping the cotton fabric into a first dye solution for dyeing, then sending the cotton fabric into a second dye solution for secondary dyeing, after the dyeing, washing the cotton fabric with water, soap-boiling the cotton fabric, and drying; S3. printing the dyed cotton fabric, preparing printing slurry, coating the cotton fabric with the printing slurry, baking and steaming; and S4. finishing the printed cotton fabric. The cotton fabric printing and dyeing process is simple, and the operation is convenient. The knitted fabric printed by the method has the advantages of being not easy to decolor and long in service life, and good economic benefit is obtained.

Owner:张家港市宏盛贸易有限公司

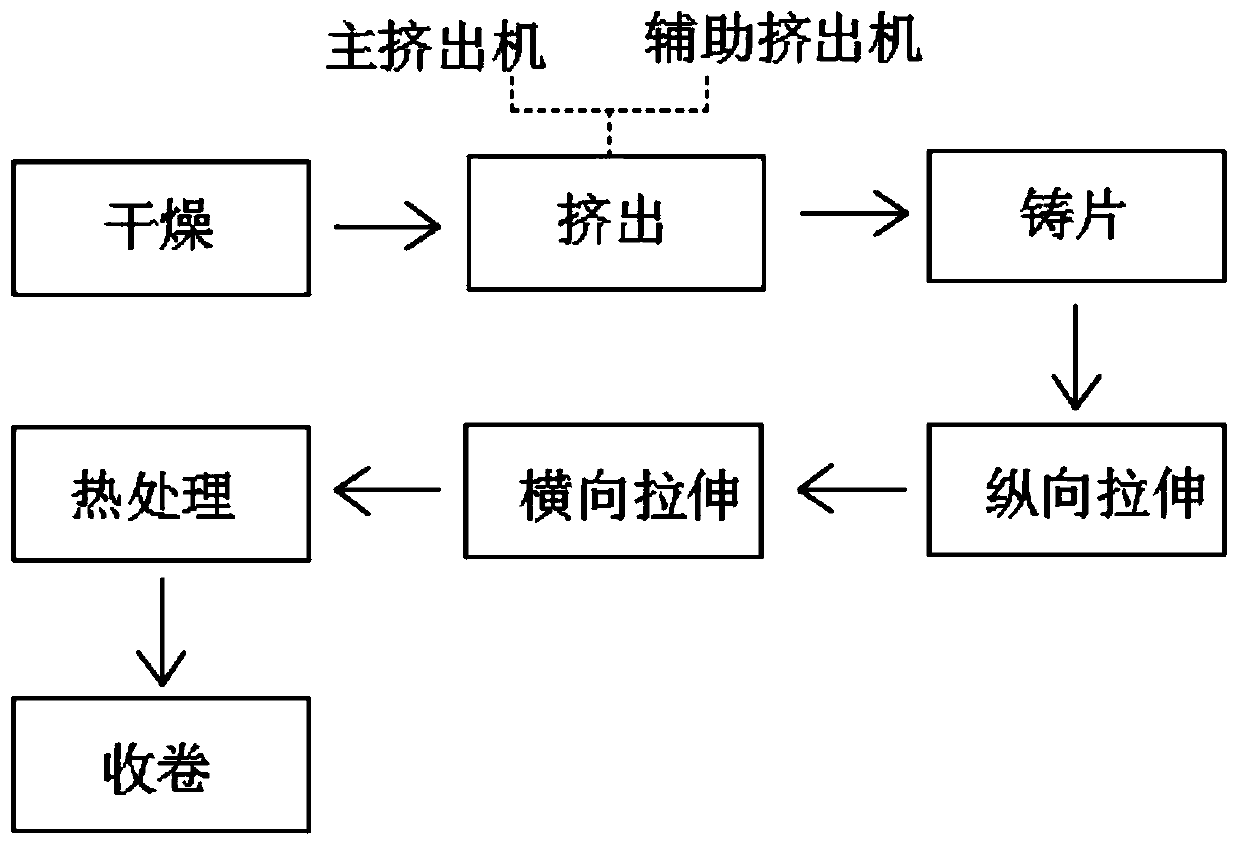

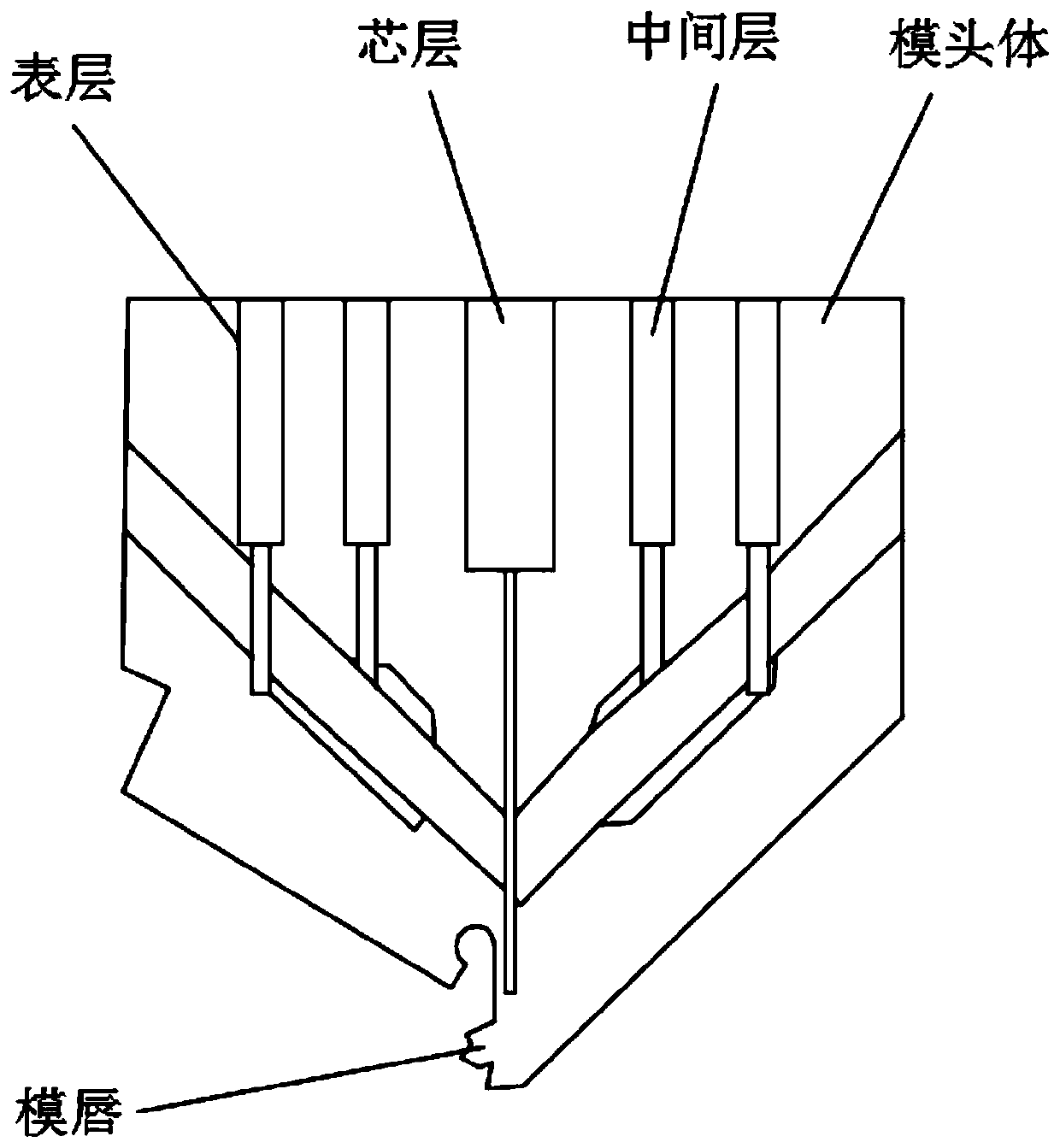

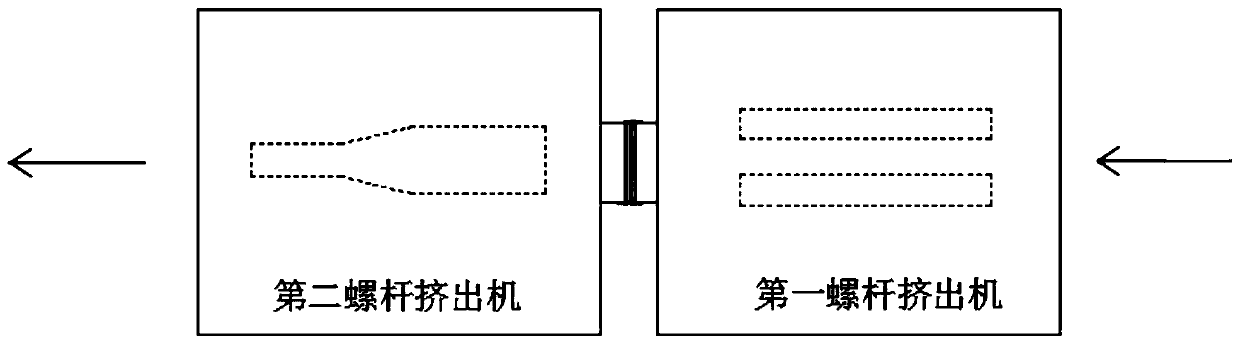

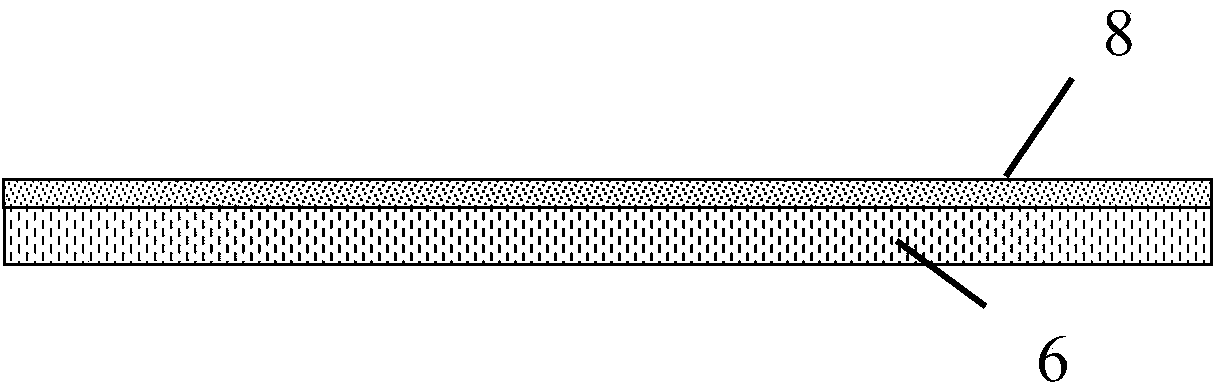

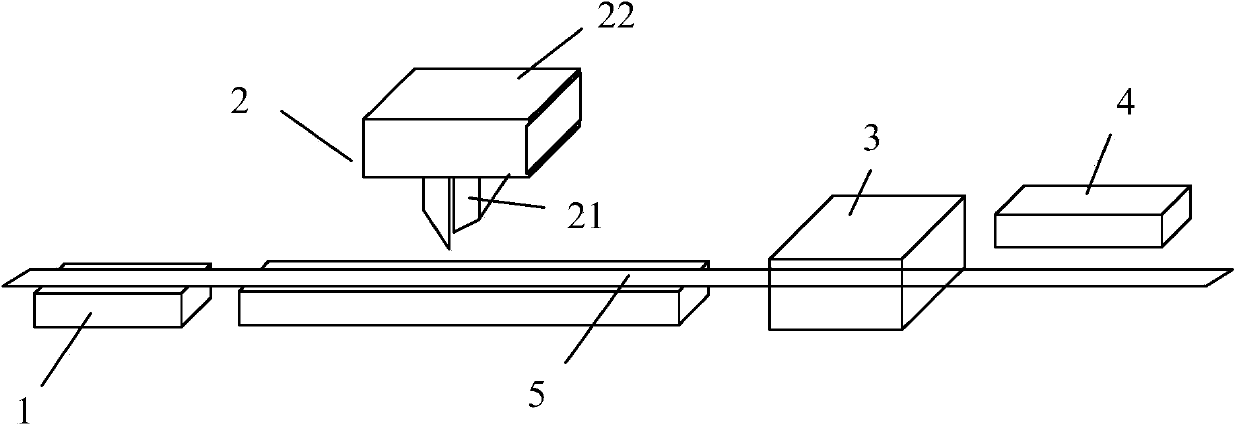

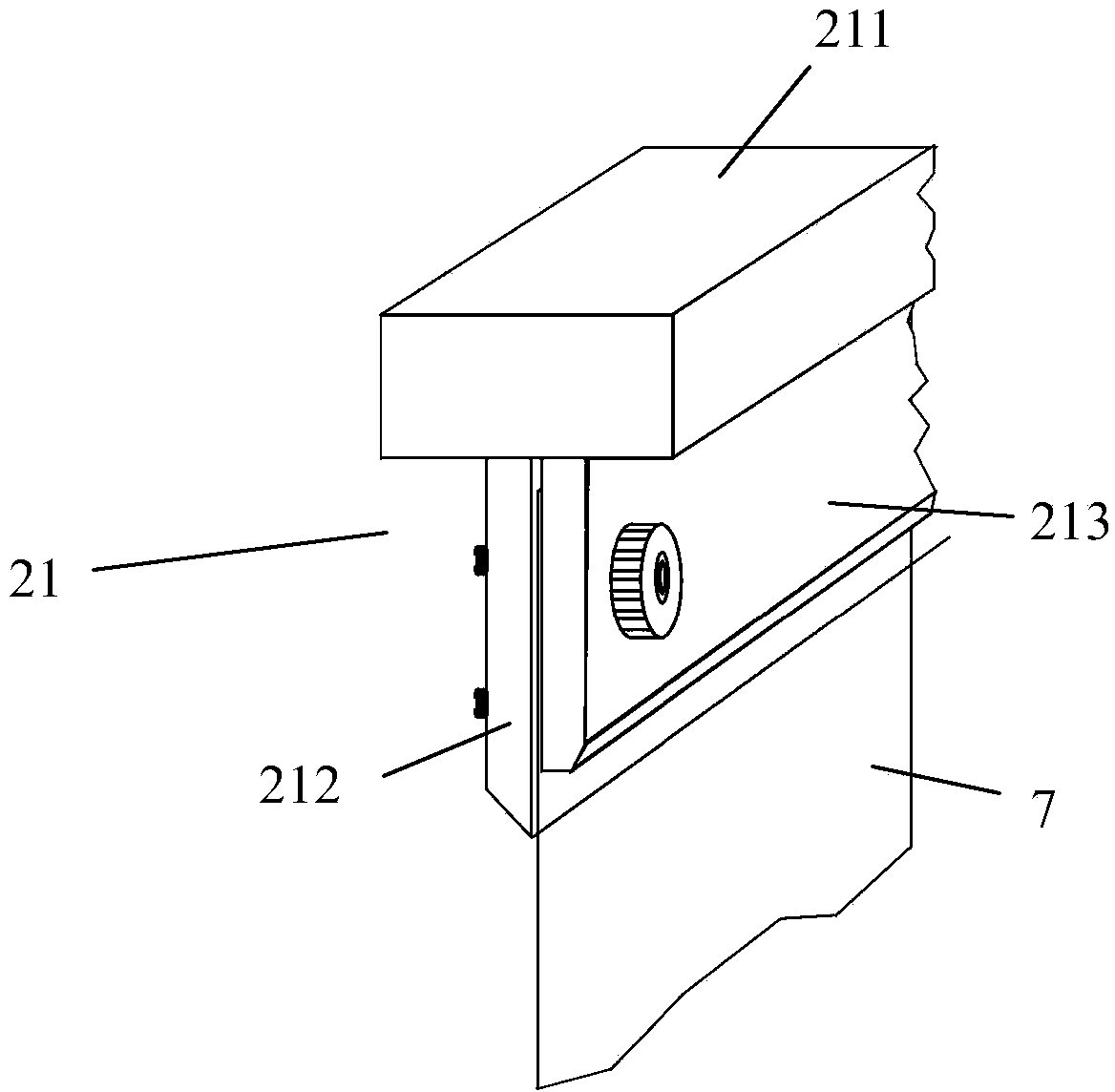

Manufacturing process of biaxially stretched color base film for manufacture process protection of electronic products

The invention discloses a manufacturing process of a biaxially stretched color base film for manufacture process protection of electronic products, and belongs to the field of manufacturing color basefilm. The manufacturing process comprises the steps of manufacture of a color masterbatch and manufacture and production of a color film by using a five-layer biaxial stretching device, specificallythe color masterbatch is produced by using a tandem type screw extruder; and the production of the color film by using the five-layer biaxial stretching device includes the following steps: drying, extruding, casting, longitudinal stretching, transverse stretching, heat treatment and winding, specifically the step of extruding includes extruding by a main extruder and extruding by using four auxiliary extruders. the four auxiliary extruders used in the step of extruding by using the four auxiliary extruders are able to make the film surface color be uniformly distributed, less in crystal point, less in bubbles, and high in gloss; the corona surface has a uniform corona value and no corona on the back surface, and the non-corona surface has no glue; the pollutant to a main batching system of a production line is less; and products are converted quickly after production is completed.

Owner:SUQIAN GETTEL PLASTIC IND

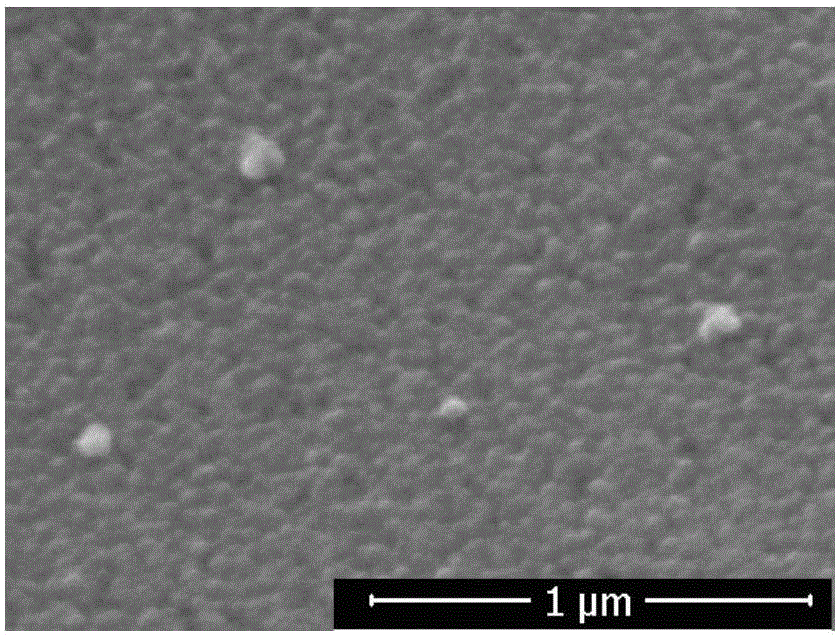

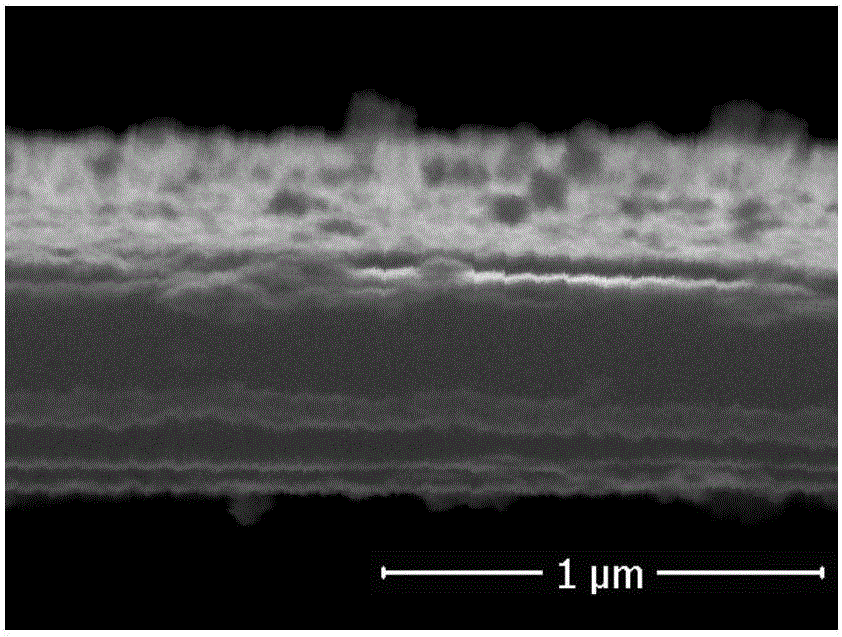

Nano anti-ultraviolet heat insulation coated glass and production method thereof

The invention relates to a nano anti-ultraviolet heat insulation coated glass which comprises a glass plate and a layer of tin antimony oxide film on the surface of the glass plate, wherein the thickness of the tin antimony oxide film is in the range of 7-10Mu m, a plurality of tin antimony oxide particles are distributed in the tin antimony oxide film, and the diameter of any one of the tin antimony oxide particles is in the range of 1-100 nm. The production method for the nano anti-ultraviolet heat insulation coated glass comprises the following steps: cleaning the glass plate by a glass washing machine, drying the clean glass plate, filtering and heating a water body containing tin antimony oxide particles by a liquid cycle filtering and heating device, making the water body form a liquid curtain by a surface spraying device and coating the glass plate with the liquid curtain, carrying out infrared radiation on the glass plate by a temperature control infrared radiation box, and cooling the glass plate. The nano anti-ultraviolet heat insulation coated glass is easy to produce and can achieve the heat insulation effect, does not influence indoor lighting and does not pollute environment.

Owner:SHANGHAI CENXING IND

Carbon black coloring pearlescent pigment and preparation method thereof

ActiveCN106009784ASimple processImprove controllabilityPigment preparation by wet methodsInorganic pigment treatmentCarbon layerControllability

The invention discloses carbon black coloring pearlescent pigment and a preparation method thereof. The carbon black coloring pearlescent pigment comprises a pearlescent pigment matrix and a carbon black coloring layer which is prepared in situ on the surface of the pearlescent pigment matrix by a treating agent. The preparation method includes: using the treating agent to envelope the pearlescent pigment matrix; calcining at high temperature in an atmosphere of inactive gas and / or reductive gas or in a vacuum condition. The preparation method is simple in process, high in controllability and repeatability and low in cost, and the carbon black coloring pearlescent pigment prepared by the method is compact in carbon layer, firm in bonding, less prone to decoloring and easy in large-scale production.

Owner:林一中

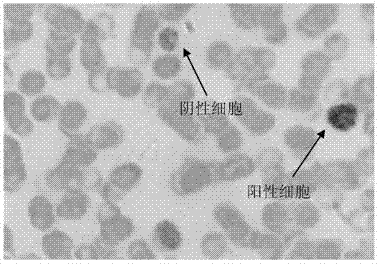

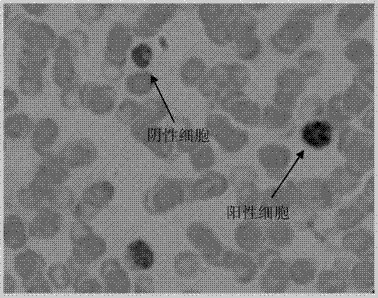

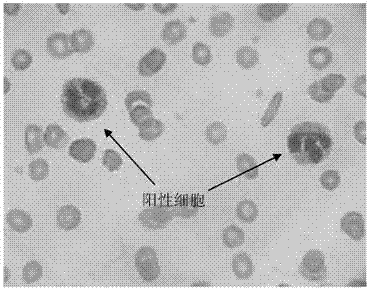

Chloroacetate AS-D naphythol AS-D chloroacetate esterase (AS-DNCE) staining solution (chemical coloring process)

ActiveCN103884562AImprove dyeing effectNot easy to decolorizePreparing sample for investigationChemistryEnzyme

The invention belongs to the field of medical in vitro diagnosis and discloses a chloroacetate AS-D naphythol AS-D chloroacetate esterase enzyme staining kit of which a component of a buffer solution comprises saponin. When the kit is used for staining, blood cells are incubated by the saponin-containing buffer solution, so that pigments can enter the blood cells through holes formed in a cell membrane through the pigments and are combined with the chloroacetate AS-D naphythol AS-D chloroacetate esterase for developing, the cells are closed again after washing, the pigmentation particles are closed in the blood cells, the chloroacetate AS-D naphythol AS-D chloroacetate esterase does not fade for a long time after staining, and staining groups are protected. The kit is lasting in staining effect, difficult to discolor, simple in composition and convenient to use and is widely applied to staining the chloroacetate AS-D naphythol AS-D chloroacetate esterase in the blood cells, and standard operation is easily realized.

Owner:SHANGHAI SUNBIO TECH

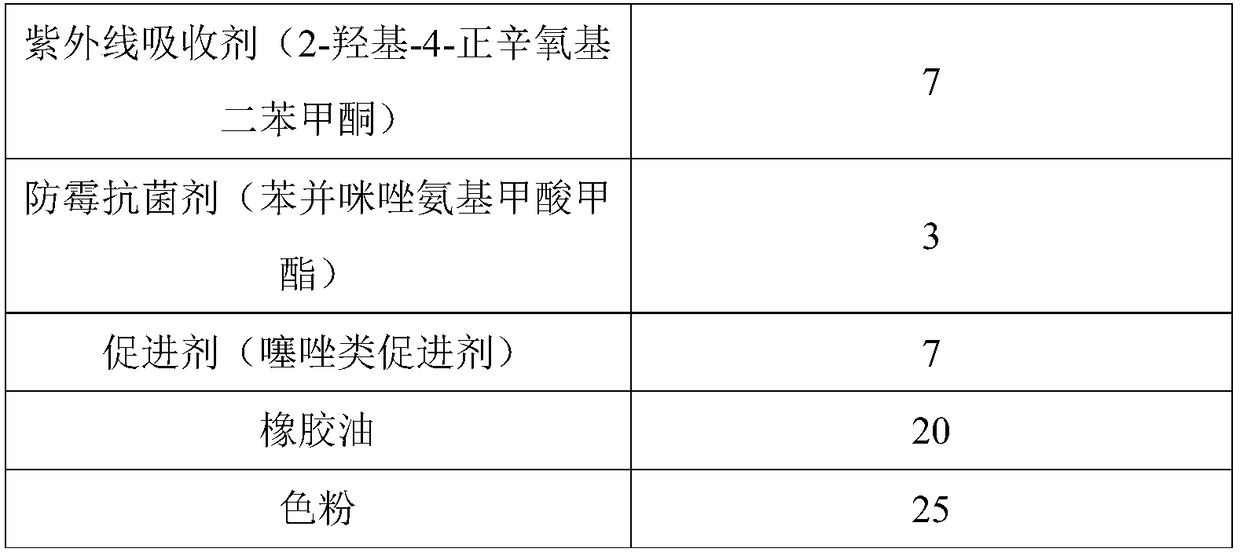

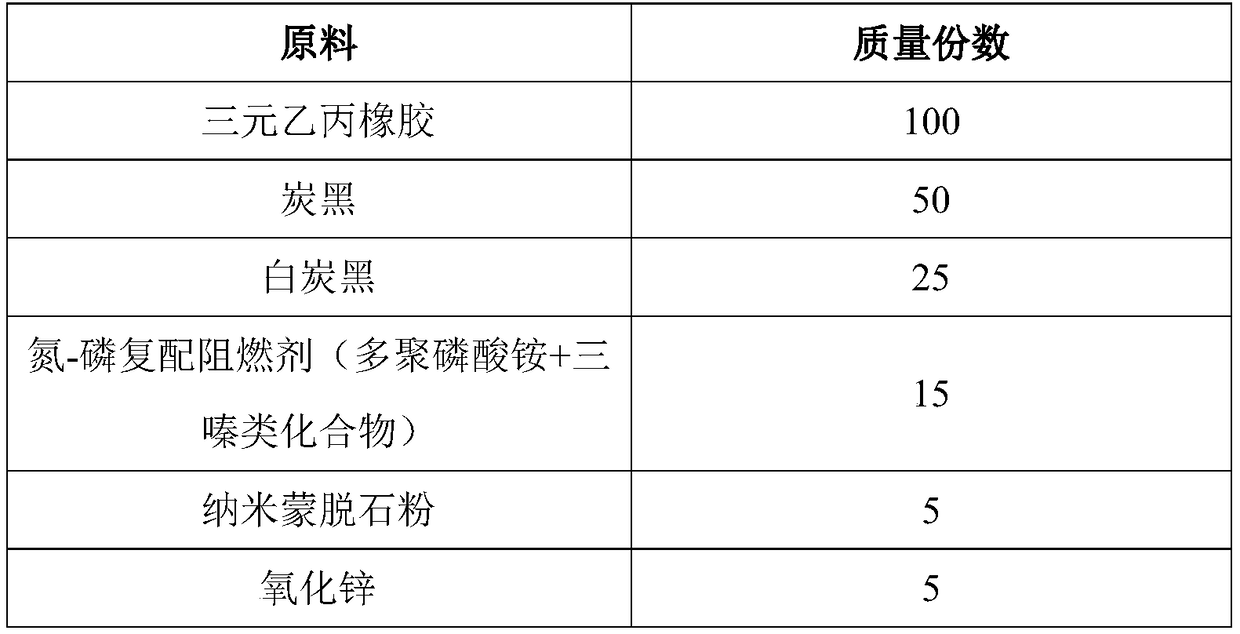

High-wear-resistance rubber floor mat and making method thereof

ActiveCN109130399AHigh strengthImprove wear resistanceSynthetic resin layered productsFlat articlesFiberPolymer science

The invention discloses a high wear-resistant rubber floor mat and a making method thereof. The rubber floor mat is made by bonding a bottom layer and a surface layer together. The bottom layer is formed by bonding waste rubber particles, the surface layer is formed by bonding wear-resistant rubber particles, and reinforcing fibers are dispersed in the surface layer. The wear-resistant rubber particles are composed of ethylene-propylene-diene monomer rubber, carbon black, white carbon black, nitrogen-phosphorus complex flame retardant, nano montmorillonite powder, zinc oxide, an antioxidant, an ultraviolet absorbent, an anti-mold and anti-bacterial agent, an accelerant, rubber oil and color powder. The making process includes the following steps of 1, preparation of the bottom later, 2, preparation of the wear-resistant rubber particles, 3, preparation of the surface layer, and 4, bonding of the surface layer and the bottom layer. The rubber floor mat has high surface strength, good wear resistance, high elasticity, flame-retardant and anti-bacterial properties, decolorizing, rubber-particle disengagement, deforming and upwarping do not easily occur, the preparation process is simple, the production cost is low, and the mat is convenient for large-scale application and popularization.

Owner:QINGYUAN CHUANAO HI TECH MATERIAL CO LTD

PVC edge sealing material and preparation method thereof

InactiveCN103937120AImprove wear resistanceNot easy to decolorizeHigh wear resistanceChlorinated polyethylene

The invention discloses a PVC edge sealing material. The PVC edge sealing material comprises, by weight, 50-150 parts of PVC powder, 40-60 parts of calcium carbonate, 1-3 parts of an internal lubricant, 1-3 parts of an external lubricant, 3-7 parts of a stabilizer, 6-18 parts of dicapryl phthalate, 1-3 parts of a PVC processing aid, 3-9 parts of chlorinated polyethylene and 1-3 parts of a pigment. The invention also discloses a preparation method of the PVC edge sealing material. The PVC edge sealing material has the advantages of high toughness, high smoothness, beautiful appearance, high strength and corrosion resistance, and passes national detection, so the material has no pollution; and the PVC edge sealing material prepared according to the above raw material proportions also has the advantages of glossy and smooth surface, high wear resistance, strong high temperature resistance, unlikely decoloring and unlikely loss. The preparation method is simple and feasible, and is suitable for large scale production.

Owner:KUNSHAN JING CHUN HARDWARE PLASTIC PROD

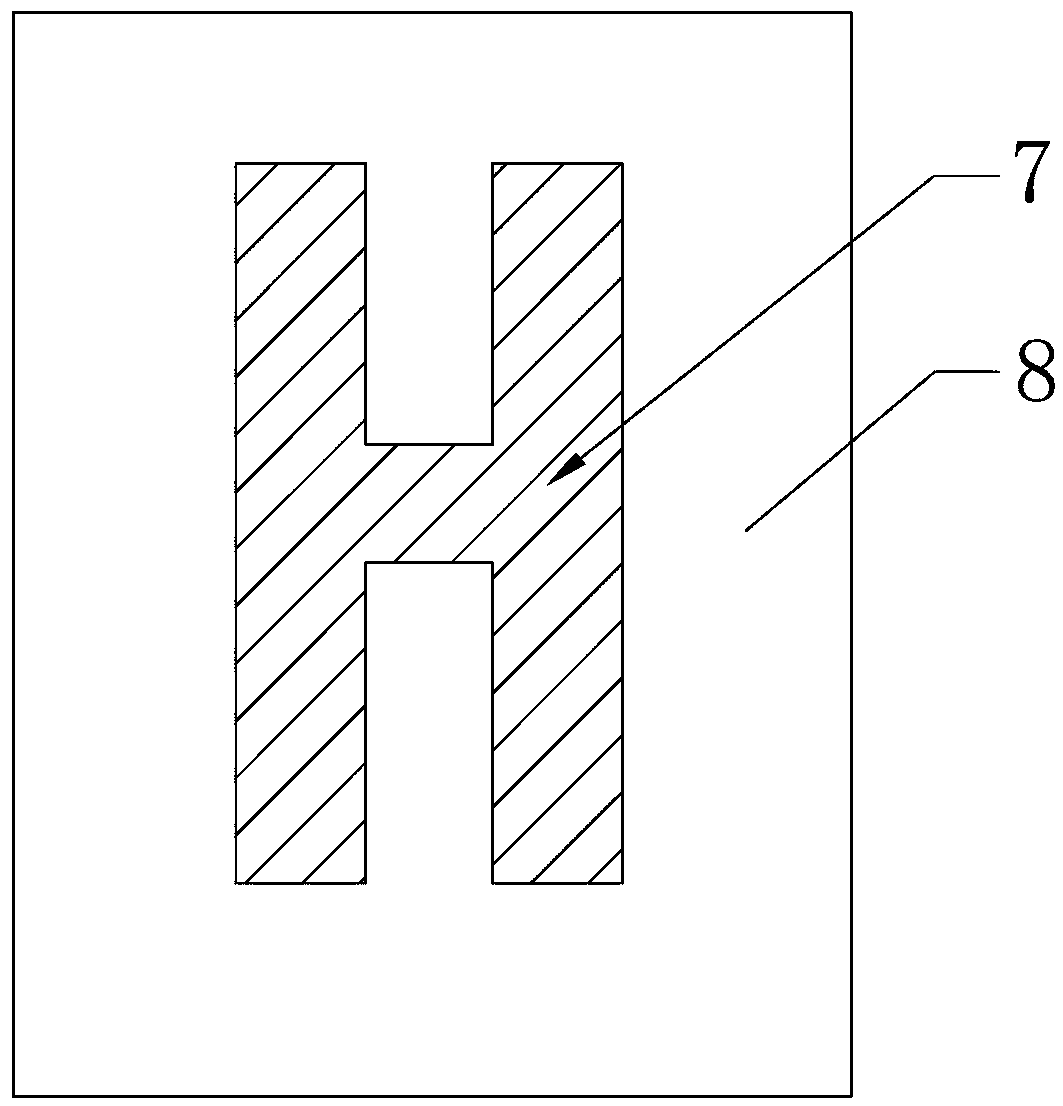

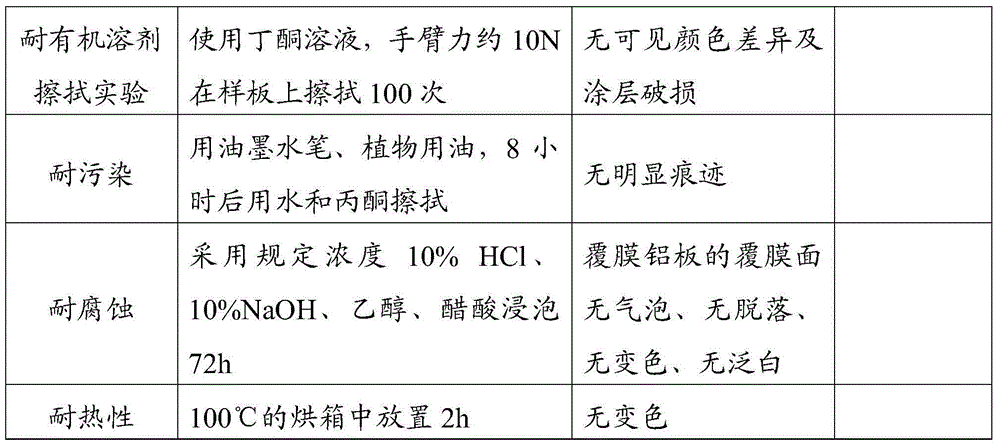

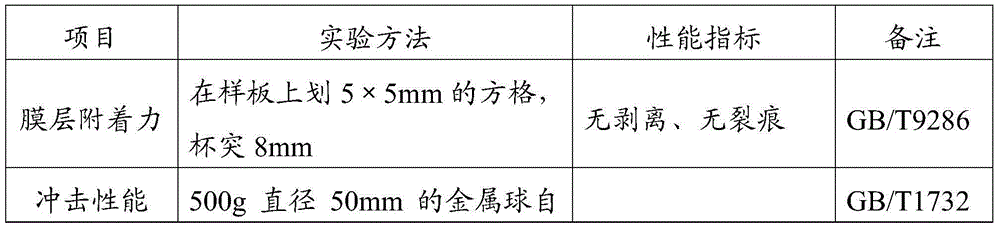

Laminated aluminum plate and preparation method thereof

ActiveCN104626679ANot easy to deform and bulgeNot easy to decolorizeSynthetic resin layered productsVacuum evaporation coatingOrganic filmHigh resistance

The invention relates to a laminated aluminum plate which comprises a base material, wherein a laminated coating, a nanometer film layer, an adhesive layer, a laminating layer and a protective film layer are sequentially arranged on one side of the base material; a laminated coating and a paint layer are sequentially arranged on the other side of the base material; the base material is obtained by performing passivation or shot blasting treatment on an aluminum plate; the laminated coating is a meshed organic film formed by chromate; the nanometer film layer is formed by coating the base material with nanometer TiC or carbon-nitrogen co-doped nanometer TiO2 by virtue of physical vapor deposition; the laminating layer is made from a PET material; and the protective film is made from a PE material. Compared with the prior art, the laminated aluminum plate disclosed by the invention is unlikely to deform and bulge as well as discolor and unglue, has high resistance to acid and base, corrosion resistance and heat resistance and can be applied to various severe environments.

Owner:ZHUHAI SPEEDBIRD NEW MATERIAL CO LTD

Track terrace

InactiveCN104878671AImprove early strengthIncrease late strengthIn situ pavingsTemporary pavingsLow noiseCondensation process

The invention provides a track terrace, aiming to solve a series of problems that in the prior art, the track terrace is not very flat and superhard, cannot resist slipping, does not have low noise, can fade and the like. The problem of low intensity of concrete of the track terrace at the early stage is solved by improving the formula of the concrete used in the track terrace; the phenomenon of bleeding in the concrete primary condensation process of the track terrace is eradicated; the deformation degree of the concrete terrace is controlled; meanwhile, the integral intensity of the concrete of the track terrace is enhanced substantially so as to achieve the use function requirements of superhardness and abrasion resistance of the track terrace are met; colorful concrete is used for pouring the track terrace, the color fade problem cannot be generated even though the terrace is abraded; meanwhile, the surface layer of the concrete terrace is provided with a surface layer so as to reinforce the superhard and abrasion resistant effects and achieve the effects of slip prevention and low noise.

Owner:SHANGHAI BUILDING DECORATION ENG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com