Preparation method of artificial stone from colored glass particles

A technology of colored glass and artificial granite, which is applied in the field of building decoration materials, can solve problems such as no technical solutions found, and achieve the effect of various colors, bright colors and good layering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

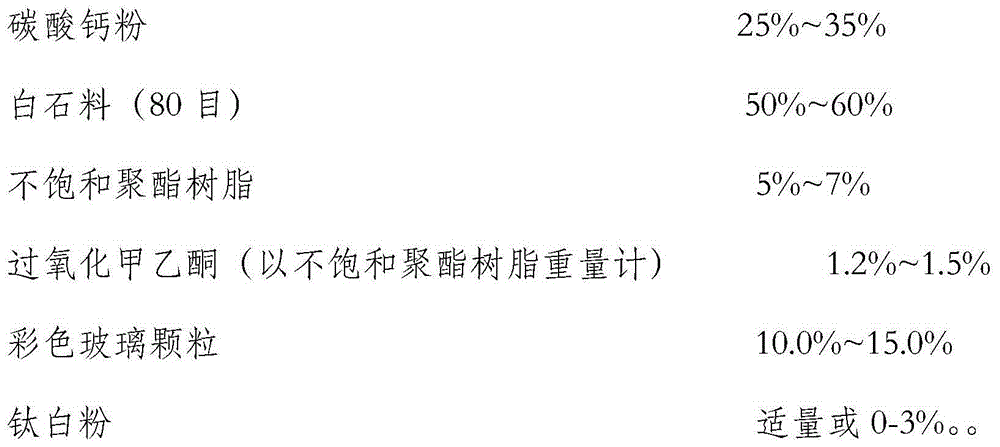

Method used

Image

Examples

Embodiment 1

[0028] ① Preparation method of colored gold glass particles, preparing colored gold glass particles with a particle size of 4mm-6mm. The specific preparation method is:

[0029] a. Weigh 100kg of transparent glass particles (4mm~6mm) in a vertical mixer, add 75g silane coupling agent KH-550 and silane coupling agent 784, 700g epoxy resin, 120g polyamide curing agent, 300g Saturated polyester resin, 60g methyl ethyl ketone peroxide, 30g ultraviolet absorber UV-531, 40r / min stirring, stirring for 5-8min;

[0030] b. After the transparent glass particles are wetted by the above reagents, add 3500g of golden glitter powder with a particle size of 0.2mm, mix and stir for 5 minutes to obtain colored gold glass particles;

[0031] c. Spread the prepared colored gold glass on a clean floor and solidify at room temperature to obtain golden colored gold glass.

[0032] ②The preparation method of colored glass particles applied to artificial granite:

[0033] d. The automatic weighing system sep...

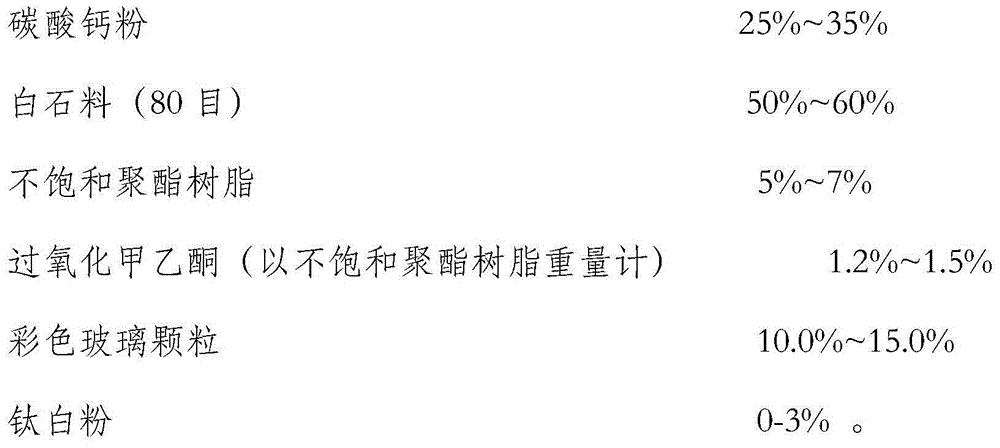

Embodiment 2

[0037] ① Preparation method of bright blue glass particles, preparing bright blue glass particles with a particle size of 2mm-4mm. The specific preparation method is:

[0038] a. Weigh 100kg of transparent glass particles (2mm~4mm) in a vertical mixer, add 80g silane coupling agent KH-550 and silane coupling agent 784, 800g epoxy resin, 140g polyamide curing agent, 330g Saturated polyester resin, 65g methyl ethyl ketone peroxide, 35g ultraviolet absorber UV-531, 40r / min stirring, stirring for 5-8min;

[0039] b. After the transparent glass particles are wetted by the above reagents, add 3800g of bright blue glitter powder with a particle size of 0.2mm, mix and stir for 5 minutes to obtain bright blue glass particles;

[0040] c. Spread the prepared bright blue glass on a clean floor and solidify at room temperature to obtain bluish bright blue glass.

[0041] ②The preparation method of bright blue glass particles applied to artificial granite:

[0042] d. The automatic weighing system...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com