Carbon black coloring pearlescent pigment and preparation method thereof

A pearlescent pigment and carbon black technology, applied in the field of inorganic pigments, can solve the problems of difficult control of the thickness of the carbon layer on the surface of pearlescent pigments, poor adhesion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

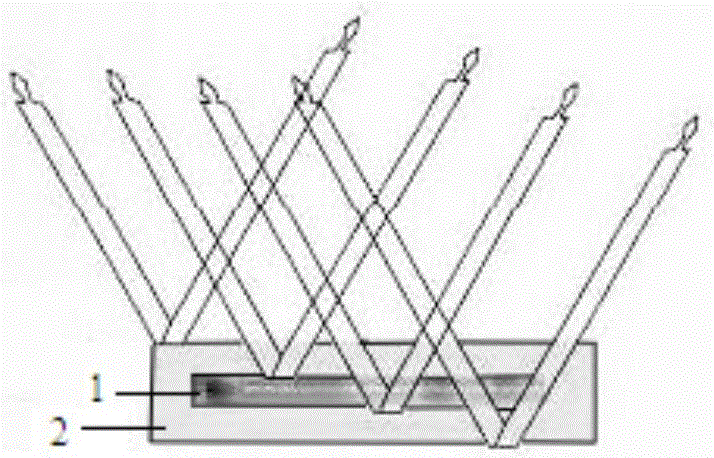

Method used

Image

Examples

Embodiment 1

[0084] Take by weighing 10g of commercially available natural mica-based titanium pearlescent pigment AG111 pigment (natural mica-based pearlescent pigment, particle diameter<15 μm, titanium dioxide coating rate 43%, use titanium tetrachloride as a depositing agent and use parallel flow hydrolysis to prepare. (so-called coating Coverage refers to the percentage of coating contained in the pearlescent pigment per unit mass. If the coating is titanium dioxide in the above-mentioned AG111, and the titanium dioxide contained in every 100g AG111g is 43g, then the coating rate of titanium dioxide in AG111 is 43%.) In the reactor, add 100g of water to prepare a suspension. Stir until the dispersion is uniform, heat the suspension to 80°C, add 2.5g of polyethylene glycol 600 to the suspension, adjust the pH to 8.5, and stir for 2 hours , filtered, and dried to obtain the precursor.

[0085] The dried precursor was placed in a vacuum furnace, evacuated to an absolute pressure of 0.01 P...

Embodiment 2

[0087] Weigh 10g of synthetic mica-based pearlescent pigment AG6531 (AG6531, using synthetic mica as the base material, particle size range 10-60 μm, Fe 2 o 3 The coating rate is about 36%, using ferric chloride as a sedimentation agent and using parallel hydrolysis method) to place in the reactor, add 55g water to it to prepare a suspension, stir until uniformly dispersed, and heat the suspension to 85 ℃, add 2g to the suspension HYDROSIL 2909 (is a HO [SiR 61 (OH)O] x6 [SiR 62 (OH)O] y6 Aqueous silane with aminopropyl and isobutyl of general formula H), adjust the pH value to 8.5, stir and react for 1 h, filter, and dry to obtain the precursor.

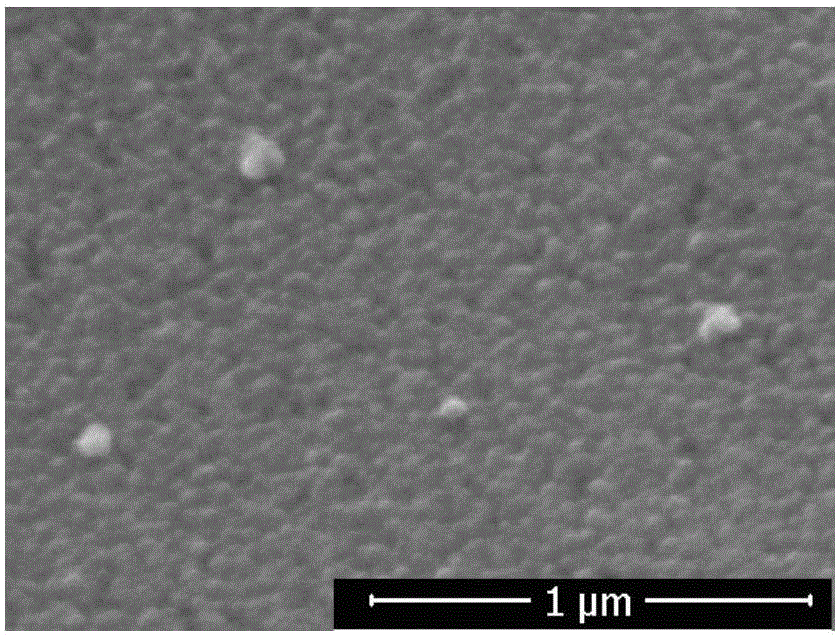

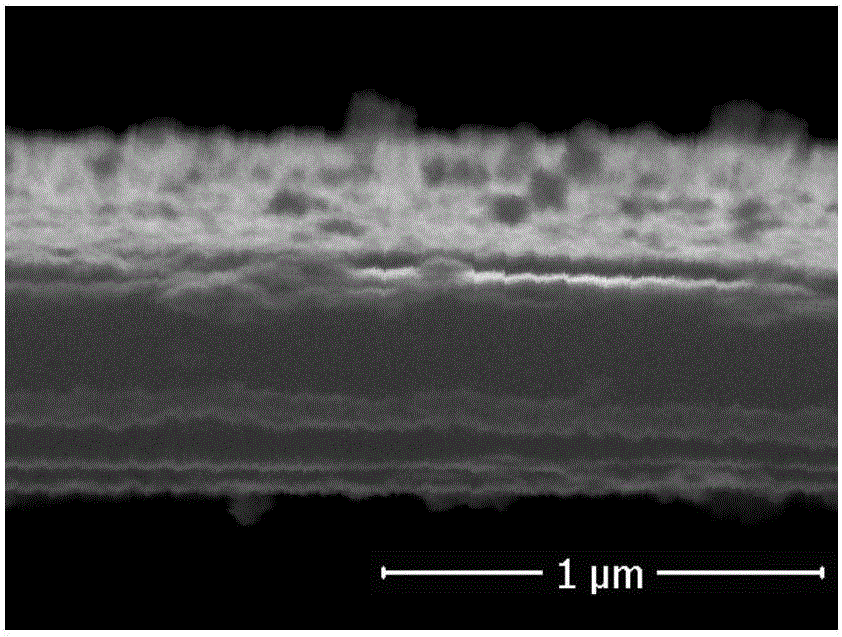

[0088] The dried precursor was placed in an atmosphere furnace, argon (Ar) was introduced, the temperature was raised to 600° C., and the temperature was kept for 1.5 h. Under the protection of argon (Ar), cool with the furnace to obtain the carbon black colored pearlescent pigment. The prepared carbon black-coated pearlesce...

Embodiment 3

[0094] Take by weighing 10g of the intermediate product (semi-finished product 2) before the calcining treatment in the synthetic mica-based pearlescent pigment AG6126 process (semi-finished product 2, this intermediate product uses synthetic mica as the base material, the particle size range is 5 ~ 5 μm, and the first layer of cladding layer is tin dioxide hydrate , the coating rate is about 0.8% in terms of tin dioxide, and is prepared by co-current hydrolysis with tin tetrachloride as the deposition agent. The second coating layer is titanium dioxide hydrate, and the coating rate after calcination is calculated in terms of titanium dioxide About 38%, using titanium tetrachloride as a sedimentation agent and using co-current hydrolysis to prepare.) Place in a reactor, add 100g of water to it to prepare a suspension. Stir until evenly dispersed, heat the suspension to 80° C., add 1.2 g of octyltriethoxysilane to the suspension, adjust the pH to 3.0, stir for 1.5 h, filter, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com