Concrete

A technology of concrete and floor cement, which is applied in the field of architectural decoration construction, can solve the problems of super easy decolorization, reduce the degree of deformation of the track floor, etc., achieve the effects of reducing maintenance and operation costs, improving flatness, and avoiding decolorization problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

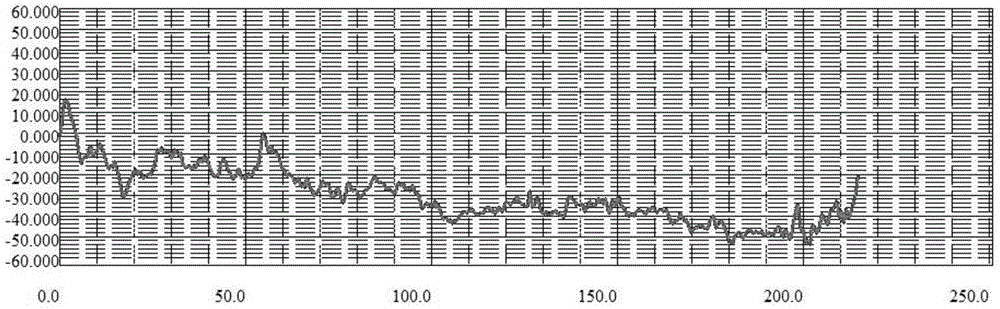

[0034] This embodiment provides a concrete for track floor, which is used to solve the problem that the early strength of ordinary concrete is low, resulting in excessive height difference of the concrete floor due to uneven shrinkage after the concrete undergoes a hydration reaction process.

[0035] Because fly ash and mineral powder have similar chemical components to cement, fly ash or mineral powder is generally used to replace cement, but both fly ash and mineral powder will reduce the early strength of concrete. After a lot of experiments, the inventor found that the early strength of concrete was not high, which would make it difficult to control the height difference of the concrete floor. Therefore, the inventor specially developed concrete with improved early strength. In the concrete of this embodiment, it is forbidden to add fly ash and mineral powder to the concrete, so as to improve the early strength of the concrete.

[0036] Improving the hydration reaction co...

Embodiment 2

[0050] This embodiment takes the construction of the concrete colored track floor of a single-track amusement vehicle in a large-scale playground project as an example. It is necessary to run single-track amusement vehicles in the interior, so the track floor of this part must not only have sufficient strength, but also have sufficient flatness, wear resistance and anti-skid performance.

[0051] The track floor in this embodiment includes a foundation floor, a concrete floor and a surface course. Wherein, the concrete floor is fixed on the foundation floor, and the surface layer is covered on the concrete floor and consolidated with the concrete floor. In order to ensure the flatness of the track floor, the concrete material used for the concrete floor is the concrete of the first embodiment.

[0052] In addition, in order to improve the wear resistance and anti-slip performance of the track floor, the inventors specially developed a superhard, wear-resistant and anti-slip s...

Embodiment 3

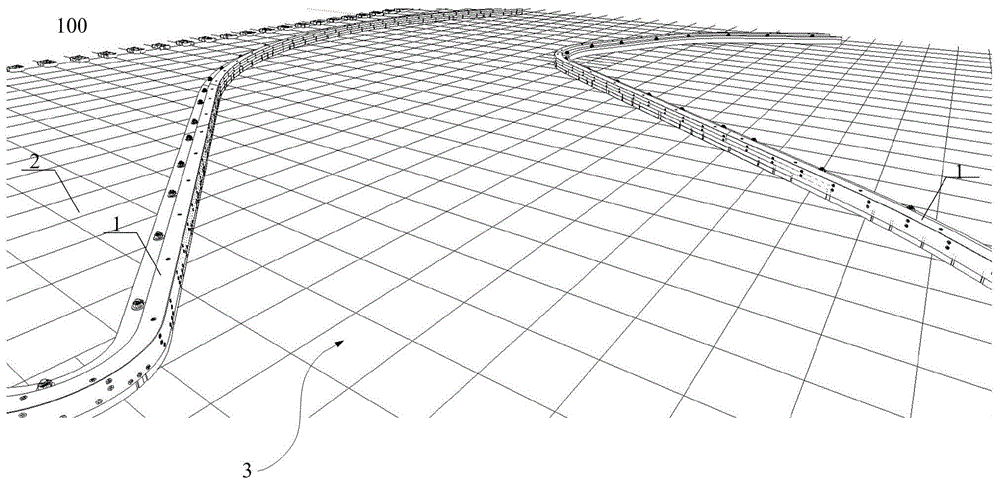

[0071] In order to further solve the problem of decreased flatness of the track floor due to the construction process, the inventor has specially developed a formwork system for the construction of the track floor in the second embodiment. Attached below figure 2 to attach Figure 8 The template system of this embodiment is explained in detail.

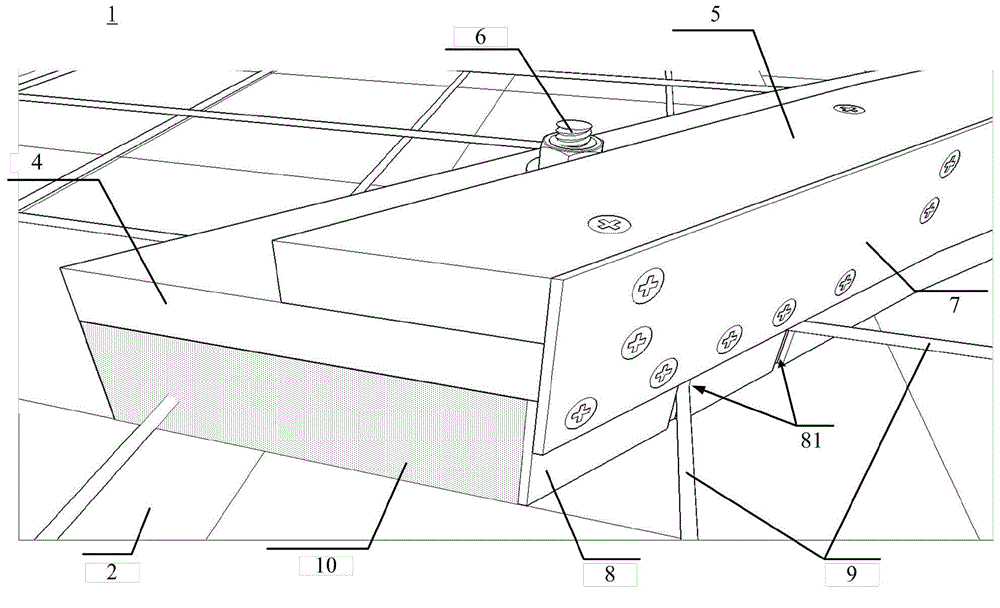

[0072] Such as figure 2 As shown, the formwork system 100 used to complete the construction of the track floor in the second embodiment includes a set of formwork groups 1 set opposite to each other. The formwork group 1 and the foundation floor 2 enclose an area 3 to be poured. Such as image 3 As shown, the template group 1 includes a horizontal template, and the horizontal template includes a horizontal lower template 4 and a horizontal upper template 5. The horizontal lower template is fixed on the foundation floor 2 by adjusting bolts 6, and the adjusting bolts 6 are located at one end of the horizontal lower template 4. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com