Fore-edge transfer printing method

A book edge and book technology, applied in the field of book edge transfer printing, can solve problems such as unfavorable reading, low efficiency of book edge printing, damaged pages, etc., so as to improve the quality of book edge printing, save the cost of book edge printing, and save printing. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0023] The mouth of the book in the present invention refers to the other three sides of the book except the spine.

[0024] The medium paper in the present invention refers to a carrier that transfers the pattern printed by the printing machine to the fore-edge.

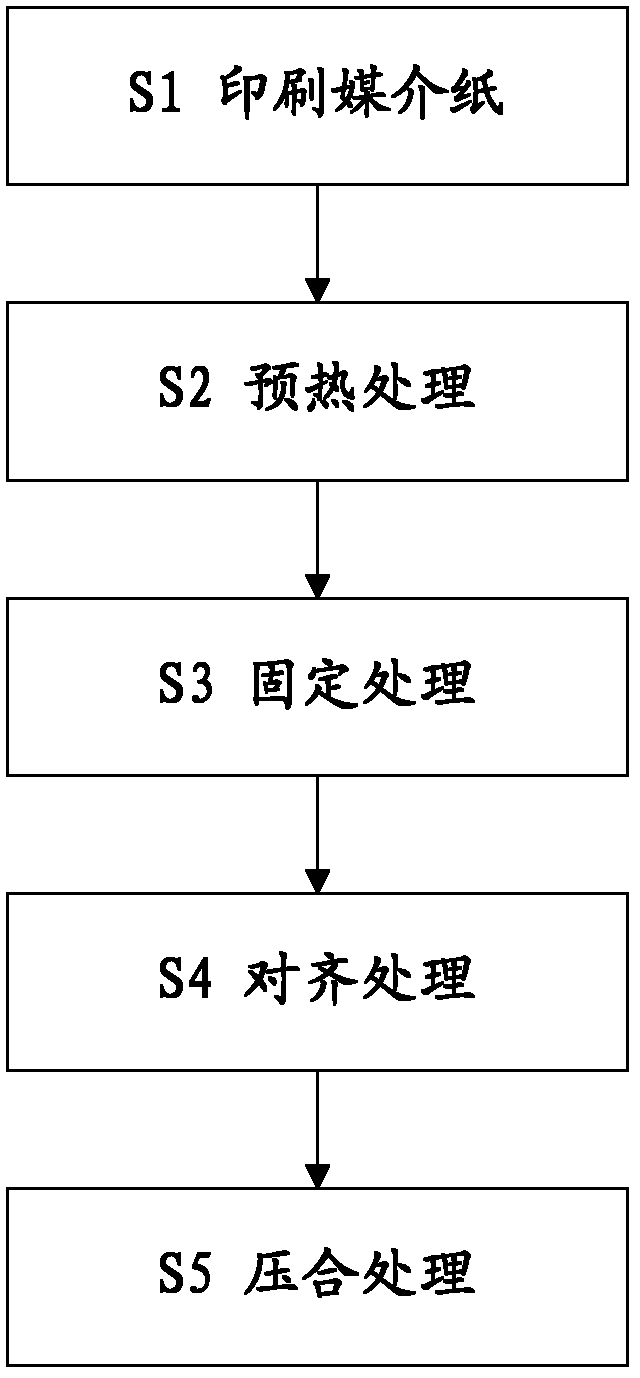

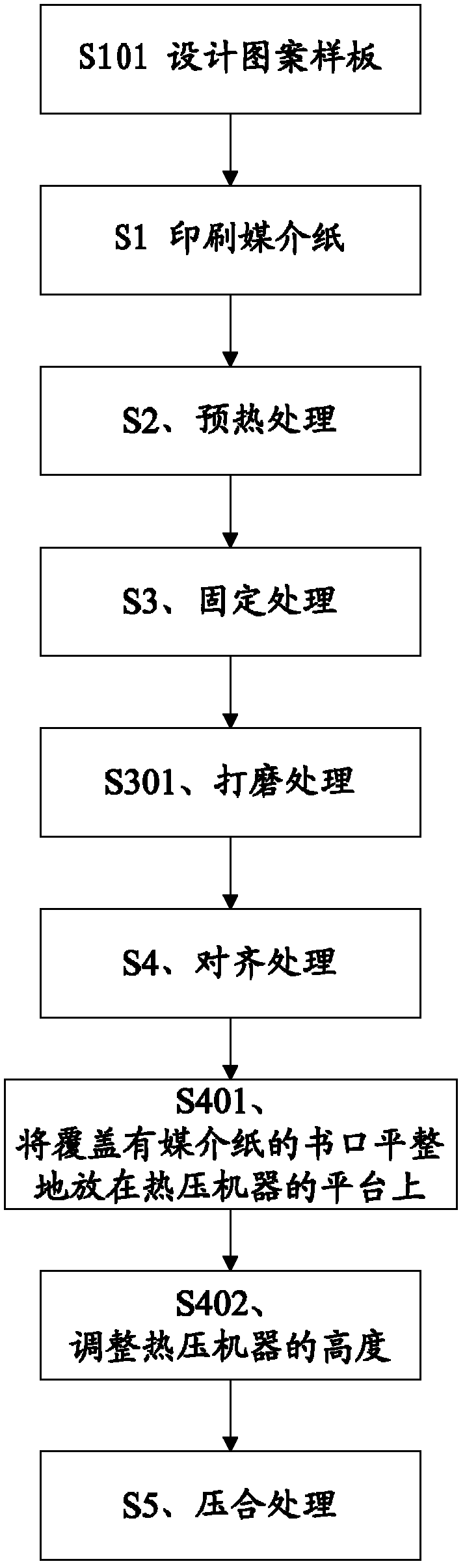

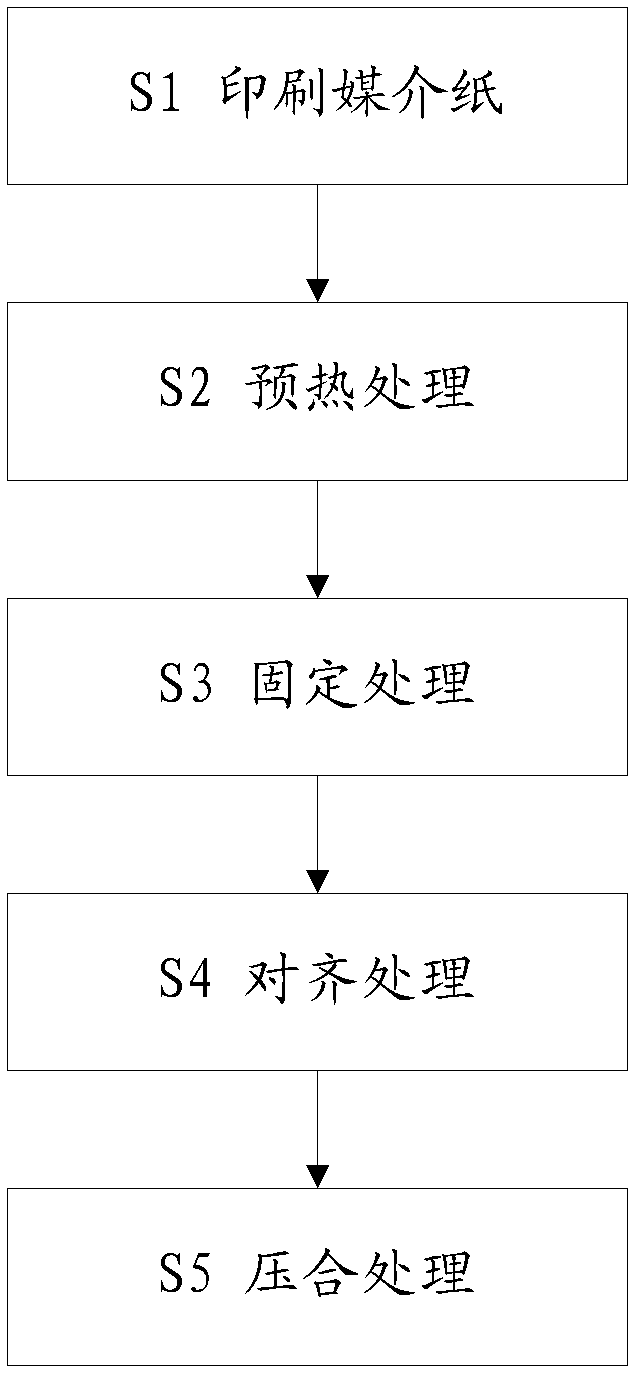

[0025] see figure 1 , the invention provides a method for book-end transfer printing, comprising the following steps:

[0026] S1, printing medium paper, printing ink patterns on the medium paper;

[0027] S2, preheating treatment, preheating the pressing plate of the hot pressing machine;

[0028] S3, fixing process, clamping the book with a clamp;

[0029] S4. Alignment processing, aligning the fore-edge surface with the layout printed with ink patterns on the medium paper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com