Patents

Literature

53results about How to "Improve glue spraying efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

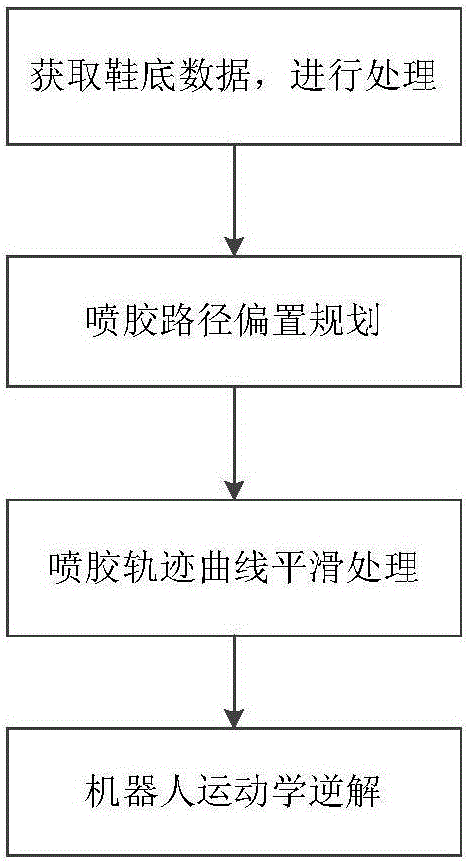

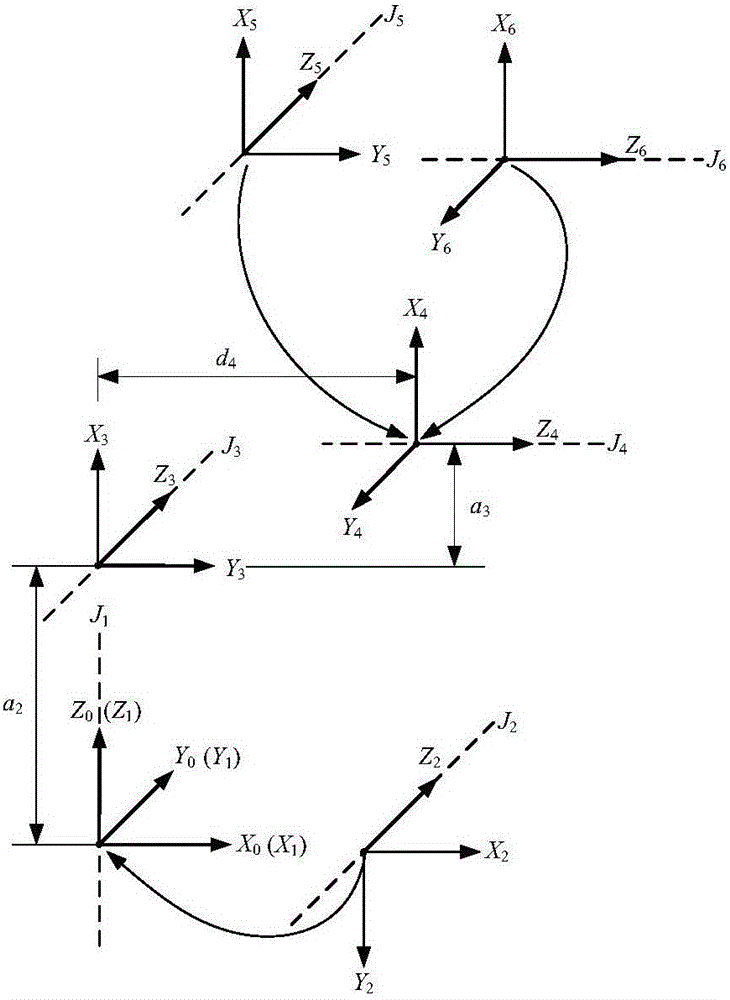

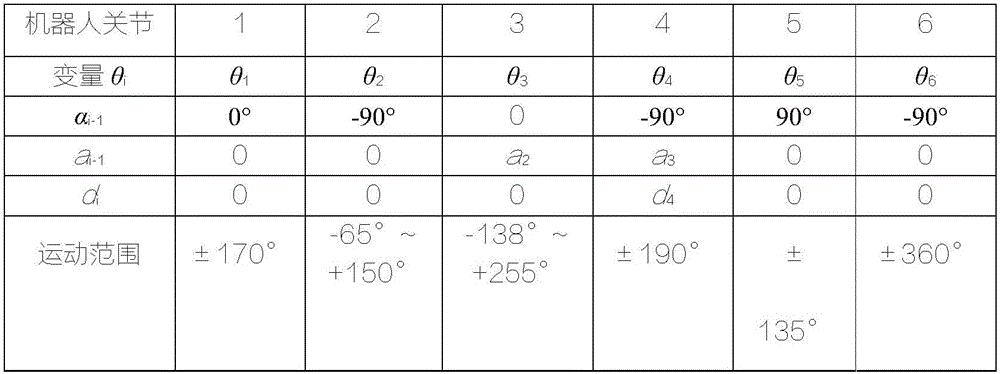

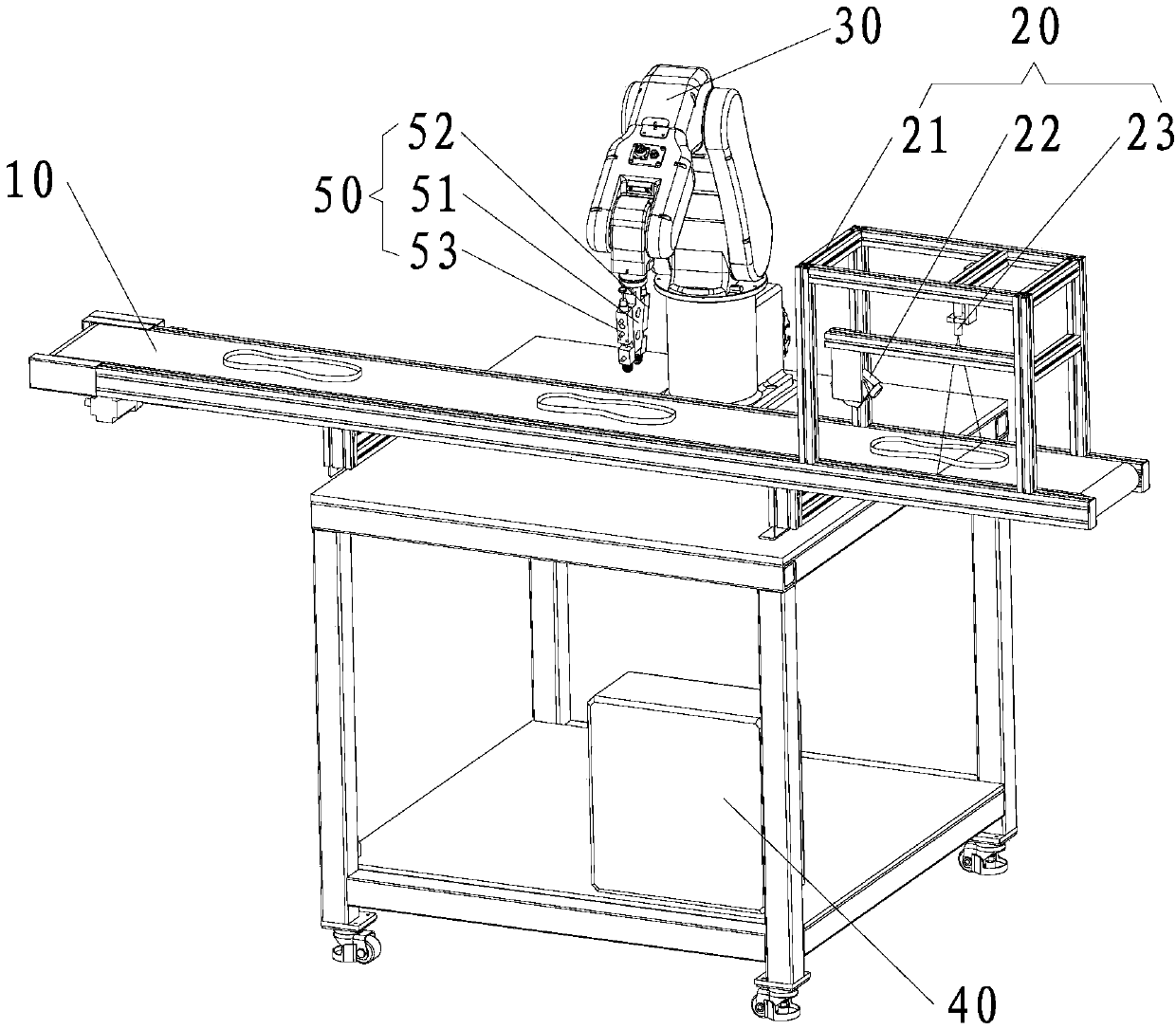

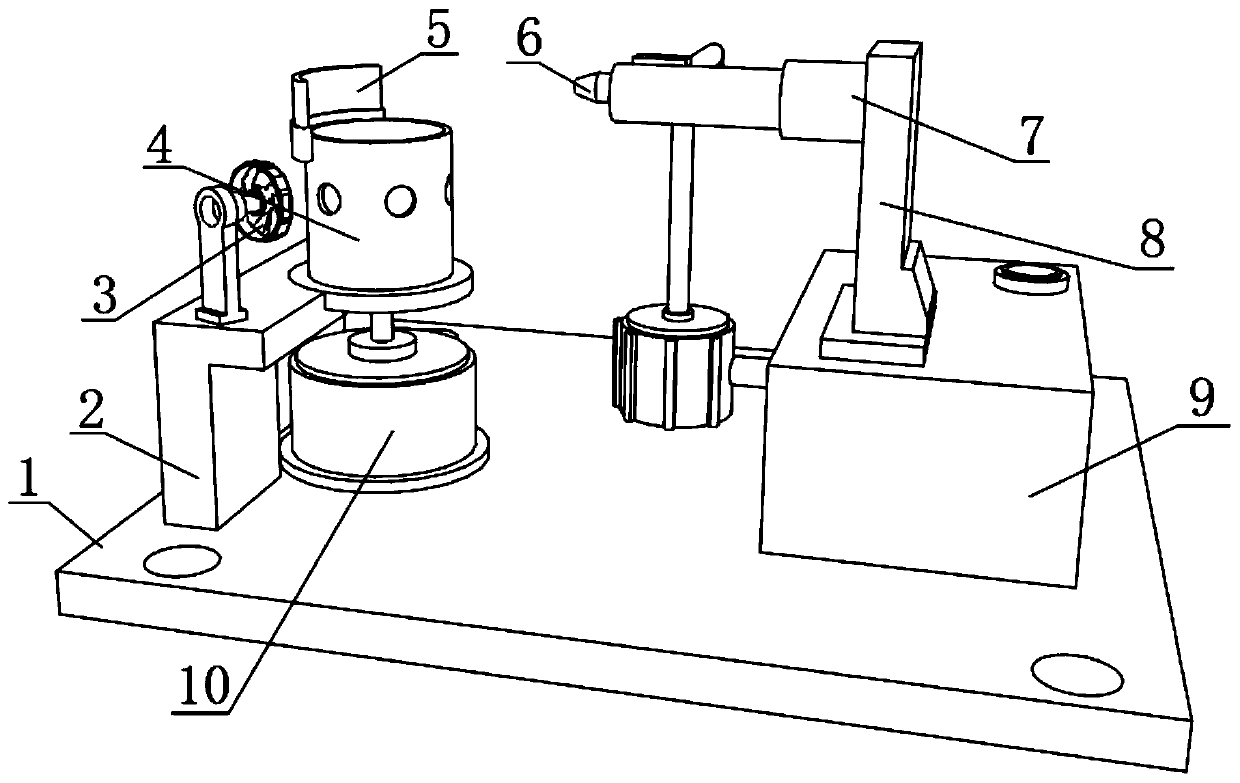

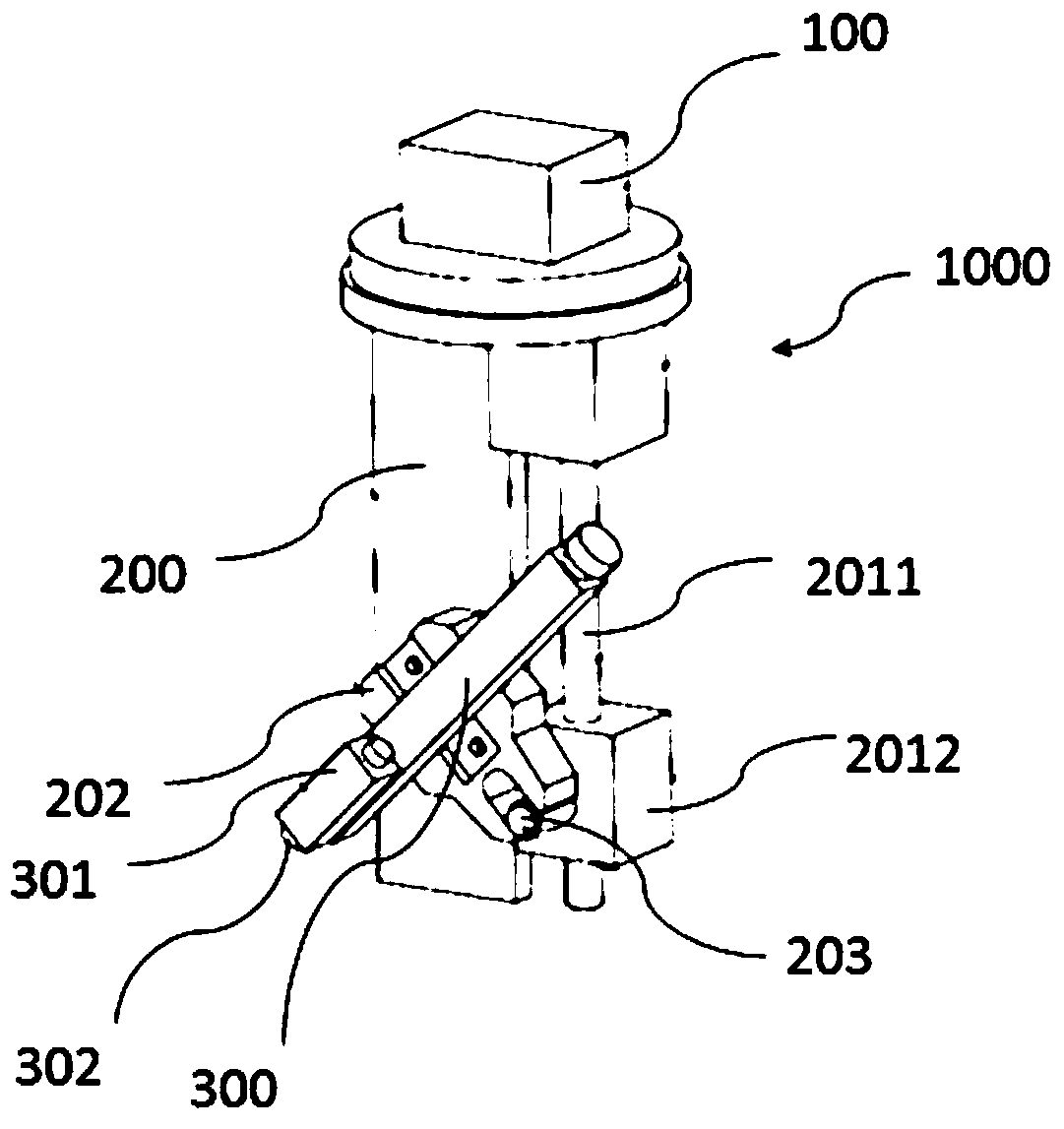

Attitude control-based sole glue spraying path planning method

An attitude control-based sole glue spraying path planning method of the present invention mainly comprises a robot, a laser profile measurement instrument, a glue gun and an industrial control computer. By using the laser profile measurement instrument to scan a sole, the three-dimensional point cloud of a sole curve is obtained, after the data is processed, a glue spraying path is planned, a control program is generated on the industrial control computer to be introduced into the robot, and the attitudes of the glue gun at the tail end of the robot are controlled according to different shoe types, so that a glue spraying process of the sole is finished, the attitudes of the glue gun can change along with the slope of a sole profile fitting curve, and the attitudes of the glue gun at the tail end of the robot can be controlled according to the different shoe types. Moreover, the glue spraying path of the present invention is smoothed, so that the commutation times of a robot motor can be reduced, and the operation speed of the robot is improved, and accordingly, the glue spraying efficiency is improved, and the working service life of the robot is prolonged.

Owner:QUANZHOU INST OF EQUIP MFG

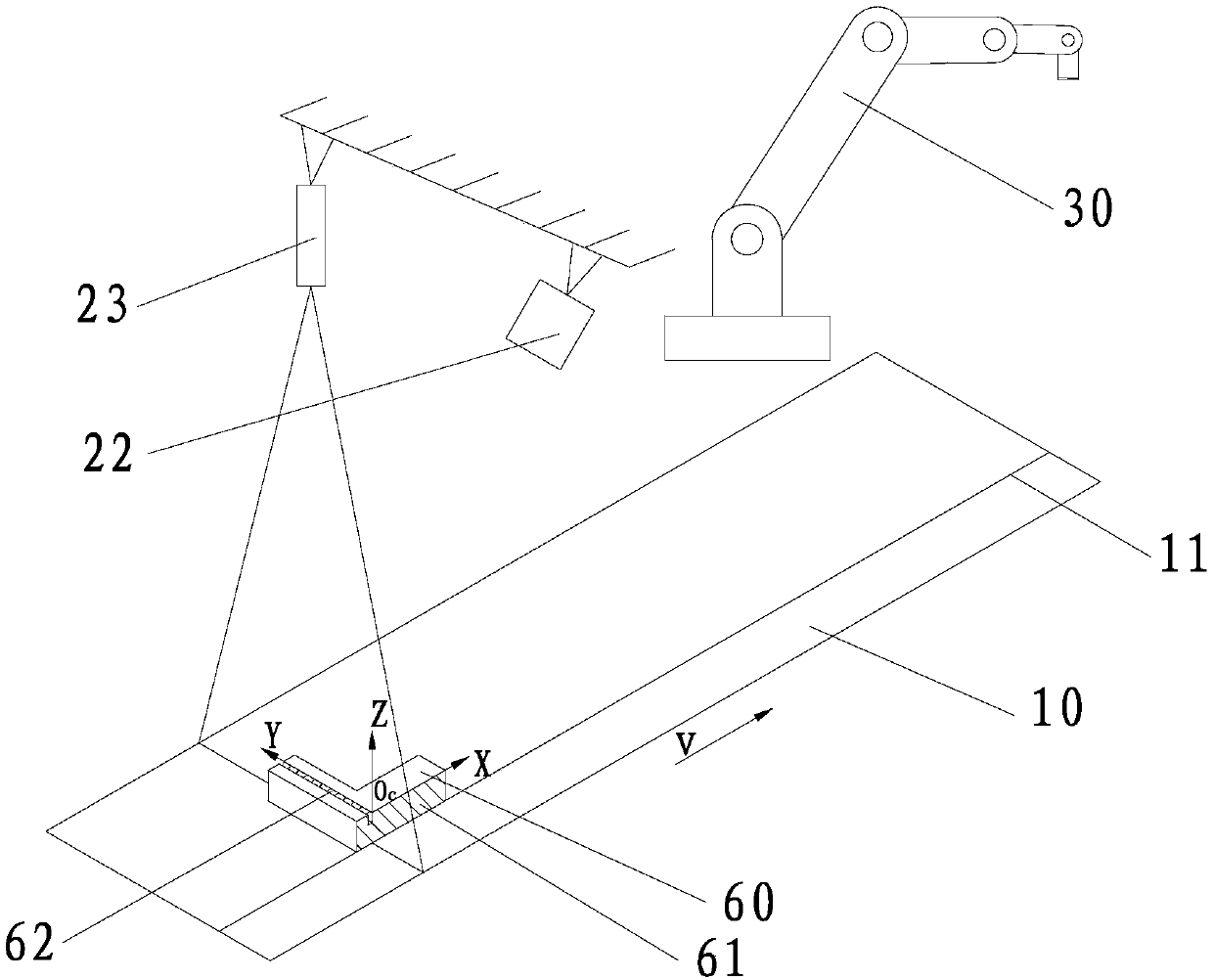

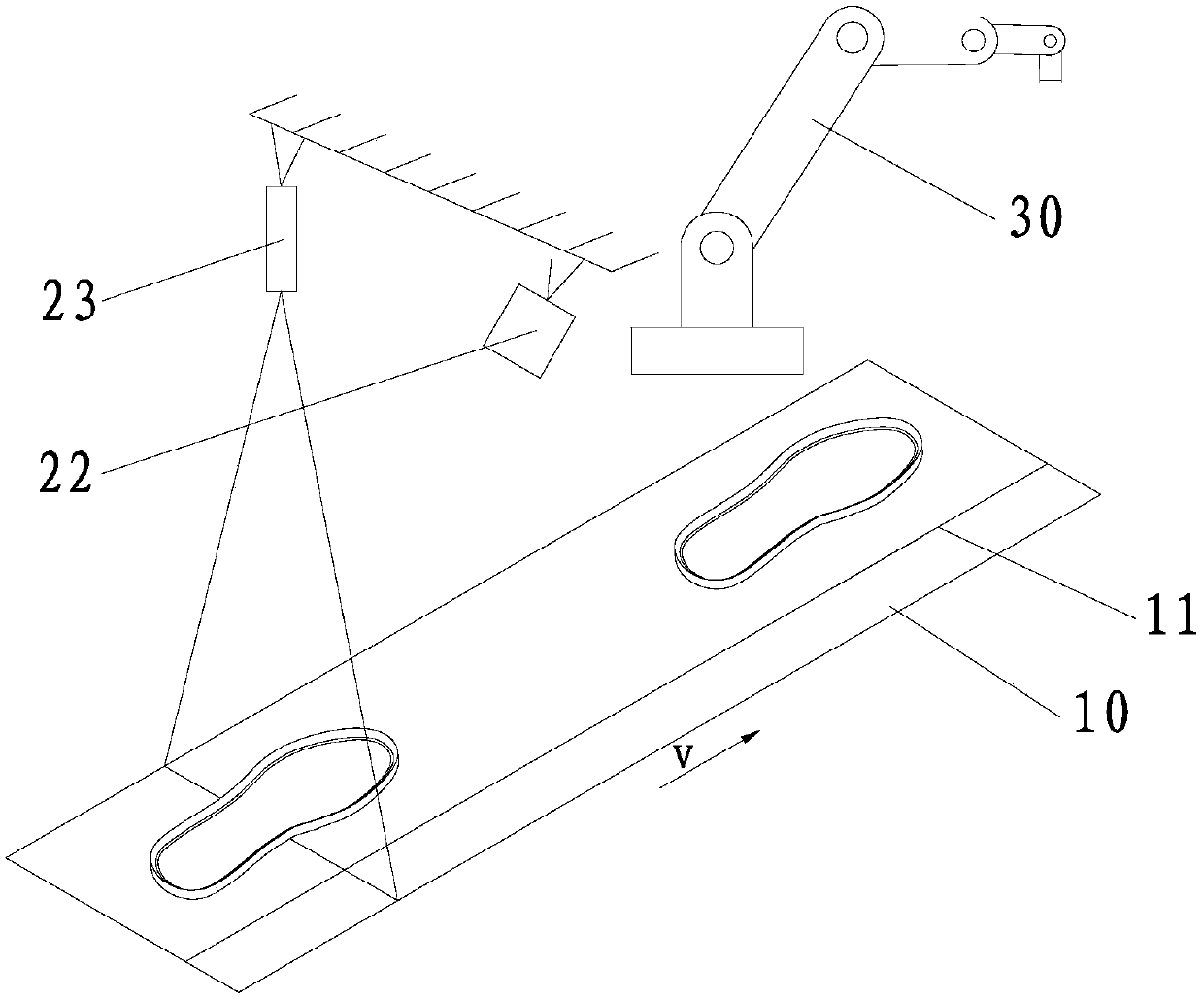

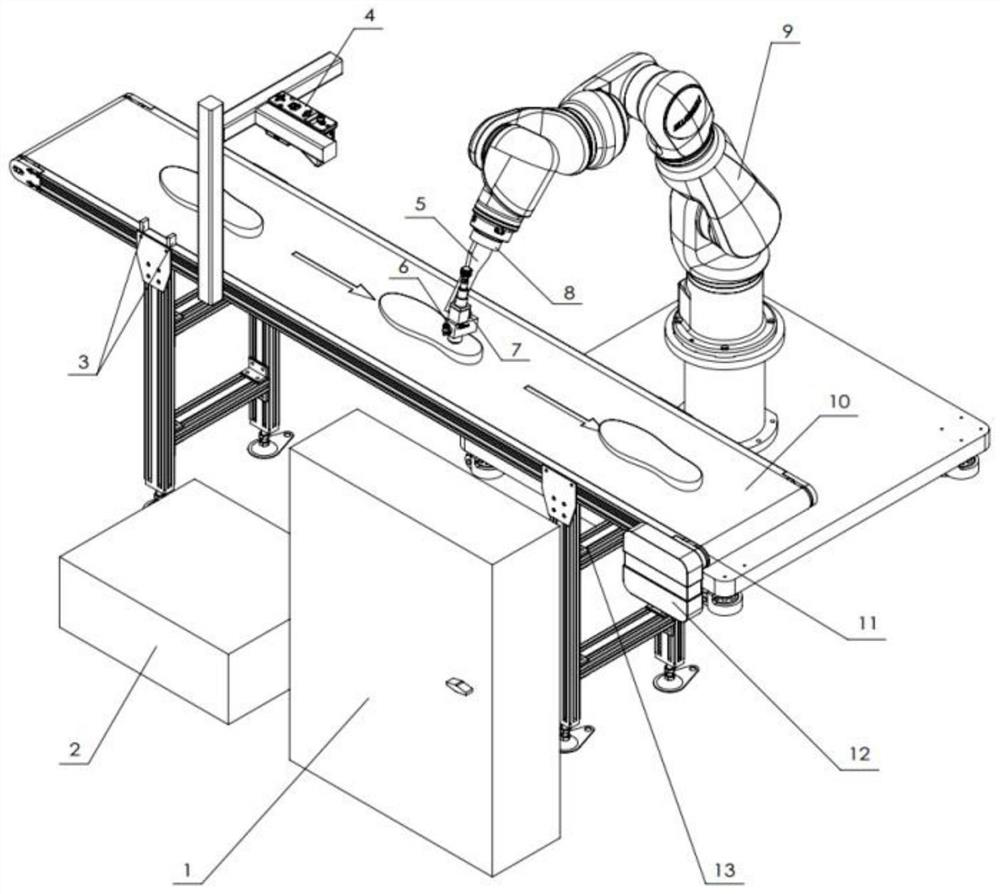

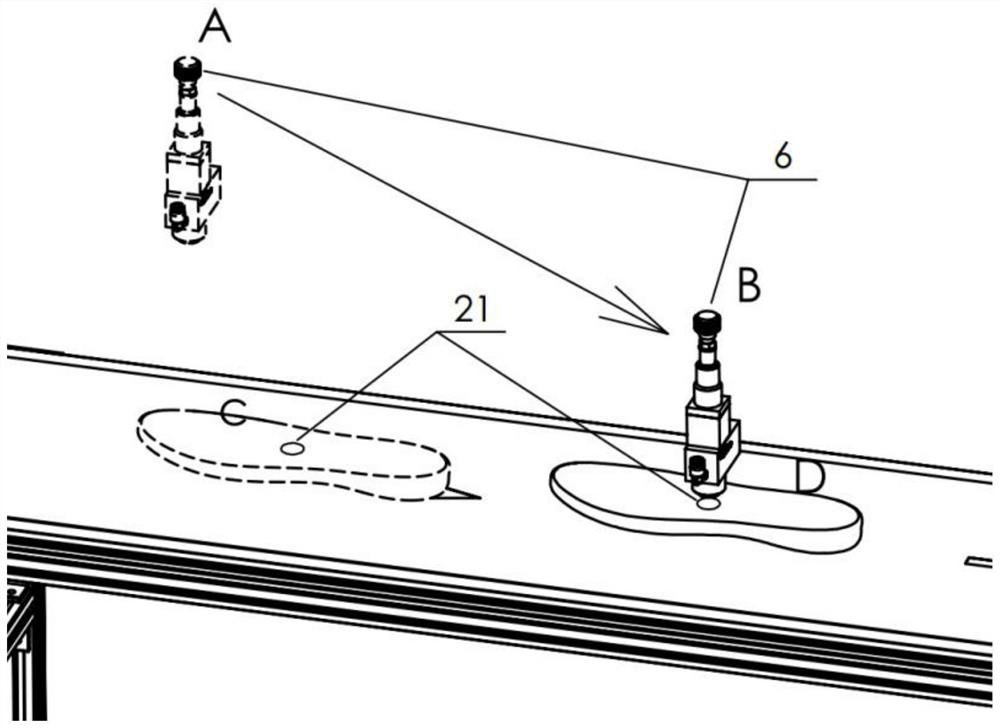

Sole glue spraying device and method based on monocular vision

The invention provides a sole glue spraying device based on monocular vision. The sole glue spraying device comprises a conveyor belt device, a visual device, a manipulator device and a control system. The invention further provides a sole glue spraying method based on monocular vision. The sole glue spraying method comprises the following steps of equipment debugging, image acquisition, image processing, measurement coordinate acquisition, track point position extraction, coordinate transformation, glue spraying action and the like. According to the device and the method, the monocular camerais adopted to replace an existing double-sided visual system; the cost is relatively low, the advantages of high three-dimensional vision measurement and detection speed, high robot glue spraying efficiency and high universality are combined, the glue application work can be rapidly completed for any shoe size and any shoe shape outline, the glue application quality meets the requirements of theshoemaking process, the labor is saved, and the labor intensity of workers and possible damage of chemical adhesives to the human body are reduced.

Owner:QUANZHOU HUAZHONG UNIV OF SCI & TECH INST OF MFG +1

Glue spraying device

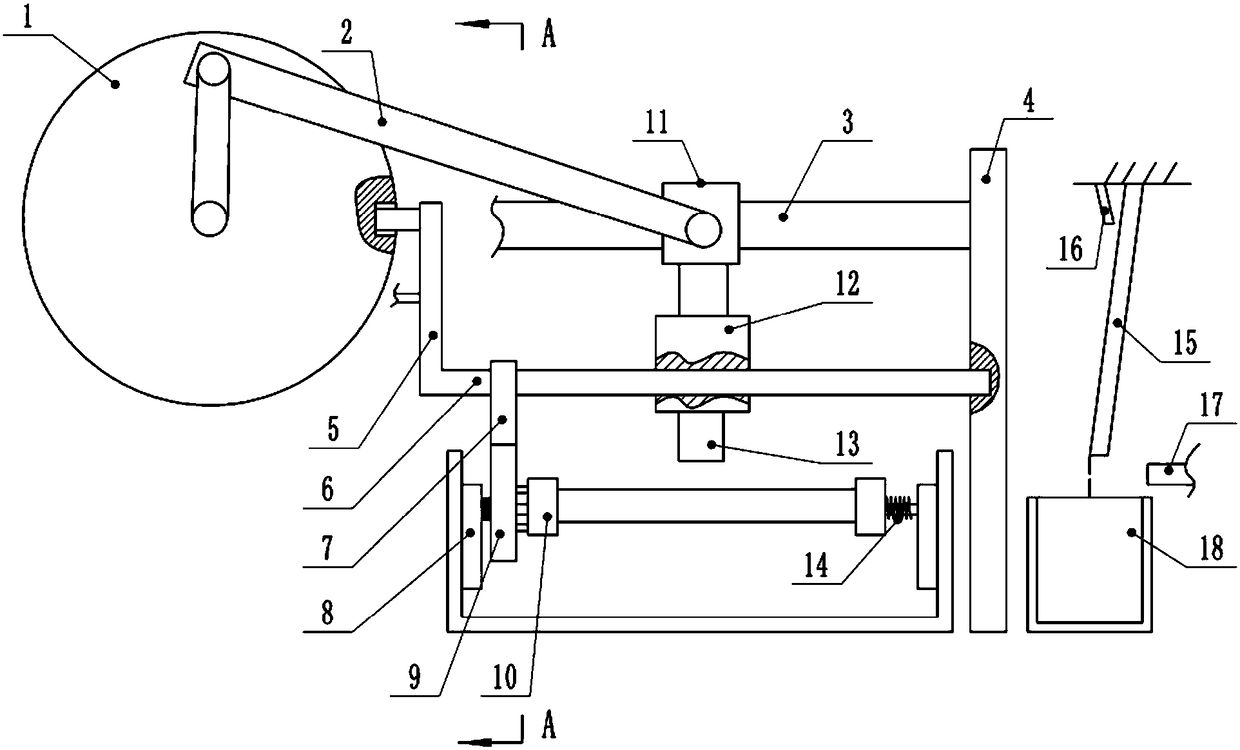

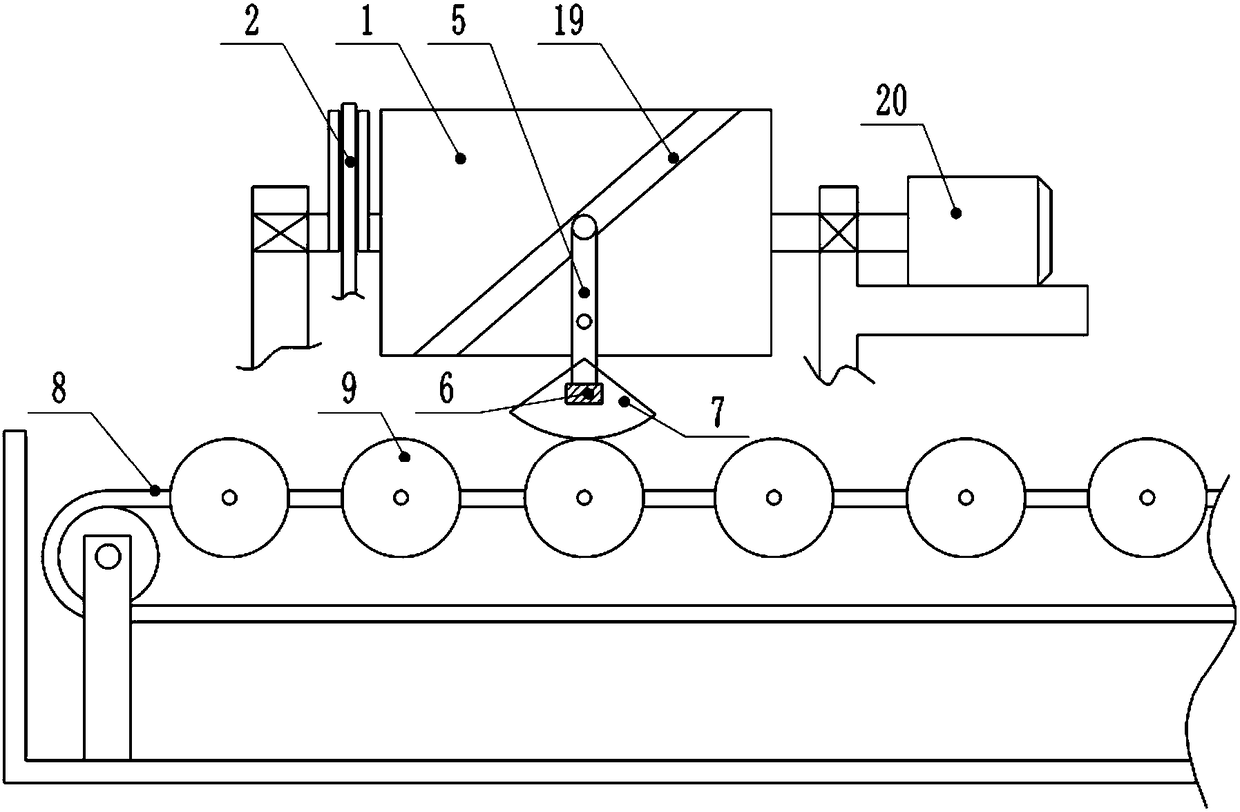

The invention belongs to the technical field of spraying equipment, and particularly relates to a glue spraying device. The glue spraying device comprises a conveying mechanism and a glue spraying part. The conveying mechanism is provided with a plurality of clamping mechanisms; the glue spraying part comprises a reciprocating movement mechanism, a reciprocating swinging mechanism and a glue spraying gun; the reciprocating movement mechanism is a slider-crank mechanism; an installation mechanism is hinged onto a slide block; the reciprocating swinging mechanism comprises a cylinder and a swinging rod; the swinging rod is hinged onto the rack; a curve sliding chute is formed in the curve surface of the cylinder; the upper end of the swinging rod is slidably connected into the curve slidingchute; the cylinder rotates to drive the swinging rod to swing in a reciprocating way through the curve sliding chute; a driving rod is fixed to the lower end of the swinging rod and is parallel to asliding rod; the installation mechanism is slidably connected onto the driving rod; a wabbler mechanism is arranged between the driving rod and the clamping mechanism; and the driving rod swings in areciprocating way so as to drive the clamping mechanism to rotate through the wabbler mechanism. When the glue spraying device provided by the scheme is used for spraying a glue, the glue spraying guncan move front and back in a reciprocating way and swinging left and right in a reciprocating way, and a workpiece can further rotate in a reciprocating way, so that a glue spraying effect is good, and the glue spraying efficiency is high.

Owner:陕西华强涂装技术有限公司

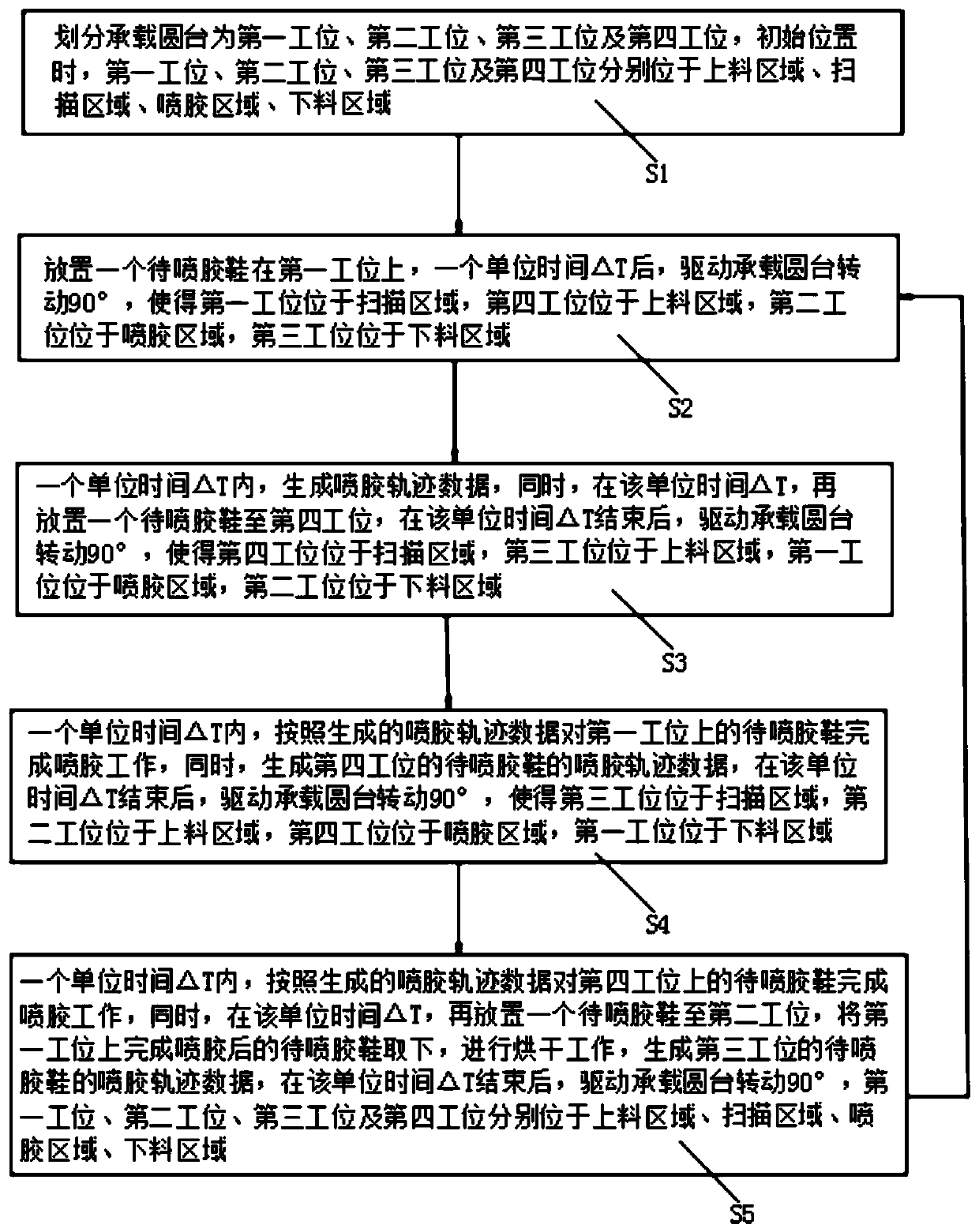

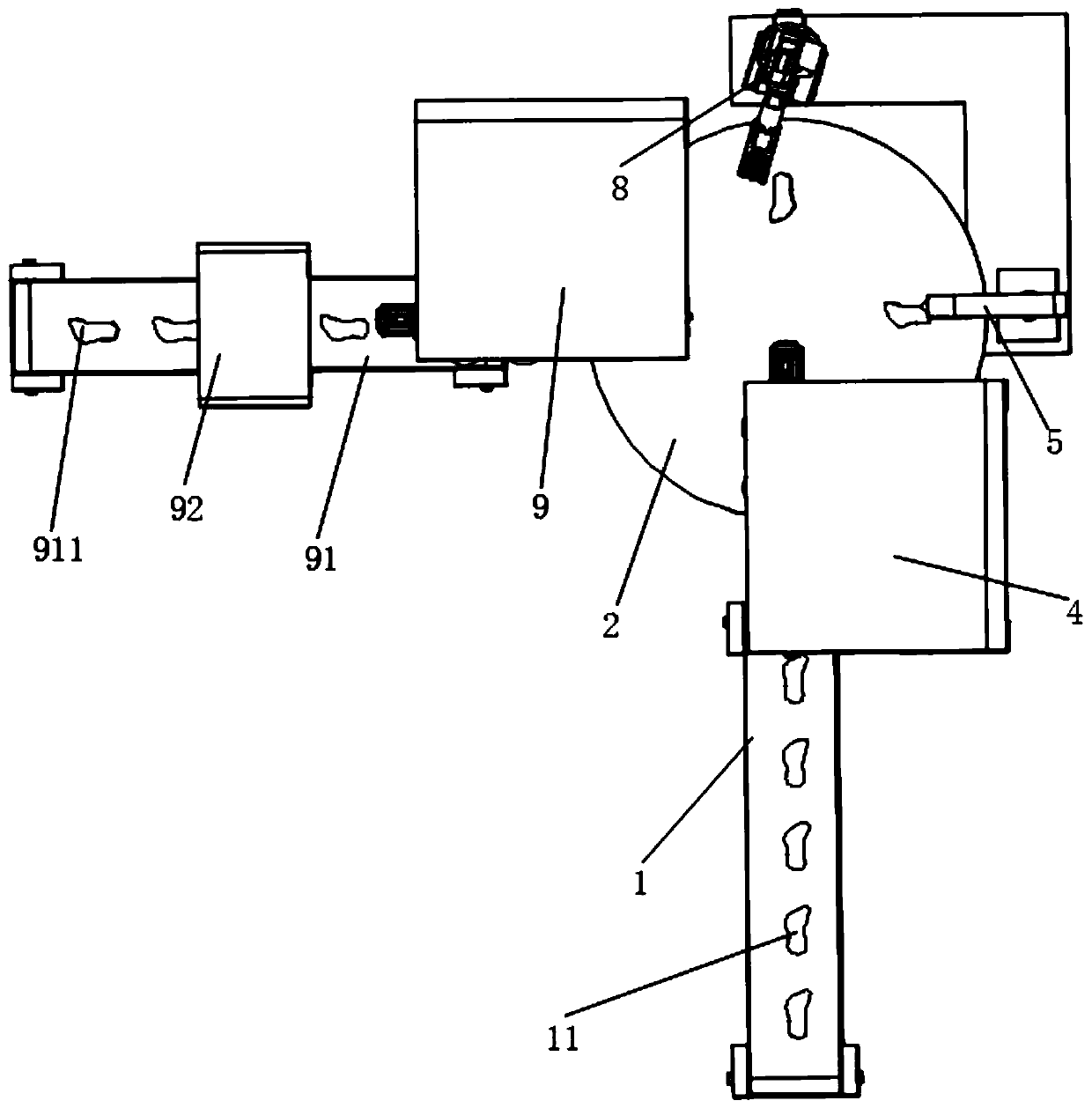

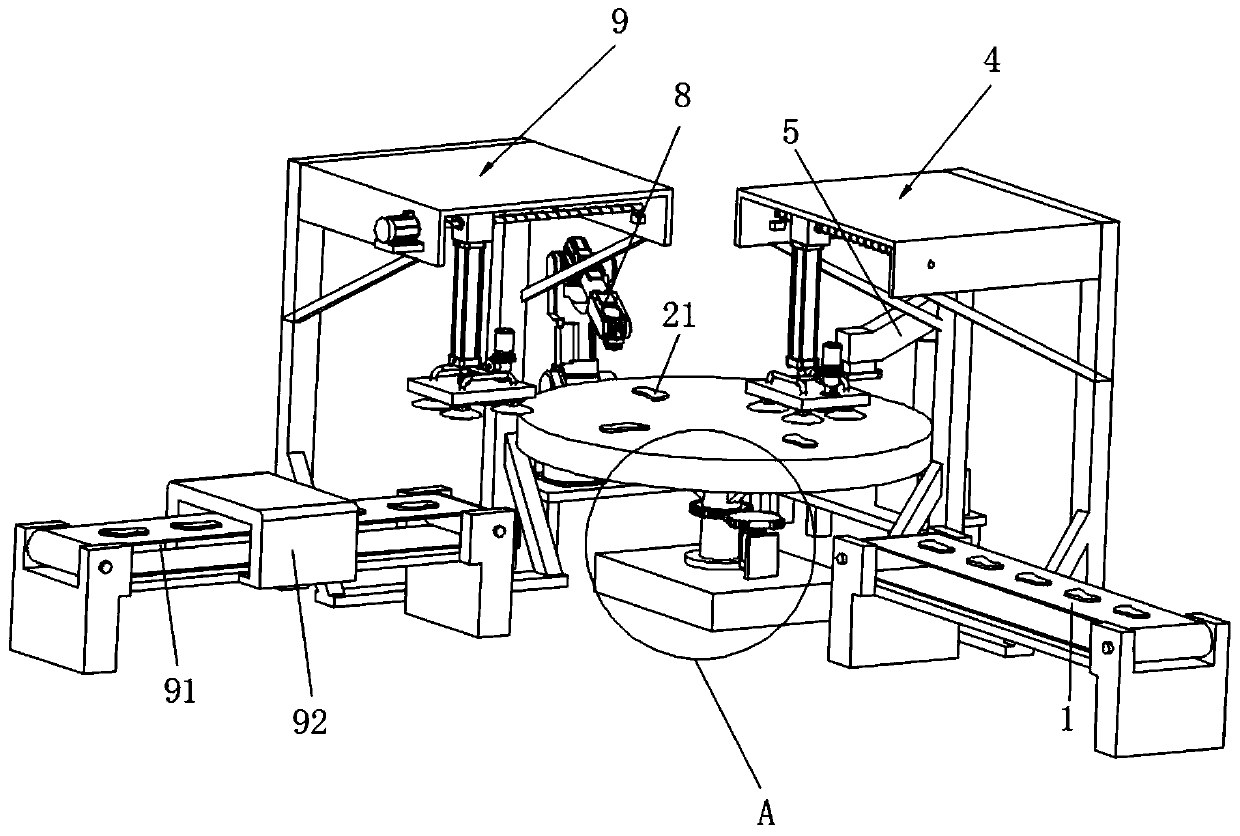

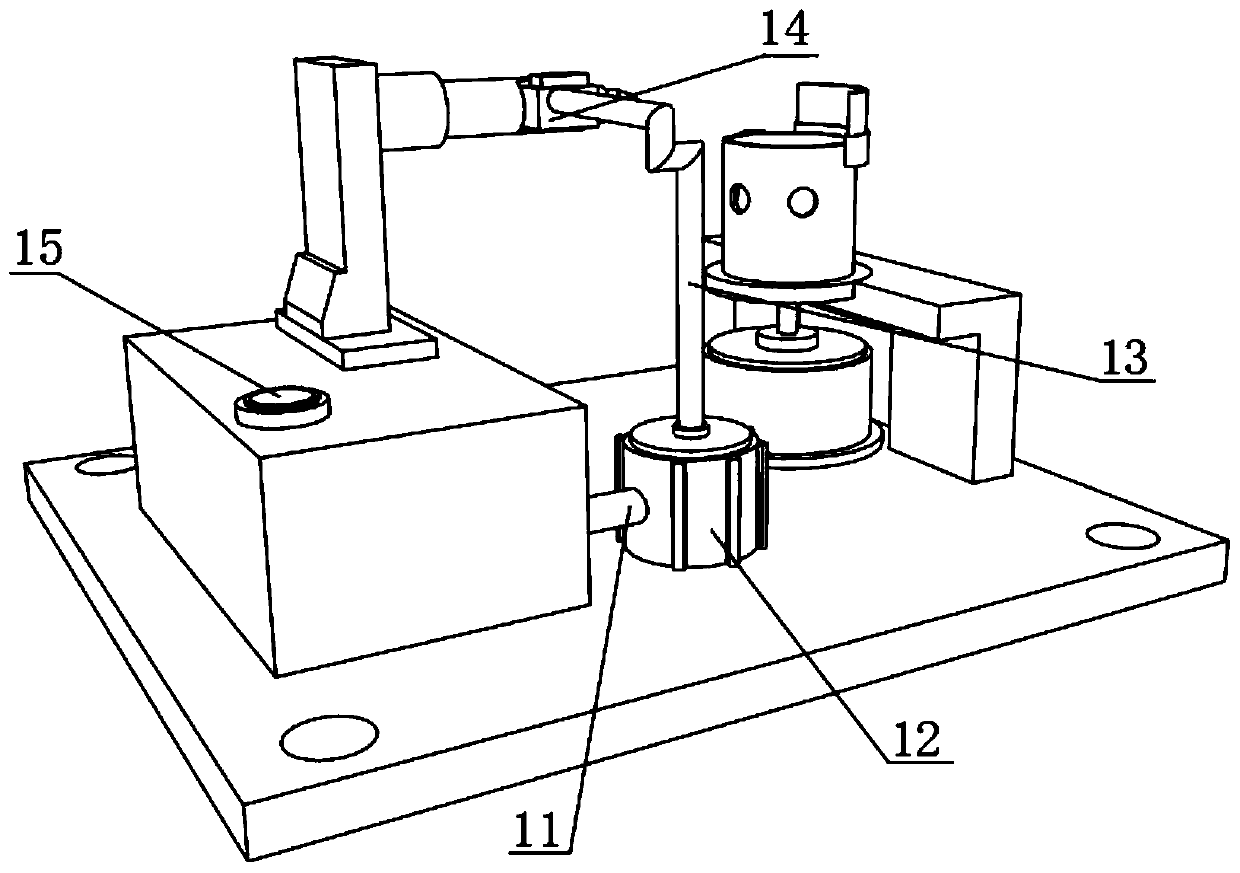

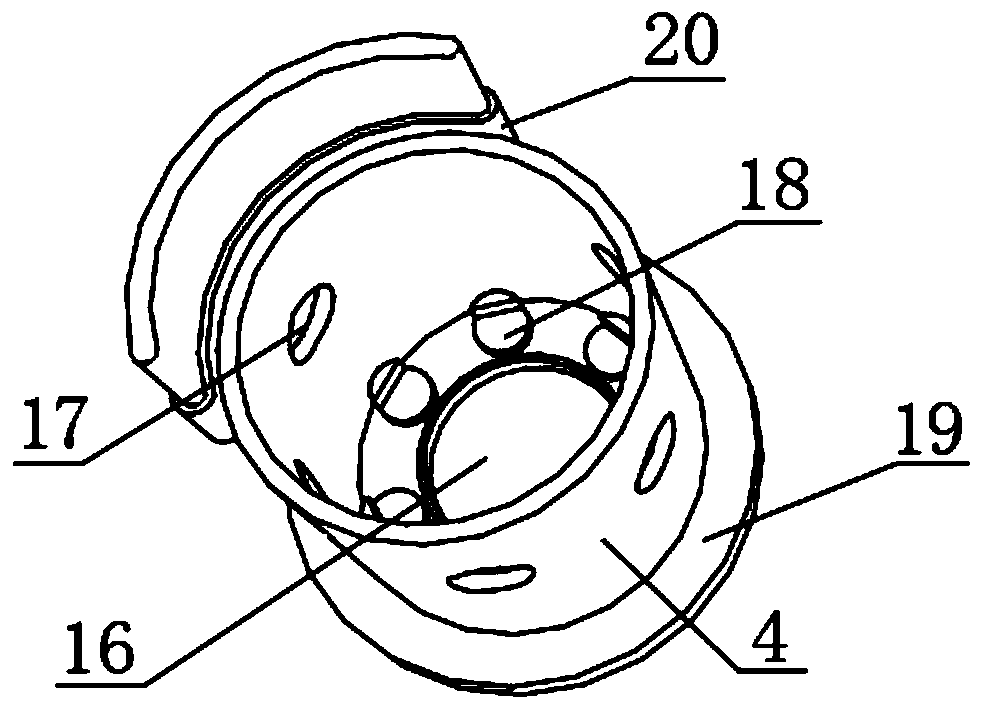

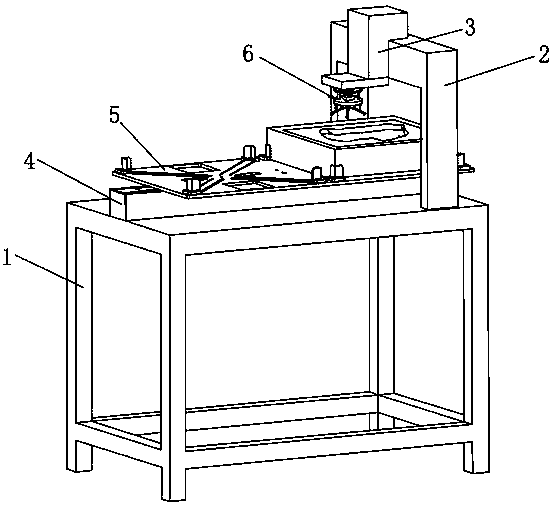

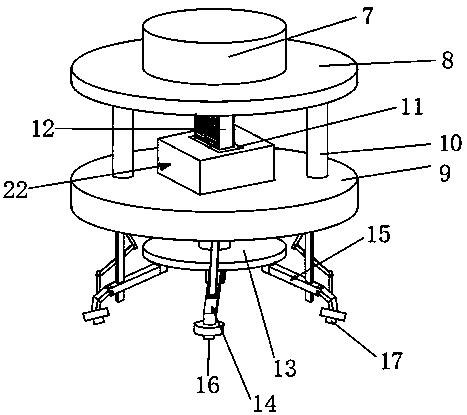

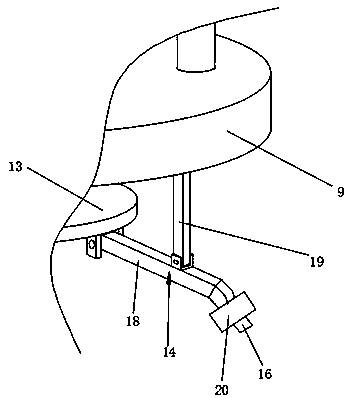

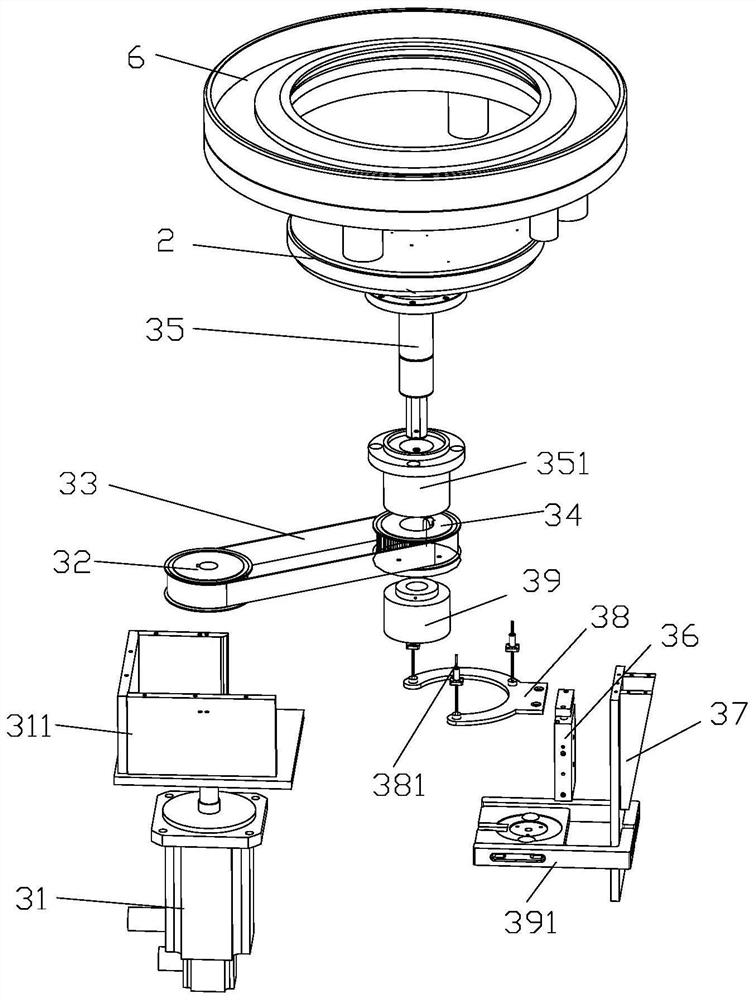

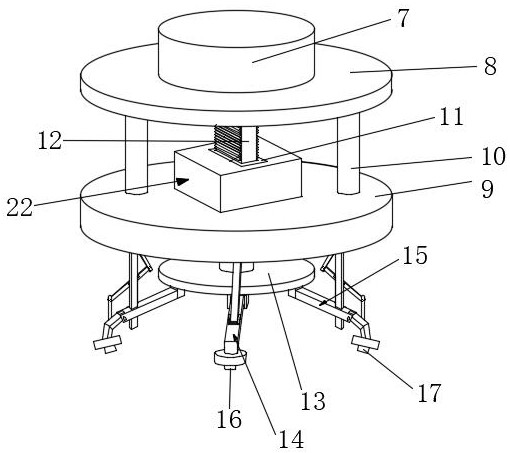

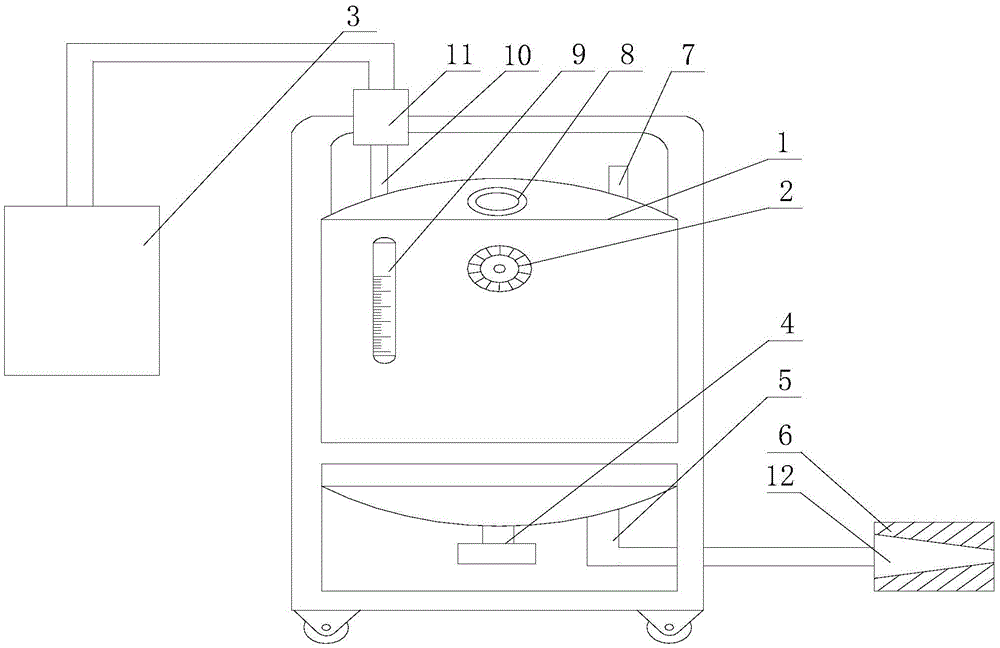

Glue spraying system and method for shoe sole processing

InactiveCN111166011AImprove glue spraying efficiencyImprove processing efficiencyShoe gluingEngineeringMaterials science

The invention relates to the technical field of shoe processing and aims at providing a glue spraying system for shoe sole processing. The system comprises a first belt conveyor, a bearing device, a feeding device, a track generation device, a glue spraying device, a blanking device and a second belt conveyor. The first belt conveyor is used for conveying shoes to be subjected to glue spraying, wherein the shoes sleeve a die. The bearing device comprises a bearing circular truncated cone and a first driving piece, four third containing grooves are formed in the bearing circular truncated cone,and the first driving piece is used for driving the bearing circular truncated cone to periodically rotate along the axis of the bearing circular truncated cone. The feeding device is used for takingout shoes to be subjected to glue spraying from the containing grooves and placing the shoes on the bearing circular truncated cone. The track generation device is used for scanning one shoe to be subjected to glue spraying on the bearing circular truncated cone and directly facing the track generation device to generate a glue spraying track. The glue spraying device is used for spraying glue. The second belt conveyor is used for conveying the shoes to be subjected to glue spraying, which are taken down by the blanking device; and a drying device is arranged on the second belt conveyor. Theglue spraying device has the advantage of improving the glue spraying efficiency of shoes.

Owner:HUIZHOU UNIV

Rotary type quick glue spraying device with instant drying function

InactiveCN111111987AShorten the timeImprove glue spraying efficiency and qualityPretreated surfacesLiquid spraying apparatusMetal cylinderEngineering

The invention discloses a rotary type quick glue spraying device with an instant drying function. The device comprises a base, wherein an L-shaped fixing frame is arranged on the outer wall of one side of the top of the base, a support is arranged on the outer wall of one side of the top of the L-shaped fixing frame, an installation groove is formed in the outer wall of one side of the top of thesupport, a motor is clamped in the installation groove, a fan is arranged at the output end of the motor, an L-shaped placing groove is formed in the outer wall of the top of the L-shaped fixing frame, a fixing barrel is welded on the inner wall of the bottom of the L-shaped placing groove, a baffle is arranged on the outer circumferential wall of one side of the fixing barrel, through holes distributed at equal distances are formed in the outer circumferential wall of the fixing barrel, a stepping motor is arranged on the outer top wall of one side, close to the L-shaped fixing frame, of thebase, and an output shaft of the stepping motor is connected with a rotating shaft through a coupler. According to the rotary type quick glue spraying device with the instant drying function, the drying work is effectively carried out in time, so that the process of putting a metal cylinder workpiece into drying equipment for drying is omitted, the time is saved, and the glue spraying efficiency and quality of the integral device are also improved.

Owner:GUANGDONG ORIENT RESIN

Glue spraying device for paperboard processing

ActiveCN111823652AIncrease pressureEffective barrierMechanical working/deformationSpraying apparatusPaperboardElectric machinery

The invention discloses a glue spraying device for paperboard processing, and relates to the technical field of paperboard glue spraying. The glue spraying device aims to solve the problem of glue solidification in paperboard transportation. The glue spraying device specifically comprises two fixing frames, wherein limiting plates are arranged on the outer walls of the opposite sides of the two fixing frames; a first guide roller and a second guide roller which are distributed at equal intervals are arranged on the outer walls of the opposite sides, close to the lower parts of the two limitingplates, of the two fixing frames correspondingly; the circumferential outer wall of each second guide roller is sleeved with the same belt, and a first motor is arranged on the outer wall of the side, close to one of the second guide rollers, of one of the fixing frames; and an output shaft of the first motor is connected with one of the second guide rollers through threads, guide holes which aredistributed at equal intervals are formed in the outer wall, close to the upper part of the first guide roller, of the other fixing frame, and a humidifying mechanism is arranged on the side, far away from the guide holes, of the other fixing frame. According to the glue spraying device, the problem of glue solidification in the transportation is effectively avoided, and particles in water vaporcan be effectively blocked.

Owner:安徽星瑞包装材料有限公司

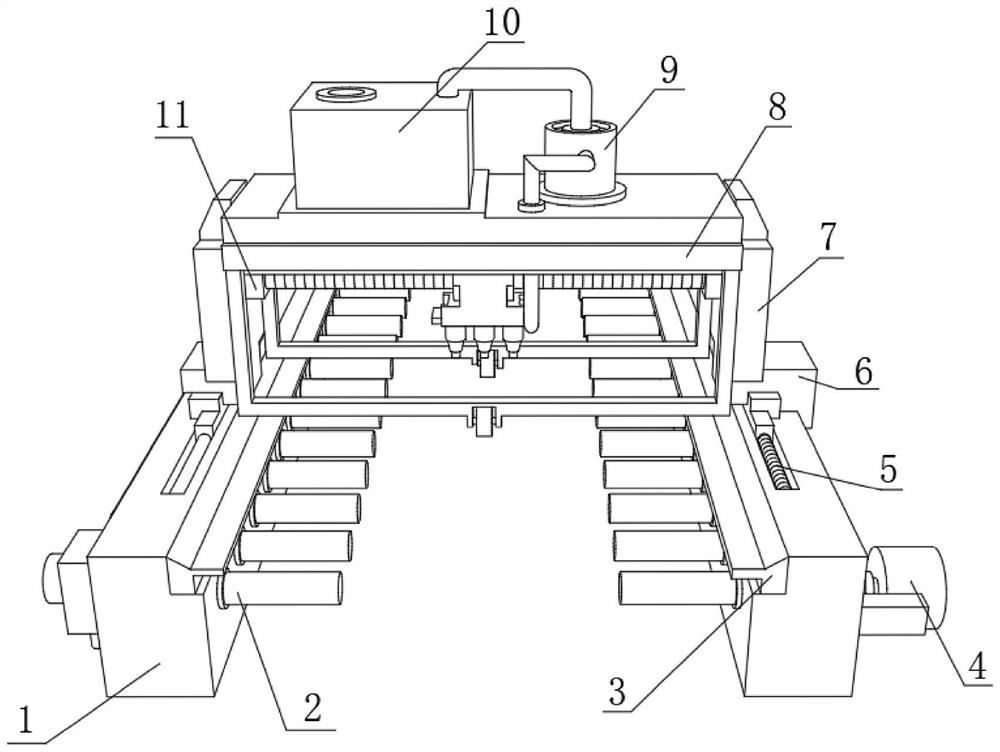

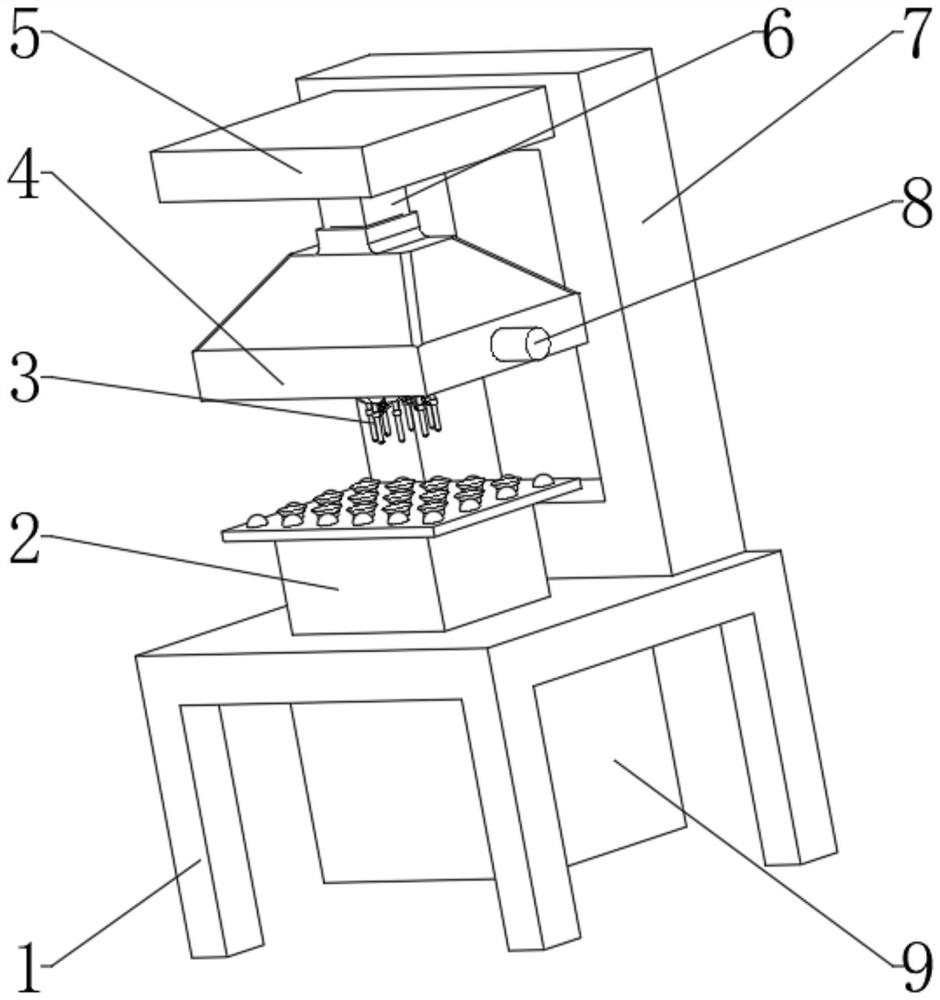

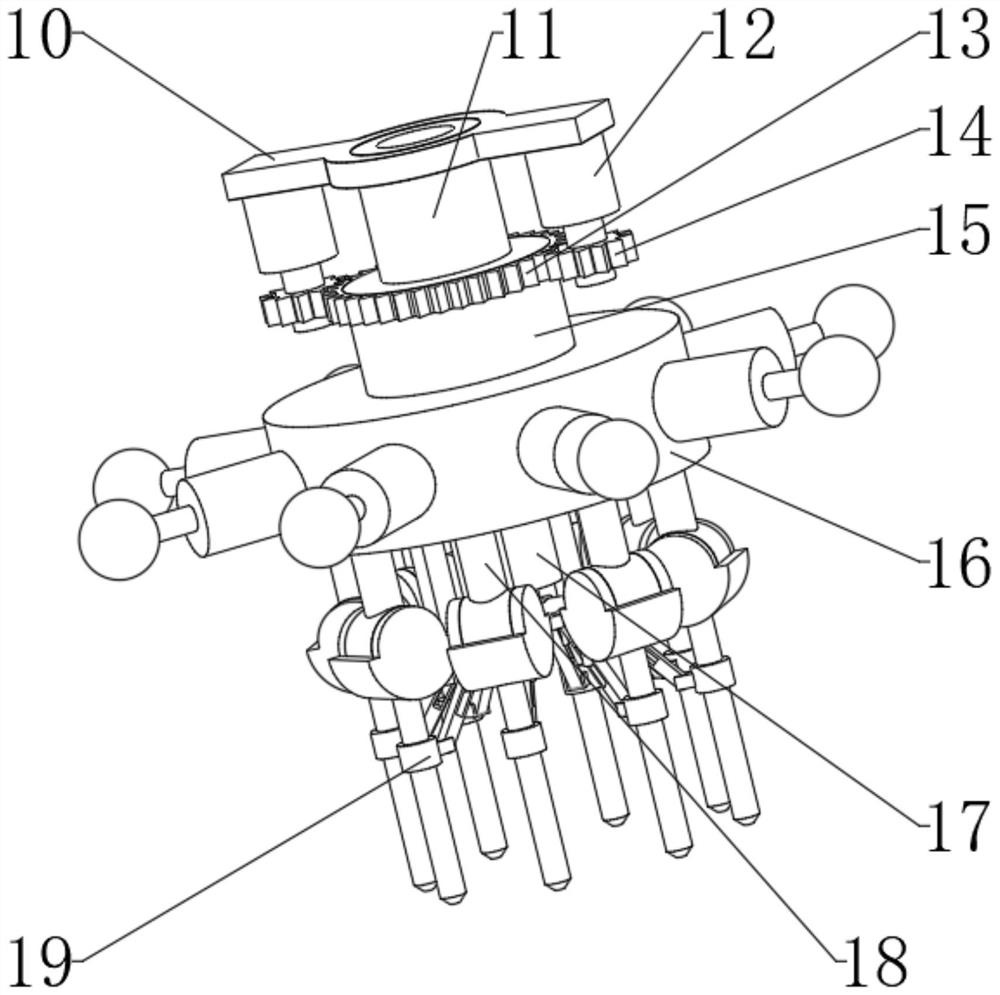

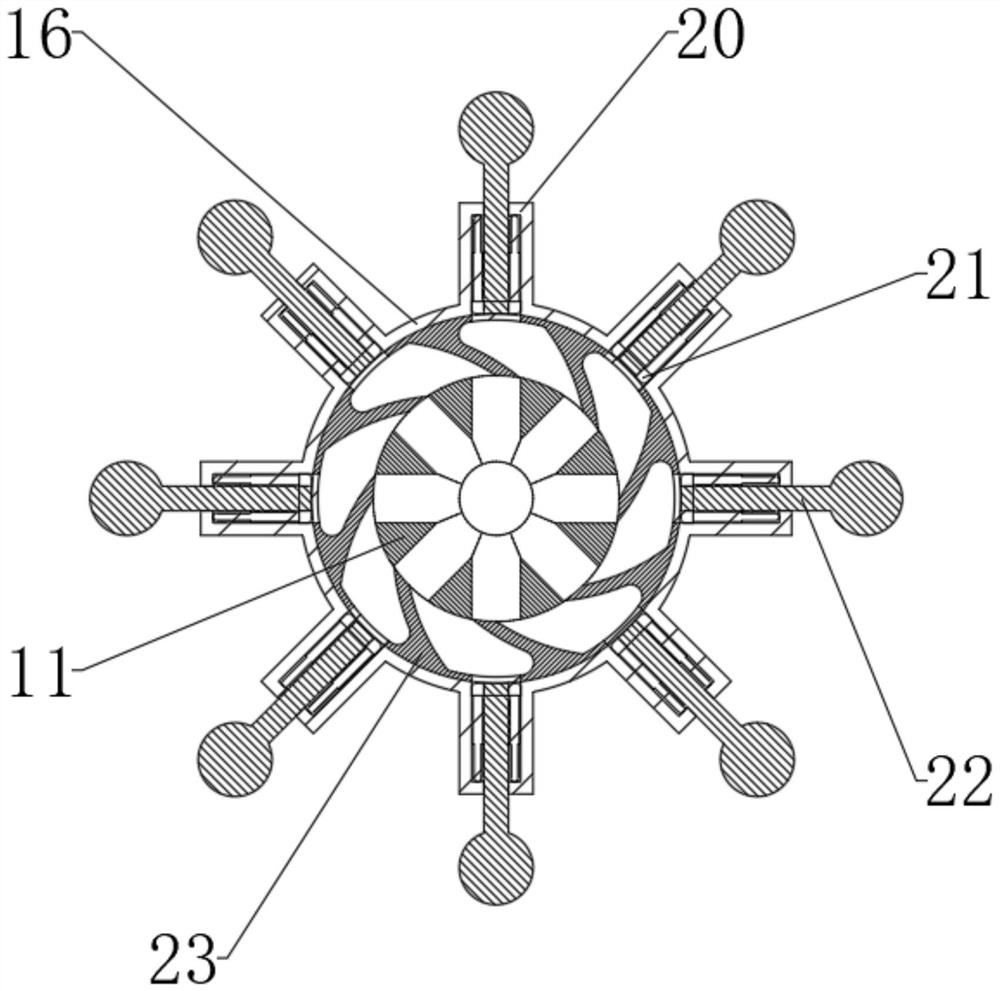

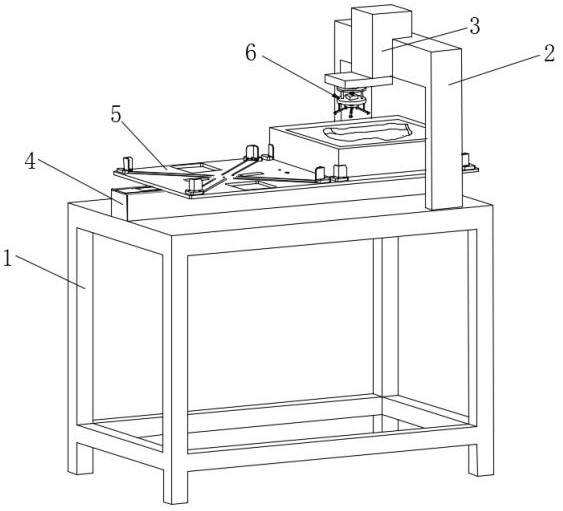

Multi-head glue spraying device for sand mold casting

The invention discloses a multi-head glue spraying device for sand mold casting. The multi-head glue spraying device for sand mold casting comprises a rack, a portal frame is arranged on the rack, a sliding block is arranged on the portal frame, a linear conveying sliding table is arranged on the rack, a multi-head glue spraying mechanism is arranged at the bottom of the sliding block, the multi-head glue spraying mechanism comprises a rotating seat which is arranged at the bottom of the sliding block, an upper base plate is arranged at the bottom of the rotating seat, a lower base plate is arranged below the upper base plate, a plurality of positioning rods are arranged between the upper base plate and the lower base plate; and a vertically-downward stroke sleeve is arranged in the middleof the lower base plate, a movable rod is arranged in the stroke sleeve, a lifting disc is arranged at the bottom of the movable rod, a plurality of first linkage frames and second linkage frames arearranged between upper base plates of the lifting disc, first atomization glue spraying heads are arranged on the first linkage frames, and second atomization glue spraying heads are arranged on thesecond linkage frames. According to the multi-head glue spraying device for sand mold casting, spraying an inner cavity of a sand mold is carried out through the multi-head glue spraying mechanism, and the multi-head glue spraying device has the characteristics of being wide in spraying face and uniform in spraying.

Owner:INST OF LASER & OPTOELECTRONICS INTELLIGENT MFG WENZHOU UNIV

Efficient glue spraying device for cartoon shoe manufacturing

InactiveCN106307821AReduce the time to open the shutterImprove work efficiencyShoe gluingEngineeringMechanical engineering

Owner:ZHEJIANG KAJIALI SHOES CO LTD

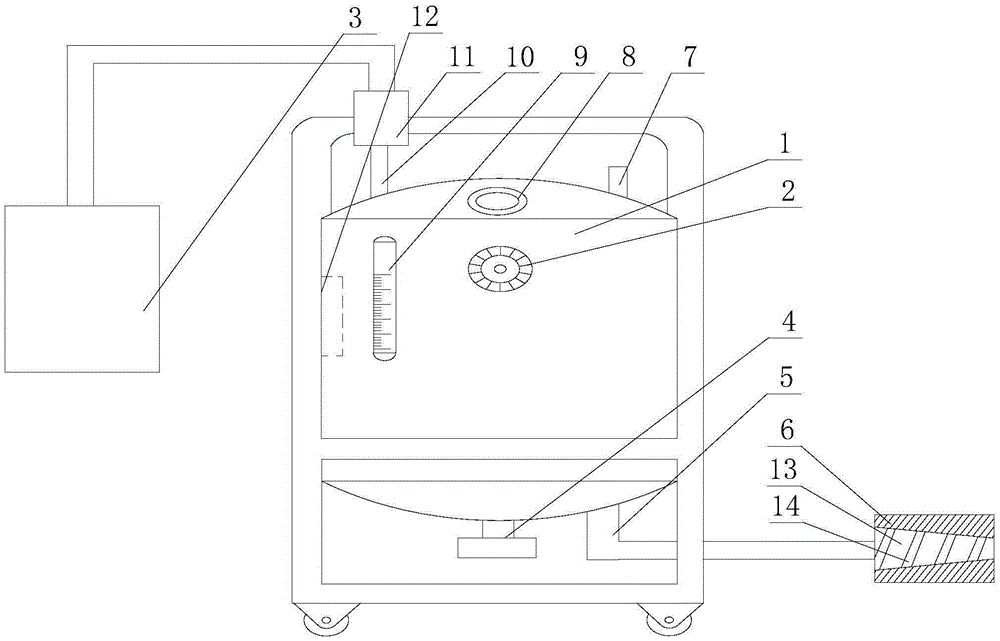

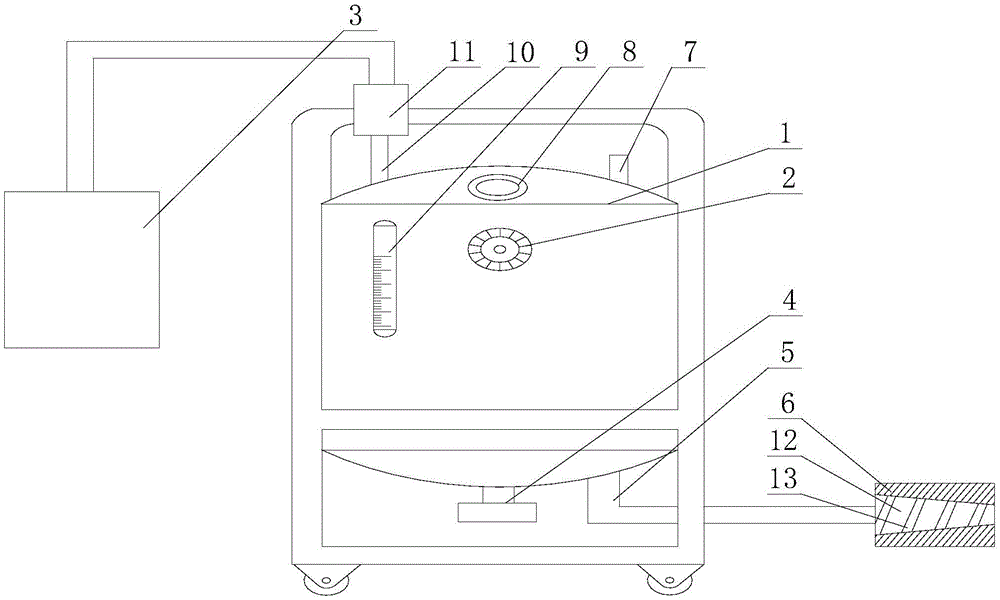

Using method for board outer wall glue coating mechanism

InactiveCN106733523AGood adhesionReduce work intensityLiquid surface applicatorsLiquid spraying apparatusSpray nozzleAir pump

The invention discloses a using method for a board outer wall glue coating mechanism. The using method includes the following steps that, a tank is filled with a certain amount of glue liquid through a glue inlet, and the initial amount of the glue liquid in the tank is read out in real time through a liquid level meter; an air pump is started, air flow starts to be injected into the tank through an air inlet pipe, and along with increase of pressure in the tank, the glue liquid is directly sprayed on the work face of a board directly through a glue outlet pipe and a spray nozzle under the effect of air pressure, so that automatic glue coating can be achieved; and after glue coating ends, the air pump is closed, a valve switch of an air outlet pipe is turned on, so that air in the tank can be exhausted till the pressure in the tank restores to the normal atmosphere state. According to the using method for the board outer wall glue coating mechanism, by means of air pressure pushing, the glue liquid is fast sprayed on the board to facilitate adhesion of a sponge, a traditional manual smearing manner is converted into mechanized automatic operation, the work intensity of workers is greatly lowered, and meanwhile, the glue spraying efficiency is improved.

Owner:重庆汉驰家具设计有限公司

Veneer gluing equipment and gluing method thereof

ActiveCN113414060AControl spray rangeExpand distribution channelsLiquid surface applicatorsCoatingsStructural engineeringMechanical engineering

The invention discloses veneer gluing equipment and a gluing method thereof, and belongs to the technical field of veneer gluing equipment. The veneer gluing equipment comprises a rack and a spray head assembly arranged above the rack, wherein the spray head assembly comprises a middle cylinder and an outer butt strap fixedly connected to the outer wall of the top of the middle cylinder; the outer wall of the middle cylinder is rotationally connected with a rotating sleeve; the outer wall of the bottom of the rotating sleeve is fixedly connected with a rotating box; the inner wall of the bottom of the middle cylinder is provided with more than three flow channels; and the outer wall of the bottom of the rotating box is provided with more than three overflow pipes which are circumferentially arranged and provided with annular cylinders on the outer walls of the bottoms. According to the veneer gluing equipment and the gluing method thereof, the glue spraying assembly is provided, and a glue circulation channel can be expanded through the more than three overflow pipes and discharge pipes, so that the glue spraying efficiency is improved; meanwhile, through rotation of the rotating box, passage of glue through the overflow pipes and the discharge pipes is accelerated, and uniform glue spraying work can be conducted within the coverage range of the glue spraying assembly; and an adjusting cylinder is started to drive a movable arm to move, and the angles of the discharge pipes are adjusted through sliding sleeves, so that the glue spraying range of the spray head assembly can be controlled.

Owner:宿州市中东木业有限公司

Automatic tire cleaning and glue spraying method

The invention discloses an automatic tire cleaning and glue spraying method. The method comprises the following steps that S1, a tire placement frame is prepared, specifically, a steel plate is prepared and laid on the floor, and a plurality of round rods are welded on the surface of the steel plate in a dot matrix manner; S2, the steel plate is erected, specifically, the bottom of one end of thesteel plate is padded with a support block, so that one end of the steel plate is lifted, tires needing to be subjected to glue spraying are arranged on the round rods one by one in a sleeving mode; S3, clear water is prepared, specifically, two water tanks and a water pump are prepared, clear water is injected into the two water tanks, and the two water tanks are marked as the water tank A and the water tank B correspondingly; and S4, tire washing water is prepared. The method is reasonable in design, high in practicability and convenient to operate, substances such as dust and oil on the surfaces of the tires can be rapidly removed, after the tires are dried and dewatered, the glue spraying procedure is conducted when the tires are not cooled, thus, connection between the glue and the tires is tight and stable, the glue spraying efficiency of the tires is improved, and the glue spraying effect is optimized.

Owner:南通骏标自密封安全轮胎科技有限公司

Using method of injecting structure capable of automatically supplementing glue

InactiveCN106733431AReduce work intensityGood adhesionLiquid surface applicatorsSpraying apparatusAir pumpSpray nozzle

The invention discloses a using method of an injecting structure capable of automatically supplementing glue. The using method of the injecting structure capable of automatically supplementing glue includes the following steps that a certain amount of glue liquid is filled into a tank through a glue inlet, and the initial amount of the glue liquid in the tank is read out in real time through a liquid level meter; an air pump is started, air flow starts to be injected into the tank through an air inlet pipe, and along with increase of pressure in the tank, the glue liquid is directly sprayed on the work face of a board directly through a glue outlet pipe and a spray nozzle under the effect of air pressure, so that automatic glue coating can be achieved; and after glue coating ends, the air pump is closed, a valve switch of an air outlet pipe is turned on, so that air in the tank can be discharged till the pressure in the tank restores to the normal atmosphere state. According to the using method of the injecting structure capable of automatically supplementing glue, by means of air pressure pushing, the glue liquid is fast sprayed on the board to facilitate adhesion of a sponge, a traditional manual smearing manner is converted into mechanized automatic operation, the work intensity of workers is greatly lowered, and meanwhile, the glue spraying efficiency is improved.

Owner:重庆汉驰家具设计有限公司

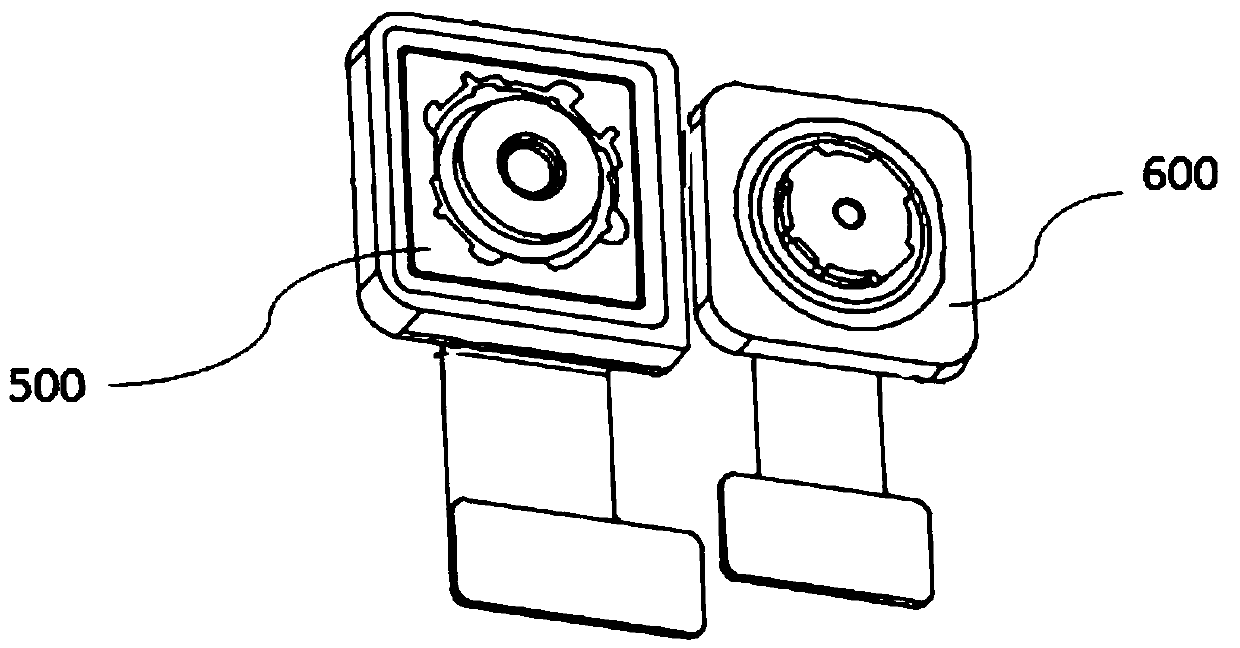

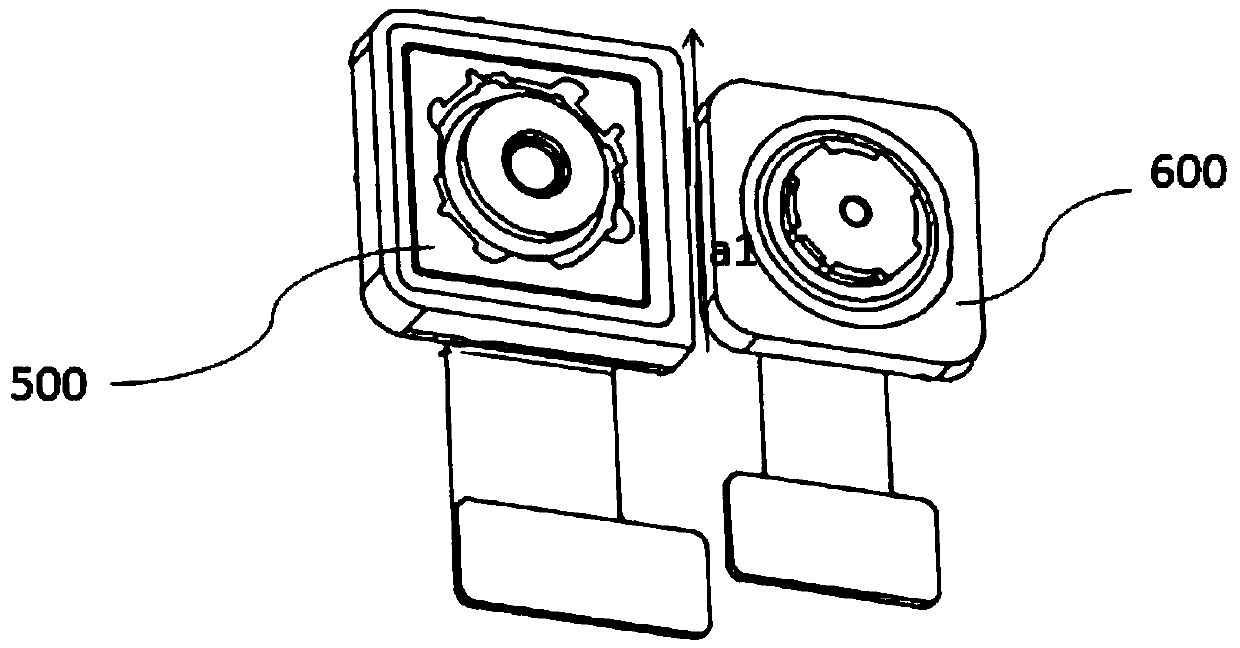

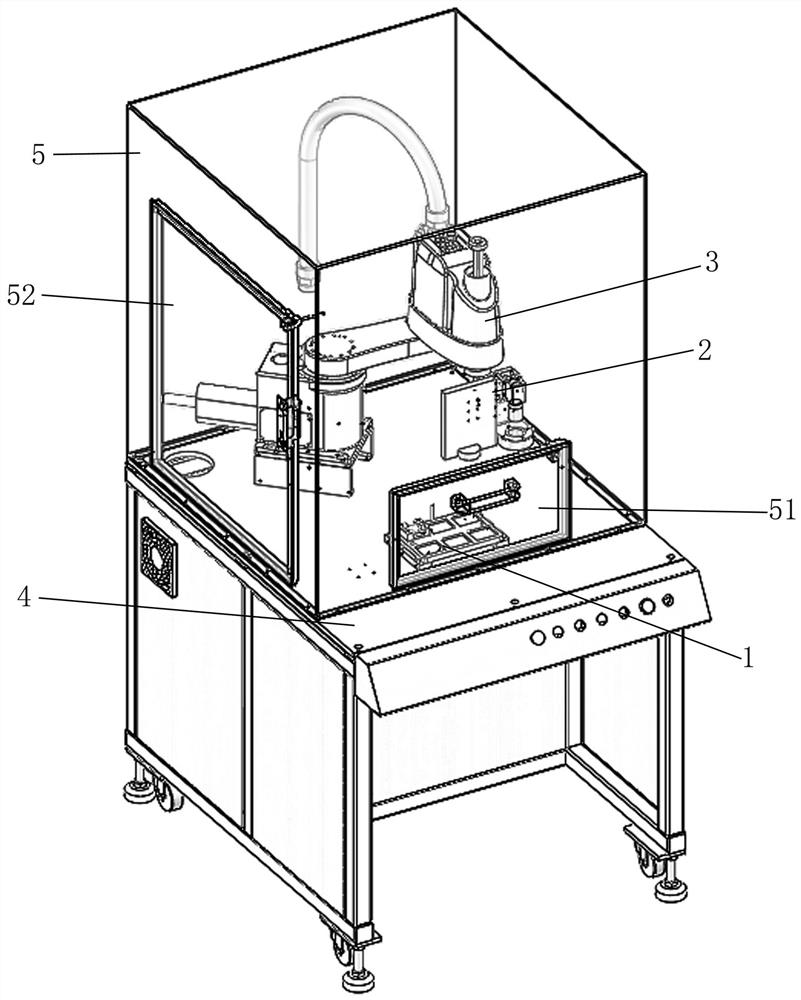

Glue spraying equipment, glue spraying method and assembling method of array camera modules

ActiveCN110935578ARealize vertical glue sprayingRealize inclined glue sprayingTelevision system detailsLiquid surface applicatorsEngineeringCamera module

Owner:NINGBO SUNNY OPOTECH CO LTD

Glue spraying equipment for semiconductor photoetching processing

InactiveCN113376966AImprove glue spraying efficiencyAvoid edge exposurePhotomechanical coating apparatusWaferEngineering

The invention discloses glue spraying equipment for semiconductor photoetching processing. The equipment comprises a glue inlet and a nozzle pipe fixedly mounted at the bottom of the glue inlet; the bottom of the nozzle pipe is provided with a plurality of glue spraying openings; and the nozzle pipe is internally provided with an anti-blocking sealing element for adjusting the number of the glue spraying openings; a limiting piece is arranged above the end part of the anti-blocking sealing element;and the lower part of the anti-blocking sealing element is connected with an auxiliary device through a connecting piece; the side surface of the auxiliary device is provided with a discharging device to deal with excess sprayed glue outside a wafer; and a material collection device is arranged below the discharging device. According to the glue spraying equipment for the semiconductor photoetching processing, the number of the glue spraying openings in the nozzle pipe can be adjusted through the anti-blocking sealing element and the auxiliary device according to the outer diameter of the wafer; a positioning scraper on the auxiliary device can remove redundant sprayed glue on the outer side of the wafer while performing positioning, so that the glue spraying efficiency of the surface of the wafer is improved, edge exposure of the wafer in the subsequent process can be avoided, and the finished product efficiency of the wafer is effectively improved.

Owner:深圳恩必德电子科技有限公司

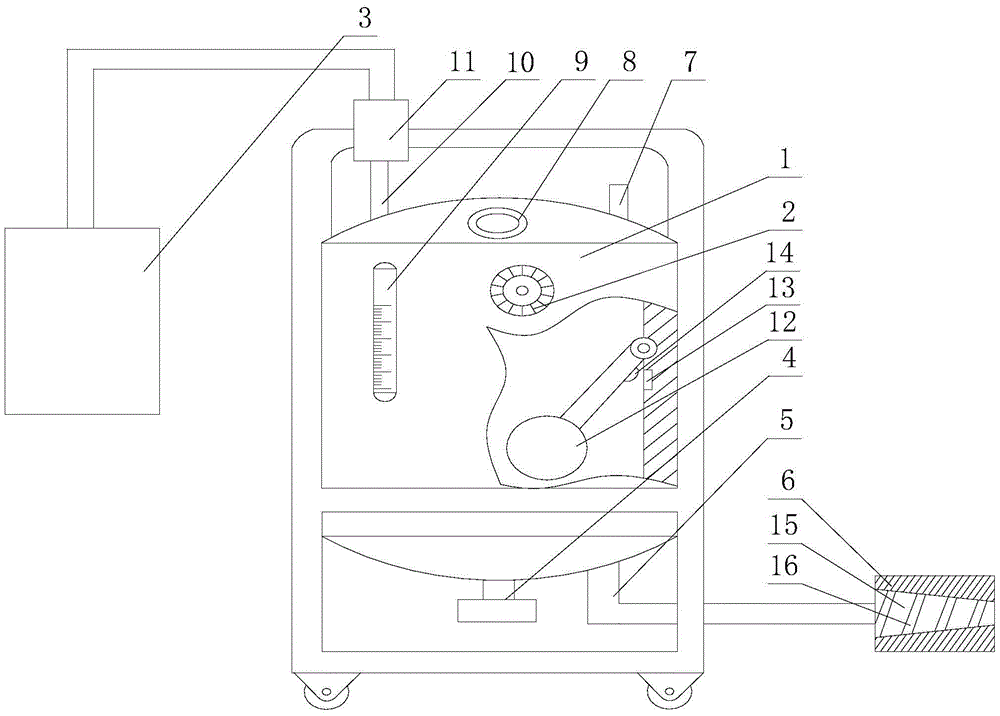

Board glue spraying mechanism

The invention discloses a board glue spraying mechanism. The board glue spraying mechanism comprises a mobile base and a tank body fixed on the mobile base; a glue inlet, and an intake pipe and an exhaust pipe communicated with the internal of the tank body are respectively arranged at the top end of the tank body; a glue outlet pipe communicated with the internal of the tank body is arranged at the bottom end of the tank body; the tail end of the intake pipe is communicated with an output end of an air pump; and the glue outlet pipe is connected with a nozzle. The board glue spraying mechanism further comprises a liquid level; the liquid level is arranged on the outer surface of the tank body; and a pressure sensor is mounted in the tank body, and is connected with the air pump through a controller. Glue is quickly sprayed on a board to conveniently bond sponges through air-pressure pushing; and a traditional manual coating mode is converted to mechanical automatic operation, so that the working intensity of workers is largely reduced, and meanwhile, the glue spraying efficiency is improved.

Owner:重庆汉驰家具设计有限公司

Use method of adhesive spraying device for wood plate frame

InactiveCN106733521AIncrease the exit speedQuick GlueLiquid surface applicatorsLiquid spraying apparatusJet flowAir pump

The invention discloses a use method of an adhesive spraying device for a wood plate frame. The use method comprises the following steps that a tank body is filled with a certain amount of adhesive solution through an adhesive inlet port; a gas flow starts to be injected in the tank body through a gas inlet pipe, and the adhesive solution is directly sprayed on a working surface of a wood plate through an adhesive outlet pipe and a nozzle under the pressure effect of air with the increasing of a pressure in the tank body; the inner diameters of the nozzle is gradually reduced in the ejection direction of the adhesive solution when the adhesive solution passes through the nozzle, so that the adhesive solution has a change of sudden reduction of a flow channel between the adhesive outlet pipe and the nozzle, and the ejection speed of the adhesive solution with a unit flow rate is suddenly increased; the adhesive solution rotates at a high speed before being ejected, and can form a conical jet flow while being ejected from the ejection end of the nozzle; and a gas pump is closed and a valve switch of a gas outlet pipe is turned on after adhesive coating is concluded, so that a gas in the tank body is exhausted until the pressure in the tank body is returned to a normal atmospheric state.

Owner:重庆汉驰家具设计有限公司

Production process of roller assembly

ActiveCN111267383AImprove glue spraying efficiencyIncrease productivityDomestic articlesChemistryManufacturing engineering

The invention relates to a production process of a roller assembly. The production process comprises the steps that A, rollers and a circular pipe are assembled, a certain number of the rollers are arranged on the circular pipe in a penetrating mode; B, glue spraying is conducted, specifically, glue is sprayed to the side faces of the rollers through a glue spraying device; C, vulcanizing treatment is conducted, specifically, the rollers are put into a drying oven to be vulcanized; D, polyurethane is poured, specifically, the rollers are put into a mould, and the polyurethane is poured into the rollers through a pouring machine; E, splitting is conducted, specifically, the rollers are taken out from the mould after the polyurethane is solidified, and the rollers are split through a cuttingdevice; and F, assembling is conducted, specifically, the rollers, a rotating shaft and a bearing are assembled together through assembling equipment. After the scheme is adopted, the production efficiency of the roller assembly can be improved.

Owner:浙江智菱科技有限公司

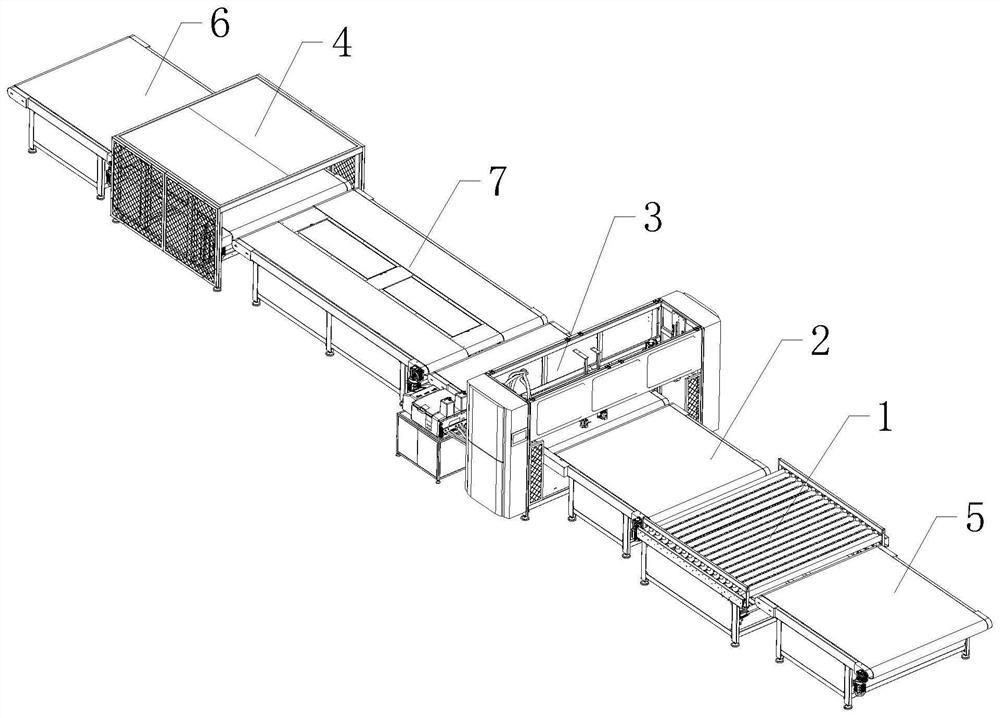

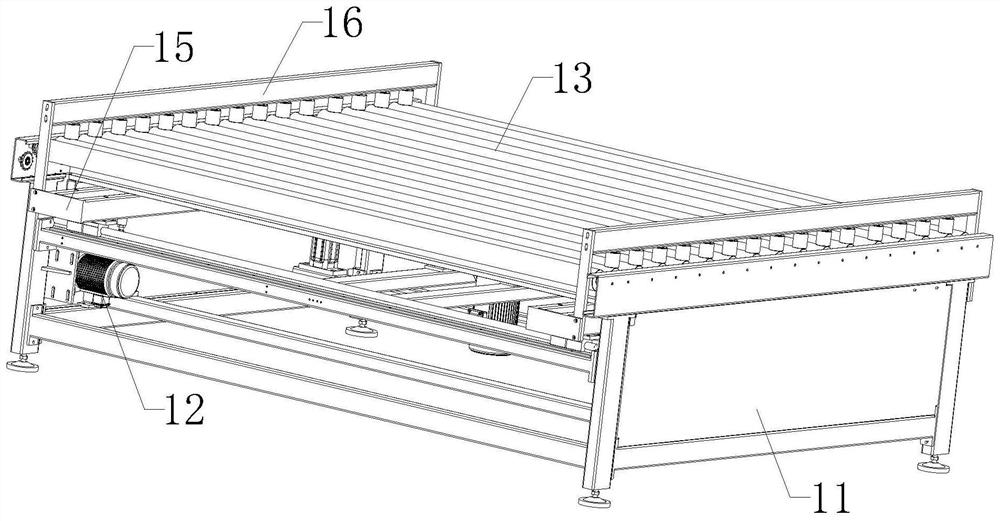

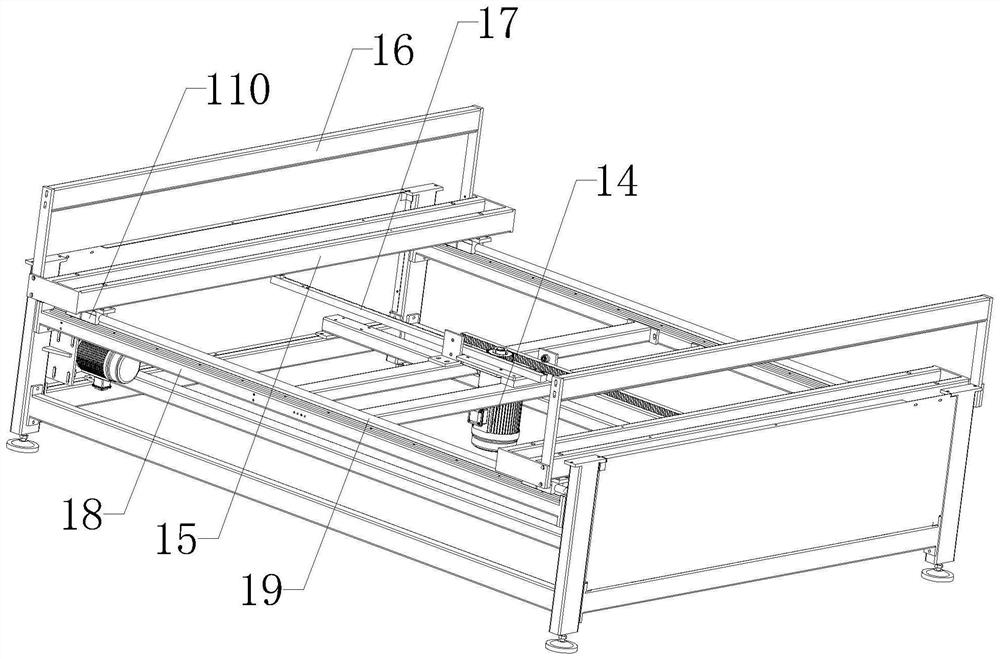

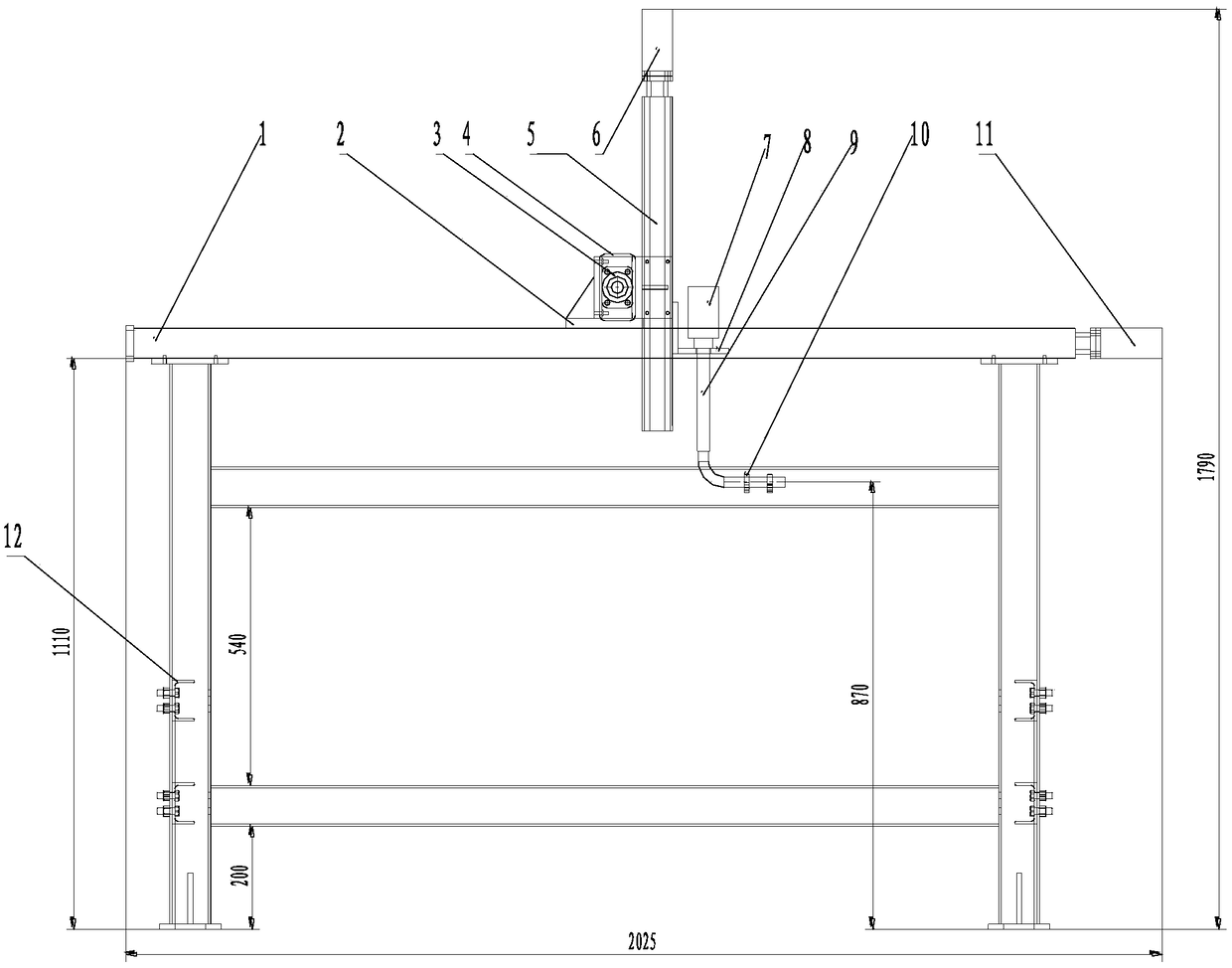

Mattress glue spraying production line

PendingCN112411018AImprove glue spraying efficiencyImprove glue spray qualityNon-woven fabricsEngineeringManufacturing line

The invention discloses a mattress glue spraying production line. The mattress glue spraying production line comprises a correction mechanism, a transfer table, an automatic glue spraying mechanism and a pressing mechanism. The correction mechanism comprises a correction bottom frame, a forward driving device, conveying rollers, a movable rail frame, a correction driving device, two movable framesand two correction frames. The transfer table comprises a transfer bottom frame, a transfer driving device and a transfer belt. The automatic glue spraying mechanism comprises an automatic glue sprayer, a support frame, a glue spraying driving device and a nozzle. The pressing mechanism comprises a pressing bottom frame, a pressing top plate, a jacking driving device, a lifting frame, a conveyingdriving device and a pressing belt. Mattress is automatically corrected, conveyed, subjected to glue spraying processing and compacted in sequence through the correction mechanism, the transfer table, the automatic glue spraying mechanism and the pressing mechanism, so that the labor investment is reduced, and the working efficiency and the product quality are improved.

Owner:佛山市科华智缝设备有限公司

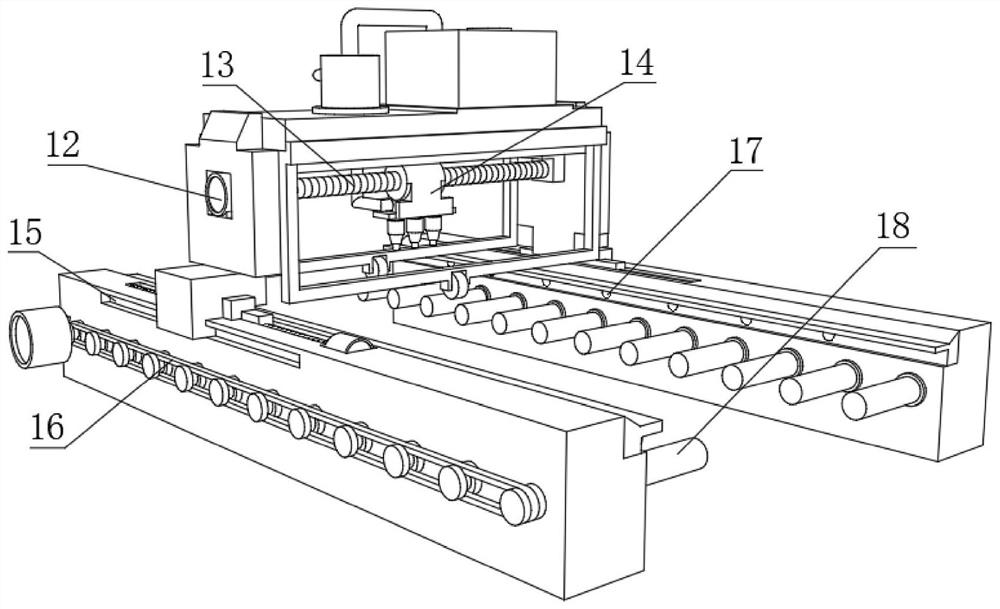

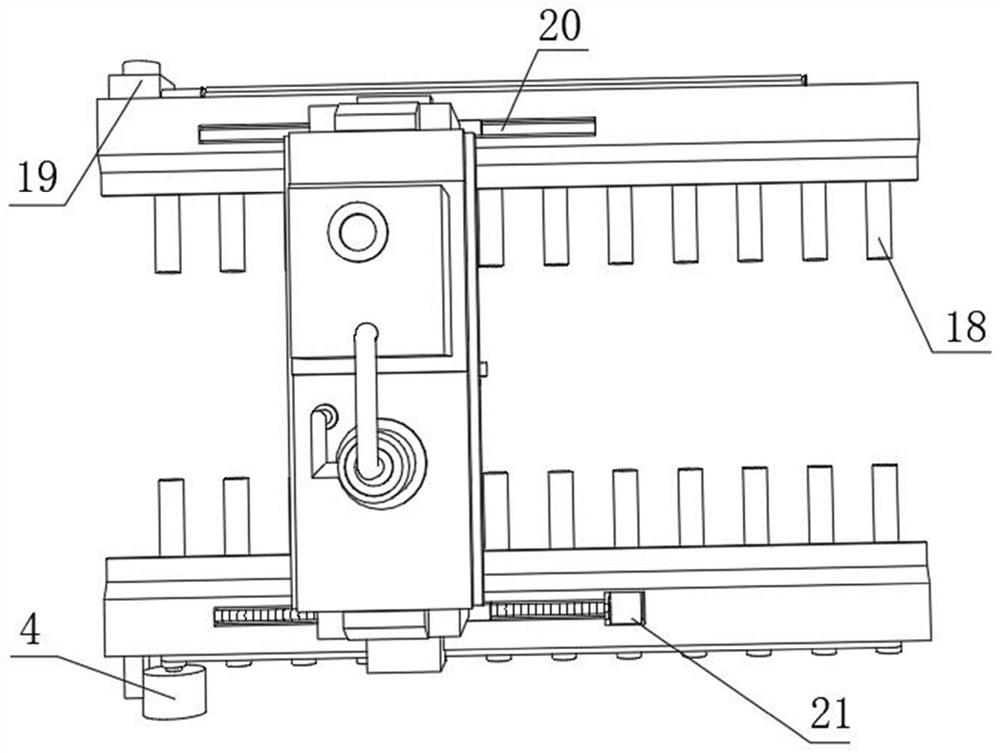

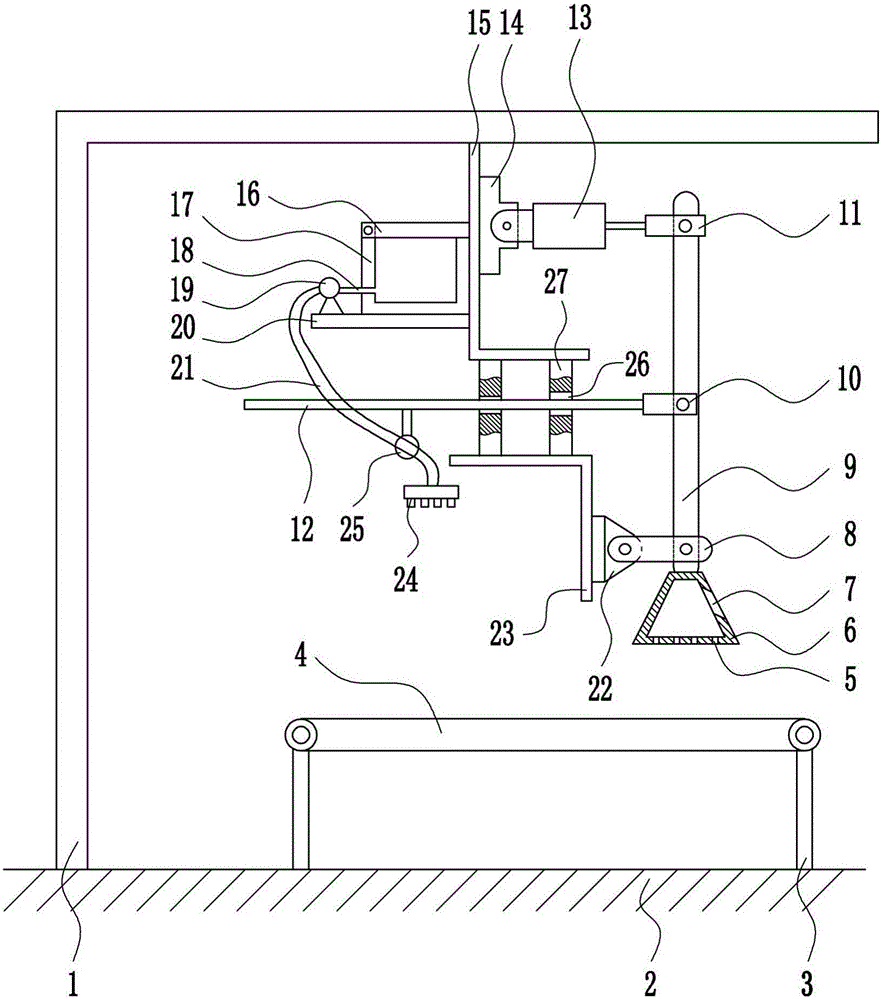

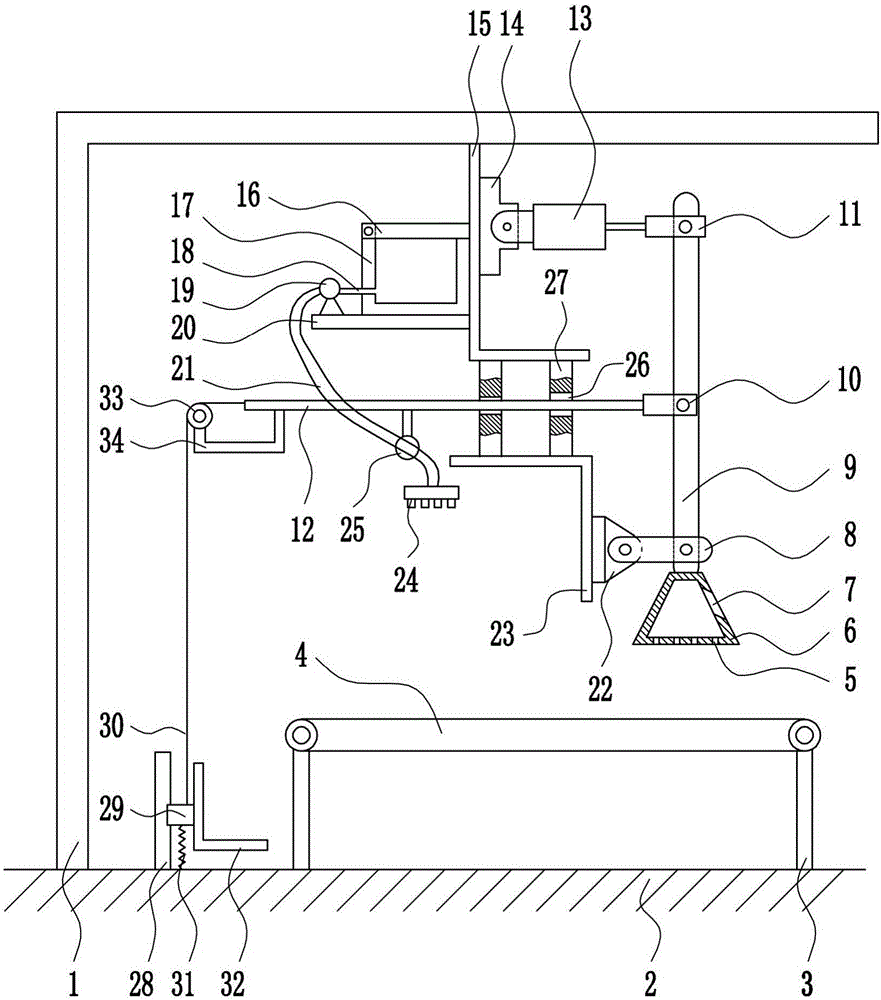

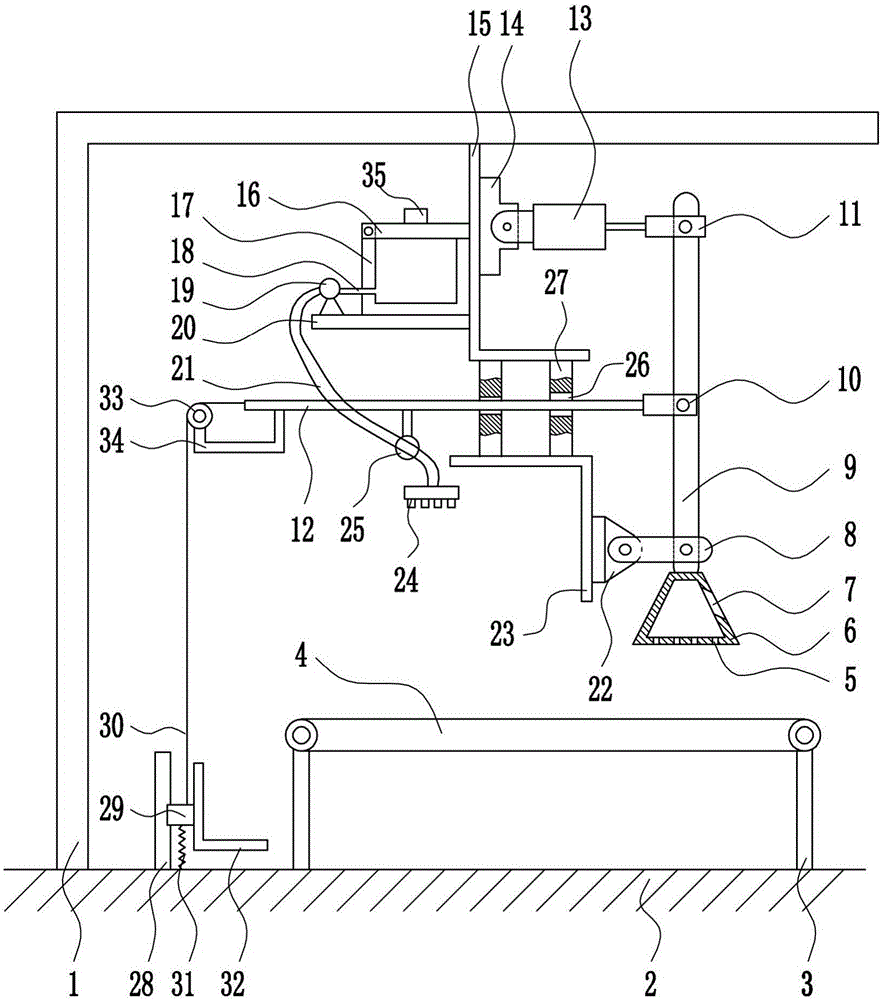

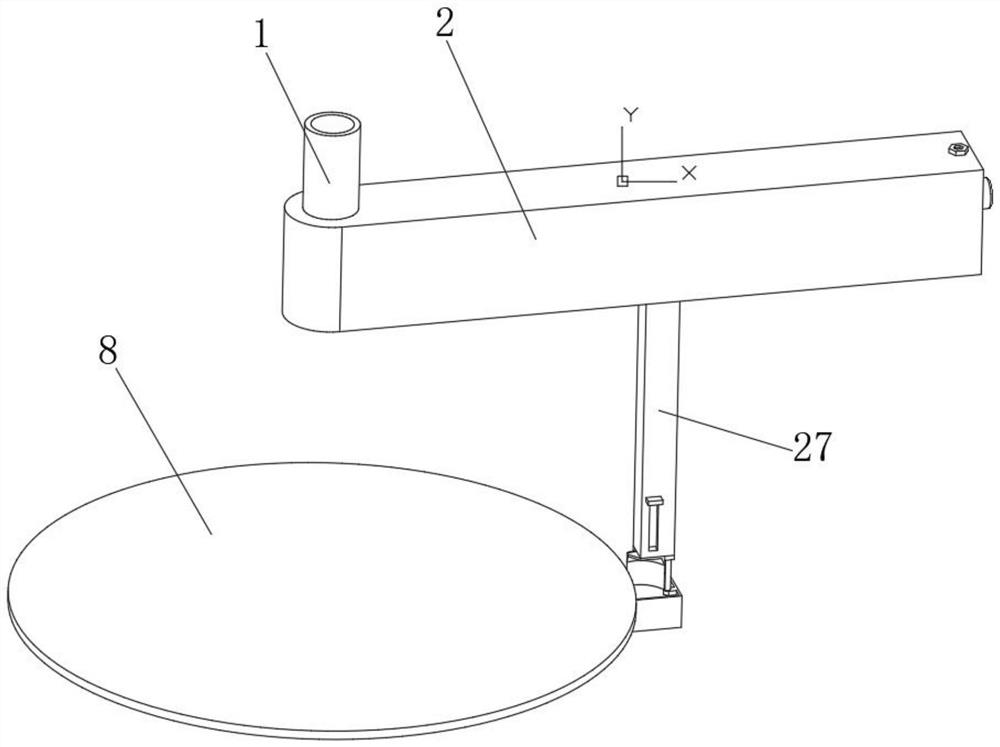

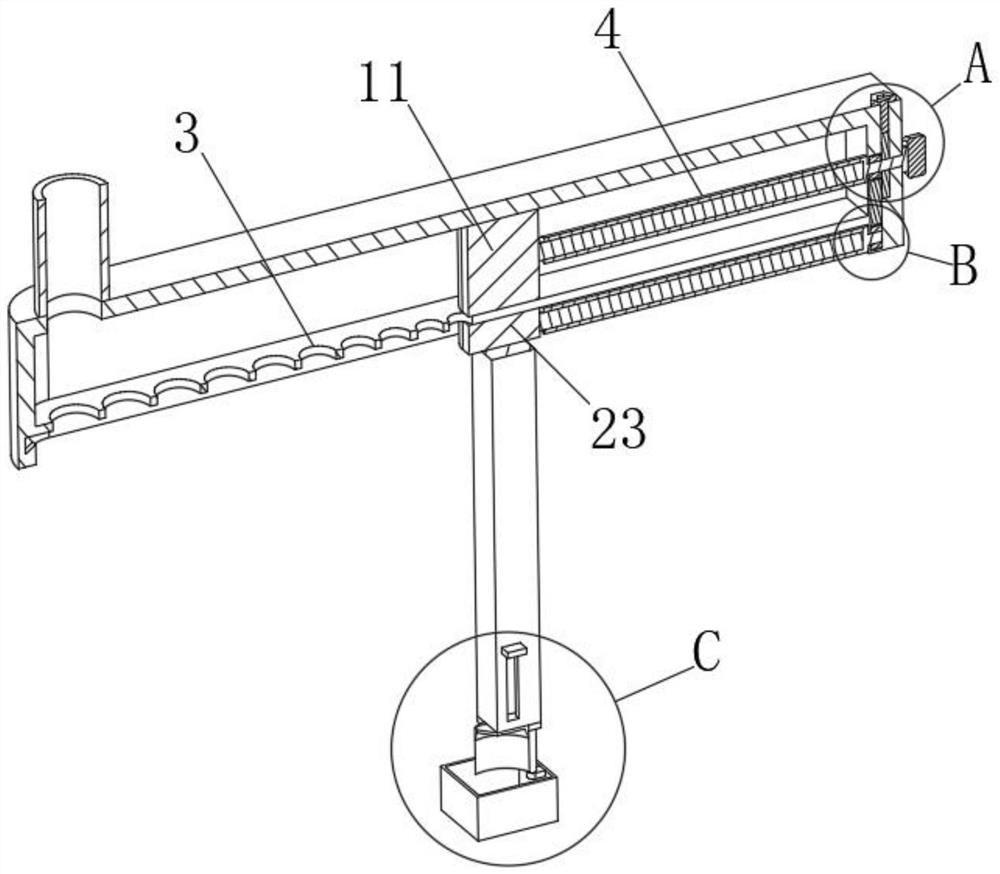

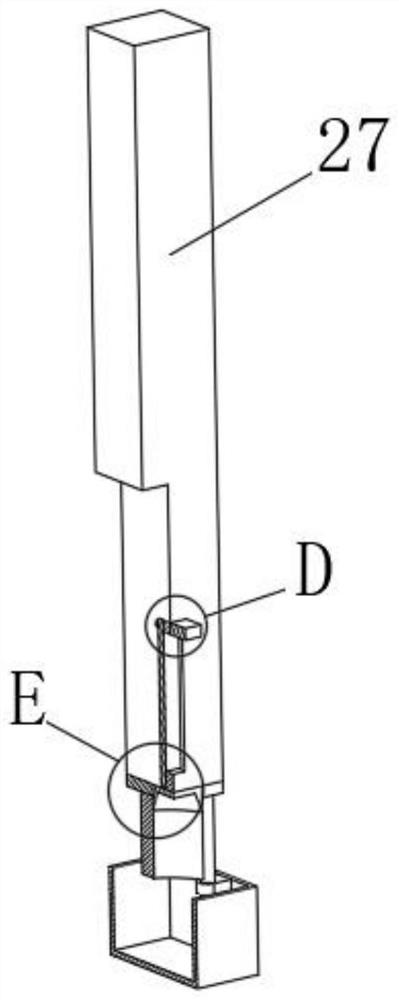

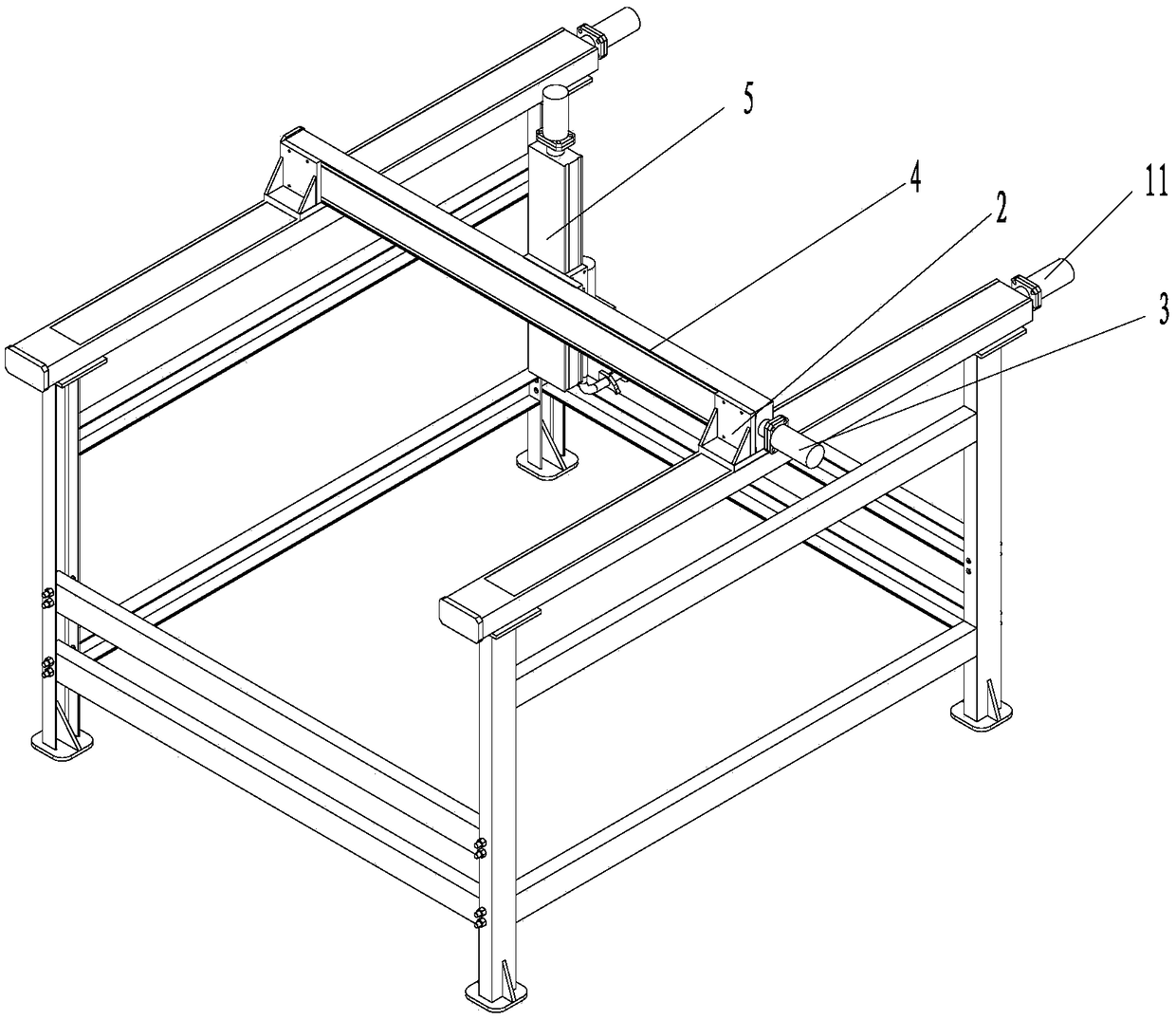

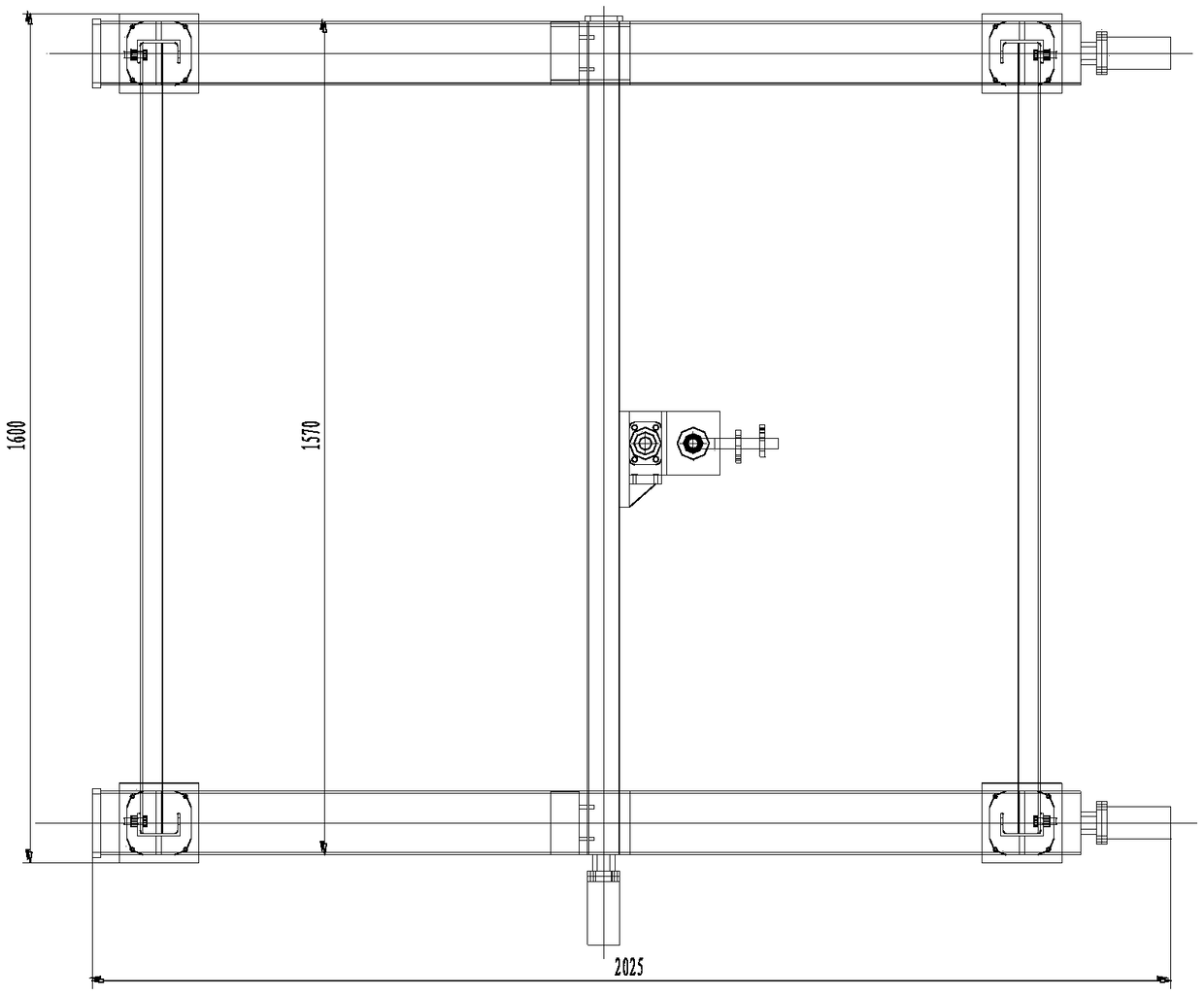

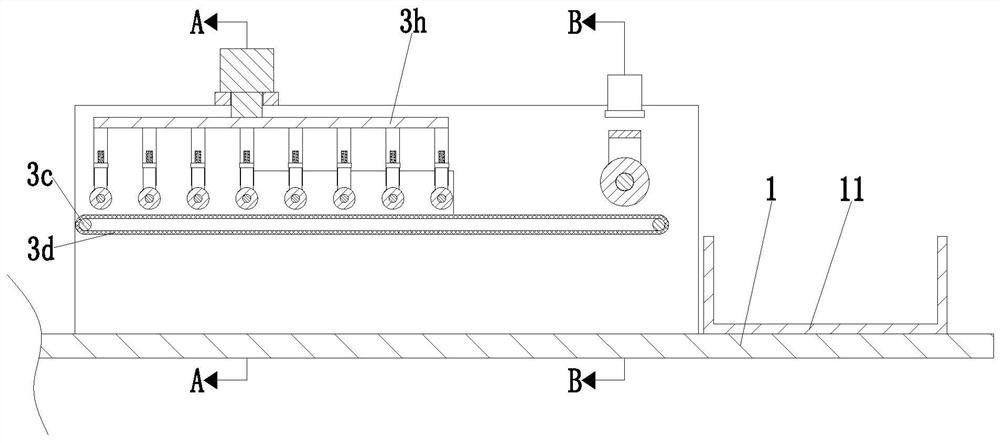

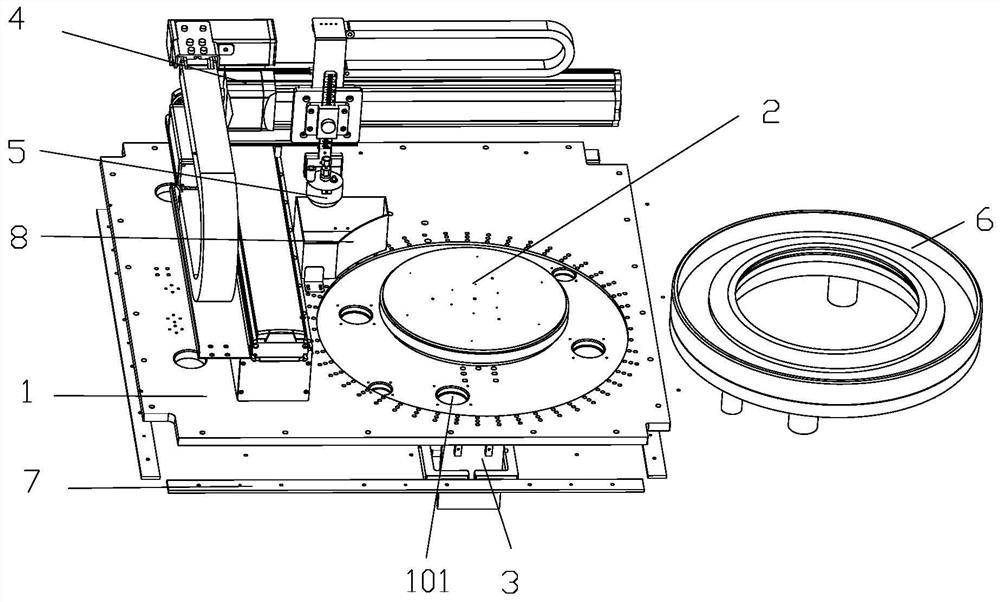

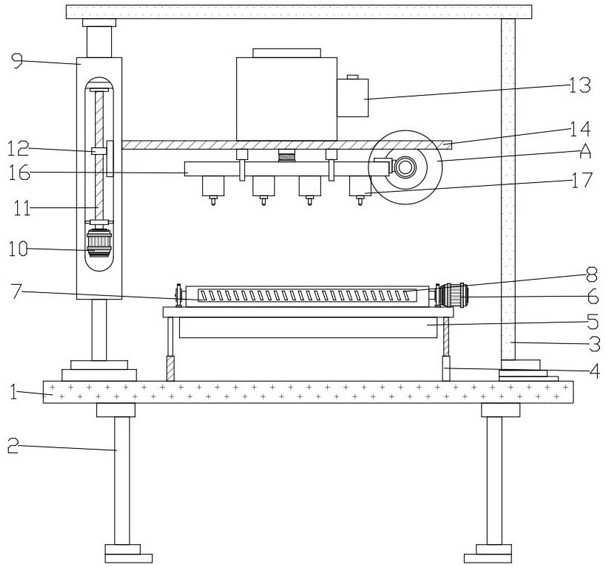

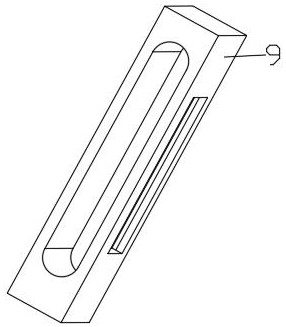

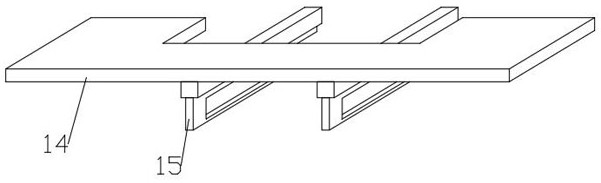

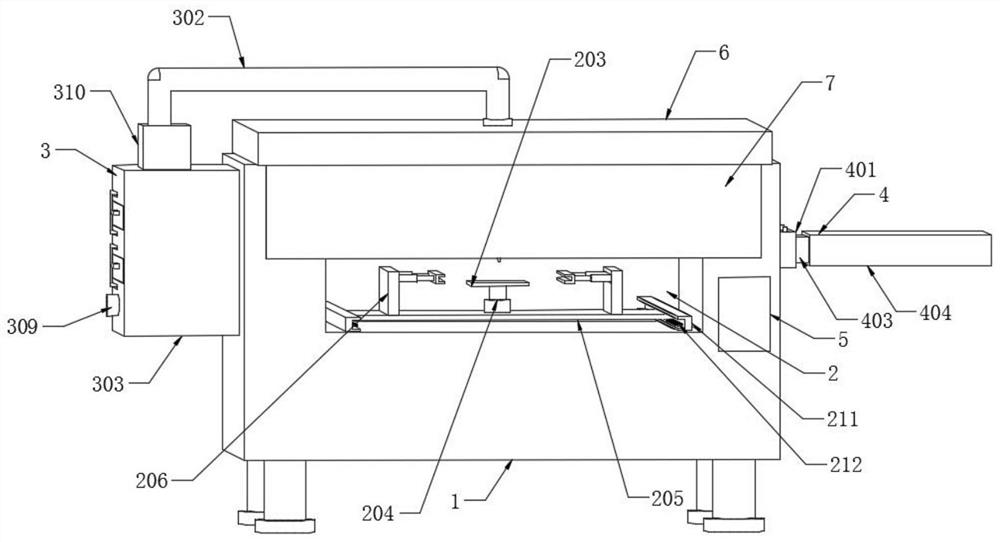

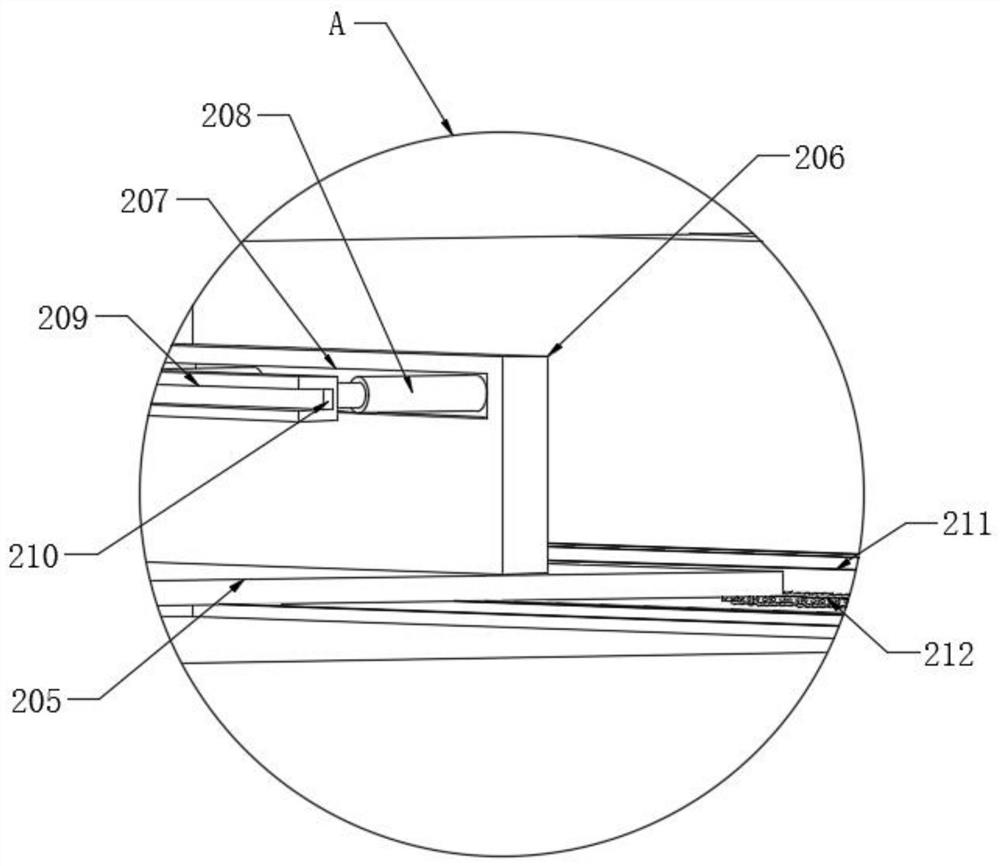

Numerical control glue spraying equipment and method

PendingCN109277233ASolve various problems caused by manual glue applicationImprove glue spraying efficiencySpraying apparatusNumerical controlEngineering

The invention discloses numerical control glue spraying equipment. The numerical control glue spraying equipment comprises three walking units and a spray gun rotating unit, wherein the three walkingunits comprise an X walking unit, a Y walking unit and a Z walking unit; the X walking unit comprises an X-axis sliding table mounting base plate, an X-axis walking sliding table and an X-axis slidingtable motor; the Y walking unit comprises a Y-axis sliding table mounting base plate, a Y-axis sliding table motor and a Y-axis walking sliding table; the Z-axis sliding table comprises a Z-axis sliding table mounting base plate, a Z-axis walking sliding table and a Z-axis sliding table motor; the X-axis sliding table mounting base plate is connected with the X-axis sliding table motor and can slide on the X-axis walking sliding table; the Y-axis sliding table mounting base plate is connected with the Y-axis sliding table motor and can slide on the Y-axis walking sliding table; and the Z-axissliding table mounting base plate is connected with the Z-axis sliding table motor and can slide on the Z-axis walking sliding table. According to the numerical control glue spraying equipment, various problems caused by manual glue coating are well solved, and the glue spraying efficiency and the glue spraying quality are greatly improved.

Owner:NO 7 ENG CO OF CHINA RAILWAY NO 8 ENG GRP CO LTD

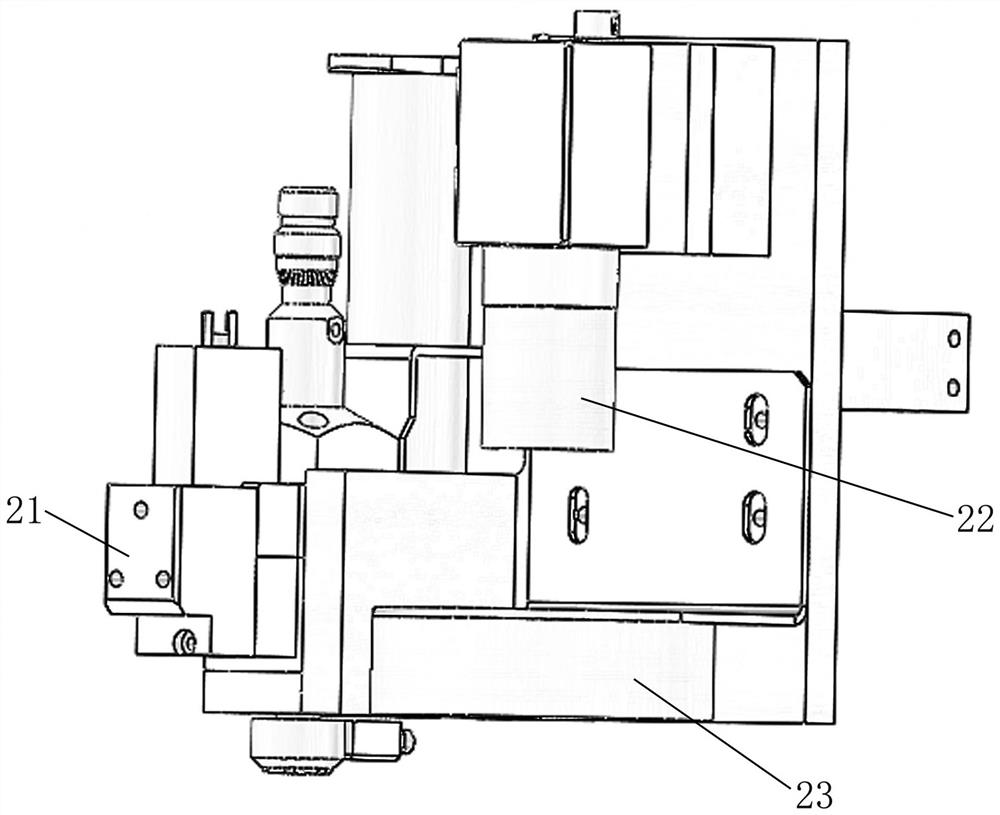

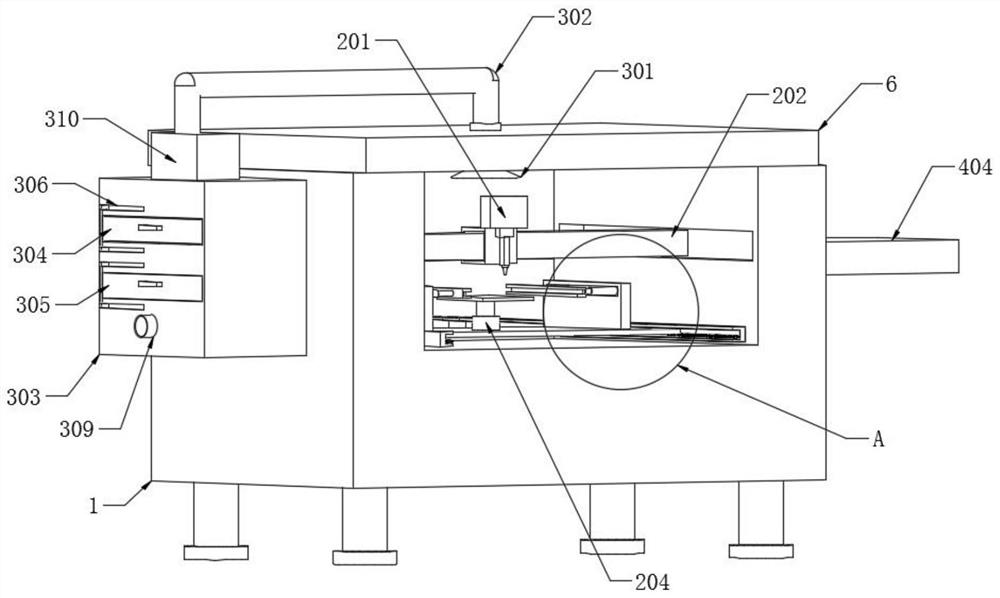

Earphone shell glue spraying device and glue spraying track generation method

PendingCN114713449AImprove glue spraying efficiency and glue spraying qualityQuick fixProgramme-controlled manipulatorLiquid surface applicatorsPhysicsRobot control

The invention relates to the field of earphone processing equipment, in particular to an earphone shell glue spraying device and a glue spraying track generation method. According to the technical scheme, the device comprises an earphone fixing mechanism, a glue spraying mechanism and a glue spraying driving mechanism in driving connection with the glue spraying mechanism, the glue spraying mechanism is provided with a glue spraying gun and a visual identification camera, the glue spraying driving mechanism adopts a multi-axis robot, and the visual identification camera and the glue spraying gun are connected with a controller of the multi-axis robot. The output end of the multi-axis robot is in driving connection with the glue spraying mechanism; point position design is carried out after a gluing outline is determined by recognizing an earphone shell, and a glue spraying gun is controlled by a robot to spray glue. The method has the advantages that the visual camera is used for shooting the earphone shell, the outline of the glue groove is determined through image recognition, after a plurality of point positions are arranged on the outline, the robot sprays glue for the first time according to coordinates of the point positions, and finally the point positions are adjusted to form a final glue spraying track, so that the glue spraying track can be rapidly determined; and the glue spraying efficiency and the glue spraying quality can be improved.

Owner:FOSHAN HUASHU ROBOTICS CO LTD

Drying equipment for coir mat production

InactiveCN105222553AEvenly heatedImprove drying effectStuffed mattressesSpring mattressesCoirEngineering

The invention relates to the technical field of coir mat machining, in particular to drying equipment for coir mat production. The drying equipment comprises a drying box, a feeding opening, a discharging opening, a conveying mechanism, a glue spraying opening and a heating mechanism are arranged in the drying box; the conveying mechanism comprises a conveying belt, and the glue spraying opening is formed above the conveying belt; the heating mechanism is arranged at the upper end inside the drying box, and the drying box further comprises an air supply mechanism which comprises a main air channel; and a plurality of branch air channels are formed in the main air channel. The drying equipment for coir mat production is even in heating.

Owner:CHONGQING LIANGNENG MACHINERY CO LTD

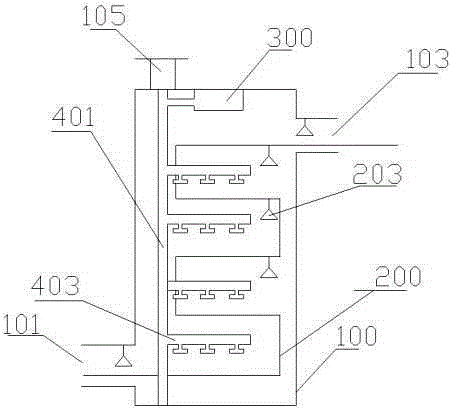

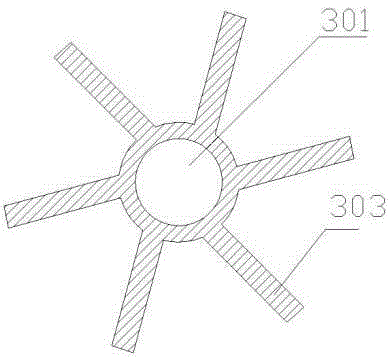

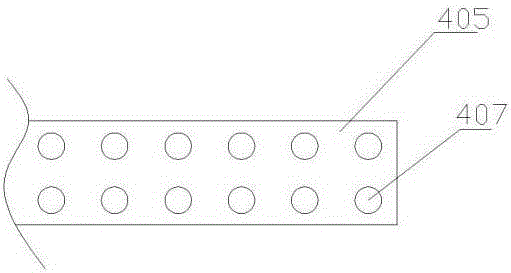

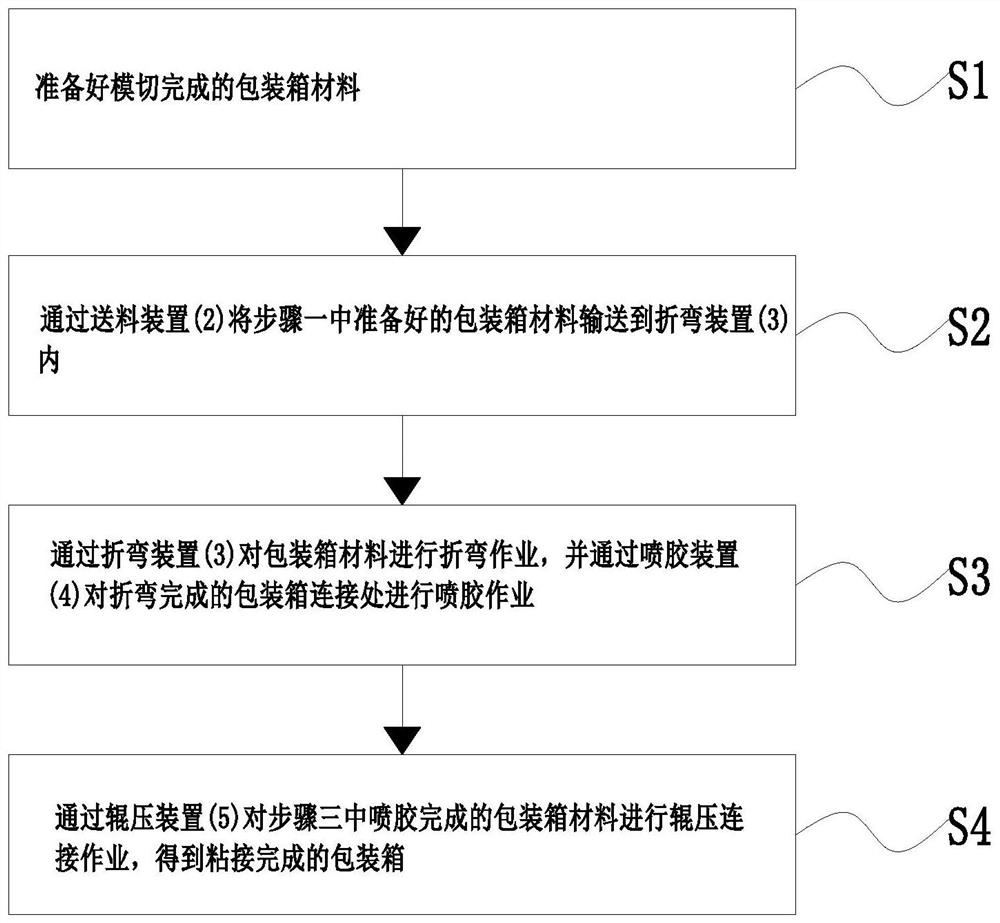

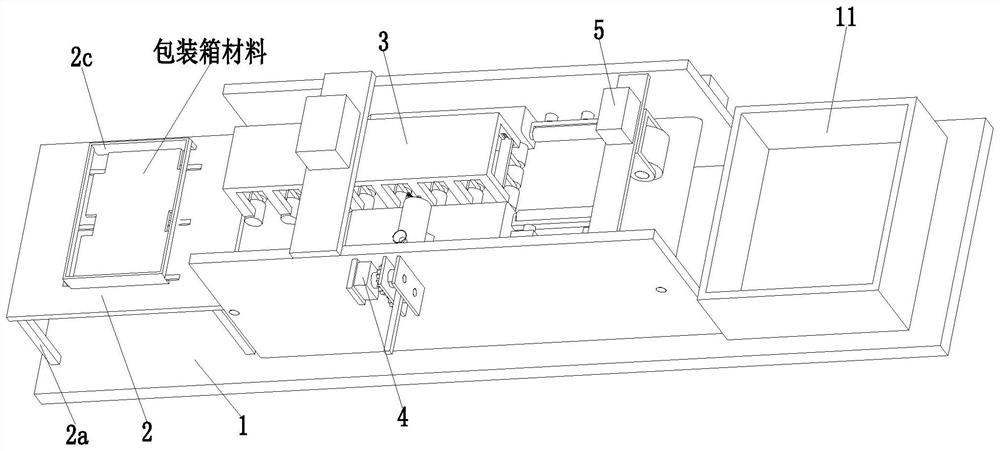

Packaging box producing, manufacturing and bonding method

PendingCN113043652AImprove delivery efficiencyImprove bending quality and efficiencyPaper-makingBox making operationsManufacturing engineeringMechanical engineering

Owner:贺保军

Use method of frame outer wall gluing mechanism

InactiveCN106733515AReduce work intensityGuaranteed to continueLiquid surface applicatorsSpray nozzlesSpray nozzleEngineering

The invention discloses a use method of a frame outer wall gluing mechanism. The use method comprises the following steps: a tank body is filled with a given amount of a glue solution through a glue feed port, and an initial amount reading of the glue solution in the tank body is read out through a liquid indicator in real time; an air pump is started, air is injected into the tank body through an air inlet pipe, with the increasing of the pressure in the tank body, the glue solution is directly sprayed onto a working face of a wood board directly through a glue discharge pipe and a nozzle under the action of air pressure, and automatic glue spraying is realized; and after the glue spraying is completed, the air pump is closed, a valve switch of an air outlet pipe is turned on, and the air in the tank body is discharged till the pressure in the tank body returns to a normal atmosphere state. Through air pressure pushing, the glue solution is quickly sprayed onto the wood board for facilitating the bonding of sponge, and the traditional manual applying mode is turned into mechanized automatic operation, so that the working strength of staff is reduced substantially, and the glue spraying efficiency is improved.

Owner:重庆汉驰家具设计有限公司

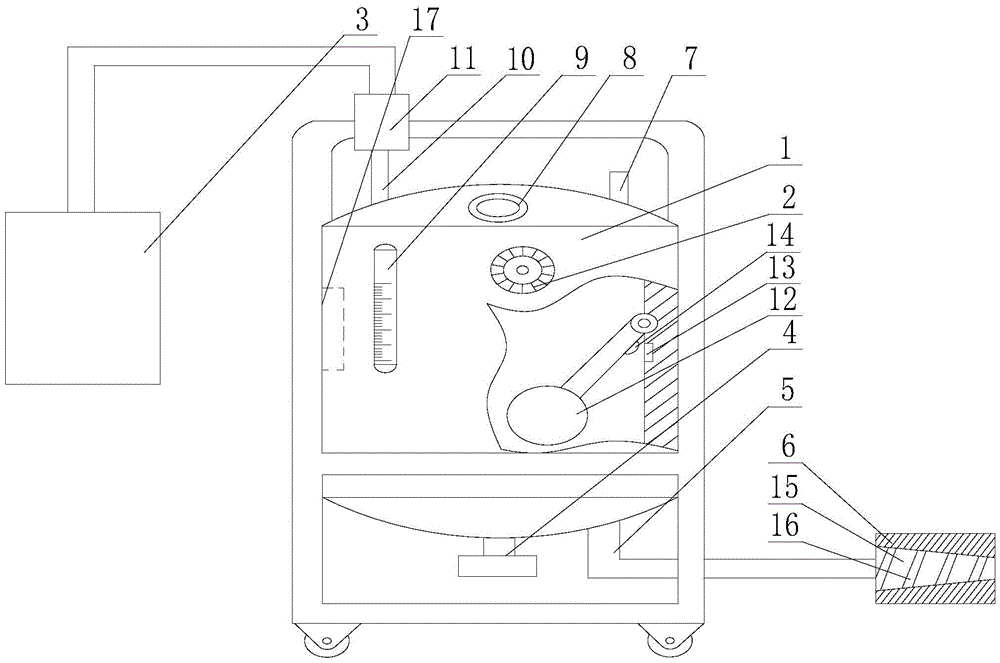

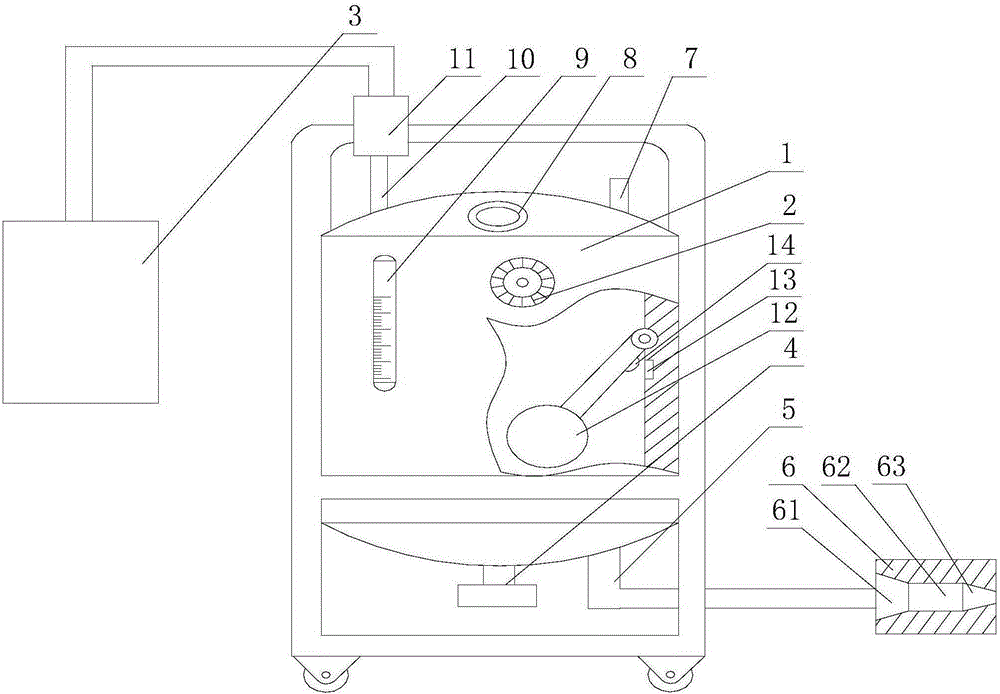

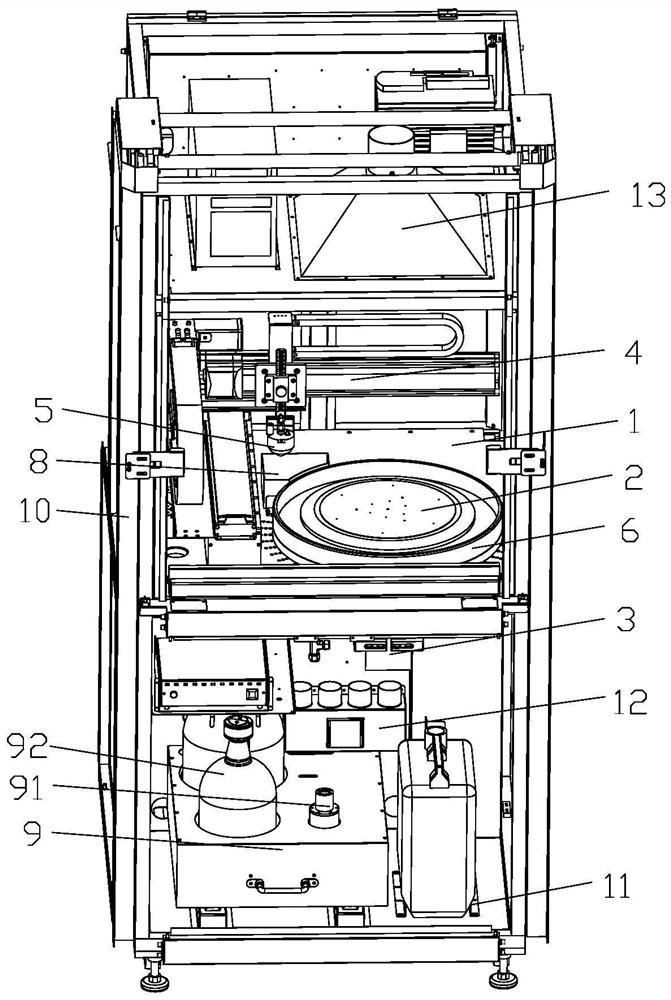

A fully automatic semiconductor wafer glue spraying mechanism and glue spraying equipment

ActiveCN109433479BImprove glue spraying efficiencyImprove glue spraying effectSpraying apparatusWaferingEngineering

The invention relates to the technical field of semiconductors, in particular to a fully-automatic semiconductor wafer glue-spraying mechanism and equipment. The fully-automatic semiconductor wafer glue-spraying mechanism comprises a glue-spraying platform, a rotary disc, a rotary lifting driving device, a horizontal and vertical moving device, a nozzle and a splashing preventing cover; the rotarydisc is arranged on the glue-spraying platform, and the rotary lifting driving device is arranged at the bottom of the rotary disc and drives the rotary disc to rise, fall and rotate; the horizontaland vertical moving device is arranged on the glue-spraying platform, the nozzle is arranged on the horizontal and vertical moving device, and the horizontal and vertical moving device drives the nozzle to move horizontally and vertically; and the splashing preventing cover is matched with the rotary disc and prevents glue liquid from splashing during glue spraying. The fully-automatic semiconductor wafer glue-spraying mechanism has the beneficial effects that the nozzle can be moved in the front-back direction and in the left-right direction, and thus the glue-spraying efficiency is improved;the rotary disc can rise and fall, and thus the glue-spraying effect is improved; and the nozzle can try to conduct spraying before working, and thus plugging of the nozzle is prevented.

Owner:深圳市克拉尼声学科技有限公司

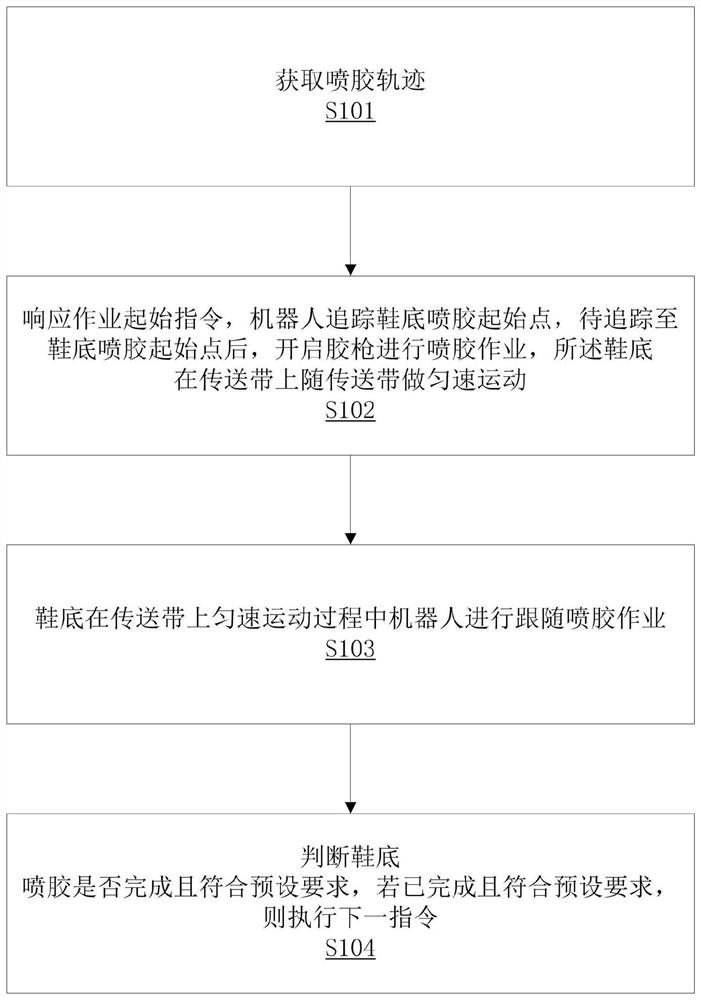

A kind of dynamic follow glue spraying method and system

ActiveCN113907490BHigh degree of automationImprove glue spraying efficiencyTotal factory controlShoe gluingControl engineeringConveyor belt

The invention relates to the technical field of robot spraying, in particular to a method and system for dynamic follow-up glue spraying. The method for dynamically following glue spraying includes the steps of: acquiring a glue spraying trajectory; responding to an operation start instruction, a robot tracks the target object glue spraying starting point, and after tracking to the target object glue spraying starting point, turns on a glue gun to spray glue During the operation, the target object moves at a uniform speed with the conveyor belt on the conveyor belt; the robot follows the glue spraying operation during the uniform movement of the target object on the conveyor belt; it is judged whether the glue spraying of the target object is completed and meets the preset requirements, if it has been completed and meets the preset requirements. If required, execute the next command. Through this method, the target object moves at a constant speed on the conveyor belt. During the process, the robot will follow the glue spraying until the glue spraying is completed and meets the preset requirements. Next, the next target object on the conveyor belt can be sprayed with glue. The entire glue spraying operation process Consistent, high glue spraying efficiency, greatly saves time and cost, and can produce higher profits.

Owner:福建屹立智能化科技有限公司

Gluing components for glued cotton production equipment

ActiveCN113638155BExpand the spraying rangeFull coatingTextile treatment machine arrangementsTextile treatment by spraying/projectingYarnProcess engineering

The invention is applicable to the technical field of glue spraying, provides a glue spraying assembly for the production equipment of glue spraying cotton, and is used for spraying glue on the surface of glue spraying cotton, and solves the problem that the glue spraying assembly of the existing device has a slow feeding speed and is easy to accumulate The problem of the colloid; including: a supporting body; a cotton yarn glue spraying mechanism arranged on the supporting body, the cotton yarn glue spraying mechanism is used for spraying the colloid on the surface of the cotton yarn layer; the glue spraying mechanism connected with the cotton yarn glue spraying mechanism drives The component is used to adjust the position of the cotton yarn glue spraying mechanism; the cotton yarn placement mechanism installed on the supporting body; the invention is provided with a cotton yarn glue spraying mechanism, and the cotton yarn glue spraying mechanism and the driving component of the glue spraying mechanism cooperate to expand the cotton yarn glue spraying mechanism The range of glue spraying works with the cotton yarn placement mechanism, so that both sides of the cotton yarn layer can be fully coated. The cotton yarn glue spraying mechanism includes a colloid flow equalization mechanism, which avoids the clogging of the colloid and improves the glue spraying efficiency.

Owner:南通富士抽纱品有限公司

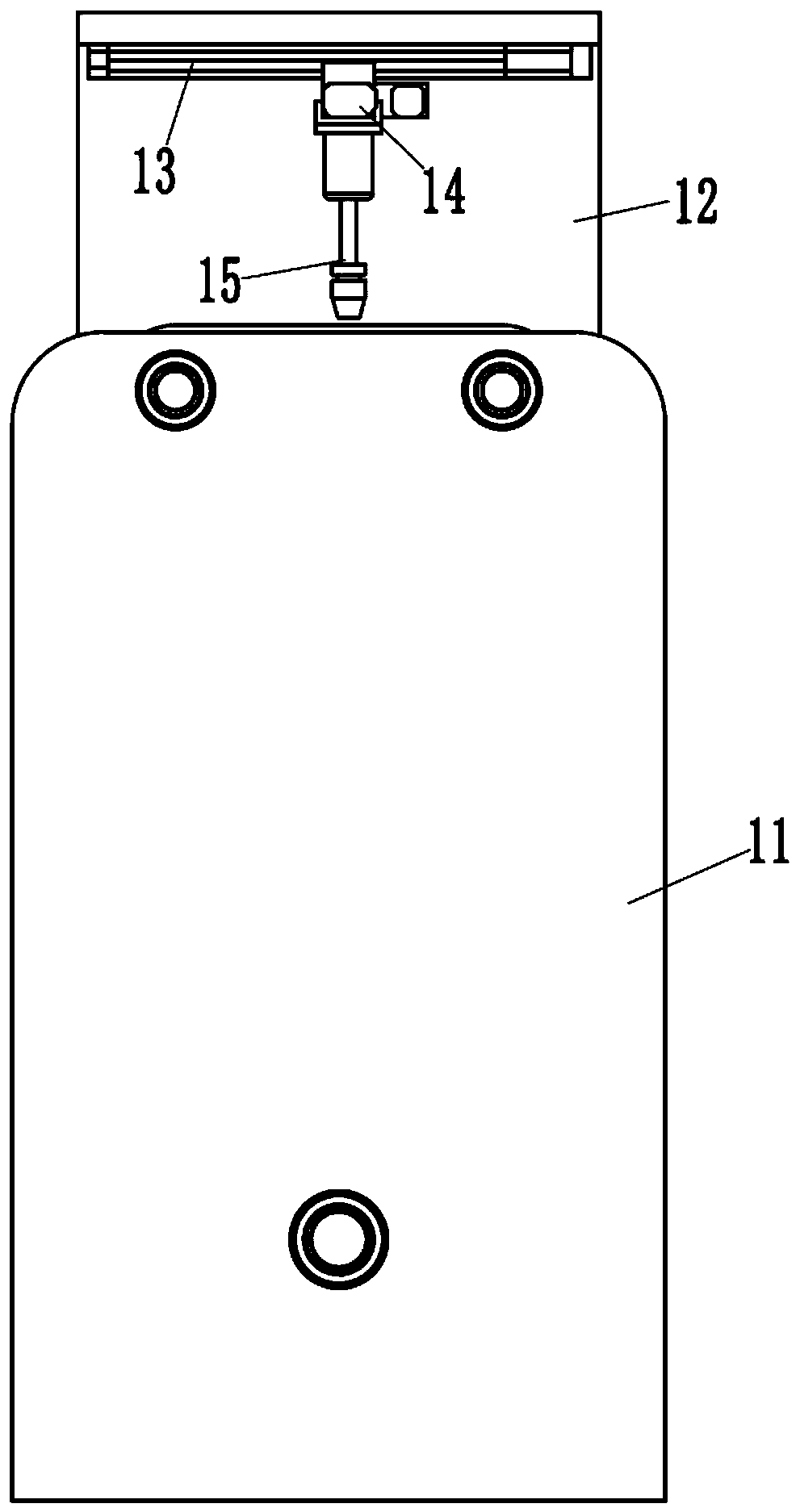

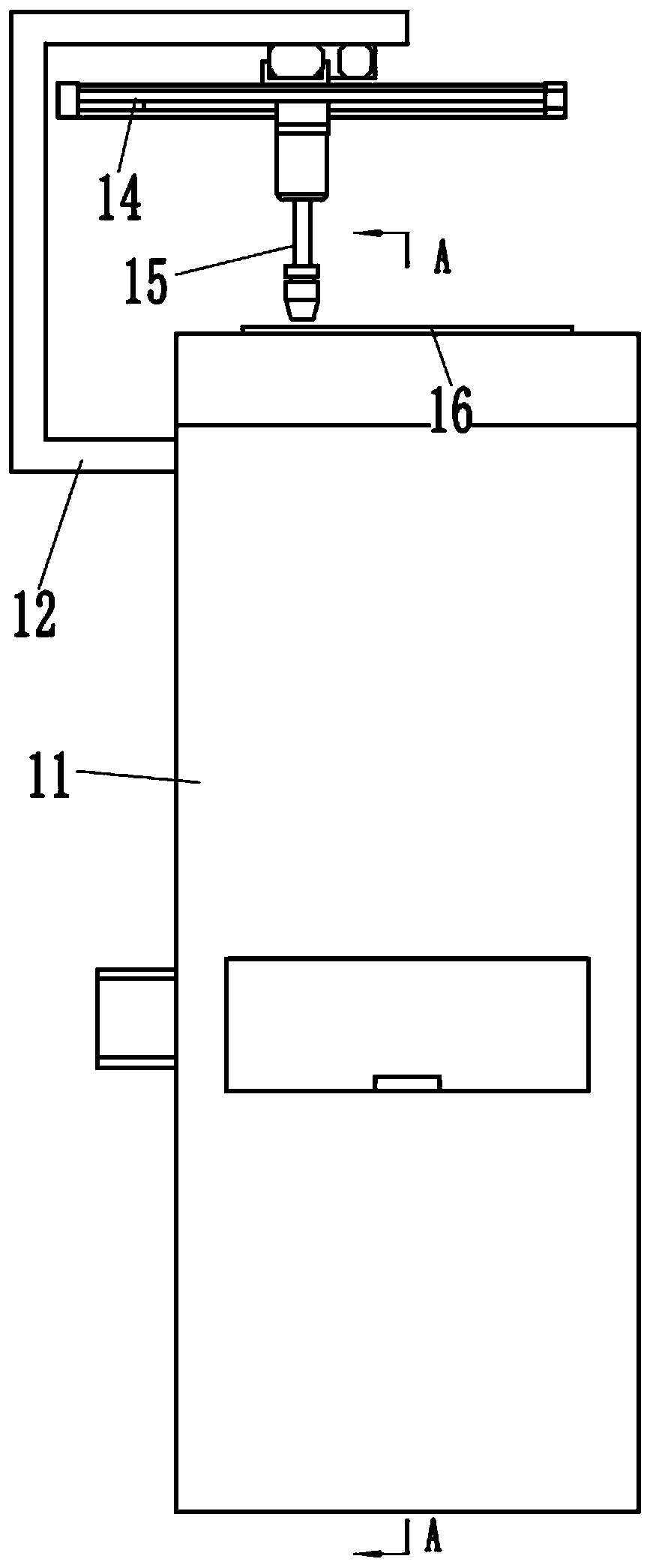

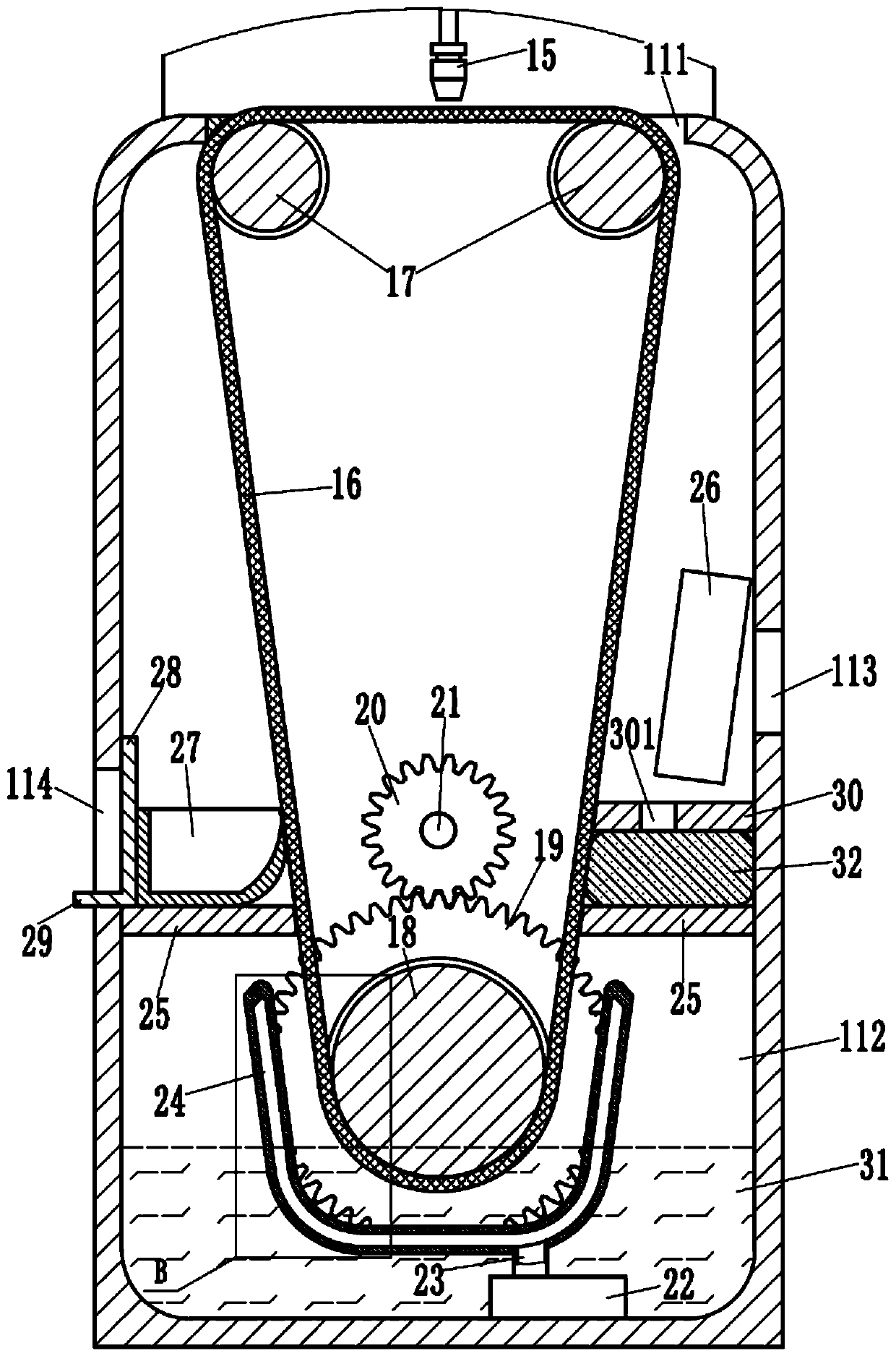

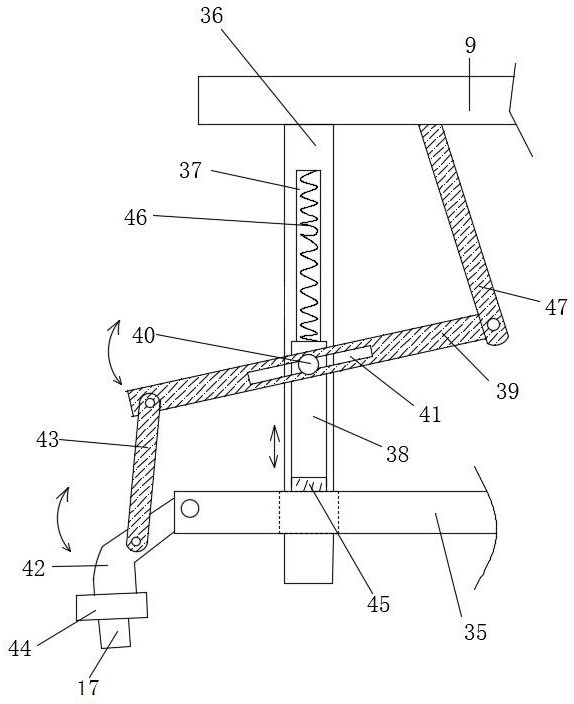

Self-cleaning glue spraying machine

ActiveCN111054589AEasy to cleanSave cleanup timeLiquid surface applicatorsCleaning using toolsGear wheelWater pipe

The invention discloses a self-cleaning glue spraying machine. The machine comprises a case and a glue spraying head, wherein a supporting belt is arranged below the glue spraying head; the supportingbelt is tensioned on two driven belt pulleys and one driving belt pulley, the driving belt pulley and the two driven belt pulleys are hinged on the case, a reduction gear is fixed on the driving beltpulley, the upper side of the reduction gear meshes with a driving gear, and the driving gear is connected with a servo motor; and a cleaning pool is arranged at the bottom end of the case, cleaningliquid is contained in the cleaning pool, a water pump is fixed on the bottom surface of the case, the water pump is connected with a 'U'-shaped liquid spraying part through a water pipe, the liquid spraying part is located on the outer side of the driving belt pulley, a ventilating opening is formed in the middle of a right-side arm of the case, and the inner side of the ventilating opening is provided with an air heater. According to the machine, the supporting belt is used for replacing a glue spraying face board, and the supporting belt is cleaned and air-dried through the liquid sprayingpart and the air heater, so that the cleaning is convenient and rapid, the cleaning time is effectively reduced, and the glue spraying efficiency is improved.

Owner:FOLLOWE SUZHOU ELECTRONICS TECH CO LTD

A multi-head glue spraying device for sand mold casting

InactiveCN111283149BImprove rangeEvenly distributedMoulding toolsCircular discStructural engineering

Owner:INST OF LASER & OPTOELECTRONICS INTELLIGENT MFG WENZHOU UNIV

Glue sprayer for lithium battery protection plate

PendingCN113843104AEasy to adjustAvoid damageLiquid surface applicatorsDispersed particle separationStructural engineeringMechanical engineering

The invention discloses a glue sprayer for a lithium battery protection plate, and relates to the technical field of glue spraying of lithium battery protection plates. The glue sprayer aims at solving the problems that when glue spraying is carried out on an existing lithium battery protection plate, manual operation of workers is needed, the glue spraying efficiency is reduced, the task load of the workers is increased, adjustment is inconvenient to achieve according to the size of the protection plate, the environment is polluted, and the body health of the workers is influenced. According to the scheme, the glue sprayer comprises a glue sprayer body, a glue spraying assembly is arranged in the glue sprayer body, the glue spraying assembly is of an electric telescopic clamping structure, and a filtering assembly is arranged on one side of the glue sprayer body. The glue sprayer can be adjusted according to the size of the lithium battery protection plate, a lithium battery circuit board can be prevented from being damaged, the task load of the workers is reduced, the glue spraying efficiency is improved, the pollution to the environment can be reduced, and the damage to the health of the workers is reduced.

Owner:惠州云图电子有限公司

Use method of adhesive applying treatment mechanism for outer surface of wood plate

InactiveCN106733522AReduce work intensityImprove glue spraying efficiencyLiquid surface applicatorsLiquid spraying apparatusSpray nozzleAirflow

The invention discloses a use method of an adhesive applying treatment mechanism for the outer surface of a wood plate. The use method comprises the following steps: a certain amount of adhesive solution is filled in a tank body through an adhesive inlet port; a gas flow starts to be injected in the tank body through a gas inlet pipe, and the adhesive solution is directly sprayed on a working surface of the wood plate through an adhesive outlet pipe and nozzles under the pressure action of air with the increasing of a pressure in the tank body; the inner diameters of the nozzles are gradually reduced in the ejection direction of the adhesive solution when the adhesive solution passes through the nozzles, so that the adhesive solution has a change of sudden reduction of a flow channel between the adhesive outlet pipe and the nozzles, and the ejection speed of the adhesive solution with a unit flow rate is suddenly increased; and a gas pump is closed and a valve switch of a gas outlet pipe is turned on after adhesive coating is concluded, so that a gas in the tank body is exhausted until the pressure in the tank body is returned to a normal atmospheric state. According to the use method disclosed by the invention, a traditional manual applying manner is transformed into mechanical automatic operation, so that the working intensity of working personnel is greatly lowered, and the adhesive spraying efficiency is increased.

Owner:重庆汉驰家具设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com