Earphone shell glue spraying device and glue spraying track generation method

A trajectory generation and glue spraying technology, which is applied to the surface coating liquid device, manipulator, program control manipulator, etc., to achieve the effect of improving glue spraying efficiency and glue spraying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

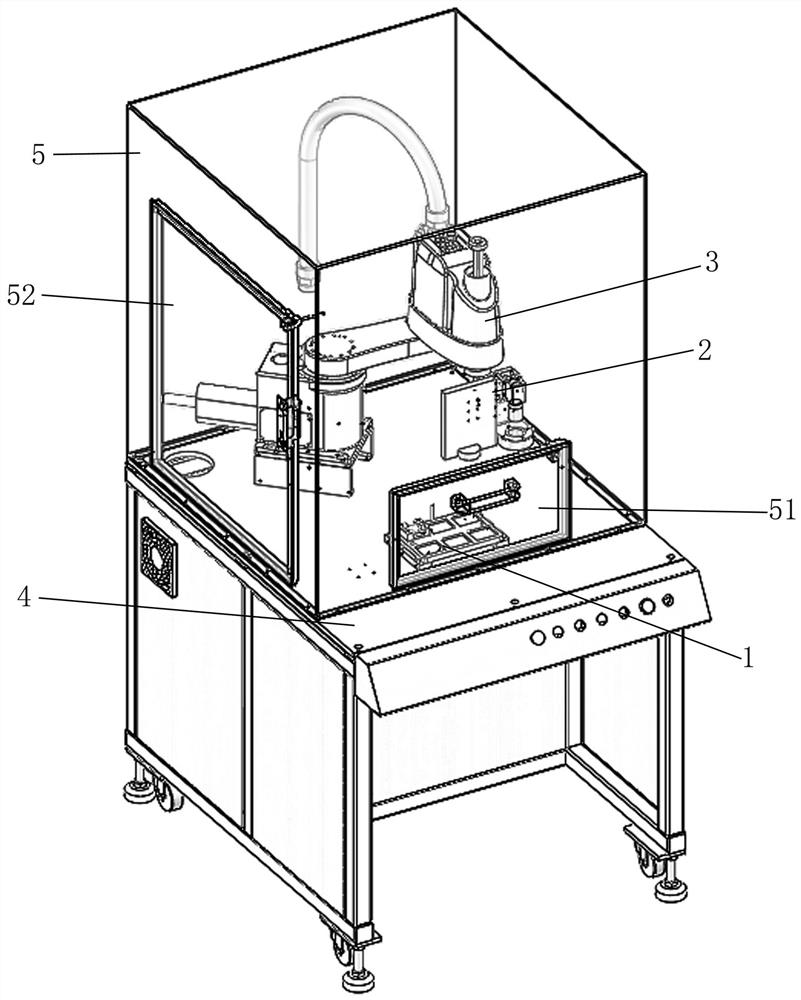

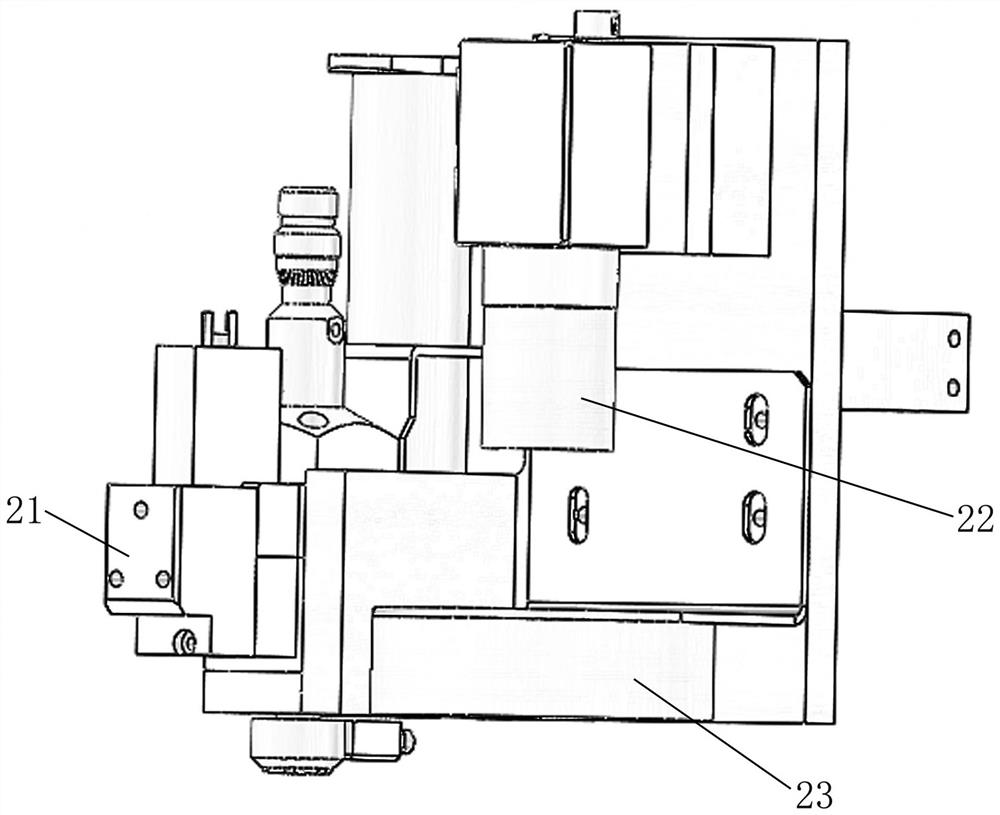

[0017] Example 1, refer to Figure 1-2 , an earphone shell glue spraying device, comprising an earphone fixing mechanism 1, a glue spraying mechanism 2 and a glue spraying driving mechanism 3 drivingly connected with the glue spraying mechanism 2, the glue spraying mechanism 2 is provided with a glue spray gun 21 and a visual identification The camera 22 and the glue spraying drive mechanism 3 use a multi-axis robot. The visual recognition camera 22 and the glue spray gun 21 are connected to the controller of the multi-axis robot, and the output end of the multi-axis robot is driven and connected to the glue spray mechanism 2; the earphone fixing mechanism 1 and The glue spraying drive mechanism 3 is all arranged on the workbench 4 , and the upper cover of the workbench 4 is provided with a soundproof and dustproof cover 5 .

[0018] In this embodiment, the earphone fixing mechanism 1 is used to place the earphone shell, and make the side of the glue groove inside the earphone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com