Packaging box producing, manufacturing and bonding method

A bonding method and packaging box technology, which is applied in the directions of packaging, transportation and packaging, and box making operations, can solve the problems of uneven glue application, influence of bonding effect, and dirty outer wall of the packaging box, so as to improve the transportation efficiency, The effect of improving bending quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

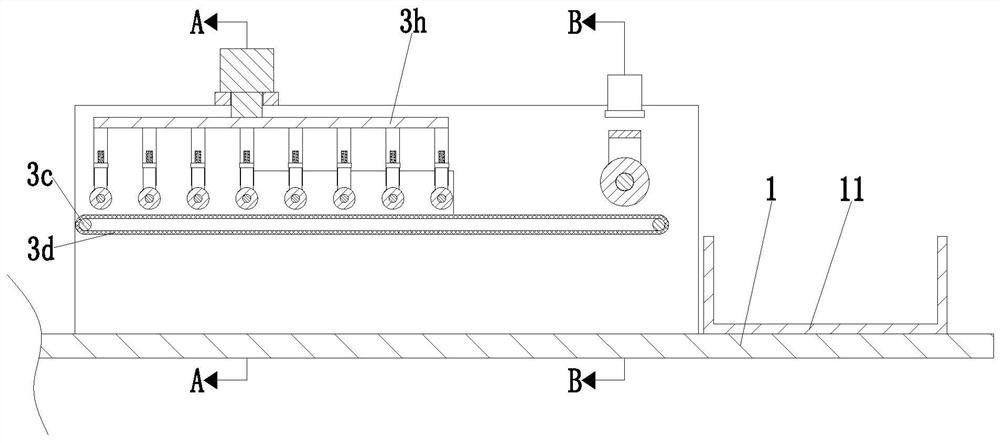

[0041] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

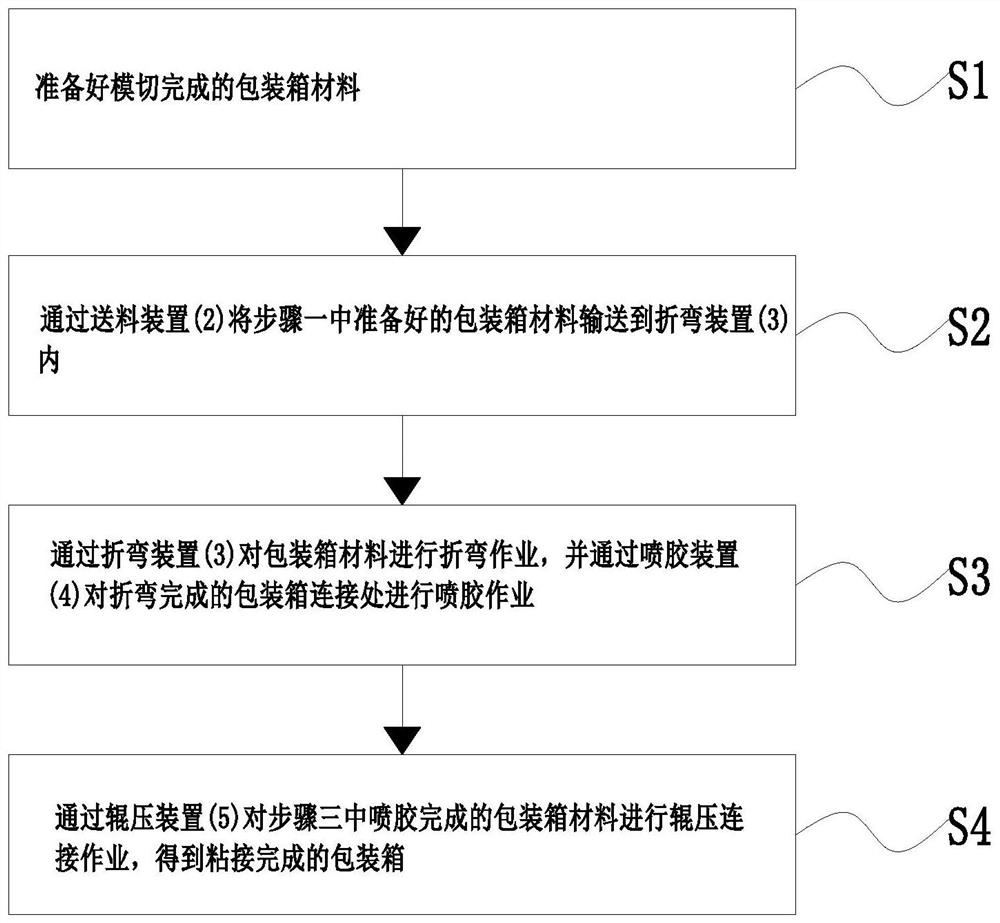

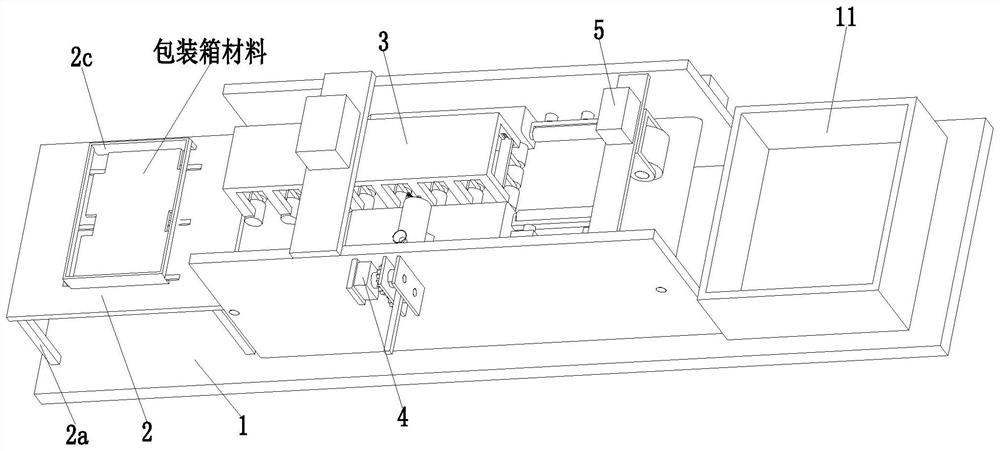

[0042] Such as Figure 1 to Figure 15 Shown, a kind of packaging box production and bonding method mainly includes the following steps:

[0043] Step 1, material preparation, ready to die-cut packing box materials;

[0044] Step 2, conveying operation, conveying the packaging box material prepared in step 1 to the bending device 3 through the feeding device 2;

[0045] Step 3, bending and spraying glue, bending the packaging box material through the bending device 3, and spraying glue on the joint of the bent packaging box through the glue spraying device 4;

[0046] Step 4, roll forming, the roll pressing device 5 is used to carry out the rolling connection operation on the packaging box materials sprayed in step 3, to obtain the packaging box th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com