Patents

Literature

33results about How to "Reduce the number of commutations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Control method for four-way valve

ActiveCN101504236AReduce the number of commutationsReduce startup timeFluid circulation arrangementCompression machines with reversible cycleHeat regenerationIndoor air

The invention discloses low-reversing reliability and frequency method for controlling a four-way valve, which comprises control processes under the following use conditions: during heat generation, time A is determined according to an ambient temperature and an unloading electromagnetic valve is turned off at the same time, then the cold air-resistance operation of an indoor fan and an inverter compressor are started, a pilot valve of a four-way wave is turned on to act when the inverter compressor operates for 180+A seconds, and the four-way valve realizes inversion and an outdoor fan operates at the same time; for machine stop during heat generation, the inverter compressor and the outdoor fan are turned off first, then the unloading electromagnetic valve is turned on to allow an exhaust pipe and an intake pipe to be communicated continuously for time B, and finally the pilot valve of the four-way valve is controlled to be turned off to reset and the indoor fan is turned off at the same time, wherein the time B is between 5 and 15 seconds; and during heat regeneration, the unloading electromagnetic valve is turned off first and the pilot valve of the four-way valve is controlled to be turned on to act at the same time, then the inverter compressor is started, and the indoor fan starts cold air-resistance operation and the outdoor fan starts operation when the inverter compressor operates for 180 seconds.

Owner:安徽奥克斯智能电气有限公司

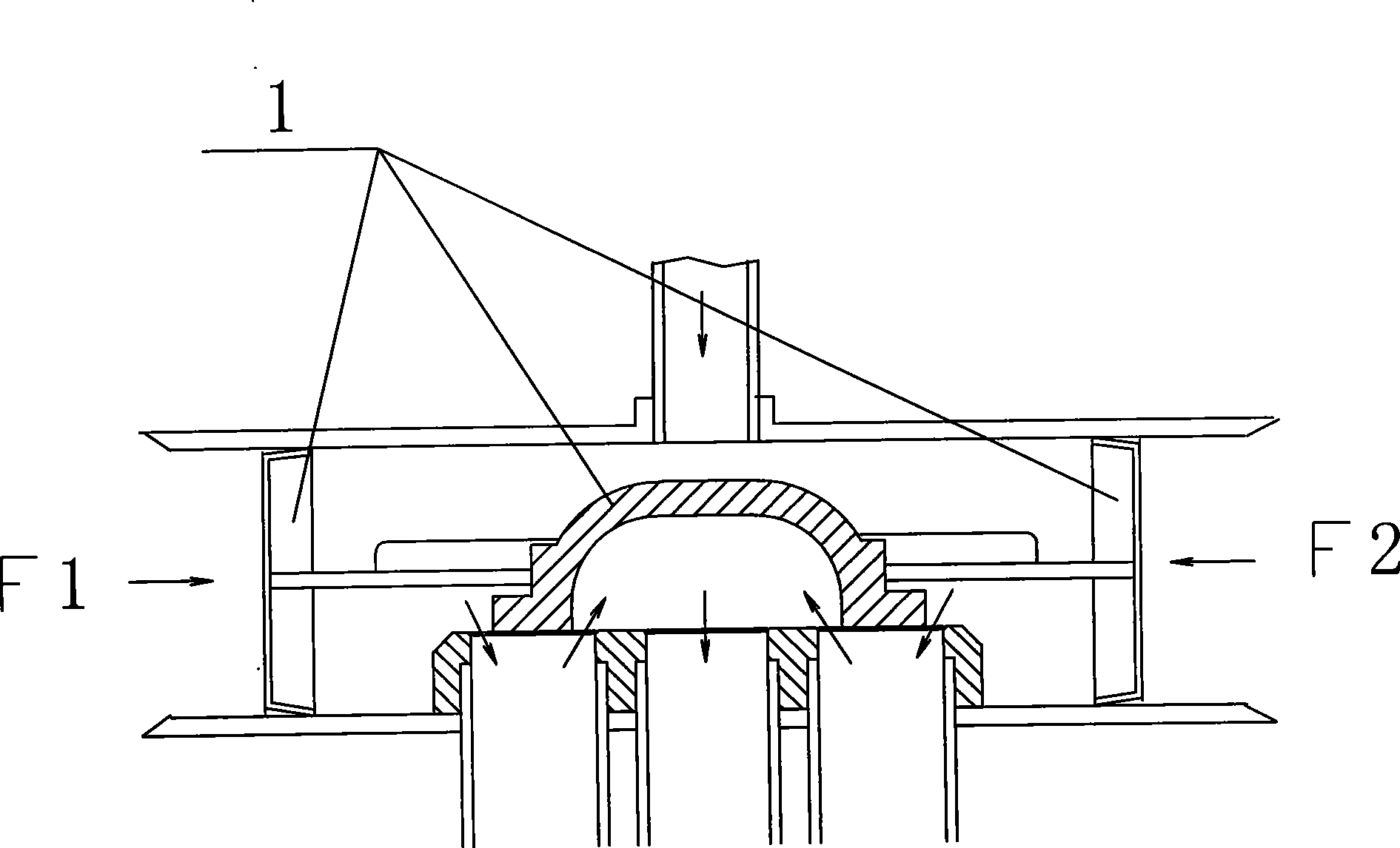

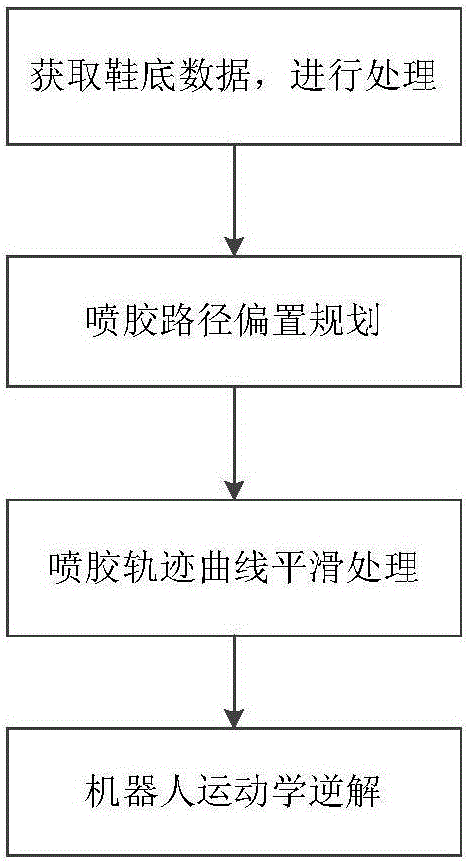

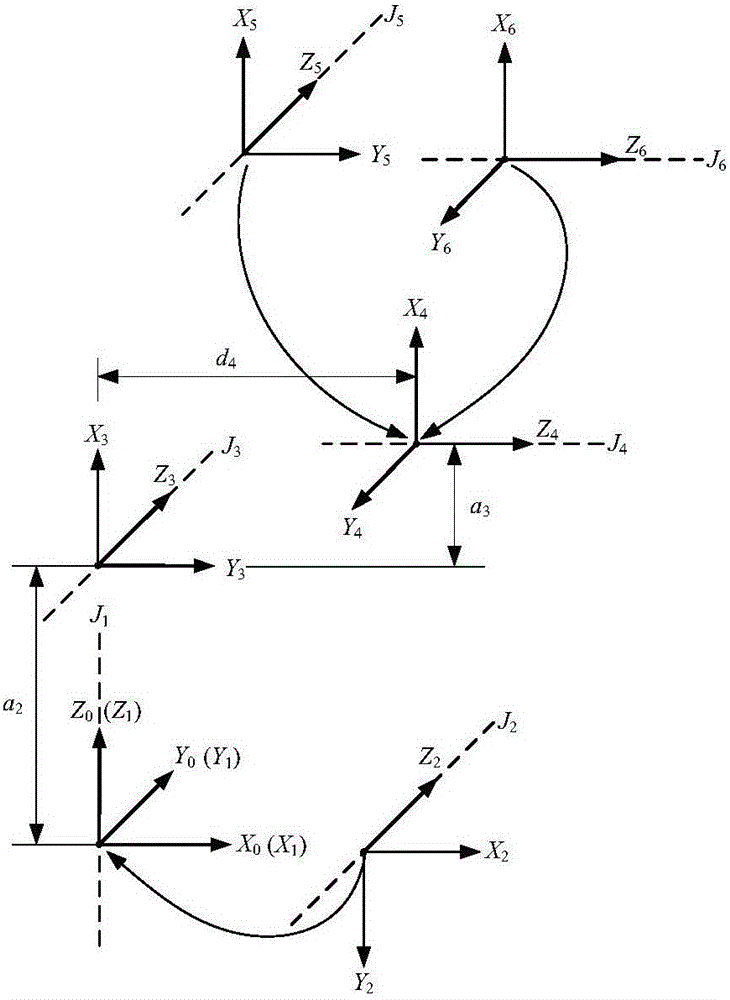

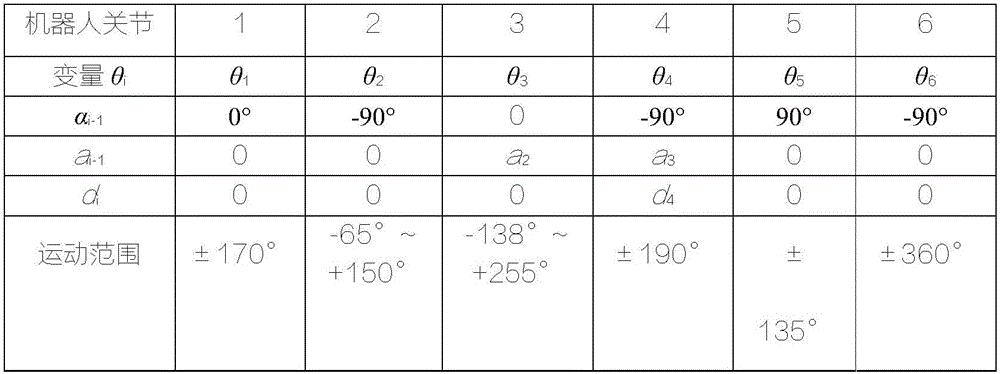

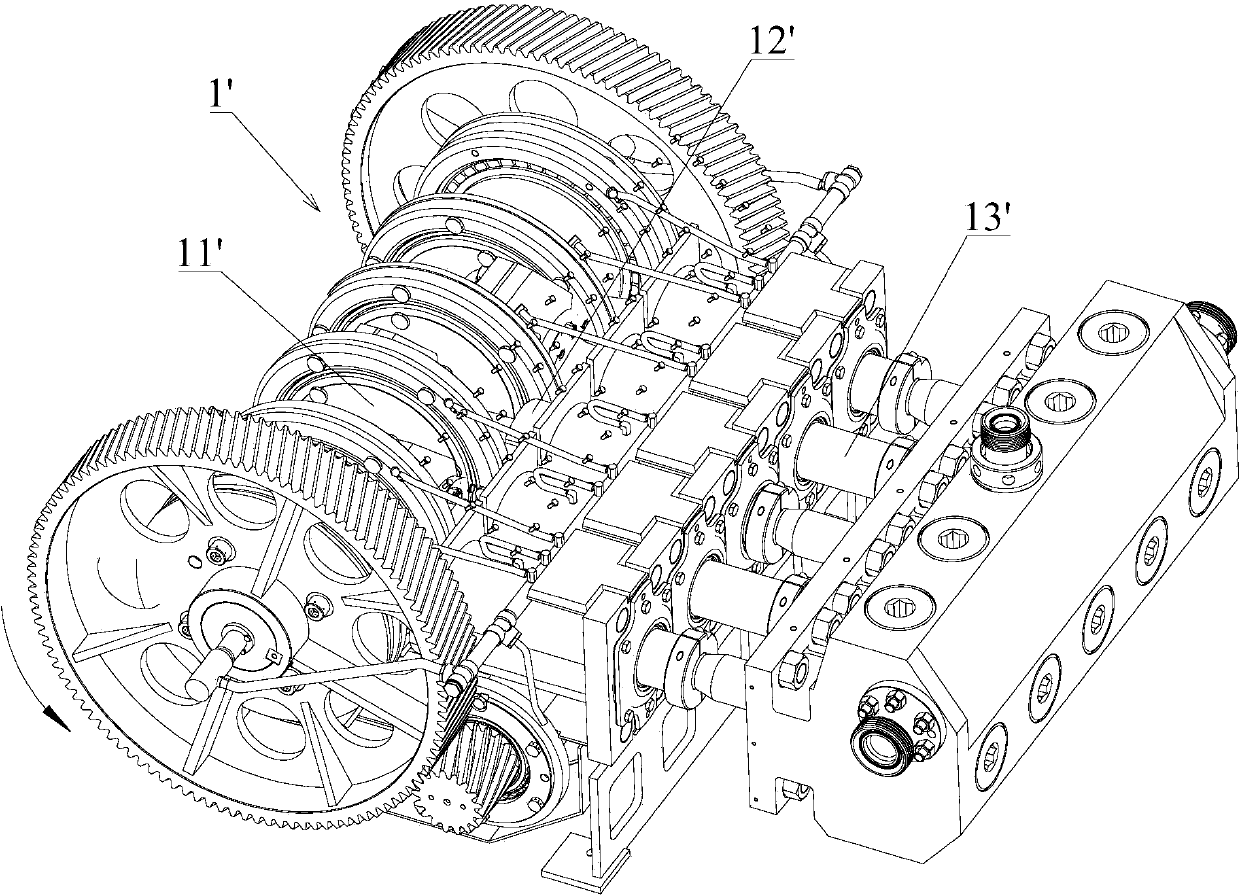

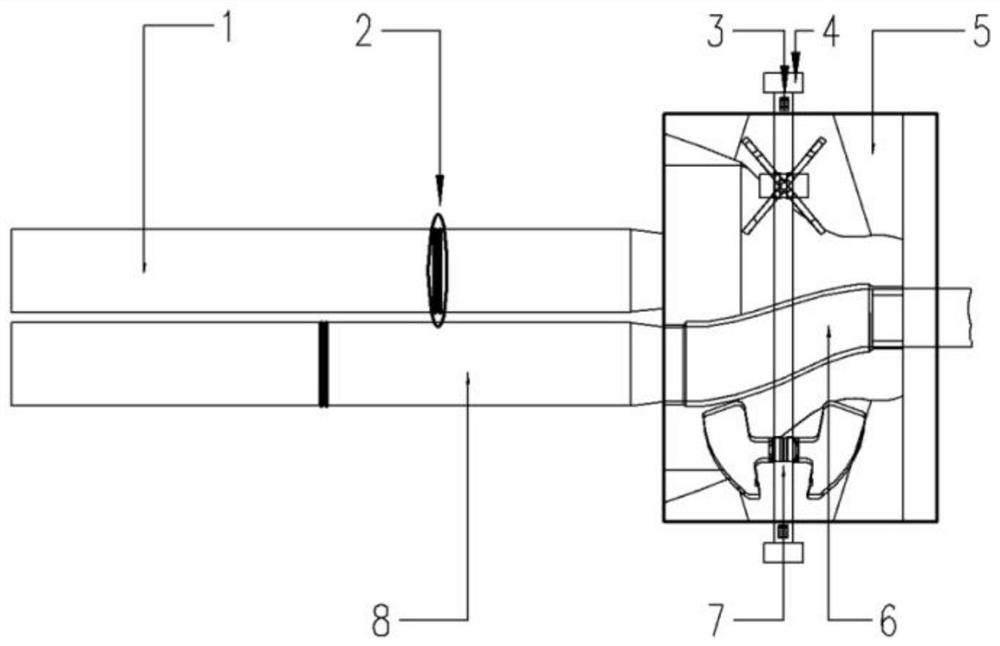

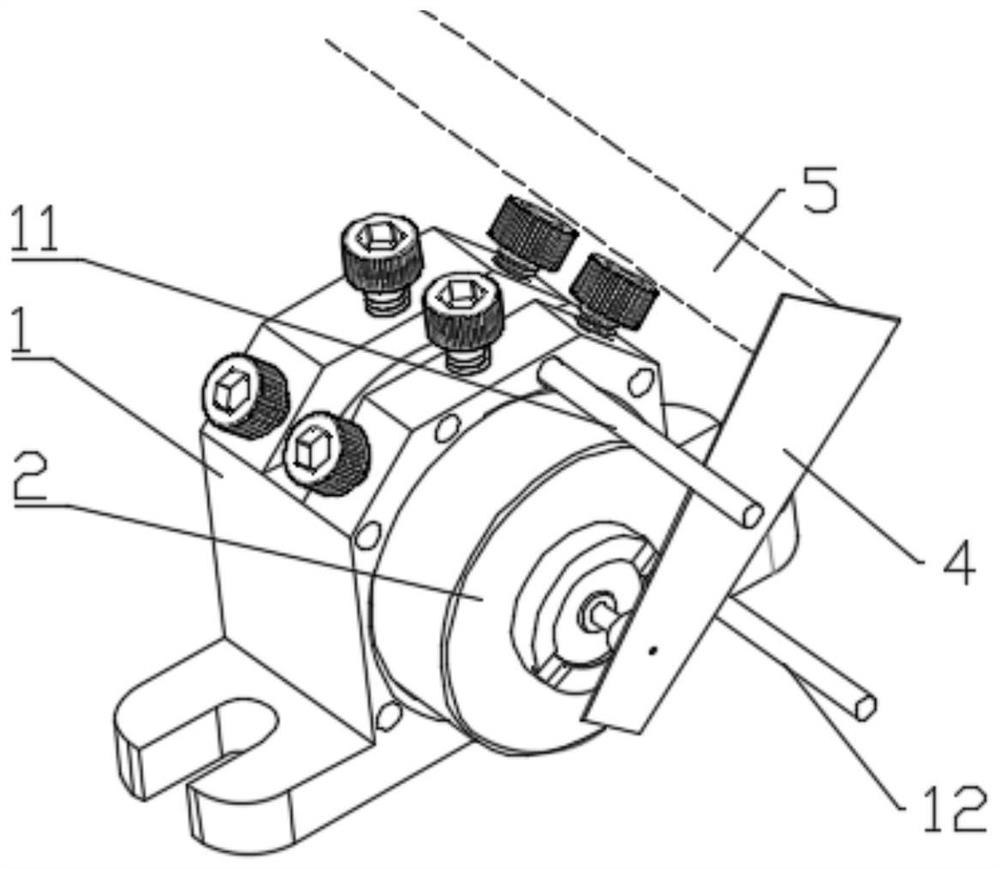

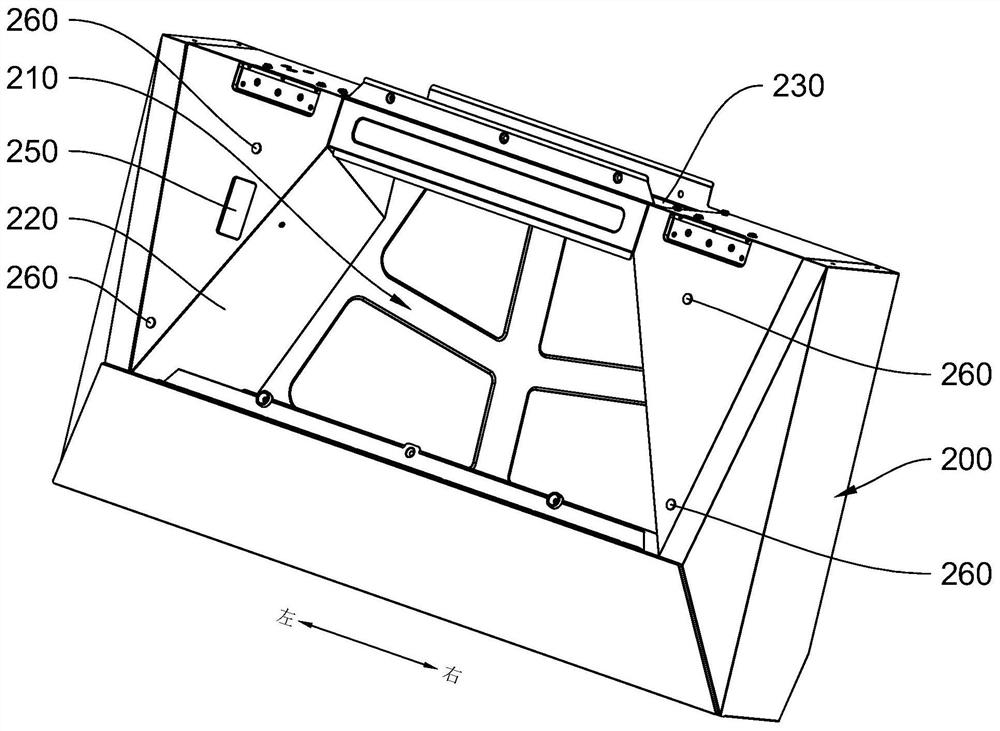

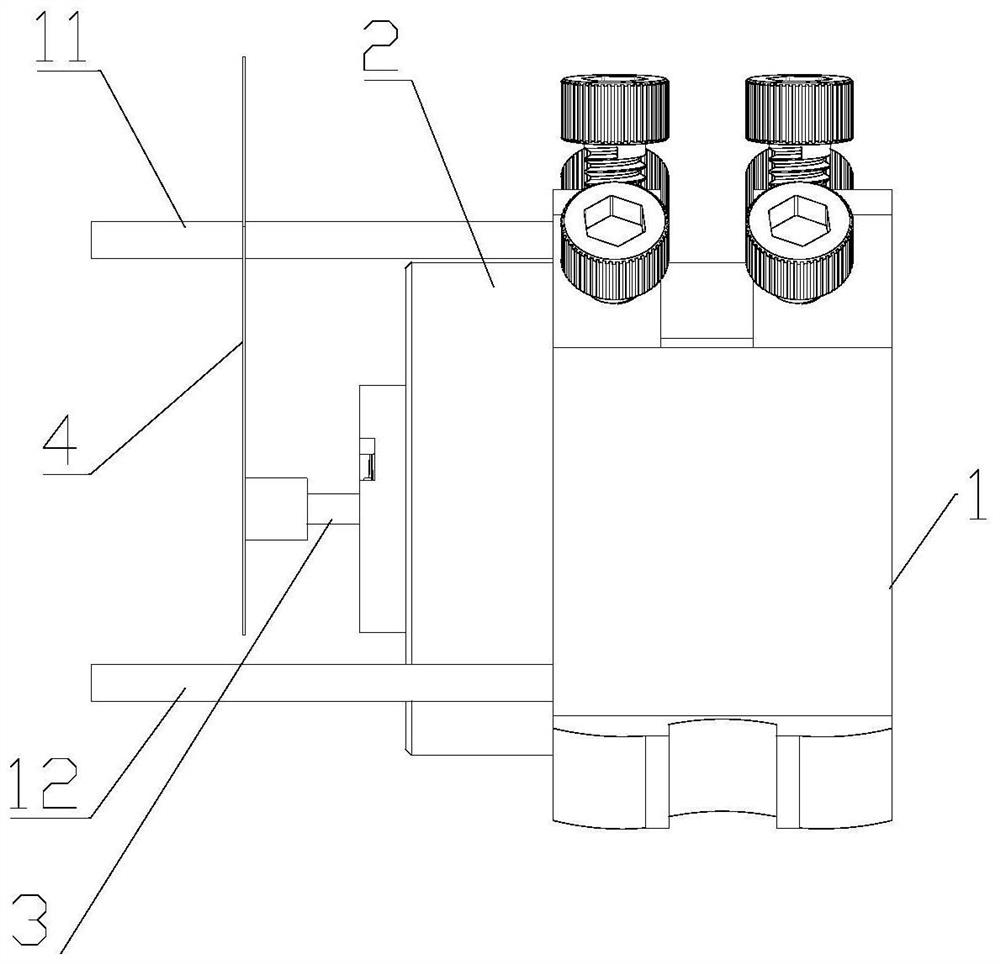

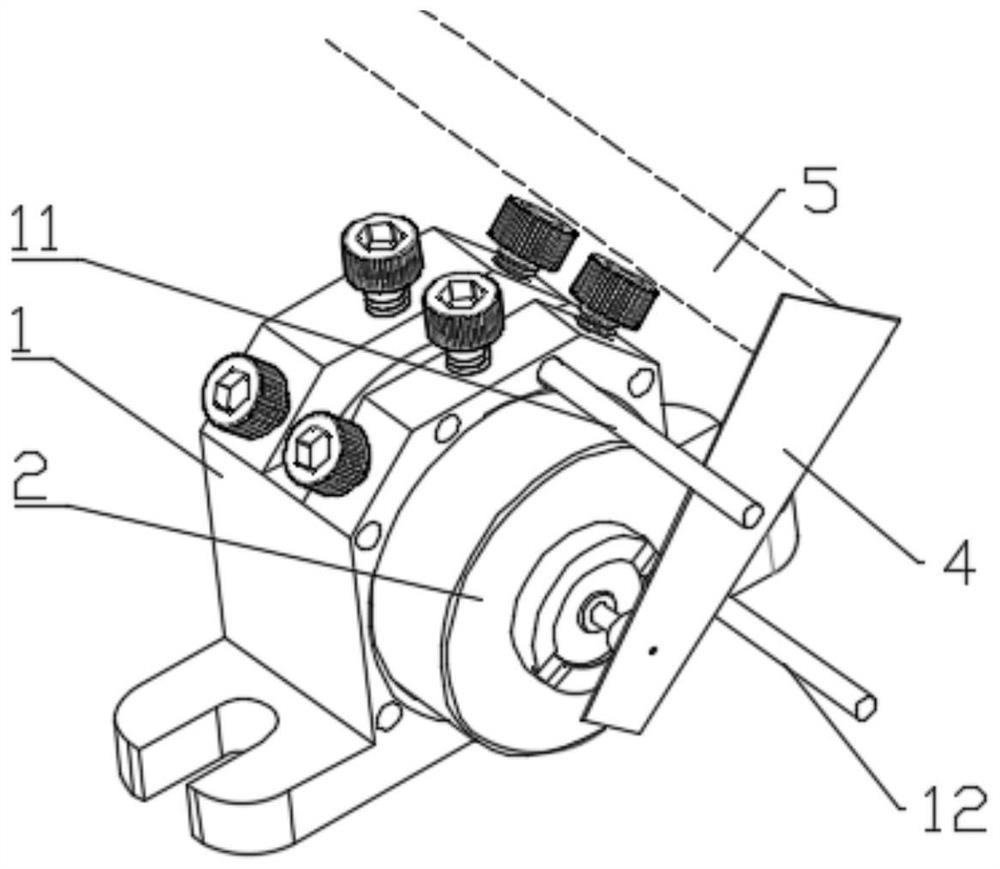

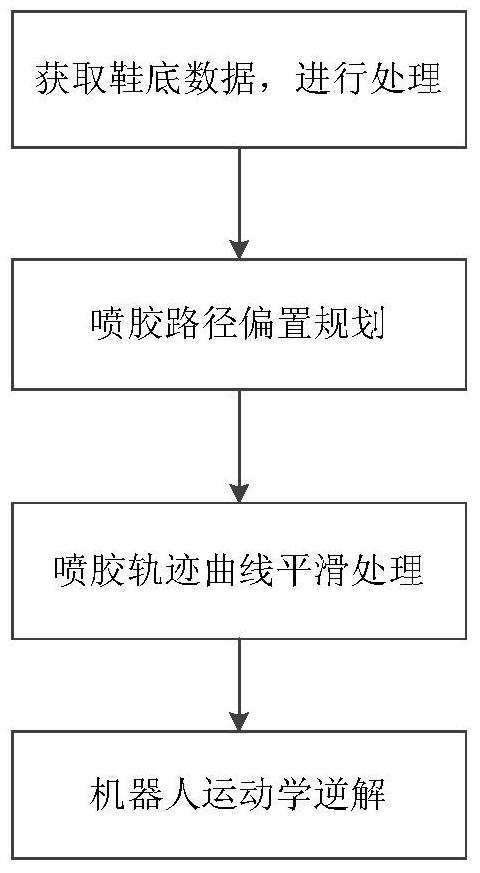

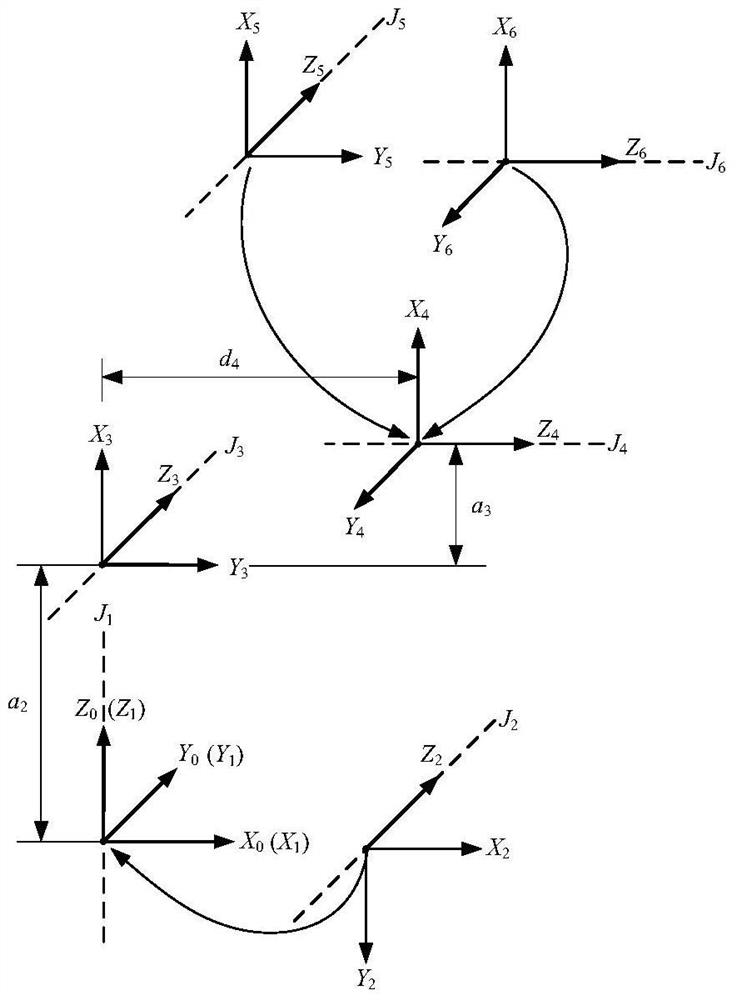

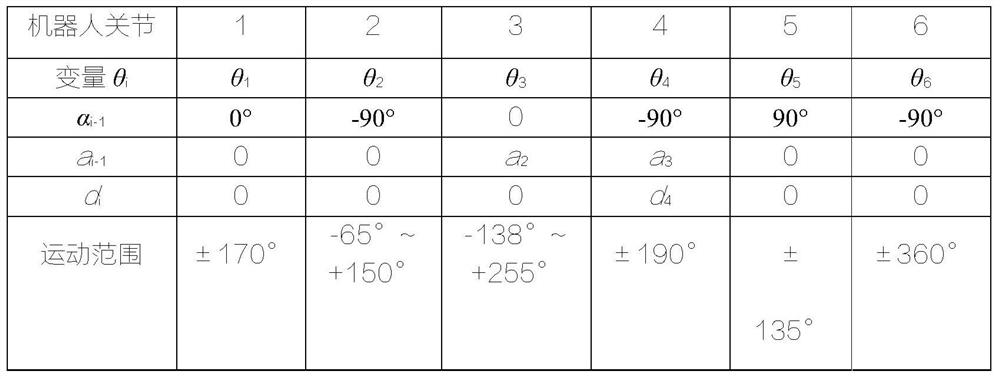

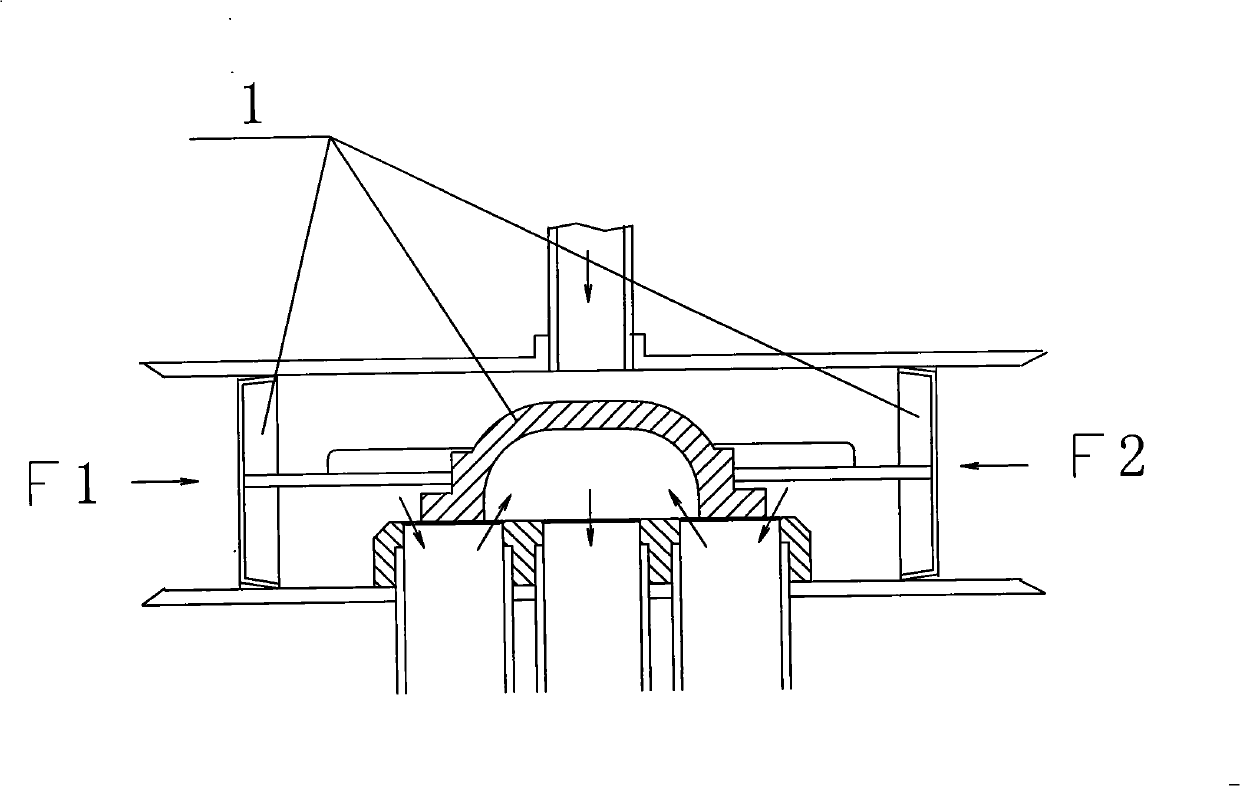

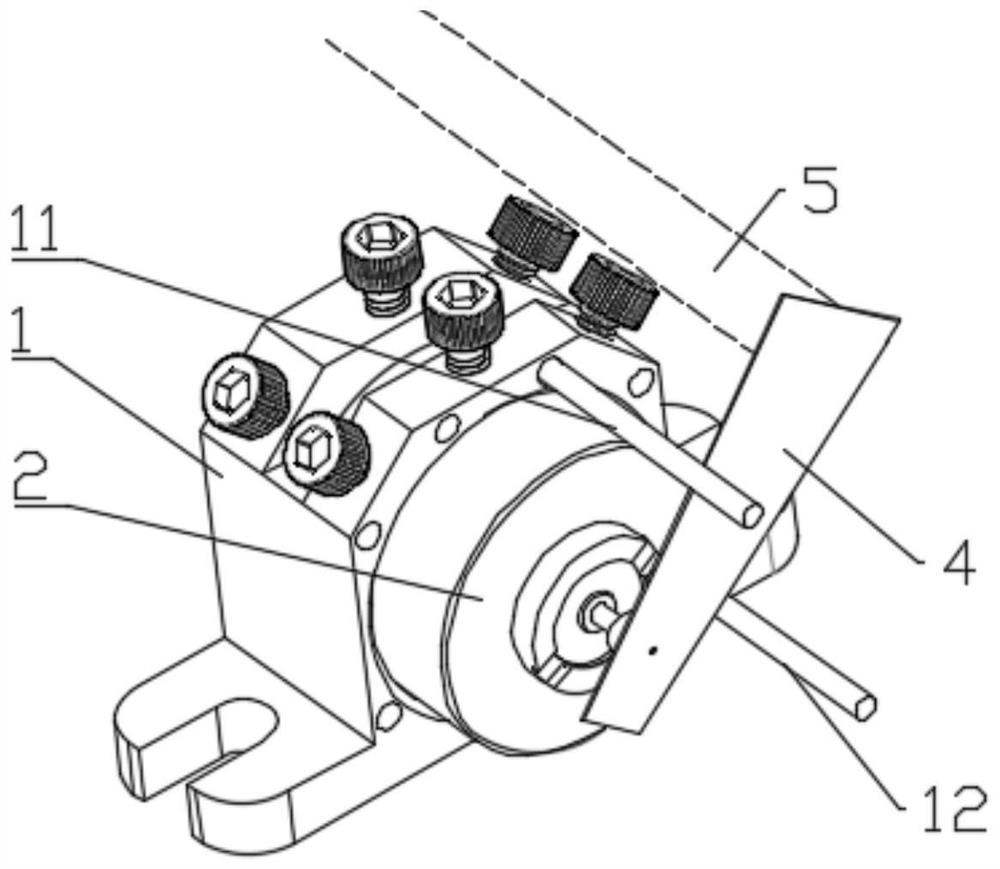

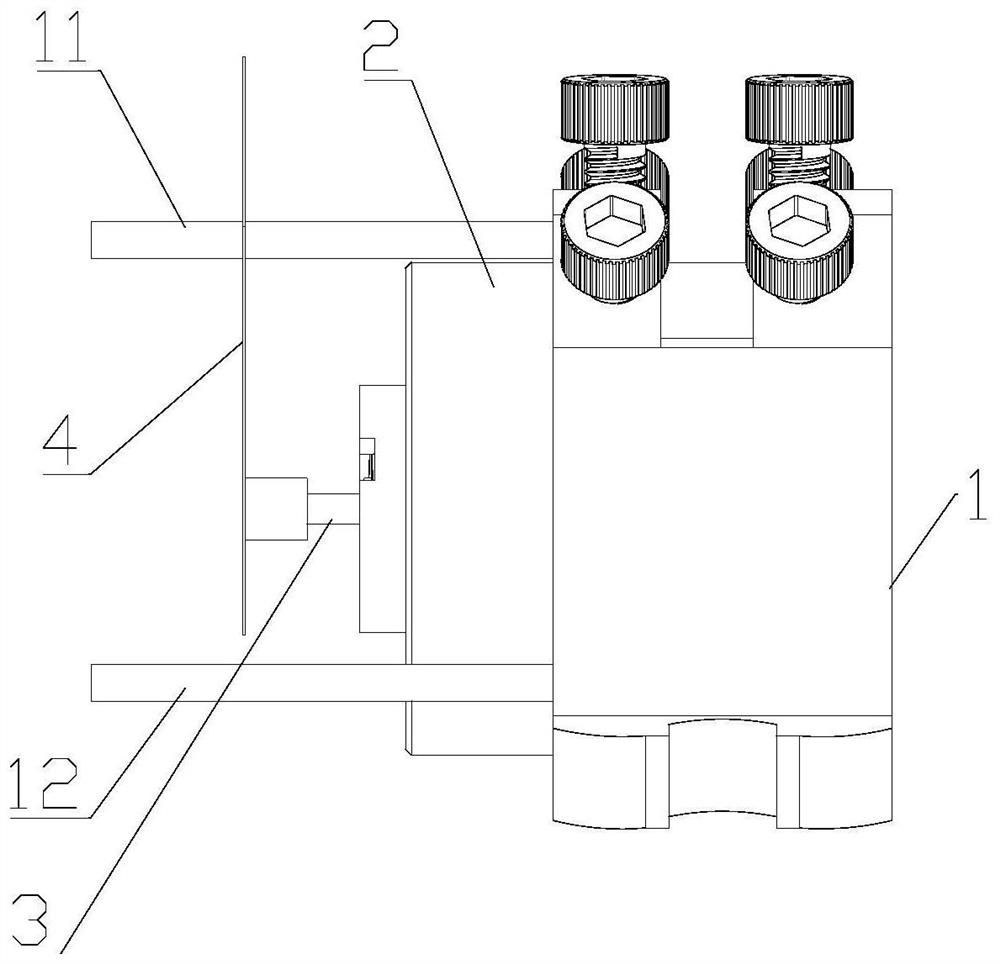

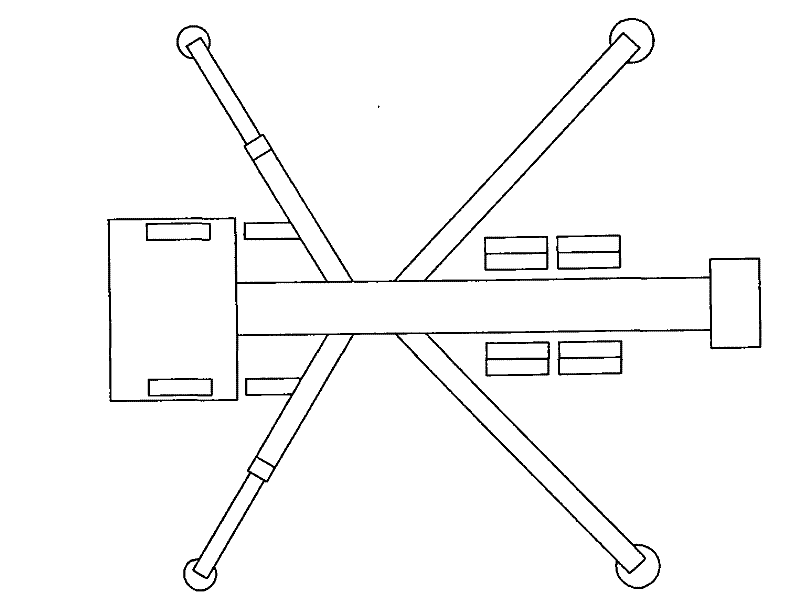

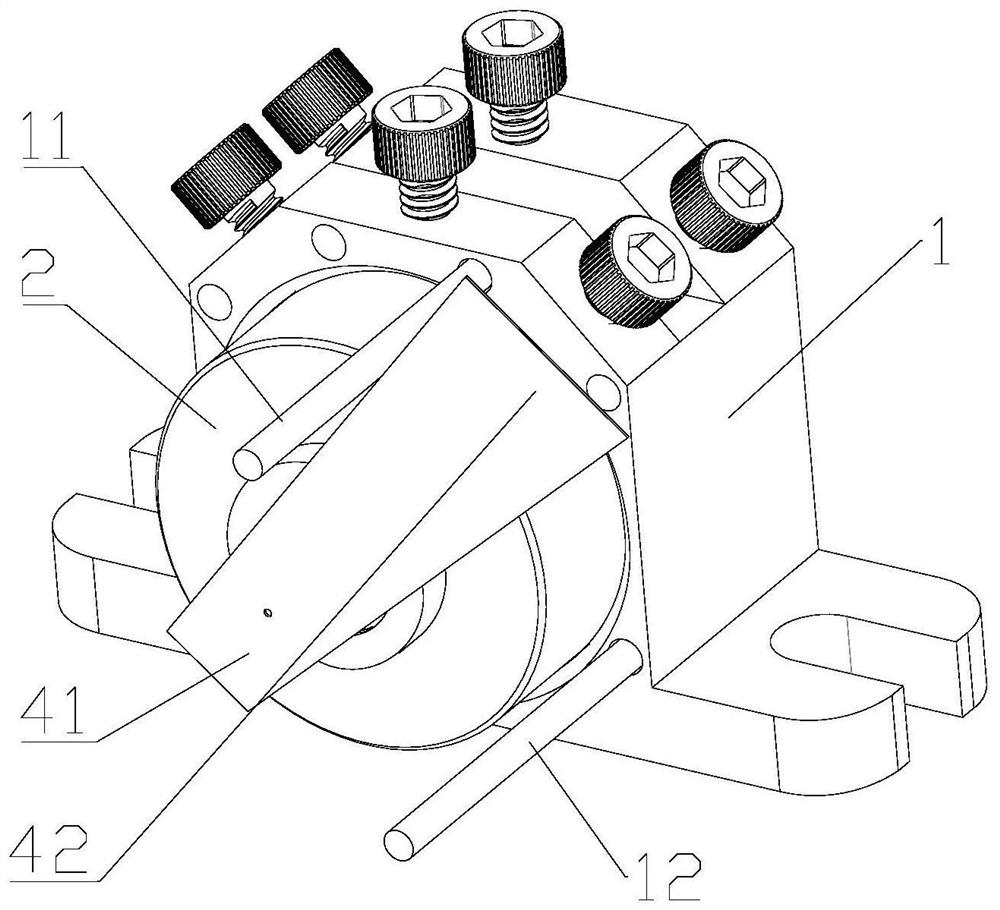

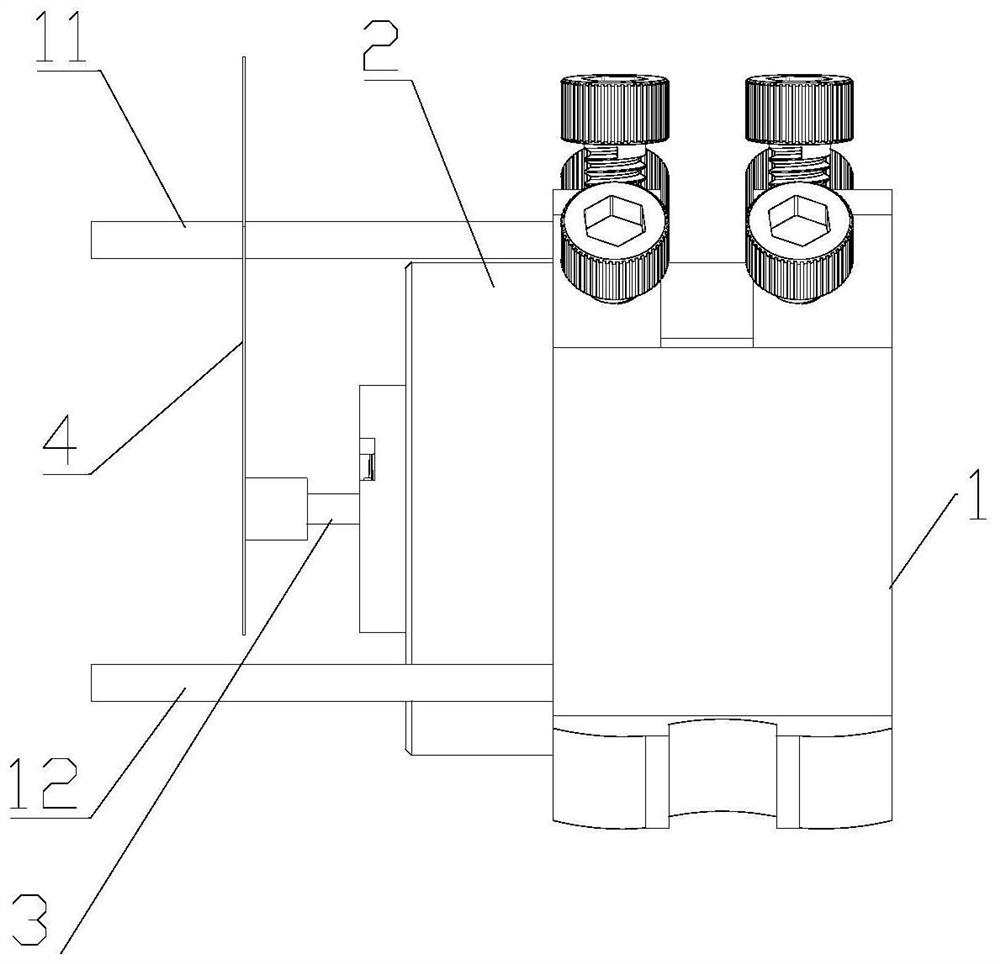

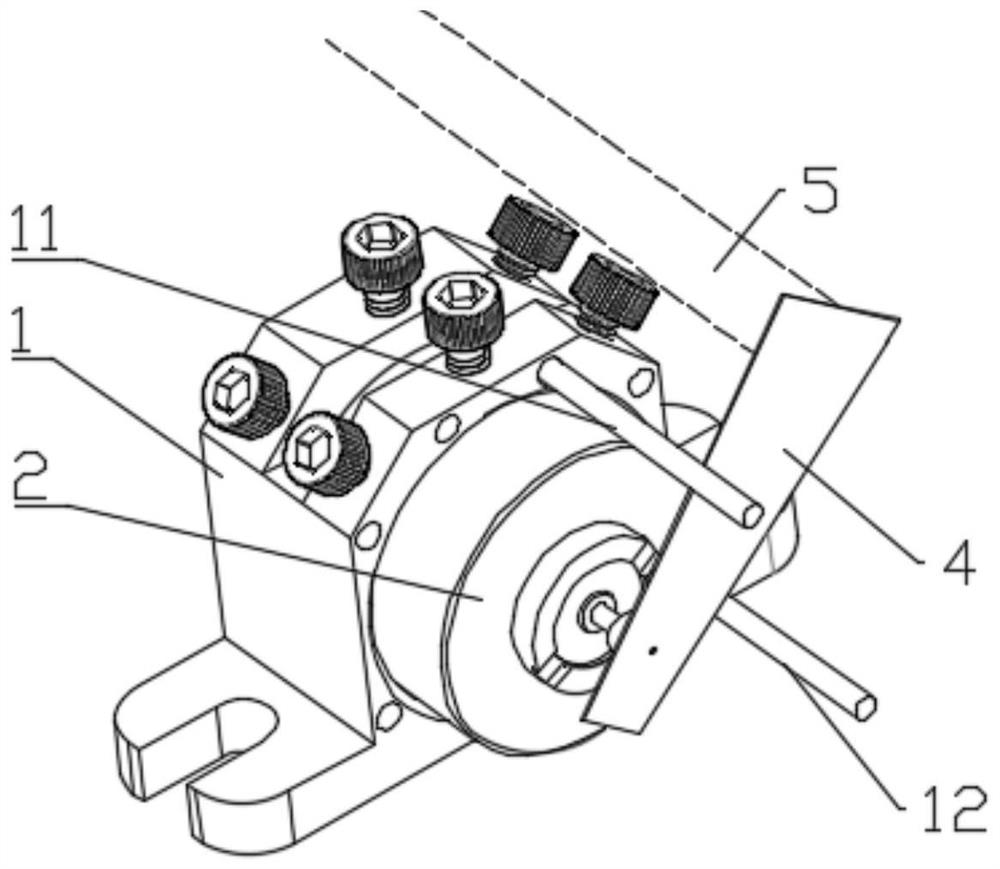

Attitude control-based sole glue spraying path planning method

An attitude control-based sole glue spraying path planning method of the present invention mainly comprises a robot, a laser profile measurement instrument, a glue gun and an industrial control computer. By using the laser profile measurement instrument to scan a sole, the three-dimensional point cloud of a sole curve is obtained, after the data is processed, a glue spraying path is planned, a control program is generated on the industrial control computer to be introduced into the robot, and the attitudes of the glue gun at the tail end of the robot are controlled according to different shoe types, so that a glue spraying process of the sole is finished, the attitudes of the glue gun can change along with the slope of a sole profile fitting curve, and the attitudes of the glue gun at the tail end of the robot can be controlled according to the different shoe types. Moreover, the glue spraying path of the present invention is smoothed, so that the commutation times of a robot motor can be reduced, and the operation speed of the robot is improved, and accordingly, the glue spraying efficiency is improved, and the working service life of the robot is prolonged.

Owner:QUANZHOU INST OF EQUIP MFG

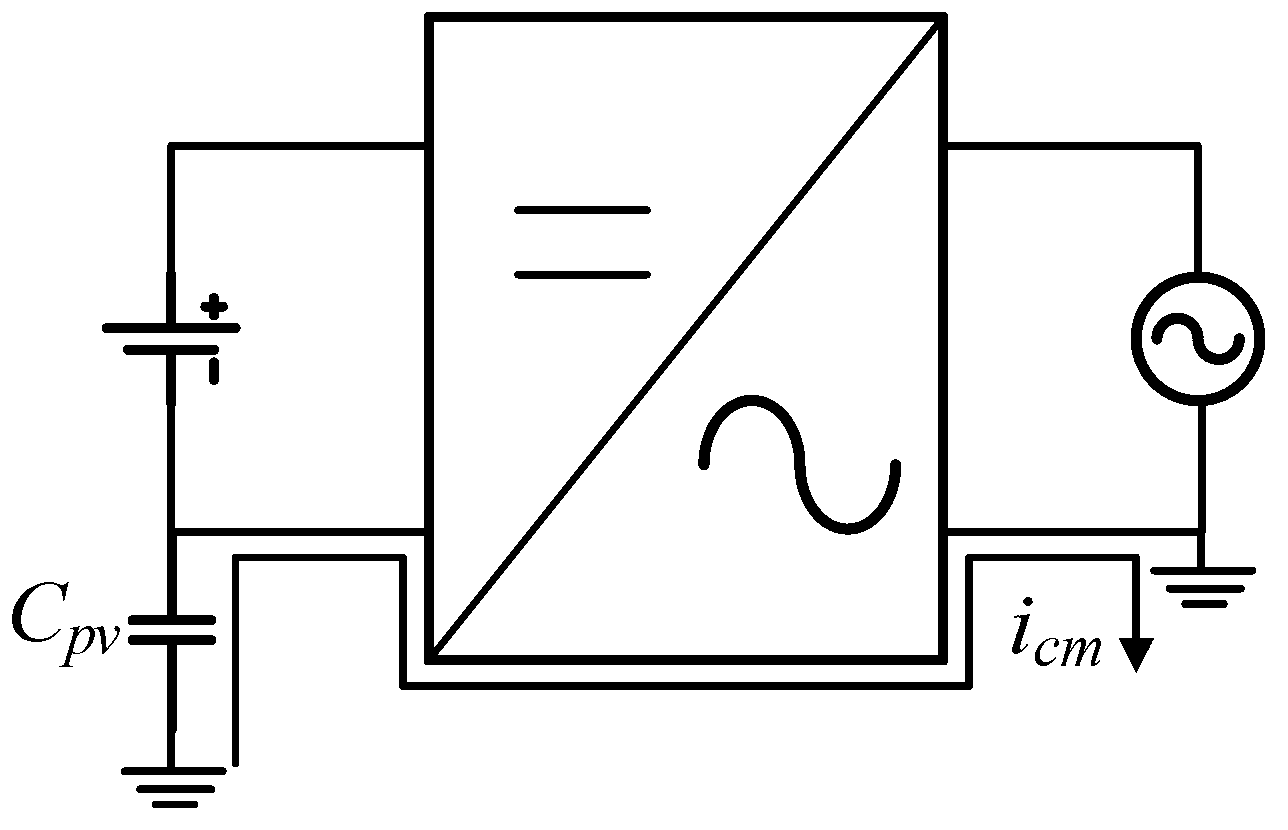

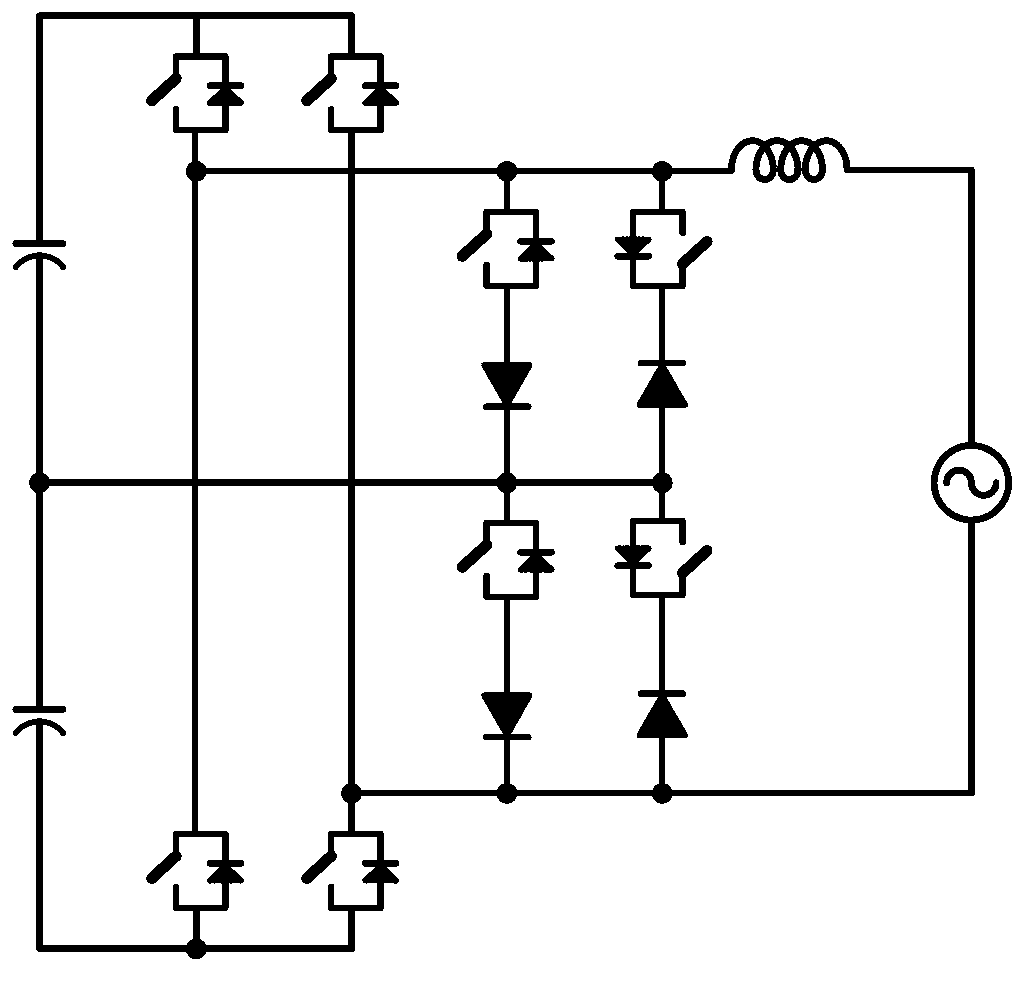

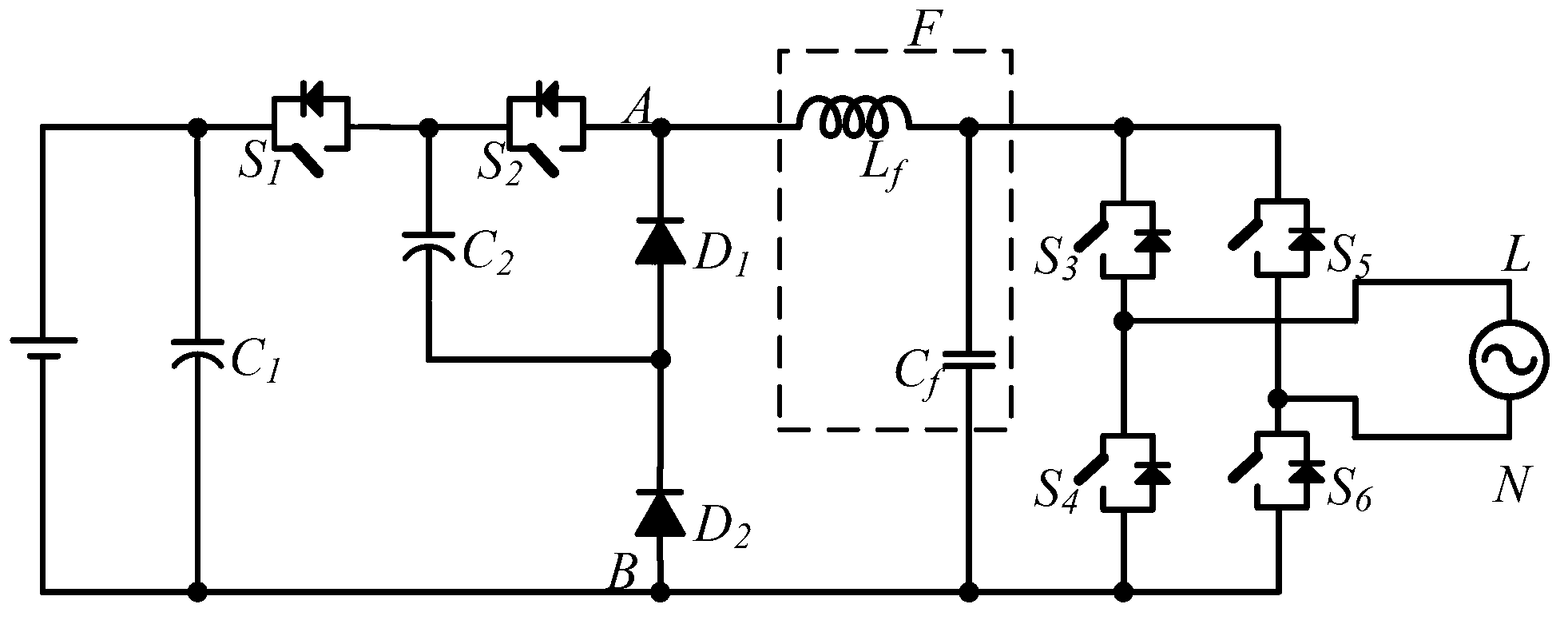

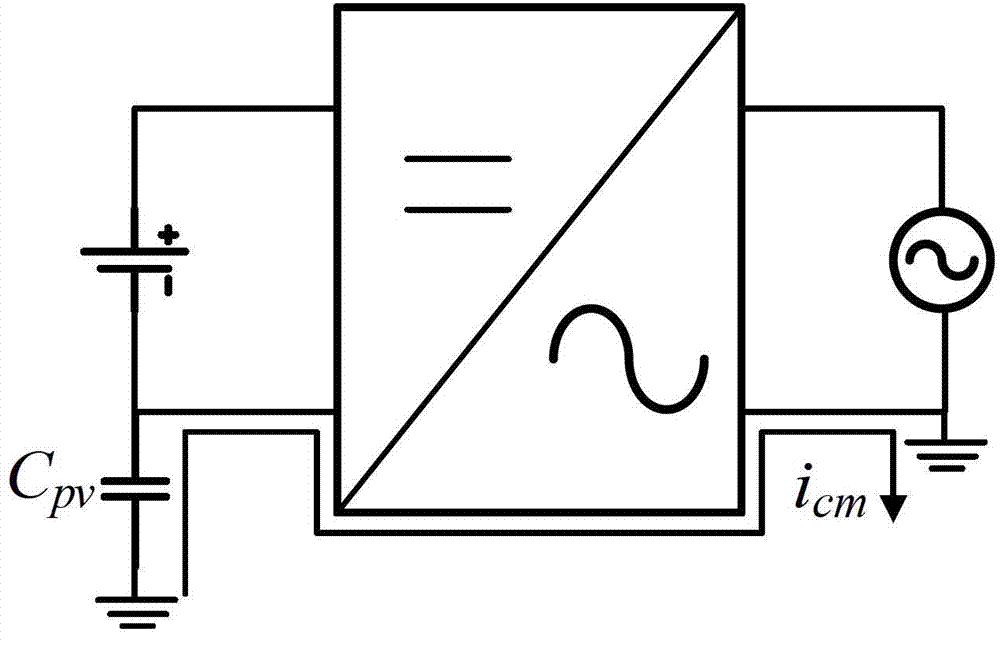

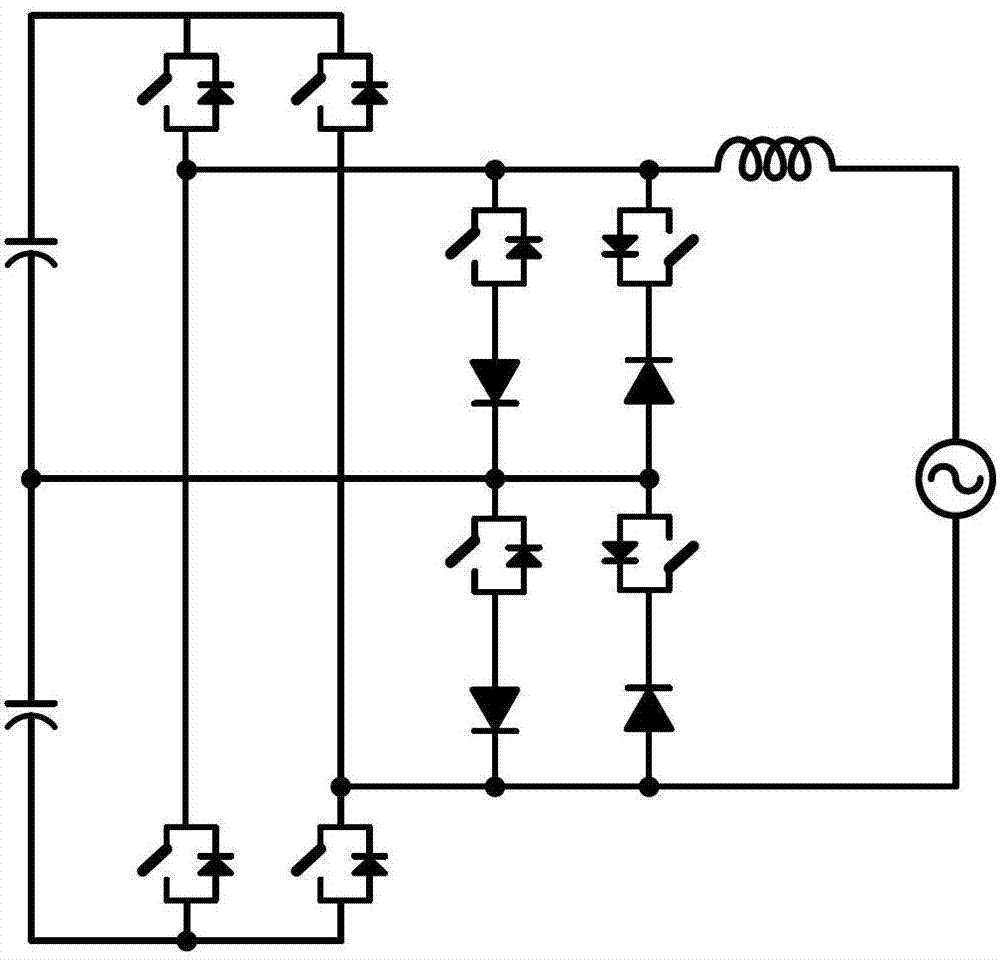

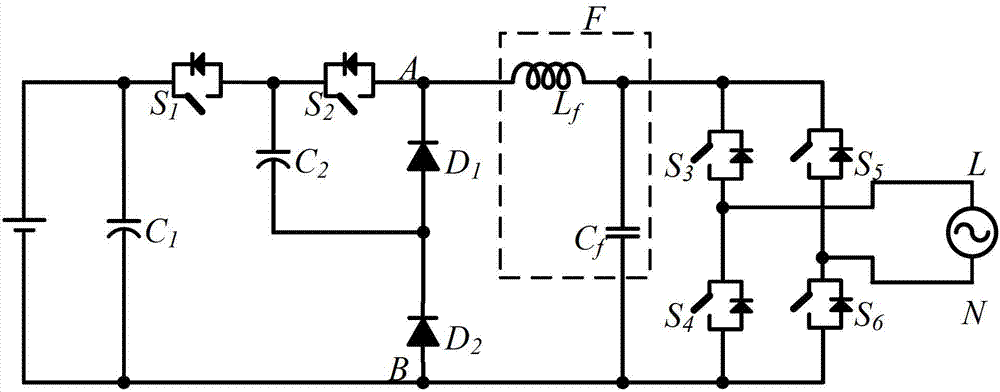

One-phase five-level inverter

ActiveCN103326606AReduce distractionsEnsure personal safetyAc-dc conversionDc-dc conversionPower inverterThree level

The invention discloses a one-phase five-level inverter. The one-phase five-level inverter comprises a common ground type three-level switching circuit, a filter circuit and a power frequency inversion circuit. For being realized specifically, the inverter comprises six power switches from S1 to S6, two diodes from D1 to D2, and a one-phase output filter F. The output of the inverter is five levels, and the inverter has the advantages of being high in inversion efficiency and reliability and simple in control mode. Meanwhile, through the voltage clamp mode, the inverter can eliminate high-frequency common mode current danger in a non-isolated type grid-connected inverter system effectively. Thus, the inverter is especially suitable for being applied to a non-isolated type photovoltaic grid-connected system.

Owner:HOYMILES POWER ELECTRONICS INC

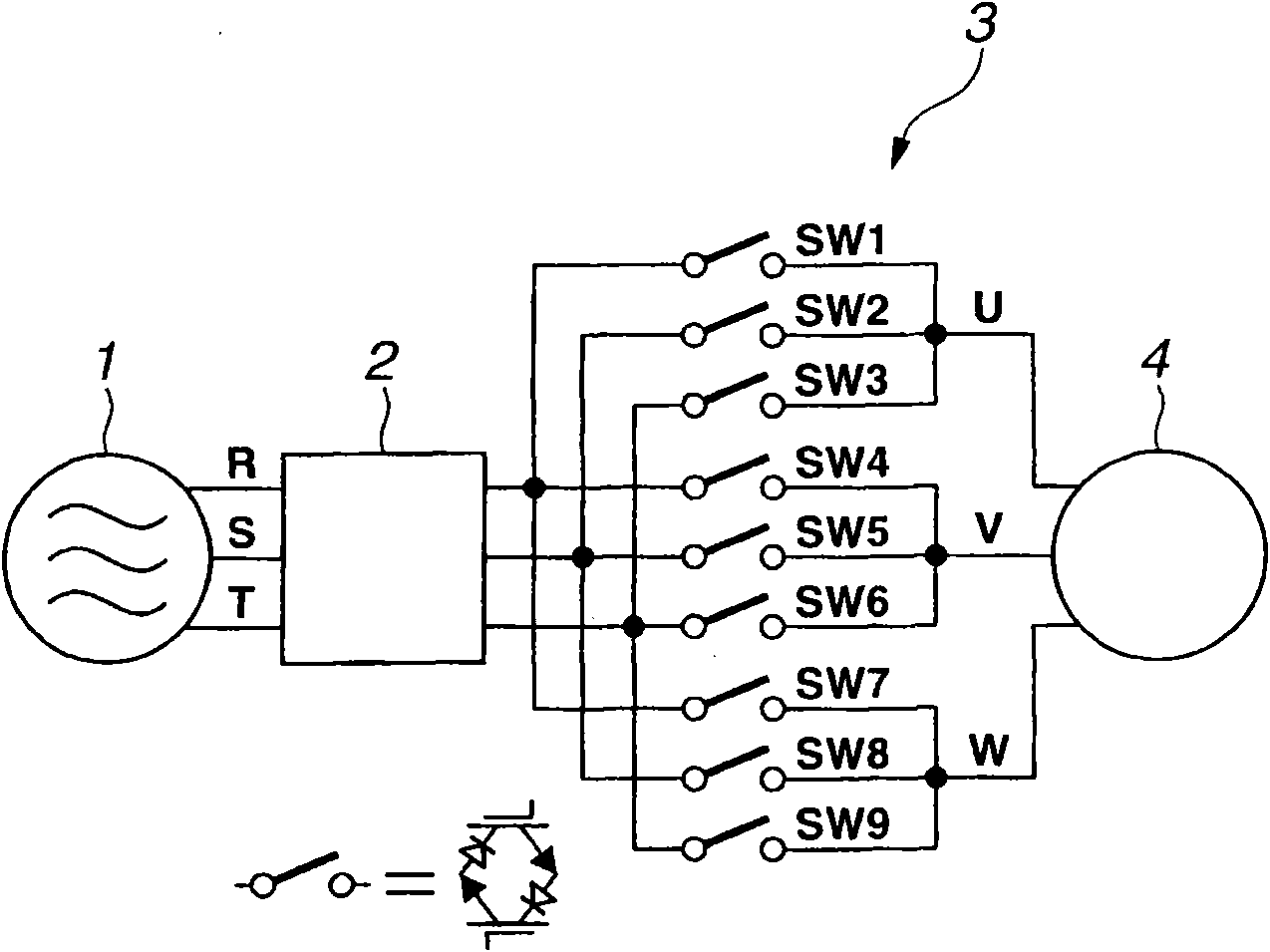

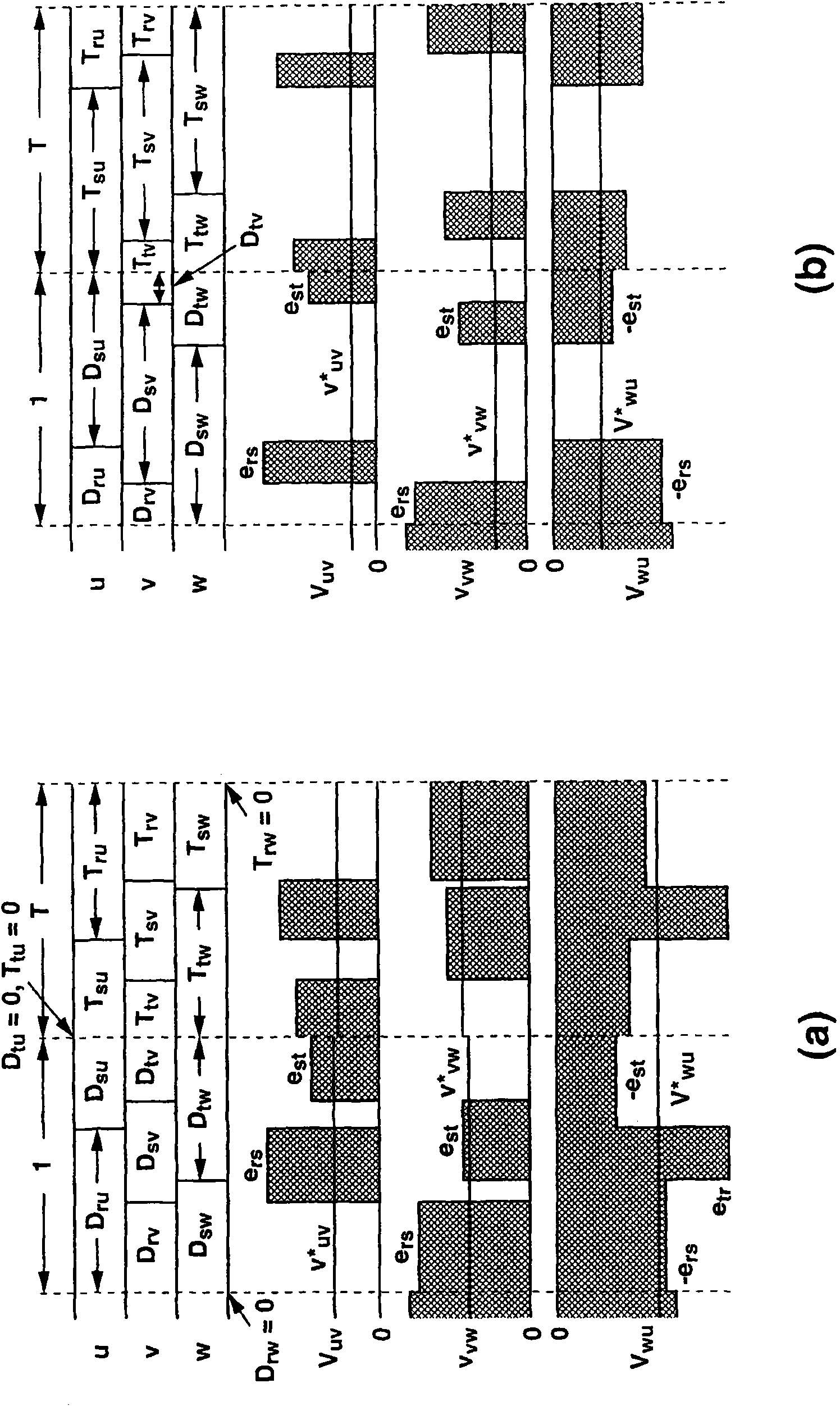

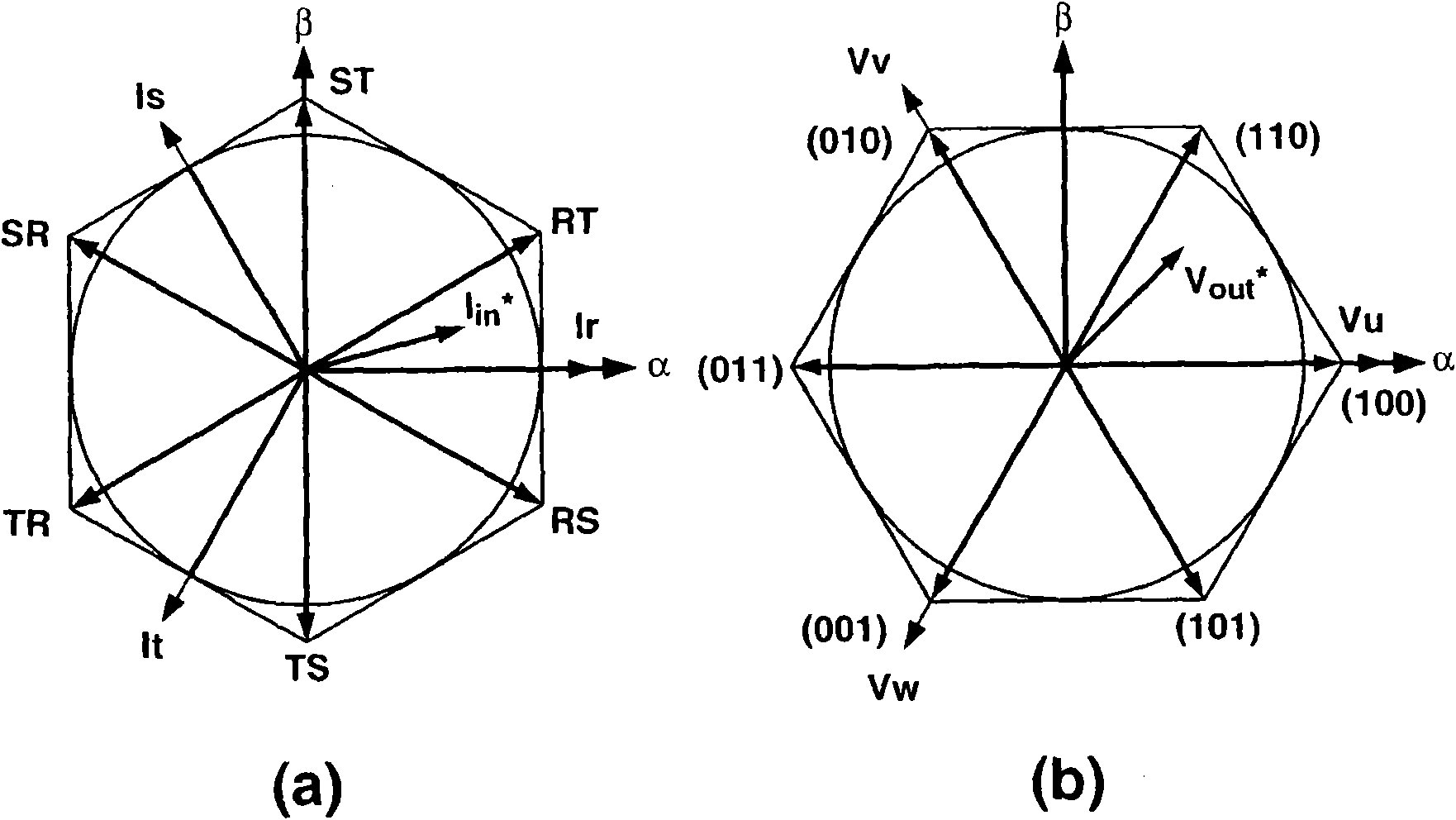

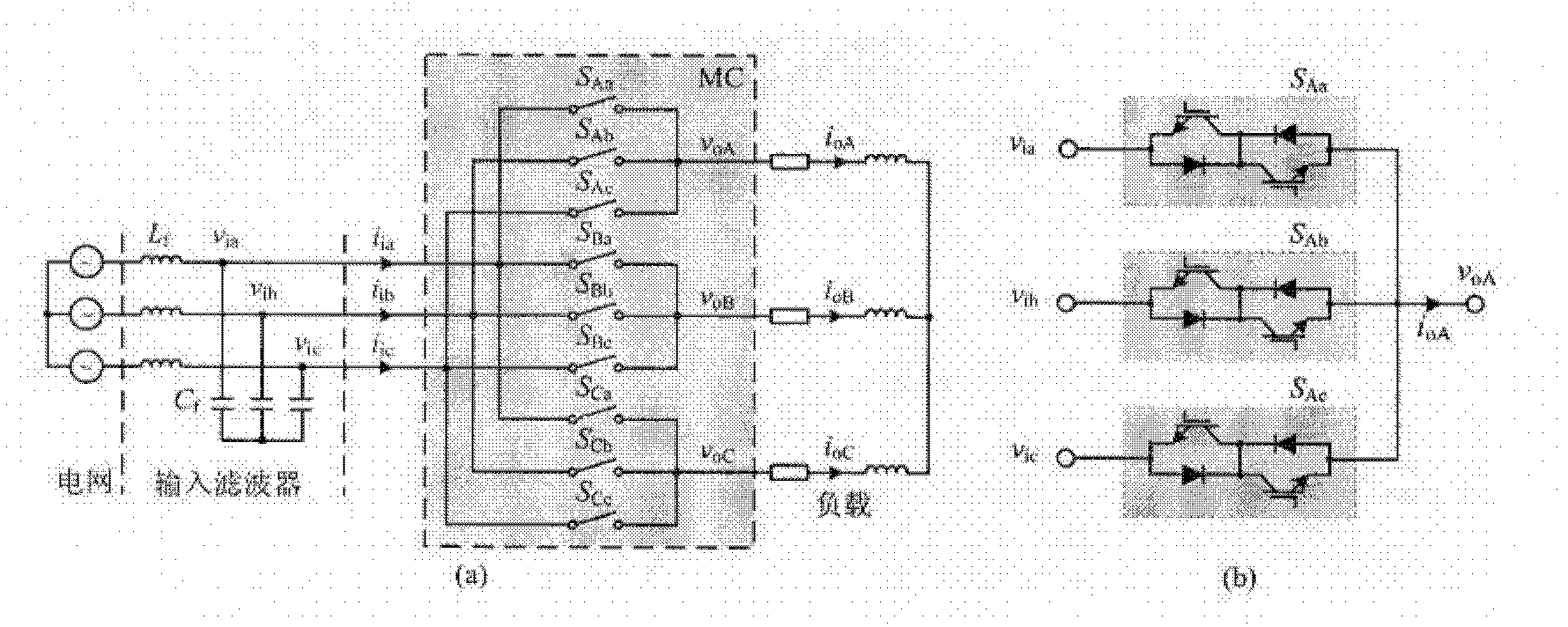

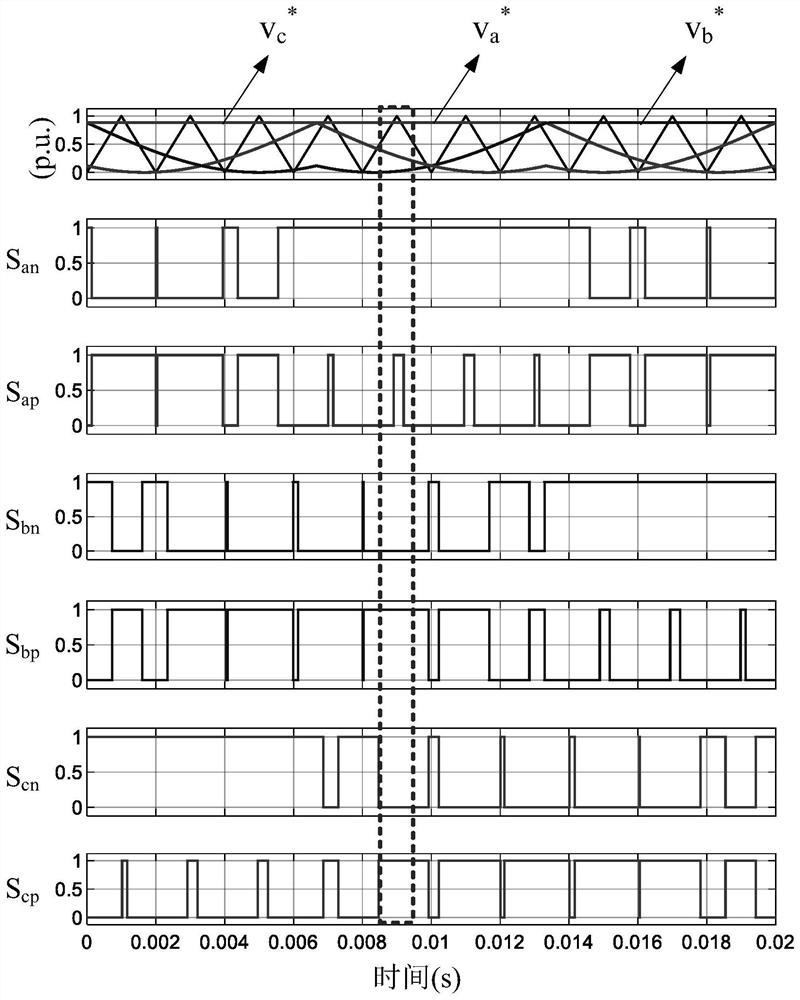

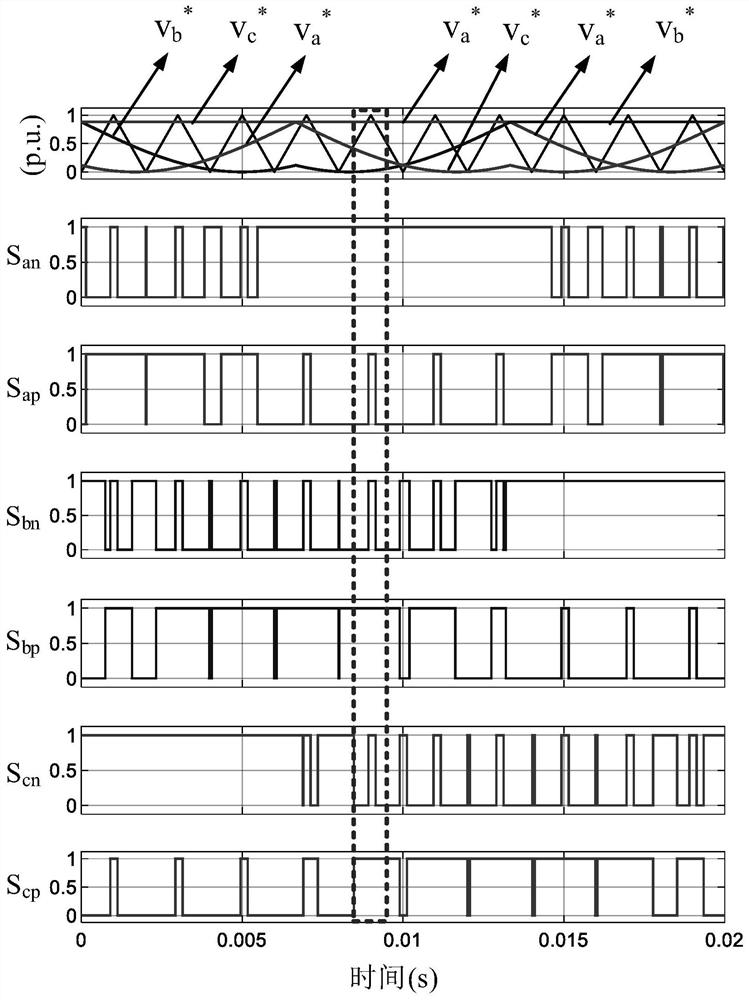

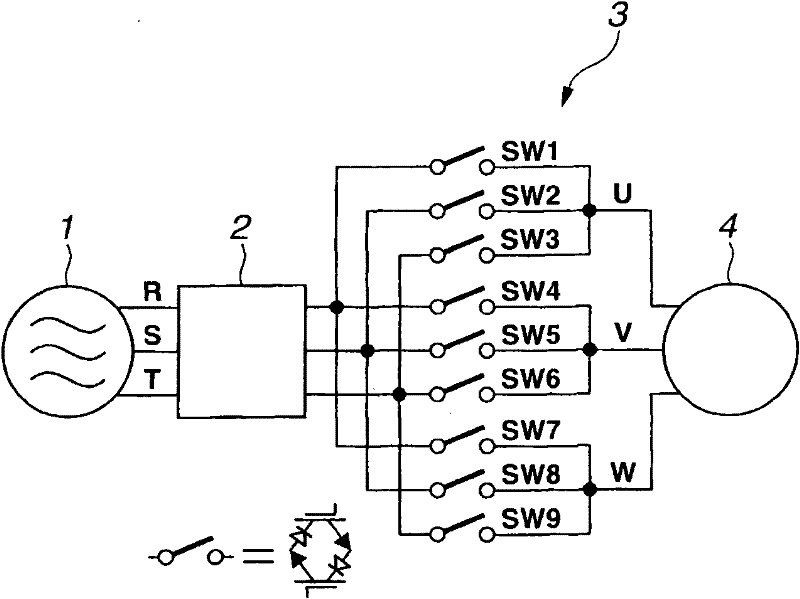

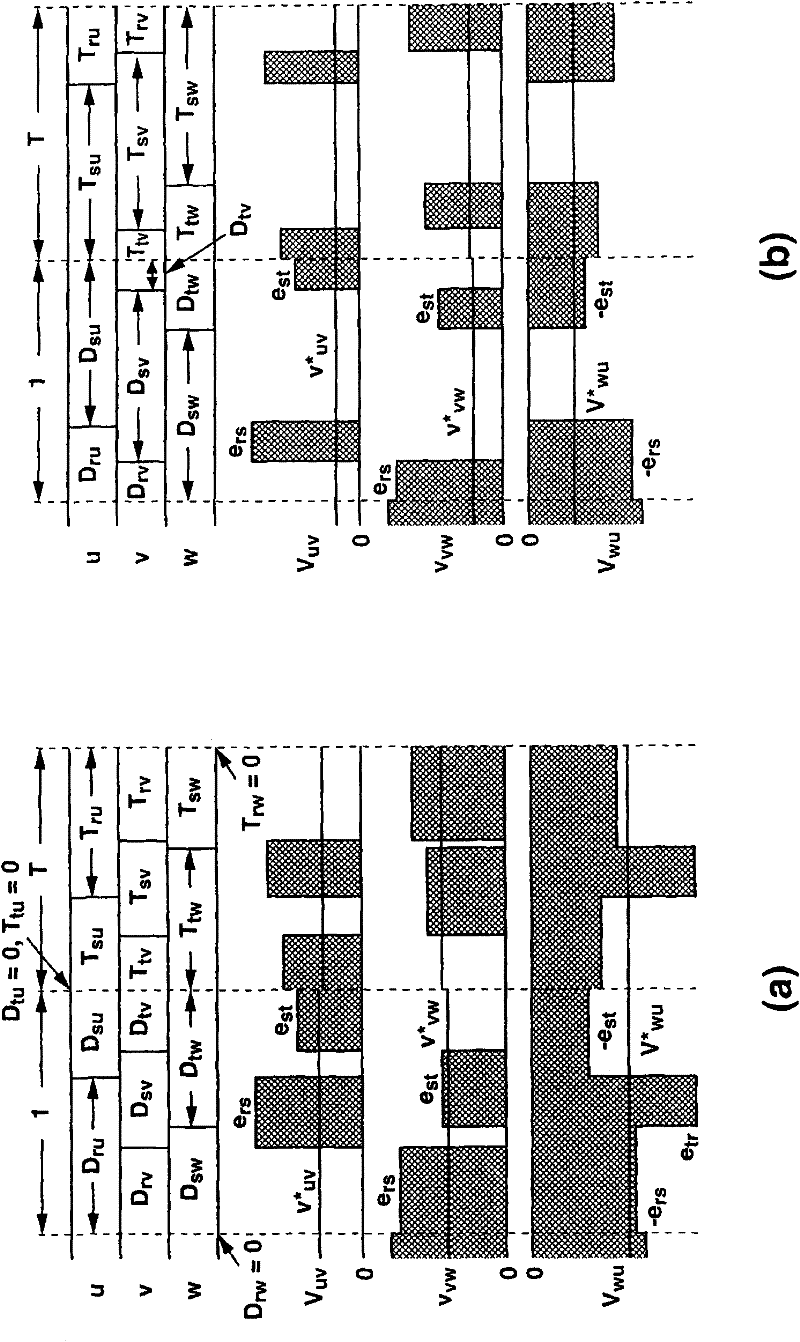

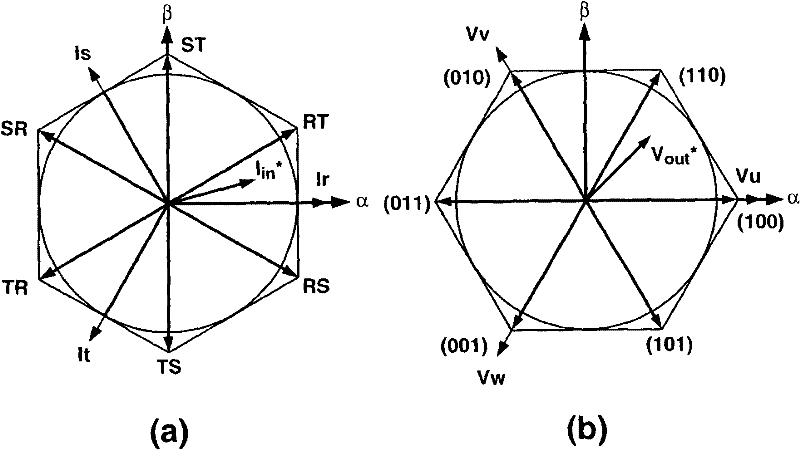

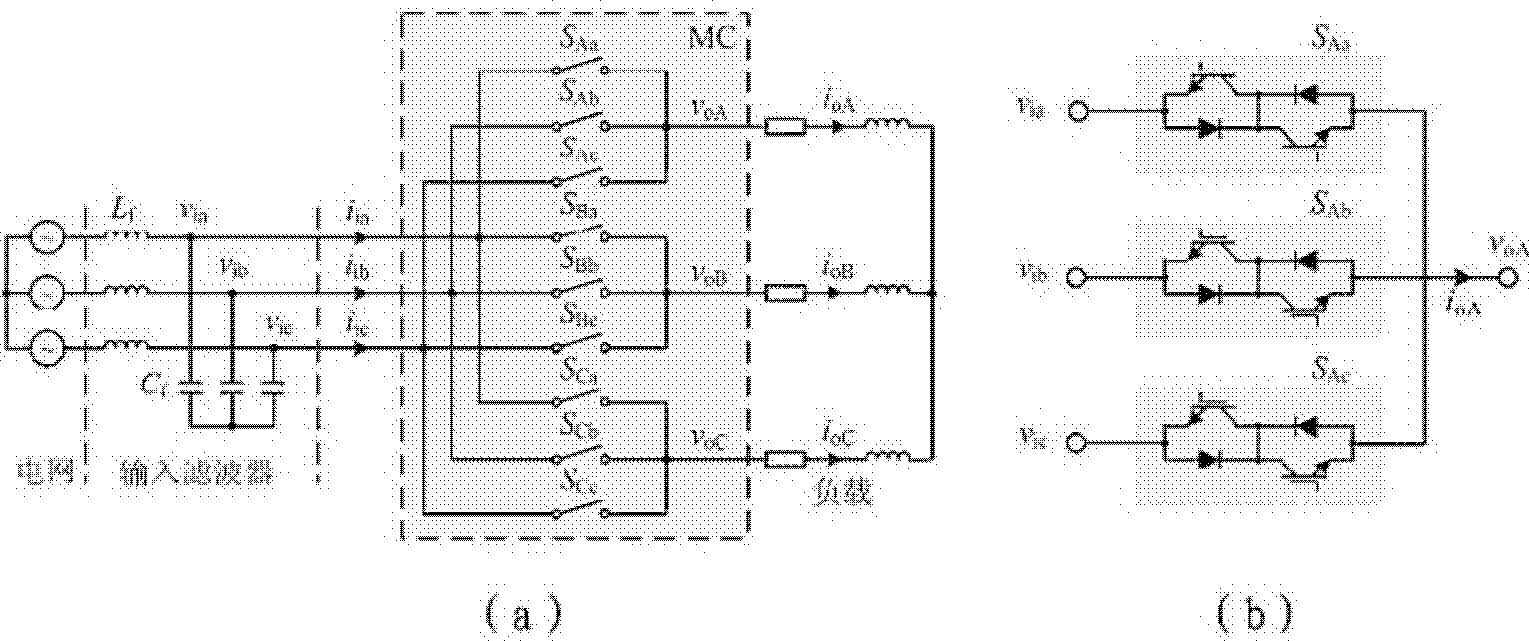

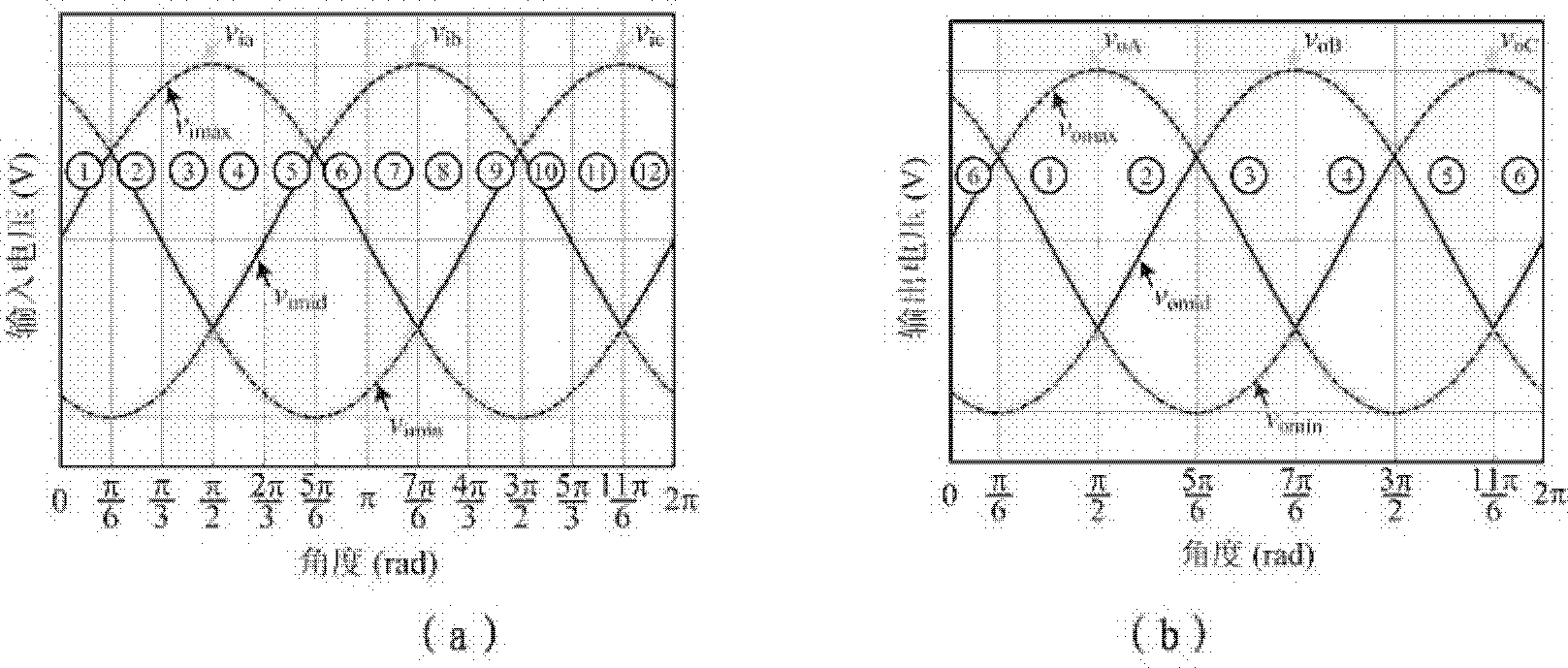

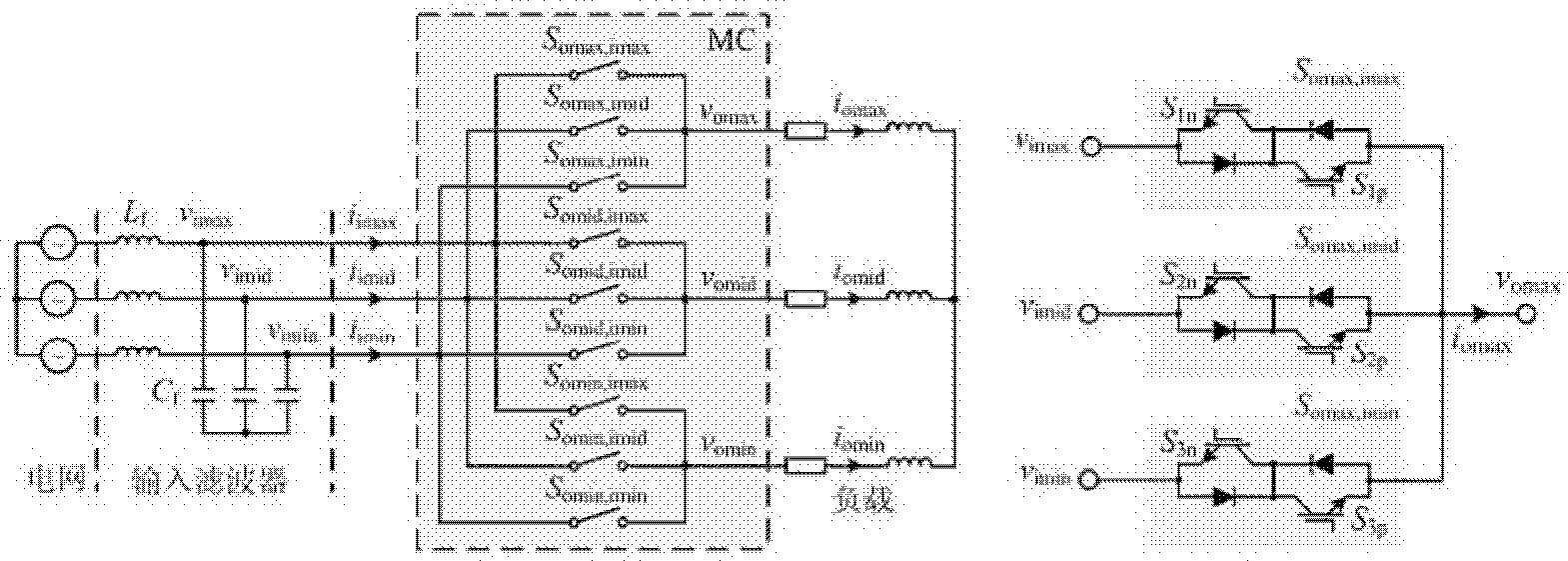

Matrix converter space vector modulation method

InactiveCN101632217AReduce the number of commutationsReduced number of carriersAc-dc conversionAc-ac conversionCarrier signalAC power

To provide a space vector modulation method for a matrix converter which uses only one carrier for three phases upon carrier comparison. Provided is a matrix converter space vector modulation method which PWM-controls bidirectional switches (SW1 to SW9) of a matrix converter (3) by space vector modulation from a multi-phase AC power source. A switching pattern using a virtual indirect space vector is converted into a switching pattern formed by a combination of five vectors using direct conversion space vectors. Among the converted switching patterns, a switching pattern satisfying a predetermined condition is selected and duties of the five vectors of the selected switching pattern are calculated by using a duty relationship expression of the direct conversion space vectors. The matrix converter is PWM-controlled according to the calculated duties.

Owner:MEIDENSHA ELECTRIC MFG CO LTD

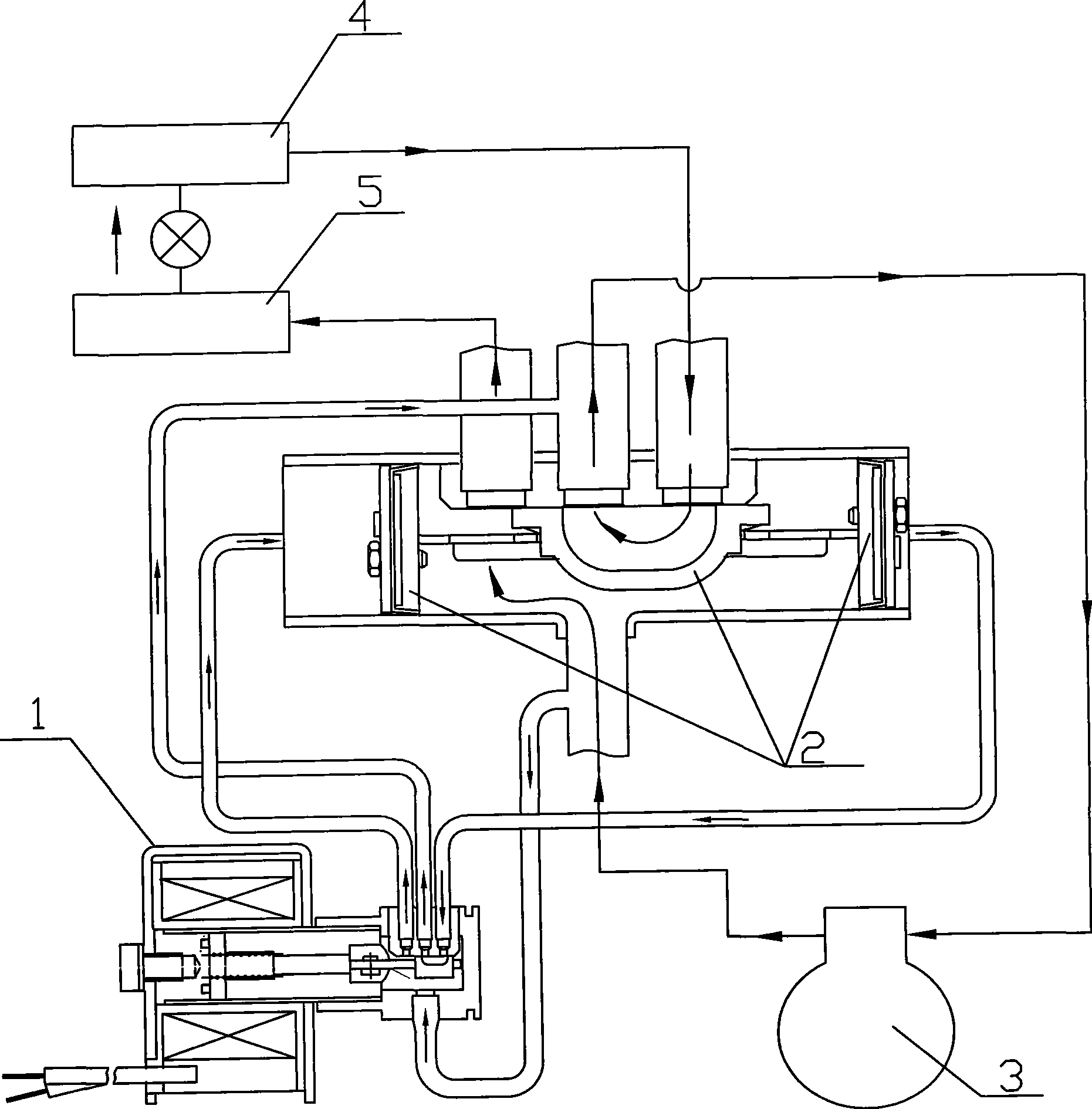

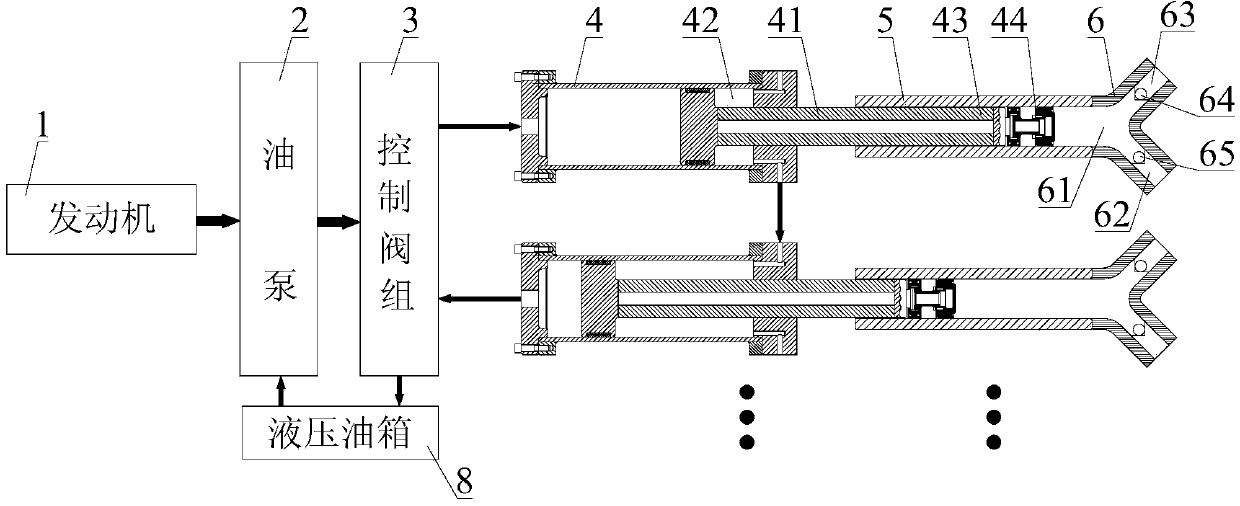

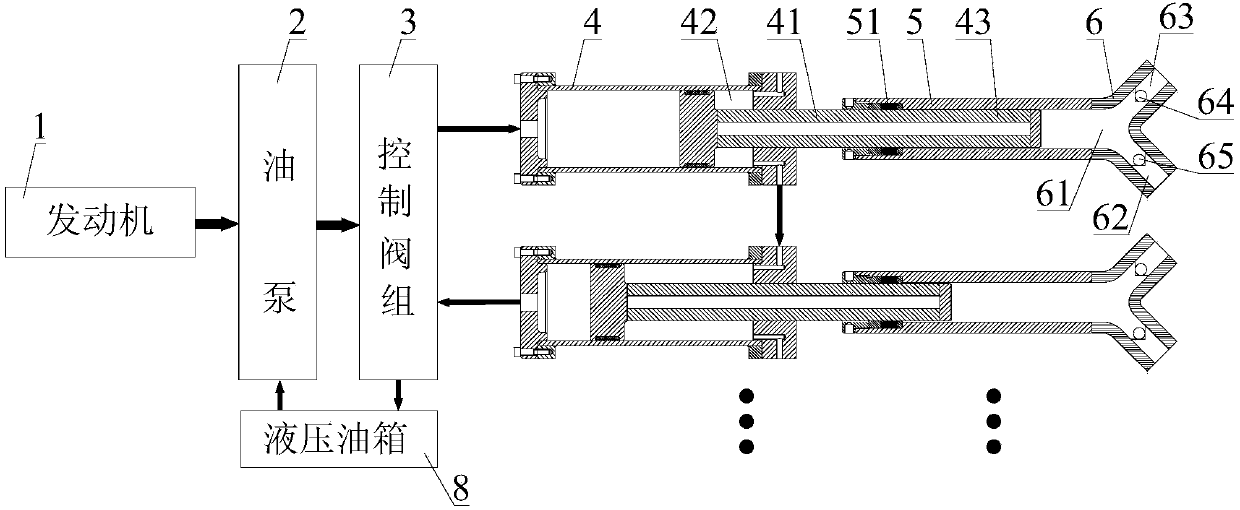

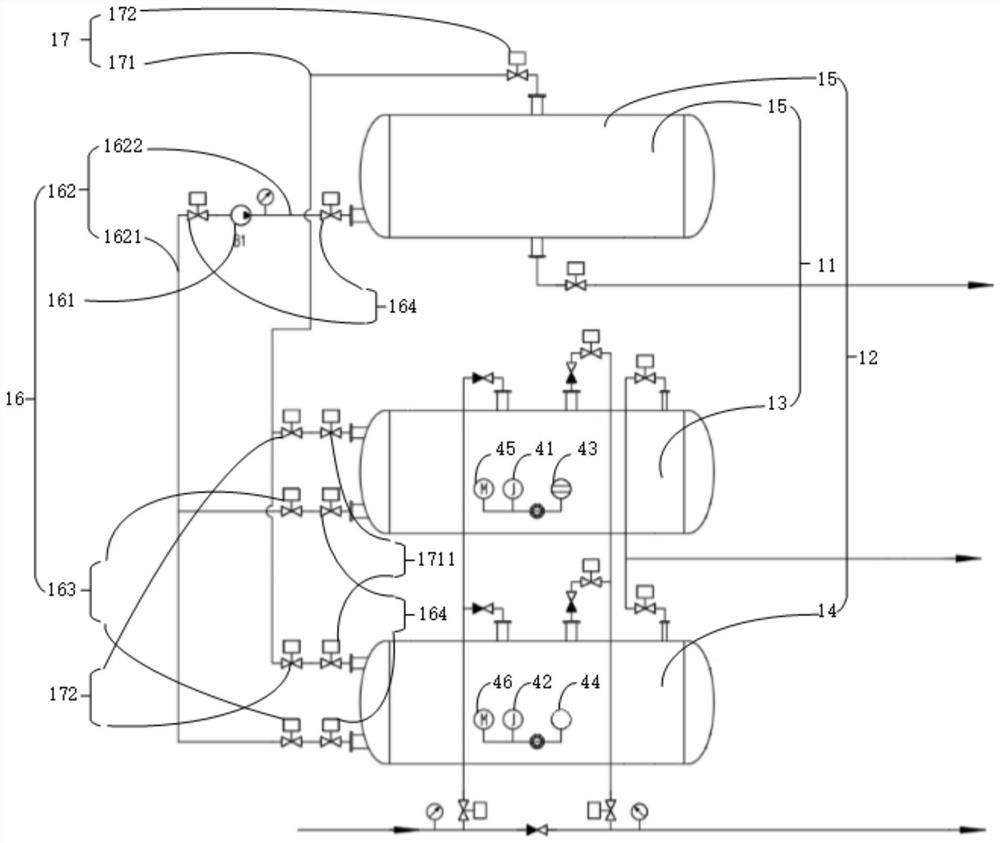

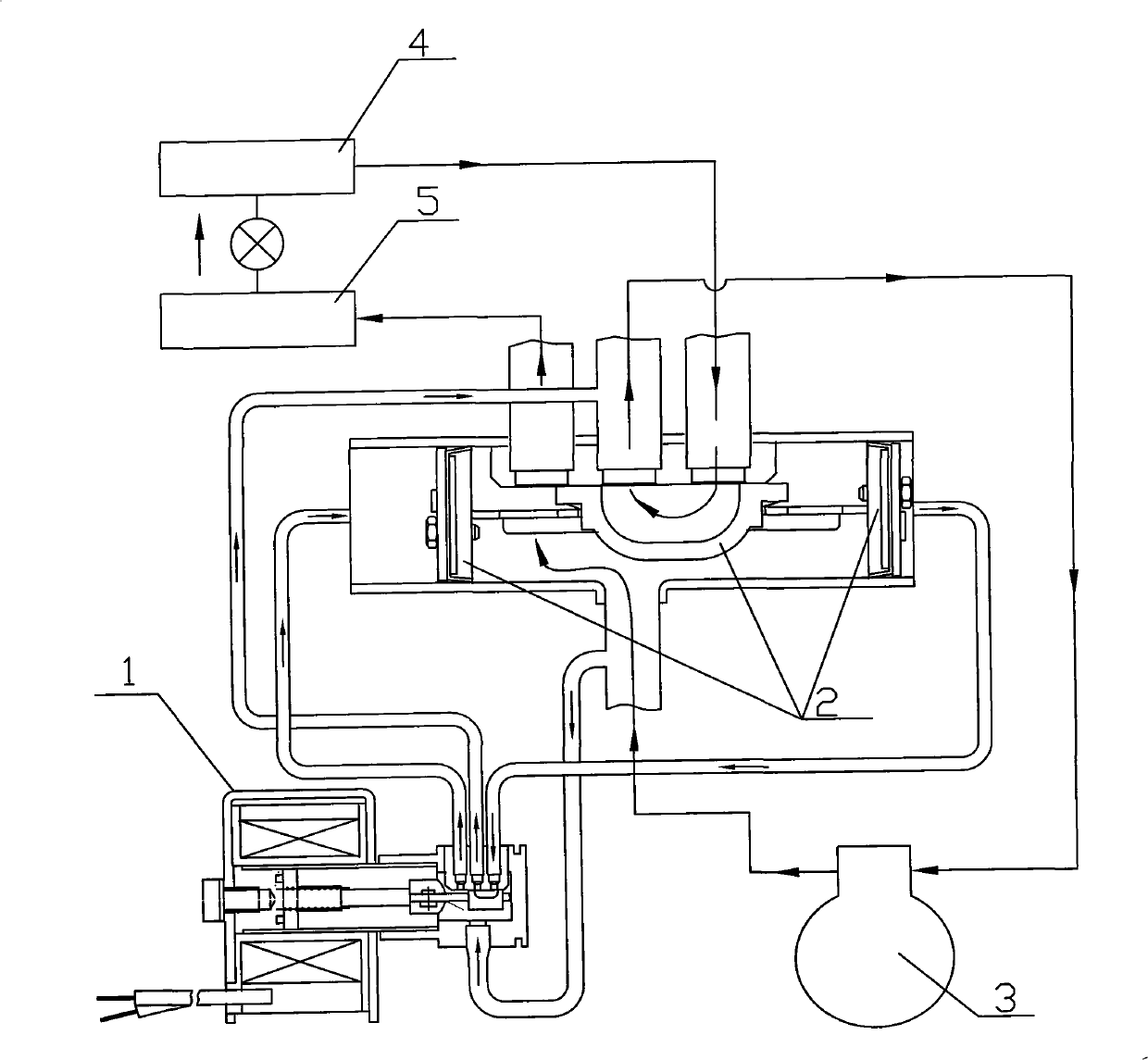

Fracturing pump system and fracturing truck

ActiveCN103742381AFlexible arrangementSimple structureFluid removalPiston pumpsEngineeringControl valves

The invention discloses a fracturing pump system and a fracturing truck. In the fracturing pump system, a first conveying mechanism and a second conveying mechanism comprise oil cylinders, supercharging cylinders and distribution valves. Each distribution valve comprises a first channel, a second channel and a third channel, wherein the first ends of the first channel, the second channel and the third channel are connected, a suction valve is arranged in the second channel, and a discharge valve is arranged in the third channel. Plug bodies are arranged at the extending end of piston rods of the oil cylinders and movably arranged in the supercharging cylinders, and outlets of the supercharging cylinders are connected with the second end of the first channel. An engine is used for driving an oil pump. A control valve group is used for controlling oil inlet and return states of the oil cylinders. By using the fracturing pump system, a stroke can be effectively increased, stoke times can be decreased, the service life of easily damaged parts can be prolonged, an output pressure and flow coverage range can be effectively widened, the structural complexity can be effectively reduced, the cost can be saved, and the lubrication and cooling requirements can be effectively reduced.

Owner:SANY PETROLEUM INTELLIGENT EQUIP CO LTD

M12 large-size silicon wafer cutting process

ActiveCN111531733AImprove quality and yieldReduce thicknessWorking accessoriesFine working devicesWire cuttingSilicon chip

The invention relates to an M12 large-size silicon wafer cutting process, and belongs to the technical field of crystalline silicon processing. The M12 large-size silicon wafer cutting process comprises the following steps of performing rod adhesion, namely fixing a silicon rod and a workpiece plate; performing feeding, namely assembling the silicon rod and the workpiece plate into a cutting machine to be cut; adding cutting fluid, namely adding the cutting liquid into the cutting machine; performing preheating before cutting, namely opening the cutting liquid and a wire net, and performing reciprocating wiring; cutting, namely setting cutting parameters and cutting the silicon rod; and performing blanking, namely setting retracting parameters, and enabling the silicon rod to be graduallyseparated from the wire net. According to the M12 large-size silicon wafer cutting process, a wear condition of a diamond wire can be reduced, the abnormal and bad edge breakage of the adhesive surface of the silicon wafer is effectively reduced, the diamond wire consumption is reduced, and the M12 large-size silicon wafer cutting process has the characteristics that the phenomenon of edge breakage of the silicon wafer is remarkably reduced and the slicing cost is reduced.

Owner:乐山高测新能源科技有限公司

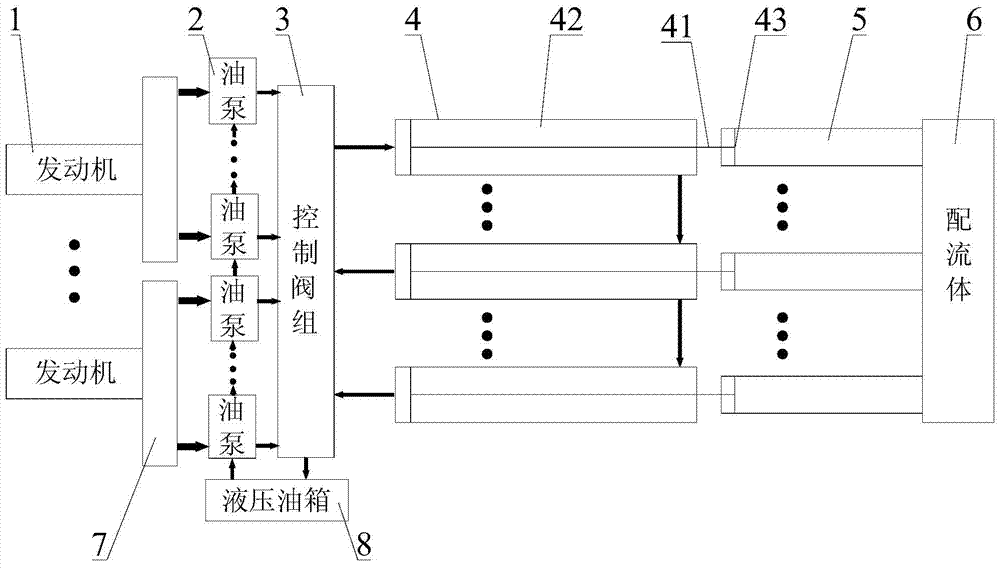

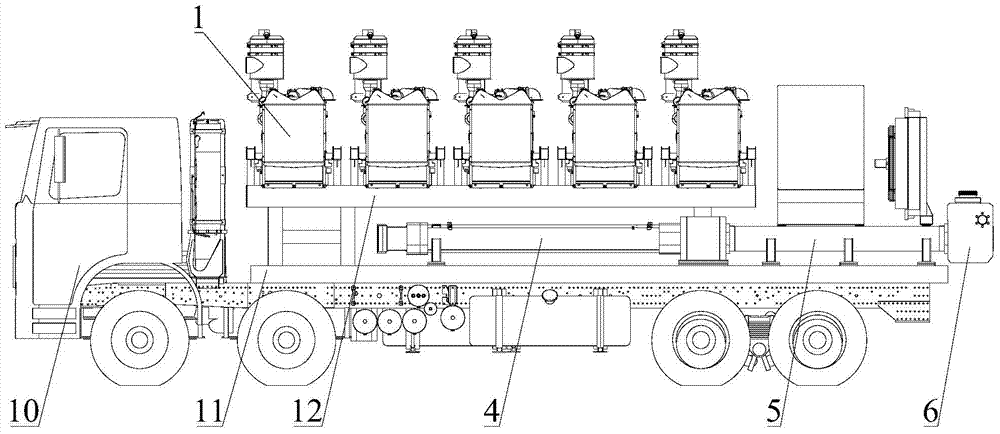

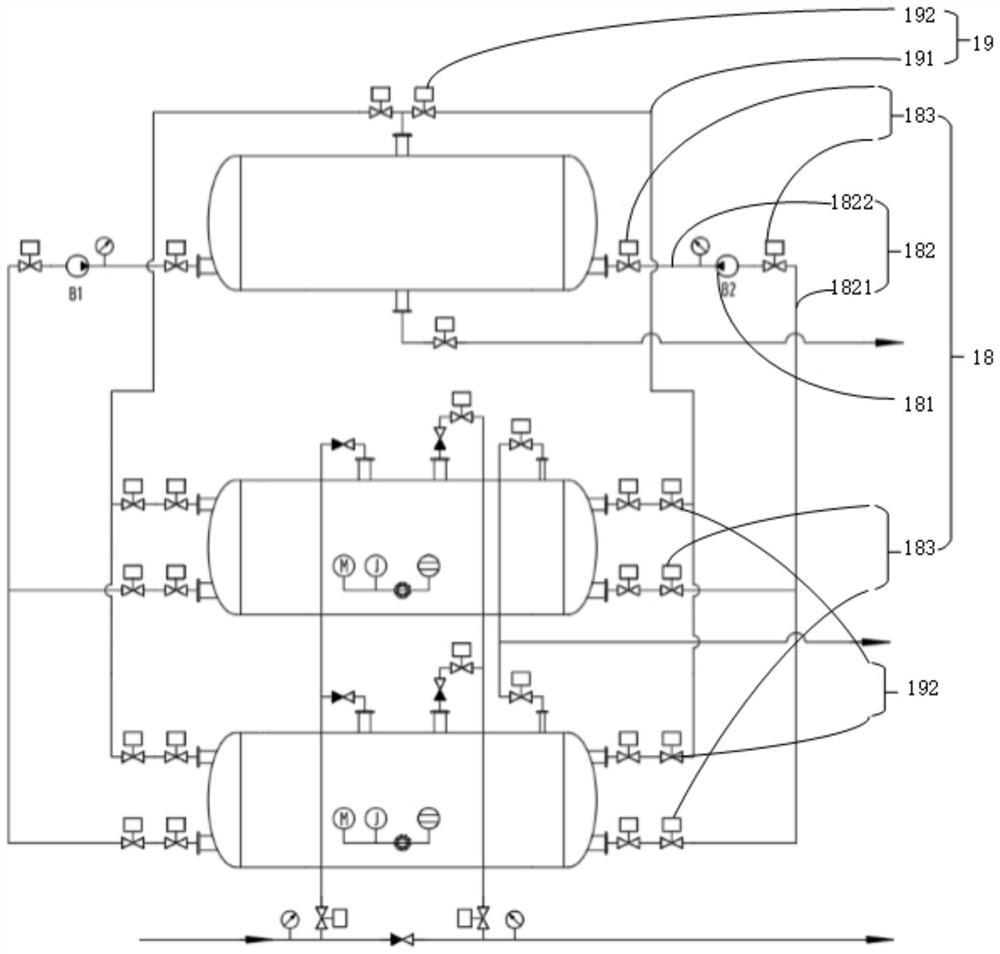

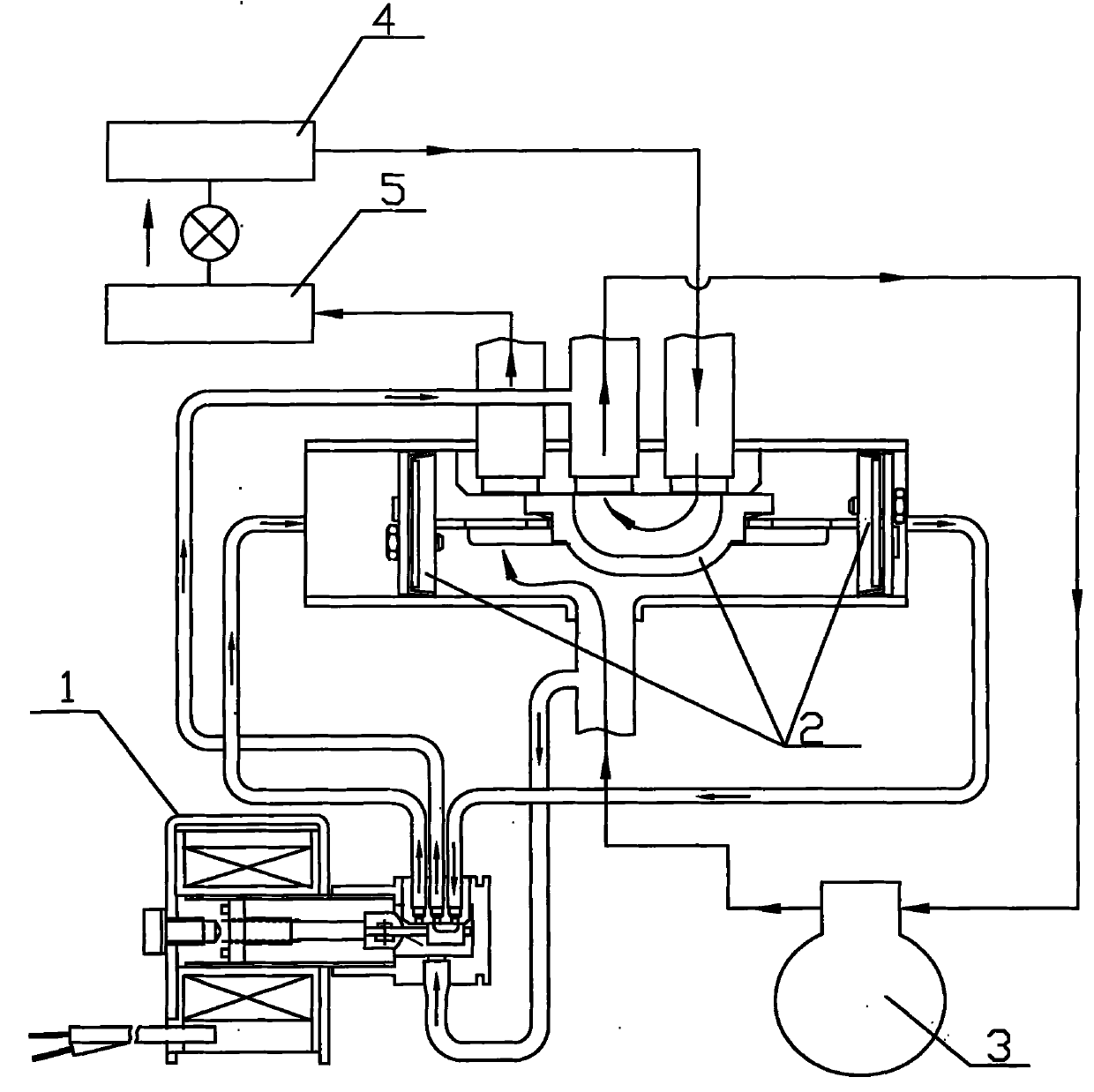

Fracturing truck and drive conveying system thereof

InactiveCN103775302AReduce the number of commutationsExpand the range of selectionServomotorsFluid removalModel selectionTruck

The invention discloses a fracturing truck and a drive conveying system thereof. The drive conveying system of the fracturing truck comprises one or more engines, a plurality of oil pumps, a control valve set, a first conveying mechanism and a second conveying mechanism. The first conveying mechanism and the second conveying mechanism respectively comprise an oil cylinder and a pressure cylinder. A plug body is arranged at the extending end of a piston rod of each oil cylinder, and each plug body is movably arranged in the corresponding pressure cylinder. When the number of the engine is one, the engine is used for driving multiple oil pumps, and when the number of the engines is multiple, each engine is used for driving at least one oil pump. The control valve set is used for controlling the oil inlet and oil returning state of the oil cylinder in the first conveying mechanism and the oil cylinder in the second conveying mechanism. According to the fracturing trunk and the drive conveying system thereof, the output pressure and flow coverage range can be effectively increased, the model selection difficulty and the cost of related parts can be effectively lowered, meanwhile, the safety redundancy rate of the drive conveying system of the fracturing truck can be effectively improved, and the service life of a conveying mechanism can be prolonged.

Owner:SANY PETROLEUM INTELLIGENT EQUIP CO LTD

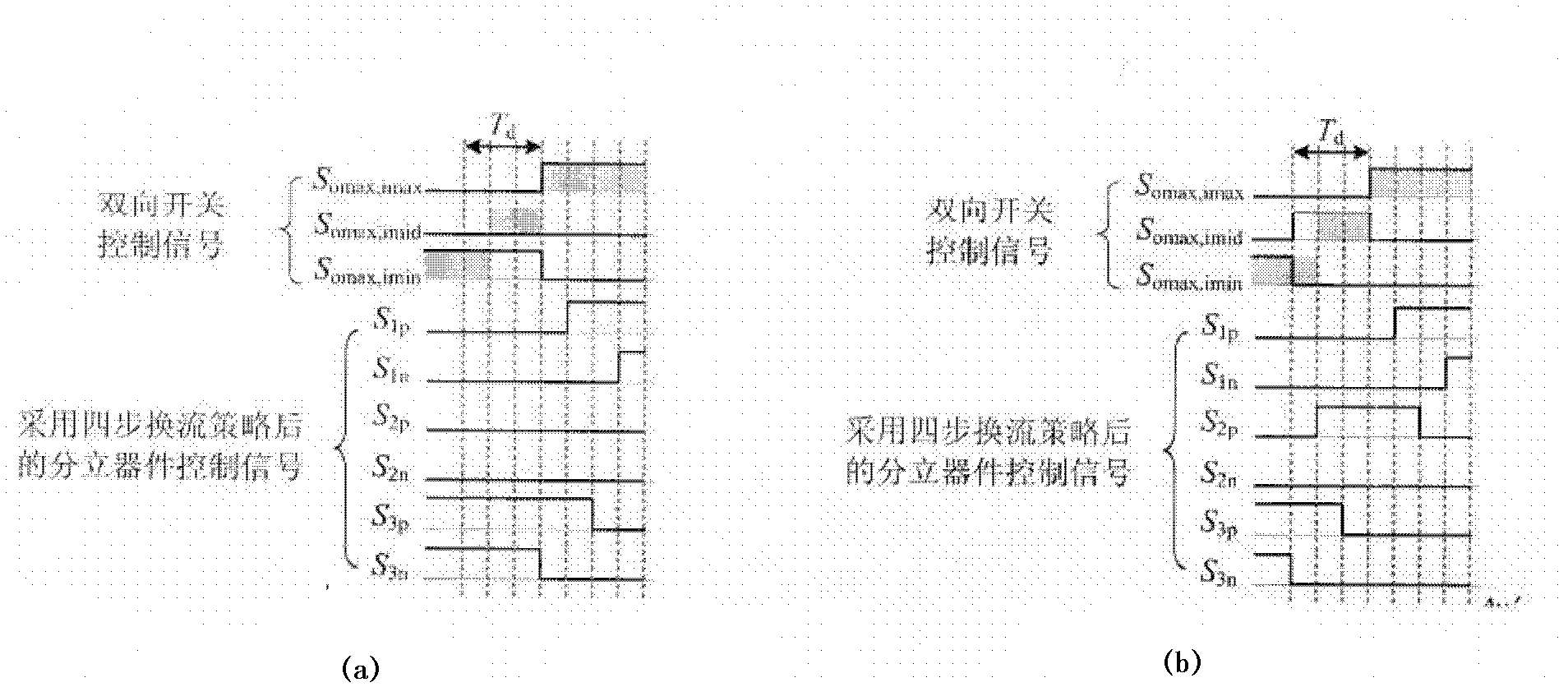

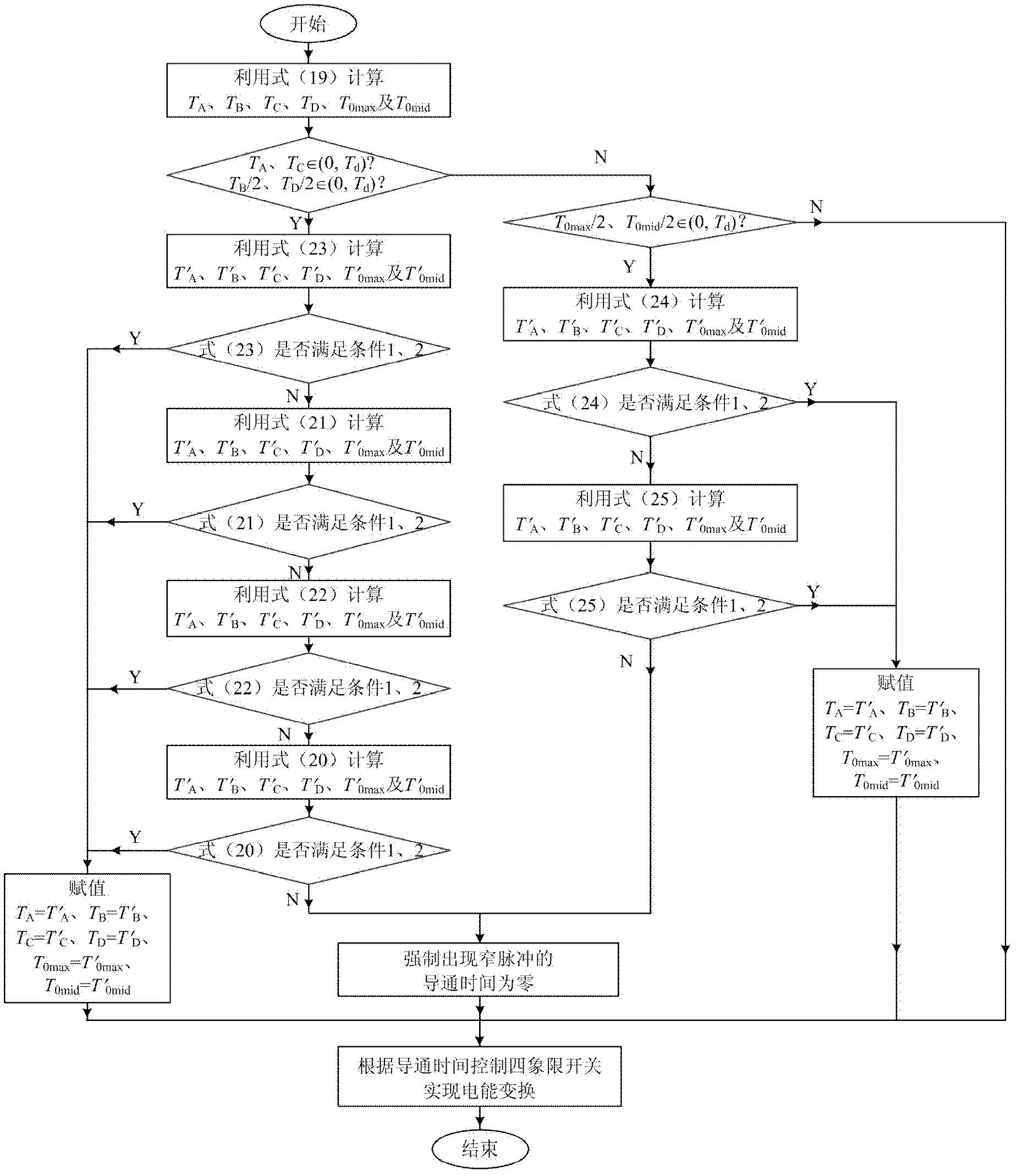

Narrow pulse suppression and electric energy quality improvement method for matrix converter

InactiveCN102545642AReduce switching lossesReduce the number of commutationsConversion without intermediate conversion to dcPower qualityHigh Powered Field

The invention discloses a narrow pulse suppression and electric energy quality improvement method for a matrix converter. The method is characterized in that: the matrix converter adopts double-voltage modulation; and when control signals of six switches for line voltage synthesis have narrow pulses in a certain switching period, six groups of new modulation functions for switch control are reconstructed and calculated according to the positions of the narrow pulses. The new functions are characterized in that: the new functions comprise instantaneous output current detection information; one of the six switches is kept in an off state; and the modulation functions simultaneously meet input current and output voltage modulation requirements. On the premise of no increase of the switching loss and the number of commutation times of the matrix converter, the number of the narrow pulses is effectively decreased, and the input and output waveform quality of the matrix converter is improved; and the method is particularly suitable for middle and high power places in which commutation time is long.

Owner:TIANJIN UNIV

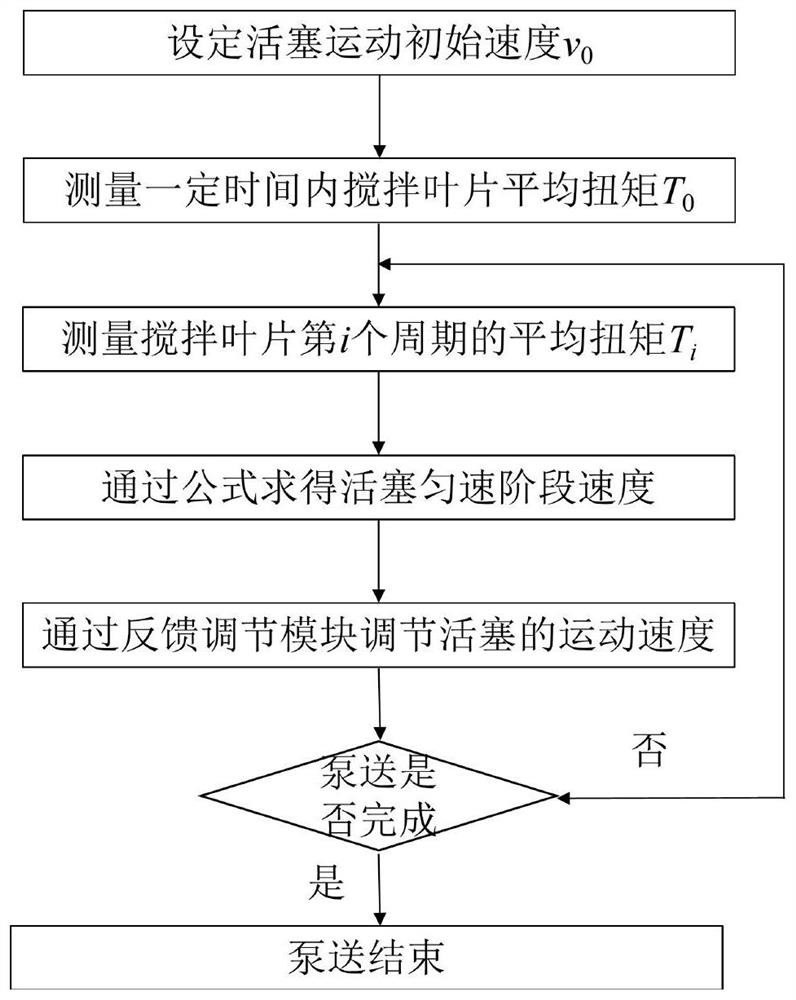

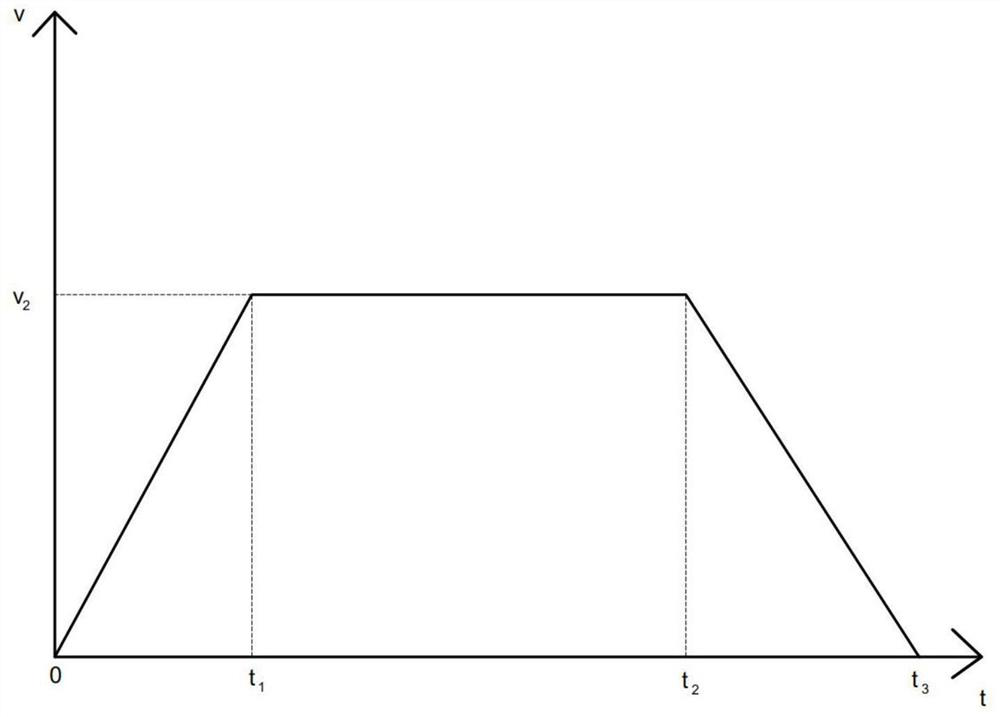

Piston motion speed matching method for improving concrete pumping material suction performance

ActiveCN113187712AReduce the number of commutationsImprove pumping efficiencyPump controlPumpsClassical mechanicsEngineering

The invention provides a piston motion speed matching method for improving concrete pumping material suction performance. The piston motion speed matching method mainly comprises the steps that (1) the rotating speed of stirring blades in the concrete material suction process is given, the average torque T0 of the stirring blades at the rotating speed is measured through a torque sensor, then the optimal speed of piston motion is calculated and corrected, and the piston motion speed is adjusted through a feedback adjusting module; and (2) the piston material suction motion speed is divided into three stages, namely the piston accelerated motion stage, the piston uniform motion stage and the piston decelerated motion stage. When the concrete fluidity is good, the motion speed of a piston can be increased, and the material suction frequency of the piston in unit time is increased while the material suction performance is guaranteed; and when the concrete fluidity is low, the motion speed of the piston can be decreased, the material suction amount is increased, the reversing frequency of an S pipe is decreased, abrasion of eye rings and other quick-wear parts is reduced, and energy consumption is reduced.

Owner:XIANGTAN UNIV

Stepping motor driving method and system and storage medium

ActiveCN112787557AFast actionReduce the number of commutationsDynamo-electric converter controlPhysical medicine and rehabilitationMotor drive

The invention discloses a stepping motor driving method and system and a storage medium, and the method comprises the steps: presetting the rotation stroke of a stepping motor according to an application scene; in response to the forward rotation command, starting from the starting position, driving the stepping motor to perform double-phase acceleration to the middle position of the rotation stroke, and then driving the stepping motor to perform double-phase deceleration to the holding position to stop; holding the single coil at the holding position; and in response to the reverse rotation command, driving the stepping motor to perform double-phase acceleration to the middle position of the rotation stroke, and then driving the stepping motor to perform double-phase deceleration to the start position to stop. By adopting the method, the stepping motor can be quickly and stably started and stopped in a fixed stroke.

Owner:杭州微伽量子科技有限公司

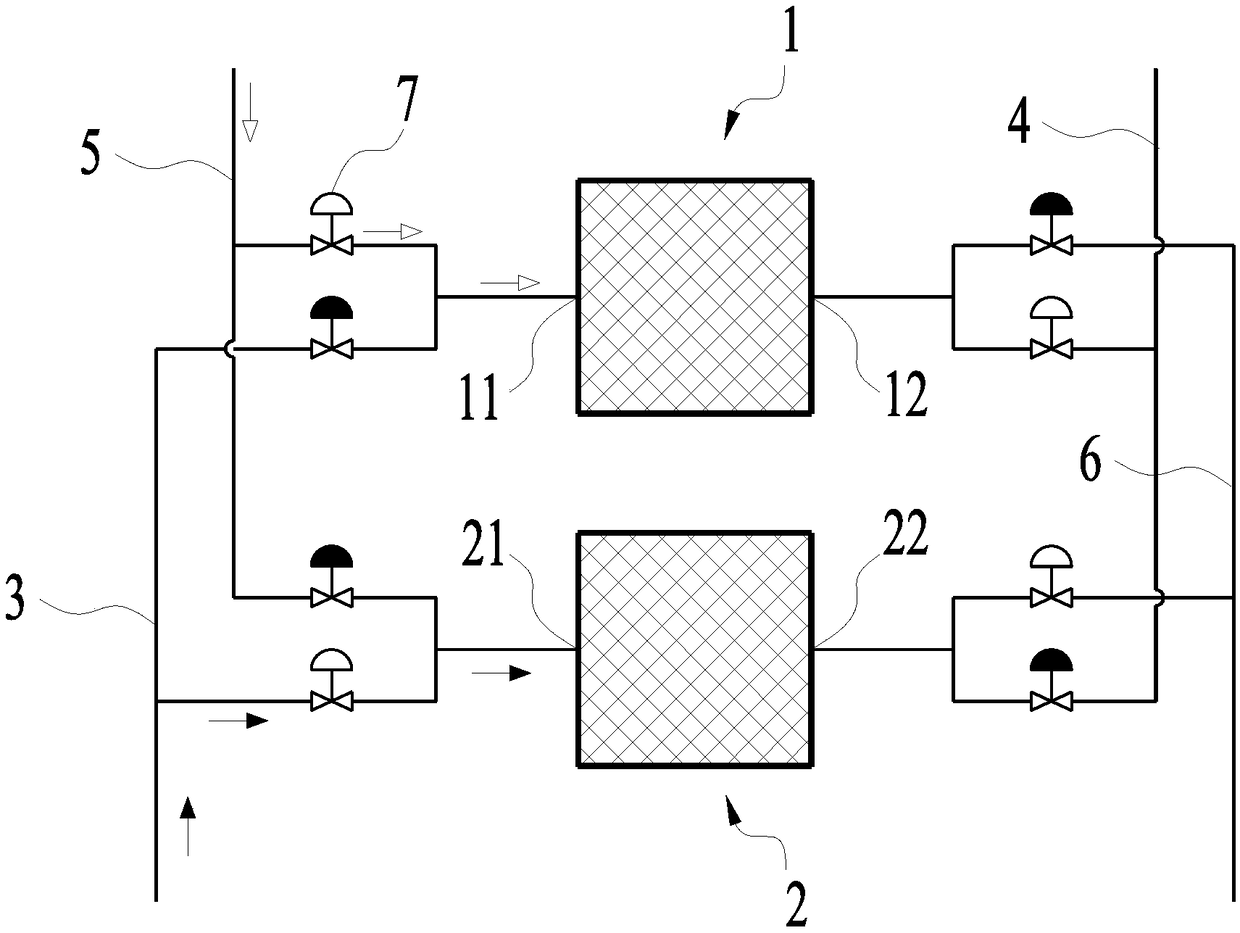

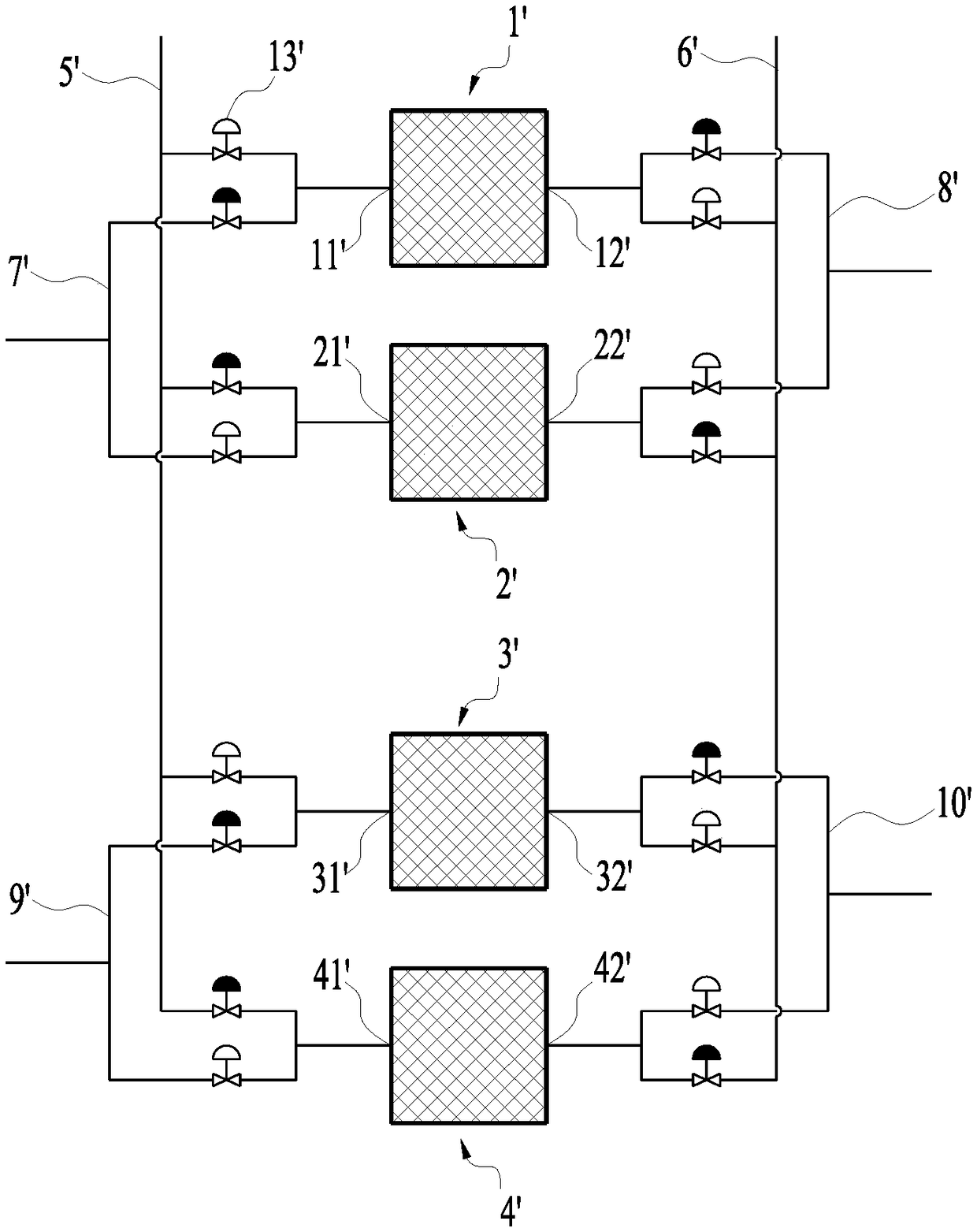

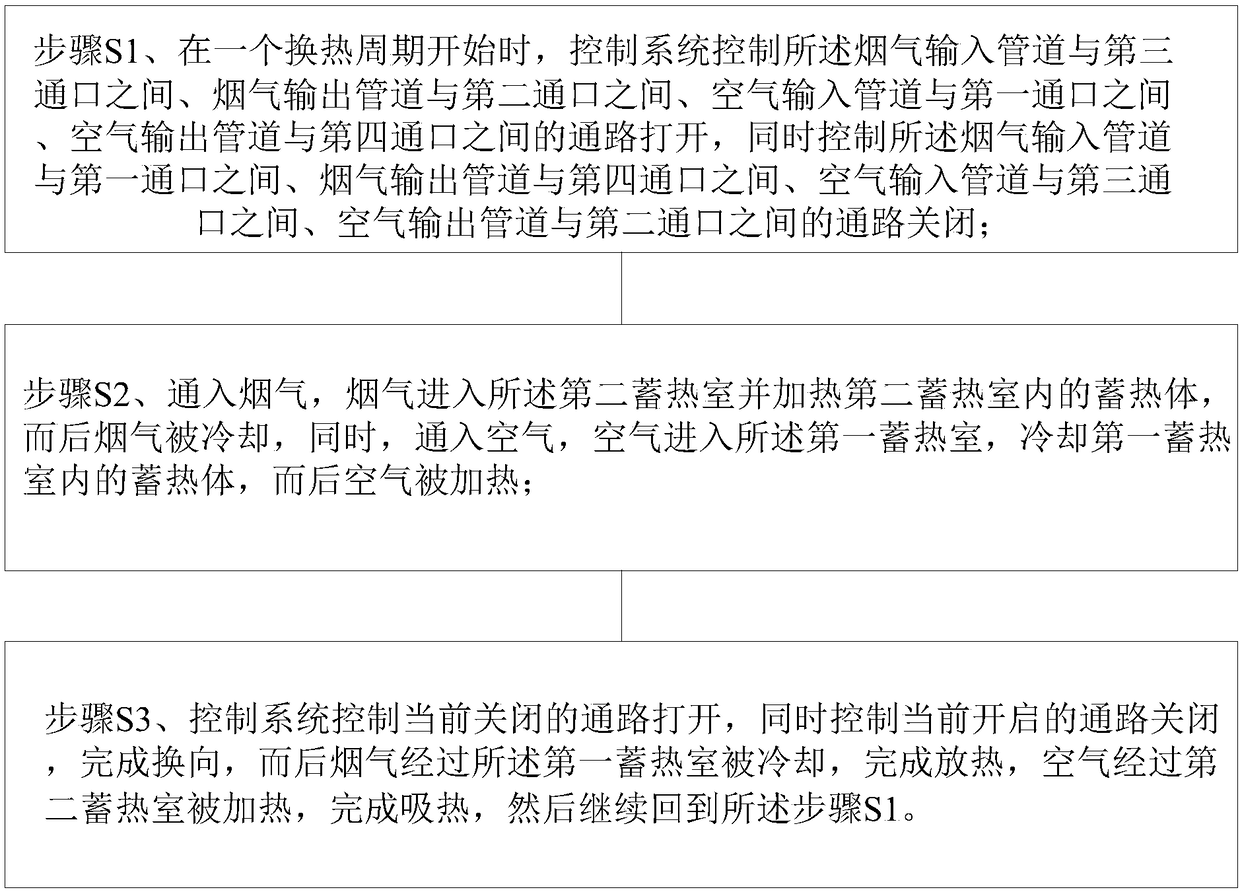

Furnace kiln continuous heat exchange control device and control method

InactiveCN109373773AImprove continuous combustion stabilityReduce complexityFurnace safety devicesControl devices for furnacesFurnace temperatureCombustion

The invention provides a furnace kiln continuous heat exchange control device. The device comprises a first heat storage chamber, a second heat storage chamber, a flue gas input pipeline, a flue gas output pipeline, an air input pipeline and an air output pipeline, wherein the flue gas input pipeline, the flue gas output pipeline, the air input pipeline and the air output pipeline are communicatedwith the first heat storage chamber and the second heat storage chamber. Valves are arranged on the pipelines,wherein the pipelines is used for connecting the first heat storage chamber, the second heat storage chamber with the the flue gas input pipeline, the flue gas output pipeline, the air input pipeline and the air output pipeline. The control system controls the valves between the pipelinesand the heat storage chambers to be opened and closed periodically, so that the first heat storage chamber and the second heat storage chamber can be switched periodically between heat absorption andheat release modes. The furnace kiln continuous heat exchange control device and the furnace kiln continuous heat exchange control method have the advantages that the structure and the working process is simple, the problem of short heat exchange period, high furnace temperature and large furnace pressure fluctuation in heat storage combustion caused by frequent heat exchange in the prior art canbe solved, the continuous combustion stability of the heat storage chamber can be improved, and the waste heat recovery efficiency can be improved.

Owner:HUATIAN ENG & TECH CORP MCC +2

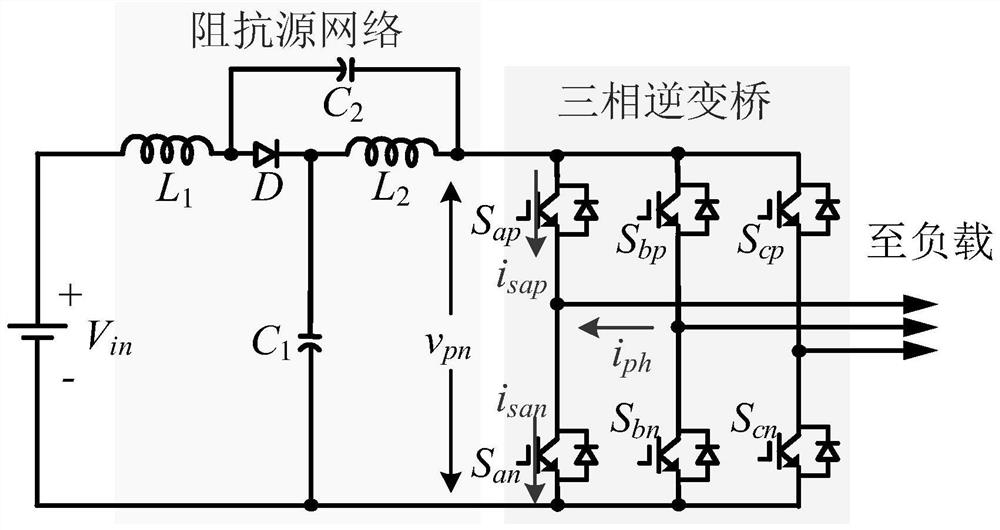

Modulation method for improving current stress of quasi-Z-source inverter switching device

ActiveCN112511033ASimplify the build processReduce the number of commutationsAc-dc conversionComputational physicsCarrier signal

The invention provides a modulation method for improving the current stress of a quasi-Z-source inverter switching device, and the modulation method comprises the steps: subtracting the maximum valueof saddle waves from saddle waves of a conventional voltage space vector modulation SVPWM with the phase difference of 120 degrees to obtain three modulating waves, wherein the maximum value of three-phase saddle waves is a straight line according to the converted waveform, and translating the straight line upwards for M / 2, wherein M is the distance between the maximum value and the minimum valueof the modulated wave after the modulated wave and the triangular carrier wave are subjected to per-unit processing between 0 and 1. According to the modulation method, the gate-level signal generation process is simple, the switching loss is low, no low-frequency alternating-current component exists on the input direct-current side, the current stress of the switching device is greatly reduced, and the service life of the switching device is prolonged.

Owner:珠海创芯科技有限公司

Matrix Transformer Space Vector Modulation Method

InactiveCN101632217BReduced number of carriersReduce the number of commutationsAc-dc conversionAc-ac conversionMatrix convertersCarrier signal

Owner:MEIDENSHA ELECTRIC MFG CO LTD

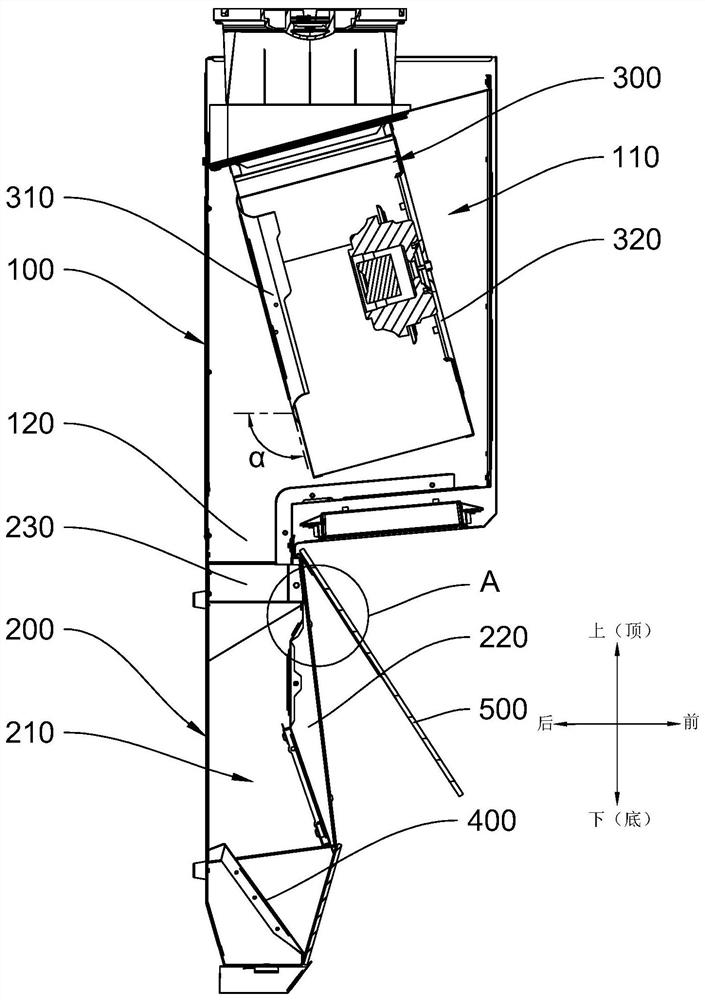

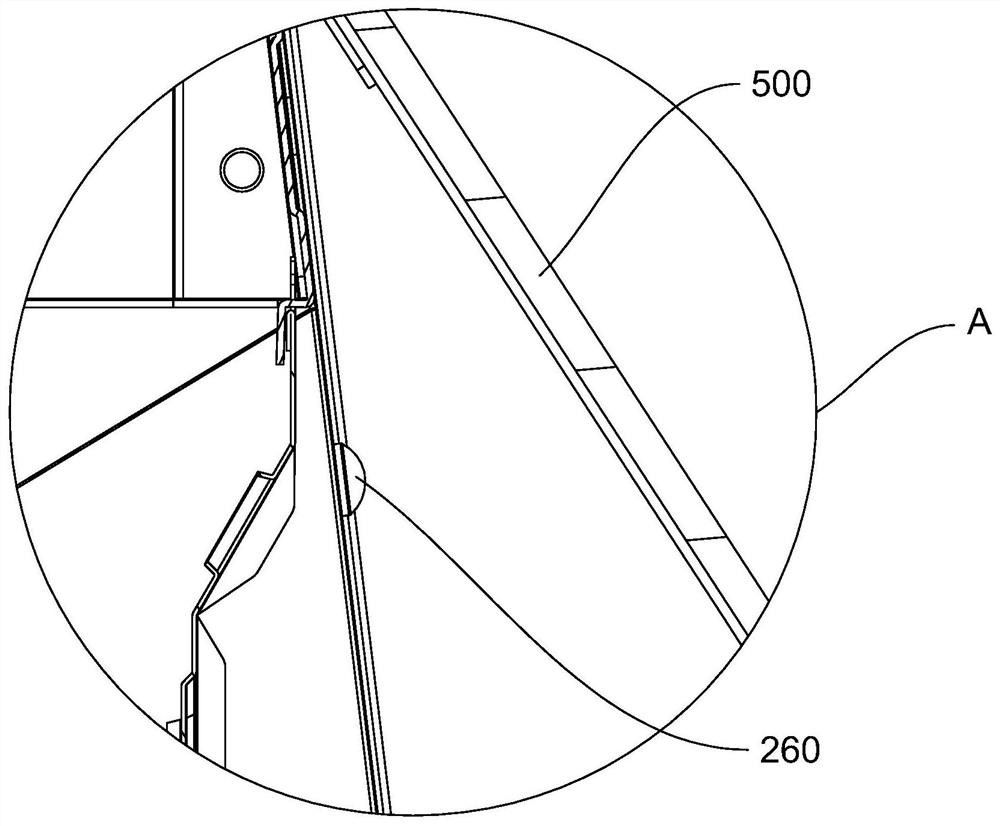

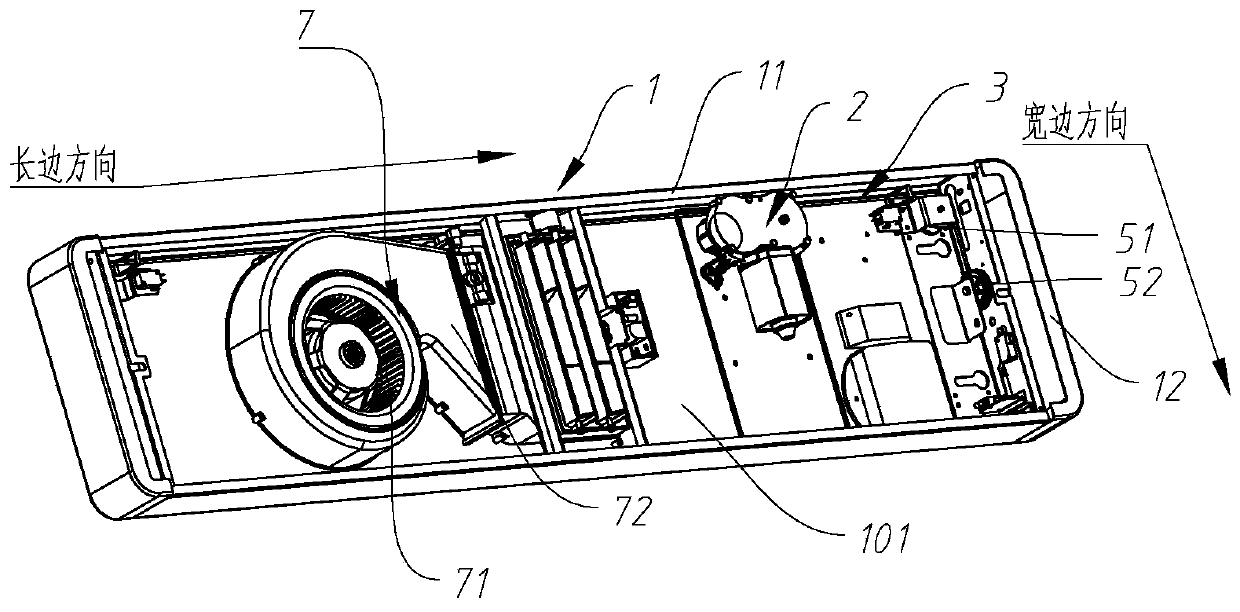

Smoke exhaust system and side-draft range hood

PendingCN112984587AImprove flow efficiencyImprove suction effectDomestic stoves or rangesLighting and heating apparatusMechanical engineeringSmoke hood

The invention discloses a smoke exhaust system and a side-draft range hood. The side-draft range hood comprises the smoke exhaust system. The smoke exhaust system comprises an air cabinet, a smoke collecting hood and a fan, wherein a first containing cavity is formed in the air cabinet, a first smoke exhaust port is formed in the top of the air cabinet, and a first smoke inlet is formed in the rear side of the bottom of the air cabinet; the smoke collecting hood is arranged at the bottom of the air cabinet, a smoke collecting cavity is formed in the smoke collecting hood, a second smoke inlet is formed in the front side of the smoke collecting hood, and a second smoke exhaust port connected with the first smoke inlet is formed in the top of the smoke collecting hood; and the fan is arranged in the first containing cavity, a first air inlet and an air outlet are formed in a shell of the fan, the first air inlet is located in the rear side of the shell of the fan, the air outlet is connected with the first smoke exhaust port, and the included angle alpha between the plane where the first air inlet is located and the horizontal plane is an obtuse angle. By the adoption of the structure, the number of times of reversing before cooking fume enters the first air inlet is reduced, the flowing efficiency before the cooking fume enters the first air inlet can be improved, and thus the effect of sucking away the cooking fume in the cooking environment is improved.

Owner:CHINABEST HOME APPLIANCE

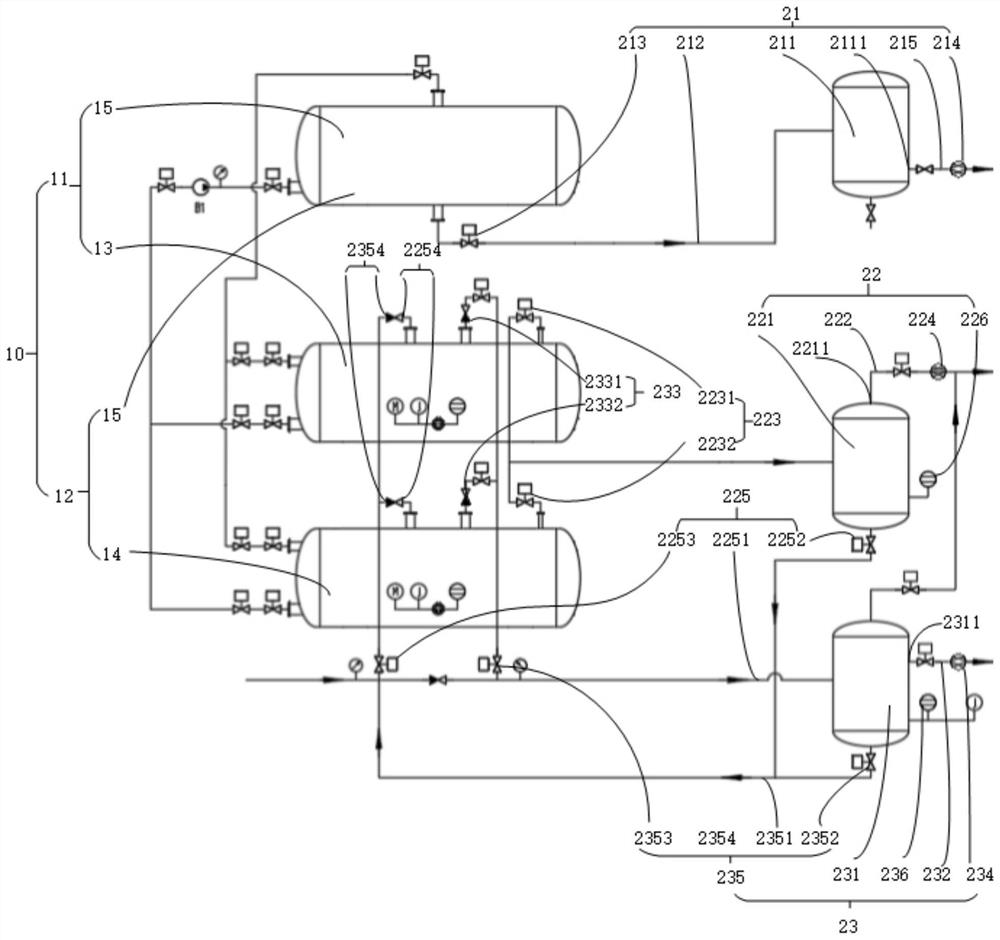

Multiphase flow distribution processing device

PendingCN114294562ALarge amount of processingAvoid damagePipeline systemsVolume meteringThermodynamicsProcess engineering

The invention provides a multiphase flow separate transportation processing device which comprises a mixed transportation mechanism, the mixed transportation mechanism comprises a first tank body, a second tank body, a third tank body and a reversing mechanism, the first tank body and the second tank body communicate with the third tank body, the first tank body and the third tank body form a first processing mechanism, and the second tank body and the third tank body form a second processing mechanism; the reversing mechanism communicates with the first treatment mechanism and the second treatment mechanism; and the distributing and conveying mechanism is connected with the first tank body, the second tank body and the third tank body so as to distribute and convey gas and / or liquid with different densities separated from the first tank body, the second tank body and the third tank body. And by arranging the third tank body, the treatment capacity of the crude oil mixture before reversing can be increased, so that the reversing times in the separation and transportation treatment process are reduced, and the damage to internal equipment of the device caused by impact during reversing is reduced.

Owner:GUANGDONG GUANFU ENERGY TECH PTE LTD +1

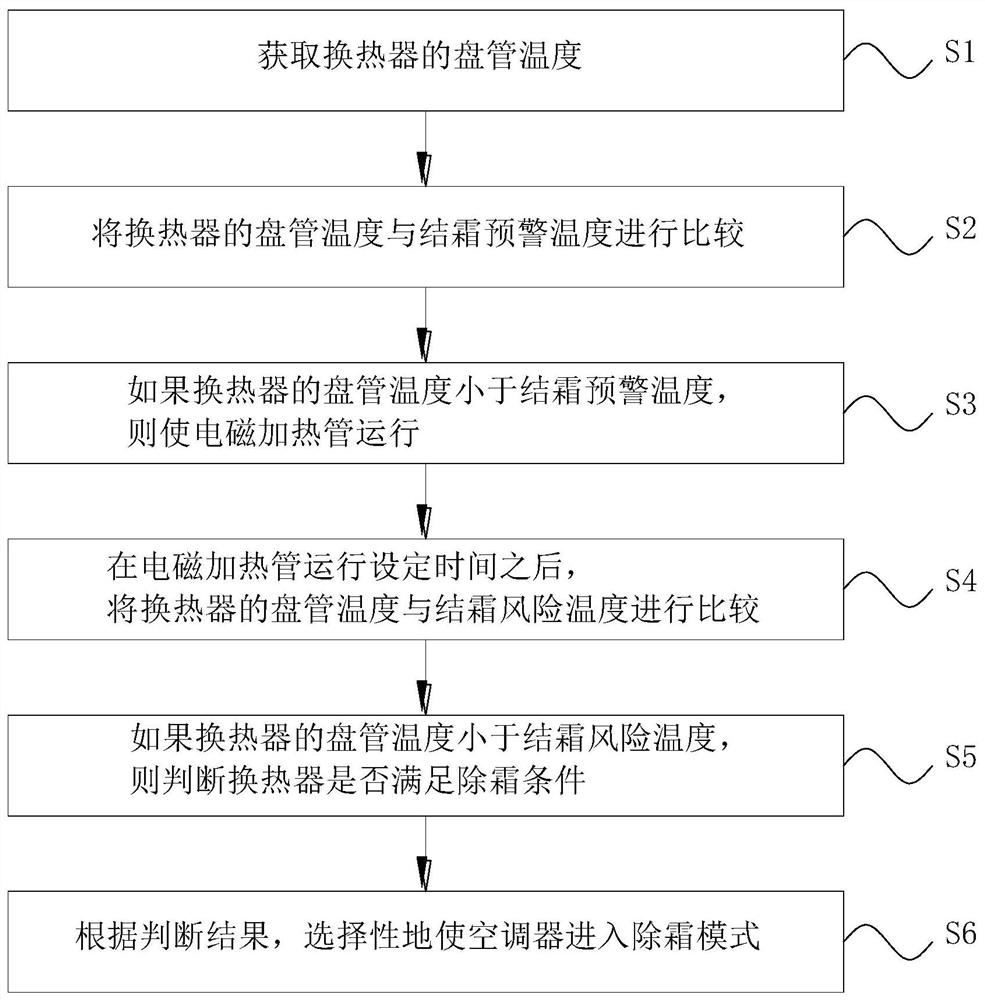

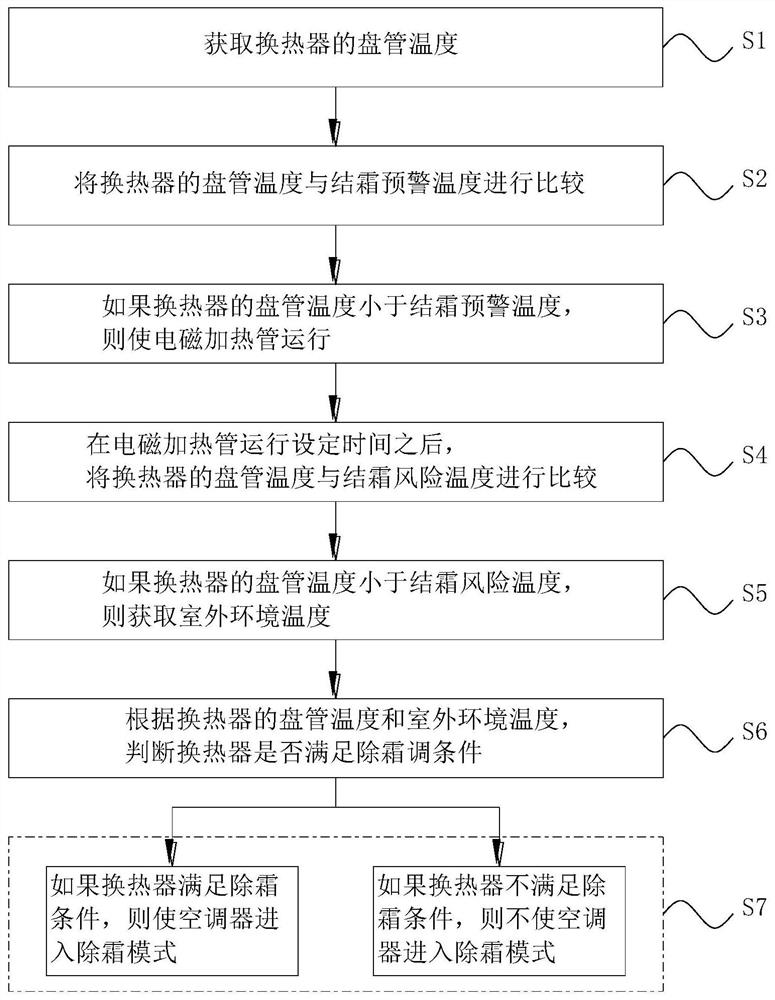

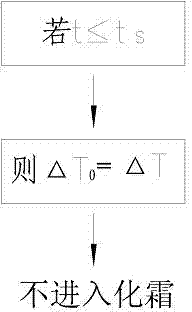

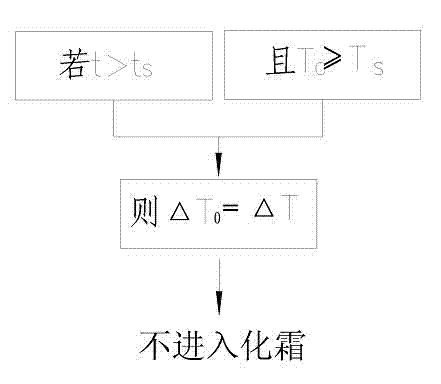

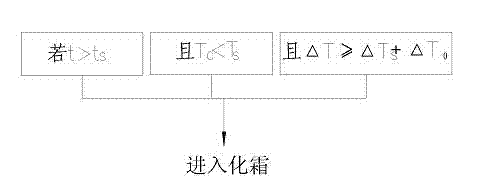

Control method for air conditioner, and air conditioner

ActiveCN111609518AReduce the number of times you enter defrost modeReduce the number of commutationsMechanical apparatusSpace heating and ventilation safety systemsEngineeringRefrigerant

The invention belongs to the technical field of air conditioners, and particularly provides a control method for an air conditioner, and the air conditioner. The air conditioner comprises an indoor unit and an outdoor unit, and a refrigerant heating component is arranged on a heat exchanger of the outdoor unit; the control method comprises the steps of acquiring the coil temperature of the heat exchanger and comparing the coil temperature with frosting warning temperature; operating the refrigerant heating component if the coil temperature of the heat exchanger is lower than the frosting warning temperature; comparing the coil temperature of the heat exchanger with the frosting risk temperature after the refrigerant heating component runs for a set time; judging whether the heat exchangermeets the defrosting conditions if the coil temperature of the heat exchanger is lower than the frosting risk temperature; and enabling the air conditioner to enter the defrosting mode selectively according to the judgment results. Through such arrangement, the number that the air conditioners enters the defrosting mode can be reduced, and the number that the air conditioner stops running in the heating mode; the influence on indoor temperature is reduced, and the reversing number of a four-way valve can be further reduced; and the service life of the four-way valve is prolonged.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +1

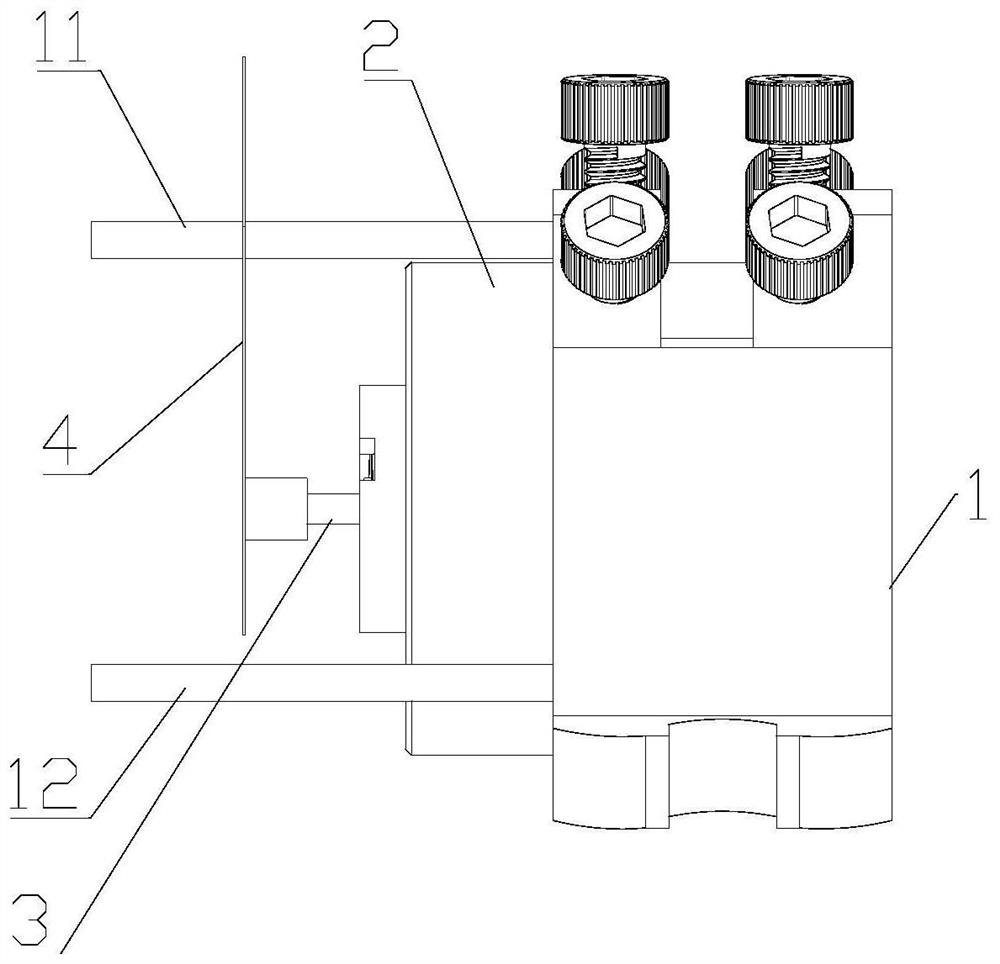

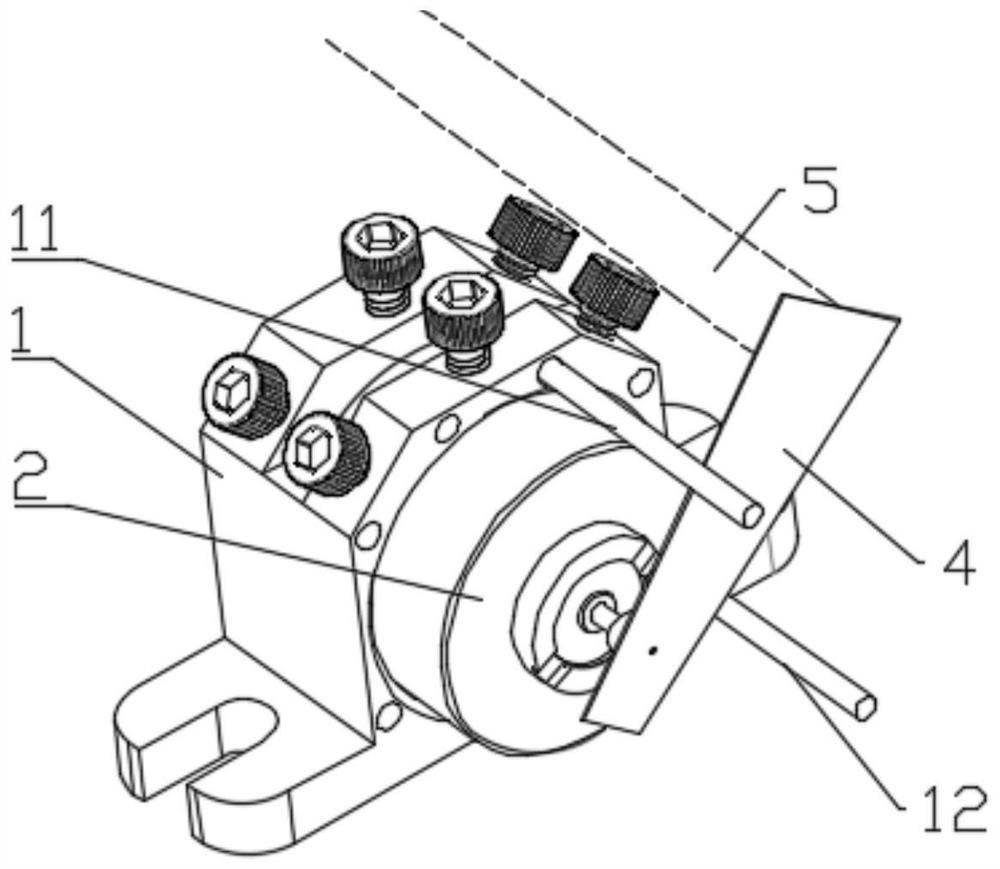

Quantum absolute gravimeter

ActiveCN112666624AOpen quicklyRapid disconnectionDynamo-electric converter controlGravitational wave measurementControl systemElectric machine

The invention discloses a quantum absolute gravimeter, which comprises a control system, a laser system and a probe system which are connected with one another through electric wires and / or optical fibers, the light path switch is arranged on a light emitting path of the laser system and comprises a power source, a control assembly and an execution assembly, the power source, the control assembly and the execution assembly are connected with one another, and the execution assembly is arranged on one side of the light emitting path of the laser system. The execution assembly comprises a light blocking part and a stepping motor connected with the light blocking part and used for driving the light blocking part to rotate so as to open or close a light path, the stepping motor comprises a rotor and at least a first winding and a second winding which are arranged in a certain circumferential direction of the outer side of the rotor, and the control assembly is connected with the first winding and the second winding. The stepping motor is driven to rotate by controlling the direction and the size of current in the first winding and the second winding, so that the light blocking component blocks or avoids light. The gravimeter can achieve the quick switching-on or switching-off of the laser band.

Owner:杭州微伽量子科技有限公司

A planning method for sole glue spraying path based on attitude control

Owner:QUANZHOU INST OF EQUIP MFG

Control method for four-way valve

ActiveCN101504236BImprove commutation reliabilityReduce the number of commutationsFluid circulation arrangementCompression machines with reversible cycleElectricityFour-way valve

The invention discloses low-reversing reliability and frequency method for controlling a four-way valve, which comprises control processes under the following use conditions: during heat generation, time A is determined according to an ambient temperature and an unloading electromagnetic valve is turned off at the same time, then the cold air-resistance operation of an indoor fan and an inverter compressor are started, a pilot valve of a four-way wave is turned on to act when the inverter compressor operates for 180+A seconds, and the four-way valve realizes inversion and an outdoor fan operates at the same time; for machine stop during heat generation, the inverter compressor and the outdoor fan are turned off first, then the unloading electromagnetic valve is turned on to allow an exhaust pipe and an intake pipe to be communicated continuously for time B, and finally the pilot valve of the four-way valve is controlled to be turned off to reset and the indoor fan is turned off at thesame time, wherein the time B is between 5 and 15 seconds; and during heat regeneration, the unloading electromagnetic valve is turned off first and the pilot valve of the four-way valve is controlled to be turned on to act at the same time, then the inverter compressor is started, and the indoor fan starts cold air-resistance operation and the outdoor fan starts operation when the inverter compressor operates for 180 seconds.

Owner:安徽奥克斯智能电气有限公司

Defrosting control method for intelligent air cooling heat pump

InactiveCN102022872BReduce the frequency of defrostingReduce the number of commutationsCorrosion preventionRefrigeration safety arrangementElectricityFrost

Owner:劳特斯空调(江苏)有限公司

A single-phase five-level inverter

ActiveCN103326606BReduce distractionsEnsure personal safetyAc-dc conversionDc-dc conversionPower inverterThree level

The invention discloses a one-phase five-level inverter. The one-phase five-level inverter comprises a common ground type three-level switching circuit, a filter circuit and a power frequency inversion circuit. For being realized specifically, the inverter comprises six power switches from S1 to S6, two diodes from D1 to D2, and a one-phase output filter F. The output of the inverter is five levels, and the inverter has the advantages of being high in inversion efficiency and reliability and simple in control mode. Meanwhile, through the voltage clamp mode, the inverter can eliminate high-frequency common mode current danger in a non-isolated type grid-connected inverter system effectively. Thus, the inverter is especially suitable for being applied to a non-isolated type photovoltaic grid-connected system.

Owner:HOYMILES POWER ELECTRONICS INC

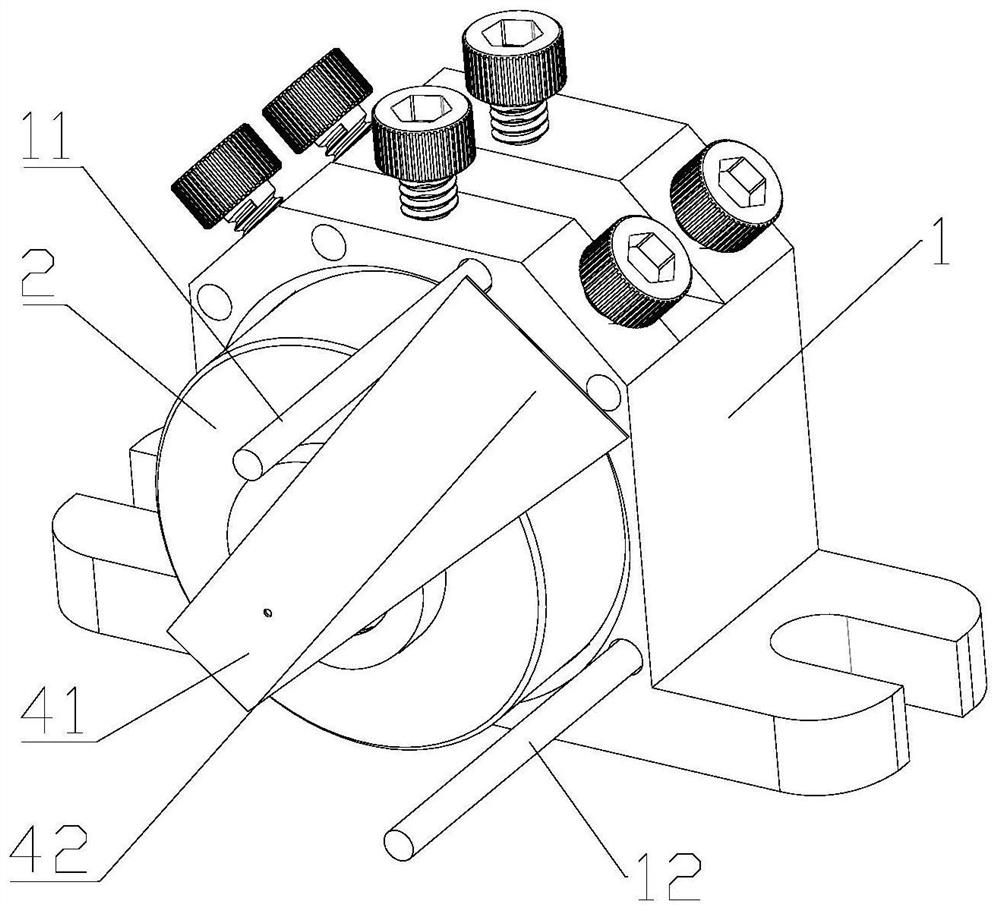

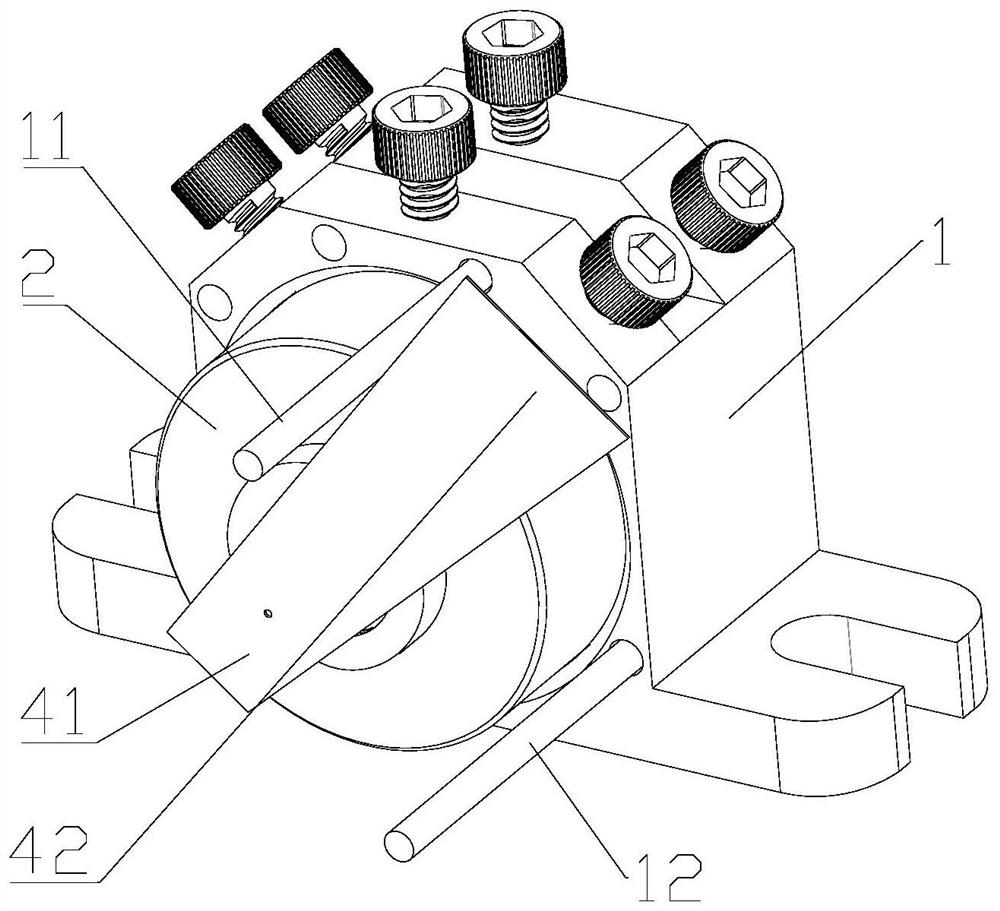

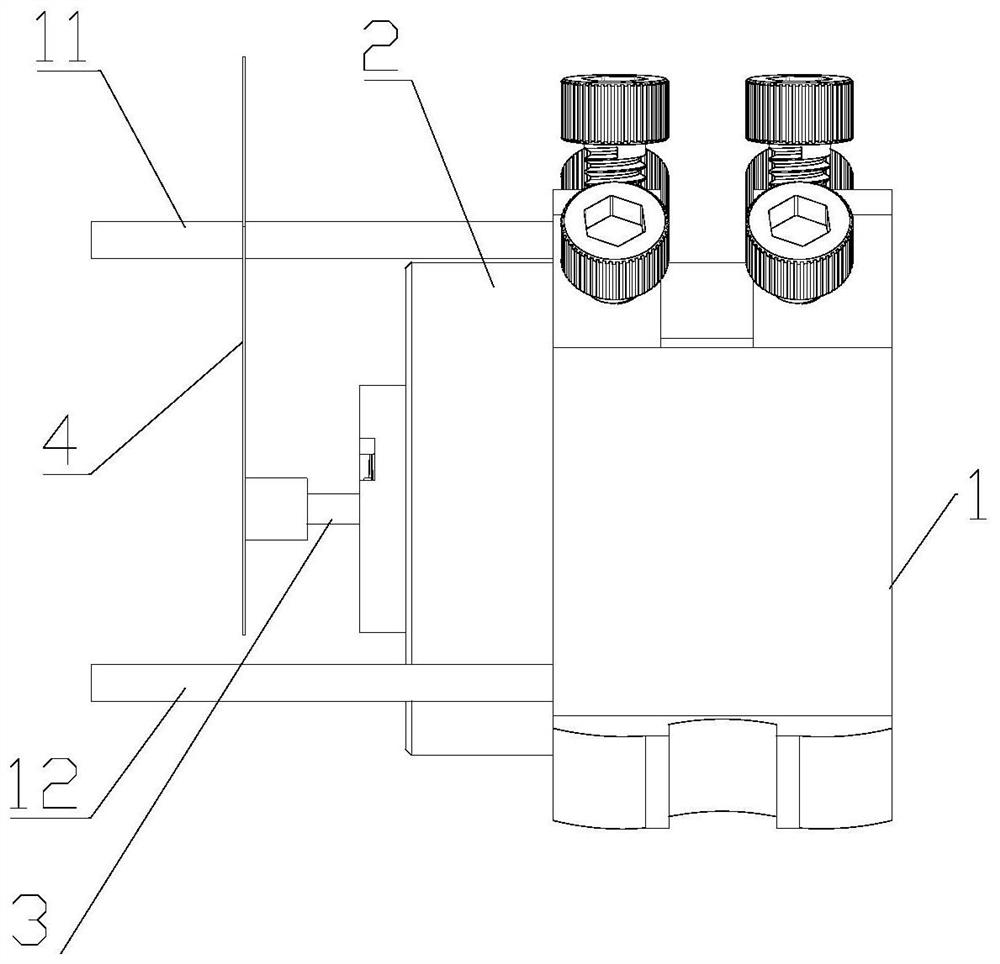

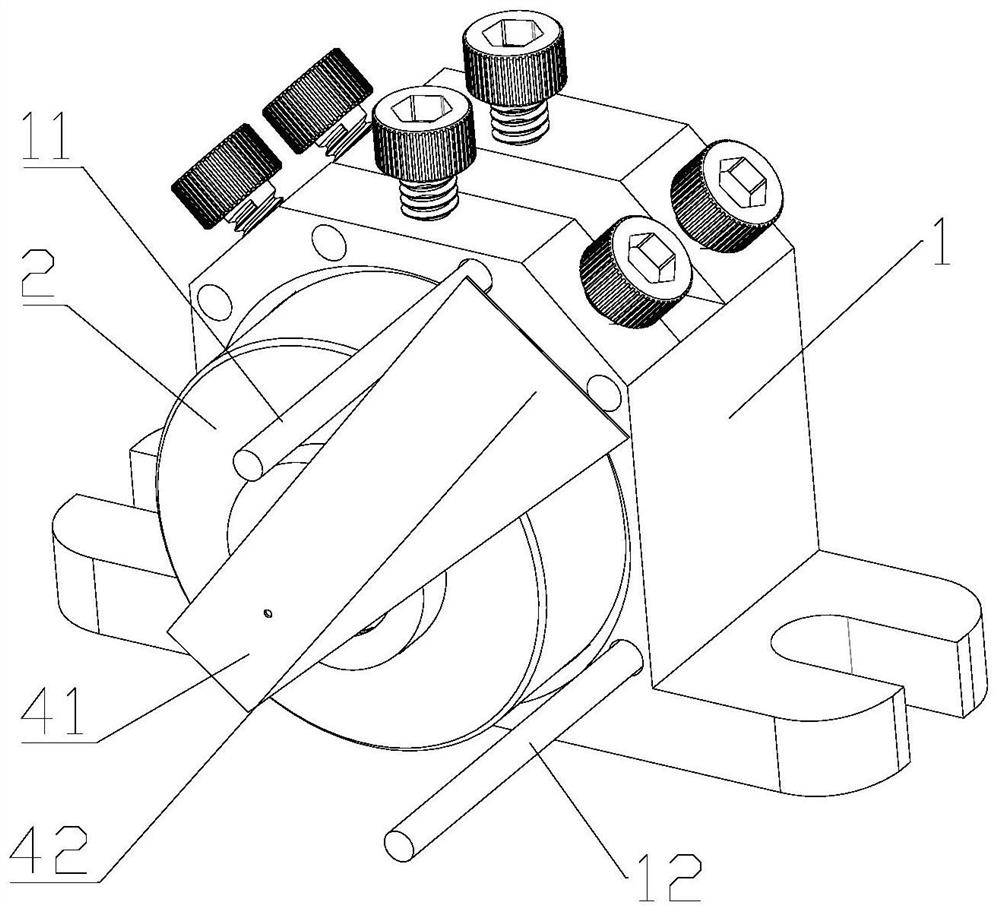

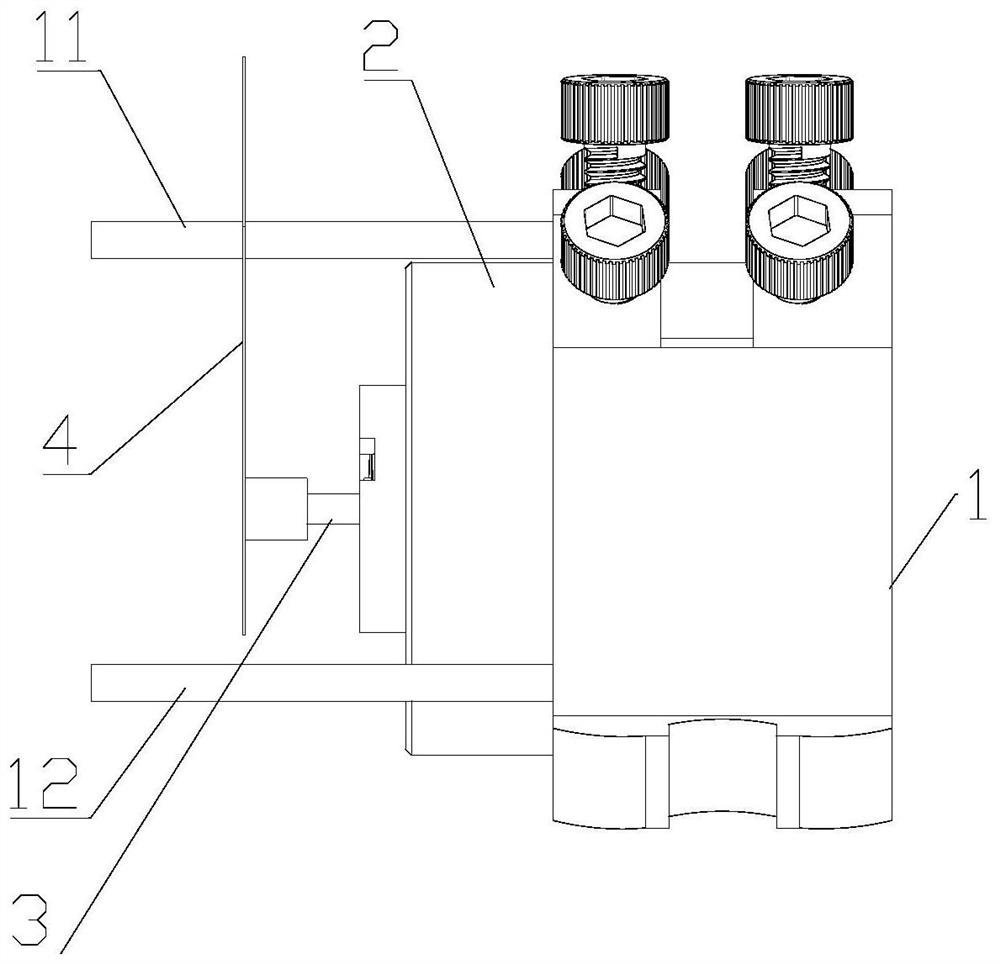

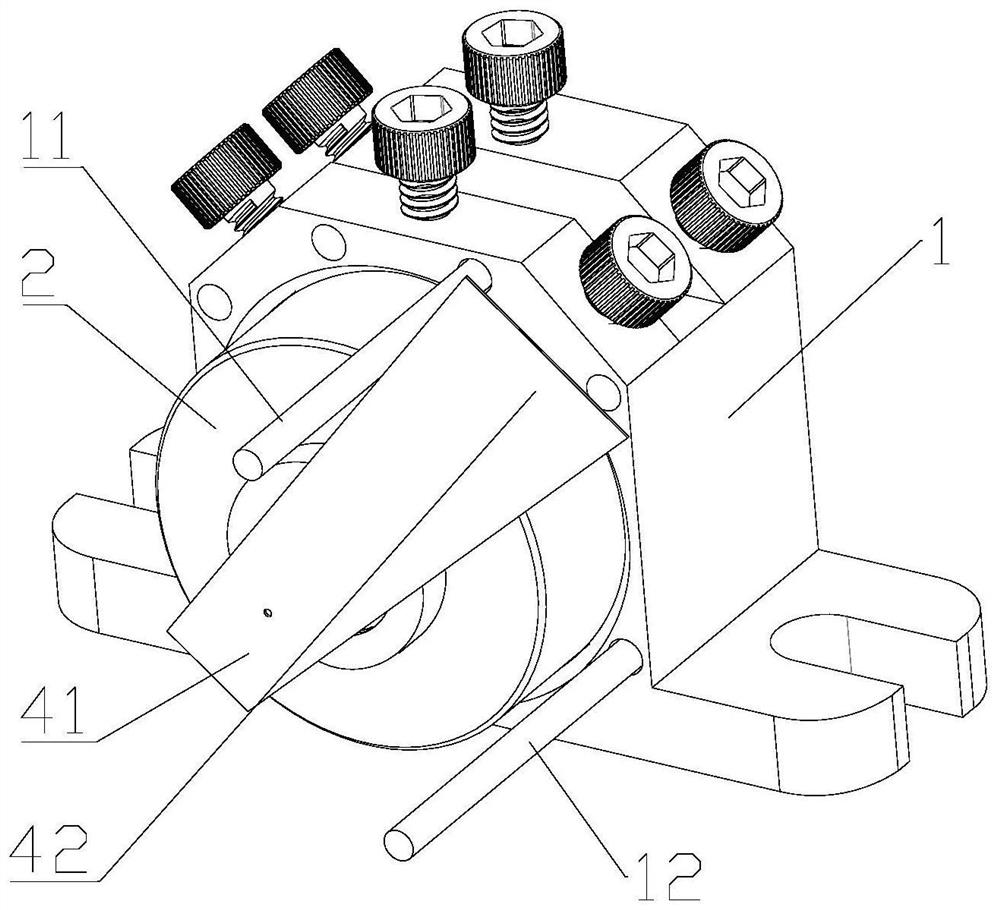

Light source device and light path switch thereof

ActiveCN112821821AFast actionMeet fast switching needsDynamo-electric converter controlElectric machineEngineering

The invention discloses a light source device and a light path switch, the light path switch comprises a power supply, a control assembly and an execution assembly, the power supply, the control assembly and the execution assembly are connected with one another, the execution assembly is arranged on one side of a light path and comprises a light blocking part and a stepping motor, and the stepping motor is connected with the light blocking part and used for driving the light blocking part to rotate so as to open or close the light path; the light blocking part is provided with a fixed end and a movable end, the fixed end is connected with the output end of the stepping motor, and the movable end extends outwards in a certain radial direction of the stepping motor to form a light blocking part; the stepping motor comprises a rotor, a first winding and a second winding, the first winding and the second winding are at least arranged in the certain circumferential direction of the outer side of the rotor, the control assembly is connected with the first winding and the second winding, and the stepping motor is driven to rotate by controlling the direction and the magnitude of currents in the first winding and the second winding. Therefore, the light blocking part is driven to rotate so as to enable the light blocking part to block or avoid light rays. The light path switch has the advantages of high switching speed and low power consumption.

Owner:杭州微伽量子科技有限公司

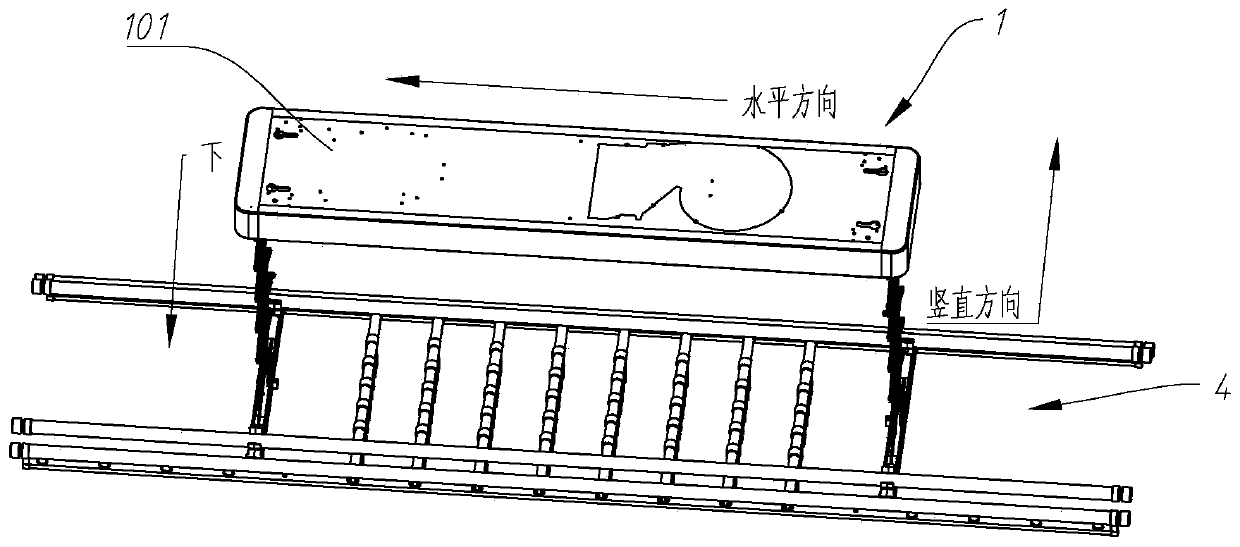

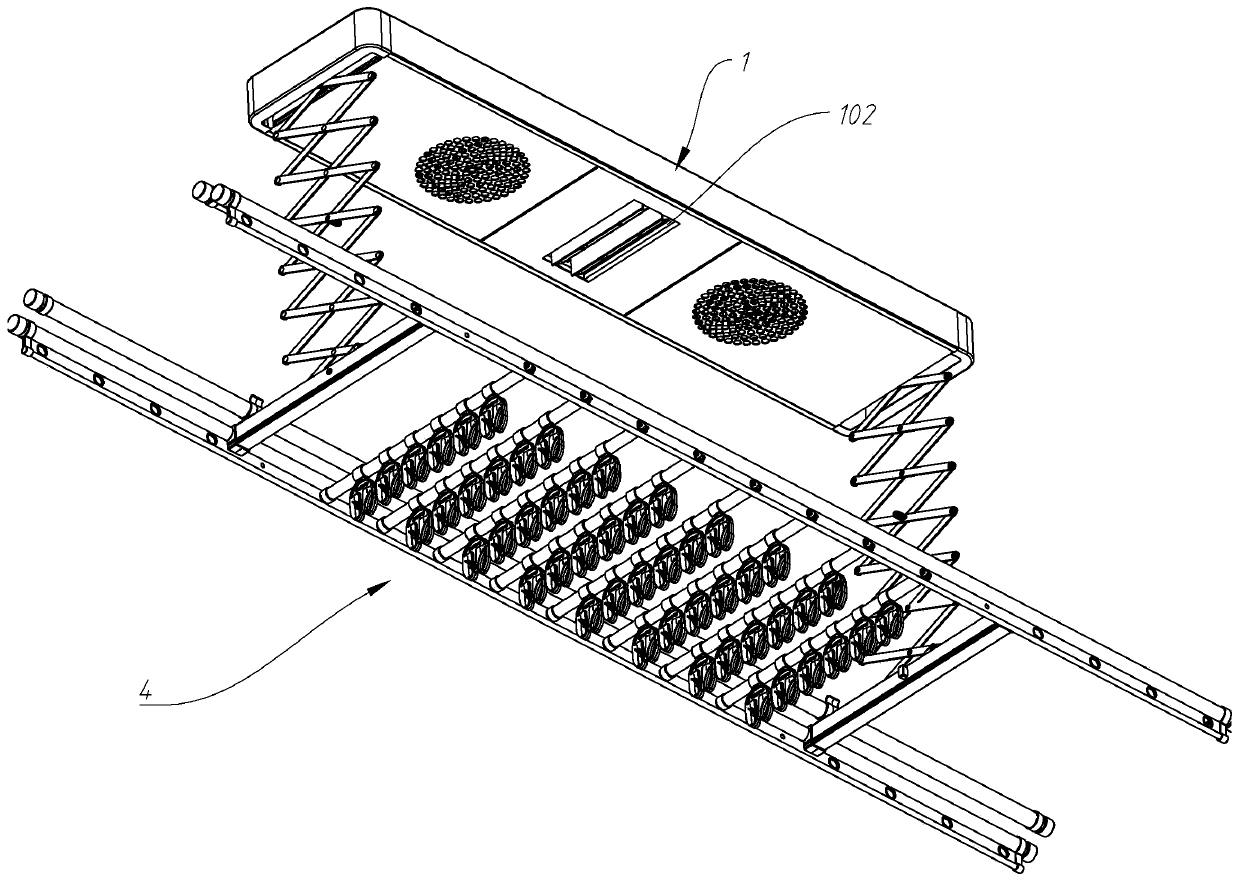

Electric clothes drying machine

PendingCN110499630AMake full use of spaceLower vertical heightOther drying apparatusTextiles and paperEngineeringMechanical engineering

The invention discloses an electric clothes drying machine, and belongs to the technical field of clothes drying machines. Shells of the existing clothes drying machines are relatively high and cannotbe thin, the application range of the clothes drying machines is narrow, and popularization and sales are not facilitated. A winder is assembled on the side wall or the end wall of an adjacent machine shell, and the extending direction of a rotating shaft of the winder is perpendicular to the long edge of the machine shell, so that the winding direction of a pull rope is parallel to the long edgeof the machine shell. Due to continuous exploration, the existing technical prejudice that the pull rope has to be centrally arranged is broken, and a pull rope side end arranging structure is provided. The pull rope is arranged along the side end of the machine shell and adjacent to the side wall of the machine shell, can avoid a fan, an air duct and other parts, and fully utilizes the space ofthe machine shell. The pull rope, the fan and other parts are not in the same vertical surface, and the vertical height of the machine shell can be effectively reduced, so that the machine is compactin structure, popularization and sales can be facilitated, the reversing frequency of the pull rope can be effectively reduced, friction of the pull rope is reduced, the service life of the pull ropeis prolonged, and popularization and sales of the electric clothes drying machine are facilitated.

Owner:AUPU HOME STYLE CORP LTD

Light source device and its optical path switch

ActiveCN112821821BFast actionMeet fast switching needsDynamo-electric converter controlElectric machineEngineering

The invention discloses a light source device and an optical path switch. The optical path switch includes a power supply, a control component and an execution component, and the power supply, the control component and the execution component are connected to each other. The optical component and the stepping motor connected to it are used to drive its rotation to open or close the optical path. The light blocking component has a fixed end and a movable end, the fixed end is connected to the output end of the stepping motor, and the movable end is along the A certain radial direction extends outward to form a light-shielding part; the stepper motor includes a rotor and at least a first winding and a second winding arranged along a certain circumferential direction outside the rotor, and the control assembly is connected with the first winding and the second winding respectively. connected, by controlling the direction and magnitude of the current in the first winding and the second winding to drive the stepper motor to rotate, thereby driving the light blocking part to block or avoid light. The invention has the advantages of fast switching speed and low power consumption.

Owner:杭州微伽量子科技有限公司

Quantum Absolute Gravimeter

ActiveCN112666624BOpen quicklyRapid disconnectionDynamo-electric converter controlGravitational wave measurementControl systemElectric machine

The invention discloses a quantum absolute gravimeter, which includes a control system, a laser system and a probe system connected to each other through electric wires and / or optical fibers; Components and execution components, power supply, control components and execution components are connected to each other. The execution components are arranged on one side of the light output path of the laser system. The execution components include a light blocking component and a device connected to it for driving its rotation to open or close the light path. A stepping motor, the stepping motor includes a rotor and at least a first winding and a second winding are arranged along a certain circumferential direction outside the rotor, the control assembly is connected with the first winding and the second winding respectively, by controlling the The direction and magnitude of the currents in the first winding and the second winding drive the stepper motor to rotate, so that the light-shielding component blocks or avoids light. The gravimeter enables rapid switching on and off of the laser band.

Owner:杭州微伽量子科技有限公司

A kind of m12 large size silicon wafer cutting process

ActiveCN111531733BImprove quality and yieldReduce thicknessWorking accessoriesFine working devicesWire cuttingEngineering

The invention relates to an M12 large-size silicon wafer cutting process, which belongs to the technical field of crystalline silicon processing. Cutting; adding cutting fluid: adding cutting fluid to the cutting machine; preheating before cutting: turning on cutting fluid and wire mesh, reciprocating wire; cutting: setting cutting parameters to cut silicon rods; blanking: setting retracting parameters , the silicon rod is gradually separated from the wire mesh, which can reduce the wear and tear of the diamond wire, effectively reduce the abnormal and bad edge collapse of the adhesive surface of the silicon wafer, thereby reducing the wire consumption of the diamond wire, which has the characteristics of significantly reducing the edge collapse phenomenon of the silicon wafer and reducing the cost of slicing.

Owner:乐山高测新能源科技有限公司

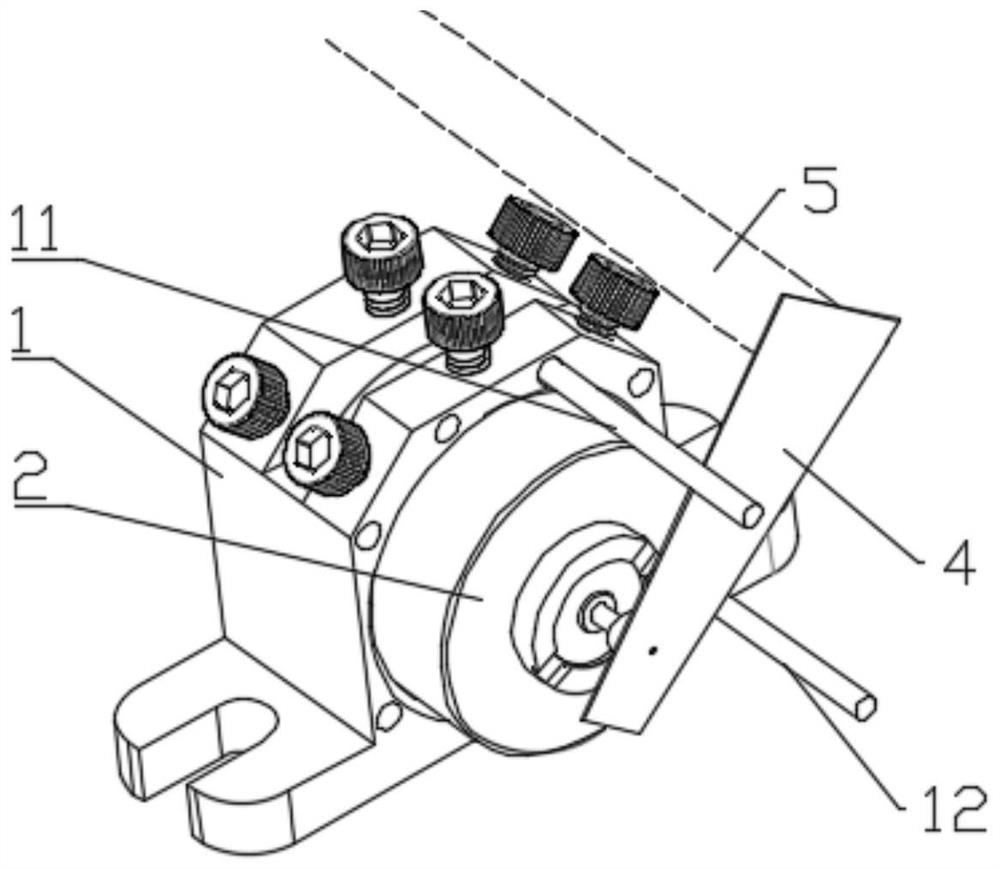

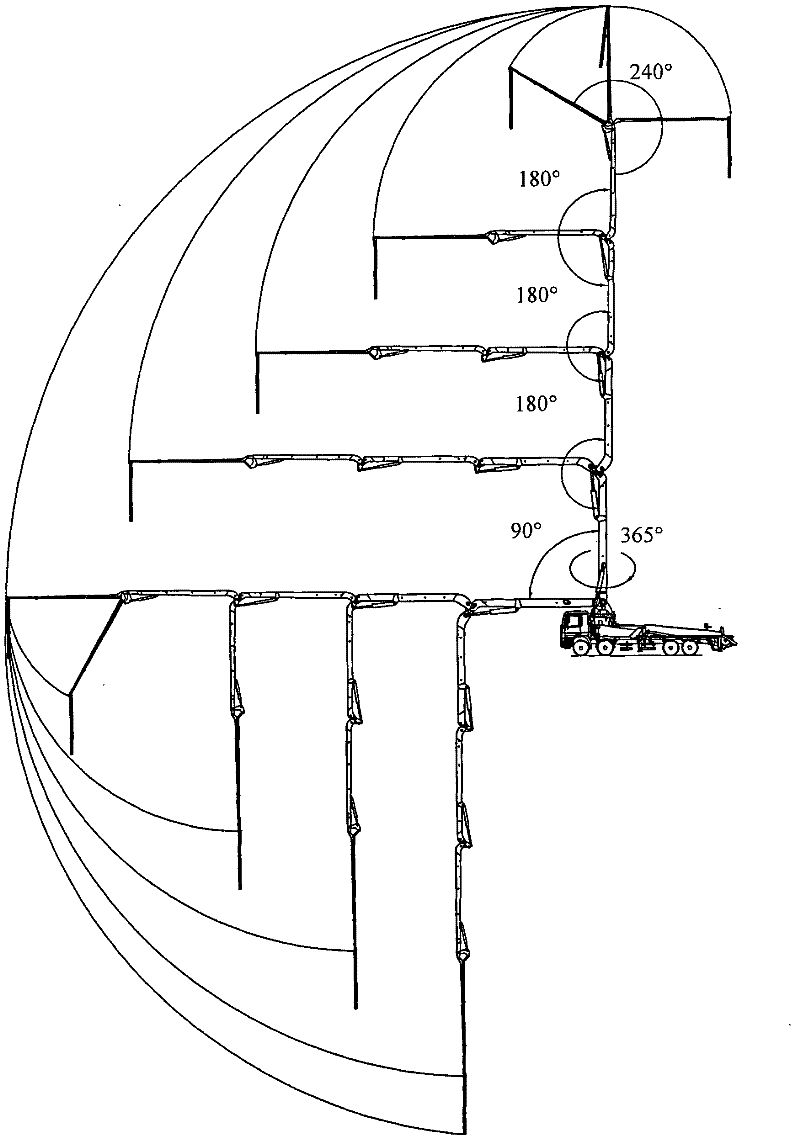

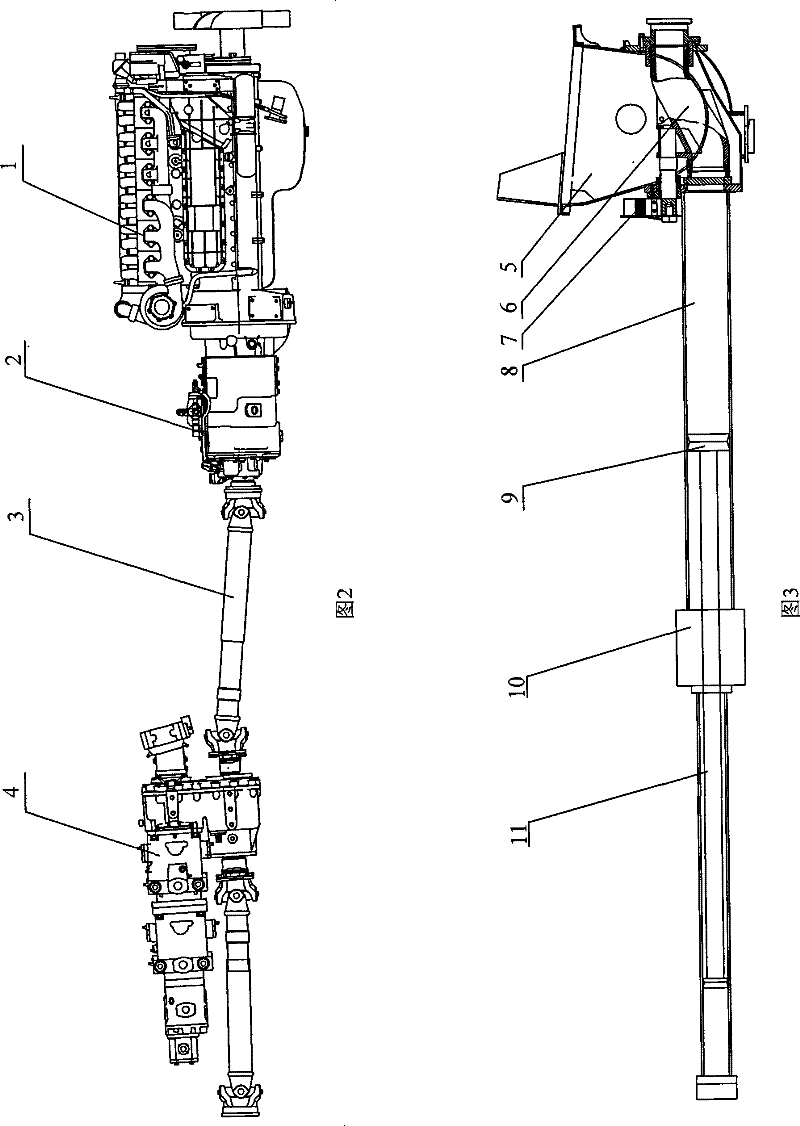

47-meter r-type foldable arm rack concrete pump truck and a producing method thereof

ActiveCN101550763BReduce weightHigh strengthAuxillary drivesStands/trestlesRemote controlStructural engineering

The invention relates to a 47-meter R-type foldable arm rack concrete pump truck and a producing method thereof. The 47-meter R-type foldable arm rack concrete pump truck comprises an arm rack system,a power system, a pump sending system, an electric system and a hydraulic system. The 47-meter R-type foldable arm rack concrete pump truck is characterized in that the hydraulic system is provided with a hydraulic element used for checking actual workload transmission, a main oil pump is a variable inclined-disc type axial plunger piston pump, the hydraulic system uses a closed loop, a five-section rolling foldable arm rack is in fulcrum-type R-shaped fold, support legs are JJ-shaped double-swinging telescopic support legs, and a main oil cylinder is of a guiding-sleeve piston-rod sealing structure. The arm-rack system of the product of the invention is controlled by an electric-proportion multi-path valve and remotely controlled by a wireless remote control system. The arm rack oil cylinder has a bidirectional interlock function, effectively guarantees the work safety and the reliability of the arm rack and enables the intelligence of the whole system to be higher. The elements independently work and are not mutually interfered. The product of the invention has the characteristics of energy saving, high effect and low intelligence and worker labor intensity, and can be widely used in the projects of city building, bridges, foundation construction, and the like.

Owner:柳工建机江苏有限公司

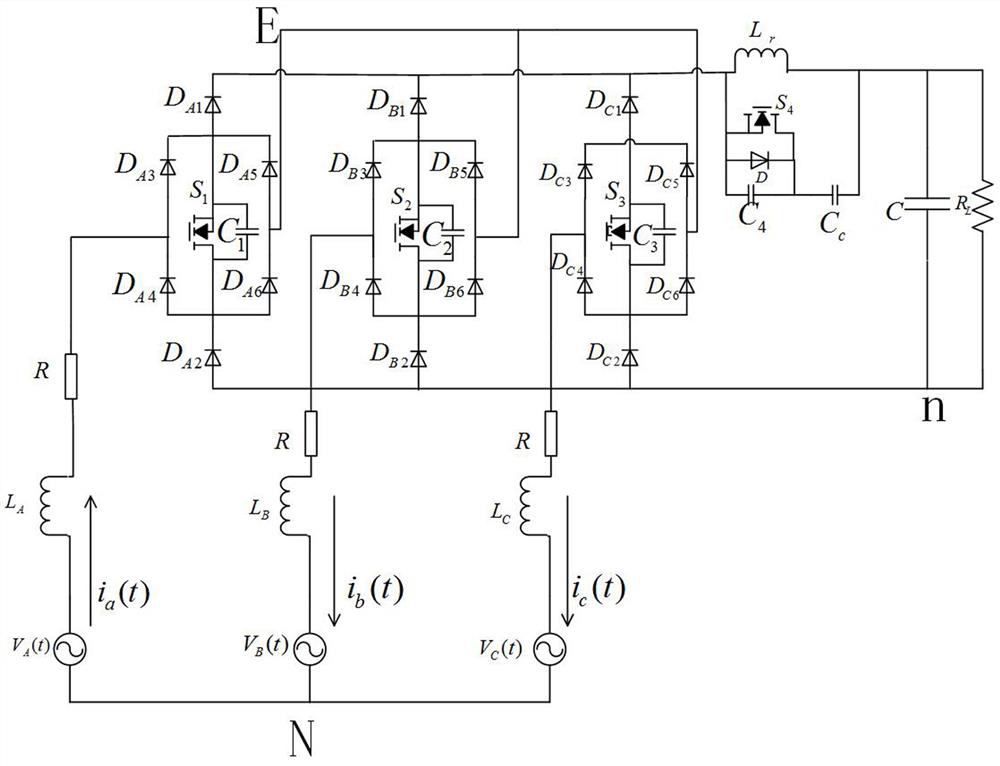

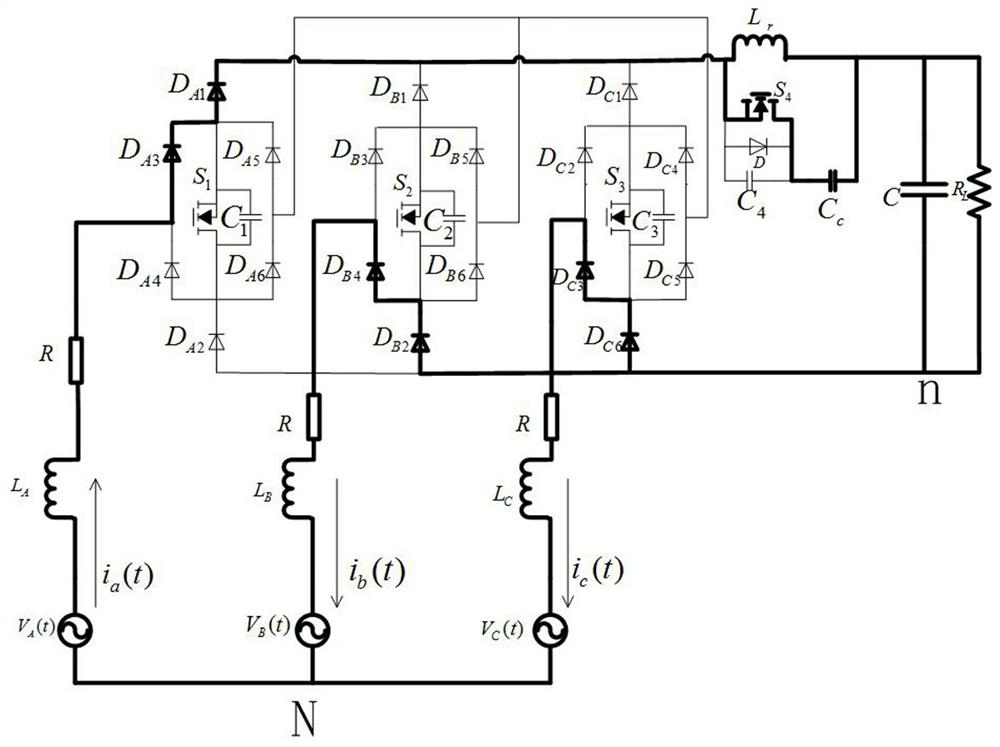

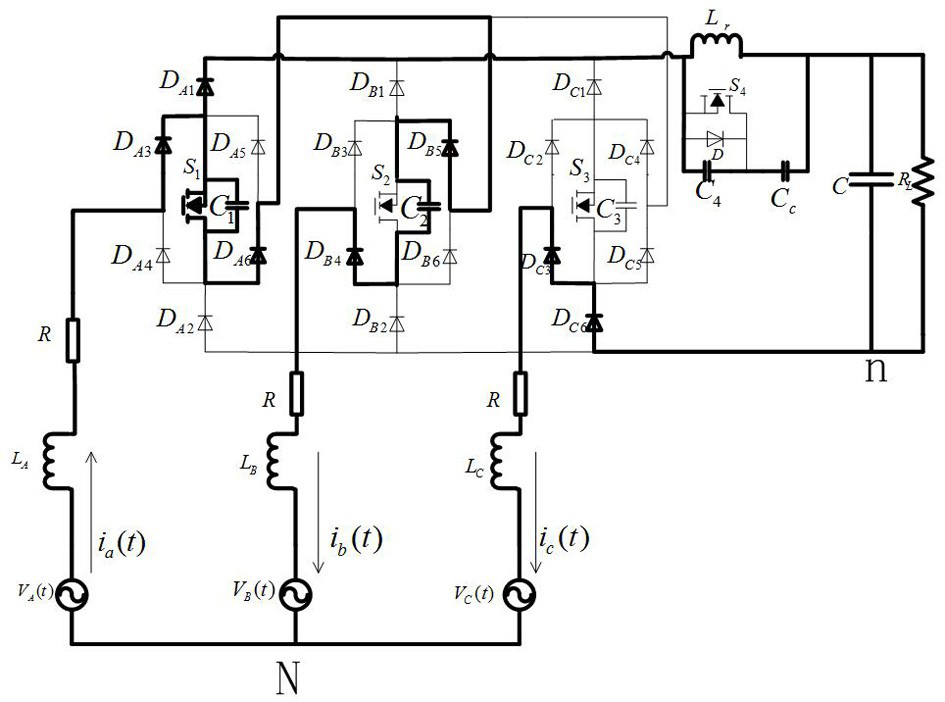

A Three-Phase Three-Switch Two-Level Rectifier Based on Zero-Voltage Soft Switching

ActiveCN109713929BReduced number of power switchesReduce in quantityEfficient power electronics conversionAc-dc conversionCapacitanceSoft switching

A three-phase three-switch two-level rectifier based on a zero-voltage soft switch includes a three-phase two-level rectification circuit, a resonance circuit and a filter capacitor C, wherein the three-phase two-level rectification circuit includes a first rectification bridge arm, a second rectification bridge arm, and a third rectification bridge arm that are connected in parallel. Compared with traditional three-phase two-level rectifiers, the three-phase three-switch two-level rectifier omits three full-control power devices and corresponding switch driving circuits, and a high power factor unidirectional rectifier has the advantages of reduced number of power switches, short circuit natural protection, small energy processing of an active switch and the like under the condition of not requiring bidirectional power flow; the two-level rectifier has a large advantage in the case of low output voltage; and in addition, compared with a traditional three-level active rectifier, midpoint voltage of a direct current bus does not need to be controlled, the phenomenon of unbalanced neutral point potential is completely eradicated, and the number of sensors and controllers is reduced.

Owner:深圳市瀚仑达实业有限公司

Narrow pulse suppression and electric energy quality improvement method for matrix converter

InactiveCN102545642BReduce switching lossesReduce the number of commutationsConversion without intermediate conversion to dcPower qualityMatrix converters

The invention discloses a narrow pulse suppression and electric energy quality improvement method for a matrix converter. The method is characterized in that: the matrix converter adopts double-voltage modulation; and when control signals of six switches for line voltage synthesis have narrow pulses in a certain switching period, six groups of new modulation functions for switch control are reconstructed and calculated according to the positions of the narrow pulses. The new functions are characterized in that: the new functions comprise instantaneous output current detection information; one of the six switches is kept in an off state; and the modulation functions simultaneously meet input current and output voltage modulation requirements. On the premise of no increase of the switching loss and the number of commutation times of the matrix converter, the number of the narrow pulses is effectively decreased, and the input and output waveform quality of the matrix converter is improved; and the method is particularly suitable for middle and high power places in which commutation time is long.

Owner:TIANJIN UNIV

Driving method, system and storage medium of stepping motor

ActiveCN112787557BFast actionReduce the number of commutationsDynamo-electric converter controlSimulationElectric machinery

The invention discloses a driving method, system and storage medium of a stepping motor. The method includes: setting the rotation stroke of the stepping motor in advance according to the application scene; The stepper motor accelerates to the middle position of the rotation stroke in two phases, and then drives the stepper motor to decelerate in two phases to the holding position and stops; at the holding position, the single coil maintains; in response to the reverse rotation command, drives the stepping motor to accelerate to the rotation stroke in two phases The middle position, and then drive the stepping motor two-phase deceleration to the initial position to stop. By adopting the method, the stepper motor can be started and stopped quickly and smoothly in a fixed stroke.

Owner:杭州微伽量子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com