Control method for four-way valve

A control method and four-way valve technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as easy failure, four-way valve reversing failure, and low four-way valve reversing reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

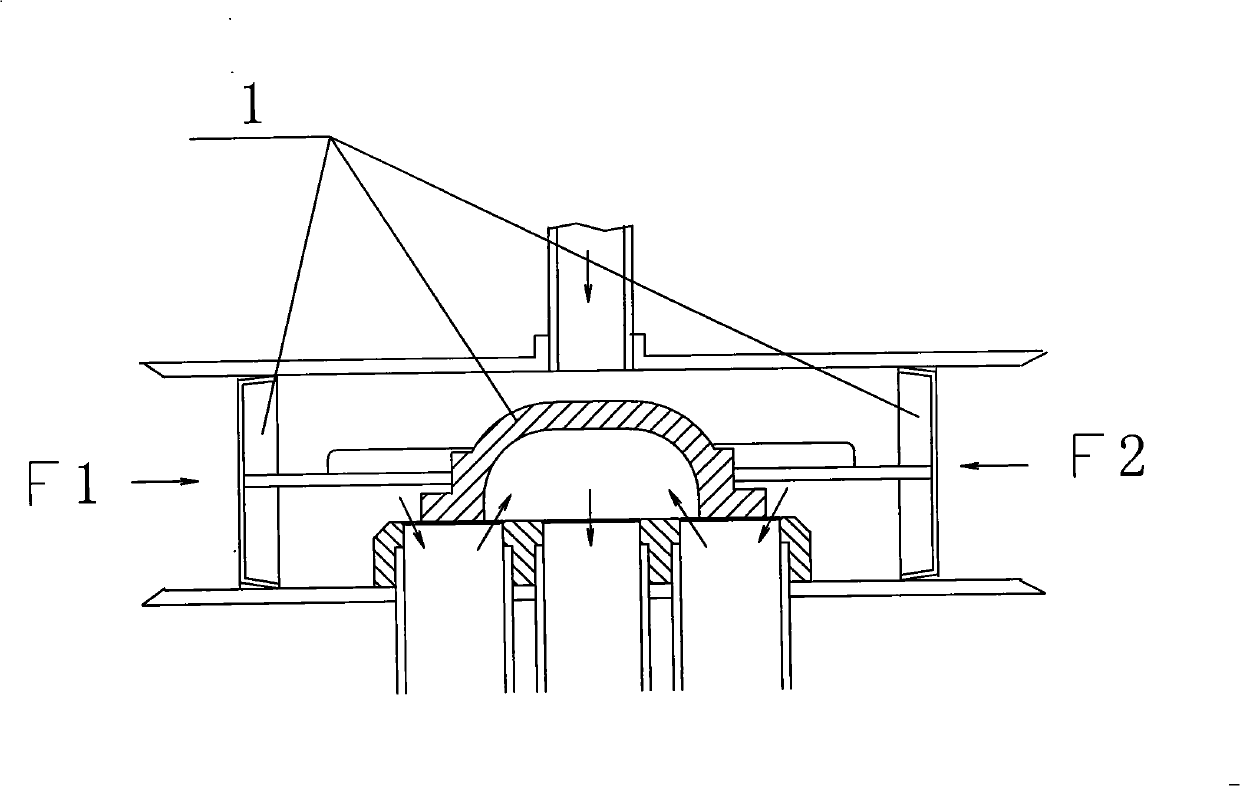

[0027] figure 1 Shown is the basic structure of the four-way valve in the prior art, which generally consists of a valve body, a main slide valve 1, a pilot valve 2 and other related accessories. figure 1 The middle arrow is the flow direction of the refrigerant, figure 1 The connection relationship between the four-way valve and the variable frequency compressor 3, the indoor unit 4, and the outdoor unit 5 is also drawn in the figure, so as to facilitate the understanding of the basic structure and working characteristics of the four-way valve in the prior art.

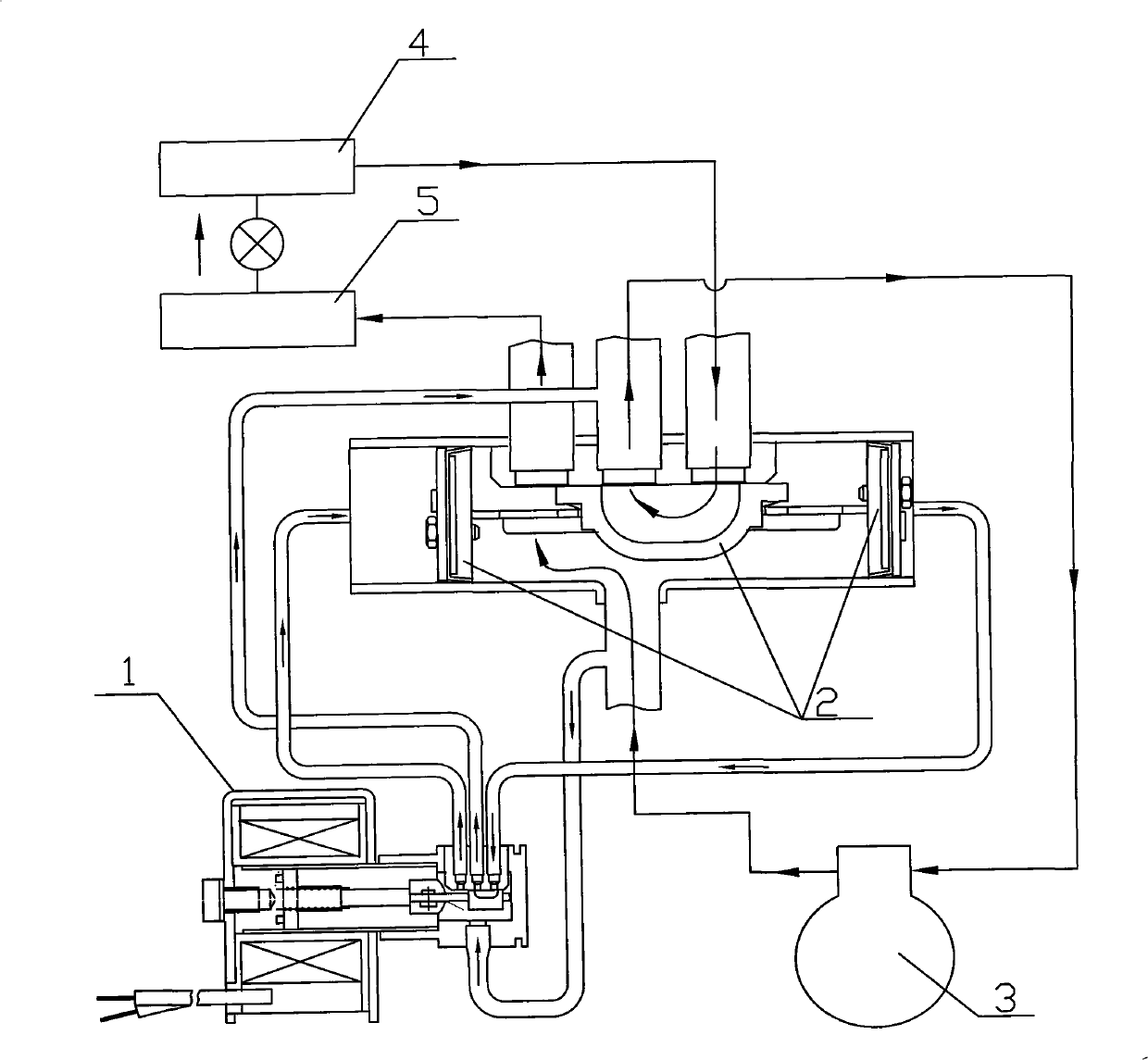

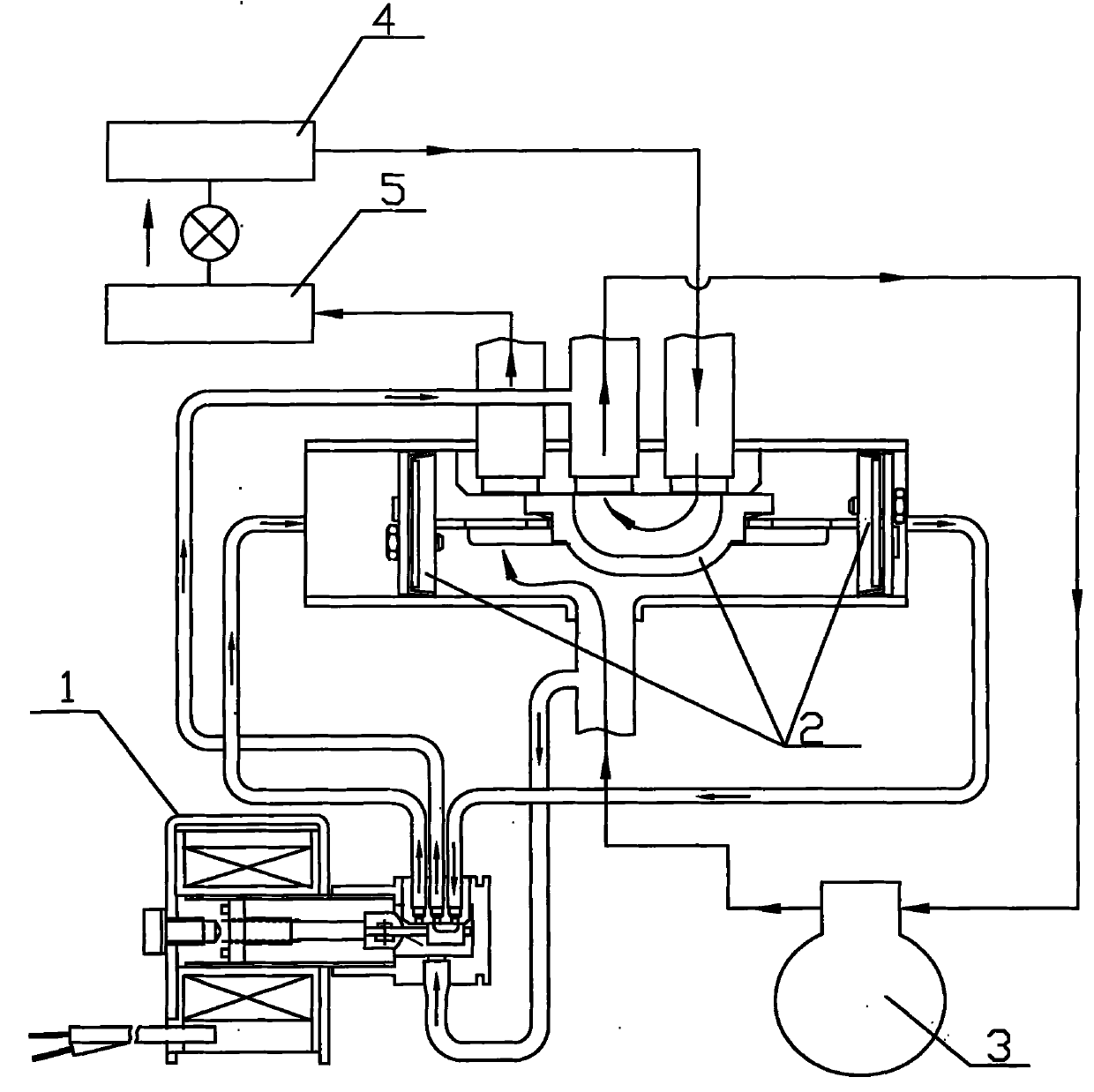

[0028] figure 2 It is a schematic diagram of the position and state of the main slide valve 1 of the four-way valve when the blow-by gas is in the state, figure 2 The arrow in is the flow direction of the refrigerant, from which we can see that when the blow-by gas is in the stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com