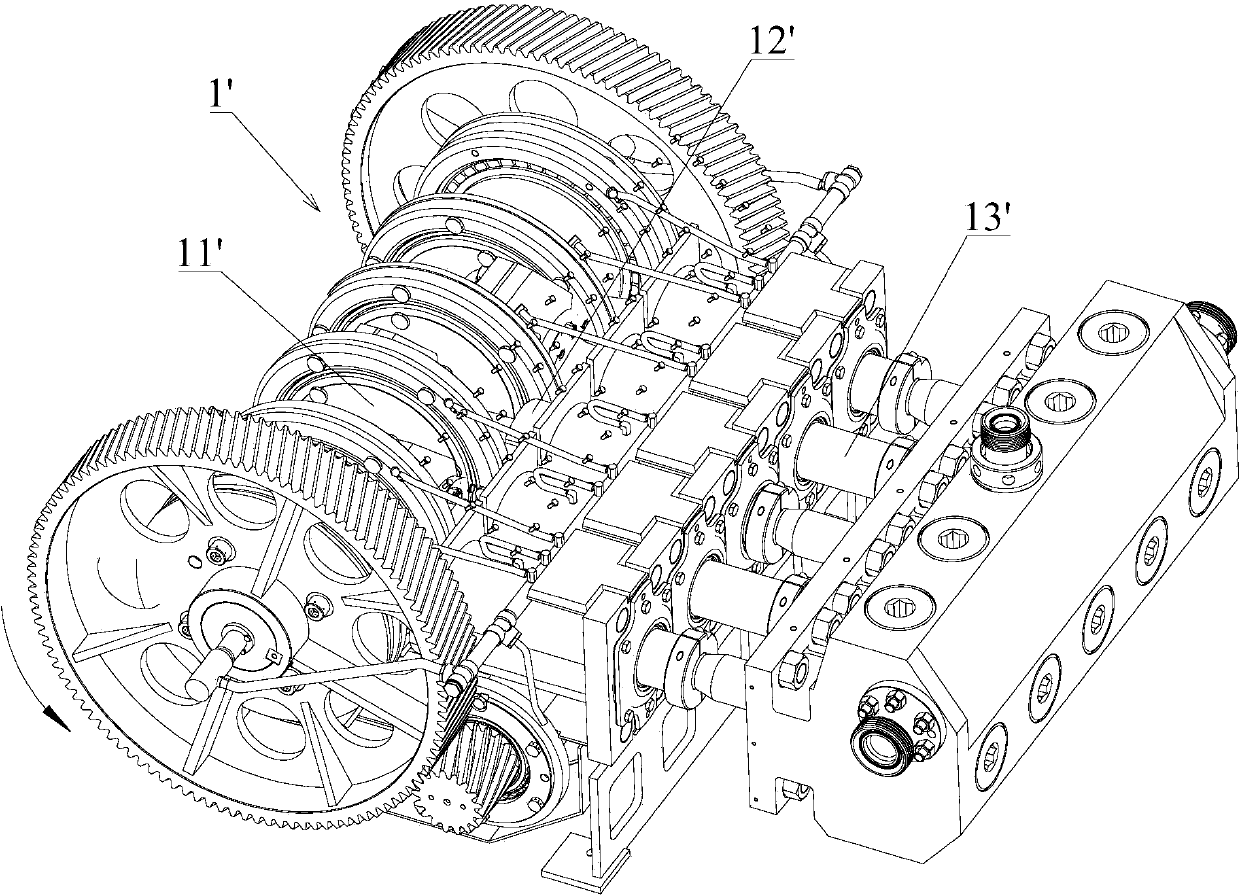

Fracturing pump system and fracturing truck

A technology for fracturing pumps and fracturing trucks, which is applied in the direction of pumps, piston pumps, liquid displacement machines, etc. It can solve the problems of only tens of hours of service life, high requirements for lubrication and cooling, and low suction efficiency. Simplicity, low lubrication and cooling requirements, and improved suction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] It should be pointed out that the description and sequence of specific structures in this section are only descriptions of specific embodiments, and should not be considered as limiting the protection scope of the present invention. In addition, the embodiments in this section and the features in the embodiments can be combined with each other under the condition of no conflict.

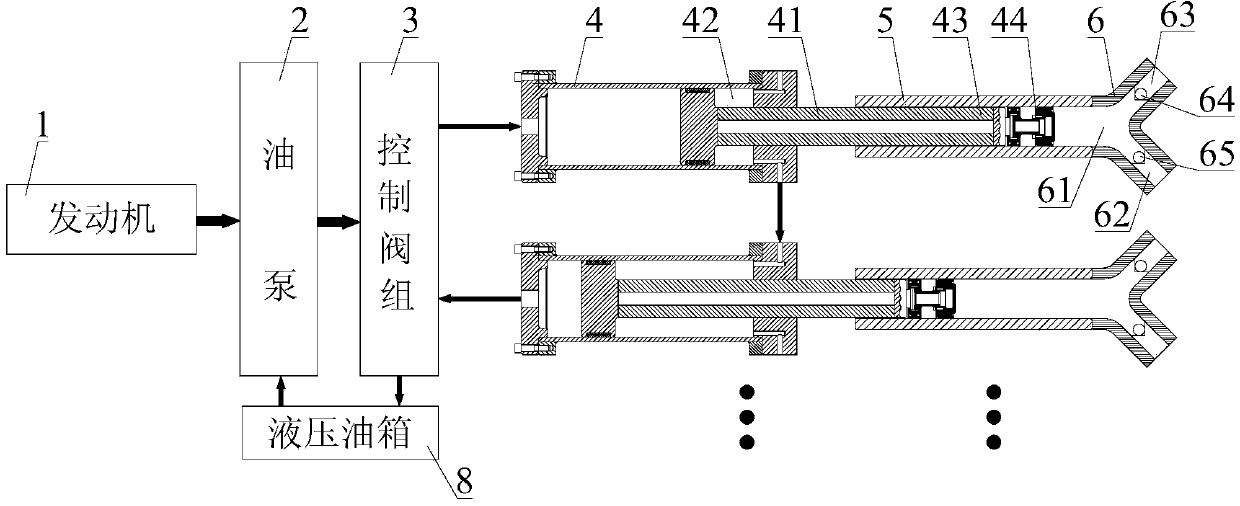

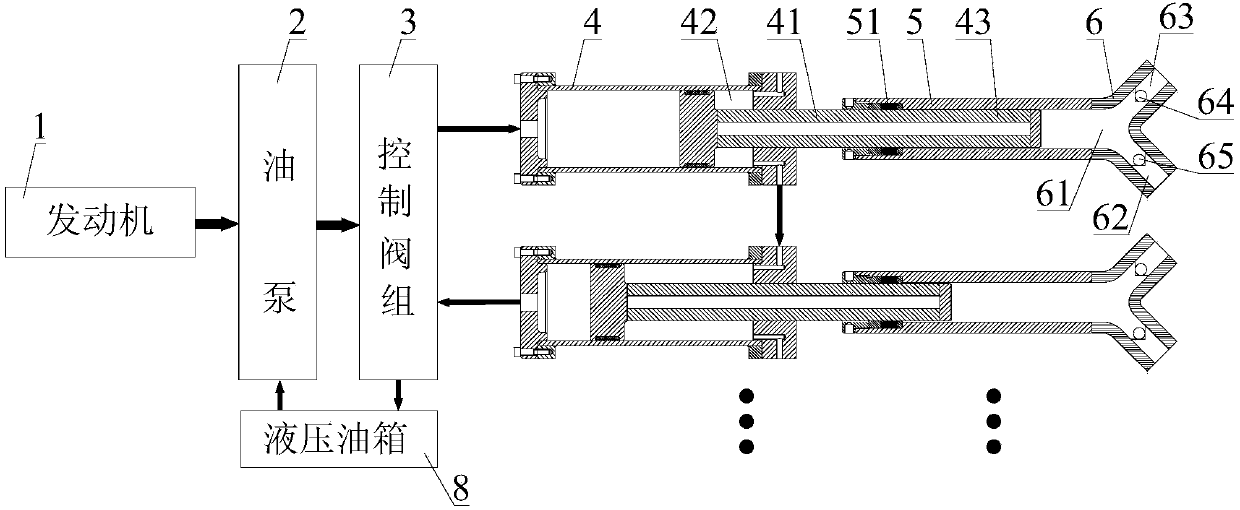

[0049] Please refer to Figure 2 to Figure 5 , the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0050] combine figure 2As shown, the fracturing pump system of the first embodiment of the present invention may include an engine 1, an oil pump 2, a control valve group 3, a hydraulic oil tank 8, a first conveying mechanism and a second conveying mechanism.

[0051] Wherein, the first conveying mechanism and the second conveying mechanism both include an oil cylinder 4, a booster cylinder 5 and a distribution valve 6; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com